Patents

Literature

690results about How to "Realize the processing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent manufacturing method and system

InactiveCN106529871ALow costRealize the processing effectLogisticsManufacturing computing systemsPersonalizationProduct order

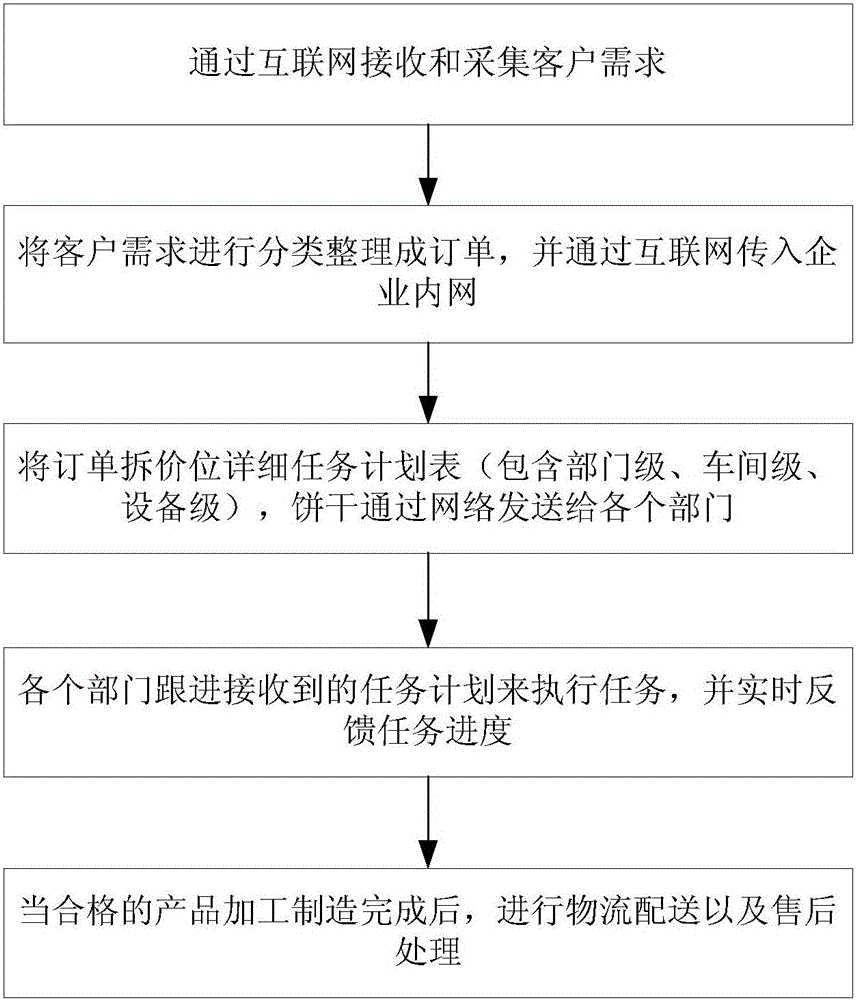

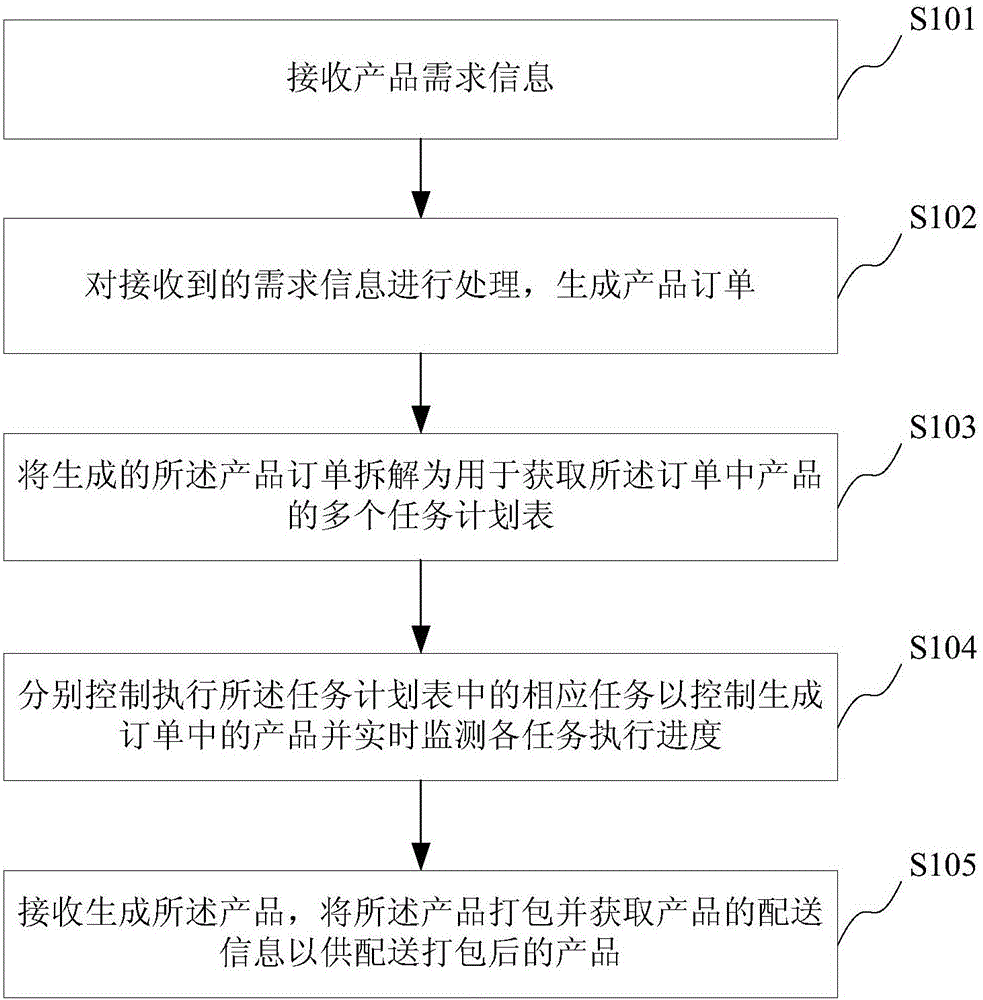

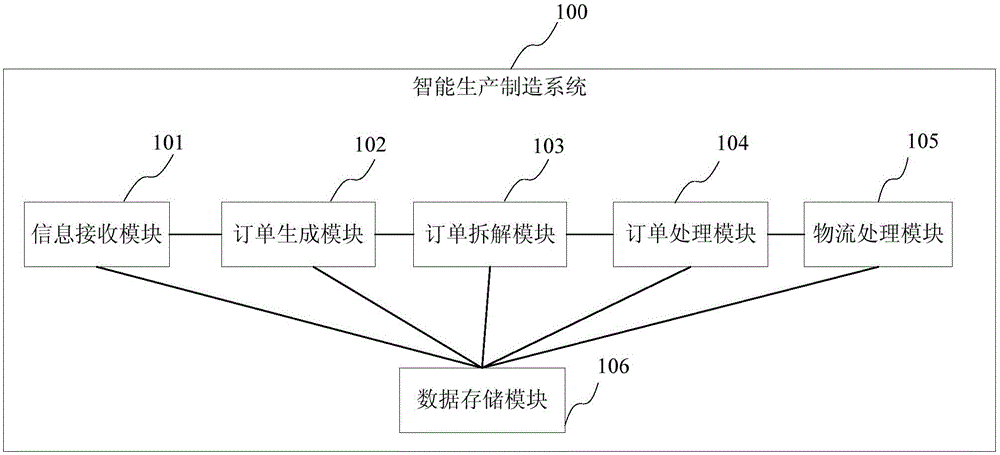

The invention provides an intelligent manufacturing method and system. The intelligent manufacturing method comprises the following steps: receiving product demand information and processing the received product demand information to generate a product order; decomposing the generated product order into a plurality of task plan tables for obtaining products in the order; executing corresponding tasks in the task plan tables to generate the products in the order in a controlled manner, and monitoring execution progress of each task in real time; and receiving the generated products, packaging the products and obtaining delivery information of the products to realize delivery of the packaged products. The method and system enable the order to be directly decomposed into production demands; and after production is finished and quality check passes, the products are delivered automatically according to the delivery information on the order, thereby realizing product customized production, processing and delivery, reducing stock to the maximum degree, saving cost for enterprises and realizing "smart factory", "smart production" and "smart logistics".

Owner:SHANGHAI FORESIGHT ROBOTICS CO LTD

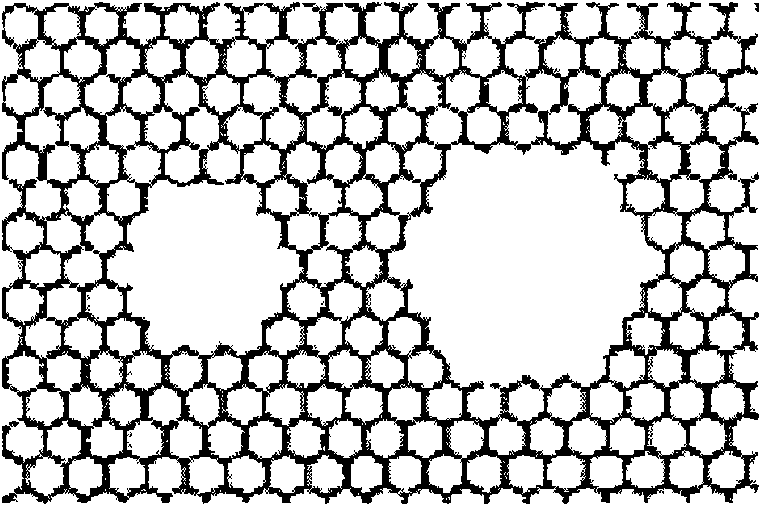

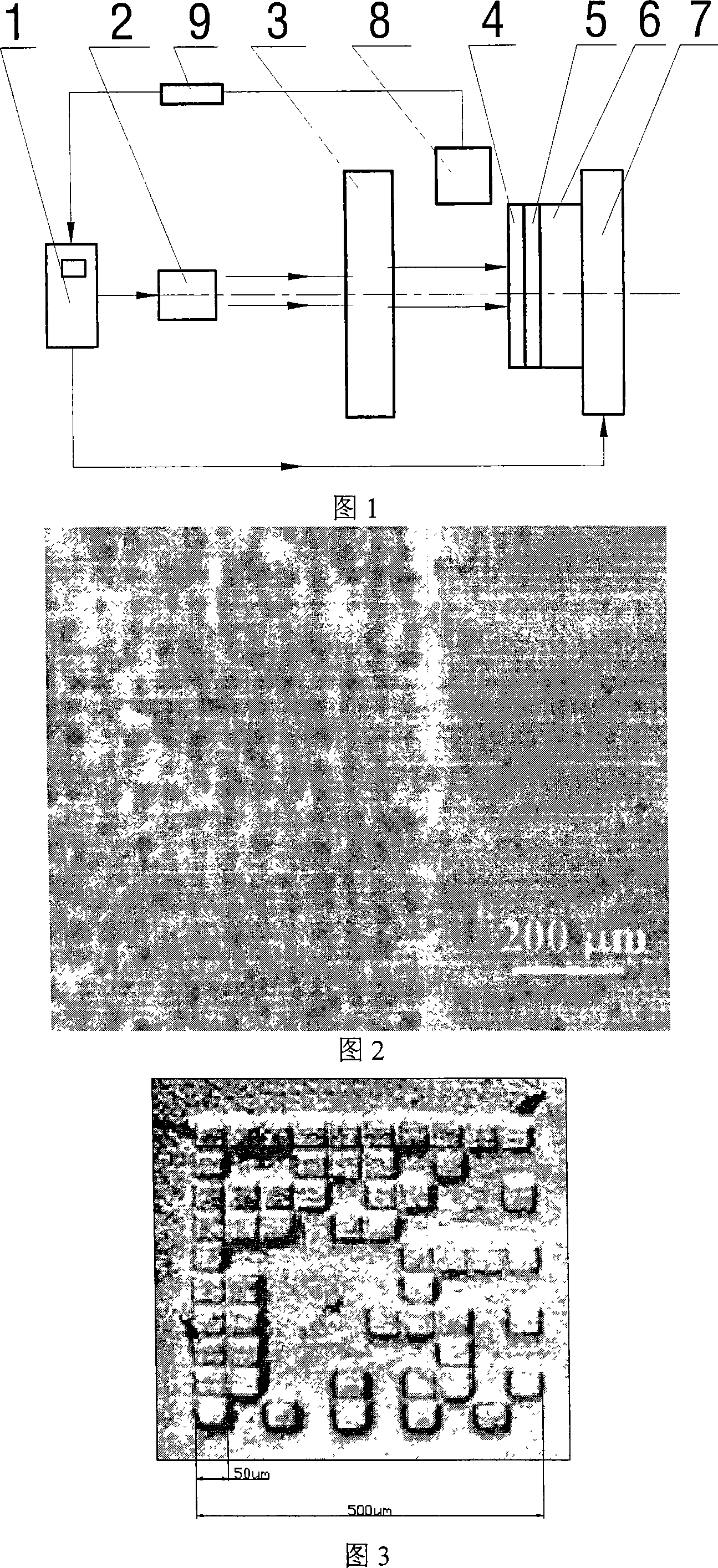

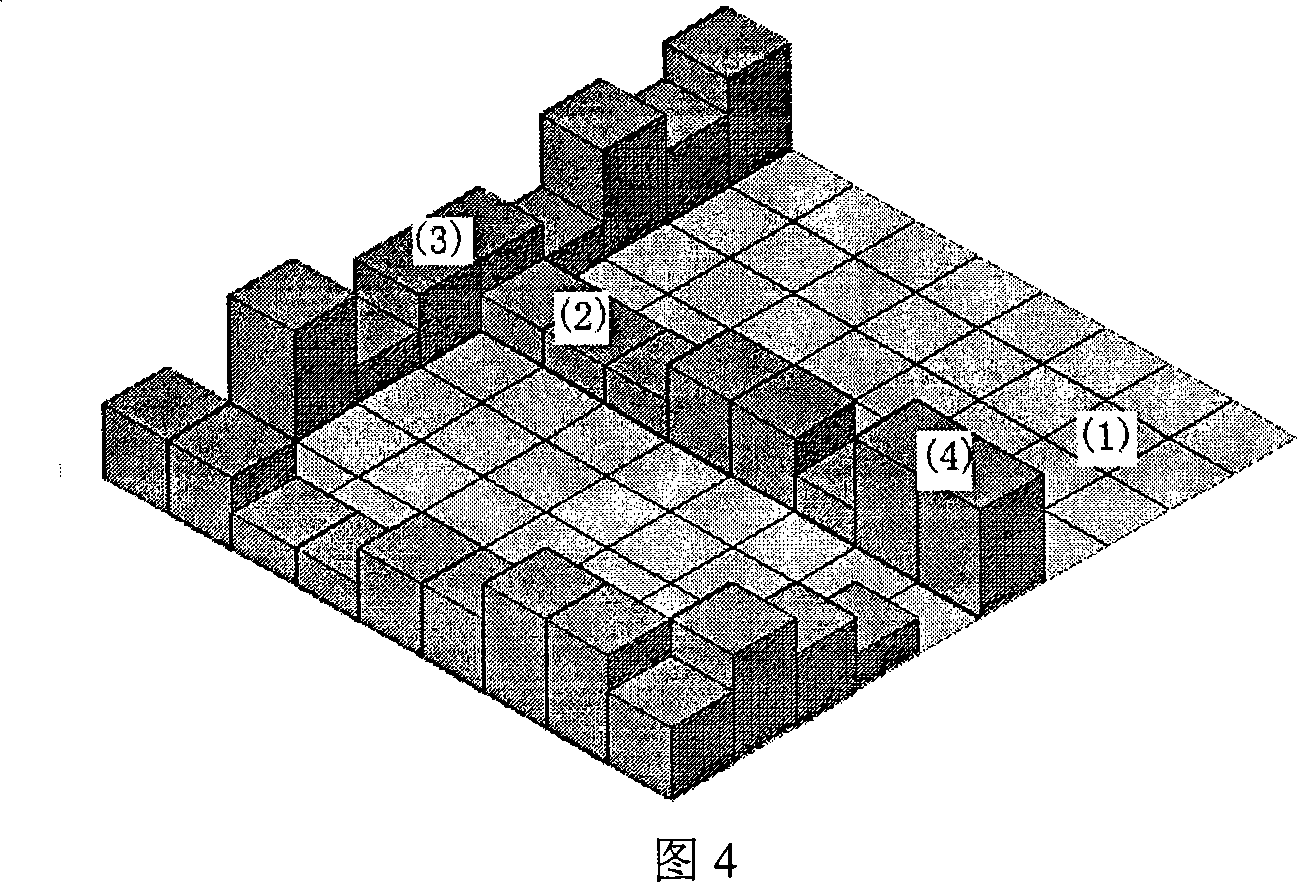

Anisotropic etching method of graphite or graphene

ActiveCN101996853AGood size controlRealize the processing effectNanostructure manufactureSemiconductor/solid-state device manufacturingHydrogenCrystal orientation

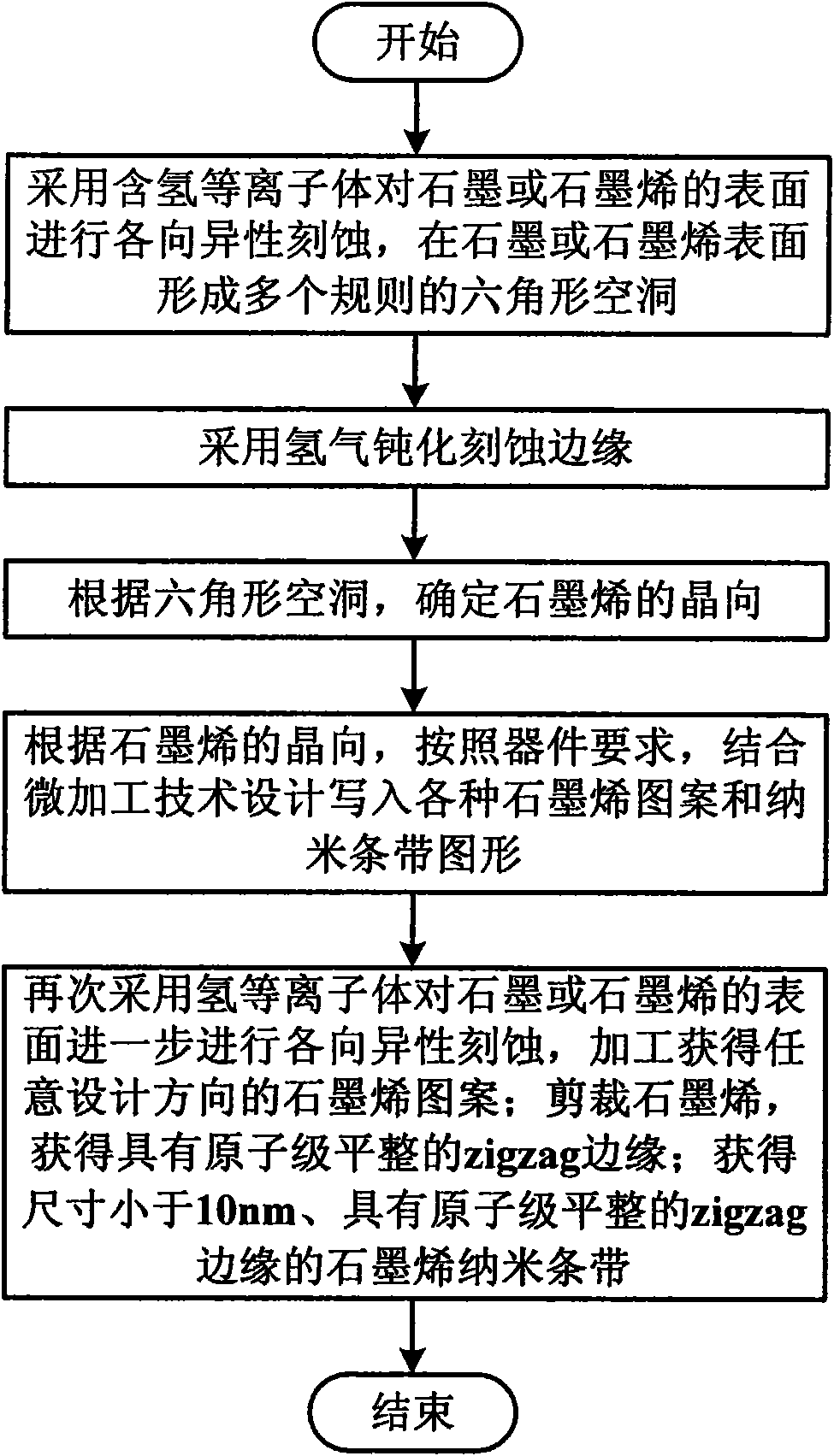

The invention discloses an anisotropic etching method of graphite or grapheme, which is used for realizing crystal orientation of graphene, graphene cutting and patterning. The method comprises the following steps of: performing anisotropic etching on the surface of graphite or grapheme by adopting hydrogen-containing plasma, and forming a plurality of regular hexagonal holes on the surface of graphite or grapheme. All the hexagonal holes have the same orientation, the orientation is matched with the crystal orientation of graphene, etched edges have atomic scale smoothness, and all the edge structures are zigzag configurations. The invention overcomes the limitations existing in the traditional etching method of graphite or grapheme and realizes cutting and patterning graphene with controllable size and atomic scale smooth edges.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

