Patents

Literature

58results about How to "Realize grinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

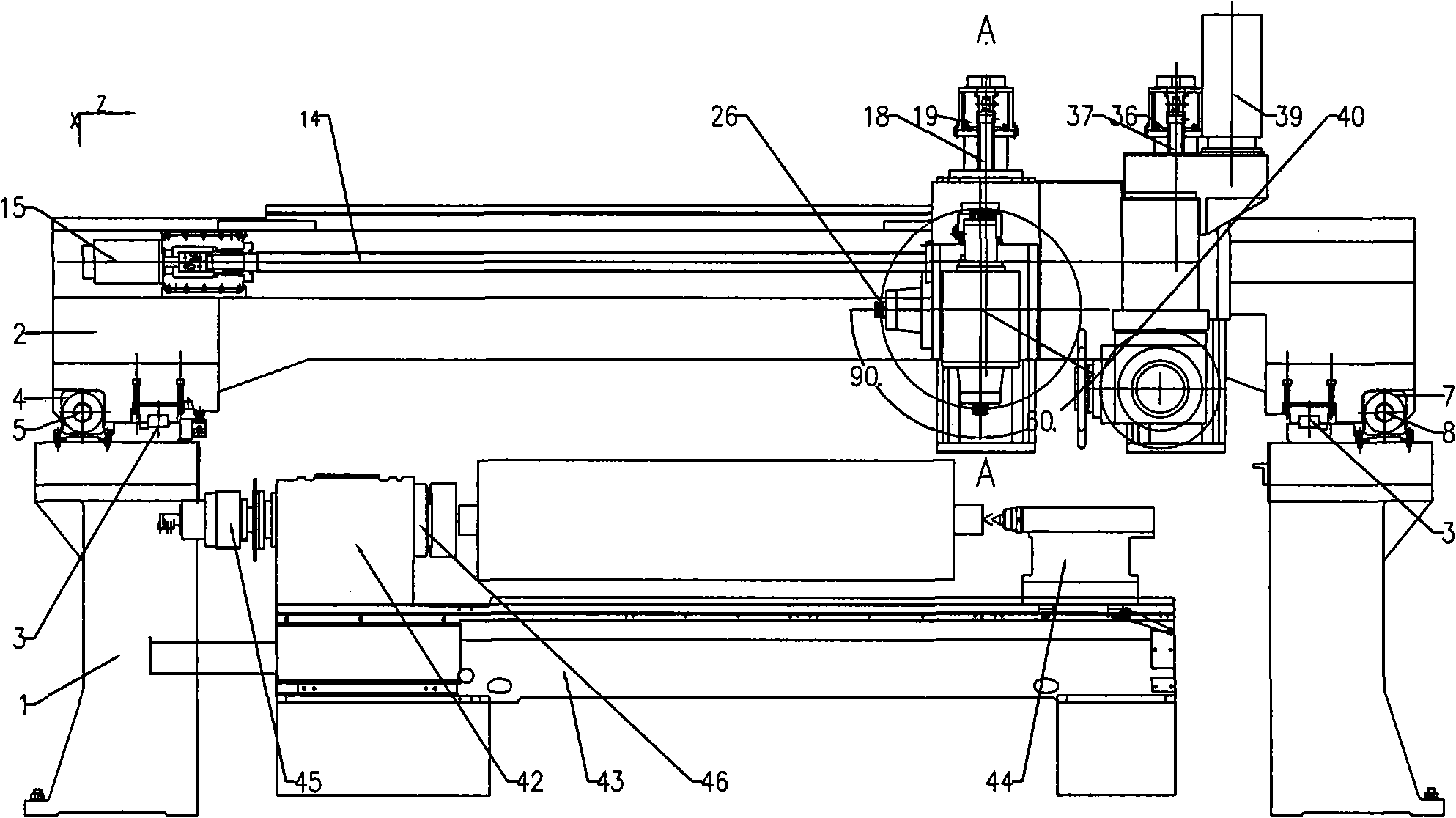

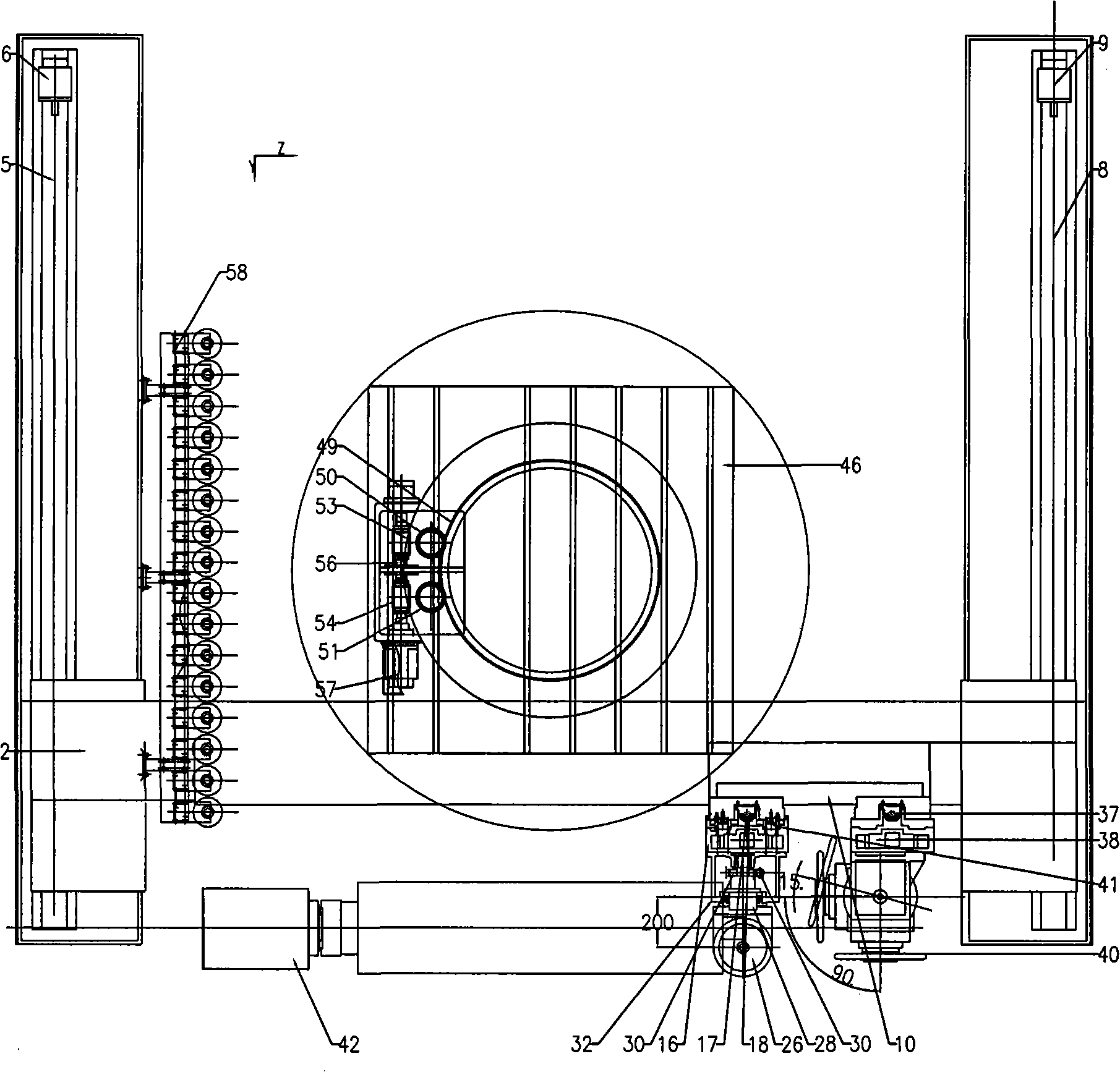

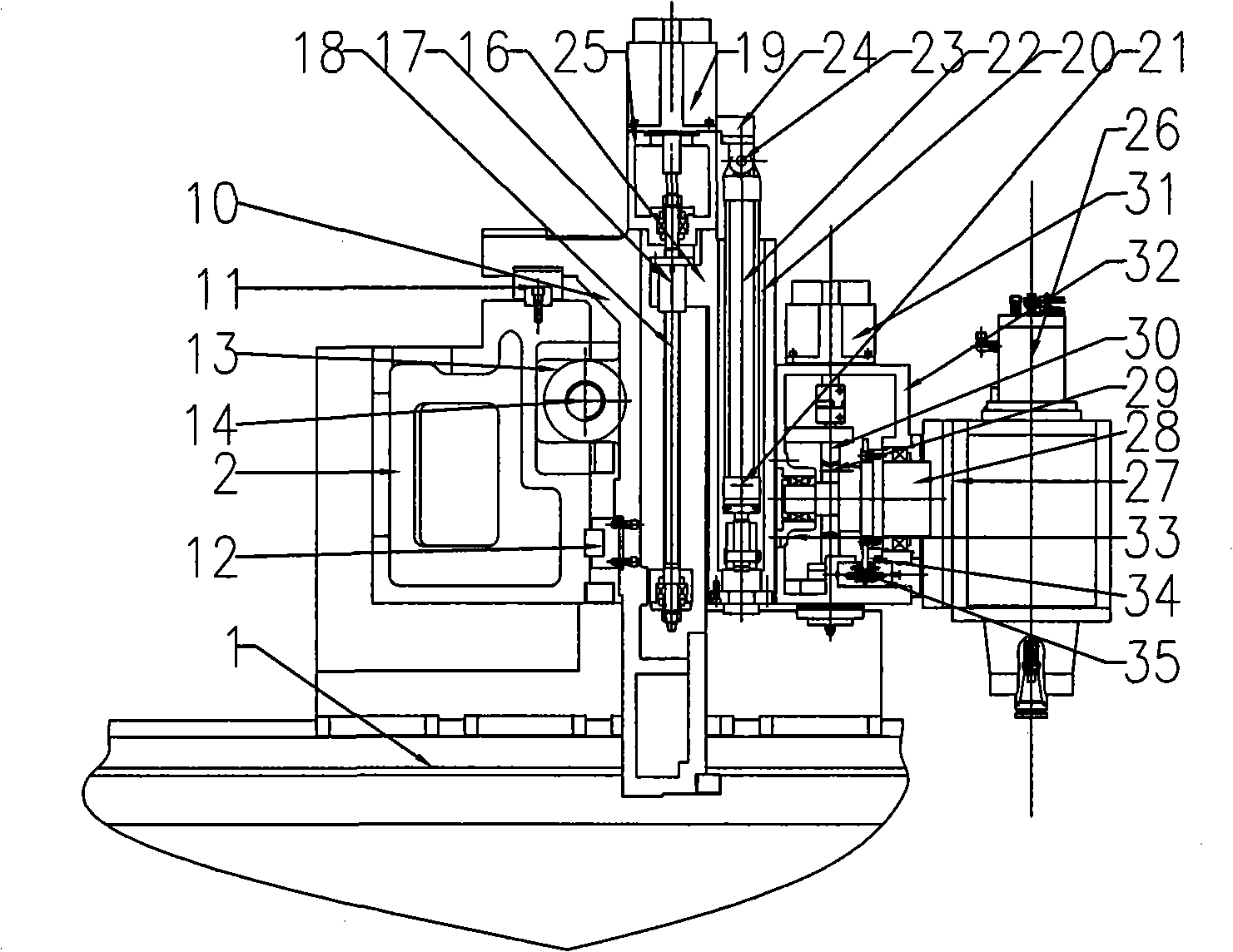

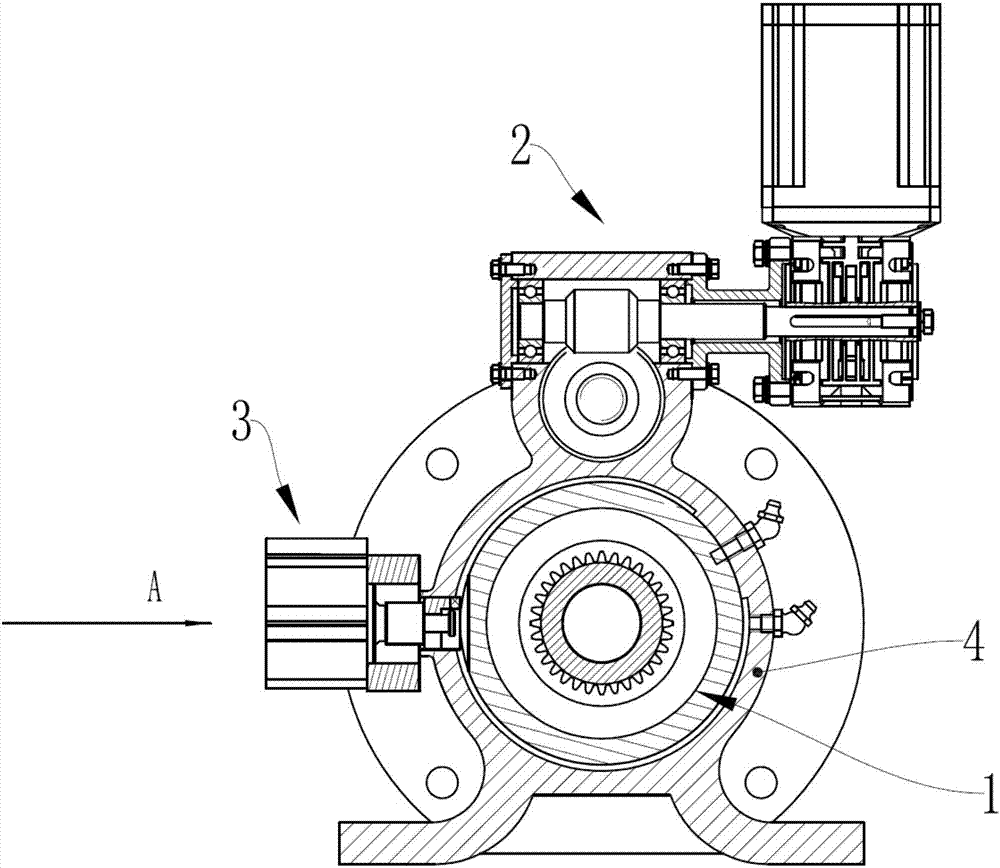

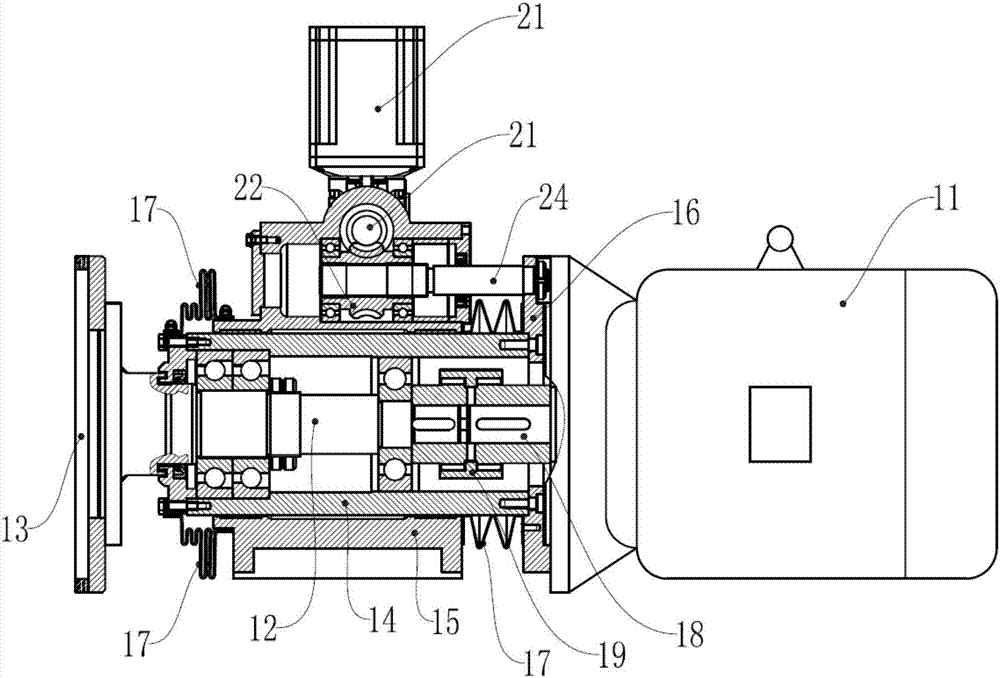

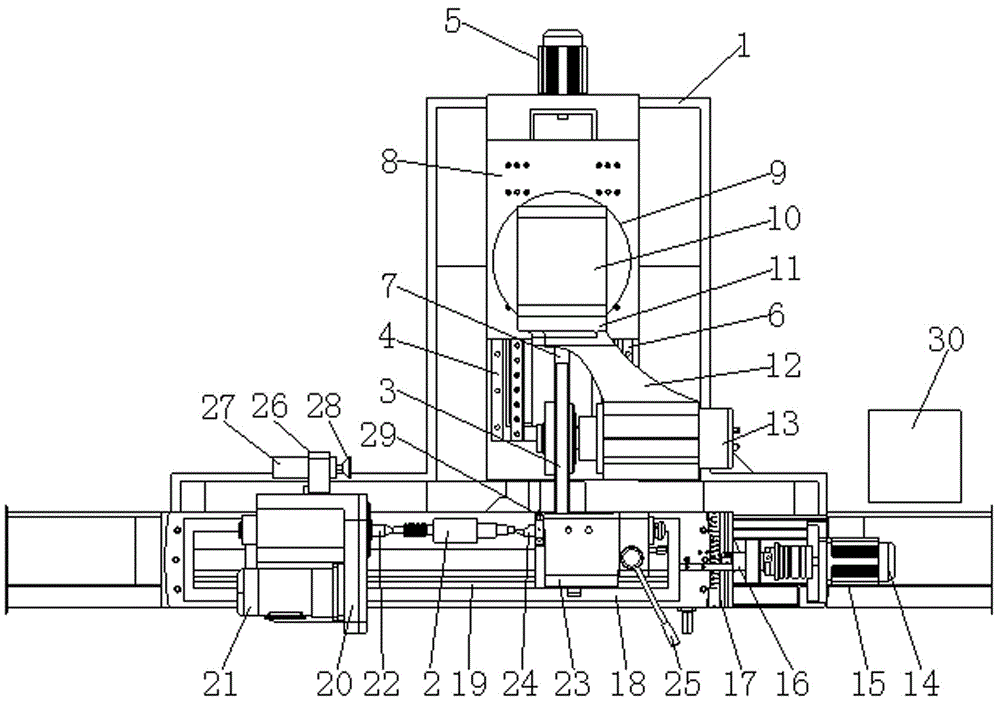

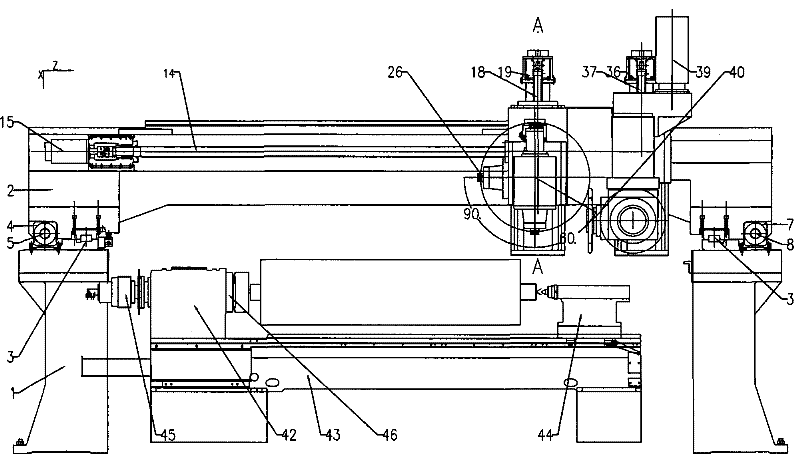

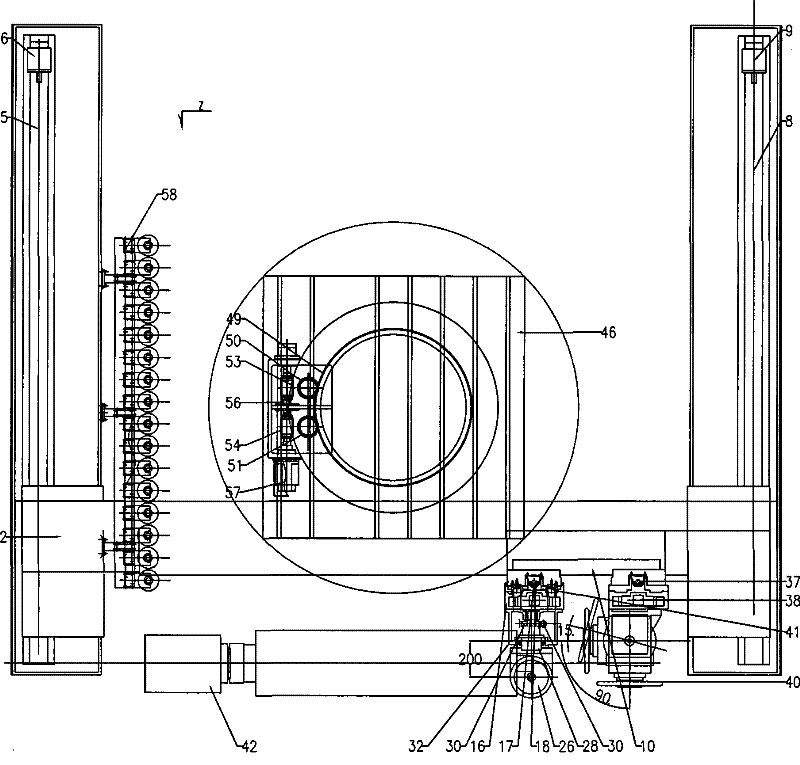

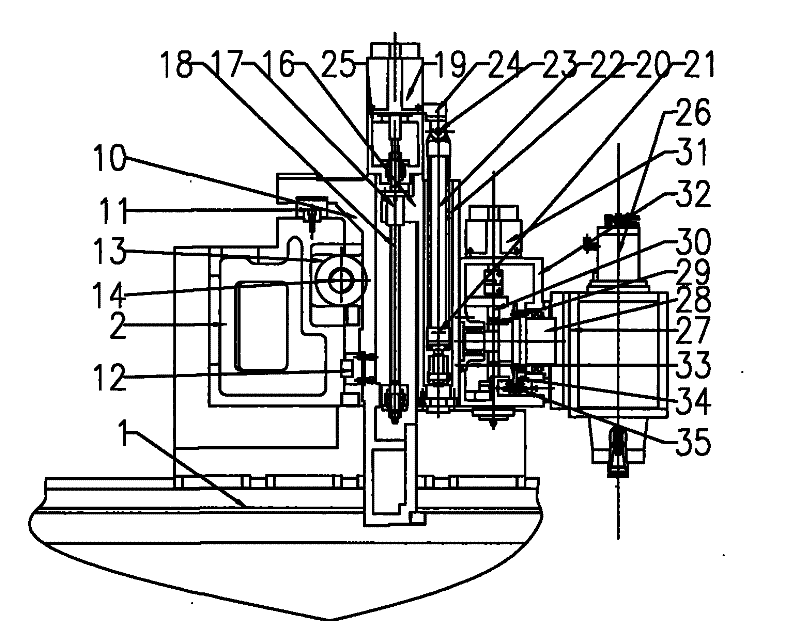

