Compression and conveying device for rural garbage treatment

A technology of garbage disposal and conveying device, applied in the directions of transportation and packaging, presses, loading/unloading, etc., can solve the problems of good compression effect, high transmission efficiency, synchronously driving garbage for conveying, etc., to achieve good compression effect and transmission efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

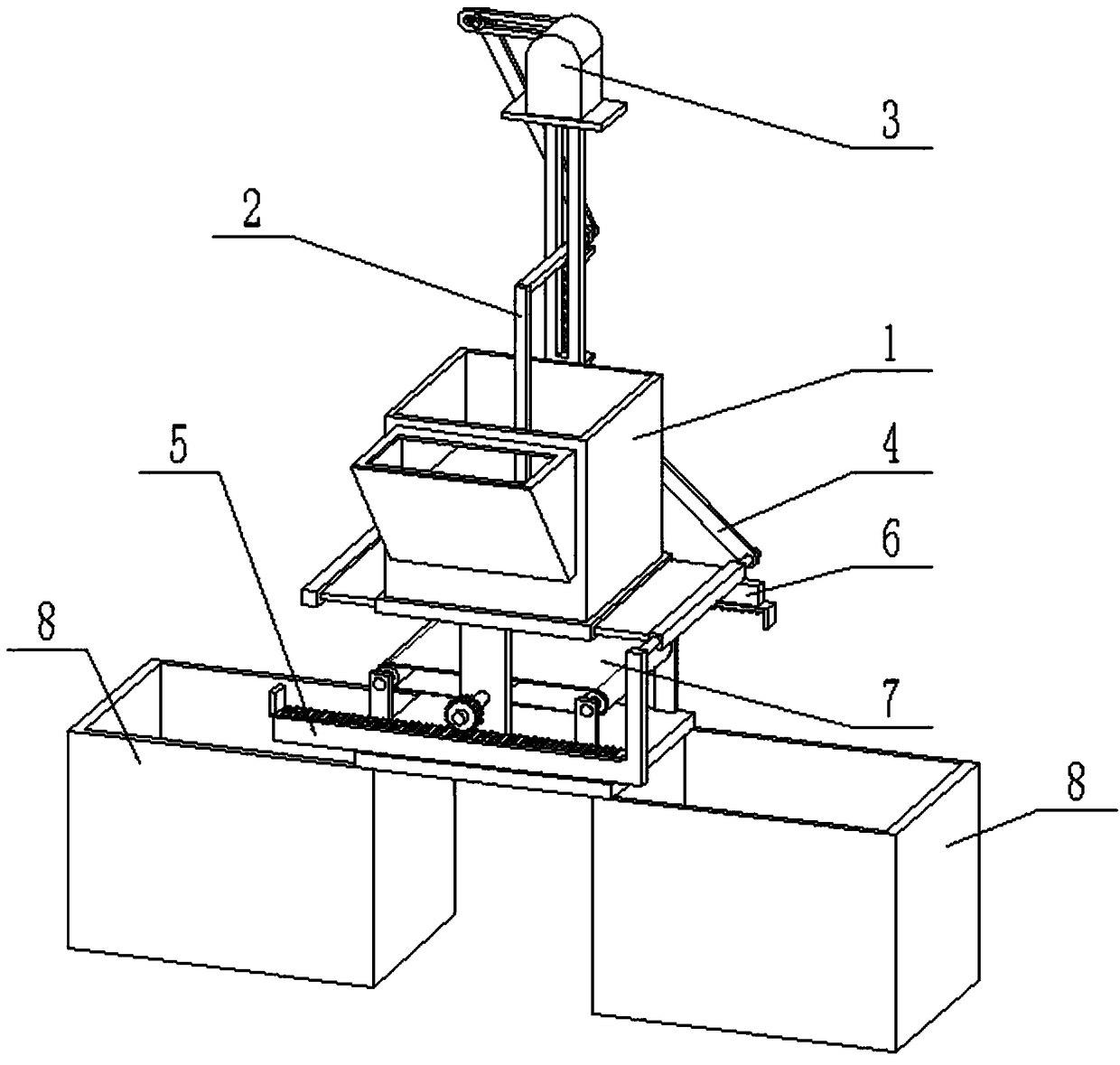

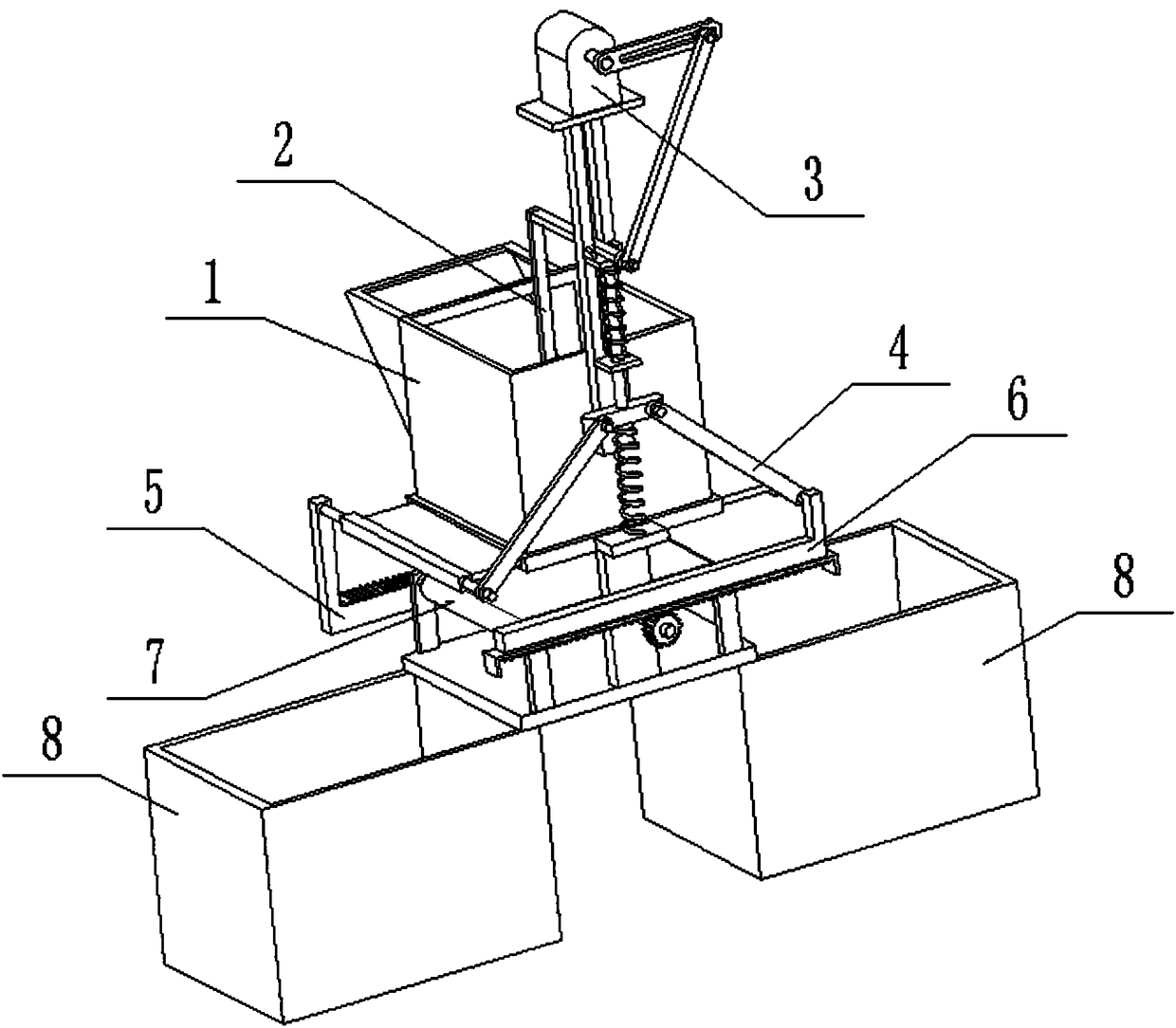

[0029] Such as Figure 1-12 As shown, the compression conveying device for rural waste treatment includes a compression box assembly 1, a waste compression assembly 2, a compression drive assembly 3, a waste discharge transmission assembly 4, a front drive rack assembly 5, a rear drive rack assembly 6, and a waste conveying assembly. Belt assembly 7 and two garbage storage boxes 8, the lower end of the compression box assembly 1 is fixedly connected to the garbage conveyor belt assembly 7, and the two sides of the bottom end of the garbage conveyor belt assembly 7 are respectively fixedly connected to a garbage storage box 8; The inside of the compression box assembly 1 is provided with a garbage compression assembly 2, the rear end of the garbage compression assembly 2 is fixedly connected to the rear end of the compression box assembly 1, the compression drive assembly 3 is arranged on the top of the garbage compression assembly 2, and the compression drive assembly 3 is conn...