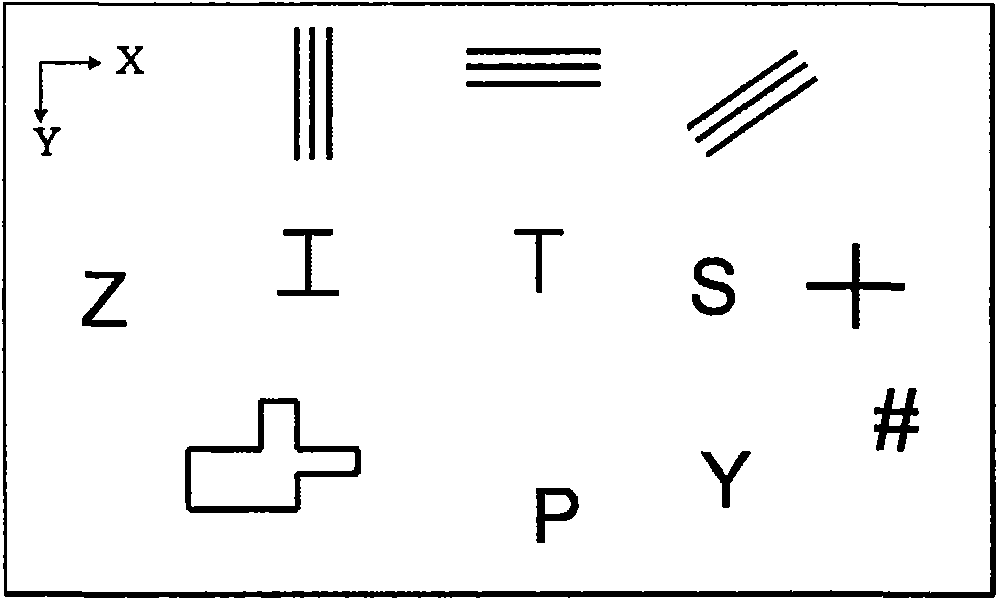

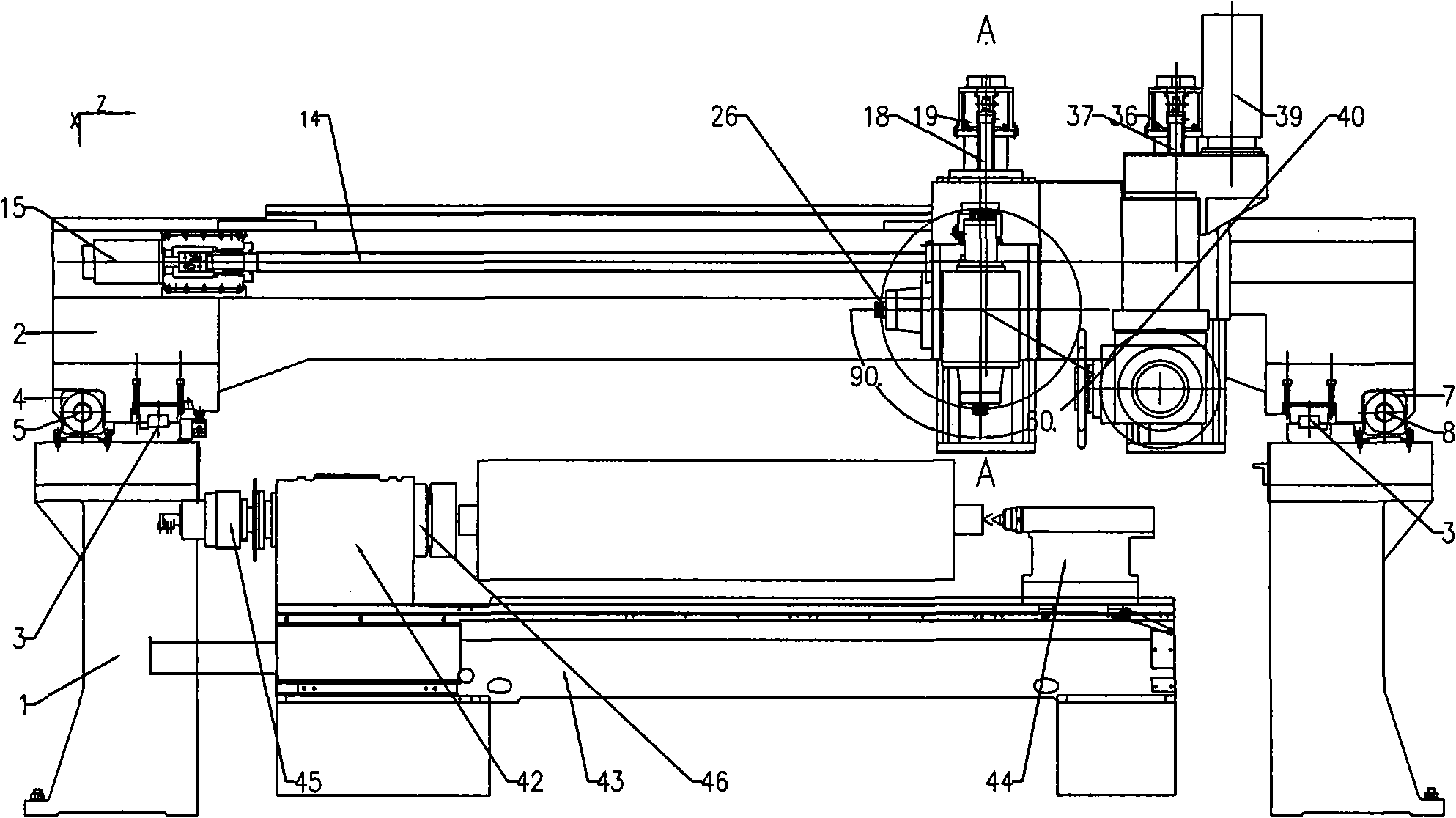

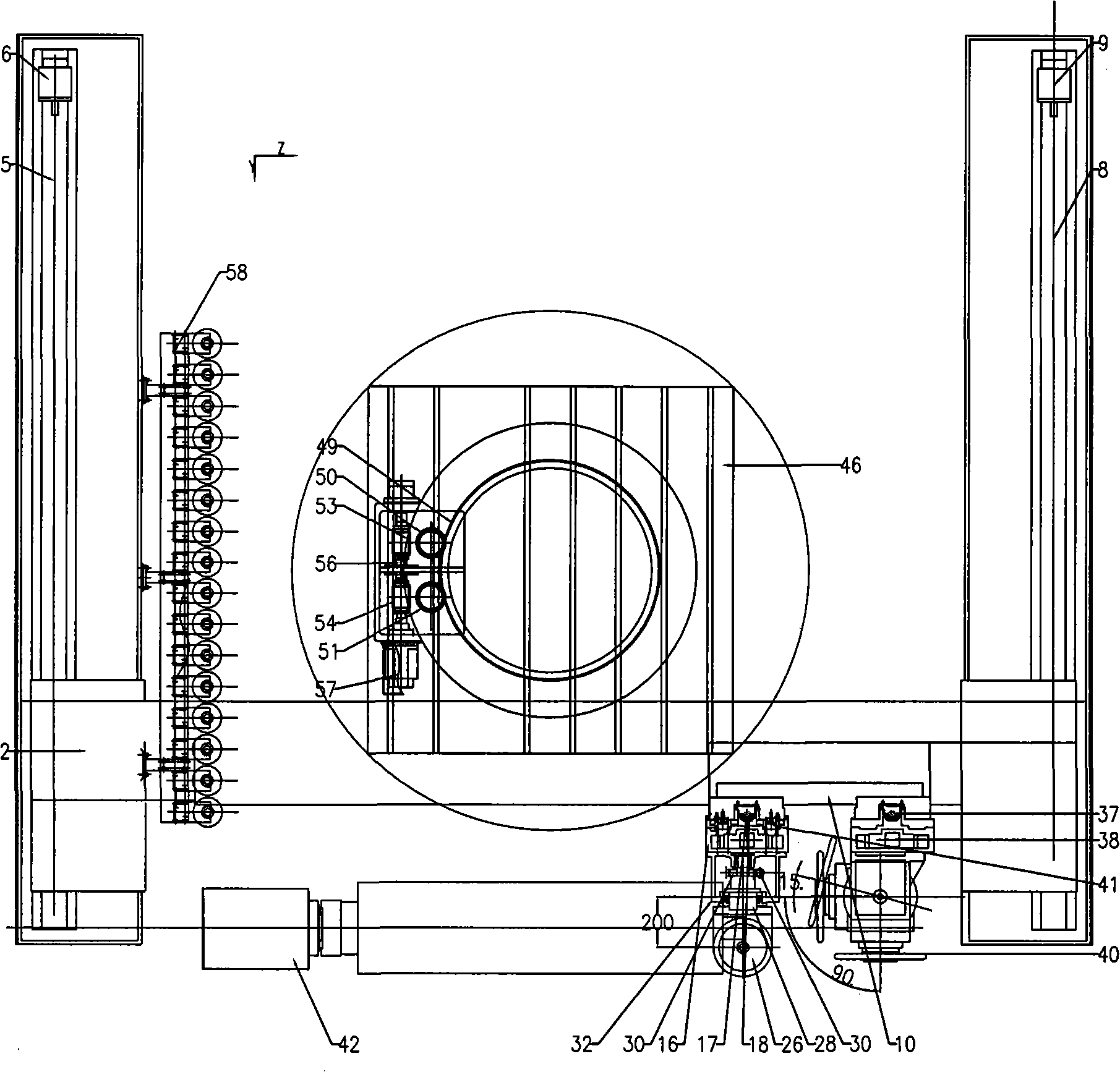

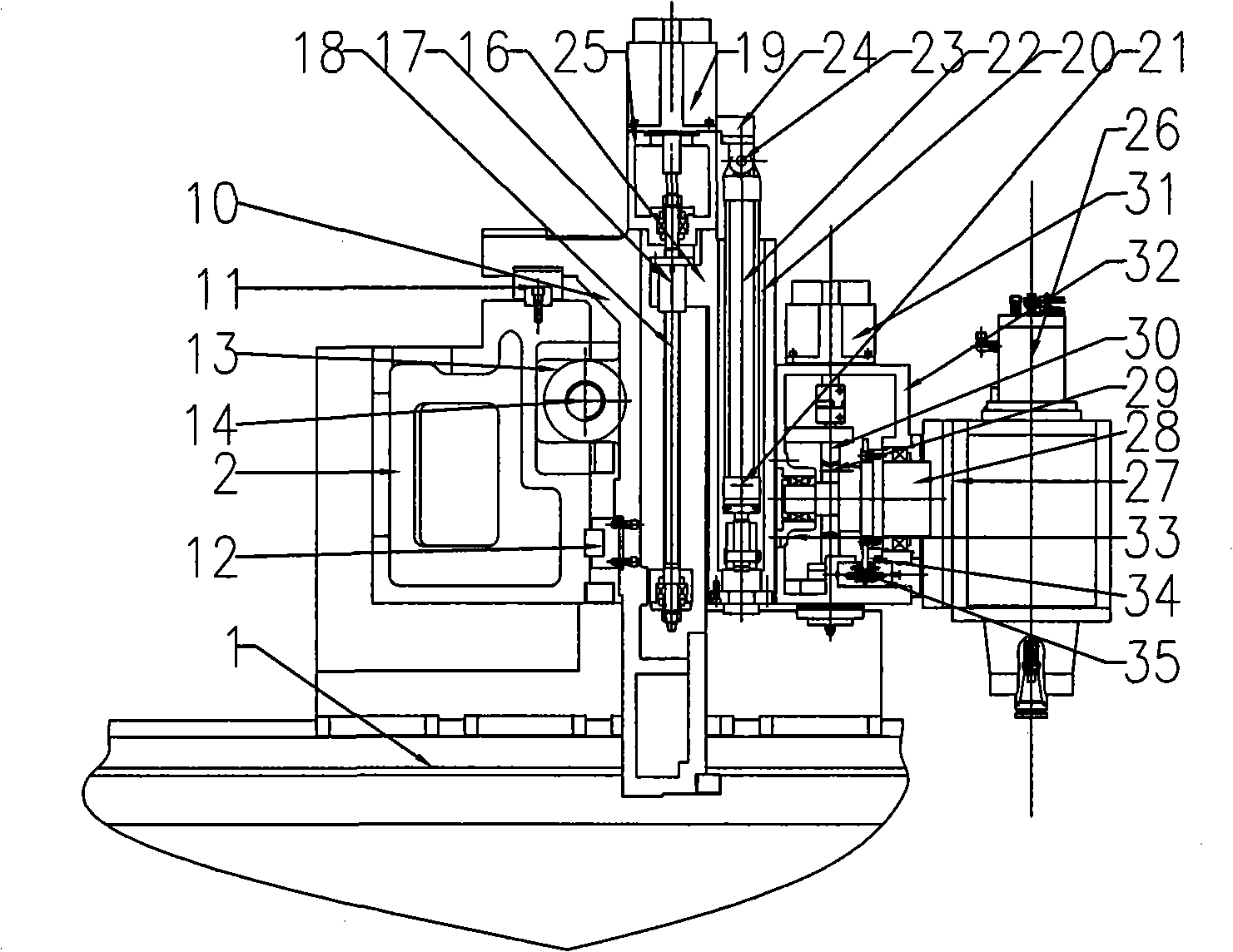

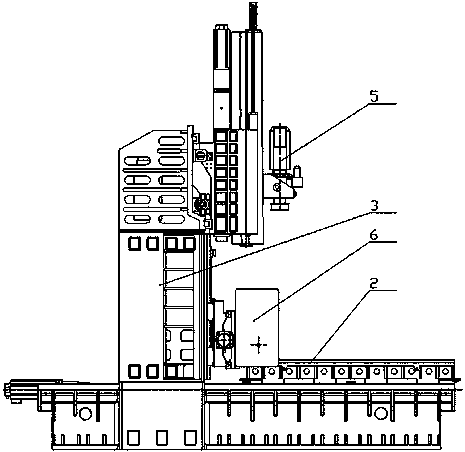

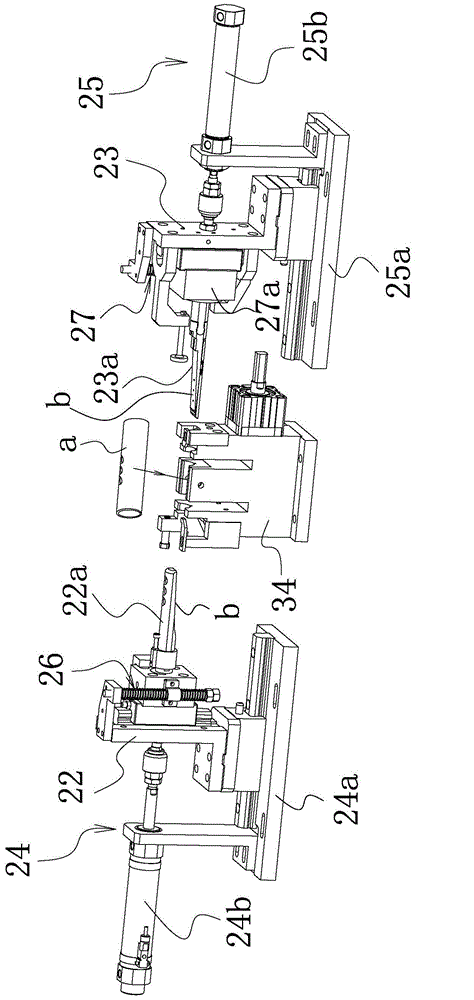

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

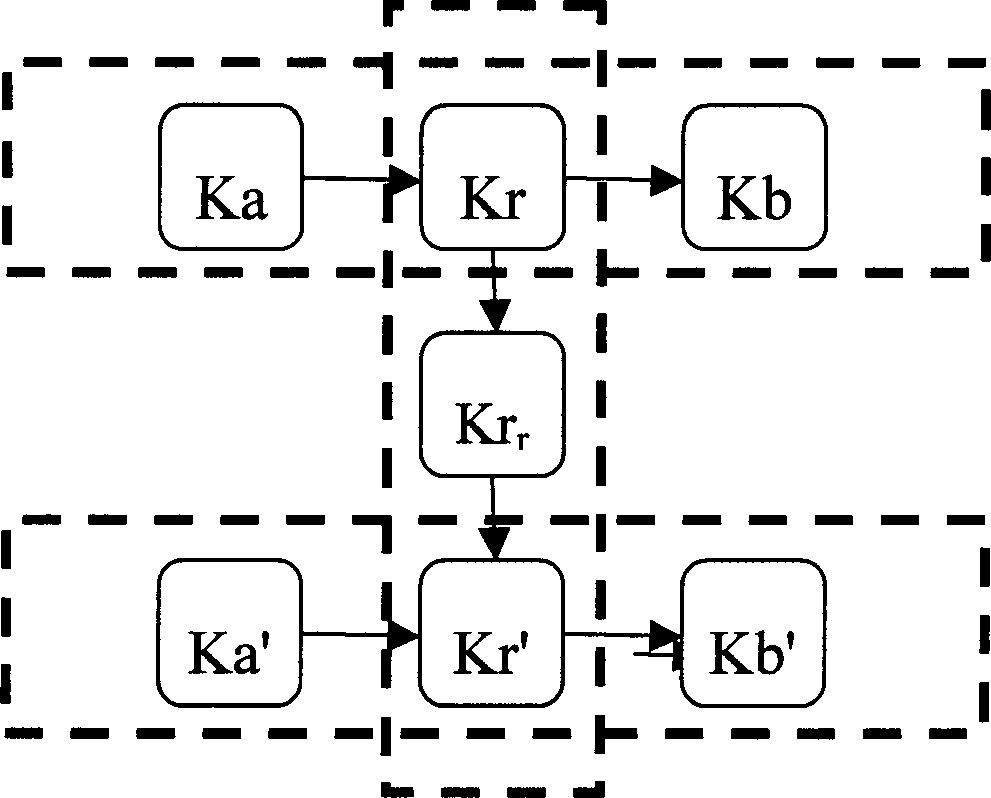

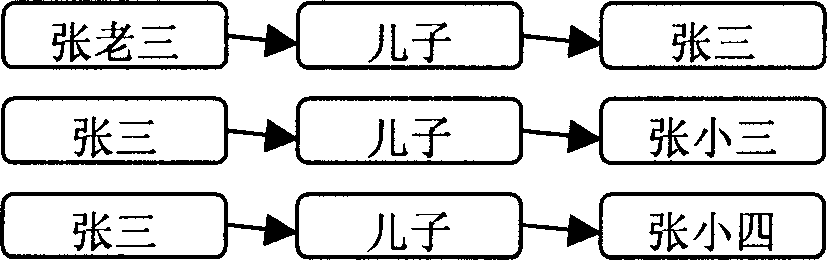

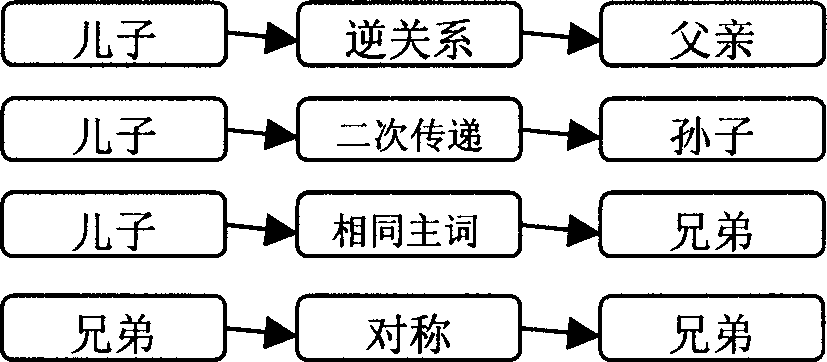

System and method for intelligent retrieval and processing of information

InactiveCN1845104AAccurateReduce redundancySpecial data processing applicationsFull text searchCombinatorial search

The invention discloses a system for intelligently searching and treating information and relative method. Wherein, said system comprises a data intelligent treating subsystem, a processing database, an issue and manage module, a search database, and an intelligent search server subsystem, while the issue and manage module comprises a data issue and synchronize module, a data develop manage module; the inventive system can treat the data to divide the data into 12 kinds. Said method comprises: inputting search condition; pretreatment; dividing the search request into simple direct search, advanced integrated search, classified browse search, full-text search, and intelligent logic search, while the first three methods directly use the relationship search engine to search; the full-text search uses full search engine; the intelligent logic search uses logic relationship to recombine the inquire condition to search with the relationship search engine; after obtaining result, feeding back the search result.