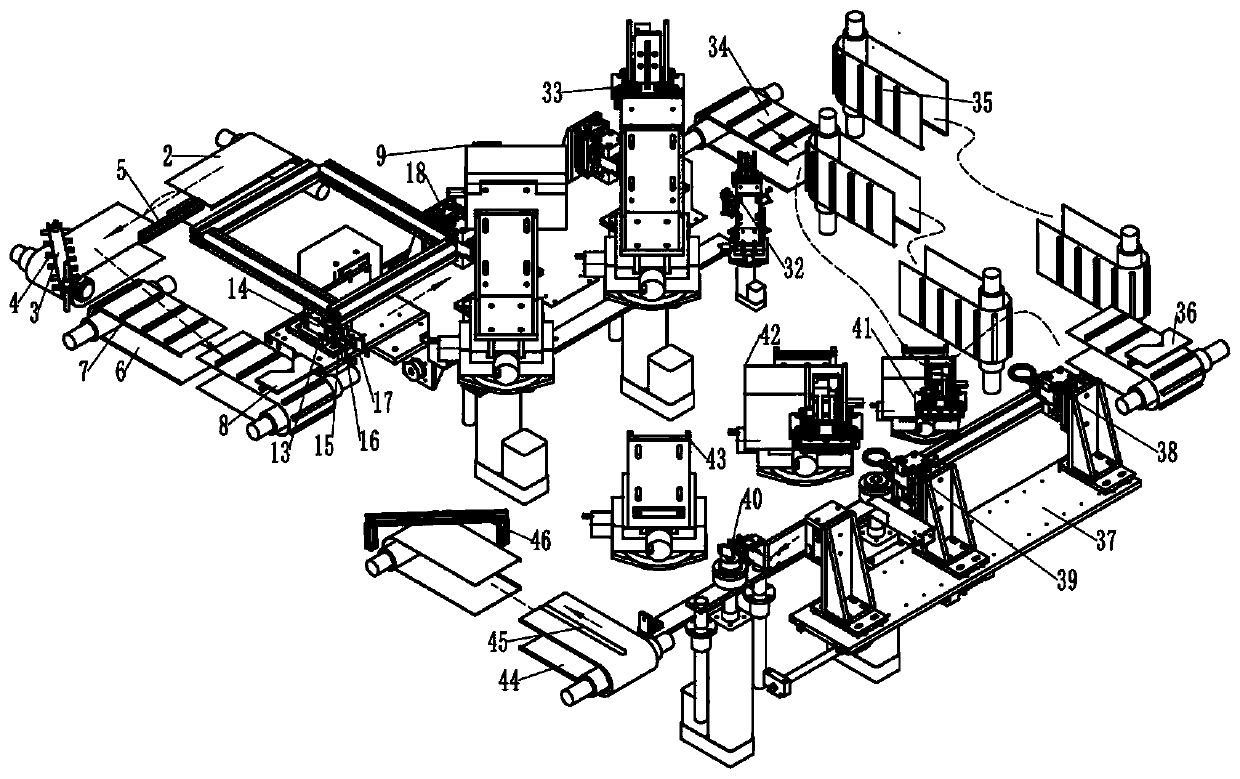

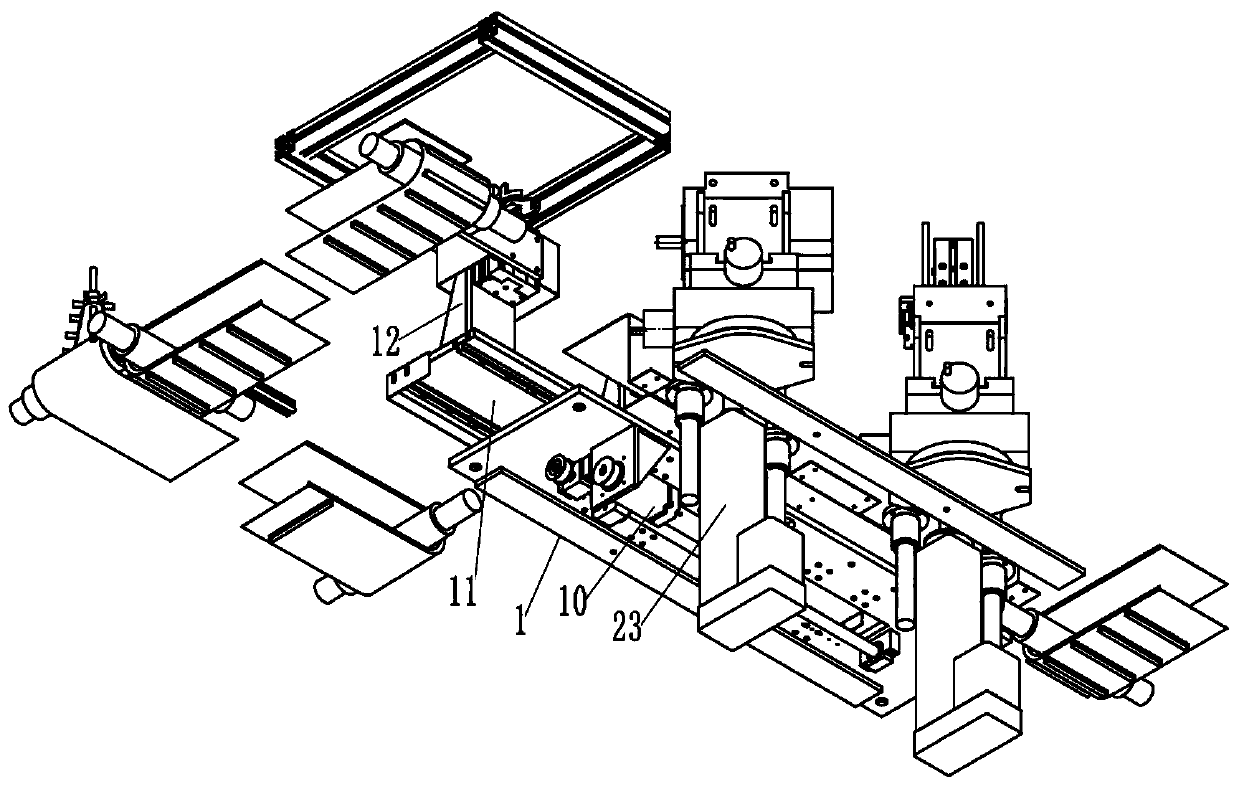

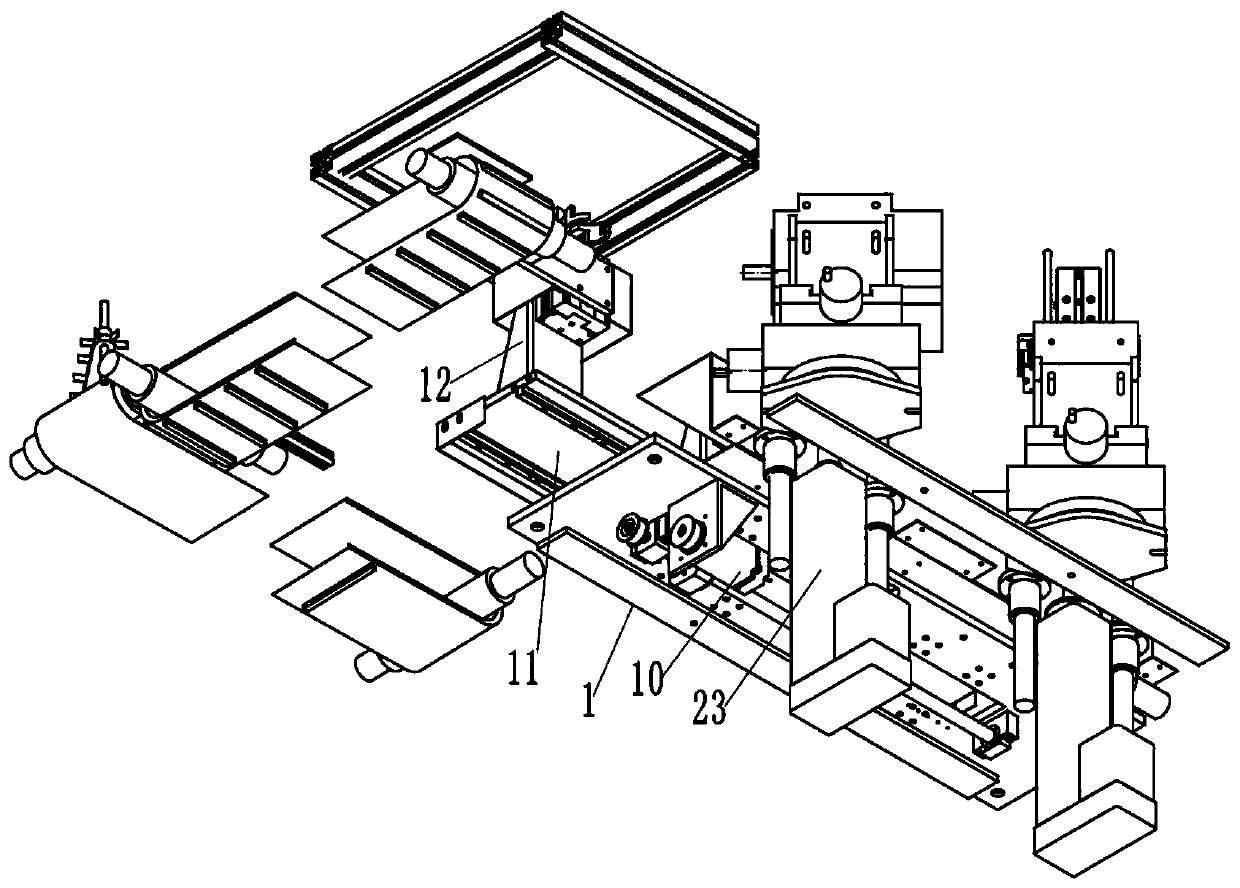

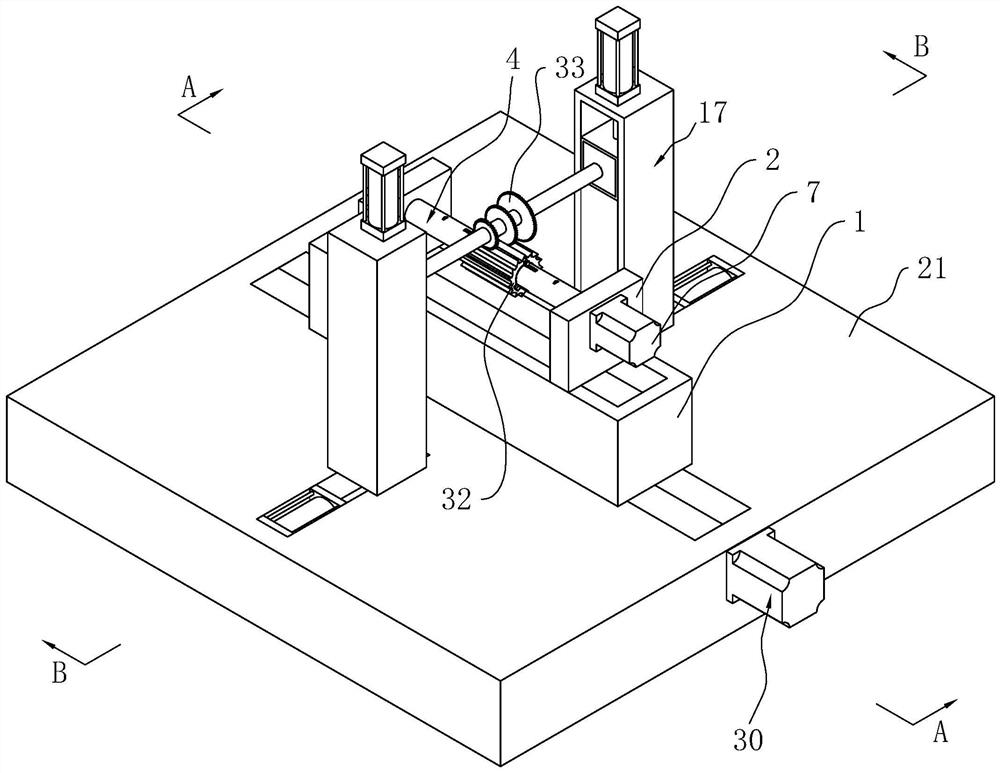

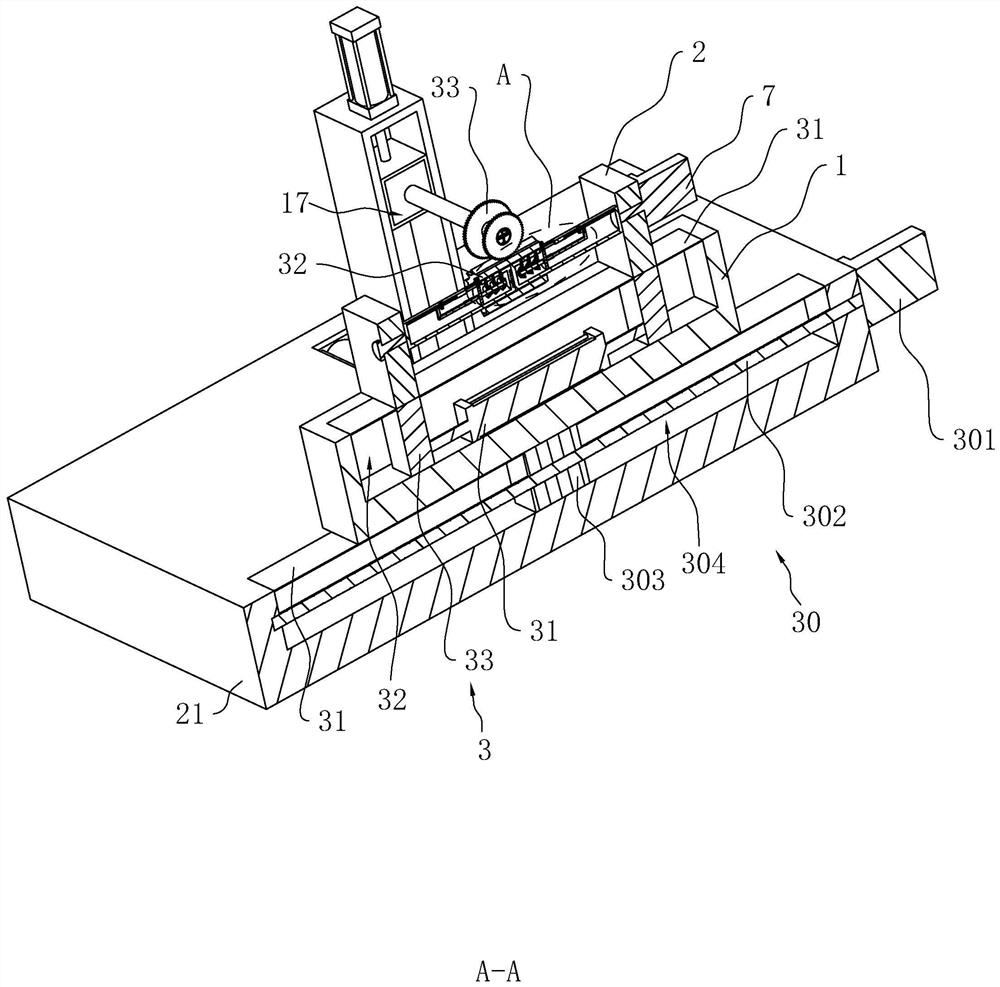

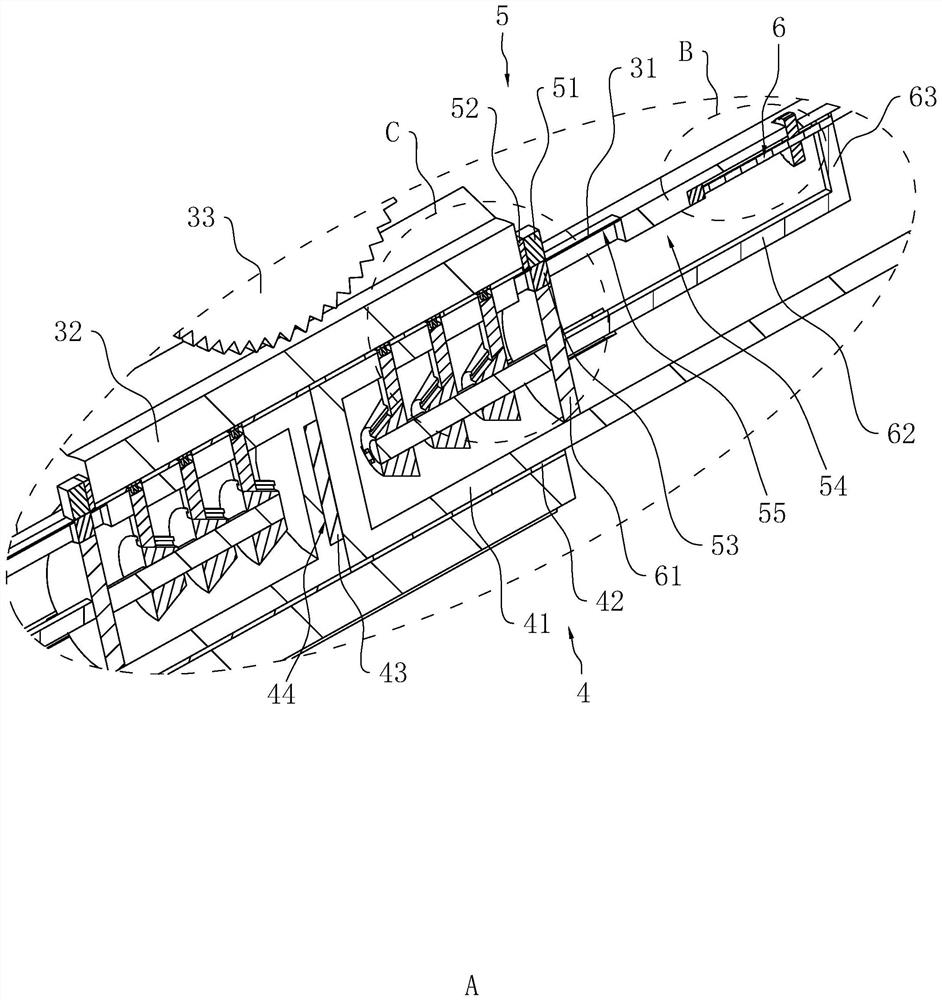

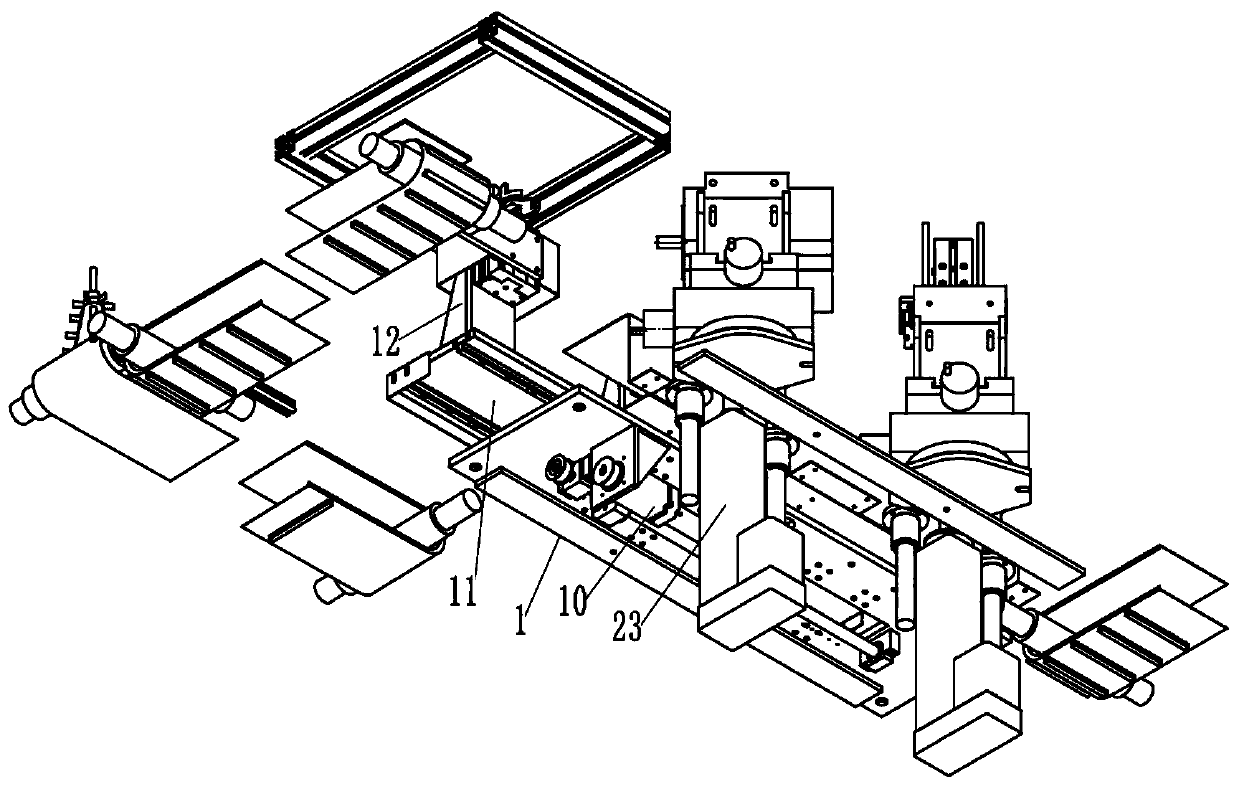

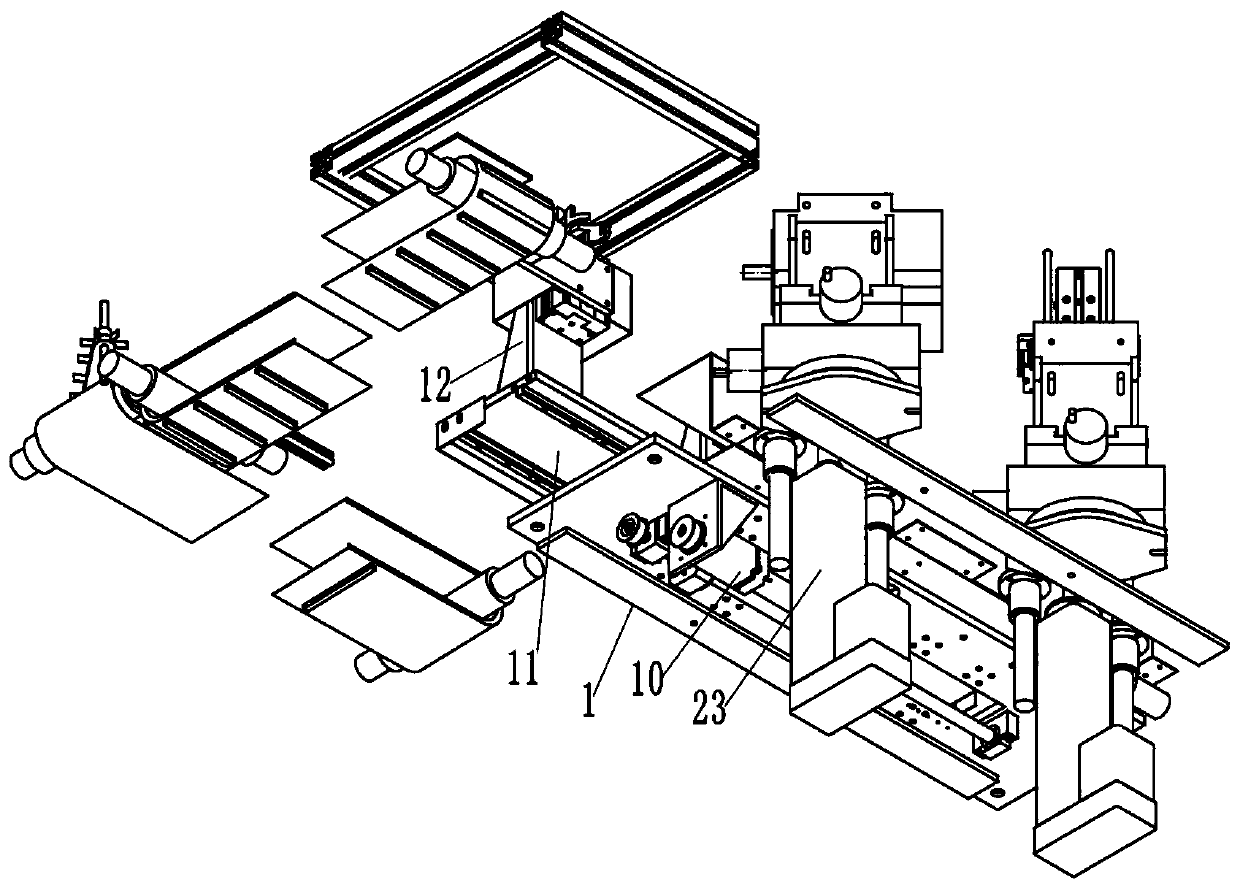

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490AEngraving and milling realizationAchieve turningGrinding machinesStone-like material working toolsEngineeringMechanical engineering

