Curling machine for metal, slitter edge

A side roll, a new type of technology, applied in the field of winding machines, can solve the problems of low economy, personnel scratches, large space occupation, etc., and achieve the effect of exquisite design concept and reduced occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

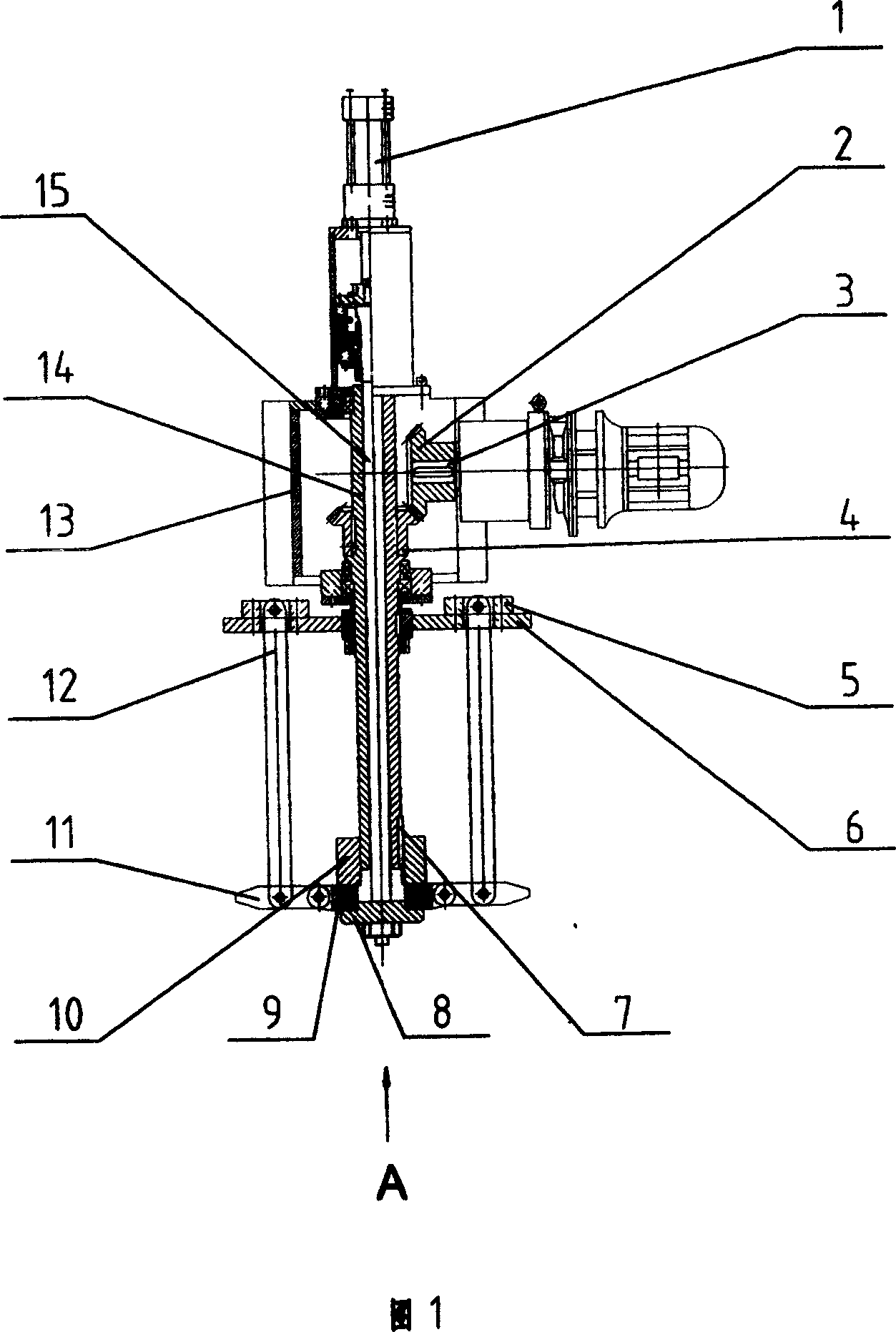

[0016] A box 13 is fixedly connected to the frame, and a hydraulic cylinder 1 is connected to the upper part of the box 13. The side of the box body 13 is connected with a drive motor, and the drive shaft 3 of the drive motor is arranged horizontally and extends into the box body 13; the end of the drive shaft 3 is connected to the bevel gear 2 with a key.

