Automatic discharging system used for stamping production line

A production line and cutting technology, applied in storage devices, metal processing equipment, feeding devices, etc., can solve the problems of silicon steel sheet production with changes in shape and size, manual cutting by workers, inability to apply various specifications, etc., to achieve convenient debugging. , easy to move and install, and the effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

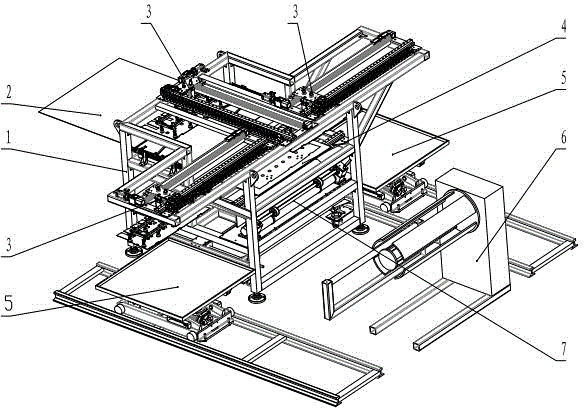

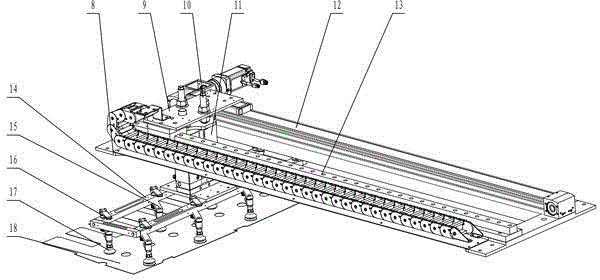

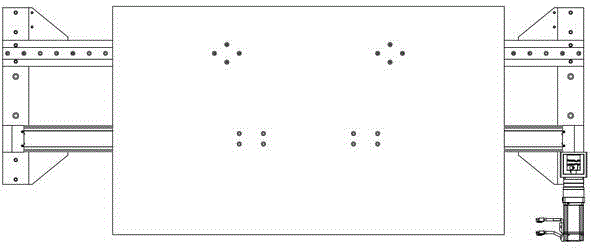

[0057] An automatic blanking system for a stamping production line, comprising a frame 1, a transport adsorption system 3, a workpiece transfer system 4, a palletizing system 5, a waste traction system 7 and a waste collection system 6; the frame 1 is equipped with a transport Adsorption system 3, workpiece transfer system 4 and waste traction system 7, at least three conveying and absorbing systems 3 are arranged on the frame 1, and a stacker is respectively arranged under the conveying and absorbing systems 3 on the left and right sides of the frame 1 System 5, a material receiving plate 2 is provided under the transport adsorption system 3 provided on the front of the frame 1, a waste traction system 7 is provided beside the workpiece transfer system 4, and a waste collection system 6 is provided beside the waste traction system 7 . The bottom of the frame 1 is equipped with a lifting platform that realizes the synchronous lifting of the overall height. The material receiv...

Embodiment 2

[0060] An automatic blanking system for a stamping production line, comprising a frame 1, a transport adsorption system 3, a workpiece transfer system 4, a palletizing system 5, a waste traction system 7 and a waste collection system 6; the frame 1 is equipped with a transport Adsorption system 3, workpiece transfer system 4 and waste traction system 7, at least three conveying and absorbing systems 3 are arranged on the frame 1, and a stacker is respectively arranged under the conveying and absorbing systems 3 on the left and right sides of the frame 1 System 5, a material receiving plate 2 is provided under the transport adsorption system 3 provided on the front of the frame 1, a waste traction system 7 is provided beside the workpiece transfer system 4, and a waste collection system 6 is provided beside the waste traction system 7 . The bottom of the frame 1 is equipped with a lifting platform that realizes the synchronous lifting of the overall height. The material receiv...

Embodiment 3

[0065] An automatic blanking system for a stamping production line, comprising a frame 1, a transport adsorption system 3, a workpiece transfer system 4, a palletizing system 5, a waste traction system 7 and a waste collection system 6; the frame 1 is equipped with a transport Adsorption system 3, workpiece transfer system 4 and waste traction system 7, at least three conveying and absorbing systems 3 are arranged on the frame 1, and a stacker is respectively arranged under the conveying and absorbing systems 3 on the left and right sides of the frame 1 System 5, a material receiving plate 2 is provided under the transport adsorption system 3 provided on the front of the frame 1, a waste traction system 7 is provided beside the workpiece transfer system 4, and a waste collection system 6 is provided beside the waste traction system 7 . The bottom of the frame 1 is equipped with a lifting platform that realizes the synchronous lifting of the overall height. The material receiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com