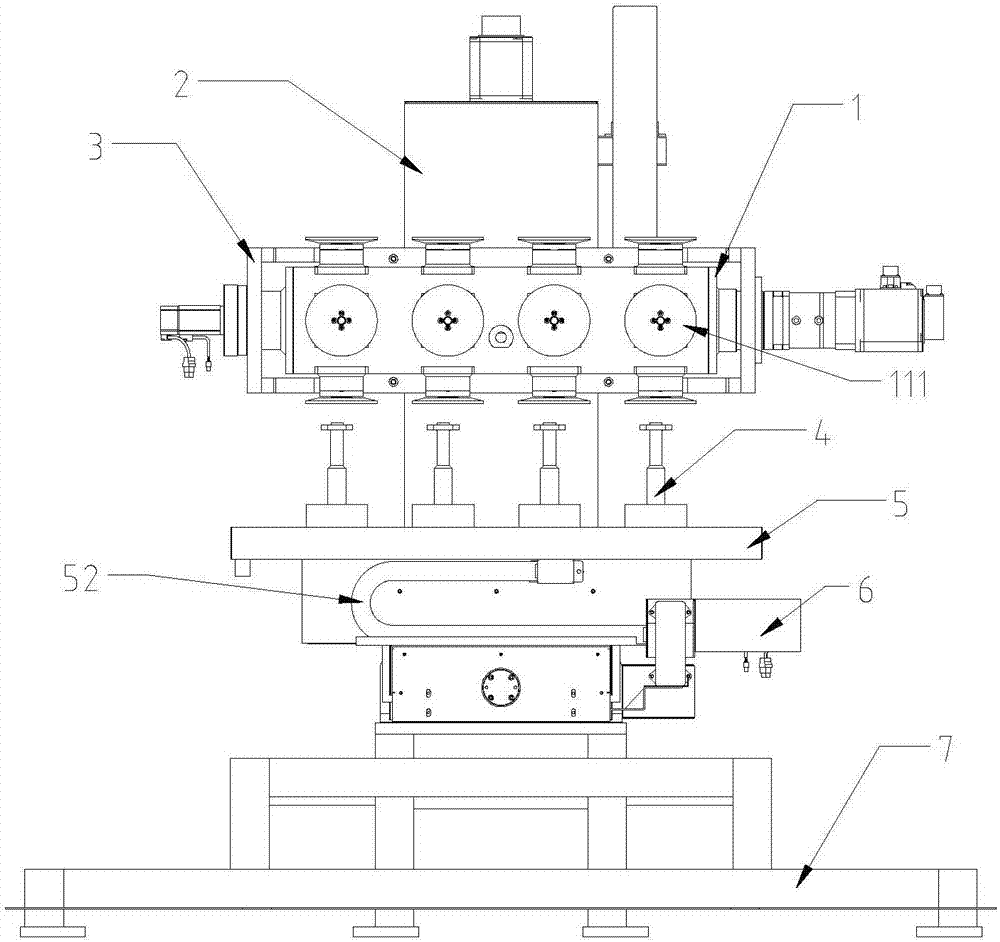

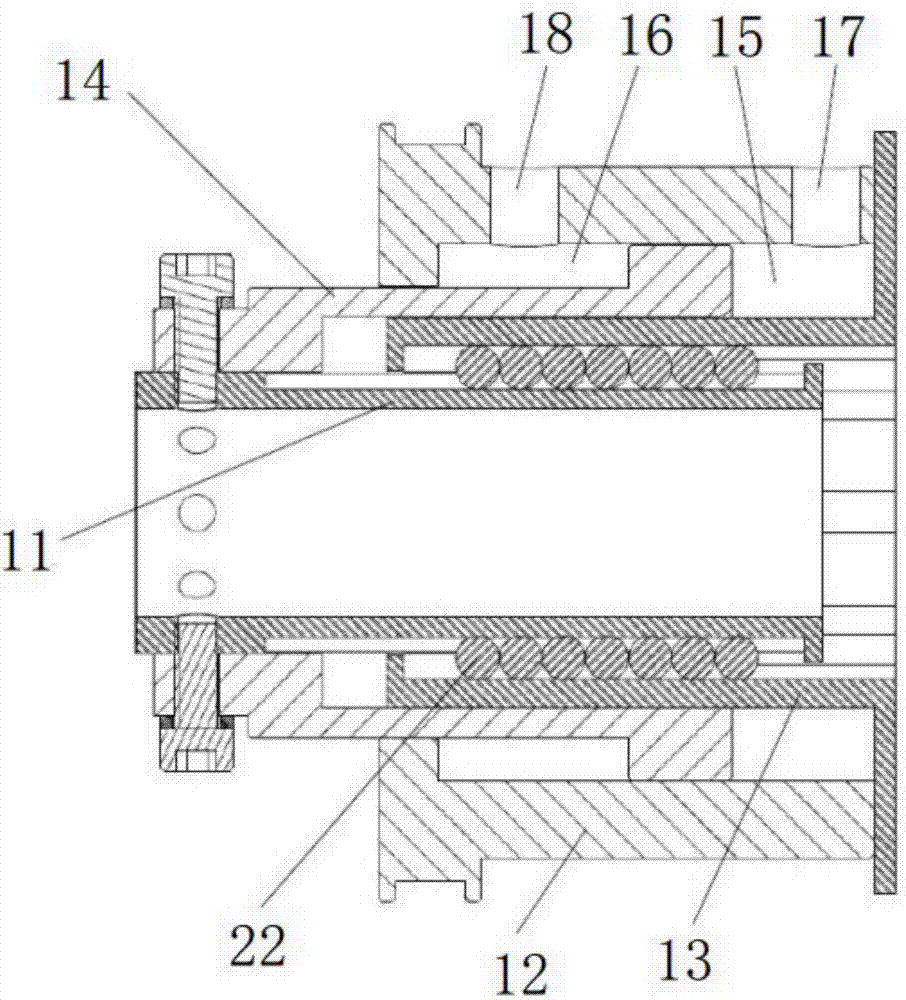

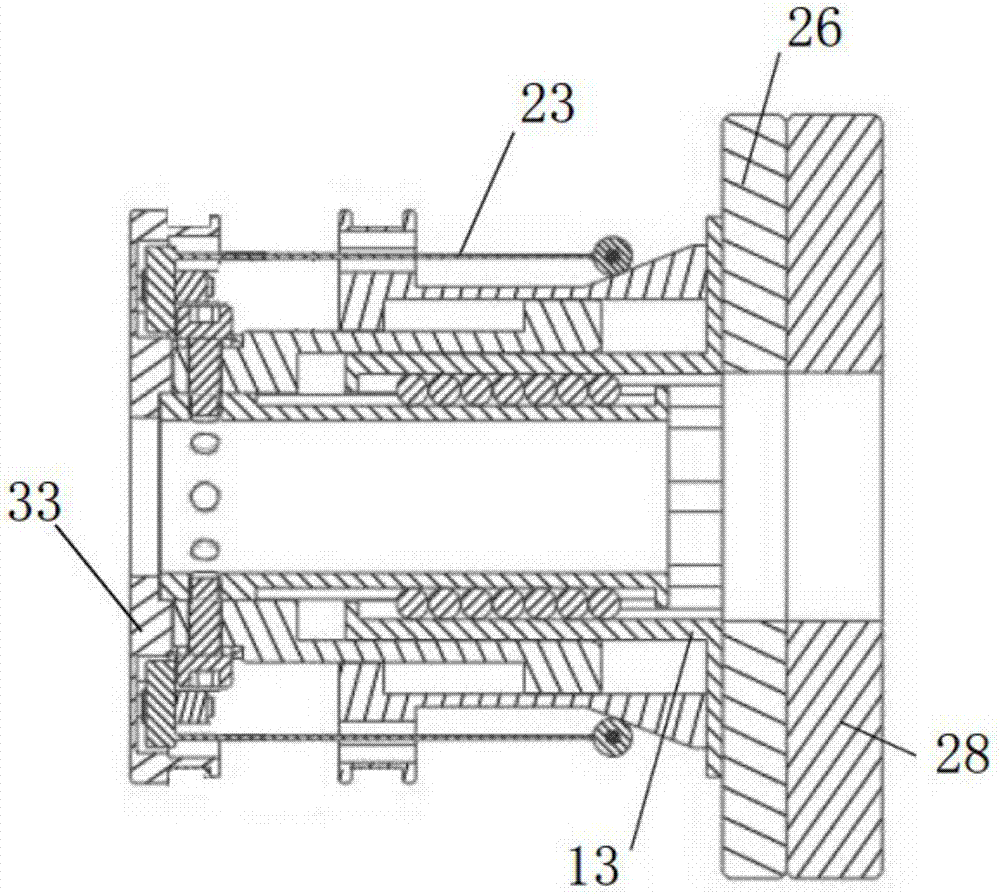

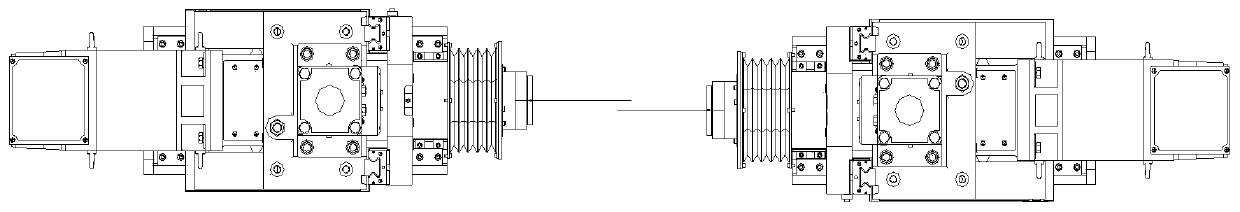

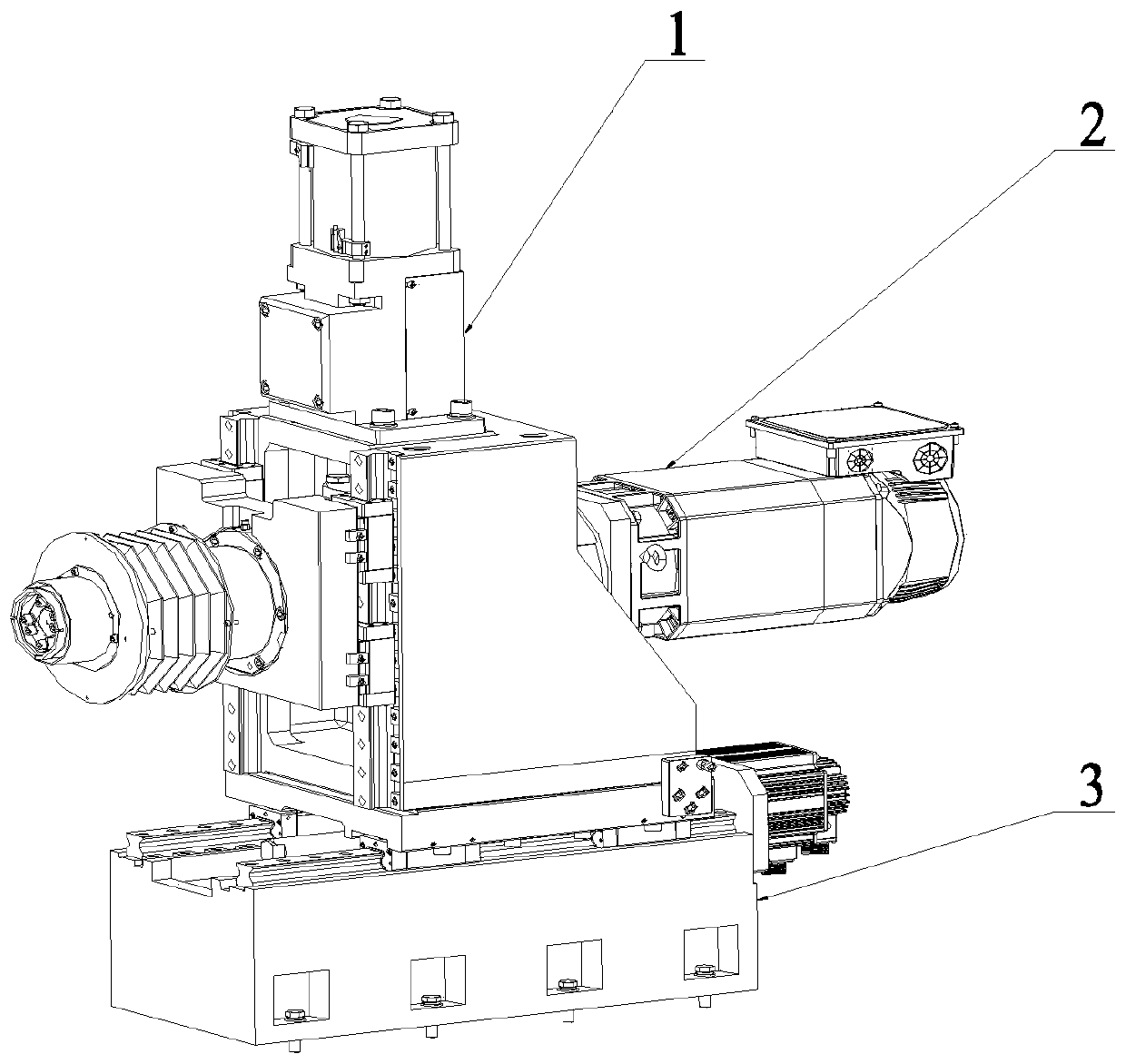

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division around the axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