Owner:赵开灏

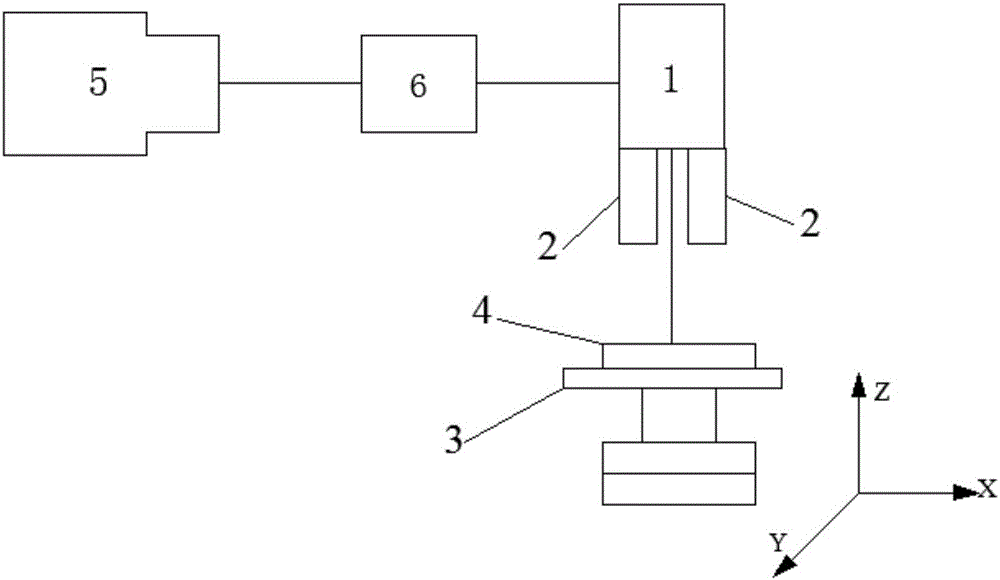

Milling, grinding and polishing device based on intelligent numerically-controlled platform

InactiveCN101983838AAchieve deterministic grindingRealize the processing effectOptical surface grinding machinesGrinding feed controlSurface typeSpatial movement

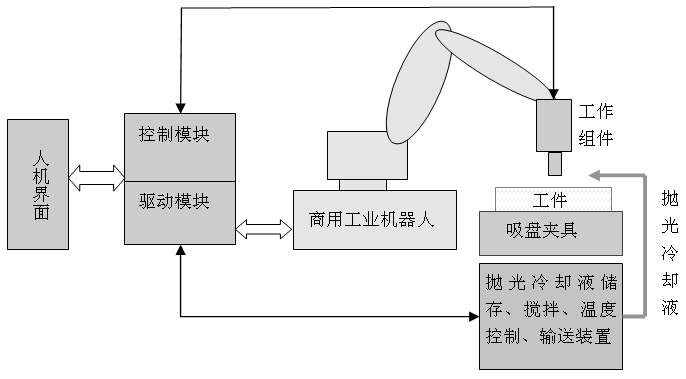

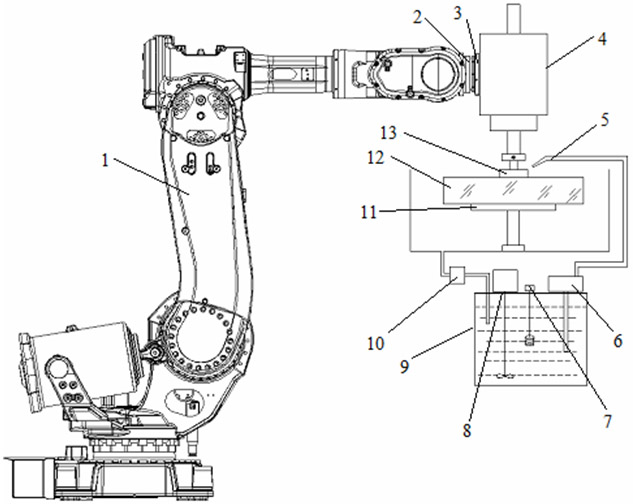

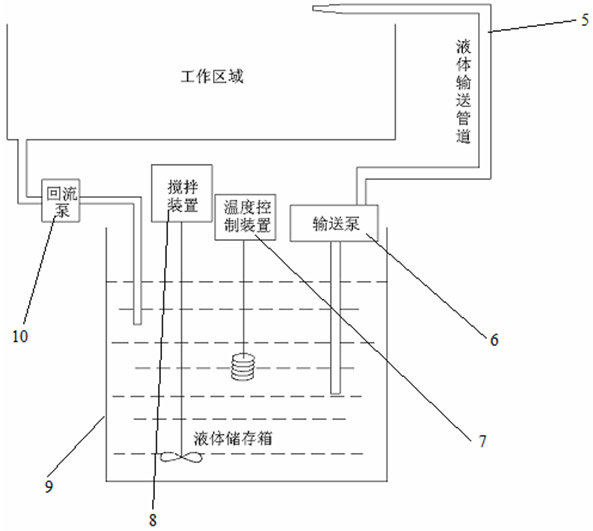

The invention relates to a milling, grinding and polishing device based on an intelligent numerically-controlled platform, belonging to the technical field of modern optical processing. The device comprises an industrial robot, a control module, a driving module, a human-computer interaction interface, a working component, a polishing and cooling liquid cyclic control system and a sucker clamp, wherein the control module and the driving module control and drive the spatial movement and spatial positioning of the industrial robot, thereby controlling the working state of the working component, namely a grinding / polishing module; the control module also controls the human-computer interaction interface and simultaneously controls a stirring device, a temperature control device and a conveying device of the polishing and cooling liquid cyclic control system; and the sucker clamp is used for clamping a workpiece to be processed. The device of the invention has low manufacturing cost, large processing caliber and wide processed surface types, and two functions of grinding and polishing can be realized by replacing grinding heads.

Owner:FUDAN UNIV +1

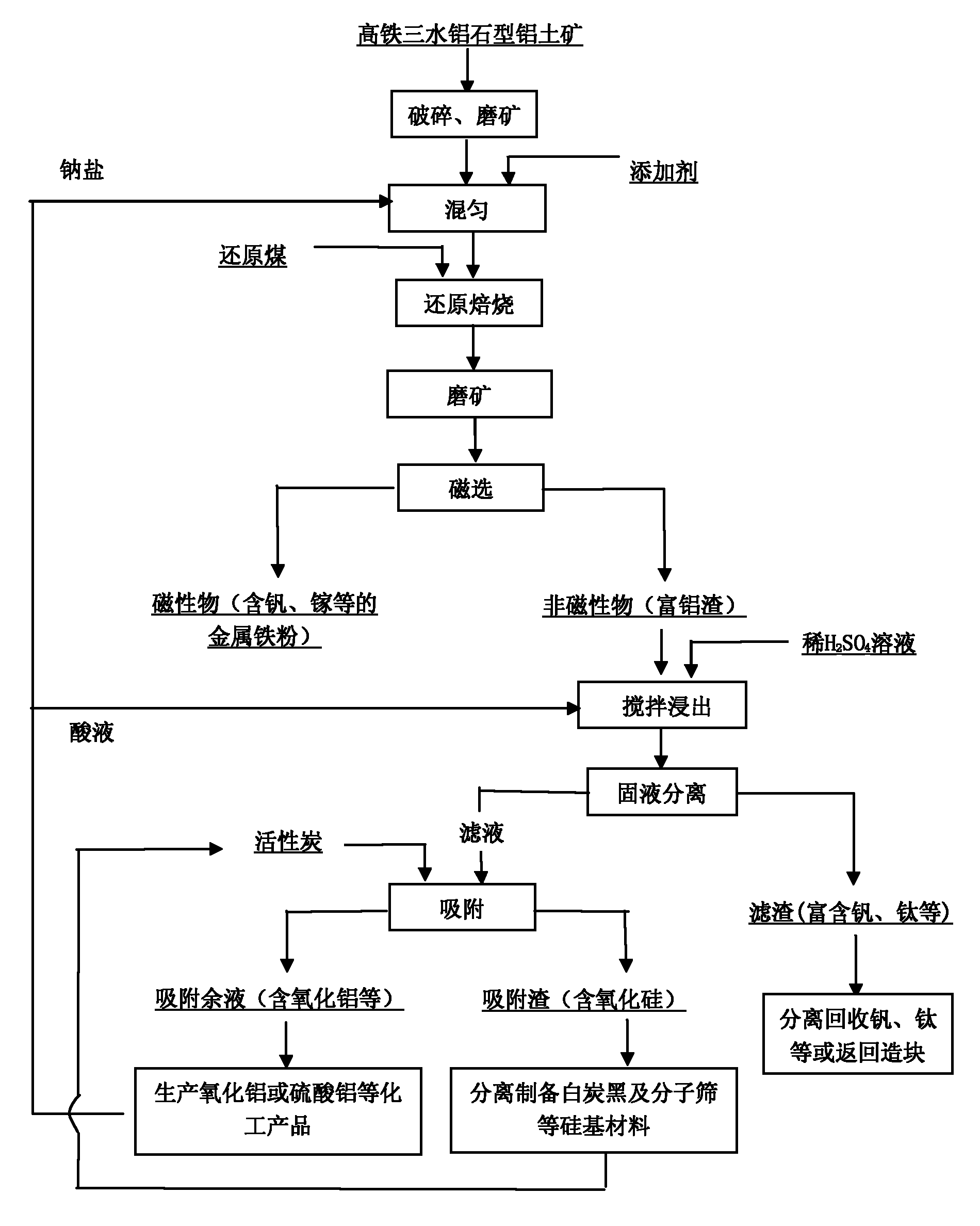

Method for comprehensive utilization of high-iron bauxite

ActiveCN101875129ARealize comprehensive utilizationRealize the processing effectSilicon compoundsWet separationSlagSorbent

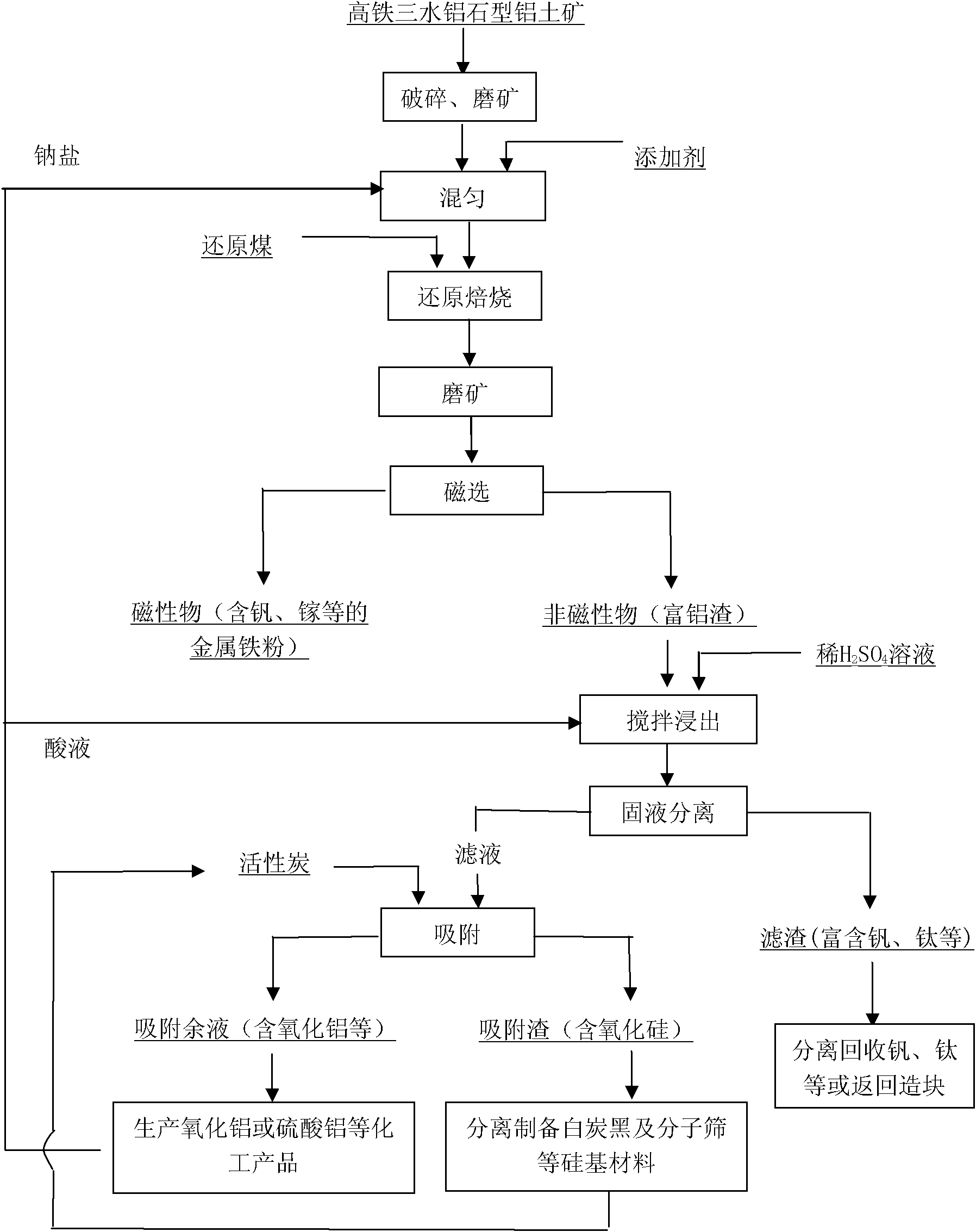

The invention discloses a method for the comprehensive utilization of high-iron bauxite. The method comprises the following steps: uniformly mixing finely ground high iron bauxite and additives, carrying out reduction roasting by using coal as a reducing agent, and carrying out ore grinding and magnetic separation after reduction to obtain directly reduced iron powder (magnetic product) and aluminum-enriched slag (non-magnetic product); carrying out agitation leaching on the aluminum-enriched slag with leaching agent to dissolve aluminum and silicon in the solution; adsorbing the silicon in the leach solution by using porous adsorbent, and further separating the adsorbed silicon to prepare white carbon black, molecular sieves and other silicon-based products; and extracting chemical products, such as aluminum oxide, aluminum sulfate or the like, from the solution after silicon separation. When high-iron bauxite is processed by using the method, aluminum, iron and silicon can be separated, and simultaneously, valuable elements can be processed into products for different purposes so as to realize value-added processing. Besides, the method has the characteristics of short flow, low energy consumption, high comprehensive utilization rate of resources and the like, thereby having wide application prospects.

Owner:CENT SOUTH UNIV

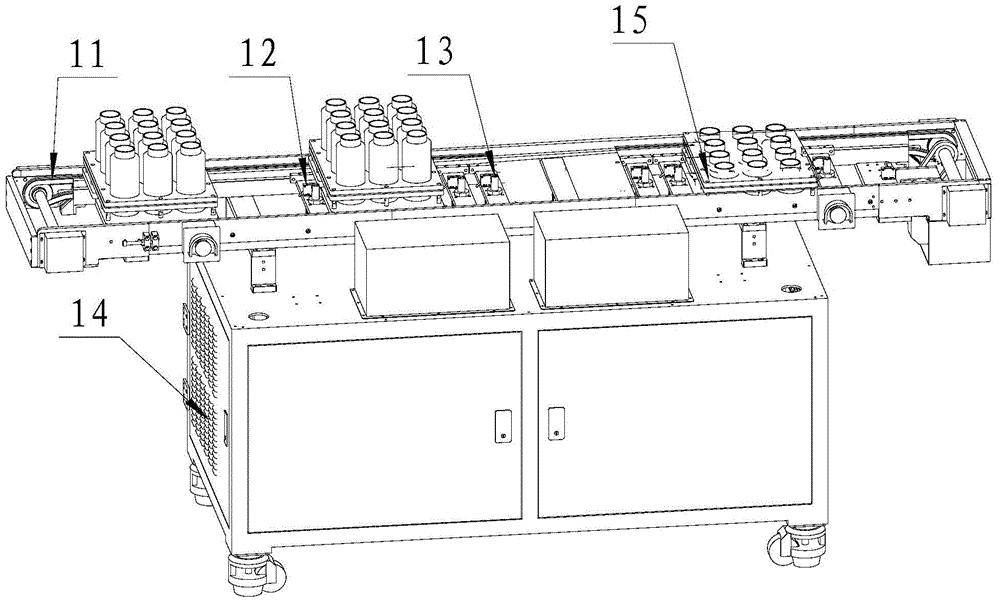

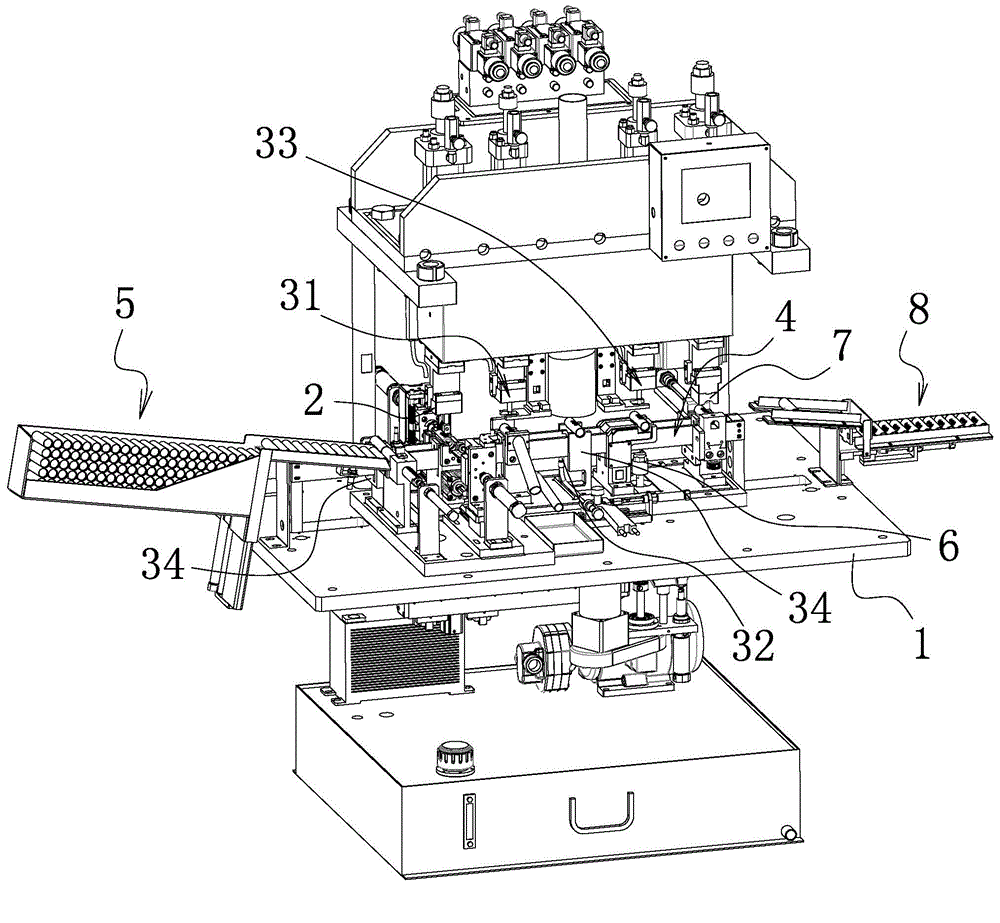

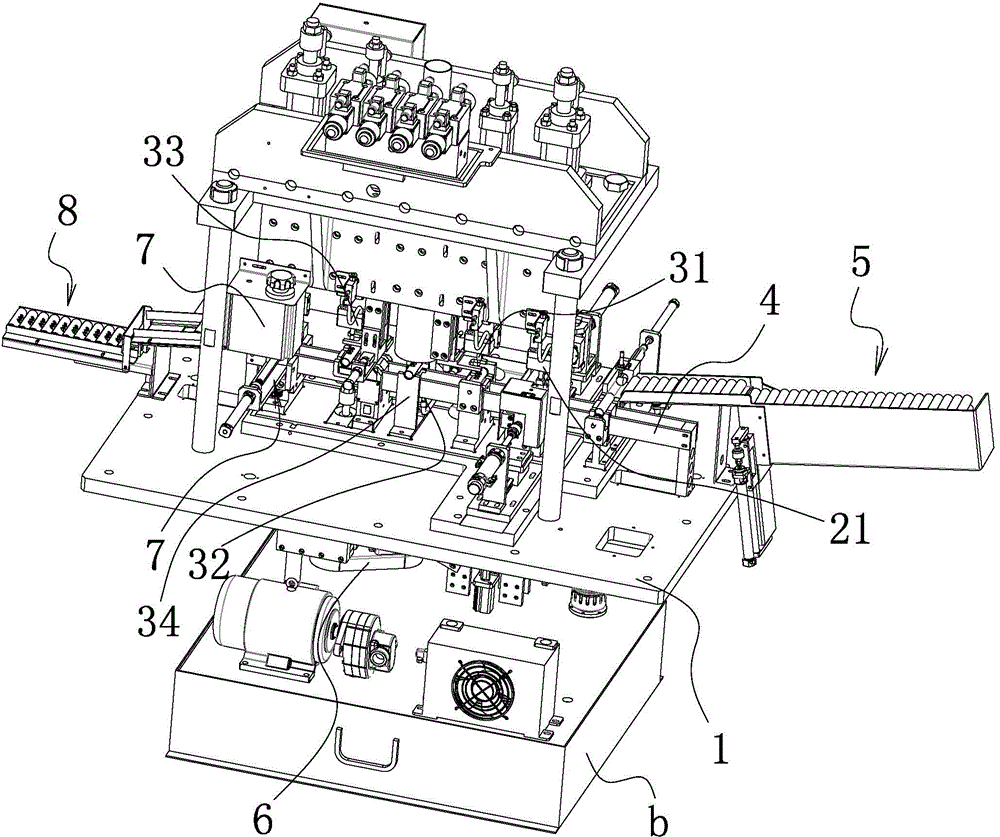

Device and method for using laser technology to mark feeding bottle

The invention relates to the laser processing technology field and discloses a device and a method for using the laser technology to mark the feeding bottle. The device for using the laser technology to mark the feeding bottle comprises an automatic material feeding mechanism, a material receiving-taking mechanism, a laser marking mechanism and a rotary disc mechanism; the automatic material feeding mechanism is provided with a product to be processed and the product to be processed is delivered to a material taking-receiving position of the material taking-receiving mechanism, and the automatic material feeding mechanism is also used for delivering processed products; the taking-receiving material mechanism takes product to be processed and puts the product to be processed on the rotary disc mechanism; the processed product on the rotary disc mechanism is taken away and is put back on the automatic material feeding mechanism; the rotary disc mechanism clamps the product to be processed and drives the product to be processed to rotate to a position corresponding to the position of a laser marking mechanism; and the laser marking mechanism performs laser marking on the product to be processed. The device and method can perform laser calibration on the glass bottle, the structure is simple, the function is reliable and easy to implement, and the automation is realized.

