Intelligent punching die

A stamping die and intelligent technology, which is applied in the field of intelligent stamping dies, can solve the problems of being unable to ensure that the flanges on both sides of the stamping opening are parallel to each other, low automation level, and low processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

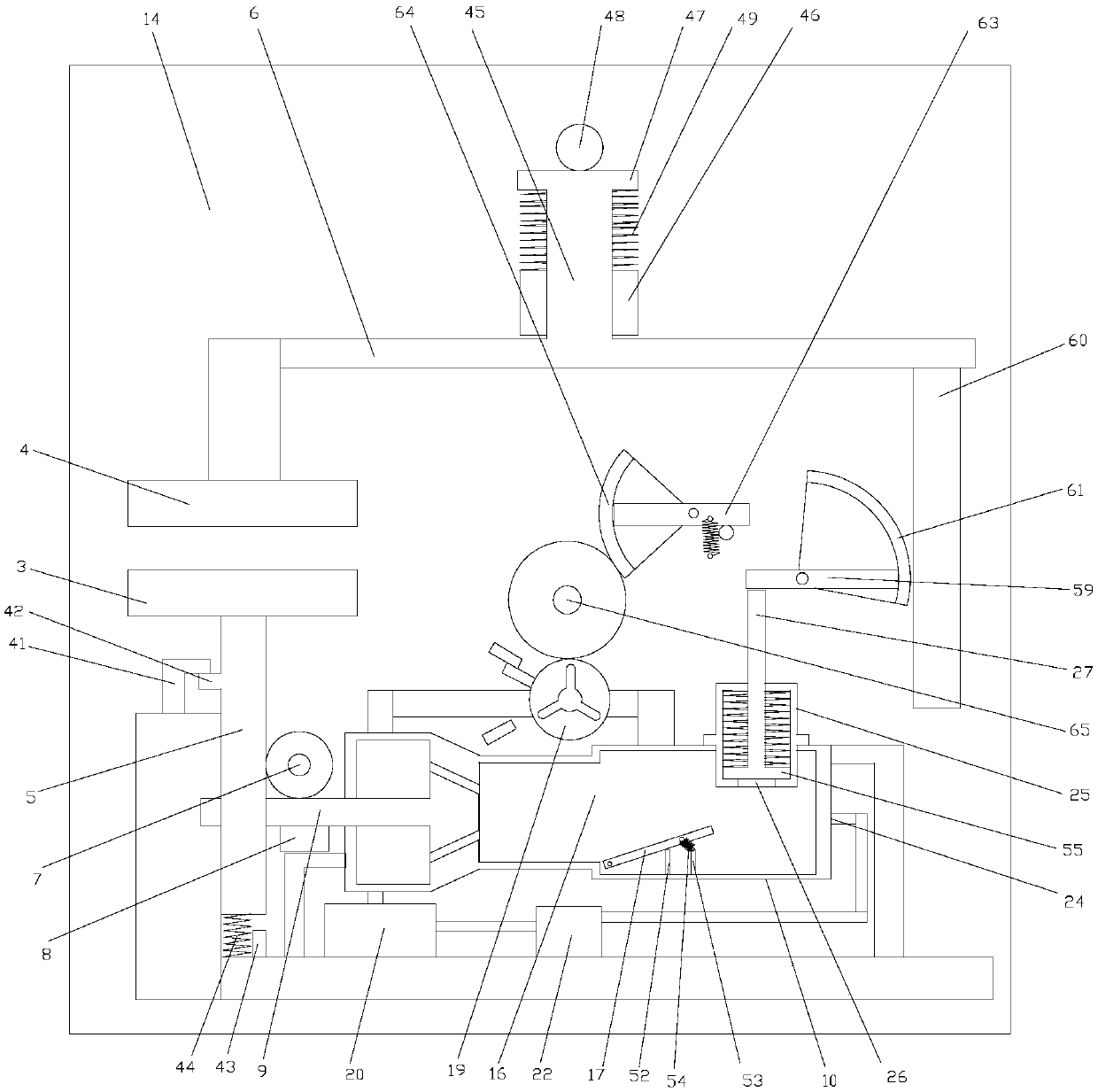

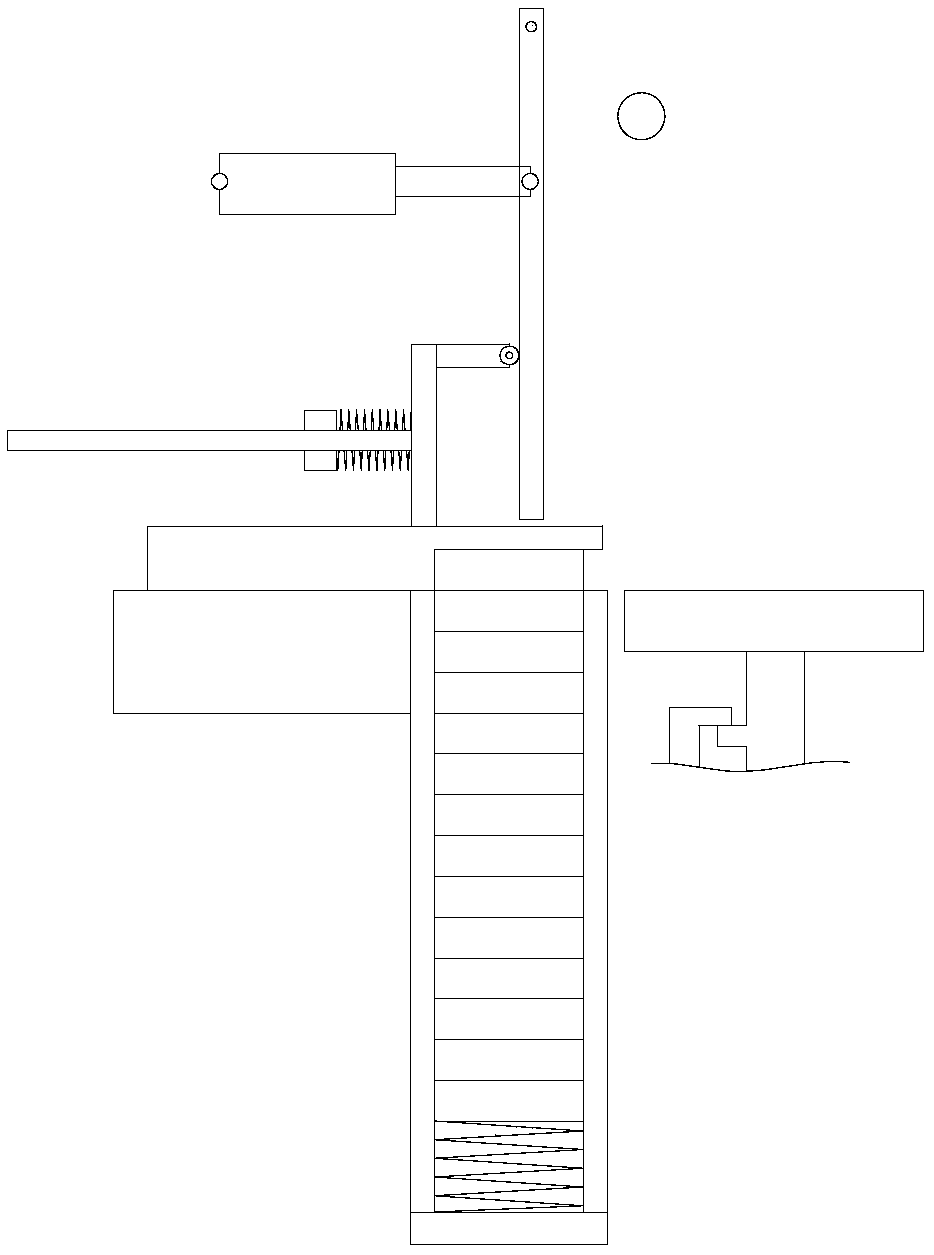

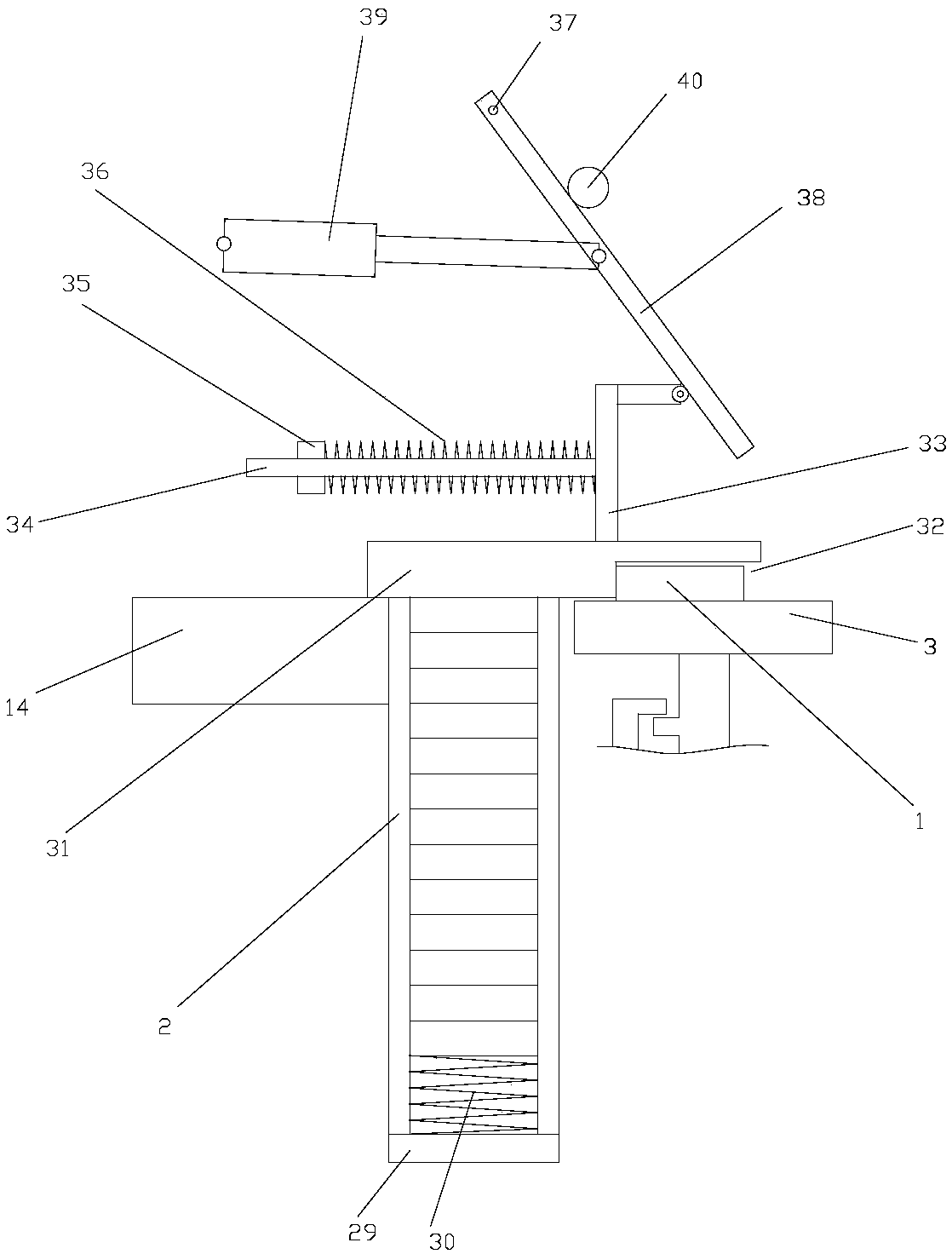

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0027] As shown in the figure, the intelligent stamping die of the present invention includes a base 14 on which the upper mold base 4 and the lower mold base 3 are slidably connected. The base 14 is provided with a barrel 2 for storing the blank 1. The base 14 There is a push assembly for pushing the blanks 1 in the barrel 2 to the lower mold base 3 one by one; All slide along the vertical direction, and then ensure that the upper mold base 4 and the lower mold base 3 can be clamped. On the base 14; the support rod 5 is provided with a first linear rack, the base 14 is rotatably connected with the first gear 7 for meshing with the first linear rack, and the base 14 is slidably connected by the guide block 8 There is a stopper rod 9, which is provided with a second linear rack for meshing transmission with the first gear 7; a valve seat 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com