Calendar for PVC film processing process

A PVC film and processing technology, applied in the field of calenders, can solve the problems of uneven cutting, affecting the quality of PVC film, etc., and achieve the effects of uniform proportion, high quality of finished products, stable and precise moving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

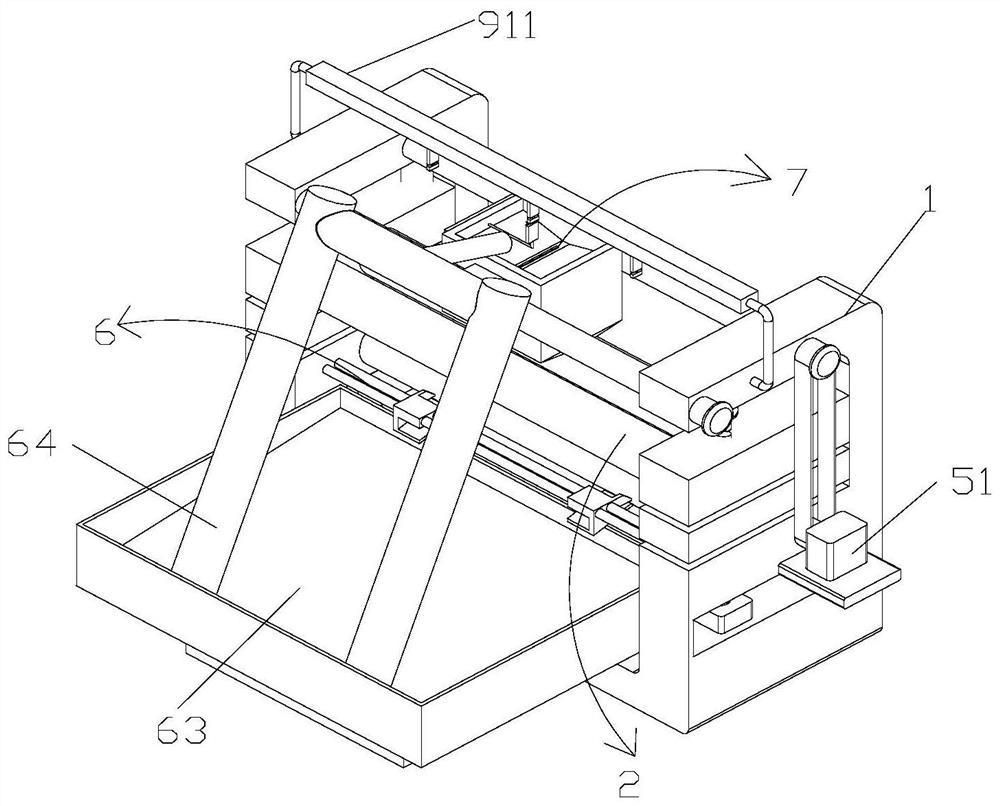

[0044] Such as Figure 1-18 As shown, a calender for PVC film processing technology includes a frame 1 and a calendering device 2; the calendering device 2 is arranged on the frame 1.

