Automatic adhesive tape winding equipment and adhesive tape winding method thereof

A tape and automatic technology, applied in the direction of electrical components, manufacturing wiring harnesses, circuits, etc., can solve the problems of low work efficiency, time-consuming and labor-intensive, uneven quality of winding tapes, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

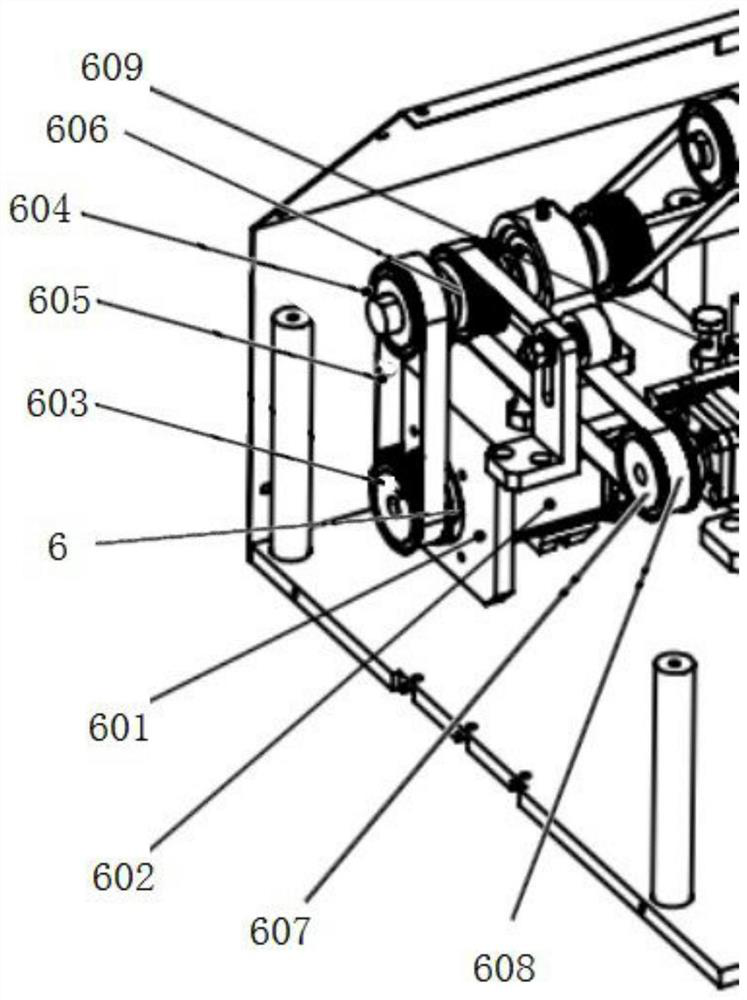

[0070] Further, as a preferred embodiment, the power module 6 includes:

[0071] The motor fixing plate 601 is located on the lower side of the upper panel 101 . In this embodiment, the motor fixing plate 601 is fixed on the lower side of the upper panel 101 by bolts.

[0072] A servo motor 602, the servo motor 602 is arranged at the lower end of the motor fixing plate 601, and the servo motor 602 is connected with the electronic control module by signal.

[0073] The first synchronous pulley 603 , the first synchronous pulley 603 is arranged on one side of the motor fixing plate 601 , and the servo motor 602 drives the first synchronous pulley 603 .

[0074] The second synchronous pulley 604 , the second synchronous pulley 604 is arranged at one end of the first transmission shaft 2 .

[0075] The first synchronous belt 605 , the first synchronous belt 605 connects the first synchronous pulley 603 and the second synchronous pulley 604 .

[0076] The third synchronous pulle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com