Owner:HANS LASER TECH IND GRP CO LTD

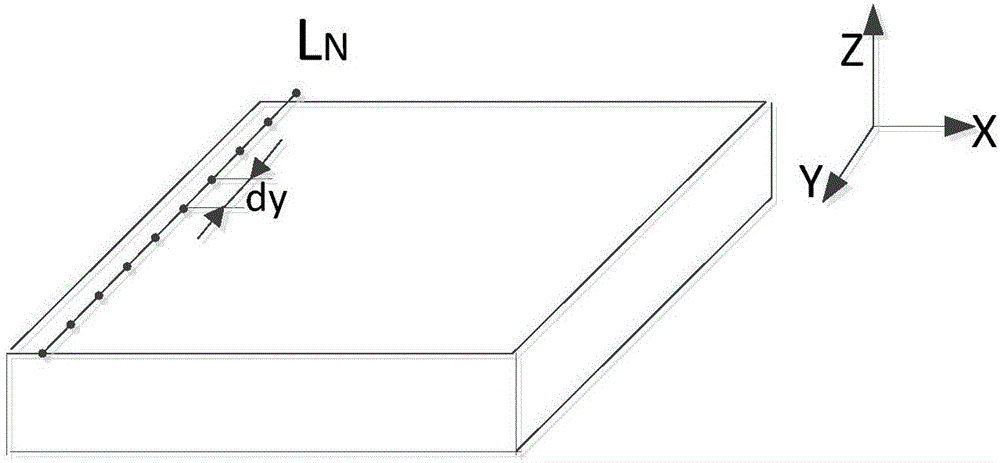

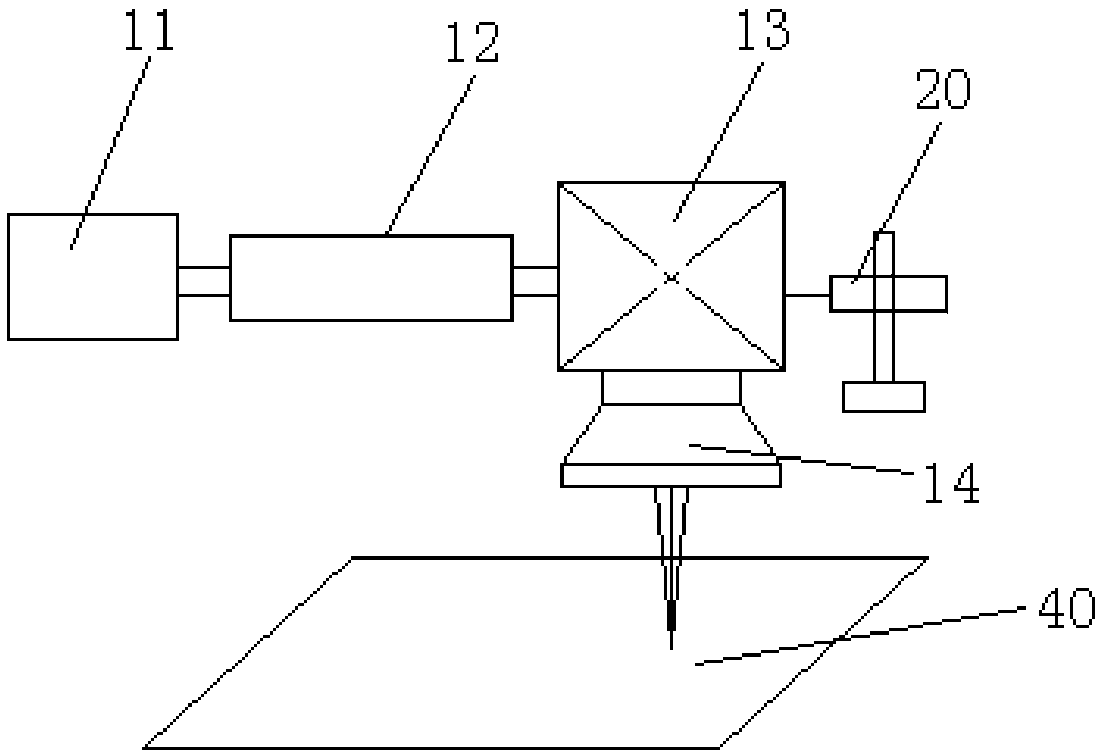

Measurement and processing integrated laser leveling polishing method

ActiveCN106001927ARealize dynamic adjustmentReduce thicknessLaser beam welding apparatusMeasurement pointLaser scanning

The invention provides a measurement and processing integrated laser leveling polishing method which comprises the steps that a workpiece is clamped; a two-dimensional laser displacement sensor and the workpiece are controlled to make relative translation movement, and a coordinate matrix of uniform measurement points is obtained; a galvanometer scanning system is controlled to scan a to-be-polished part of the surface of the workpiece according to the set scanning speed, and a new coordinate matrix of the uniform measurement points of the to-be-polished part of the surface of the workpiece is obtained after laser scanning; delta is calculated according to the function that delta is equal to z'max-z'min, if delta is less than or equal to the target smoothness of the workpiece, the operation is completed; otherwise, a laser scanning grid chart of the surface of the workpiece is constructed, and each grid in the laser scanning grid chart is endowed with a weight number k; the galvanometer scanning system is controlled to carry out k times of scanning processing on each grid in the laser scanning grid chart according to weight number k. Dynamic adjustment of processing parameters is realized and different processing parameters are used in different stages, so that the thickness of a material removed by laser scanning at every time can be increased, the leveling speed can be increased, and the processing efficiency and the processing precision can be improved.

Owner:JIANGSU KERUIXIN MACHINERY

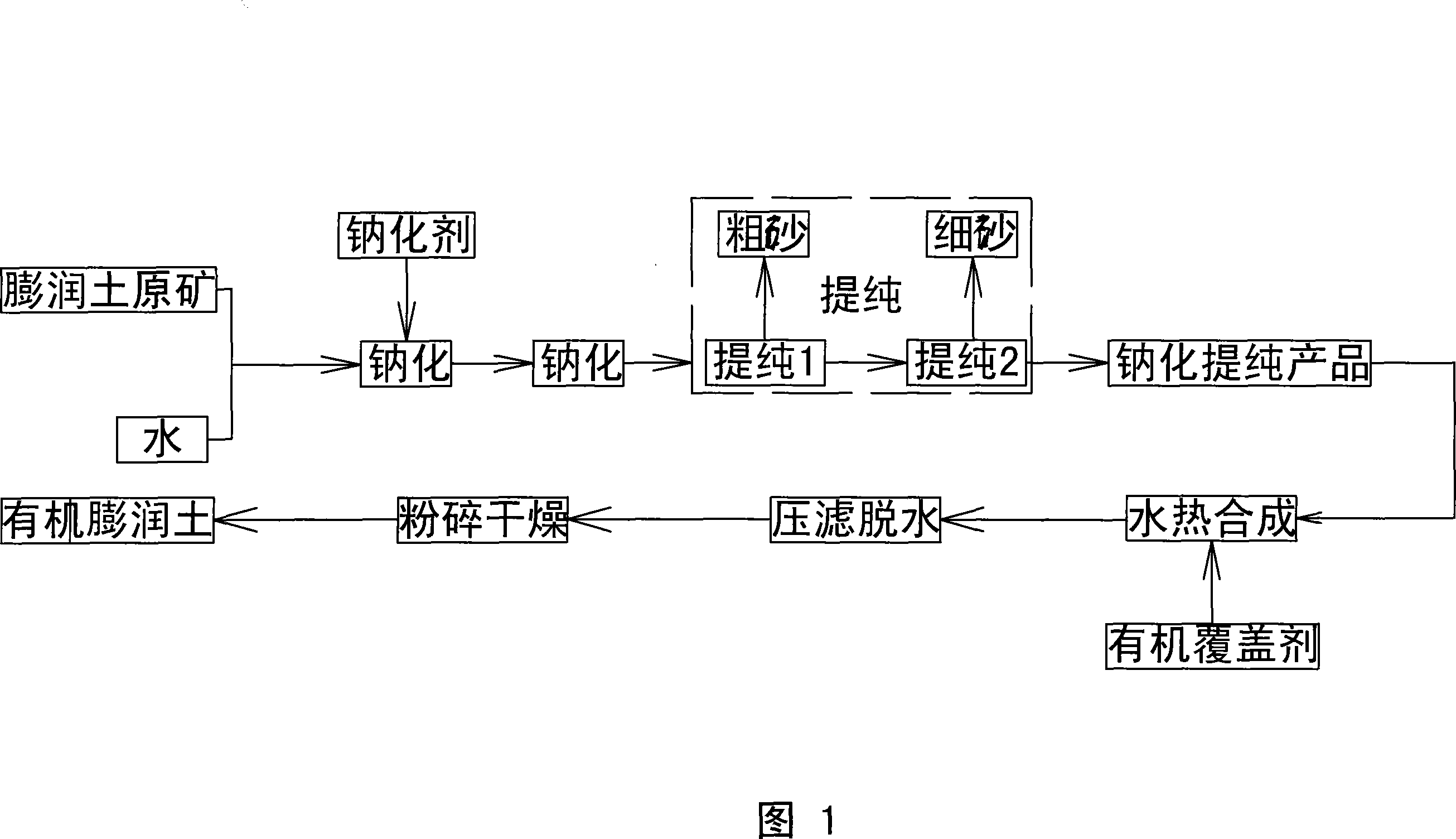

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

Five freedom degree numerically controlled fraise machine

The five freedom numerically controlled milling machine is superior to available one, which has inconvenient manufacture and installation, complicated programming, and other demerits. The five freedom numerically controlled milling machine consists of a bed, a platform pedestal, a machining tool and a main electric shaft to control the machining tool, as well as a three freedom RPS mechanism. The three freedom RPS mechanism consists of a lower platform, a moving platform and telescopic rods comprising lead screw and nut mechanism, and each of the three telescopic rods has its ends hinged separately to the lower platform and the moving platform. The milling machine of the present invention has high rigidity, high precision, simple and symmetrical structure, low cost, simple manufacture and installation, high machine accuracy and convenient programming.

Owner:HARBIN INST OF TECH

Method and device based on micro-nano laser-induced shock wave three dimensional lossless makr

InactiveCN101200022ARealize the processing effectImplement modificationDigitally marking record carriersRecord carriers used with machinesShock waveMicro nano

Disclosed is a three-dimensional lossless marking method and device based on micro-nano laser shock wave, relating to the mechanical manufacturing and laser component field. The laser shock wave is taken as the force source that makes the plastic deformation of material; the required mark is formed based on the micro-nano laser shocked light spot and by multiple shock along the track controlled by computer programme, and has the functions of mark information acquisition and recognition conversion. The invention uses the laser shock track that can be controlled by programming and the control of laser parameter of the micro-nano laser light spot shock to realize the three-dimensional high anti-falsification and the lossless property of the laser shock wave marking.

Owner:JIANGSU UNIV

Crispation-shaped green tea automatization processing method

InactiveCN101133763ARealize clean and automatic processingCurly emerald greenPre-extraction tea treatmentComputer visionAutomatic processing

The present invention relates to an automatic processing method of curled green tea, belonging to the field of tea processing technology. Said processing method includes the following steps: quickly steaming, cooling and ordering, metering, rolling, dynamically drying, further rolling, stir-frying and drying, dehydration-forming and flavouring.