[0017] The main shaft 14 is provided in the box body 13. The main shaft 14 is a hollow shaft and is perpendicular to the horizontal plane. The lower part of the main shaft 14 passes through the main shaft box 13, and the upper and middle parts of the main shaft 14 are respectively connected to the box body 13 with bearings; the main shaft 14 is in the box body 13 The inner part is keyed to a bevel gear 4, which meshes with the bevel gear 2 on the drive shaft 3.

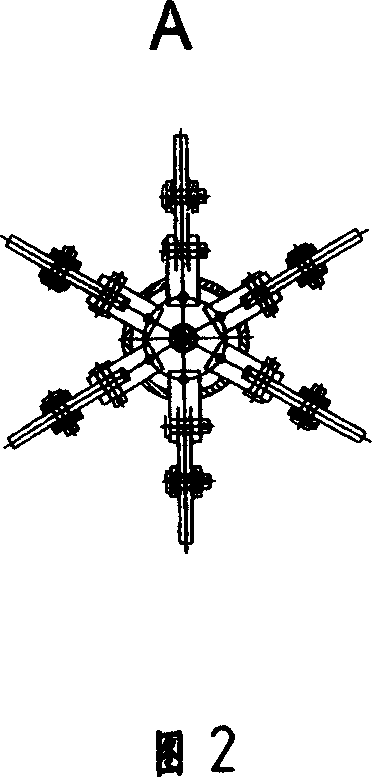

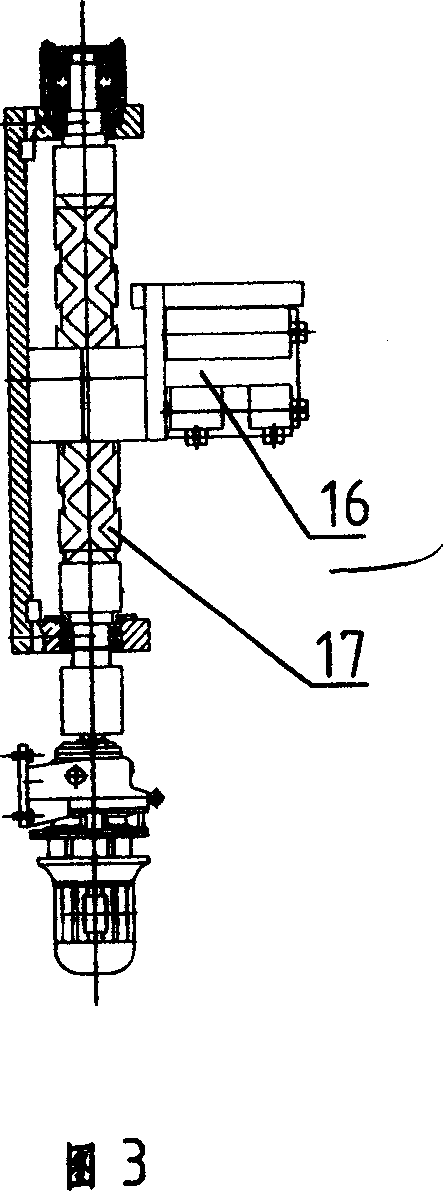

[0018] The main shaft 14 extends out of the box 13 and is close to the lower end of the box 13, and is connected to a coaxial disk 6 with a key. The disk 6 is evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com