Preparation method of block high temperature resistant silicon-charcoal composite aerogel material

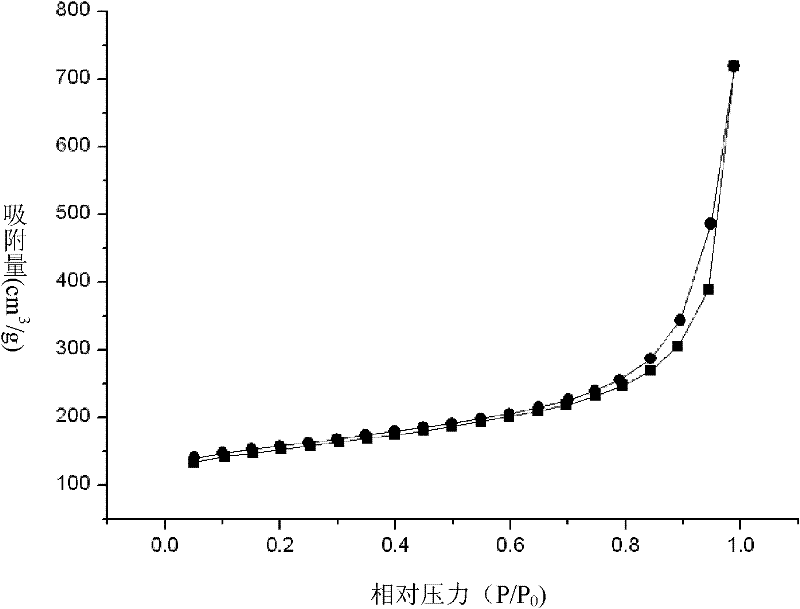

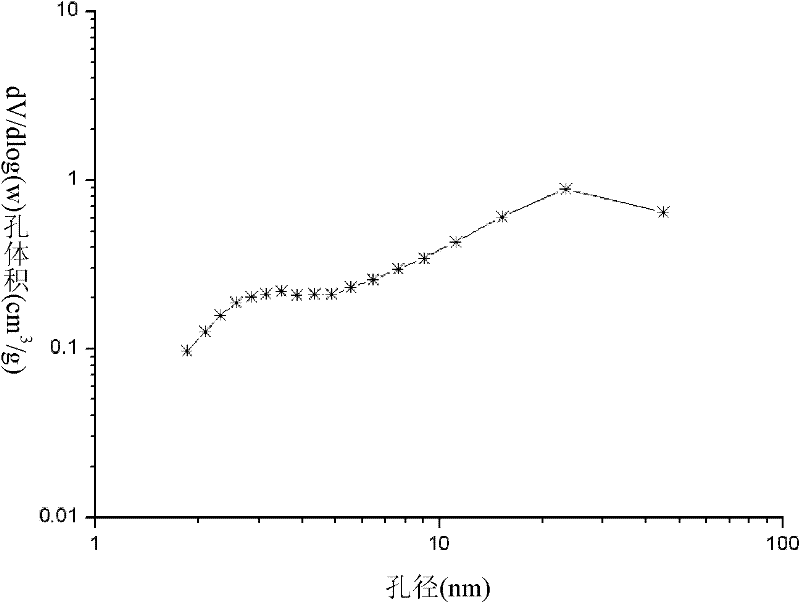

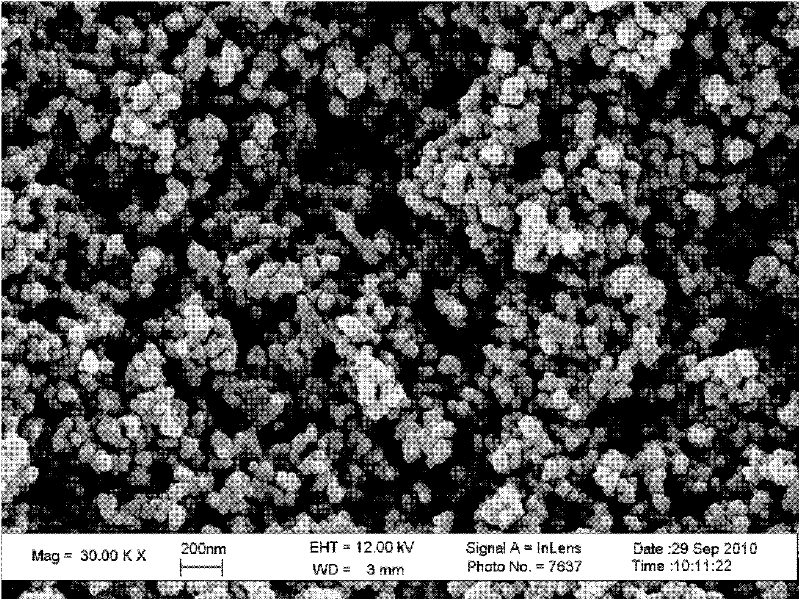

A technology of high temperature resistance and airgel, which is applied in the field of preparation of airgel materials, can solve the problems of poor airgel pore structure, large specific surface area, high strength, etc., and achieve reduced operation steps, low density, and high molding performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] (1) The molar ratio of resorcinol, formaldehyde, 3-aminopropyltriethoxysilane and deionized water is 1: 2: 0.5: 10, and the mol ratio of resorcinol and sodium carbonate is 1: 500, using methanol as a solvent to form a reactant solution (resorcinol, formaldehyde and 3-aminopropyltriethoxysilane) with a mass concentration of 6%, and place the reactant solution in a 60°C oven at a constant temperature The reaction was carried out for 70 minutes to obtain a wet gel.

[0025] (2) After the wet gel was aged in a water bath at 75°C for 10 days, the solvent was replaced with methanol, and the methanol was replaced every 6 hours for a total of 6 replacements. The degassing rate was replaced for 6 hours, then the temperature was raised to 50°C, and at 15 MPa, the degassing rate was 10 liters / minute for 4 hours, and finally the pressure was released to balance with the external atmospheric pressure at a degassing rate of 1 liters / minute, and organic gas condensation was obtained. ...

example 2

[0029] (1) The molar ratio of resorcinol, formaldehyde, and 3-aminopropyl triethoxysilane is 1: 2: 0.5: 4, and the molar ratio of resorcinol and sodium hydroxide is 1: 300, with Ethanol was used as a solvent to prepare a reactant solution with a mass concentration of the reactant of 4%, and the reactant solution was placed in an oven at 60° C. for constant temperature reaction for 300 minutes to obtain a wet gel.