Owner:肖勇

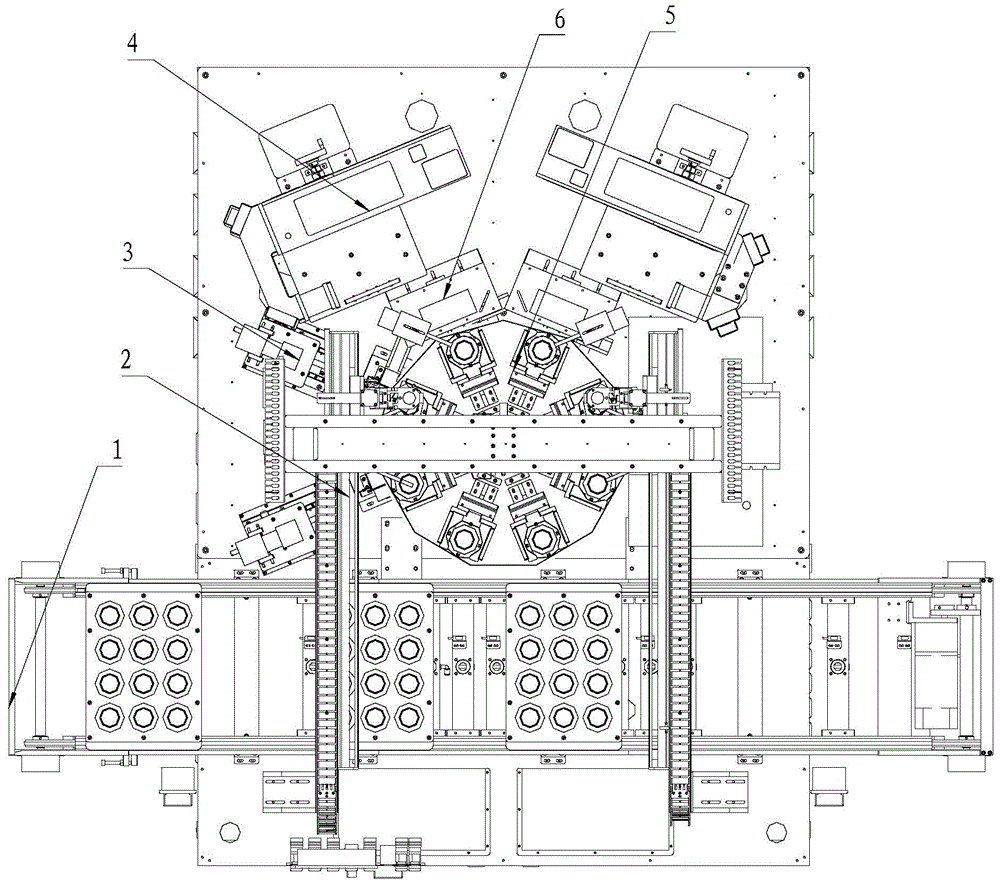

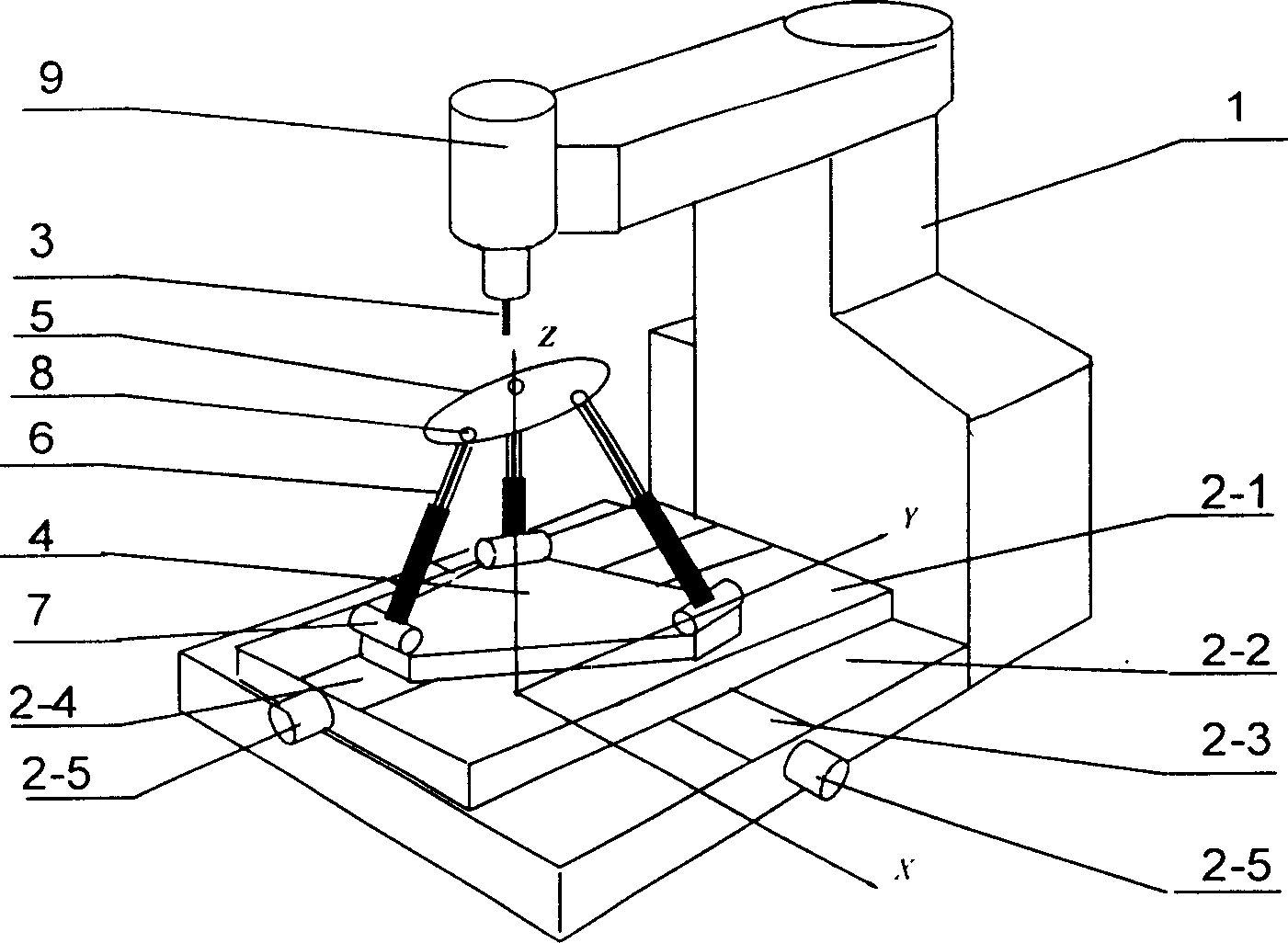

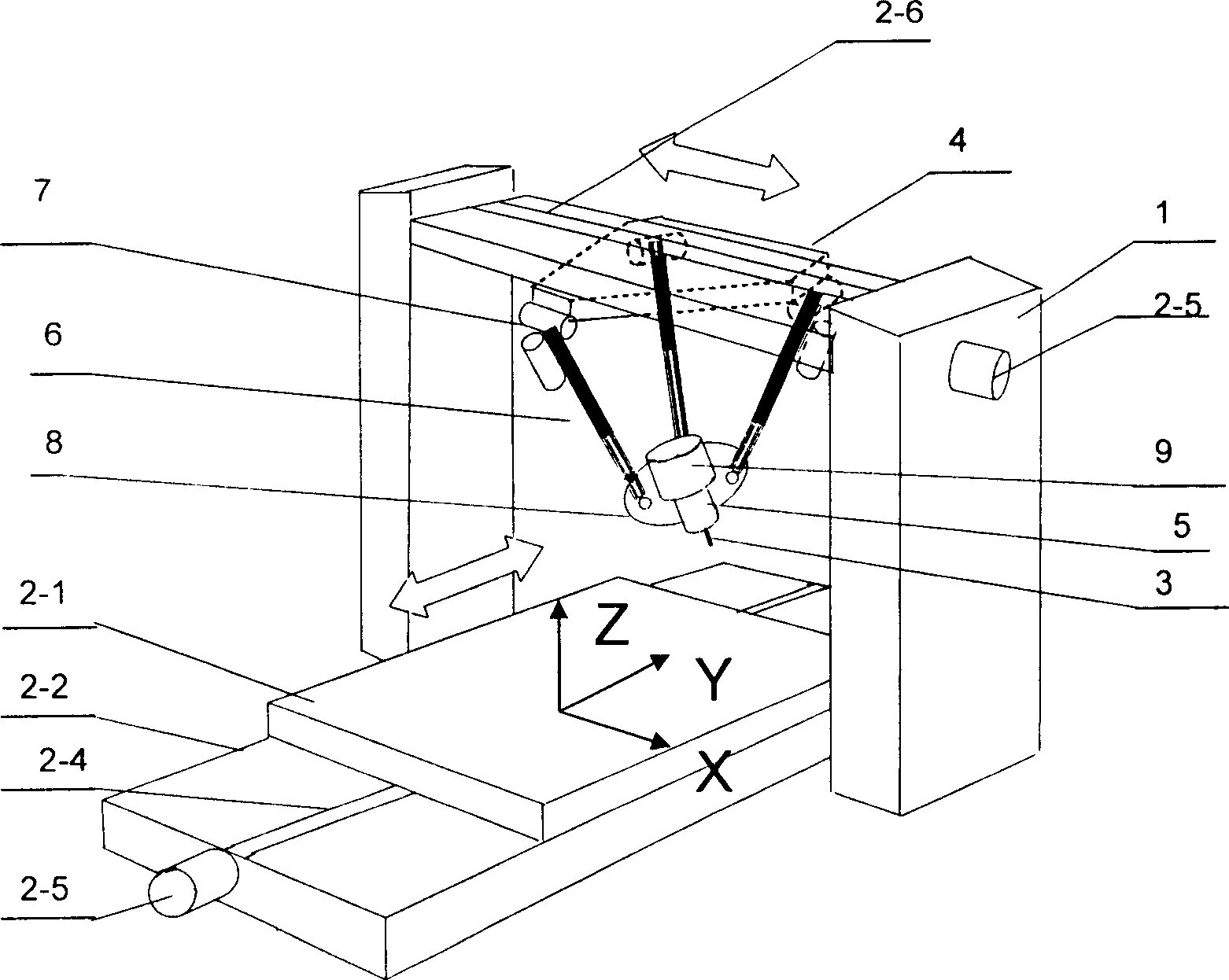

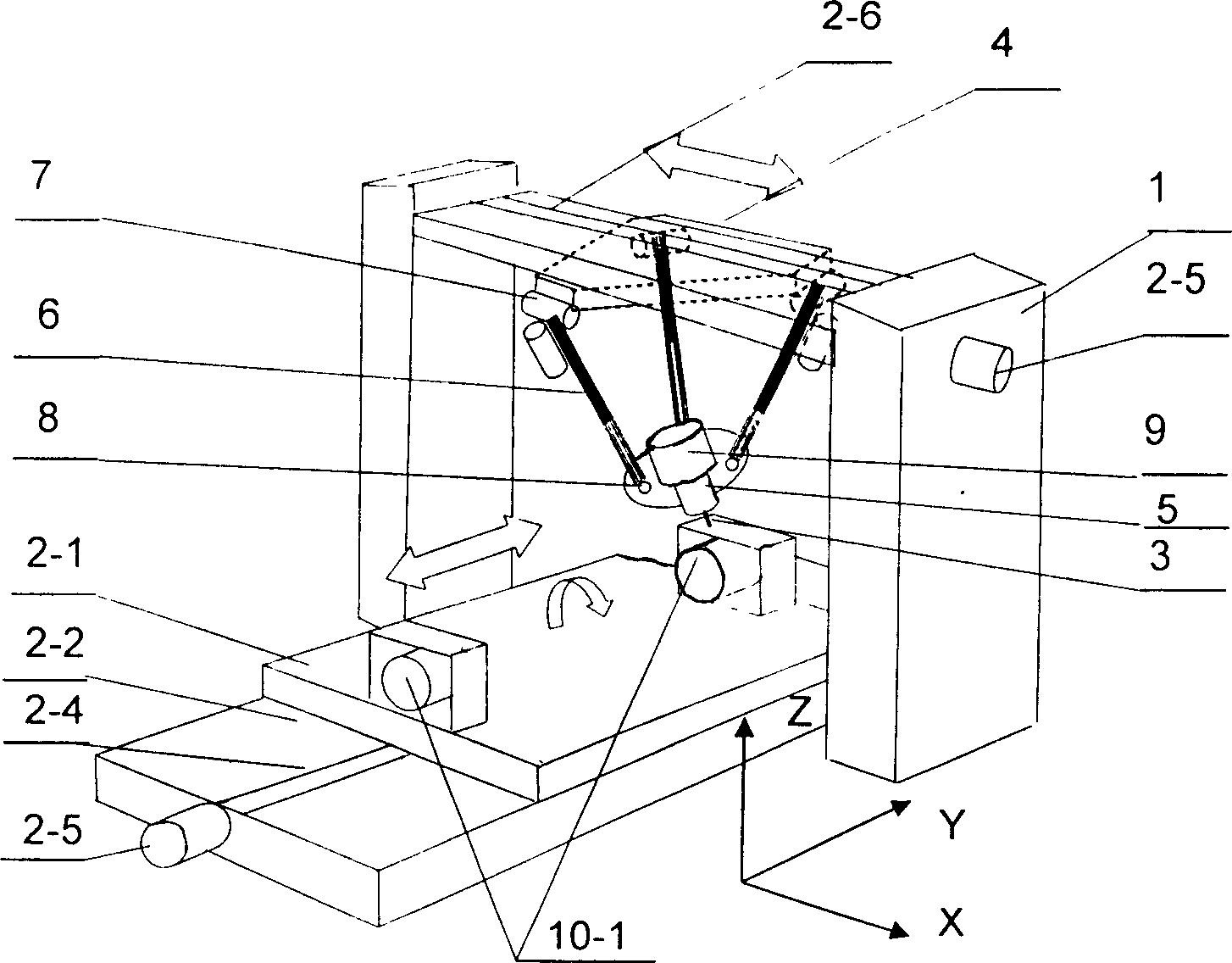

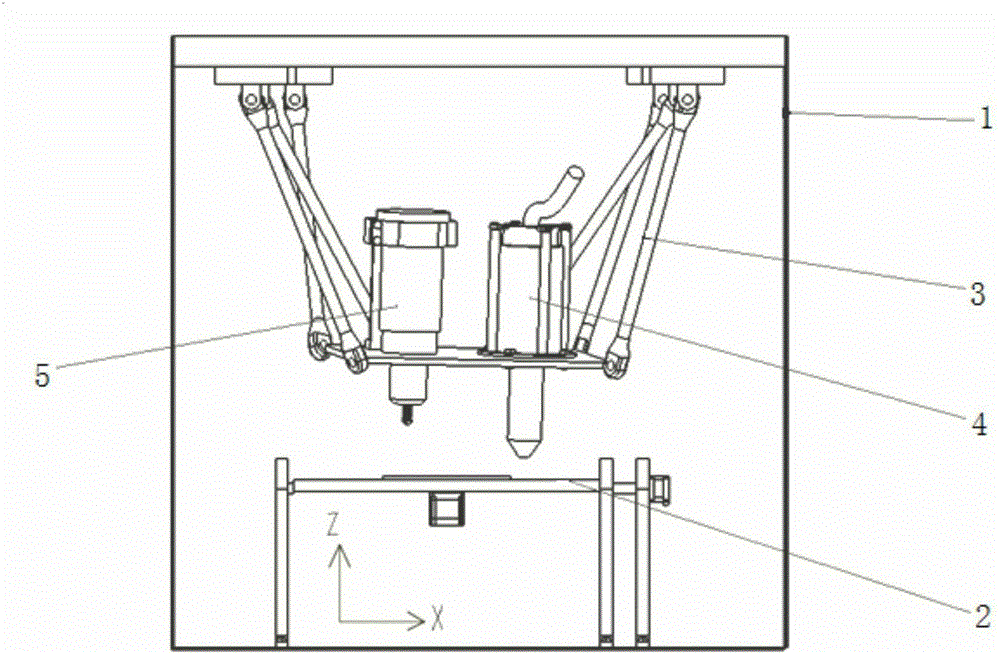

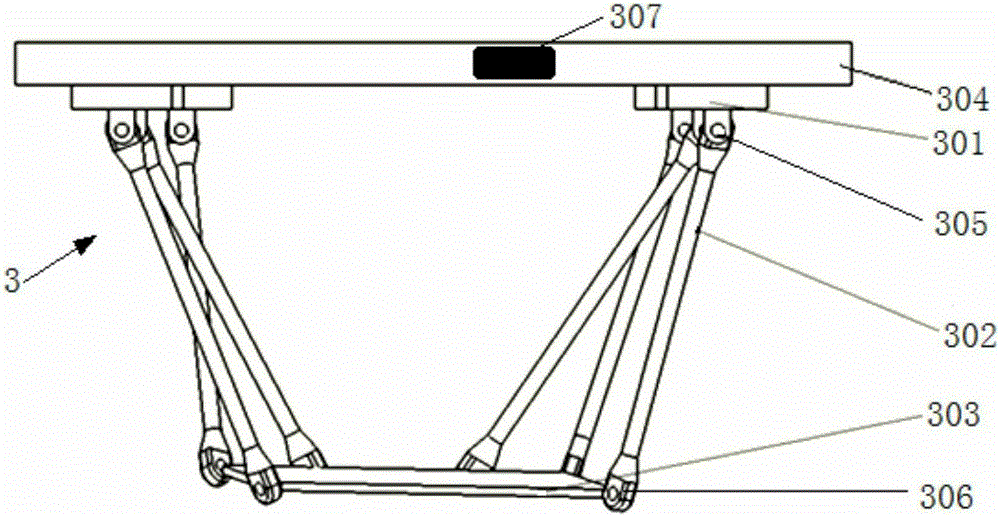

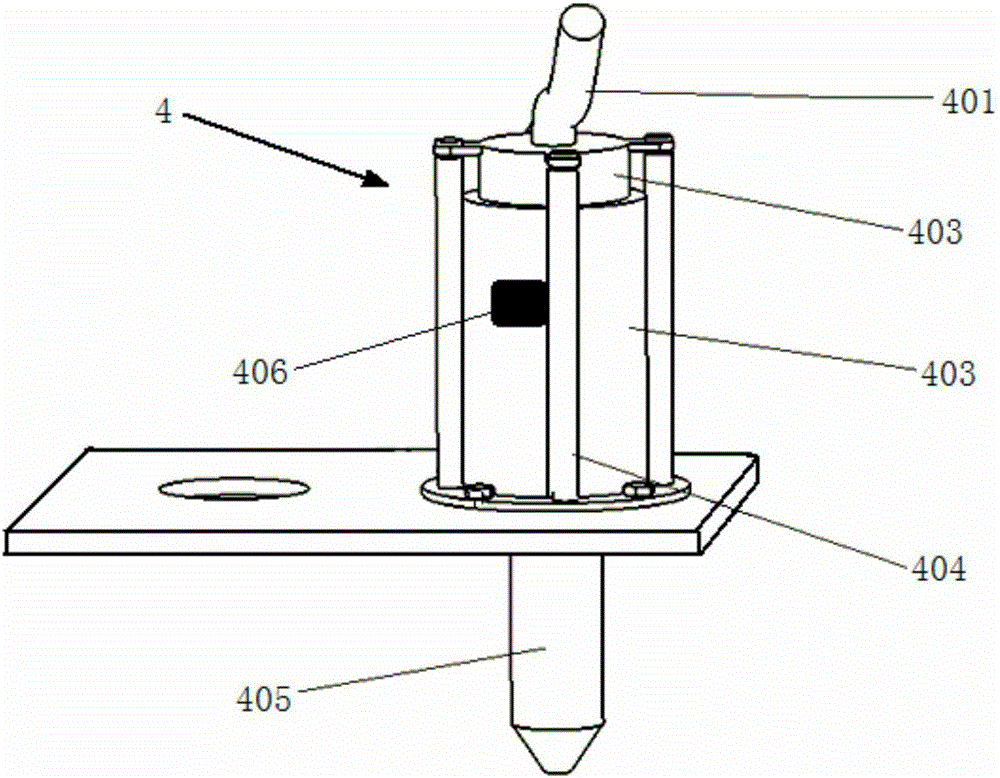

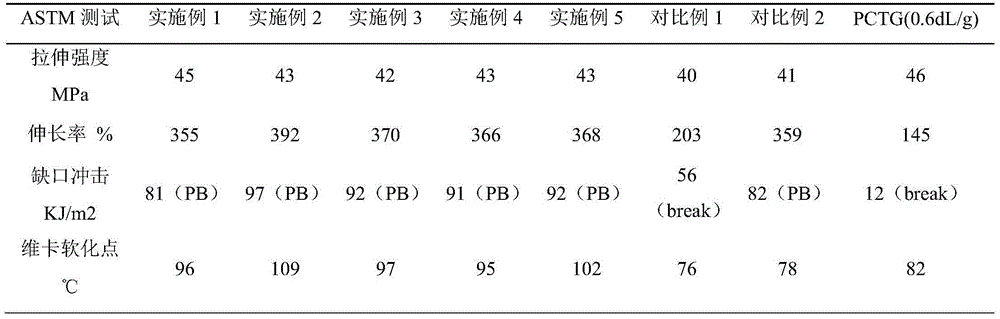

Parallel additive and subtractive composite manufacturing machine tool and composite manufacturing method thereof

ActiveCN105290789AGuaranteed machining accuracyImprove processing efficiencyOther manufacturing equipments/toolsControl systemManipulator

The invention belongs to the field of machine tool designs, and relates to a parallel additive and subtractive composite manufacturing machine tool and a composite manufacturing method thereof. The invention discloses a parallel additive and subtractive composite manufacturing machine tool. The machine tool comprises a tool body (1) and a workbench (2), and is characterized in that a parallel mechanism (3) is arranged at the top of the tool body (1), and comprises an additive manufacturing module (4) and a subtractive manufacturing module (5), the additive manufacturing module (4) is located at one side of the parallel mechanism (3), the subtractive manufacturing module (5) is located at the other side of the parallel mechanism (3), and the workbench (2) is located below the parallel mechanism (3). The machine tool disclosed by the invention is capable of rapidly realizing alternation and replacement of additive and subtractive manufacturing processes through a control system without the need of a knife-changing manipulator, and capable of effectively increasing the machining efficiency and ensuring the machining accuracy of complex parts, thus shortening a machining period, and expanding an application range for machining the complex parts, of the machine tool.

Owner:XIANGTAN UNIV

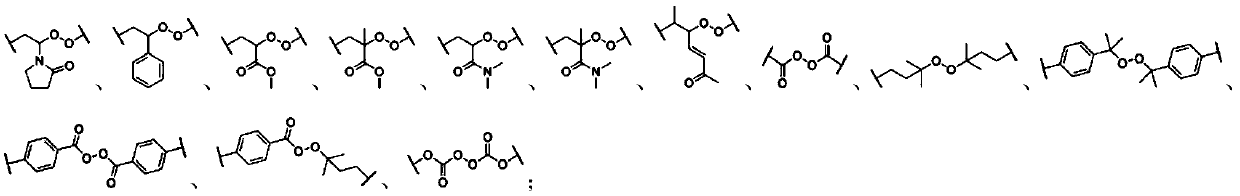

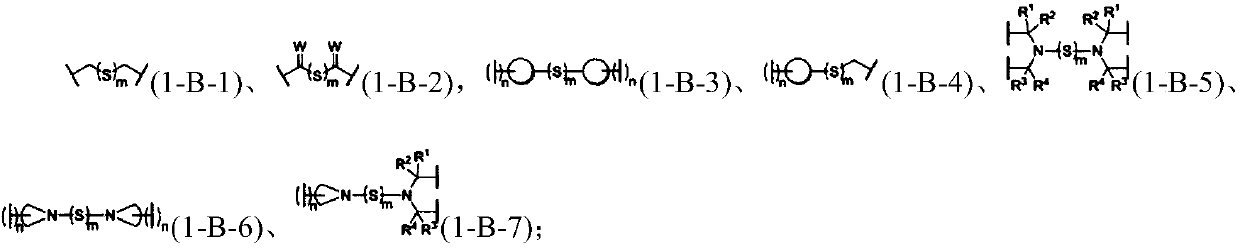

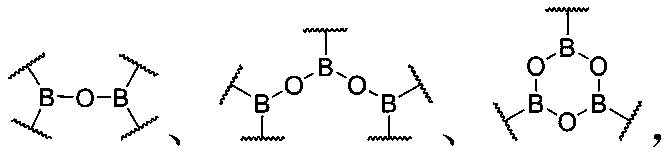

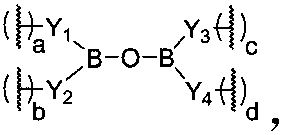

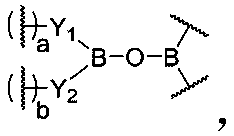

Force-induced response dynamic polymer and application thereof

The invention discloses a force-induced response dynamic polymer. The polymer chain skeleton contains at least one force-sensitive group and at least one boron-free dynamic covalent bond, optionally contains at least one boron-containing dynamic covalent bond, and also optionally contains at least one supramolecular interaction; and under the action of mechanical force, the force-sensitive group in the dynamic polymer is subjected to chemical and / or physical change to realize force-induced response. According to the dynamic polymer, the force-sensitive group with a force-induced response characteristic, the boron-free dynamic covalent bonds with different dynamic properties, the optional boron-containing dynamic covalent bond and the supramolecular interaction are introduced, so that the force-induced response dynamic polymer material with a wide controllable range, a rich structure and various properties can be prepared. The force-induced response dynamic polymer can be widely appliedas a functional coating with a force-induced response function, a self-repairing material, an energy storage device material, an energy absorbing material, a photoelectric device material, a mechanical probe and the like.

Owner:厦门天策材料科技有限公司

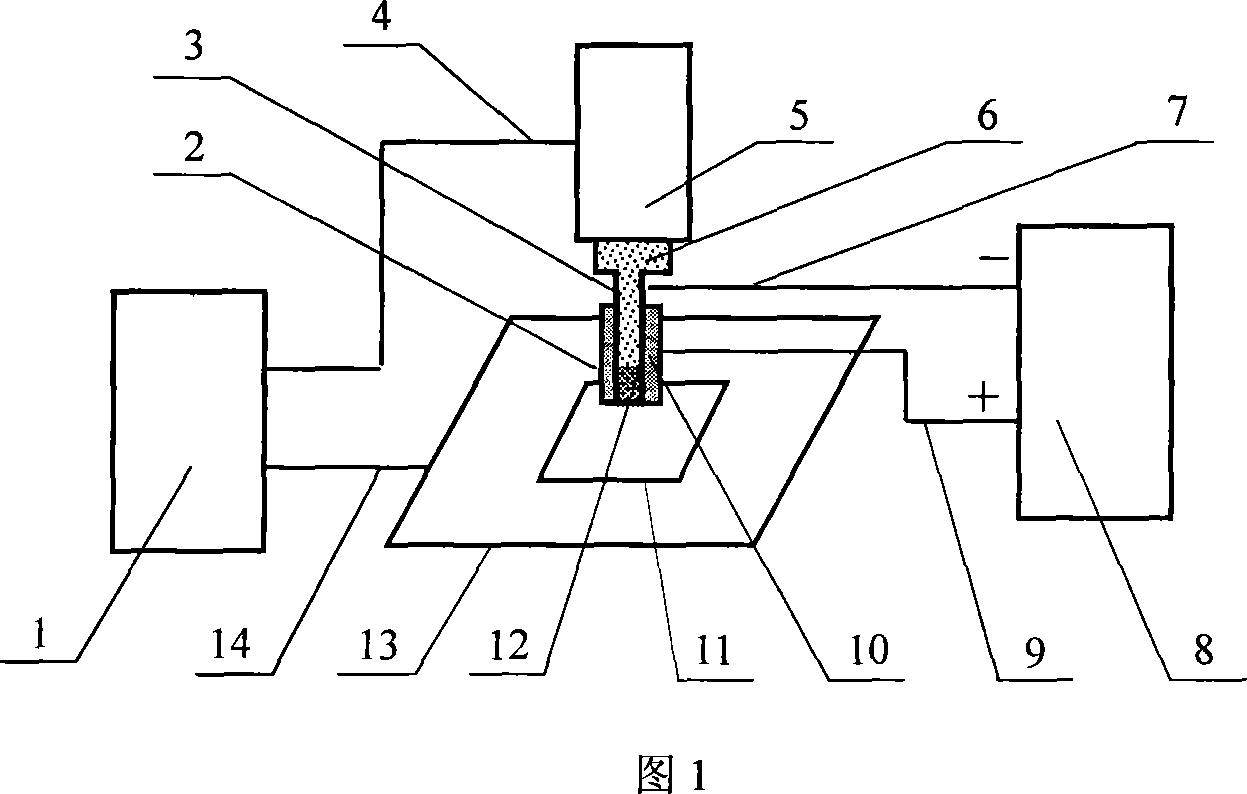

Non-conducting material electric spark milling method

ActiveCN101185983ARealize the processing effectSmall macro forceElectrical-based machining electrodesElectricityConductive materials

The invention relates to an EDM milling method used for nonconductive materials, belonging to a mechanical machining field. When machining, a tool anode and a tool cathode are respectively connected with the anode and the cathode of an impulse powder supply. The tool anode and the tool cathode are provided with tubular structures and are arranged on the same shaft, and are separated by an insulation medium layer. A conductive liquid flows from the central hole of internal tool electrodes to the surface of the nonconductive material, and triggers discharge when flowing through the ends of the tool anode and the tool cathode, and then the nonconductive material can be corrosion-removed and machined by effects of high temperatures and high voltages generated by the discharge instantaneously. A main shaft head can drive the tool anode and the tool cathode to revolve and do a Z-direction movement. A nonconductive material work piece to be machined is arranged on X and Y movable work tables, and an EDM milling to the nonconductive material work piece with a complicated shape is realized by a linkage between the main shaft head and the work tables. The EDM milling method used for nonconductive materials of the invention has the advantages that machining efficiency is high, surface quality is high and the environment is not polluted, etc.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

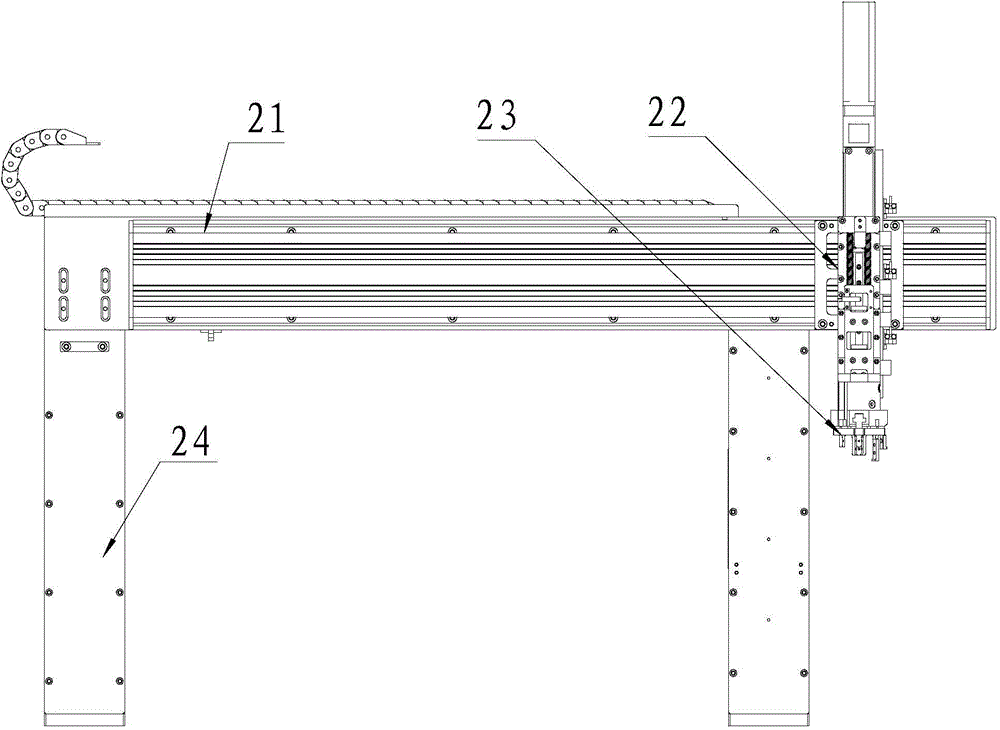

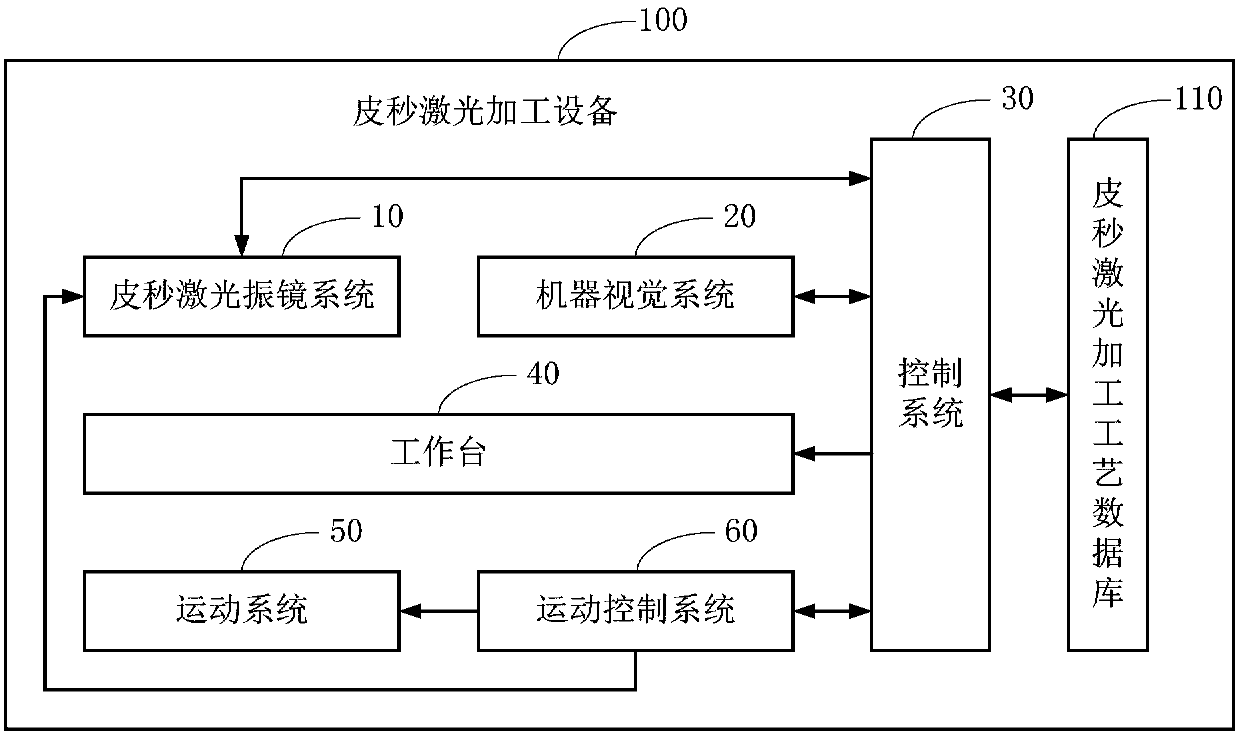

Picosecond laser machining equipment

InactiveCN107745188AAchieve positioningRealize the processing effectLaser beam welding apparatusPicosecond laserControl system

The invention relates to the technical field of laser machining, and provides picosecond laser machining equipment used for machining fragile materials. The picosecond laser machining equipment comprises a picosecond laser galvanometer system, a machine vision system, a control system, a workbench, a motion system and a motion control system; the picosecond laser galvanometer system and the machine vision system are arranged above the workbench; the picosecond laser galvanometer system and the motion system are electrically connected with the motion control system; the motion system is in mechanical connection with the workbench; and the picosecond laser galvanometer system, the machine vision system, the workbench and the motion control system are electrically connected with the control system. Through a picosecond laser machining technology, the picosecond laser precision machining of the fragile materials is realized. Superfine machining on the machining positions of the fragile materials provided with deep-layer strengthening layers can be realized, the machining of a complicated bent outline can be realized, and the machining quality and the machining efficiency are improved effectively.