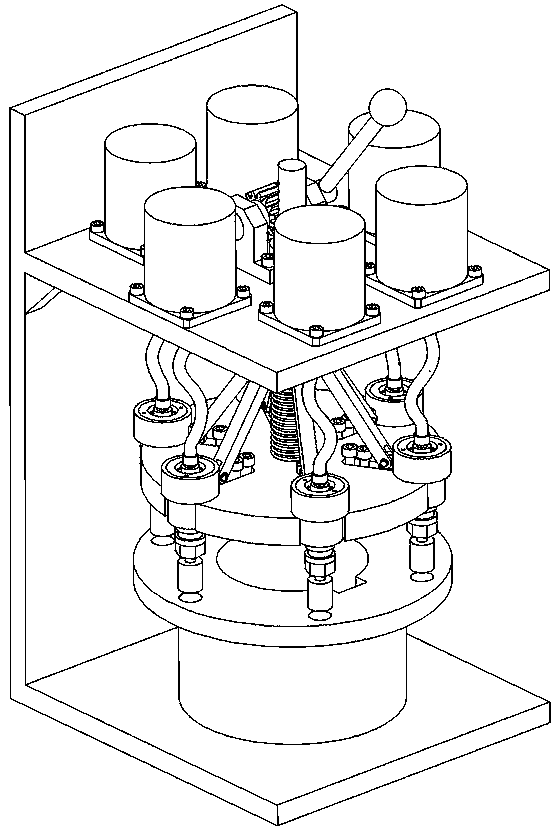

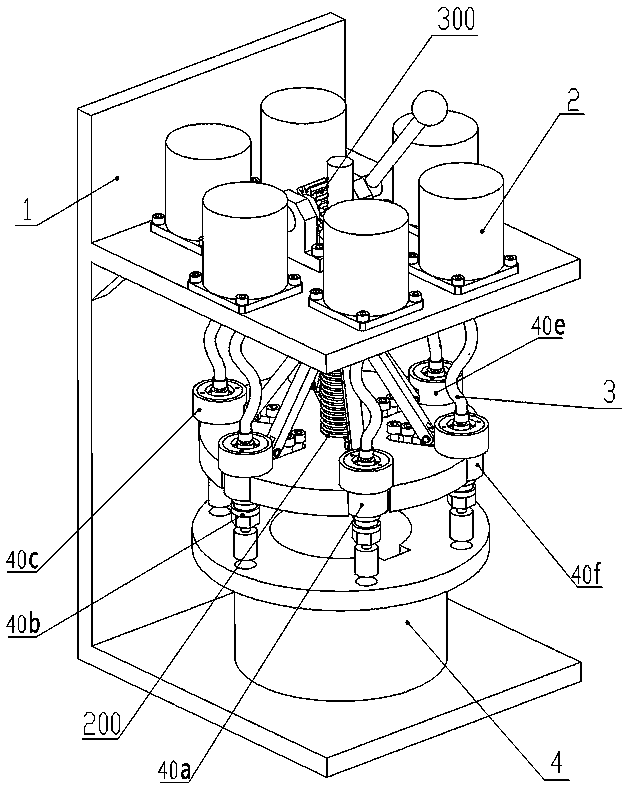

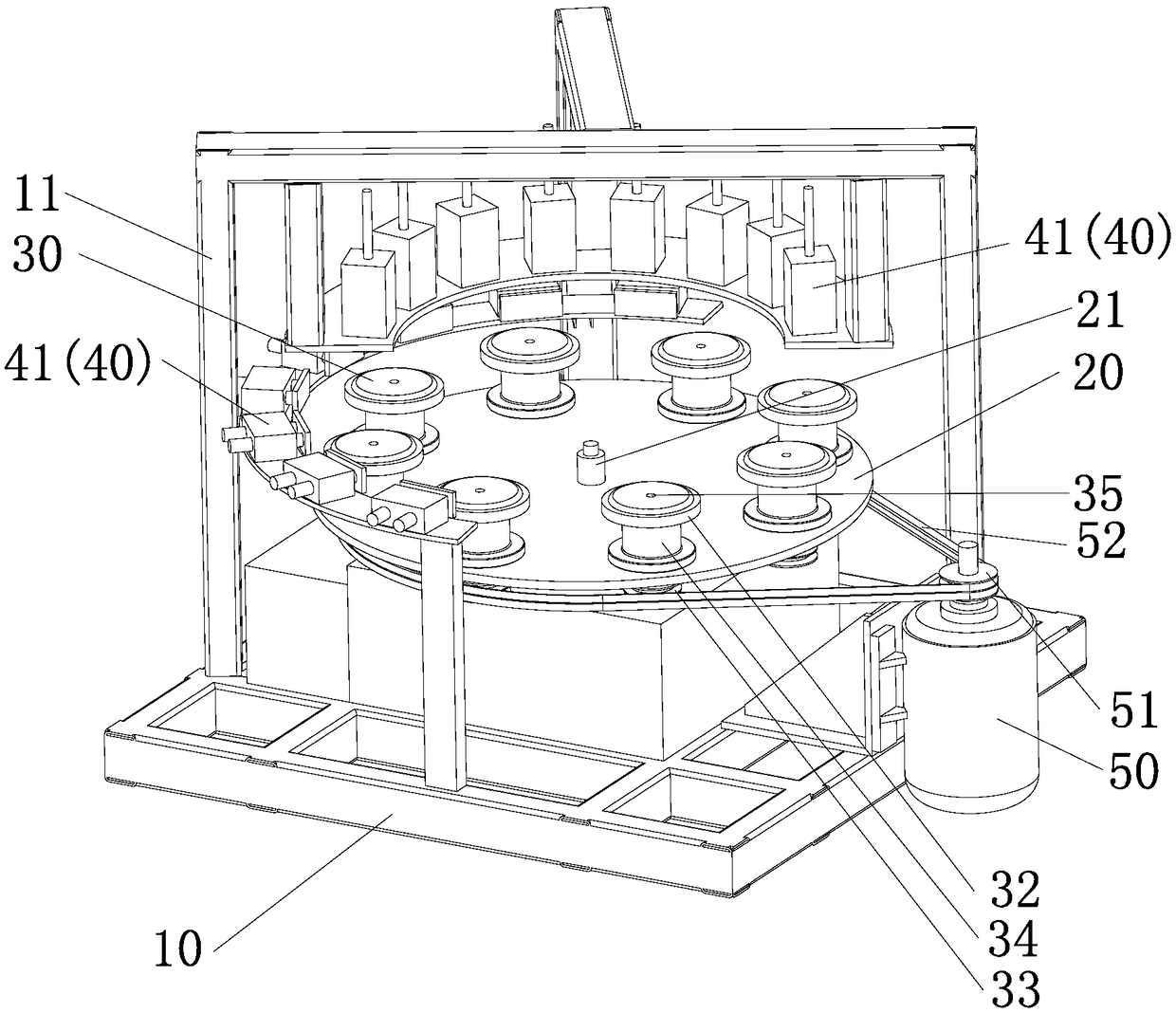

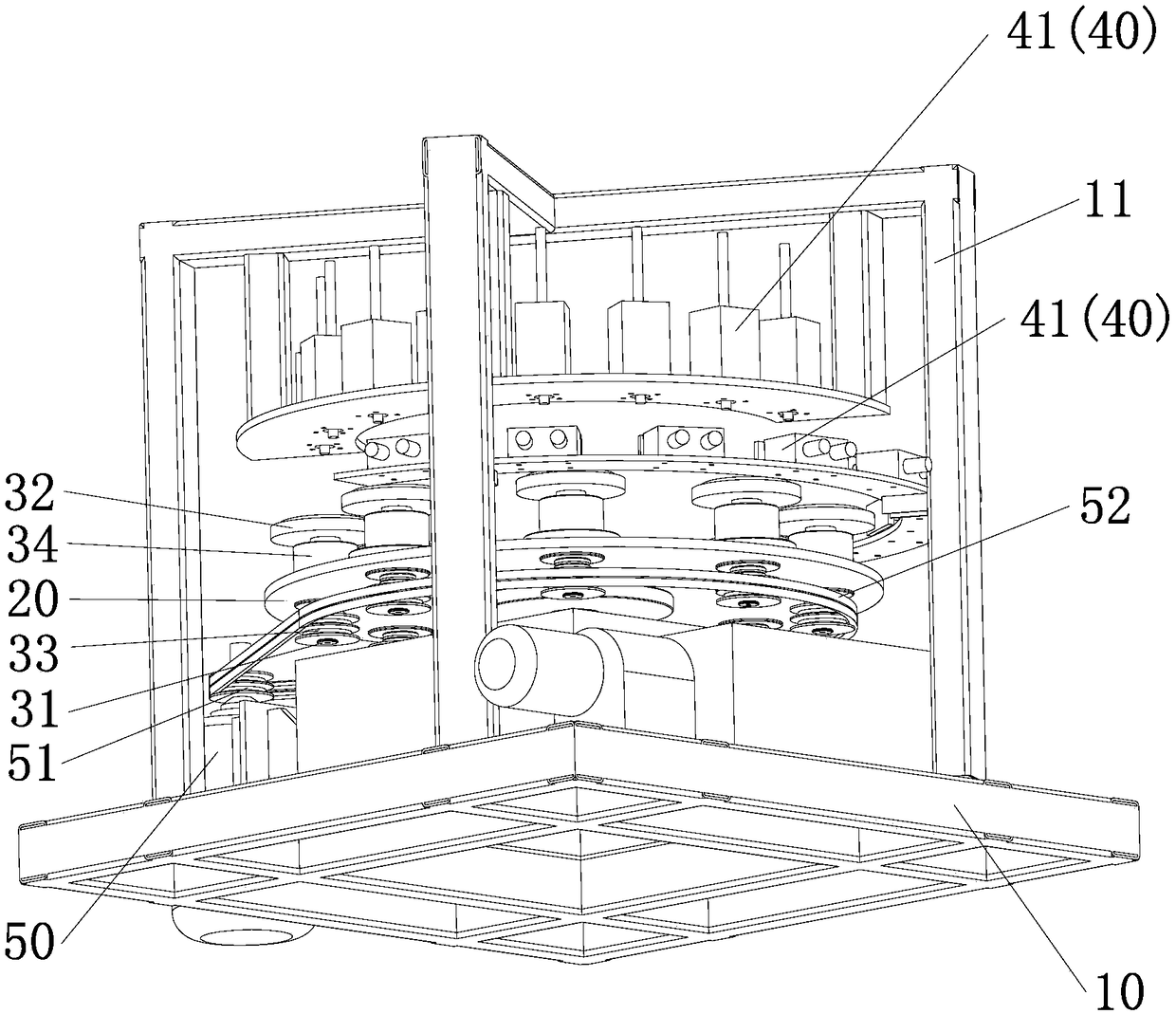

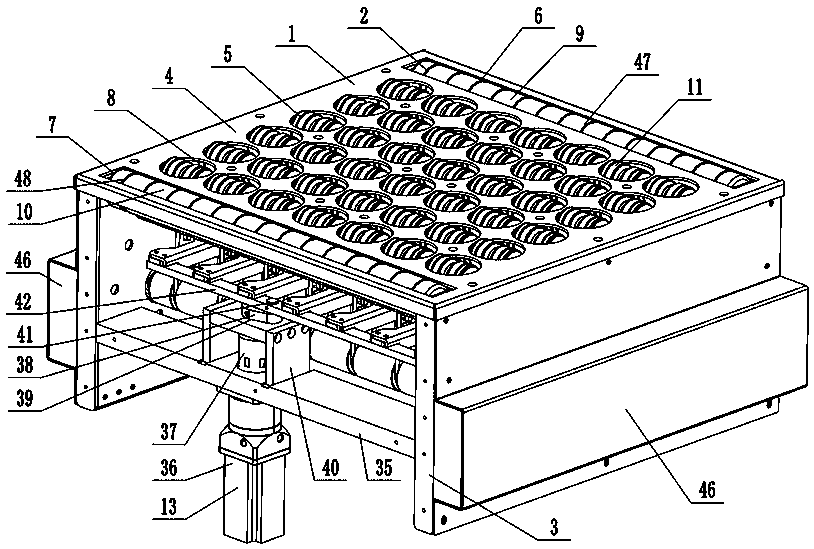

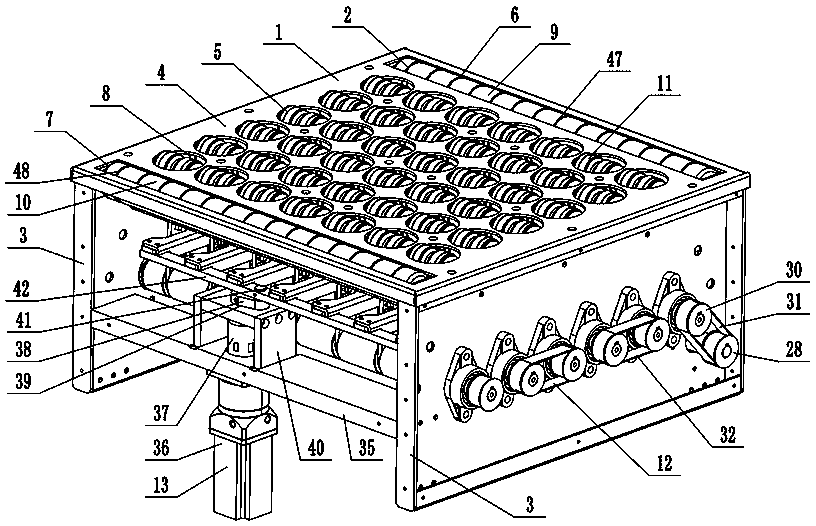

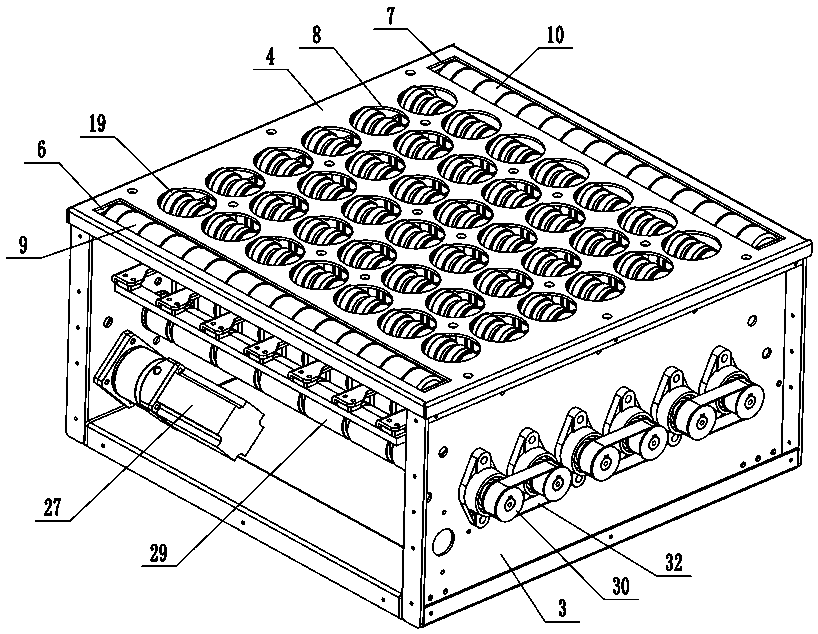

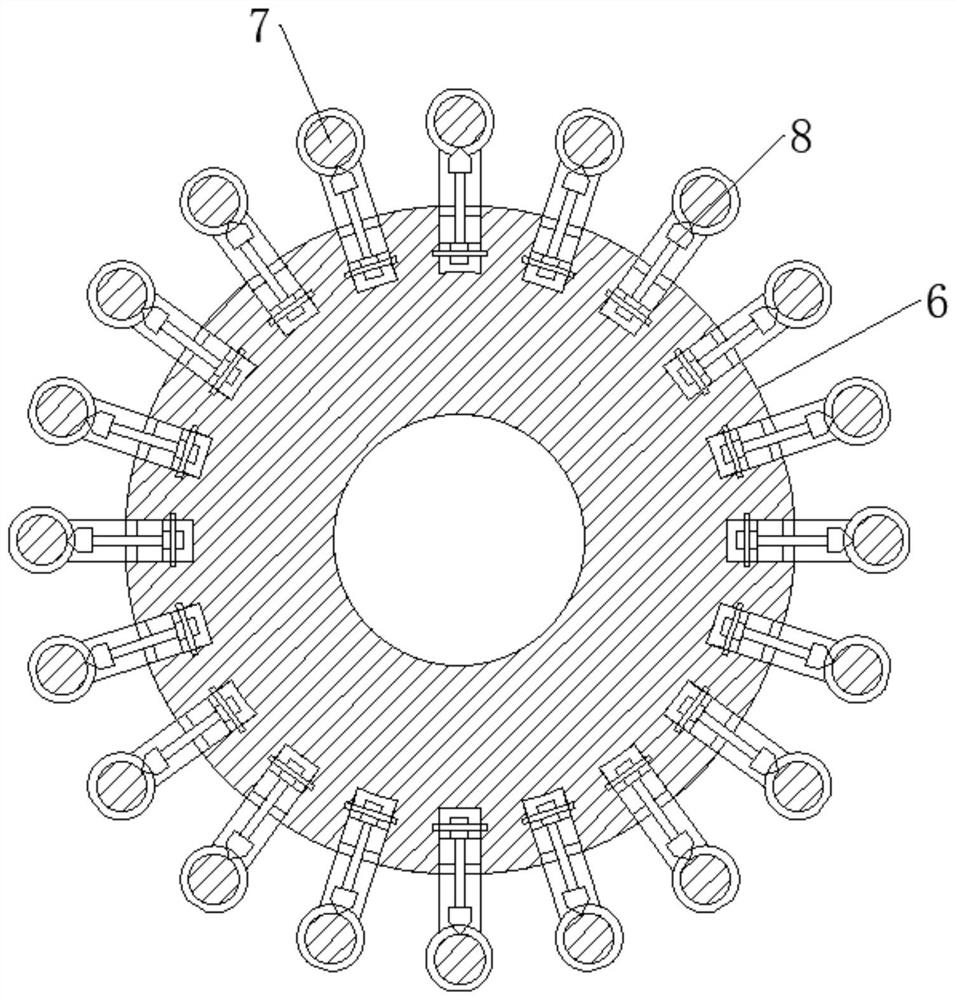

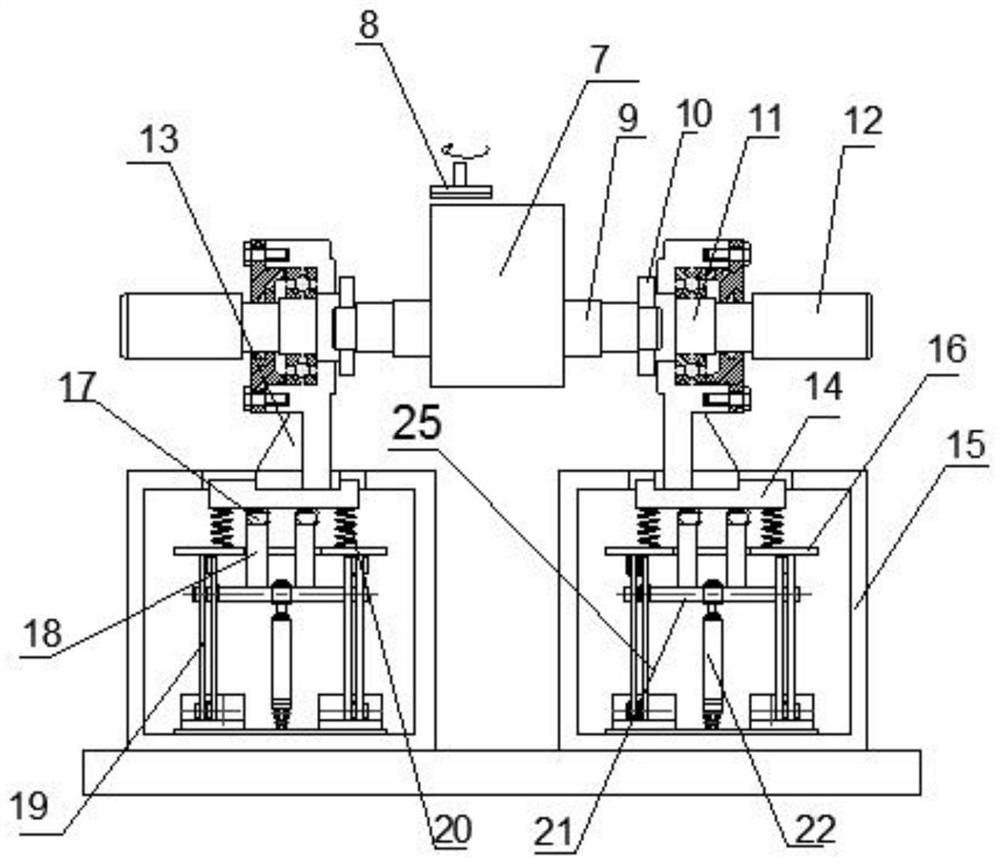

Multi-head polishing machine for annularly uniformly distributed circular holes

InactiveCN109366323ARealize grindingRealize processingRevolution surface grinding machinesGrinding headsEngineeringMechanical equipment

The invention discloses a multi-head polishing machine for annularly uniformly distributed circular holes, and relates to the field of machining and manufacturing and particularly to the multi-head polishing machine for the annularly uniformly distributed circular holes which can polish the annularly uniformly distributed circular holes at the same time and belongs to a dedicated mechanical equipment for improving machining quality of surfaces of the circular holes. The multi-head polishing machine for the annularly uniformly distributed circular holes has the advantages that axial lines of six drill chucks of the equipment are uniformly distributed on a circle, diameter of distribution pitch circles can be adjusted by adjusting height of a vertical sliding adjustment fork, so that a plurality of circular hole workpieces with different size on the distribution pitch circles can be machined at the same time; and specifications of rasp heads on the drill chucks can be changed to achievegrinding machining for the circular holes with different sizes, and the rasp heads can also be replaced with polishing heads, so that a plurality of circular holes can be machined and polished at a time.

Owner:湖南劳动人事职业学院

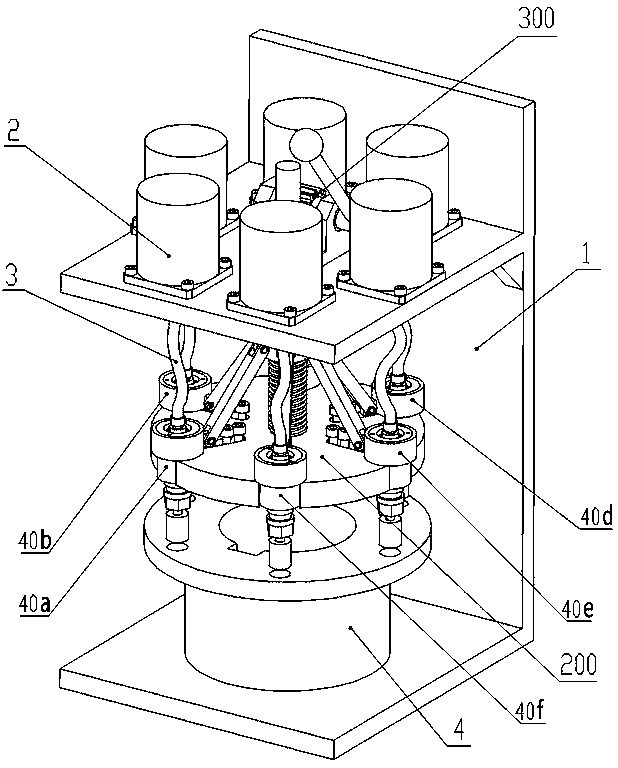

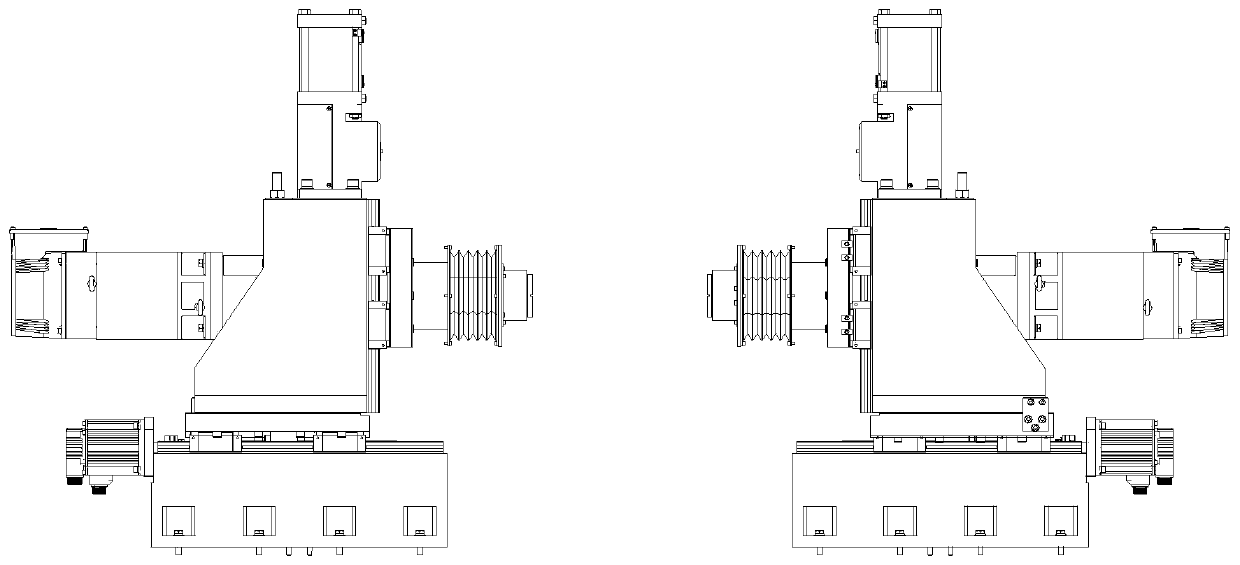

All-directional automatic polishing machine and polishing method

PendingCN107097131AAchieve rotationRealize simultaneous processingGrinding carriagesGrinding drivesMechanical engineering

The invention discloses an all-directional automatic polishing machine and a polishing method. The polishing machine comprises a polishing frame, a lifting mechanism, a grinding disc power mechanism, a tool mechanism and a translation mechanism; the tool mechanism is arranged on the translation mechanism; the translation mechanism is arranged on the polishing frame; the bottom of the lifting mechanism is connected to the polishing frame; the translation mechanism comprises an X-axle slide table mechanism and a Y-axle slide table mechanism; the grinding disc power mechanism is connected to the side surface of the lifting mechanism through a support frame; the grinding disc power mechanism comprises a grinding disc group, a grinding disc fixing module and a transmission module; the grinding disc group is assembled on a grinding disc bearing base; the grinding disc group consists of multiple grinding disc sets; and the grinding disc sets consist of multiple unit grinding discs. Multiple grinding disc sets with different specifications are provided; rotating angles of grinding disc fixed pipes are adjusted; the grinding disc sets are used for polishing bent surfaces of workpieces; and the all-directional polishing of the surfaces of the workpieces by multiple grades of precision through the grinding disc sets with different specifications is achieved.

