Automatic clipping device for server cabinet frame supporting rod

A technology for server cabinets and support rods, which is applied in the direction of shearing devices, attachments of shearing machines, knives for shearing machines, etc., and can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

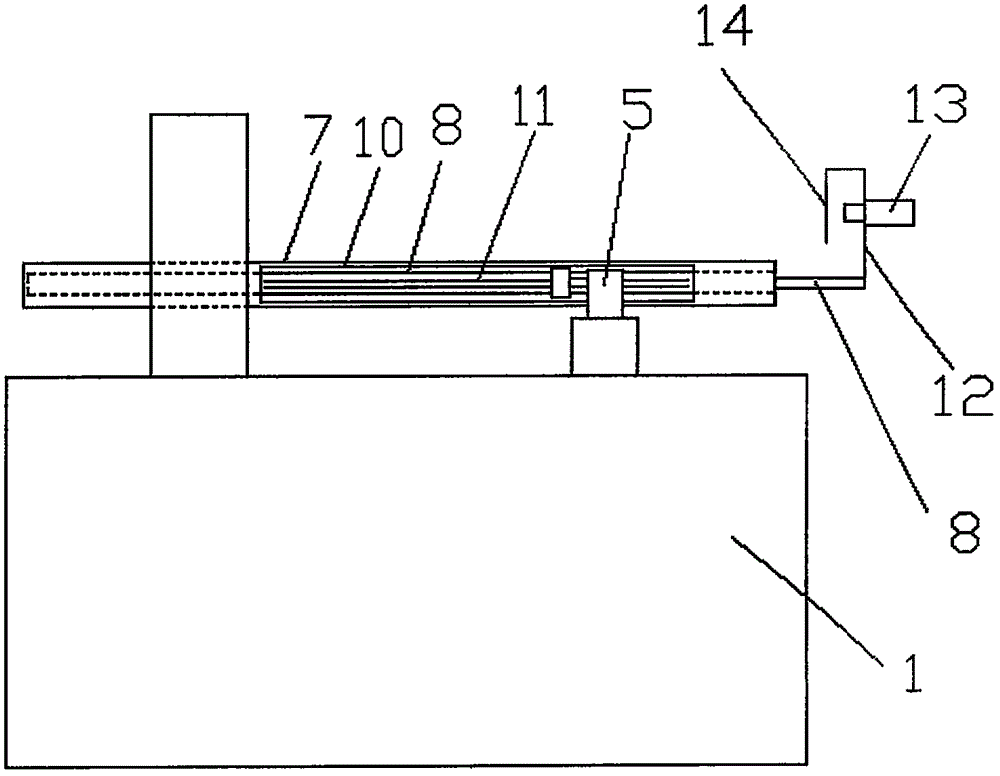

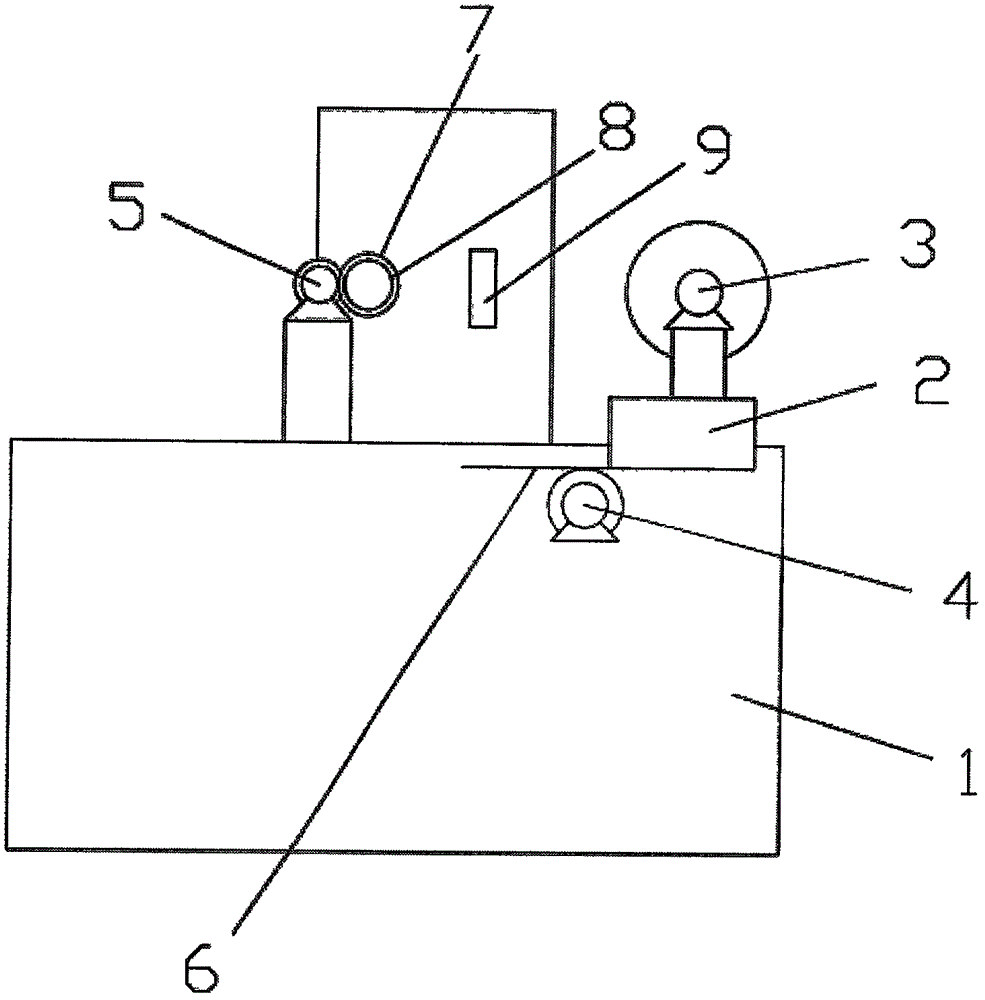

[0017] combine figure 1 , 2 , 3, an automatic cutting device for server cabinet frame support rods of the present invention includes a base, a positioning rod, a motor, a cutter seat, a cutter, a processor and a travel switch.

[0018] The positioning rod includes an outer rod and an inner rod. The inner rod is sleeved outside the outer rod and