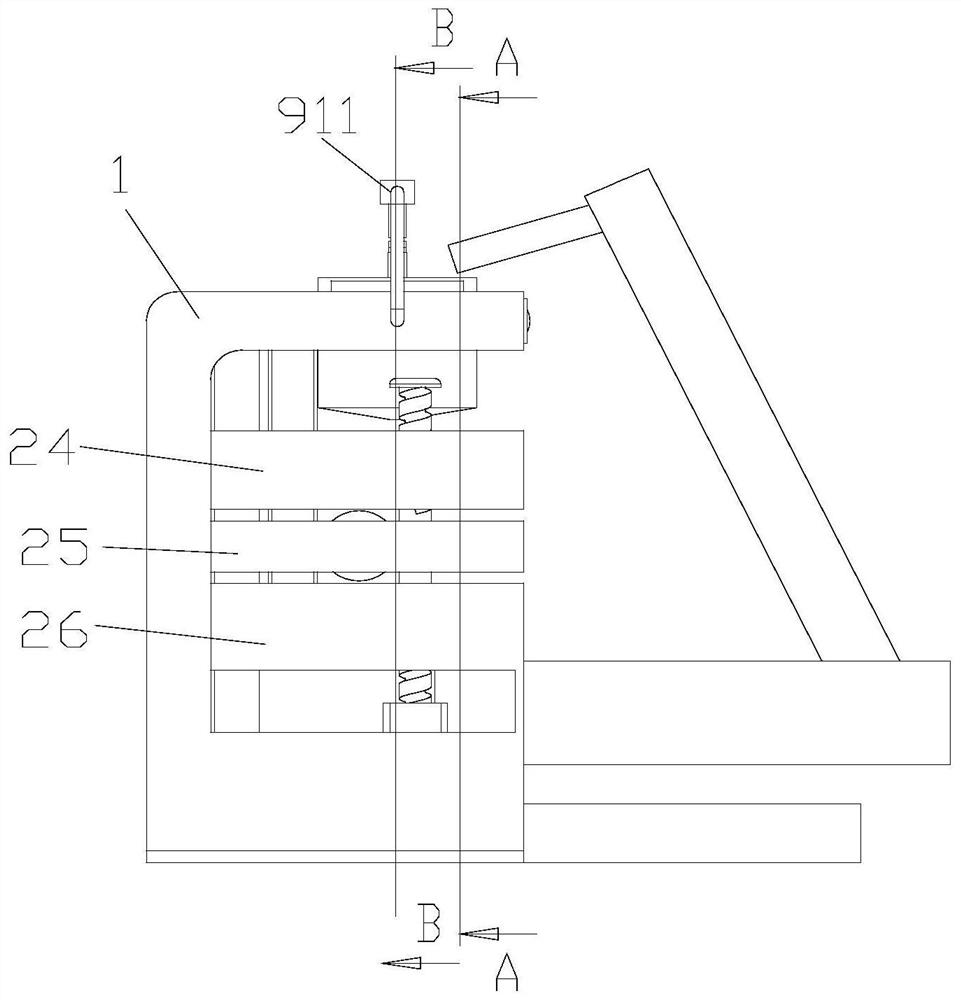

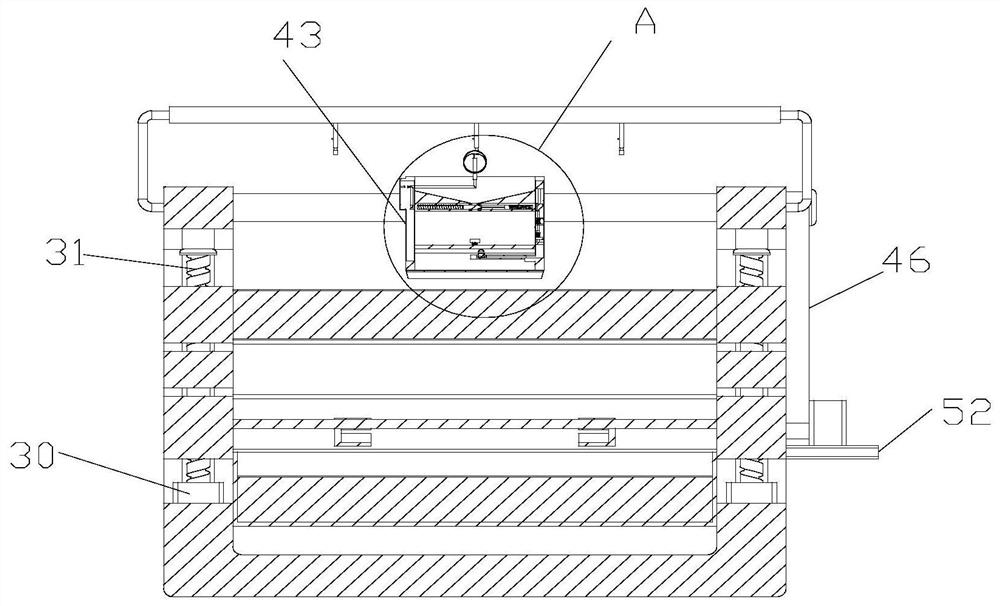

[0045] The calendering device 2 includes a first pressing roll 20, a second pressing roll 21, a third pressing roll 22, a fourth pressing roll 23, a first connecting block 24, a second connecting block 25, a third connecting block 26, a transmission device 3. Unloading device 4, flattening device 5 and leveling device 6; the first pressing roller 20 is arranged on the frame 1; the second pressing roller 21 is arranged at the rear of the first pressing roller 20, the first The pressure roller 20 is arranged in parallel with the second pressure roller 21, the third pressure roller 22 is arranged on the lower part of the first pressure roller 20; the fourth pressure roller 23 is arranged on the lower part of the third pressure roller; the first connecting block 24 The number is 2, which are fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com