Owner:广东遂联智能装备制造有限公司

Constant-force floating system

ActiveCN107498467AFlexible operationRealize grindingFluid-pressure actuator testingServomotor componentsConstant forceControl engineering

The invention discloses a constant-force floating system, and relates to the technical field of industrial automatic equipment. The constant-force floating system comprises a controller, a constant-force floating unit, an electric servo valve and a force sensor. The constant-force floating unit can achieve constant-force work, the force sensor can detect constant force and transmits the constant force information to the controller, and the controller conducts active adjustment or makes a decision according to the sensor information to control the electric servo valve so as to control flow input into the constant-force floating unit for constant force adjustment. According to the constant-force floating system, the constant force of the constant-force floating unit can be actively controlled through the controller preset program, real-time adjustment can be conducted according to feedback during using, operation of multiple situations can be achieved, the controllable degree is high, the adjusting speed is high, and precise grinding, cutting and other technology machining are particularly facilitated.

Owner:SUNRISE INSTR CO LTD

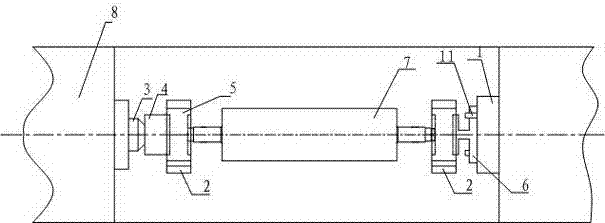

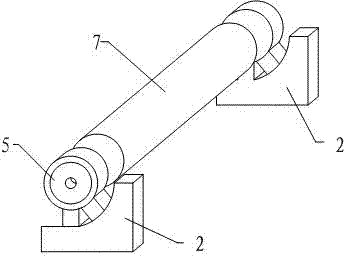

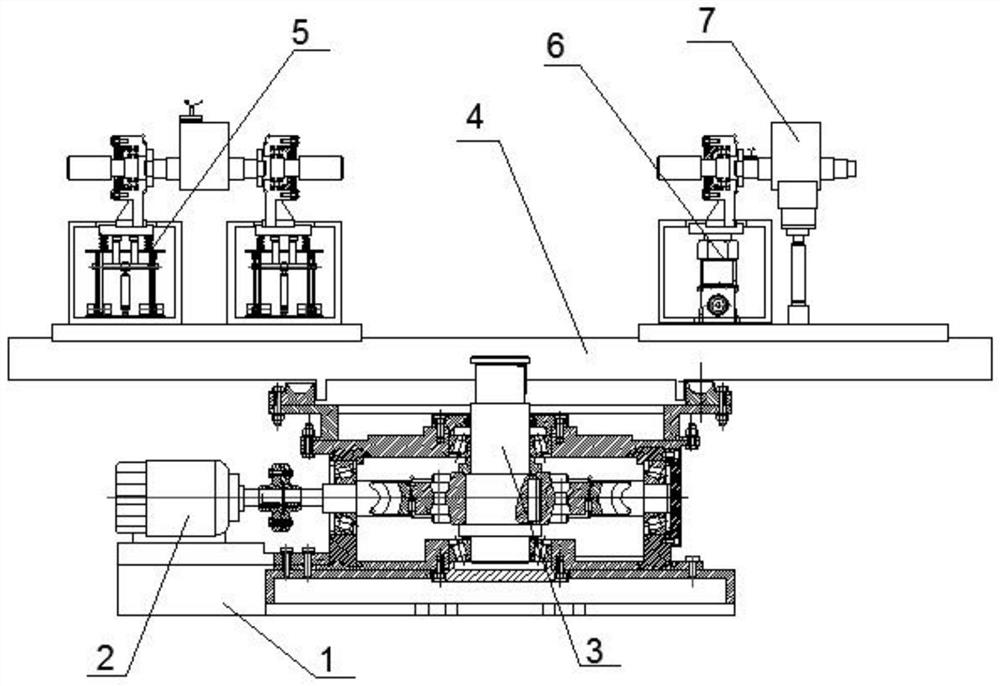

Roll grinder for grinding guide rolls of aluminum foil processing equipment

InactiveCN102922382ALow investment costIncrease profitRevolution surface grinding machinesSupporting systemFinial

The invention provides a roll grinder for grinding guide rolls of aluminum foil processing equipment, and can solve the problem that the conventional roll grinder cannot be used for grinding the guide rolls of the aluminum foil processing equipment. The invention adopts the technical scheme that the roll grinder comprises a support system for a guide roll; the support system comprises a finial, a nylon block, a rotary chuck and two brackets; the rotary chuck is provided with an adjustable pusher dog; support circles are arranged at two ends of the guide roll and are supported by the brackets; a connector is arranged on the outer side of the support circle at one end of the guide roll; one side of the connector is connected with the support circle; the other side of the connector is connected to the pusher dog of the rotary chuck in a clamping manner; the support circle at the other end of the guide roll is propped against the nylon block; and the nylon block is propped against the finial. The roll grinder can be used for grinding not only working rolls but also guide rolls, so as to ensure that an aluminum foil processing enterprise is not required to purchase a cylindrical grinder to grind the guide rolls specially any more, which reduces the investment cost and the operation cost of fixed capital and improves the utilization ratio of the fixed capital.

