Ultrasonic assisted method for preparing precursor of ternary positive material of lithium ion battery

A lithium-ion battery, ultrasonic-assisted technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of low co-precipitation yield, poor crystal form integrity, narrow particle size distribution, etc., and achieve good cycle performance, low cost, The effect of high tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

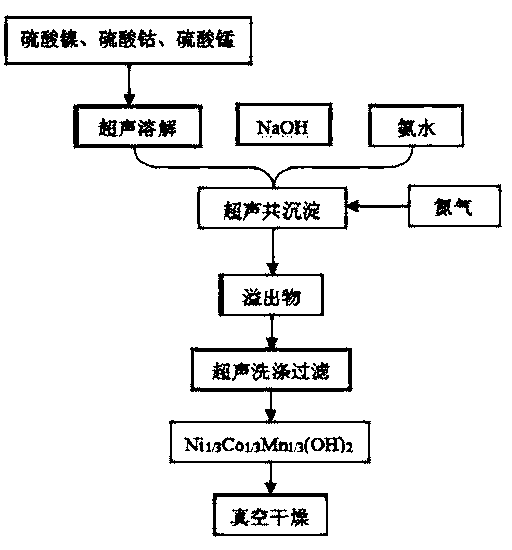

[0035] NiSO 4 , MnSO 4 , CoSO 4According to the molar ratio of Ni: Mn: Co=4:3:3, use a sulfuric acid solution with a pH value of 2.1 to assist ultrasonic dissolution to prepare a nickel-manganese-cobalt mixed solution with a total concentration of 2.0 mol / L, and prepare a 2.5 mol / L hydroxide Sodium solution, prepare an ammonia solution with a concentration of 0.5 mol / L, and use a metering pump to respectively input the nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia solution into a 1L reaction kettle with a certain bottom liquid added in advance for stirring and ultrasound Auxiliary co-precipitation reaction. Under the condition of nitrogen protection, the temperature of the reaction kettle is controlled at 50°C, the pH value is 11.5, the stirring speed is 600r / min, the ultrasonic frequency is 40kHz, and the power is 200W, until the feed liquid in the reaction kettle naturally overflows into the collection tank, the obtained precipitation, That...

Embodiment 2

[0037] NiSO 4 , MnSO 4 , CoSO 4 According to the molar ratio of Ni: Mn: Co=3:3:3, use a sulfuric acid solution with a pH value of 2.0 to assist ultrasonic dissolution to prepare a nickel-manganese-cobalt mixed solution with a total concentration of 1.0 mol / L, and prepare a 2 mol / L hydroxide Sodium solution, prepare an ammonia solution with a concentration of 3 mol / L, and use a metering pump to respectively input the nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia solution into a 1L reaction kettle with a certain bottom liquid in advance for stirring and ultrasound Auxiliary co-precipitation reaction. Under the condition of nitrogen protection, the temperature of the reaction kettle is controlled at 45°C, the pH value is 9.0, the stirring speed is 700r / min, the ultrasonic frequency is 30kHz, and the power is 500W, until the feed liquid in the reaction kettle naturally overflows into the collection tank, the obtained precipitation, That is, the ...

Embodiment 3

[0039] NiSO 4 , MnSO 4 , CoSO 4 According to the molar ratio of Ni:Mn:Co=5:2:3, the nickel-manganese-cobalt mixed solution was prepared by ultrasonic-assisted dissolution with a sulfuric acid solution with a pH value of 2.0. The total concentration was 3.0 mol / L, and a 5 mol / L hydroxide Sodium solution, prepare an ammonia solution with a concentration of 2.0 mol / L, and use a metering pump to respectively input the nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia solution into a 1L reaction kettle with a certain bottom liquid in advance for stirring and ultrasonic Auxiliary co-precipitation reaction. Under the condition of nitrogen protection, the temperature of the reaction kettle is controlled at 60°C, the pH value is 10.5, the stirring speed is 900r / min, the ultrasonic frequency is 20kHz, and the power is 800W, until the feed liquid in the reaction kettle naturally overflows into the collection tank, the obtained precipitation, That is, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com