Blanking device with good use effect and high efficiency

A blanking device and high-efficiency technology, applied in the field of polishing machines, can solve the problems of complex structure, low efficiency, no blanking device, etc., and achieve the effects of high efficiency, good effect, simple and practical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing:

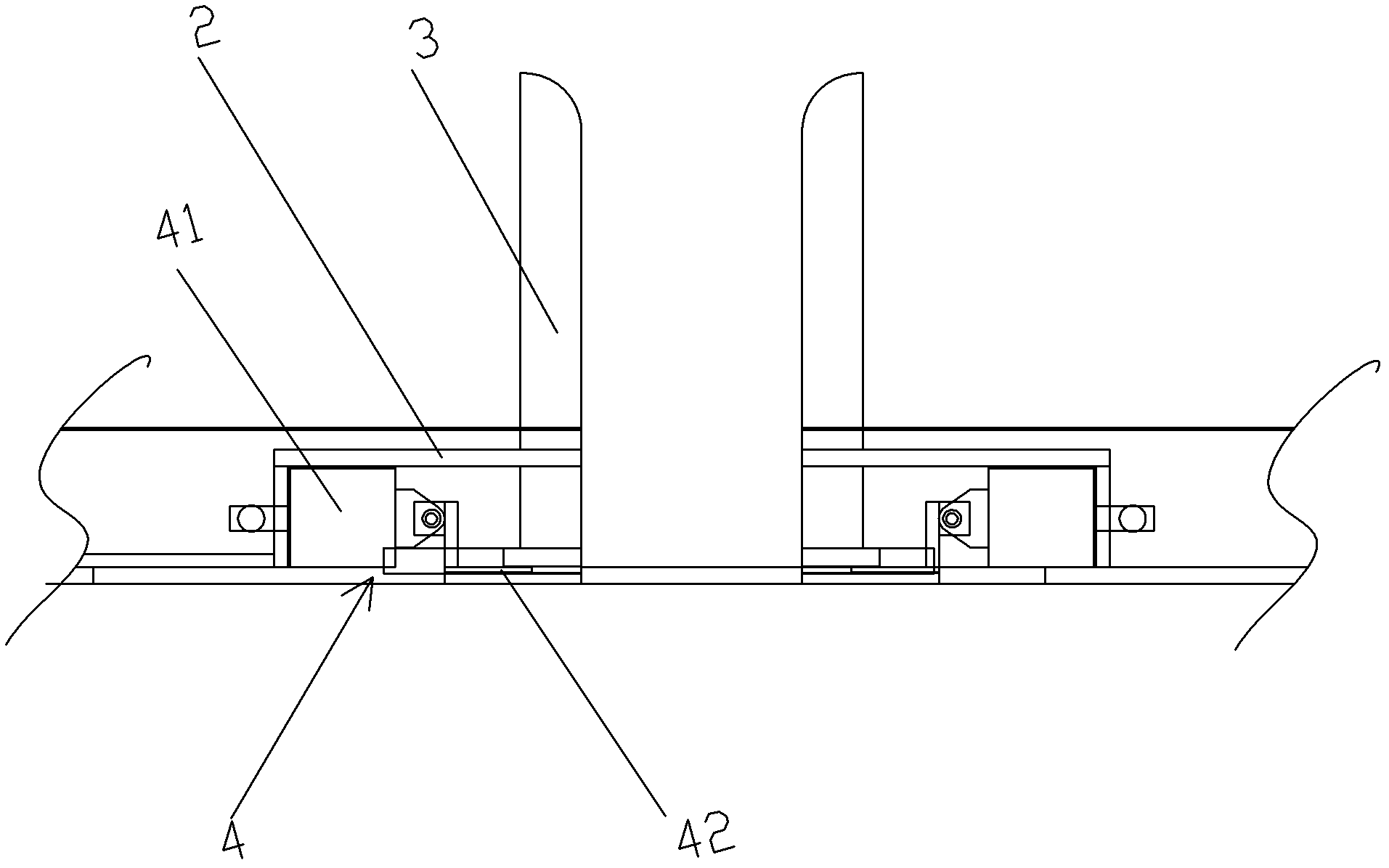

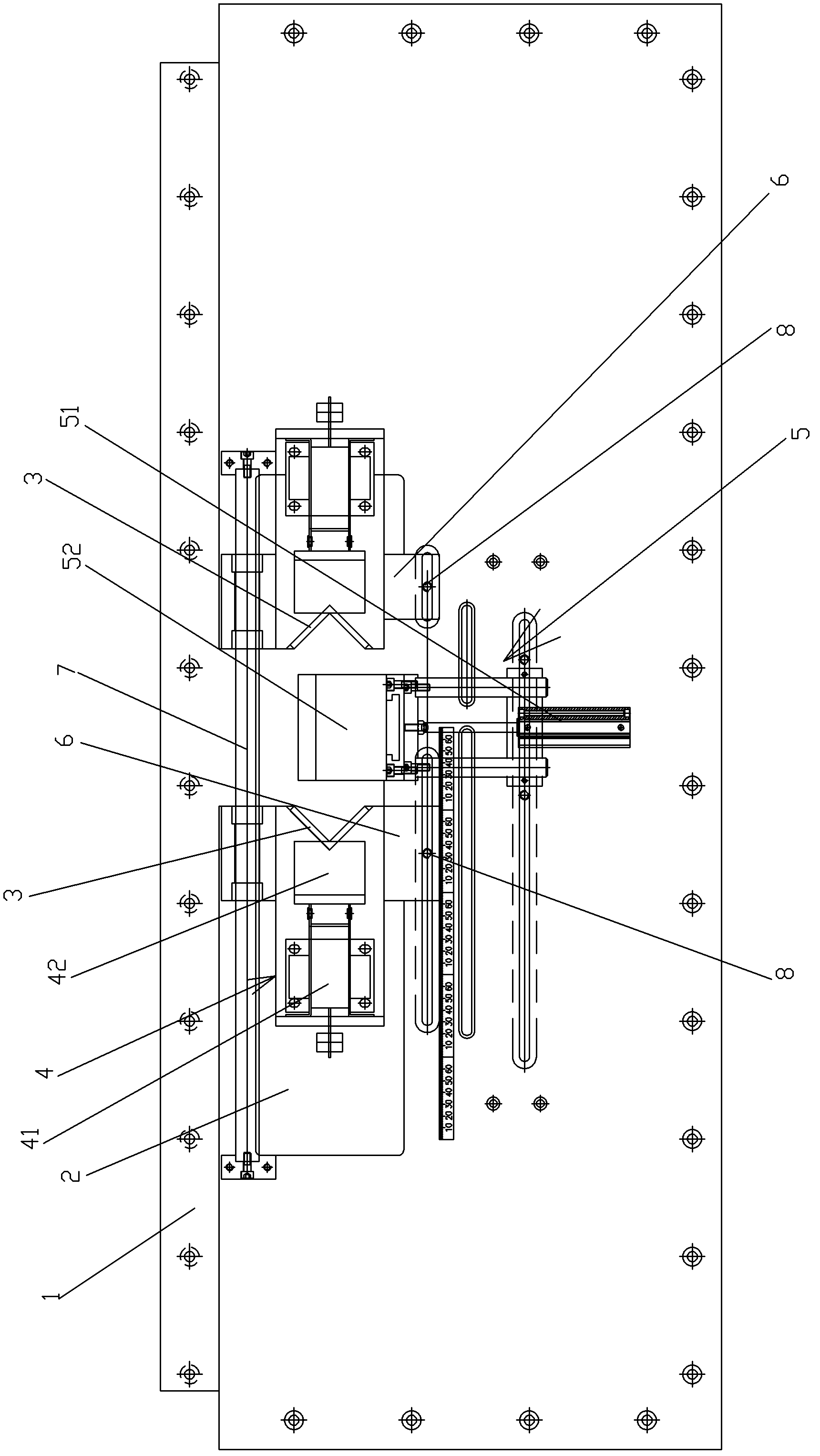

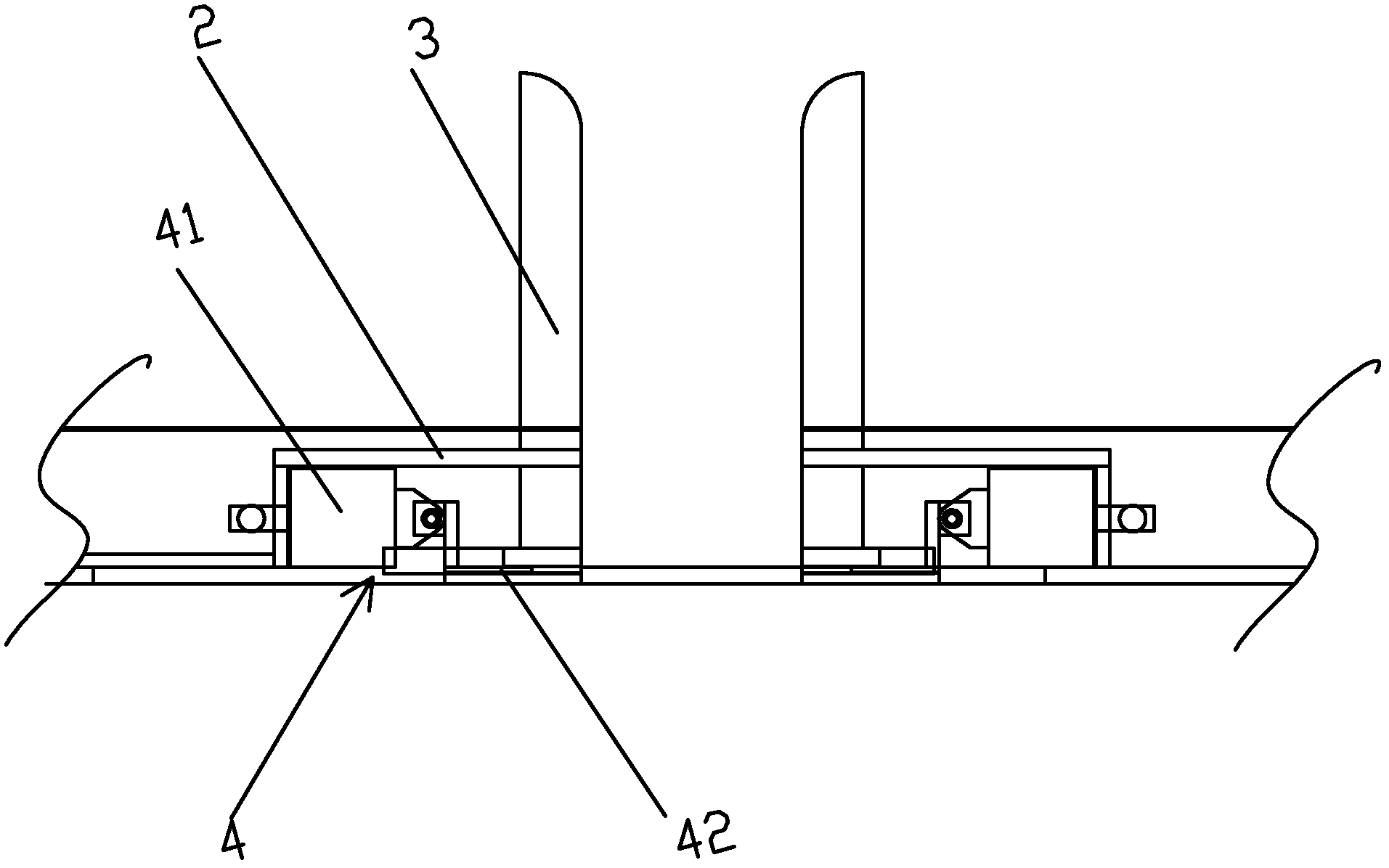

[0016] As shown in the figure, a blanking device with good use effect and high efficiency is arranged on an automatic polishing machine, and it includes a bracket 1. A working platform 2 is arranged on the bracket 1. The erected material guide bar 3 of processing workpiece. The bottom surface of the working platform 2 is provided with a main stopper assembly 4 which can block the falling of the bottom workpiece. The bottom surface of the working platform 2 is also provided with an auxiliary stopper assembly 5 that makes the bottom workpiece drop for processing and prevents the workpiece placed in the guide rod 3 from falling when the main stopper assembly 4 is in action.

[0017] Specifically, the main stopper assembly 4 includes electromagnets 41 arranged on the left and right sides of the bottom surface of the working platform 2, and the telescopic rods of the electromagnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com