Owner:QINGDAO RUNFENG ALUMINUM FOIL

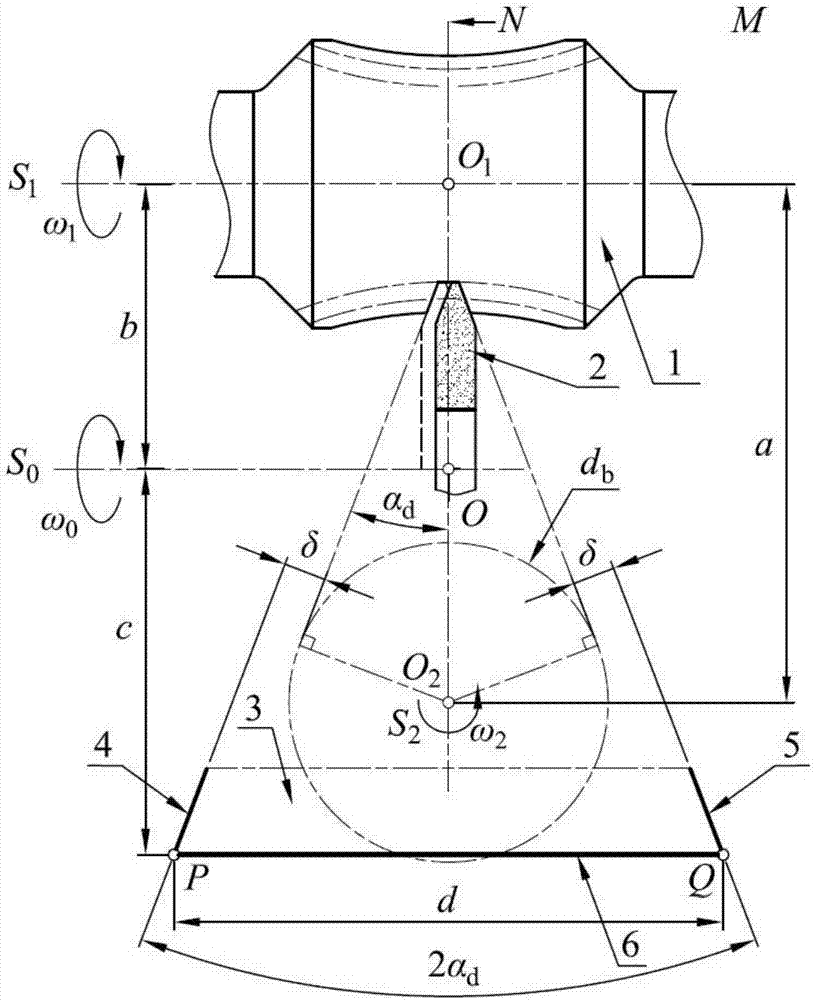

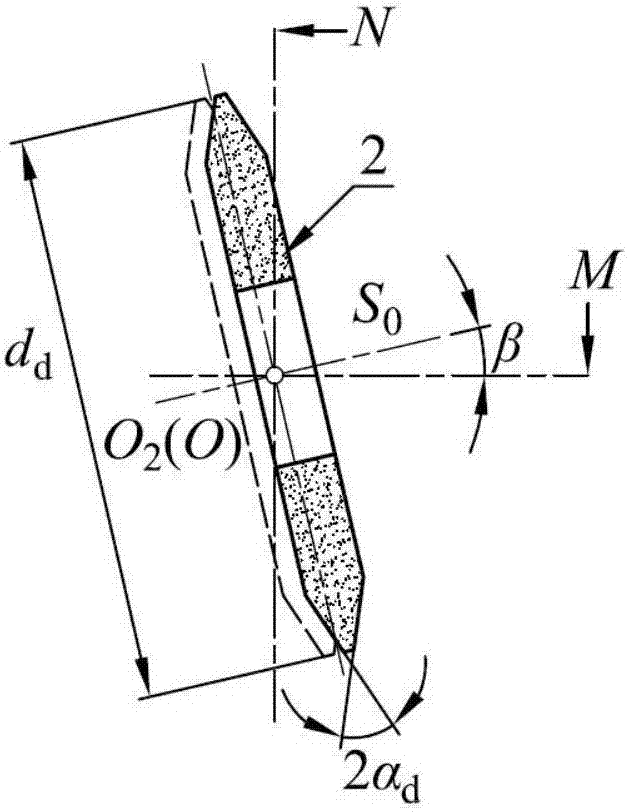

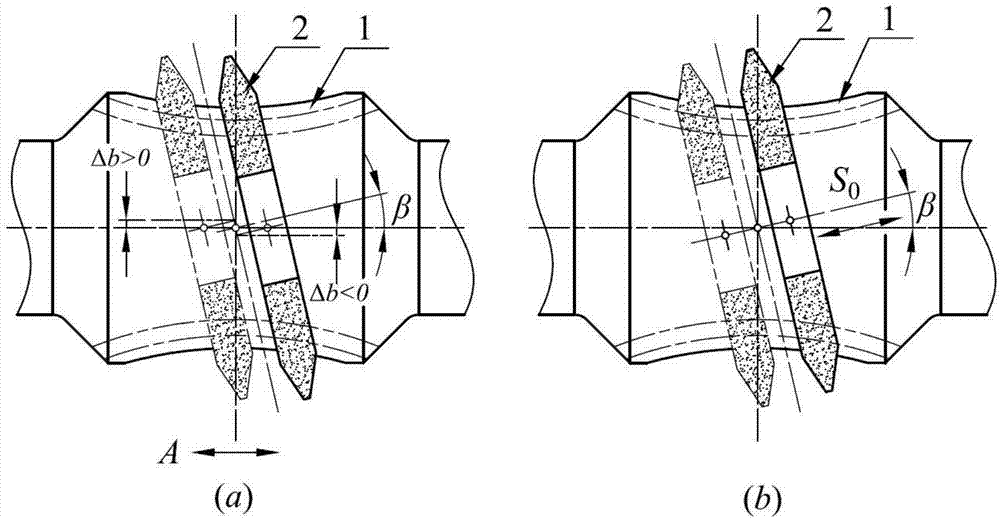

Adjustment of dipyramidal-surface enveloping worm emery cutters

ActiveCN106909729ARealize grindingImprove standardizationGeometric CADSpecial data processing applicationsEngineeringTransmission ratio

The invention relates to the technical field of double enveloping worm gear pair manufacturing, and discloses an adjustment method of enveloping worm emery cutters with dipyramidal surface. During the processing of enveloping worm tooth surface, by the means of adjusting the emery cutter distance between dipyramidal-surface emery cutters and enveloping worms as well as the offset between the generatrices at the both sides of dipyramidal-surface emery cutters and the both sides of a datum plane, the relative position of the dipyramidal-surface emery cutters and the enveloping worms is determined and the dipyramidal-surface emery cutters relatively move according to the preset transmission ratio with the enveloping worms, thereby obtaining dipyramidal-surface enveloping worm tooth surface. By the adoption of dipyramidal-surface emery cutters in the same tooth profile angles and different diameters, the processing of enveloping worm tooth faces in different parameters can be realized.

Owner:河北涞博传动机械制造有限公司

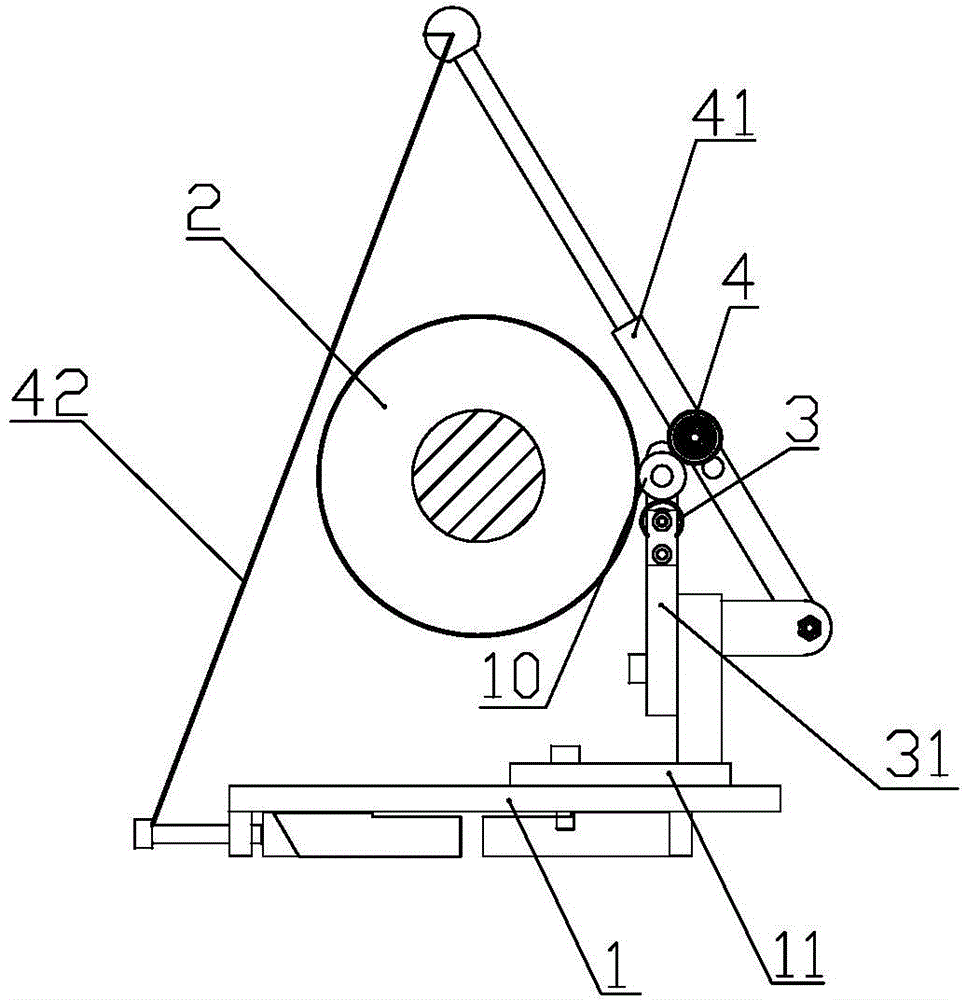

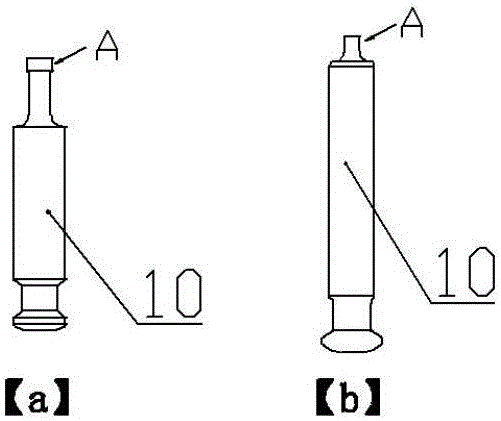

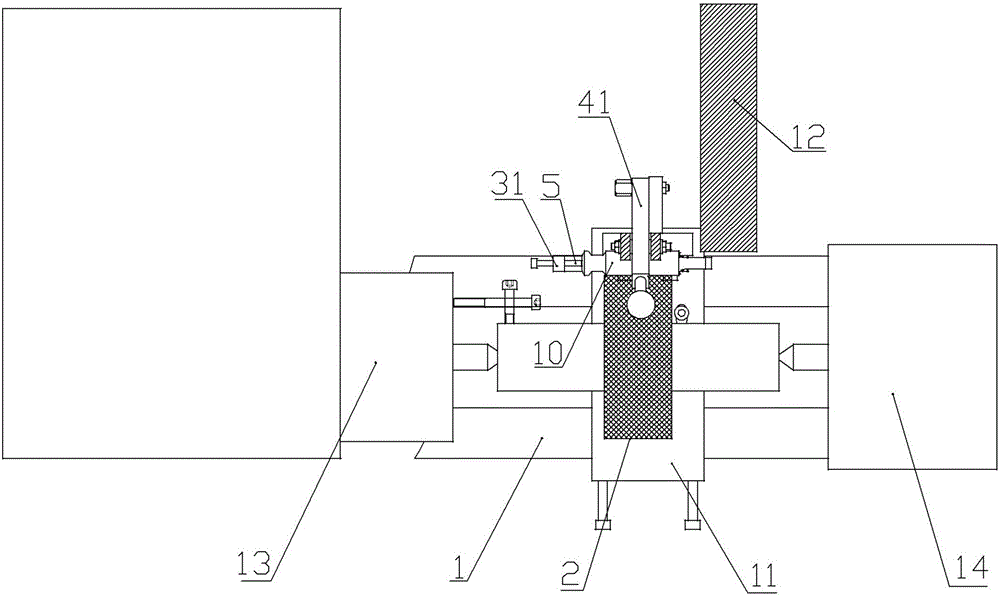

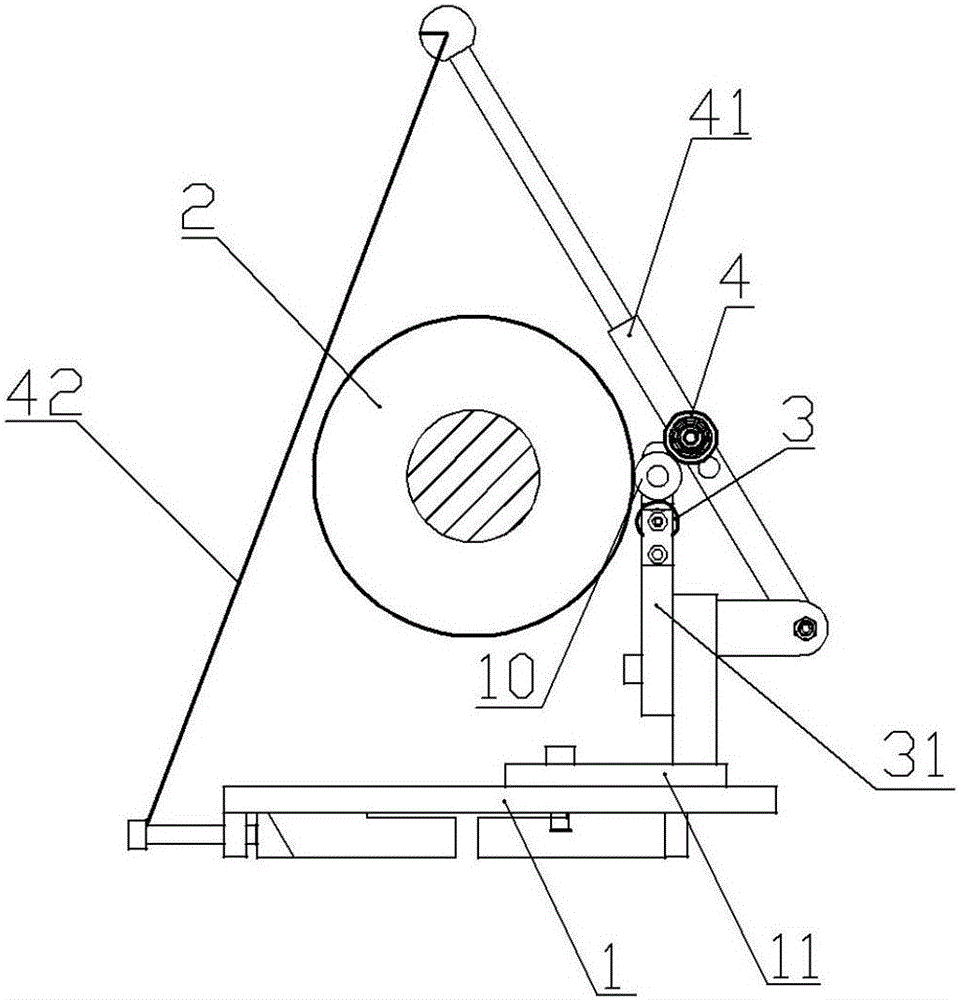

Centerless fixture for cylindrical grinding machine

InactiveCN104669080AGuaranteed axisGuaranteed working pressureRevolution surface grinding machinesEngineeringCylindrical grinding

The invention discloses a centerless fixture for a cylindrical grinding machine. The centerless fixture comprises a driving wheel, a supporting wheel and a pressing wheel, wherein the driving wheel is arranged on a rotating shaft of a grinding machine; the supporting wheel is arranged at the slanting lower part of the rear side of the driving wheel; the outer side of a support of the supporting wheel is hinged to one end of a pressing rod; the pressing wheel is arranged at the middle of the pressing rod; the other end of the pressing rod is connected with one end of a spring; the other end of the spring is connected onto a grinding machine rack; a positioning part is arranged at one end face side, which is away from a grinding wheel of the grinding machine, of the supporting wheel, on the support of the supporting wheel; a punch rod clamped among the driving wheel, the supporting wheel and the pressing wheel can be axially positioned by the positioning part; the punch rod is fixed by line contact matching between the circumferential surfaces of the driving wheel, the supporting wheel and the pressing wheel and the circumferential surface of a punch body of the punch rod; after the punch rod is fixed, the axiality of the punch rod can be directly guaranteed; the acting pressure of the pressing wheel on the punch rod is guaranteed by the pretightening force of the spring; the driving wheel is driven by the rotating shaft to rotate and drives the punch rod to rotate; the grinding processing is realized by contacting a circumferential section of the upper end to be ground of the punch rod with the grinding wheel.