the two are arranged coaxially. There is a bearing inside the outer rod. The inner rod is connected to the outer rod through the bearing. The inner rod can rotate relative to the outer rod but cannot move axially. .

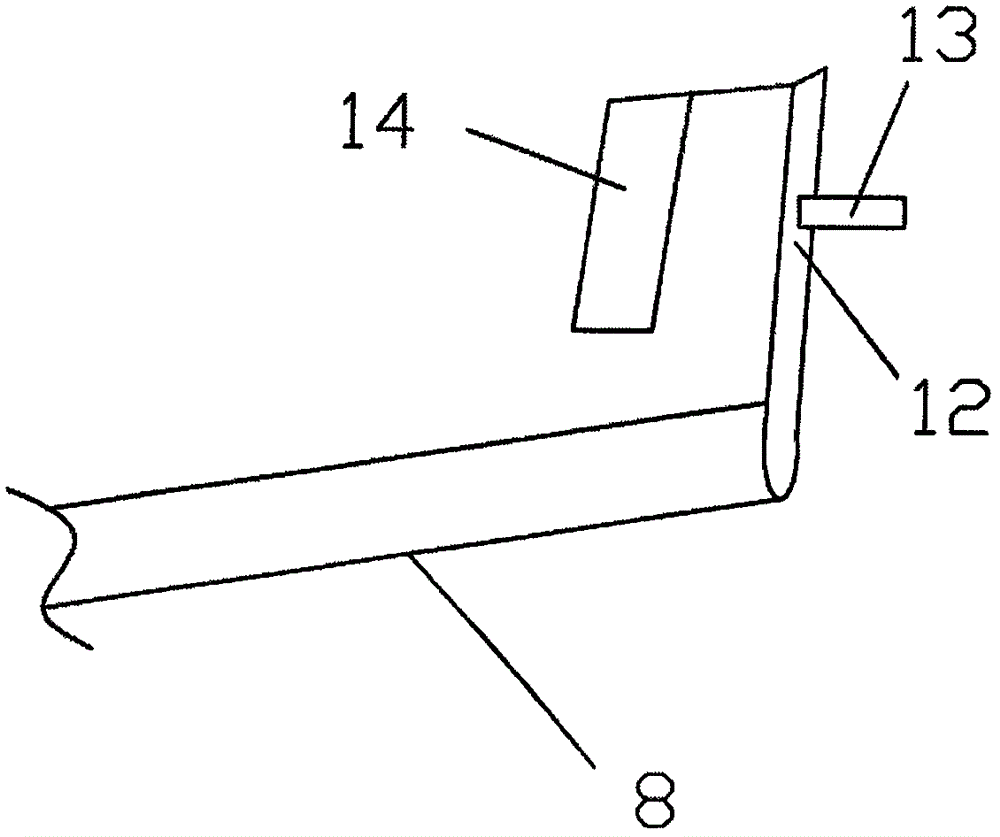

[0019] The inner rod is a stepped rod, the outer diameter of the largest part of the outer diameter of the inner rod matches the inner diameter of the outer rod, and the outer rod has an axially extending slit hole, and the outer circumference of the largest part of the inner rod is evenly provided with a ring around the inner rod. The teeth distributed on the central axis of the rod, and the teeth are exposed in the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com