Owner:SHENZHEN INSTITUTE OF INFORMATION TECHNOLOGY

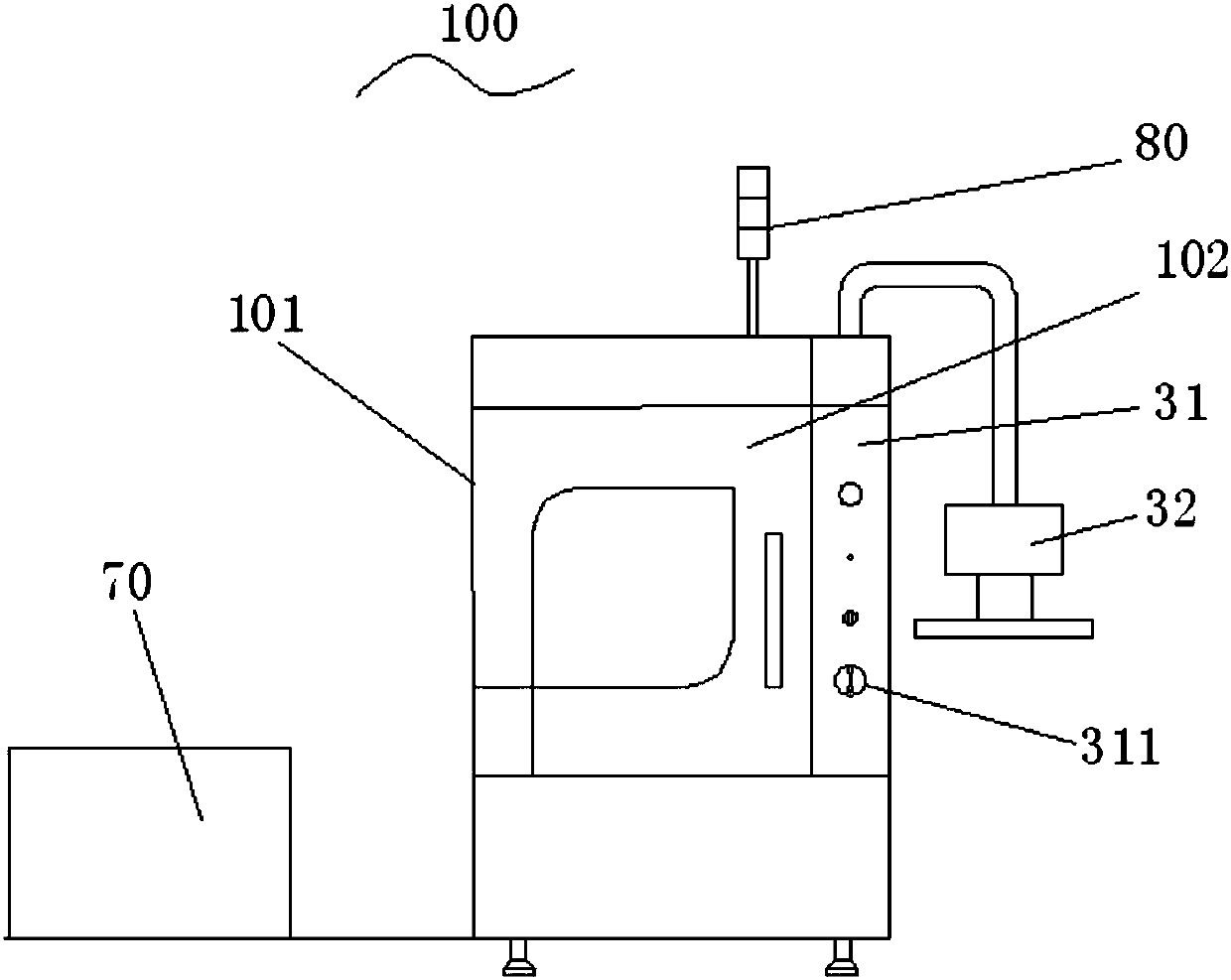

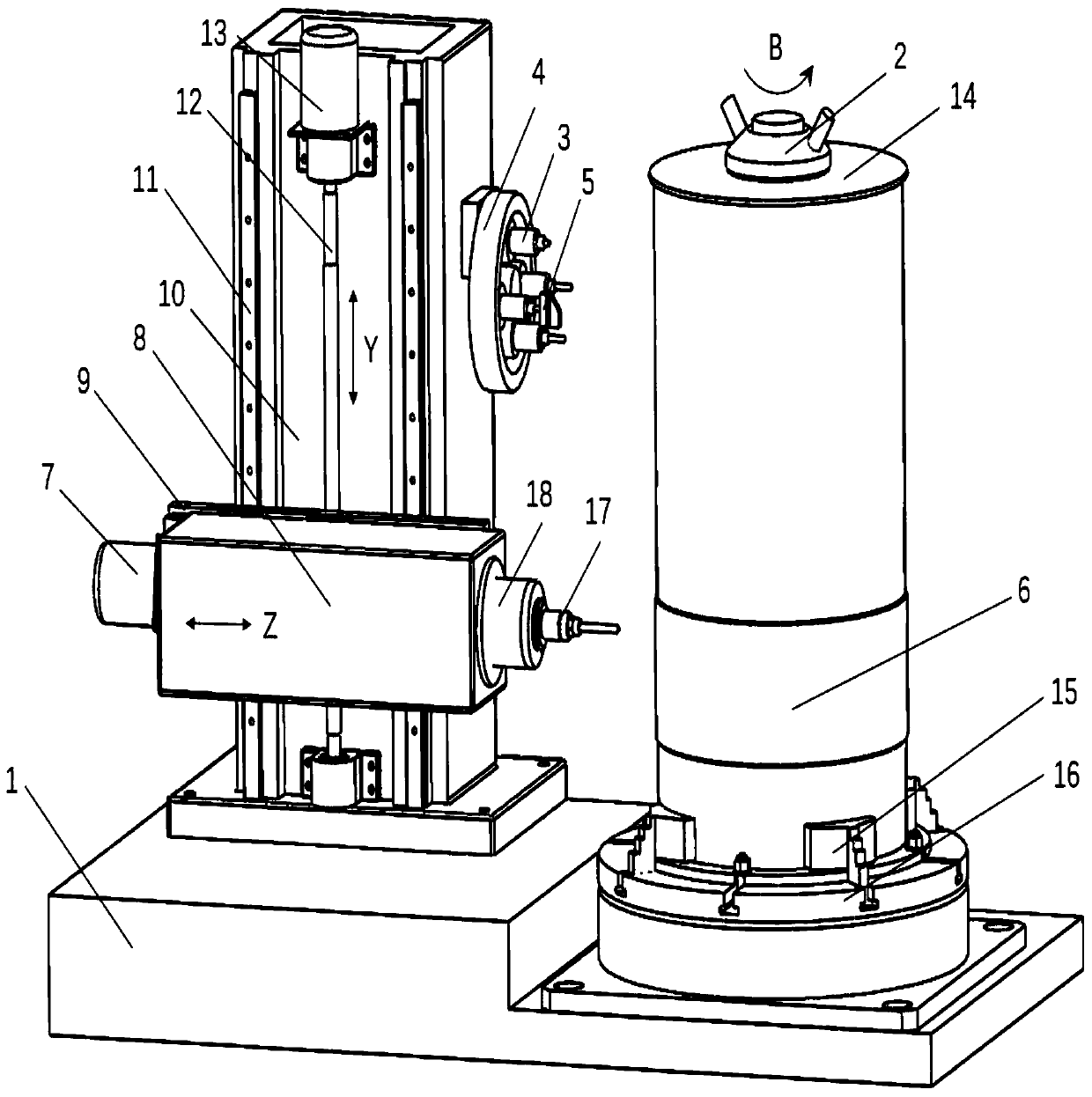

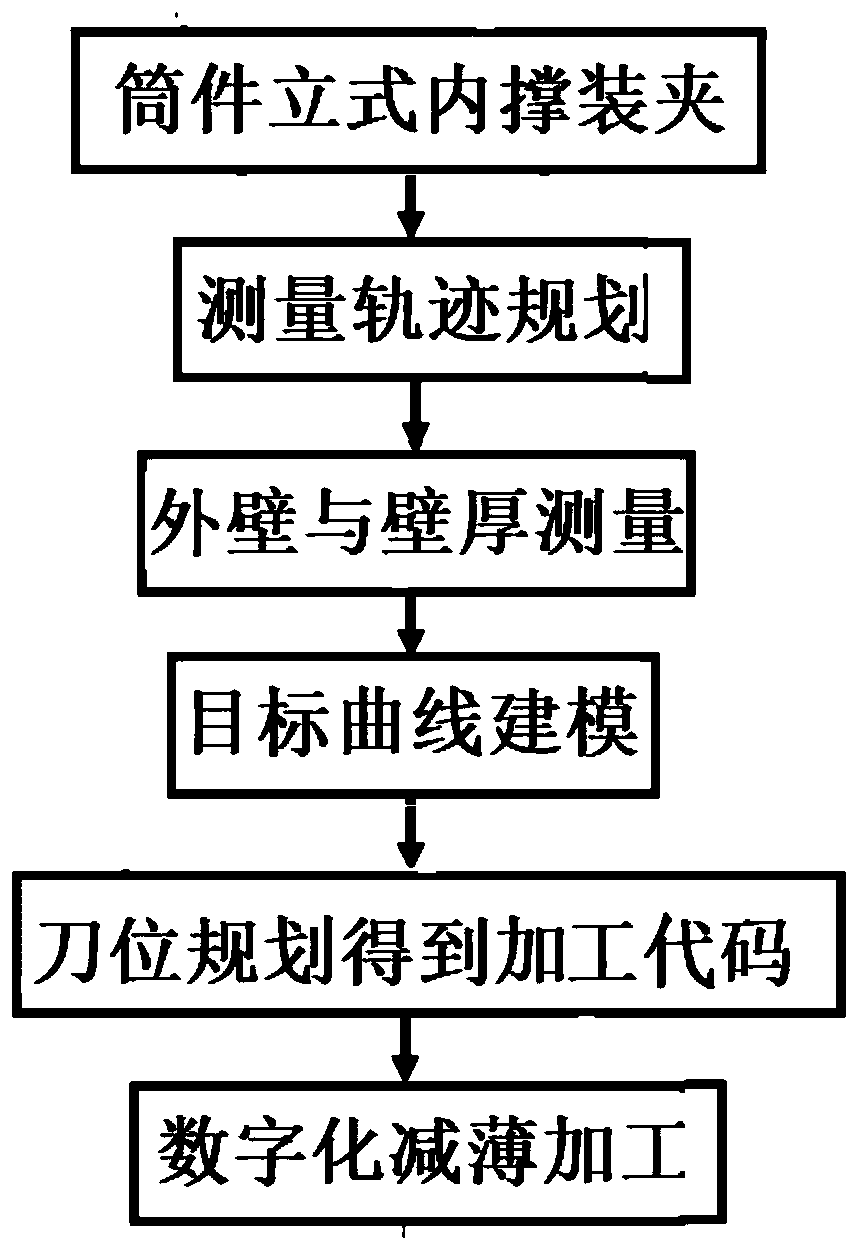

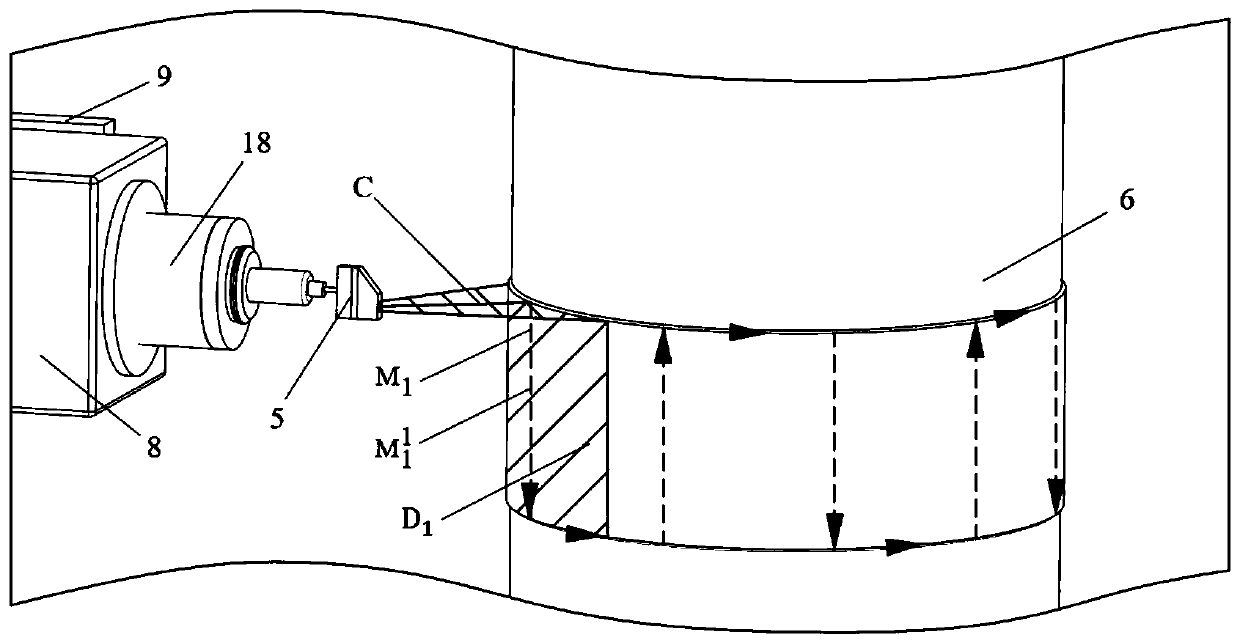

Digitalized thinning machining method for large thin-walled cylinder part

ActiveCN111195830AGuaranteed processing reliabilityEfficient digital thinning processingAutomatic control devicesMeasurement/indication equipmentsNumerical controlEngineering

The invention discloses a digitalized thinning machining method for a large thin-walled cylinder part, and belongs to the technical field of machining. The method comprises the following steps that firstly, a vertical inner support of the large thin-walled cylinder part is clamped, and the external contour and the wall thickness of a thinning section of the cylinder part are scanned and measured on a machine tool by using a line laser measurement device and an ultrasonic measurement device; then by utilizing the actual measurement data of the external contour and the wall thickness of the thin-walled cylinder part and considering the requirement for machining the residual wall thickness, a machining target curved surface of the thinning section is re-established, and a thinning machining code is automatically generated; and finally, the numerical control machine tool finishes thinning machining of the large thin-walled cylinder part through inspection. According to the method, the thinning machining target curved surface associated with the residual wall thickness is re-established by using the part external contour and wall thickness data measured on the machine tool, and the thinning machining code is generated, so that the function integration of CAD, CAM and CNC in the thinning machining of the large thin-walled cylinder part is effectively realized, the manual interventionis reduced, and partitioned thinning machining and equal-wall-thickness or variable-wall-thickness controllable machining of the large thin-wall cylinder part are achieved.

Owner:DALIAN UNIV OF TECH

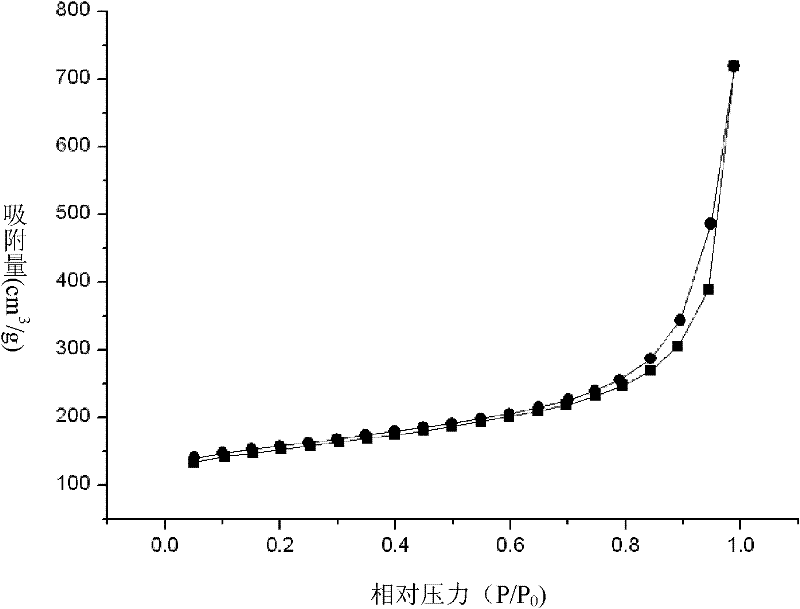

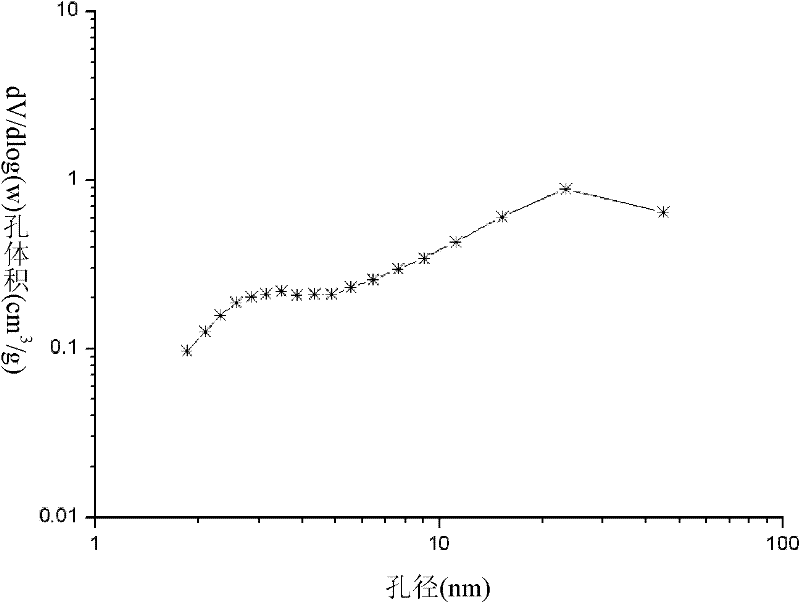

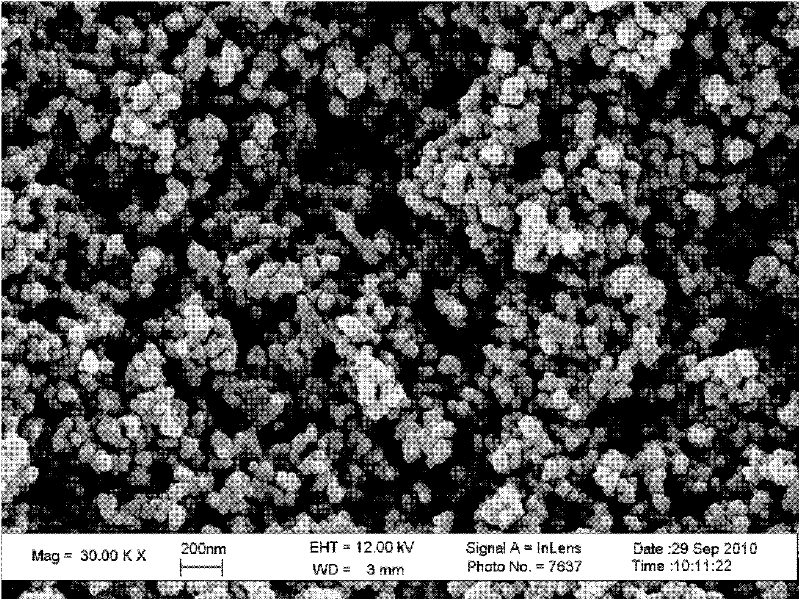

Preparation method of block high temperature resistant silicon-charcoal composite aerogel material

ActiveCN102351506AThe process is simple and easy to controlSimple and fast operationSupercritical dryingPolymer science

The invention a preparation method of a block high temperature (>=1000 DEG C) resistant silicon-charcoal composite aerogel material. According to the invention, reactants of resorcinol, formaldehyde, 3-amino propyl triethoxysilane, a hydrolysis agent of deionized water and a solvent of alcohols are prepared into wet gel through a one-step sol-gel reaction under effect of a basic catalyst. The wetgel is treated with ageing, solvent displacement, supercritical drying and high temperature heat treatment to obtain the block high temperature resistant silicon-charcoal composite aerogel. The preparation method of the invention has simple technology and good controllability. The silicon-charcoal composite aerogel prepared by the method of the invention overcomes defects of weak high temperature resistance and uneasy moulding due to low strength of aerogel; and the prepared aerogel can be used at a high temperature higher than 1000 DEG C for a long time and has characteristics of low density, large specific surface area, large pore volume, high strength and high temperature resistance.