specific Embodiment approach 2

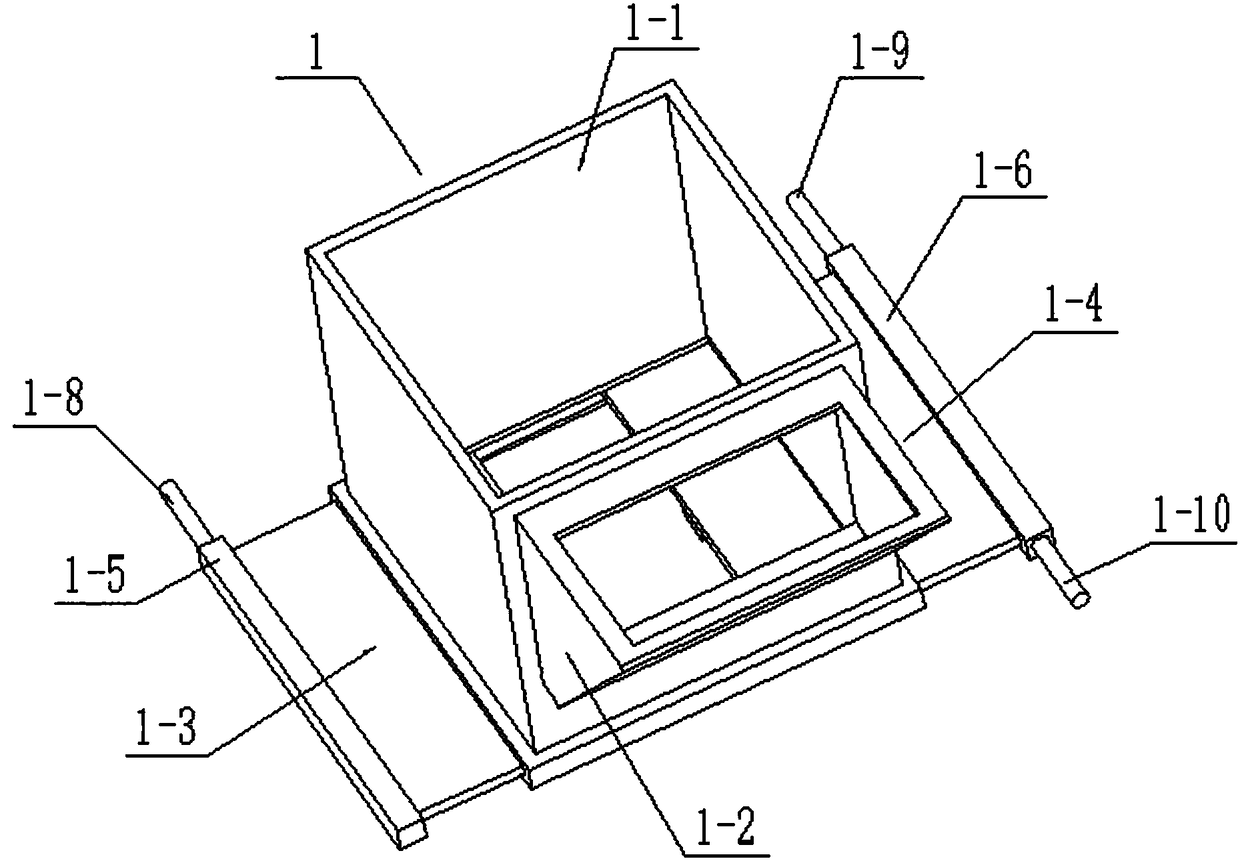

[0030] Such as Figure 1-12 As shown, the compression box assembly 1 includes a rectangular compression box 1-1, a trapezoidal feed hopper 1-2, a left box door 1-3, a right box door 1-4, a left pull rod 1-5, and a right pull rod 1-6 , limit block 1-7, first connecting rod 1-8, second connecting rod 1-9 and third connecting rod 1-10; the top and bottom surfaces of the rectangular compression box 1-1 are hollow structures, The front side of the rectangular compression box 1-1 is provided with a garbage drop opening, and the front end of the garbage drop opening is fixedly connected to the trapezoidal feed hopper 1-2; The lower end of the left side, the right box door 1-4 is slidably connected to the lower end of the right side of the continuation row compression box, the left box door 1-3 and the right box door 1-4 are relatively arranged, and the bottom surface of the left box door 1-3 The right side and the left side of the bottom surface of the right box door 1-4 are respect...

specific Embodiment approach 3

[0035] Such as Figure 1-12 As shown, the front transmission rack assembly 5 includes a front L-shaped connecting plate 5-1, a front rack plate 5-2 and a front limiting plate 5-3, and the vertical plate of the front L-shaped connecting plate 5-1 is fixedly connected On the third connecting rod 1-10; the top surface of the horizontal plate of the front L-shaped connecting plate 5-1 is fixedly connected to the front rack plate 5-2, and the top surface of the front rack plate 5-2 is provided with Rack teeth, the front rack plate 5-2 is connected to the front end of the garbage conveyor belt assembly 7; the left end of the front rack plate 5-2 is fixedly connected to the front limiting plate 5-3. When the front transmission rack assembly 5 is in use, the front L-shaped connecting plate 5-1 moves under the drive of the third connecting rod 1-10, and the front L-shaped connecting plate 5-1 drives the front rack plate 5-2 To move, the front rack plate 5-2 drives the garbage conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com