Owner:LIAOCHENG WANHE IND MFR

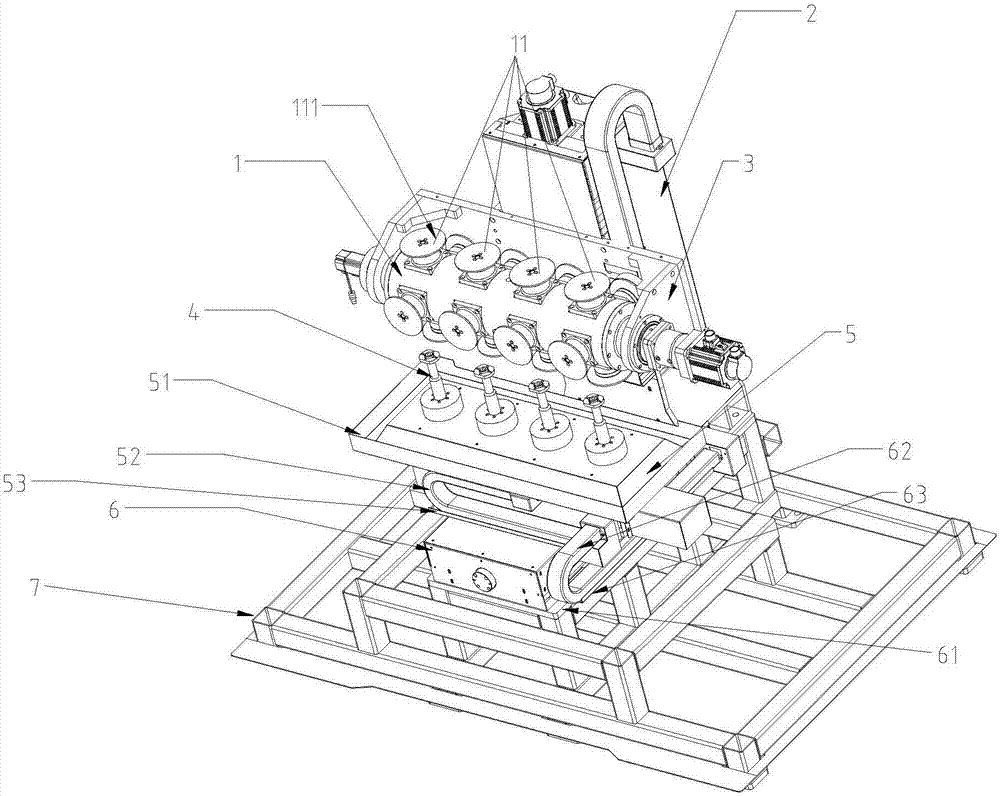

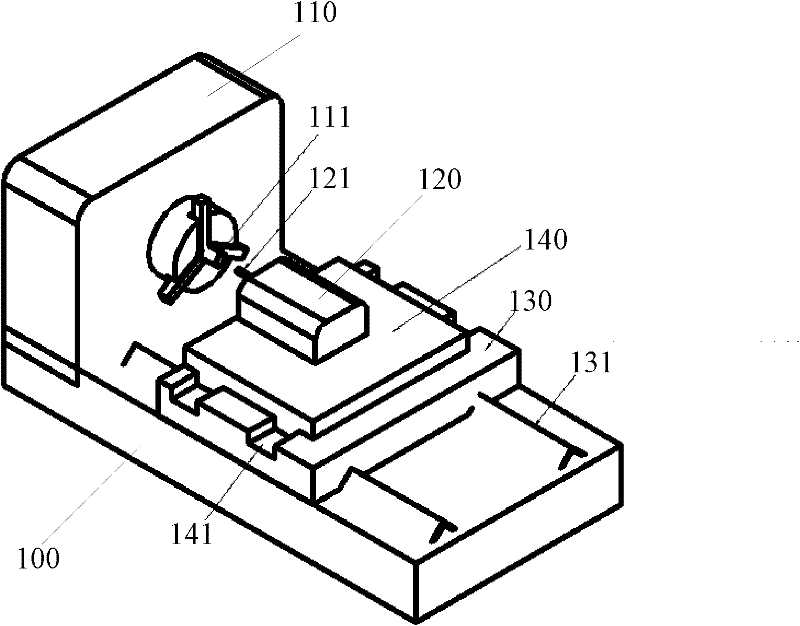

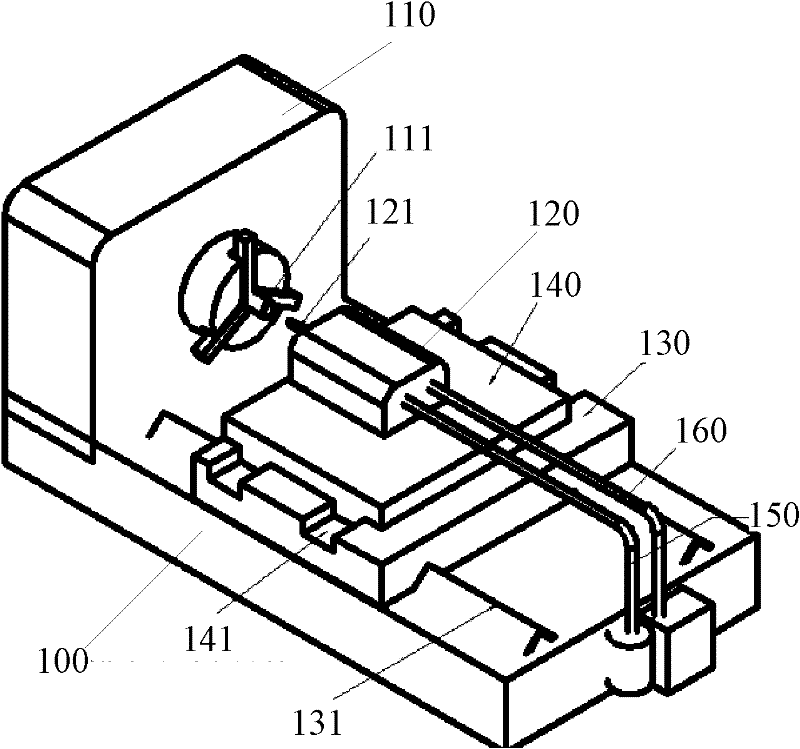

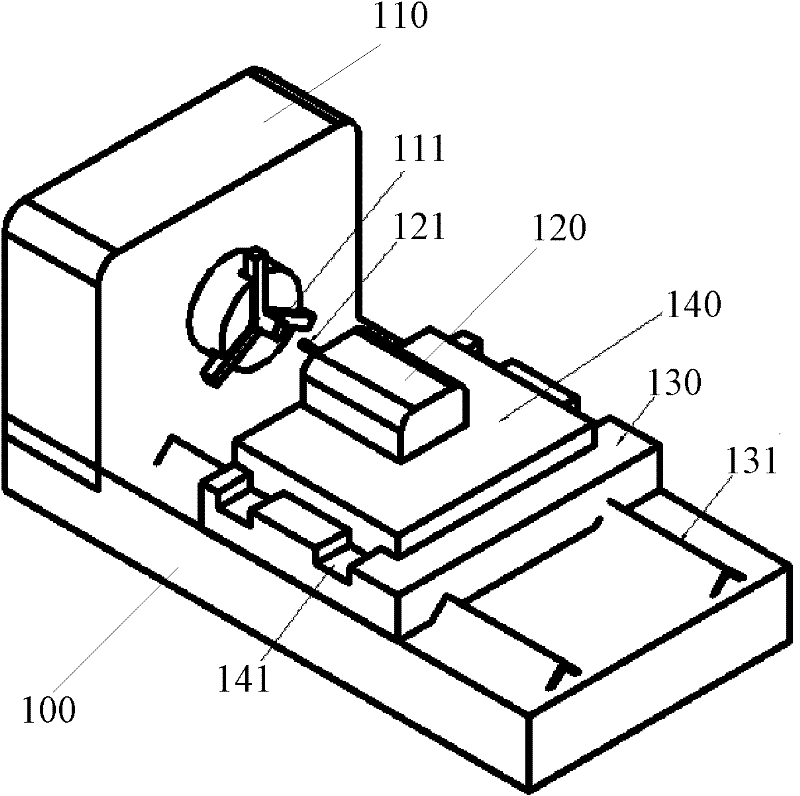

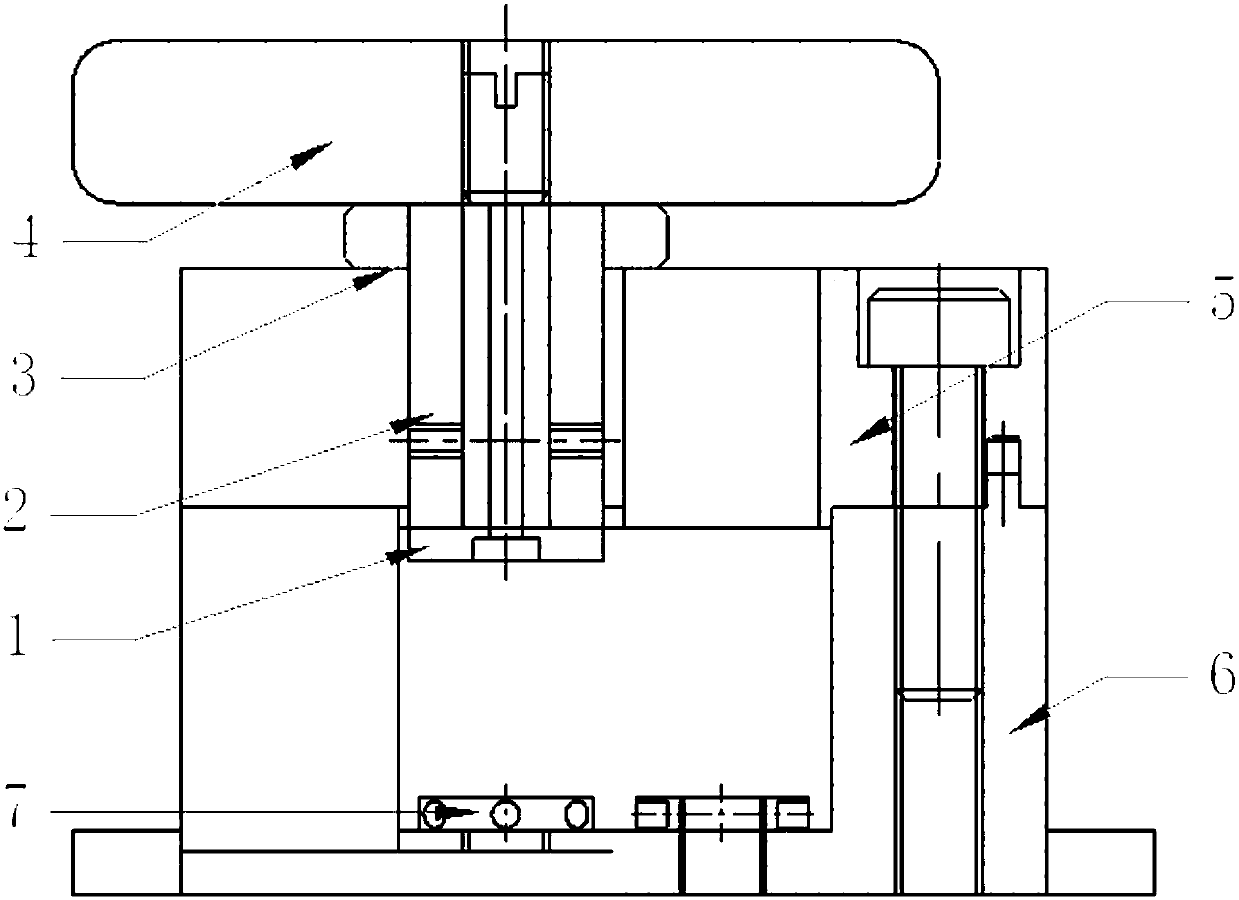

Two-axis linkage numerical control grinding machine with double spindles

InactiveCN102225521ARealize grindingReduce processing stepsEdge grinding machinesRevolution surface grinding machinesNumerical controlEngineering

The invention provides a two-axis linkage numerical control grinding machine with double spindles. The machine provided by the invention comprises a base, a workpiece spindle box and a grinding head spindle base arranged on the base, a workpiece and a work-piece spindle arranged on the workpiece spindle box, a longitudinal support plate arranged on the base through a longitudinal guide rail, and a transverse support plate arranged on the longitudinal support plate through a transverse guide rail, wherein the grinding head spindle base is arranged on the transverse support plate; and the grinding head spindle base is provided with a grinding head spindle. In the two-axis linkage numerical control grinding machine with double spindles provided in the invention, the prior numerical control art is effectively utilized, the machining operations is reduced, the grinding processes for grinding an inner hole and chamfering the mouth rounded corner of the inner hole for one time are realized, and the target that the outline and the size of the mouth rounded corner of the grinded inner hole are consistent is achieved. Furthermore, the rotation speed of the grinding head spindle is adjustable so as to be adaptable to the surface quality requirements of the inner holes the hole diameters of which are different from small to large, and the chamfered corner.

Owner:SHANGHAI DIANJI UNIV

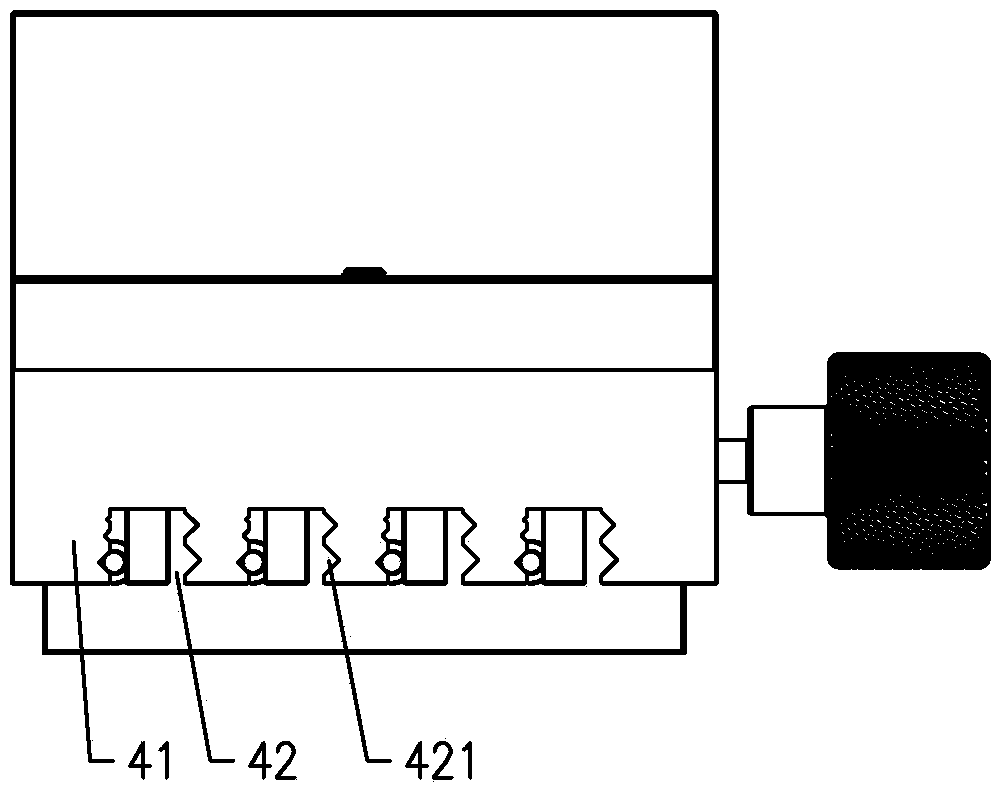

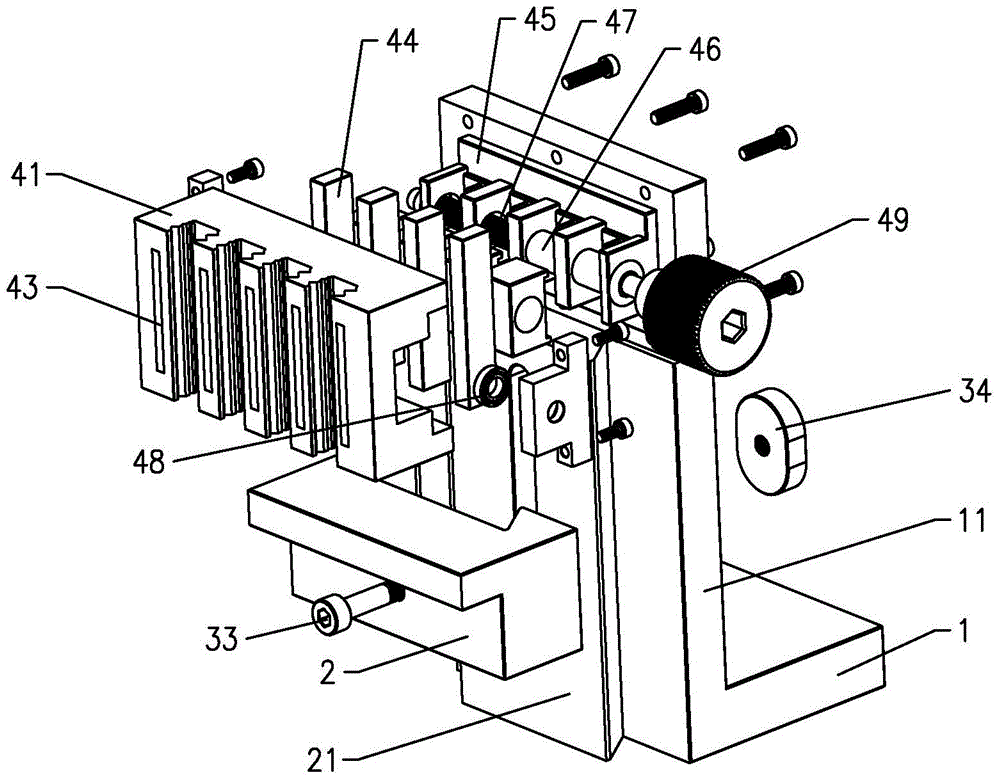

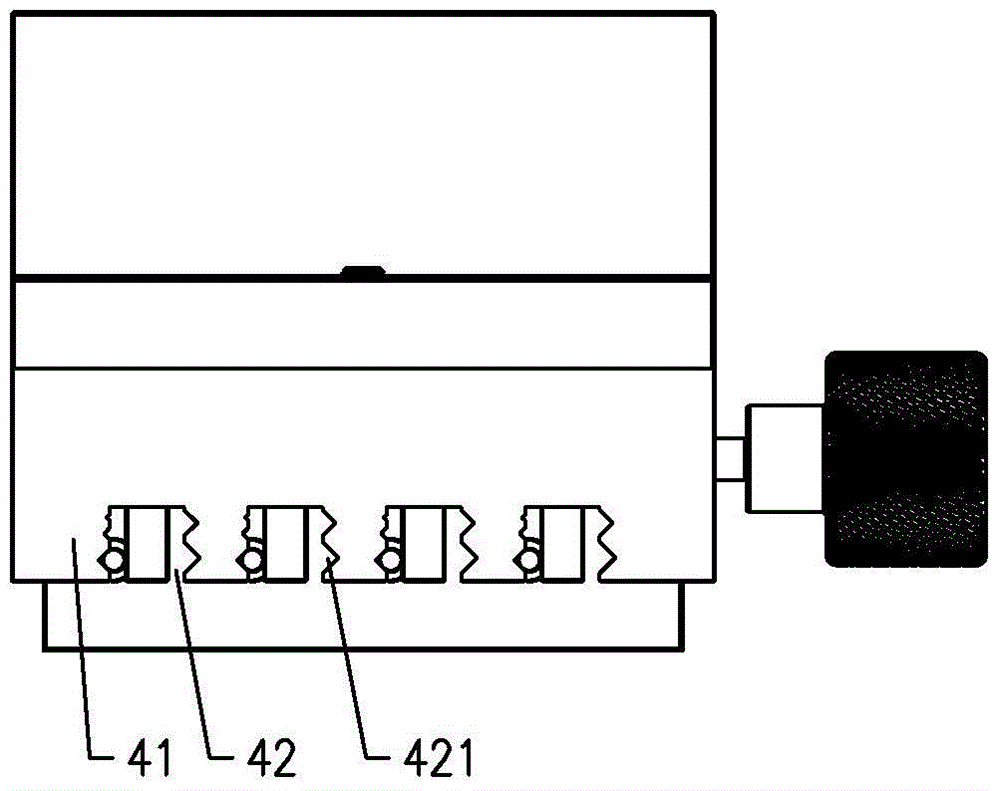

Grinding jig for ejector pins of plastic molds

ActiveCN103722491ARealize the limit functionRealize the support functionGrinding work supportsLocking mechanismEngineering

The invention discloses a grinding jig for ejector pins of plastic molds. The grinding jig comprises a base, a height adjusting seat, a locking mechanism and an ejector pin clamp. A mounting plate is vertically arranged on the base. The height adjusting seat capable of moving up and down is arranged on the lower portion of the mounting plate. The locking mechanism is arranged between the height adjusting seat and the mounting plate. The ejector pin clamp arranged on the upper portion of the mounting plate comprises a clamp base and movable press plates. The clamp base is fixedly connected with the mounting plate, a plurality of rectangular jaws are vertically arranged on the clamp base, V-shaped grooves in multiple sizes are formed in the side wall of each jaw, and the movable press plates are arranged in the jaws and are all fixedly connected to a press-plate base. Horizontal movement control of the press-plate base is realized through a horizontal movement mechanism. The grinding jig can meet multiple grinding requirements of different batches of ejector pins with different heights and different diameters.