[0030] (2) After the wet gel was aged in a water bath at 60°C for 15 days, the solvent was replaced with acetone, and the acetone was replaced every 12 hours for a total of 3 replacements, and then carbon dioxide supercritical drying was carried out at 10MPa and 25°C at 20 liters / hour. The degassing rate of 1 minute was replaced for 4 hours, then the temperature was raised to 80 ° C, and at 15 MPa, the degassing rate was 5 liters / minute for 8 hours, and finally the pressure was released at a degassing rate of 1 liter / minute to balance with the external atmospheric pr...

example 3

[0034](1) The molar ratio of resorcinol, formaldehyde, and 3-aminopropyltriethoxysilane is 1:2:1:4, and the molar ratio of resorcinol and sodium carbonate is 1:1000, with ethanol Prepare a solution with a mass concentration of 10% of the reactant as a solvent, and place the reactant solution in an oven at 60°C for 80 minutes at a constant temperature to obtain a wet gel.

[0035] (2) After aging for 10 days in a water bath at 65°C, the wet gel was replaced with absolute ethanol, and the absolute ethanol was replaced every 6 hours for a total of 3 replacements, followed by supercritical carbon dioxide drying at 10MPa and 25°C Displace with a gas release rate of 10 liters / min for 12 hours, then raise the temperature to 60°C, under 10 MPa, replace with a gas release rate of 5 liters / min for 8 hours, and finally release the pressure at a gas release rate of 3 liters / min to balance with the external atmospheric pressure , to obtain organic aerogels.

[0036] (3) The organic airgel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com