Owner:NANJING UNIV OF TECH

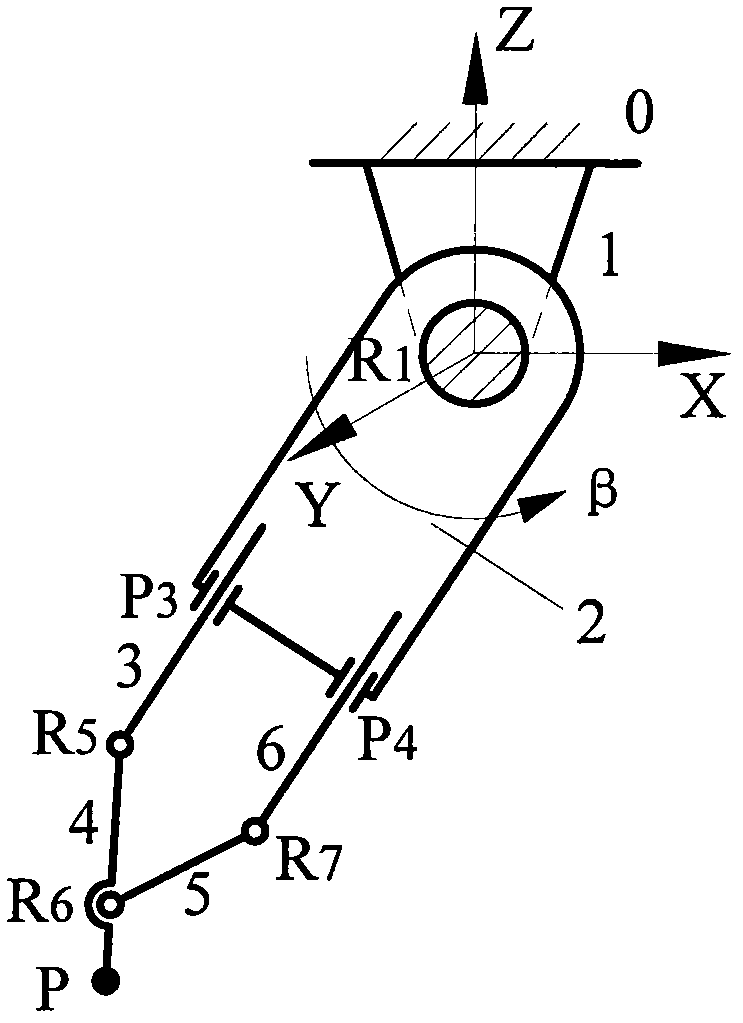

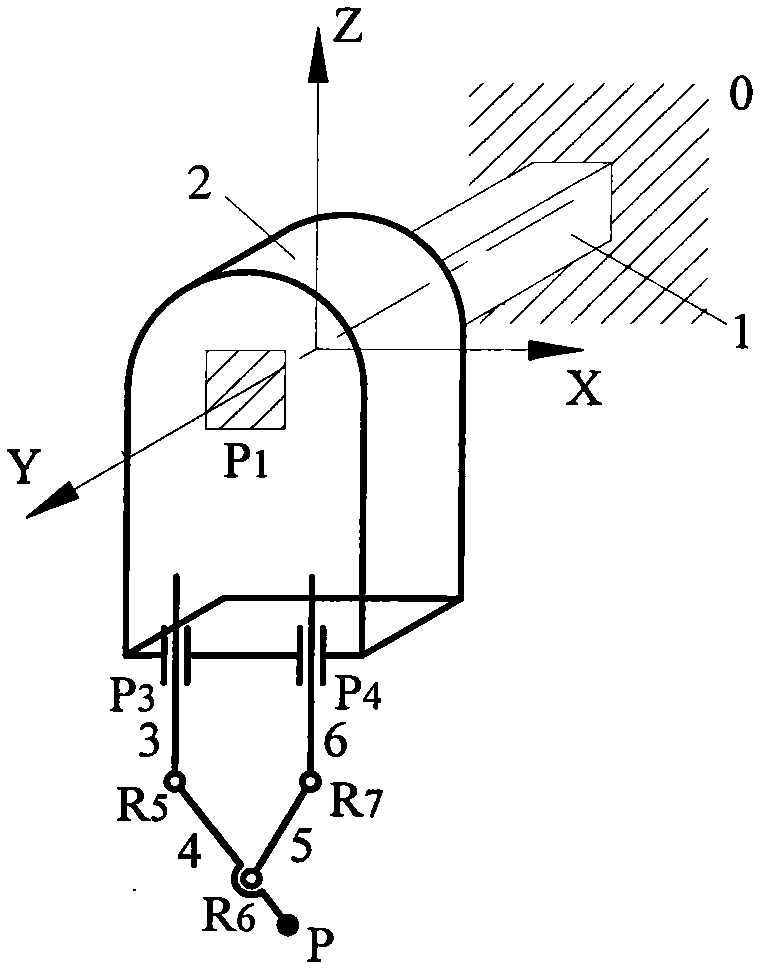

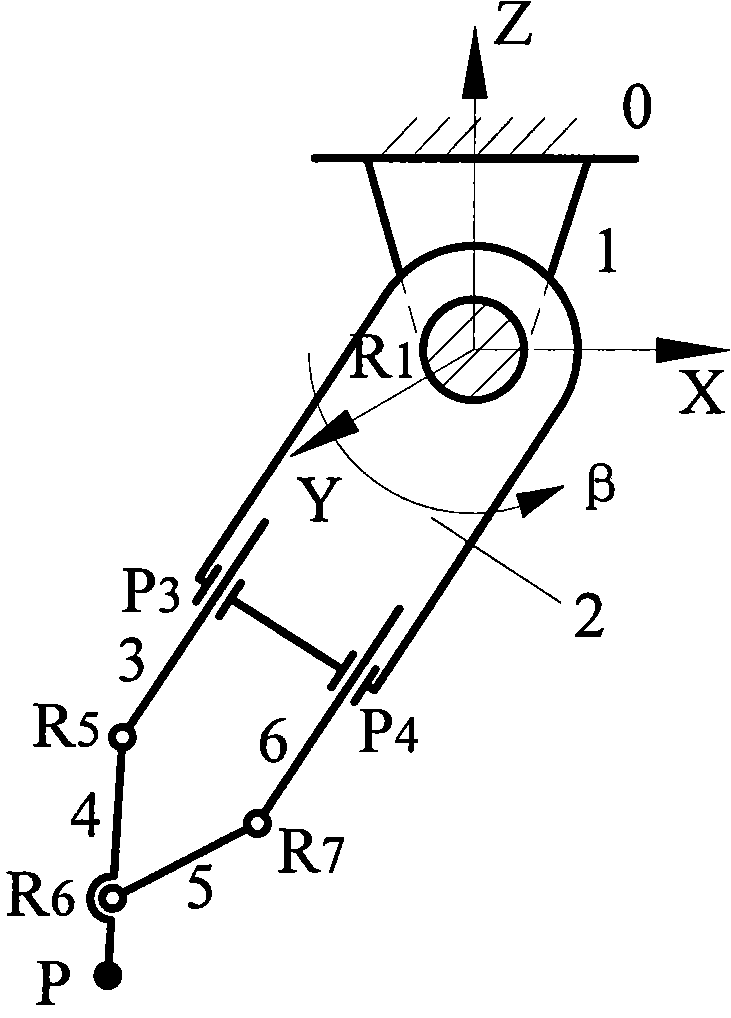

Three-degree-of-freedom decoupling hybrid robot

InactiveCN102085660AGood control decouplingEasy to manufactureProgramme-controlled manipulatorThree degrees of freedomDegrees of freedom

The invention relates to a three-degree-of-freedom decoupling hybrid robot, which comprises a machine frame (0), a suspension frame (1), an installation arm (2) and a two-degree-of-freedom plane parallel mechanism manipulator (P3-R5-R6-R7-P4), wherein the installation arm (2) is fixedly connected to the suspension frame (1) of the machine frame (0) by a rotating pair I (R1); the two-degree-of-freedom plane parallel mechanism manipulator is also arranged on the installation arm (2); and two driving sources of the installation arm (2) can be movable pairs or rotating pairs, and also can be one movable pair and one rotating pair, and a motion plane of the installation arm (2) is perpendicular to the axis of the rotating pair I (R1). The three-degree-of-freedom hybrid manipulator has the advantages of forward and inverse kinematics analytic solutions, high control decoupling performance, large work space, compact structure, low manufacturing cost and the like, flexibly moves and can realize three-degree-of-freedom operation or machining in space.

Owner:CHANGZHOU UNIV

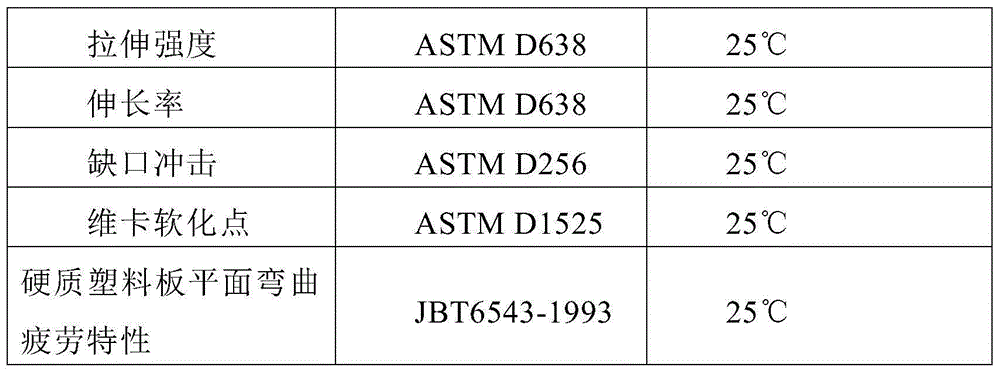

High-ductility heat-proof PCTG material and preparation method thereof

InactiveCN104610712AImprove ductility and heat resistanceGood modification effectCopolyesterDuctility

The invention relates to a high-ductility heat-proof PCTG material and a preparation method thereof. The high-ductility heat-proof PCTG material is prepared from the following components and raw materials in parts by weight: 100 parts of PCTG, 3 to 5 parts of a compatilizer, 0.5 to 0.7 part of an ester exchange inhibitor, 30 to 40 parts of high heat-resistance copolyester, and 10 to 20 parts of polyester elastomer. The preparation method comprises the following steps: drying PCTG and high heat-resistance copolyester at the temperature of 60 to 70 DEG C for 5 to 6 hours; mixing with the compatilizer, the ester exchange inhibitor and the polyester elastomer for 3 to 5 minutes through a high-speed mixer; then adding a hopper of a double-screw extruder; melting; blending; extruding; drawing into strips; cooling by water drying; and cutting into particles to obtain the high-ductility heat-proof PCTG material. Compared with the prior art, the method has advantages.

Owner:SHANGHAI SUNNY

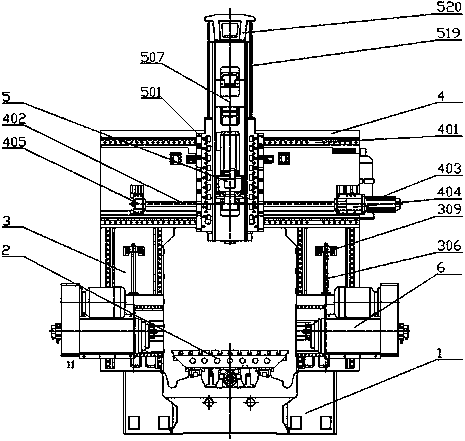

Numerical control gantry vertical and horizontal combined machining center of combination of tool magazine and main shaft on saddle

ActiveCN103350343AImprove processing efficiencyRealize heavy-duty cutting and energy-saving machiningOther manufacturing equipments/toolsLarge fixed membersStructural engineeringMachine tool

The invention relates to a numerical control machine tool, particularly to a numerical control gantry vertical and horizontal combined machining center of combination of a tool magazine and a main shaft on a saddle. The center solves the problems that the tool magazine is arranged on neither a vertical main shaft nor a horizontal main shaft of the machine tool, so that a tool can not be changed timely, and the working efficiency is lower, and a machine tool structure can not be suitable for meeting the requirements for high efficiency, precision, combination, and energy conservation. The numerical control gantry vertical and horizontal combined machining center comprises a base, a working platform, and a vertical column, wherein the vertical column is movably connected with a cross beam through a vertical column guide rail; the cross beam is movably connected with a cross beam saddle through a cross beam guide rail; the vertical column is movably connected with a vertical column saddle through the vertical column guide rail; the cross beam saddle is movably connected with a vertical main shaft device through a vertical ram guide rail; the vertical saddle is movably connected with a horizontal main shaft device; the cross beam saddle and the vertical saddle are fixed with the tool magazine through a tool magazine bracket; the base, the vertical column, the cross beam, the vertical main shaft device, and the horizontal main shaft device are provided with screw rod driving devices; the tool magazine, the screw rod driving devices, and main shaft devices are all connected with the electrical numerical control device.

Owner:HANGZHOU DATIAN CNC MACHINE TOOL

Bar shaped green tea automatization processing method

InactiveCN101133764AClean thoroughlyRealize the processing effectPre-extraction tea treatmentAir separationGreen tea

The present invention relates to an automatic processing method of strip-shaped green tea, belonging to the field of tea processing technology. Said processing method includes the following steps: steaming, cooling and ordering, air separation, rolling, primary dehydration, further rolling, dehydration and strip-forming, etc.

Owner:肖勇

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

Spicy salted duck processing method

InactiveCN105077331AStrong fragranceIn line with the principle of first low temperature and then high temperatureFood preparationForeign matterFood flavor

The present invention relates to the technical field of meat product processing, in particular to a spicy salted duck processing method. The spicy salted duck processing method comprises the following steps: using compound seasonings and fried sauce as pickling materials, conducting rolling and pickling for raw materials, cold-wind drying the rolled and pickled raw materials, baking the dried raw materials, performing metal foreign matter detection, etc. The purpose of the invention is to provide a spicy salted duck processing method which is suitable for industrial production and produces the spicy salted duck with sauce flavor. The spicy salted duck has the following advantages: the produced spicy salted duck is tough in meat quality, is mellow in fragrance, has a unique sauce fragrance and a mellow Ouyue flavor, and is suitable for large-scale production.

Owner:TENGQIAO FOOD CO LTD

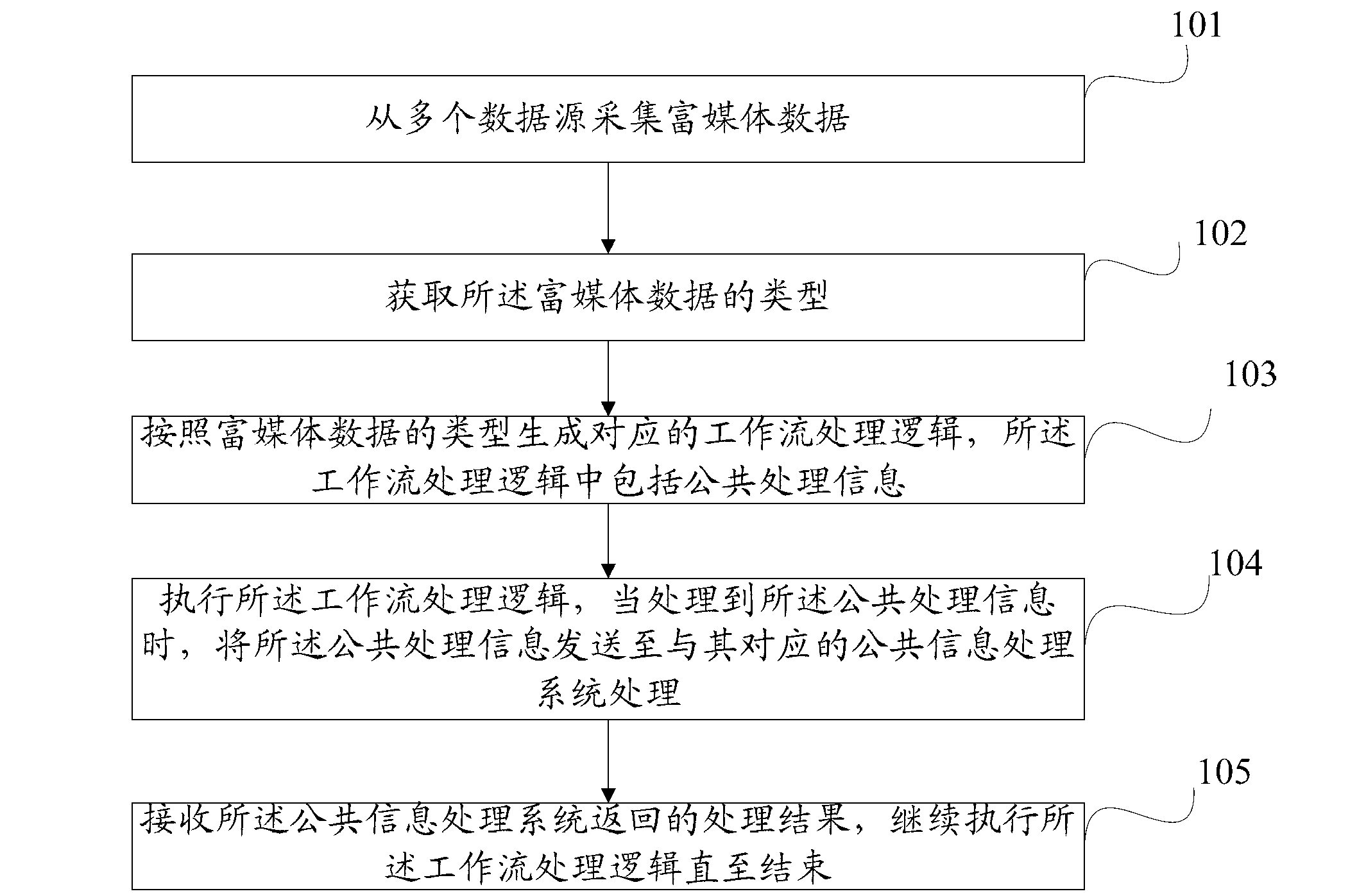

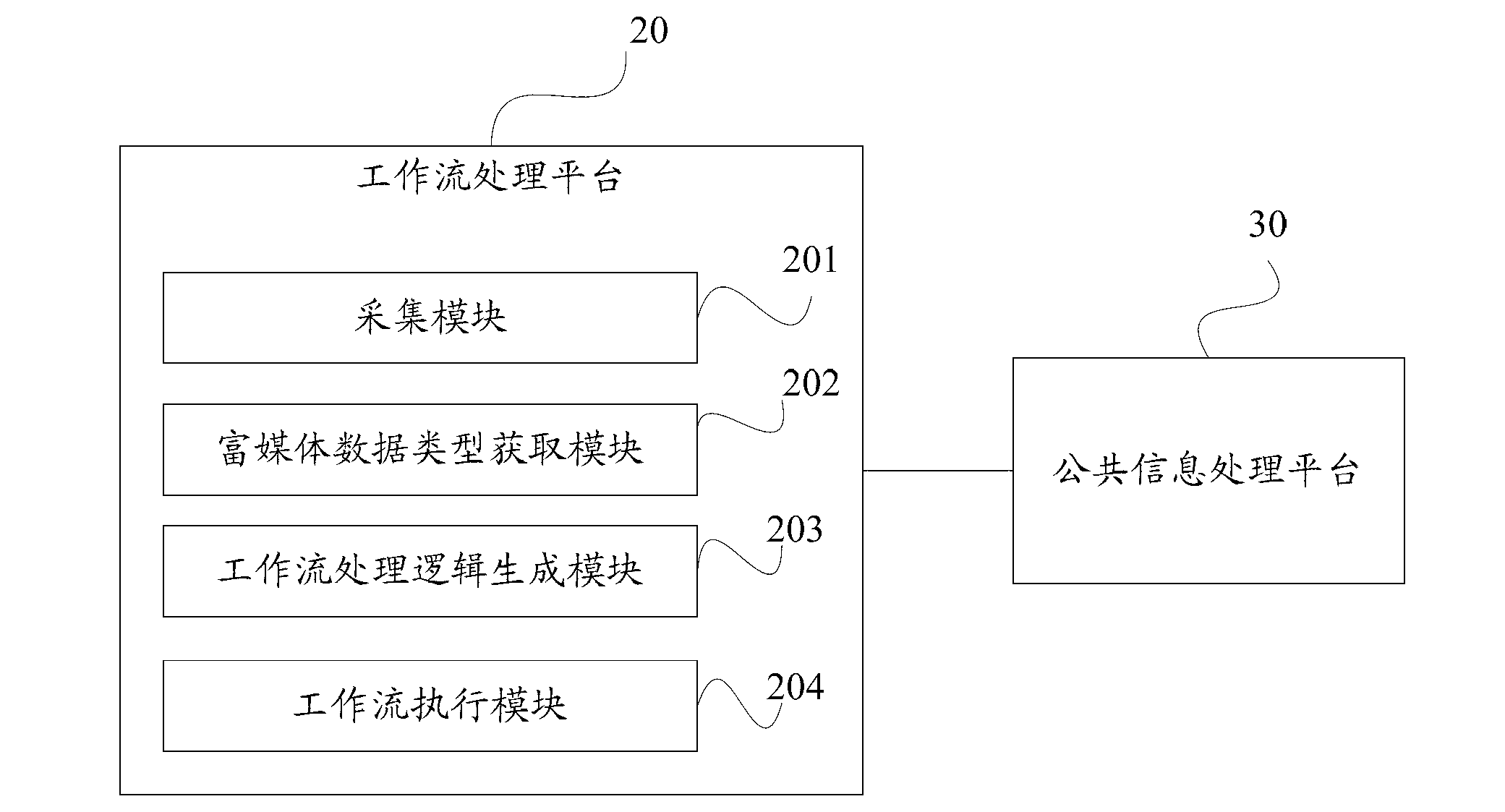

Method and device of rich media data content creation

InactiveCN103065223AAchieve preparationRealize the processing effectResourcesSpecial data processing applicationsInformation processingData content

The invention provides a method and a device of rich media data content creation, wherein the method includes that a corresponding workflow processing logic is generated according to the type of rich media data. The workflow processing logic includes public processing information and is carried out. When needs to be processed, the public processing information is sent out to a public information processing system which corresponds to the public processing information to be processed. A processed result returned by the public information processing system is received and the workflow processing logic is continuously carried out until the end. According to the method and the device of the rich media data content creation, parallel creation and processing of rich media data of various types can be achieved, and thus the rich media data content creation in a large scale is achieved.

