Automatic discharging equipment

A technology of automatic unloading and equipment, which is applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., and can solve the problems of affecting the return of the carrier, high labor costs, and material drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

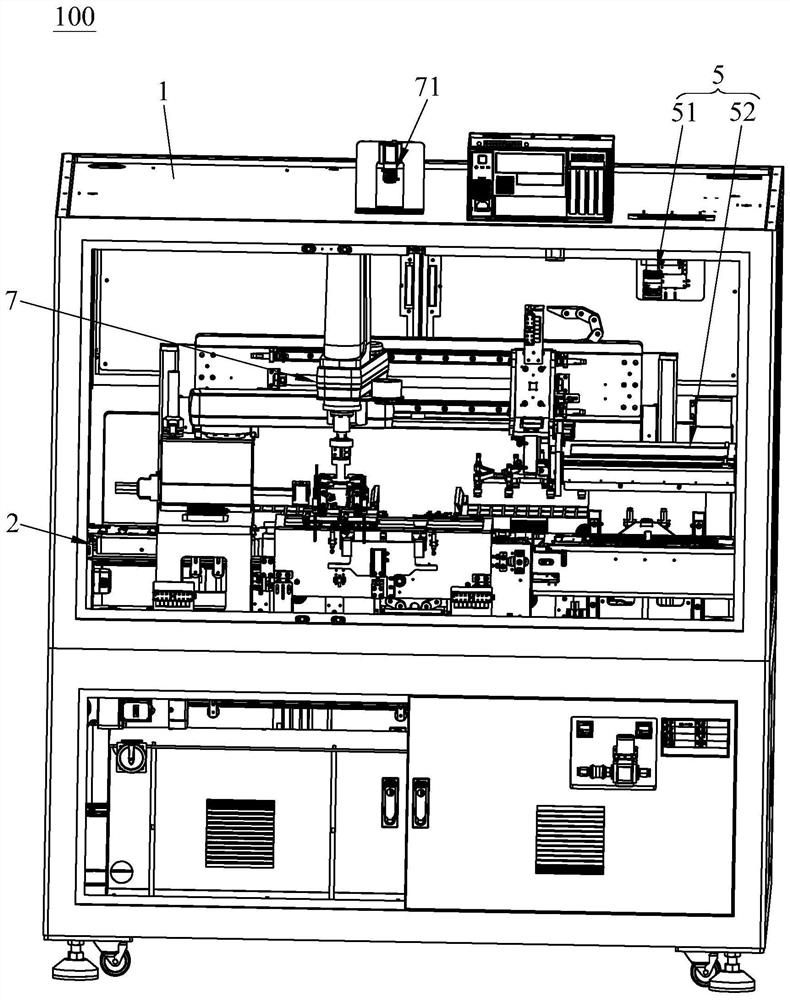

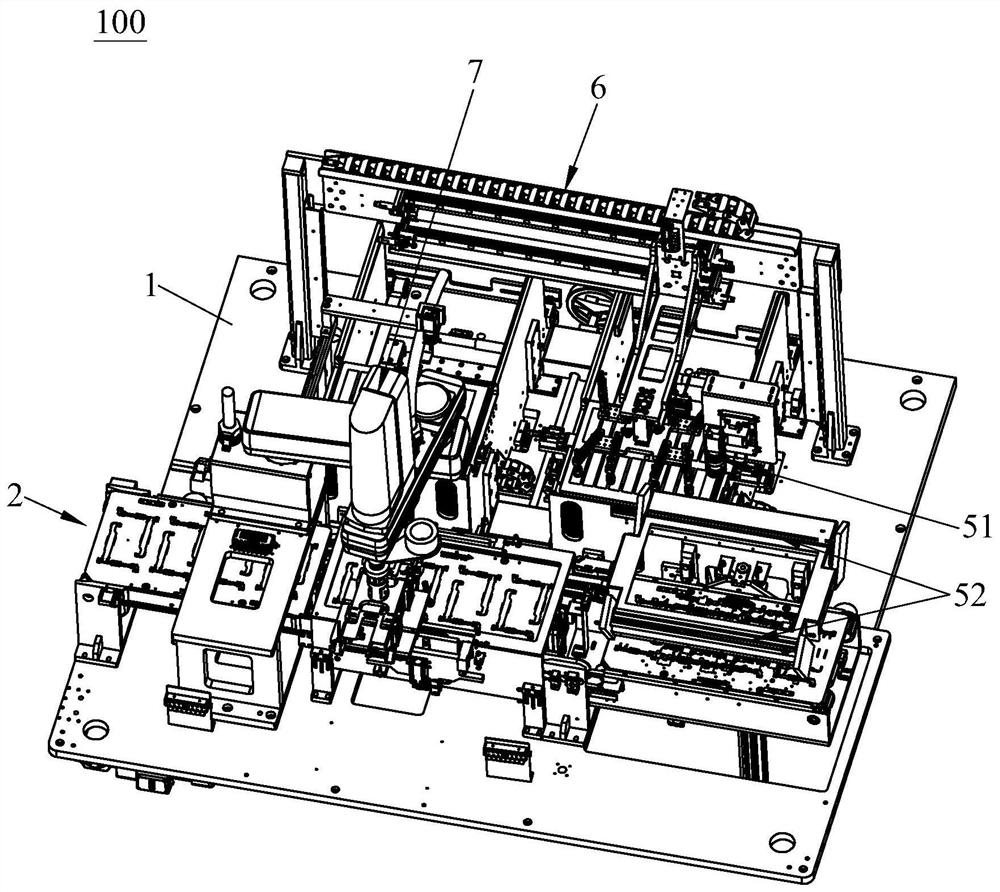

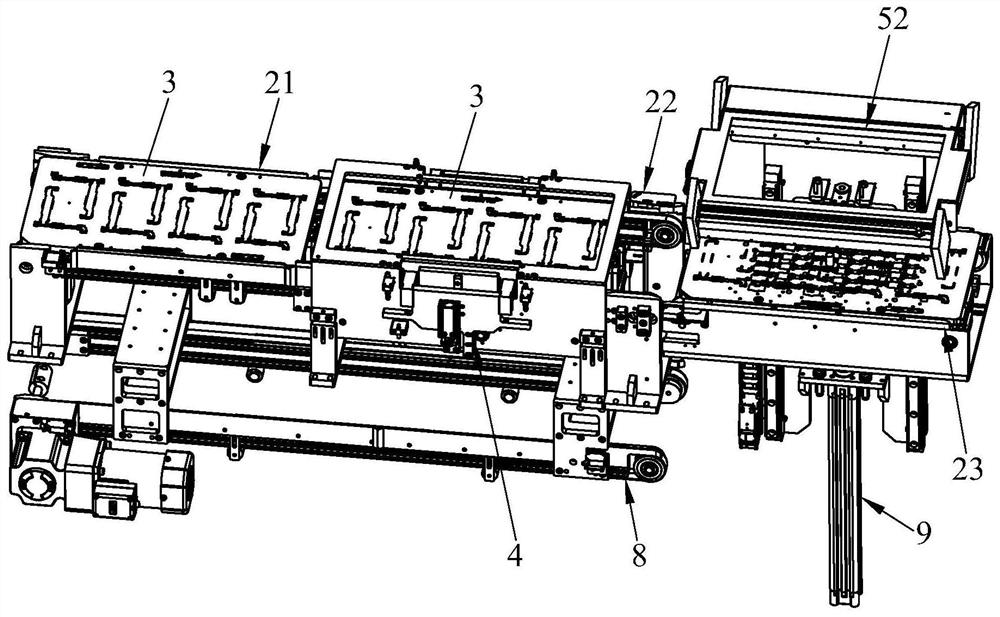

[0034] see Figure 1 to Figure 3 , the automatic unloading device 100 of the present invention comprises a frame 1, a carrier conveying mechanism 2, a carrier 3, a jacking mechanism 4, a residue detection mechanism 5, a tray 64 feeding mechanism 6 and a manipulator 7, and the carrier conveying mechanism 2 is set on the frame 1, the carrier 3 is located on the carrier conveying mechanism 2 and is used to load workpieces, the carrier conveying mechanism 2 is used to convey the carrier 3, the jacking mechanism 4 and the residual material detection mechanism 5 are along the carrier conveying mechanism The conveying direction of 2 is set on the frame 1 in turn, the jacking mechanism 4 is used to jack up the carrier 3 located on the carrier conveying mechanism 2, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com