Owner:CHINA DIGITAL VIDEO BEIJING

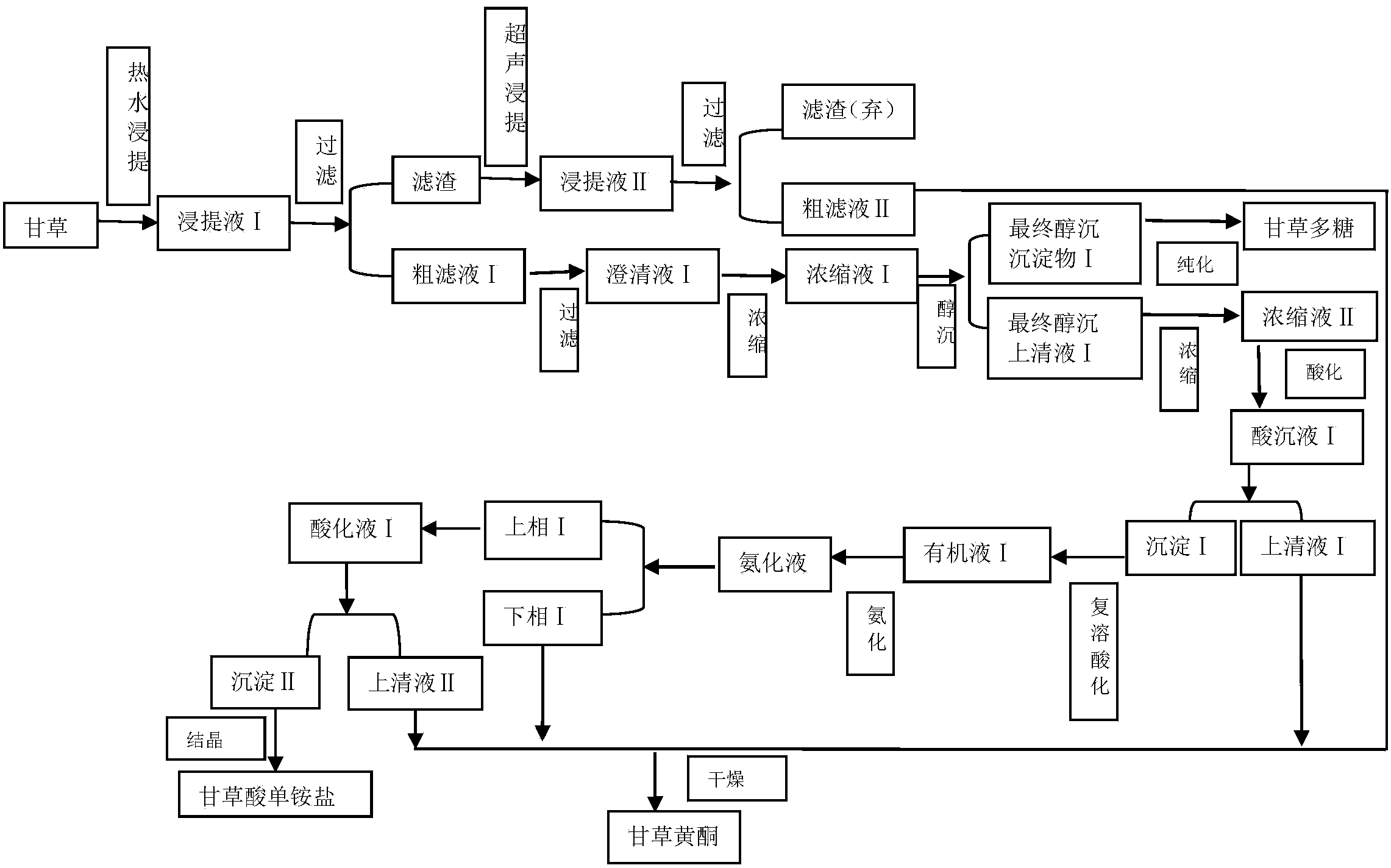

Method for preparing liquorice active substances

InactiveCN103860631AImprove use valueRealize the processing effectSugar derivativesSteroidsPre treatmentChemistry

The invention discloses a method for preparing liquorice active substances. The method comprises the following steps: pretreatment and hot water extraction treatment of raw materials and ultrasonic auxiliary extraction treatment, alcohol precipitation treatment, purification treatment, acid precipitation treatment, redissolution treatment, ammoniated treatment, acidification treatment, crystallization and purification of liquorice residues. The method can be used for fully utilizing liquorice source, and achieving the separation of different effective components during extraction to avoid the loss of other several active substances during single extraction; the production cost is low, the operation is simple, the production efficiency is high, and no environment pollution is produced; by utilizing the method, continuous production is achieved, and the products obtained according to the method have high quality; the method is easily popularized and utilized and provides a new approach for comprehensive utilization of liquorice; by utilizing the method, the comprehensive utilization value of liquorice is improved.

Owner:内蒙古普凡生生物科技有限公司 +1

Integrated automatic punching and flanging machine for valve pipes

InactiveCN104646488AImprove product qualityReasonable designMetal-working feeding devicesStripping-off devicesPunchingMechanical equipment

The invention belongs to the technical field of mechanical equipment and particularly relates to an integrated automatic punching and flanging machine for valve pipes. According to the integrated automatic punching and flanging machine for the valve pipes, the technical problems of low automation degree and poor product processing quality in the prior are solved. The integrated automatic punching and flanging machine for the valve pipes comprises a machine frame, wherein a large-hole punching device, a small-hole punching device, an annealing device and a hole flanging device are sequentially arranged on the machine frame; the large-hole punching device punches three large holes in a workpiece; the small-hole punching device punches a small hole opposite to the middle large hole in the workpiece; the annealing device anneals the workpiece; the hole flanging device flanges the outer side of the small hole; a plurality of pipe placement frames in one-to-one correspondence to the large-hole punching device, the small-hole punching device, the annealing device and the hole flanging device are arranged on the machine frame; a material transferring mechanism used for sequentially transferring the workpiece on all the pipe placement frames to enable the large-hole punching device, the small-hole punching device, the annealing device and the hole flanging device to sequentially process the workpiece is further arranged on the machine frame. The integrated automatic punching and flanging machine for the valve pipes has the advantages that the processing quality of products is improved, and the automation degree is high.

Owner:ZHUJI RUN TUO MECHANICAL AUTOMATION TECH

Combined hybrid cross-linked dynamic polymer and application thereof

The invention discloses a combined hybrid cross-linked dynamic polymer, which contains at least one boron-containing dynamic covalent bond, at least one other dynamic covalent bond and an optional hydrogen bond, and contains at least one dynamic covalent cross-linked network, wherein the cross-linking degree of other dynamic covalent bond cross-linking reaches a gel point or above. By introducingthe boron-containing dynamic covalent bonds with different dynamics, other dynamic covalent bonds and optional hydrogen bonds into the combined hybrid cross-linked dynamic polymer, a dynamic polymer material with a wide controllable range, rich structures and various properties can be prepared. The dynamic polymer contains the difference between the boron-containing dynamic covalent bond, the other dynamic covalent bond and the hydrogen bond, so that the polymer can show dynamic reversible effects with orthogonality and synergism under different conditions, and therefore, the polymer shows good self-repairing characteristics and rich stimulus responsiveness. The dynamic polymer can be widely applied as a self-repairing material, a tough material, a sealing material, an interlayer adhesiveand the like.

Owner:厦门逍扬运动科技有限公司

Thermoplastic composite solid propellant and preparation method thereof

ActiveCN107867962AAchieve moldingImprove securityNon-explosive fillers/gelling/thickening agentsAmmonium perchlorate explosive compositionsInherent safetyPlasticizer

The invention provides a thermoplastic composite solid propellant applicable to a solid booster. The thermoplastic composite solid propellant is prepared from components in percentage by mass as follows: 55%-70% of an oxidant, 10%-20% of a thermoplastic resin adhesive, 10%-20% of a plasticizer, 5%-20% of metal fuel and 3%-8% of auxiliaries. According to the prepared thermoplastic composite solid propellant, relative independence of mixing and pouring, integrated formation of the propellant and secondary formation of engine charge can be realized according to temperature adjustment, and melt mixing and formation of the thermoplastic propellant can be realized at relatively low temperature lower than 90 DEG C, so that inherent safety of preparation of the thermoplastic propellant is greatlyimproved; compared with a traditional thermosetting propellant, crosslinking curing process is omitted, technological process is shortened, recovery and repeated processing of waste products can be realized, and production cost is reduced. The thermoplastic propellant is prepared with a hot melt mixing-cooling formation technology, and application of components absorbing moisture easily in the propellant is realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

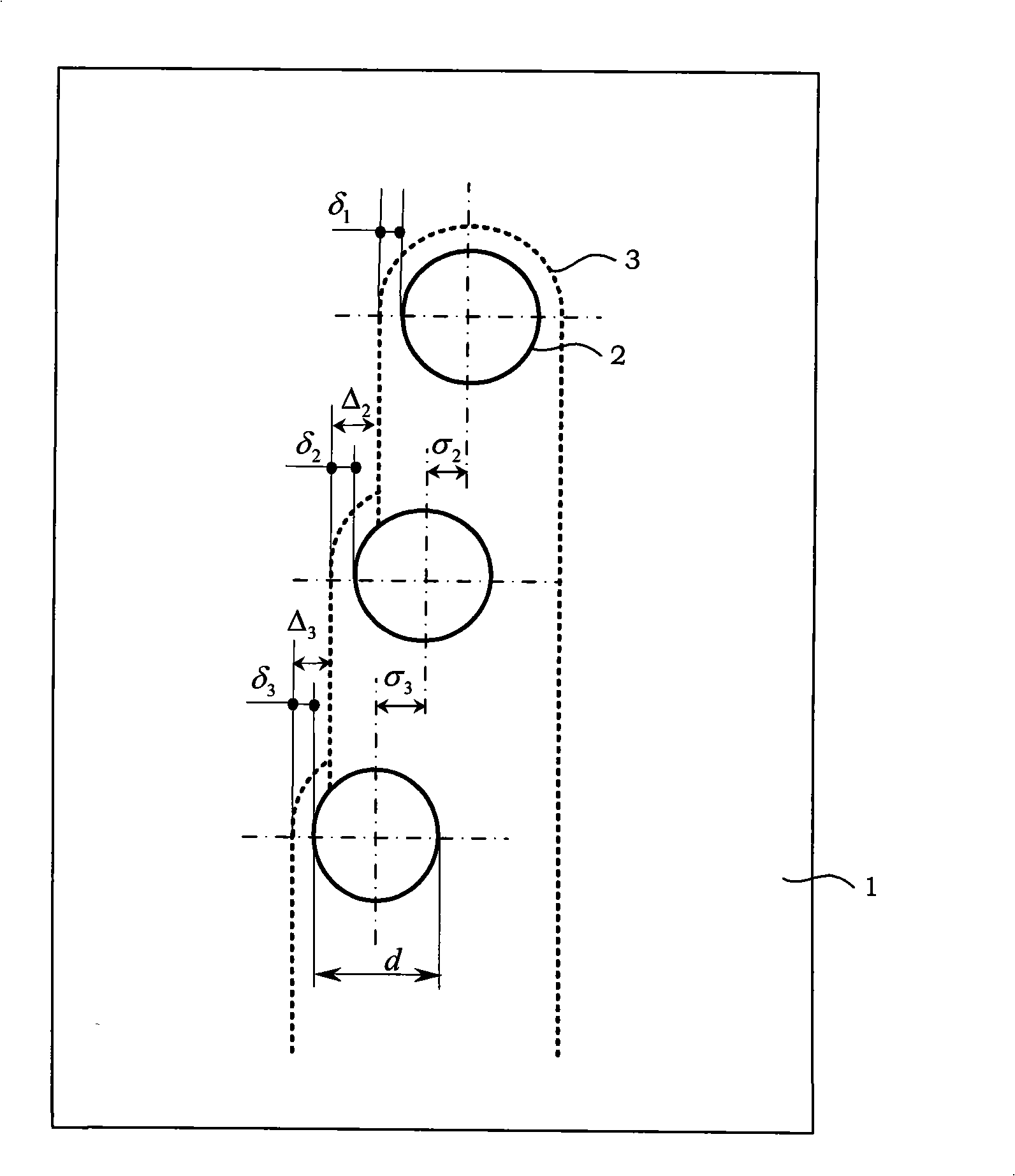

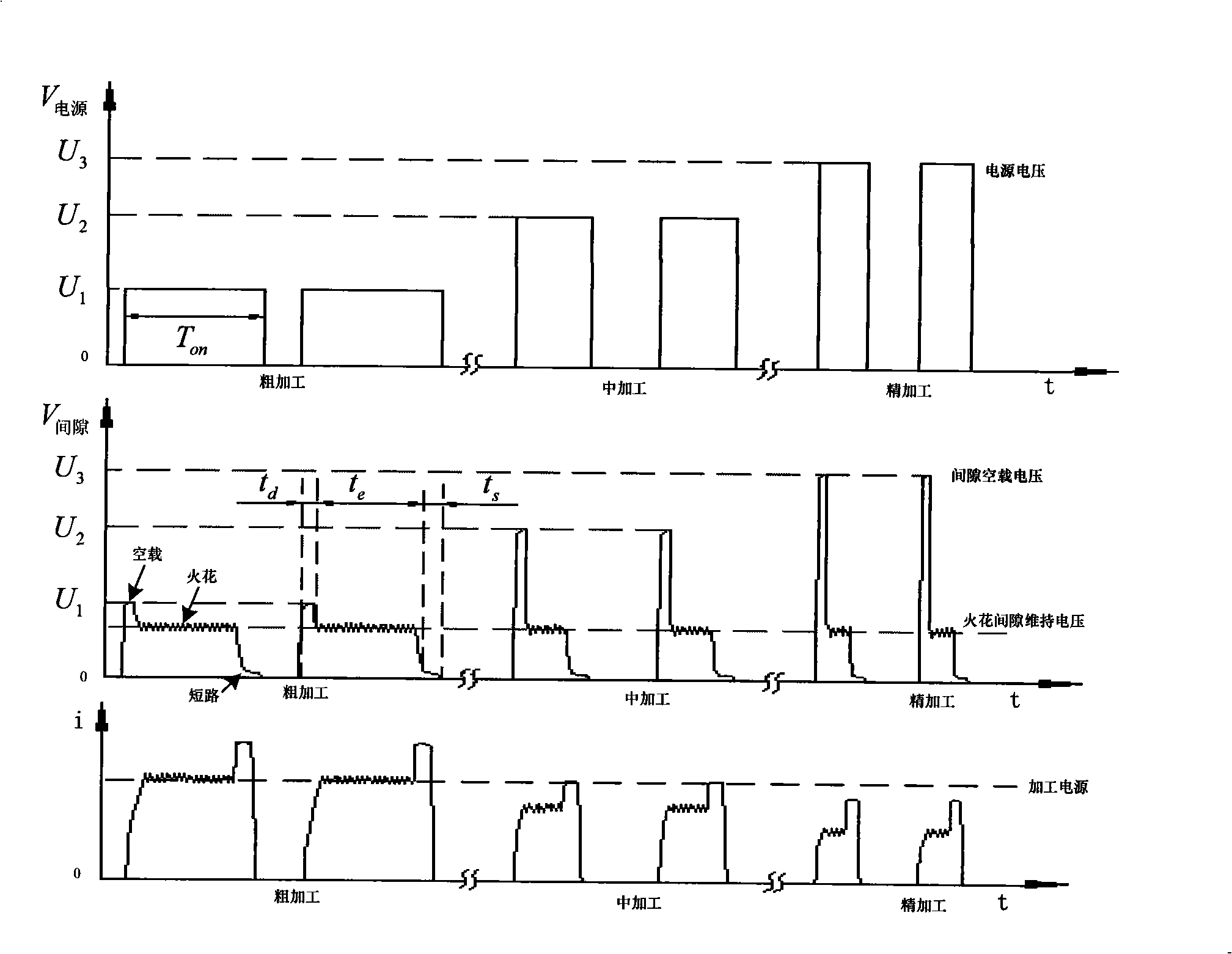

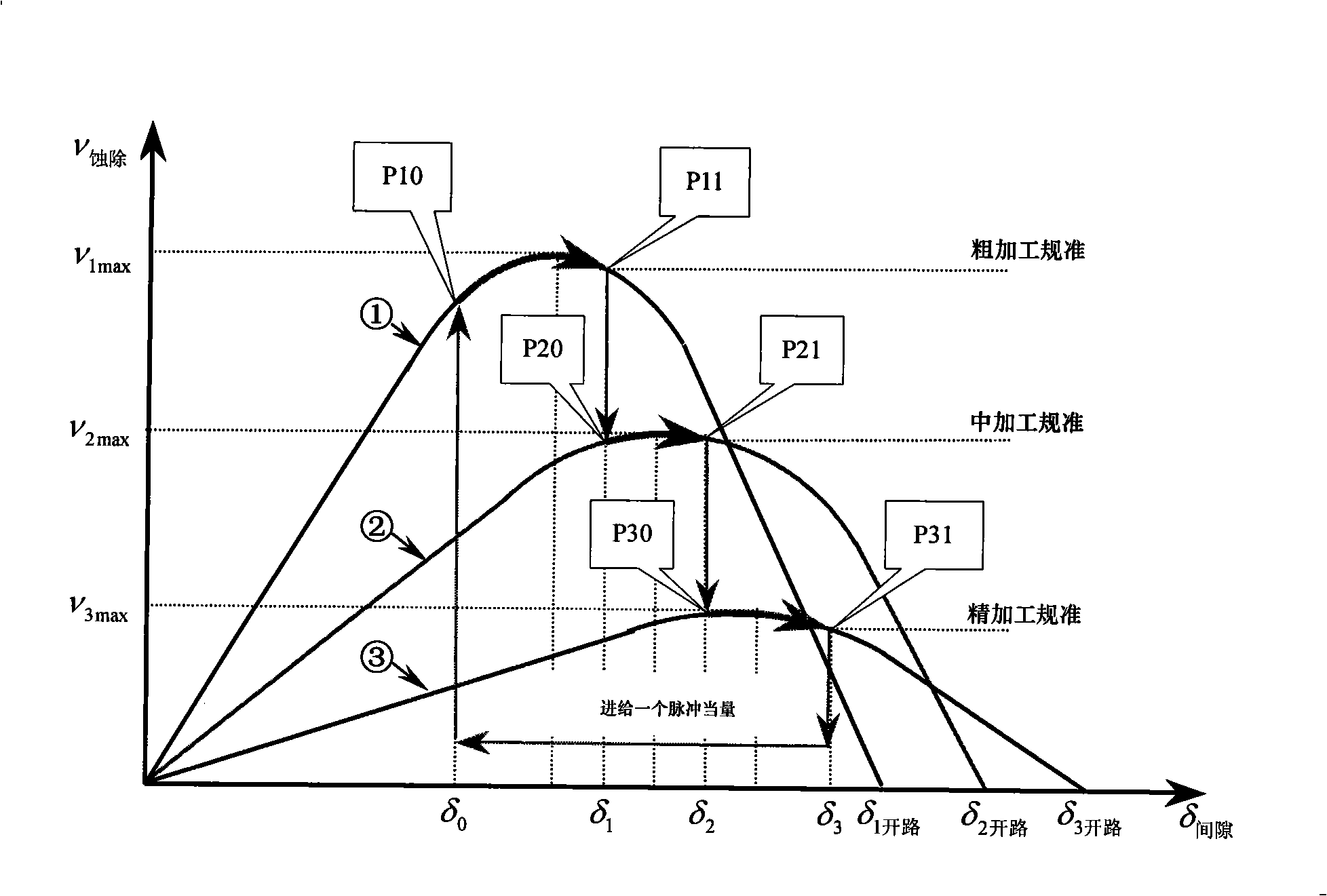

Coarse and precision composite processing method suitable for numerical control electrospark wire-electrode cutting

InactiveCN101259550ARealize rough machiningRealize the processing effectNumerical controlWire cutting

The invention discloses a coarse, middle and fine composite processing method which is applicable to numerical control electrical discharge wire cutting, the composite processing method sets the specification standards of the coarse processing, the middle processing and the fine processing according to parameters of output pulse voltage and current of a pulse power supply; then the contrast of the gap differences is carried out by the current single side discharge gap Delta gap, the coarse processing gap Delta 1, the middle processing gap Delta 2 and the fine processing gap Delta 3 which are detected by a servo control system, thus obtaining the states of the coarse processing, the middle processing and the fine processing. The output parameters of the pulse power supply are automatically circulated and changed in the specification standards of the coarse processing, the middle processing and the fine processing throughout the processing process, thus realizing the purpose of one-step forming composite processing of the coarse processing, the middle processing and the fine processing.

Owner:HARBIN INST OF TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com