Owner:GOERTEK INC

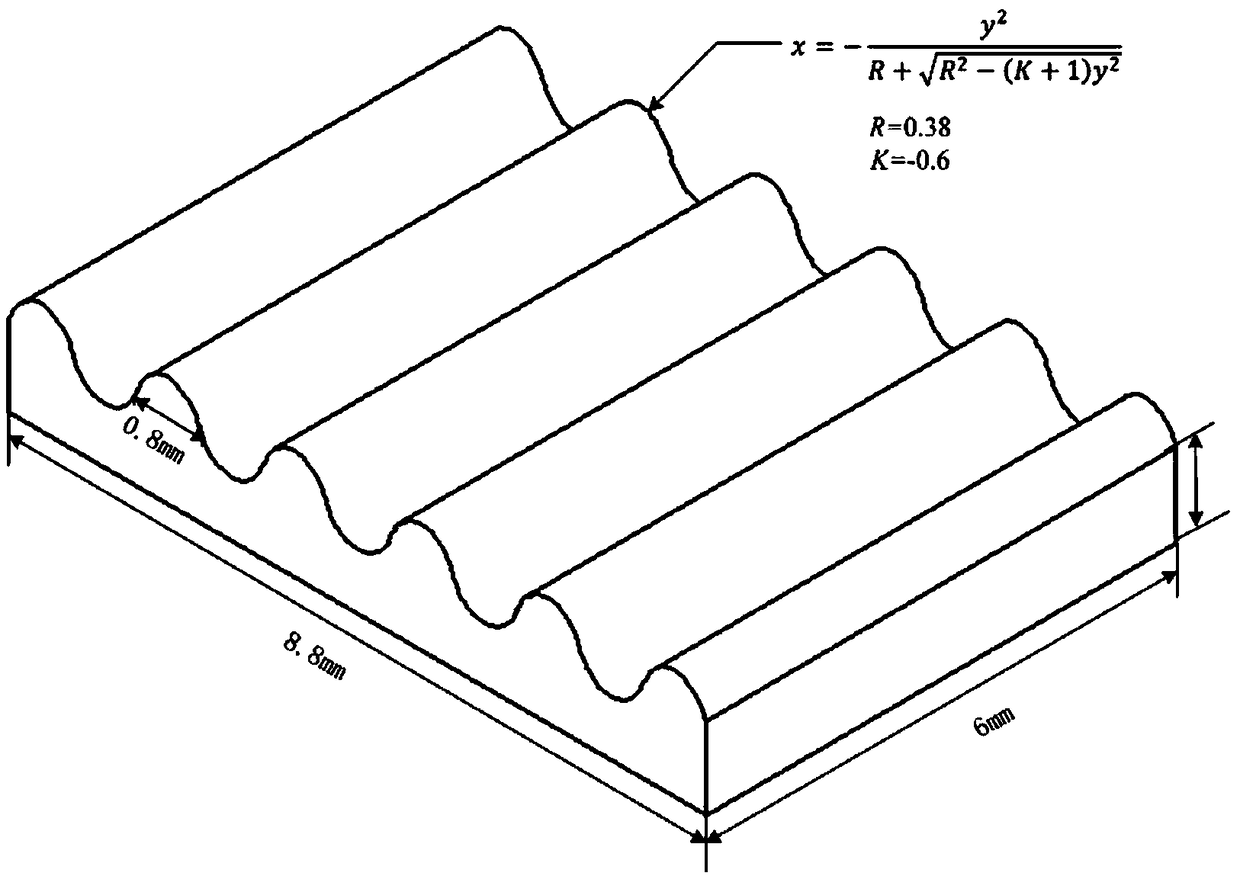

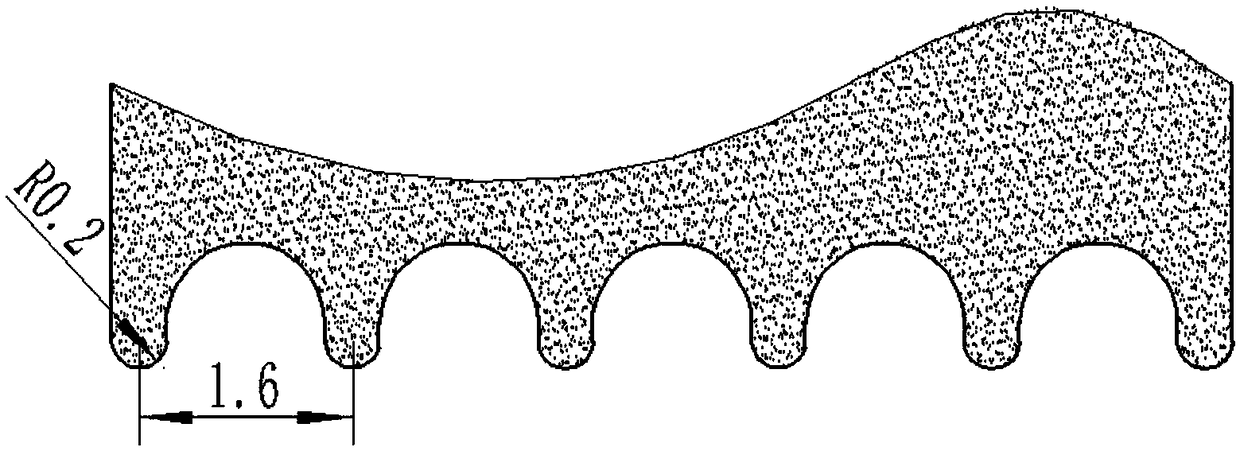

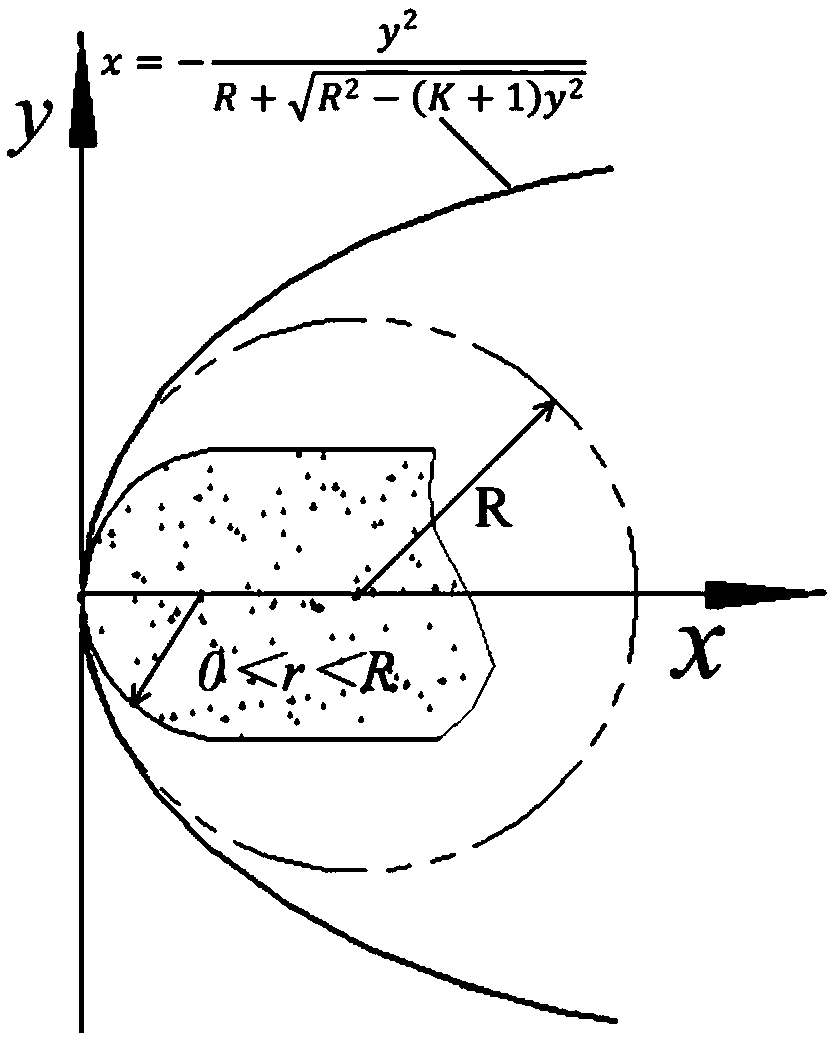

Method for grinding cylindrical array structure with high-order curve section by arc array grinding wheel

ActiveCN108747602AShorten processing timeUniform wearAbrasive surface conditioning devicesUnit structureSection plane

The invention discloses a method for grinding a cylindrical array structure with a high-order curve section by an arc array grinding wheel. The grinding wheel is trimmed into an arc array structure with repeated k-order sections, and an array cylindrical surface is ground through the arc array grinding wheel in a variable tangential point reciprocating manner according to the curve tangency principle; and the movement path of the grinding wheel in the high-order curve section plane of the cylindrical surface is an equidistant parallel line at the distance of r from a high-order curve. After the tangential point of the grinding wheel is changed once in the high-order curve section plane, the grinding wheel does reciprocating motion in the direction perpendicular to the high-order curve section plane for one time, so that the grinding of one generating line of the cylindrical surface is finished. Since the grinding wheel is of an array structure, the grinding process of all high-order curve section cylindrical arrays can be finished as long as the grinding of one cylindrical structure unit in the array structure is finished. After the section unit structure of the grinding wheel is trimmed into an arc, the tangential points between the grinding wheel and workpieces are ensured to form the high-order curve through the interpolation motion of a machine tool; and the array structureis ground in a variable tangential point manner, and the grinding accuracy is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

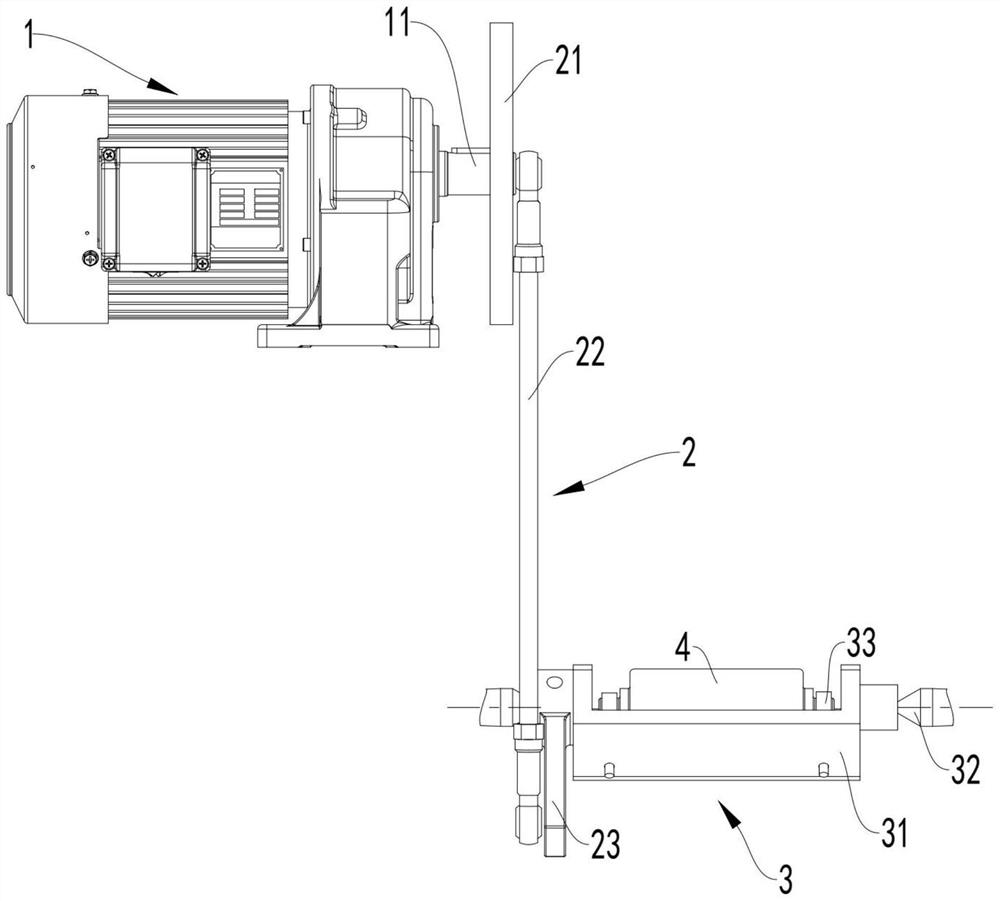

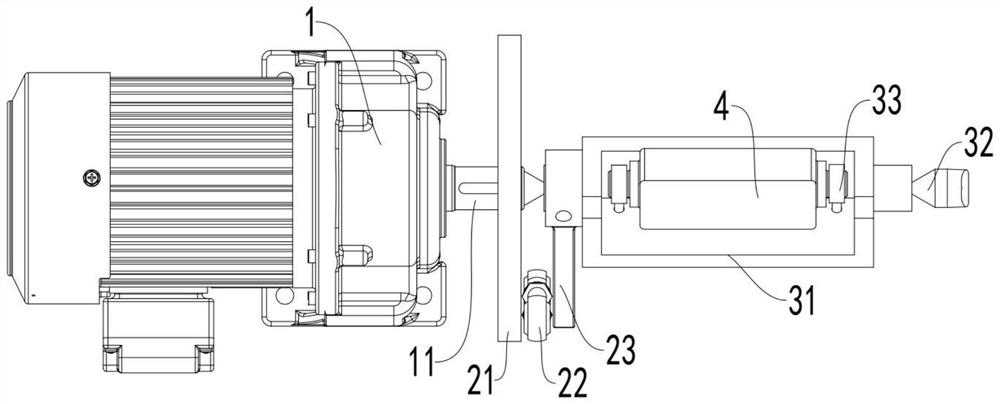

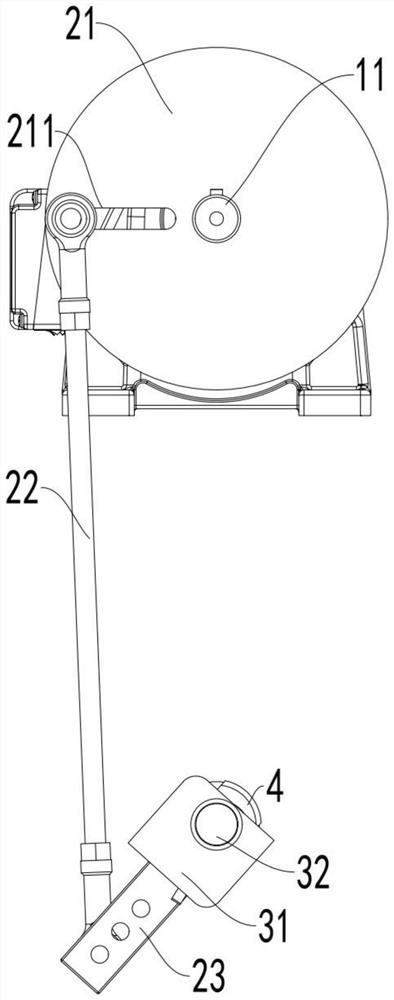

Edge grinding head device capable of realizing automatic feeding

ActiveCN107283311ARealize grindingRealize loss automatic feed compensationEdge grinding machinesGrinding wheel securing apparatusMotor driveEngineering

The invention discloses an edge grinding head device capable of realizing automatic feeding. The edge grinding head device comprises a grinding assembly, a feeding assembly and a fixed base, wherein the grinding assembly is mounted in the fixed base, and the feeding assembly is mounted on the outer side of the fixed base; the grinding assembly comprises a grinding motor, a grinding head shaft, an edge grinding wheel, a sliding sleeve and a connecting flange plate; and the feeding assembly comprises a feeding motor, a turbine, a worm and an adjusting screw rod, the feeding motor is mounted at the top of the fixed base, the feeding motor drives the adjusting screw rod to move axially, and thus the sliding sleeve is driven to move axially. The feeding motor drives the worm to rotate, the turbine meshed with the worm is driven to rotate, threads of the adjusting screw rod are matched with inner hole threads of the turbine, accordingly the adjusting screw rod is driven to move axially, and therefore the sliding sleeve is driven to slide along an inner hole of the fixed base, and automatic feeding compensation for edge grinding wheel losses is realized.

Owner:GUANGDONG SINID TECH

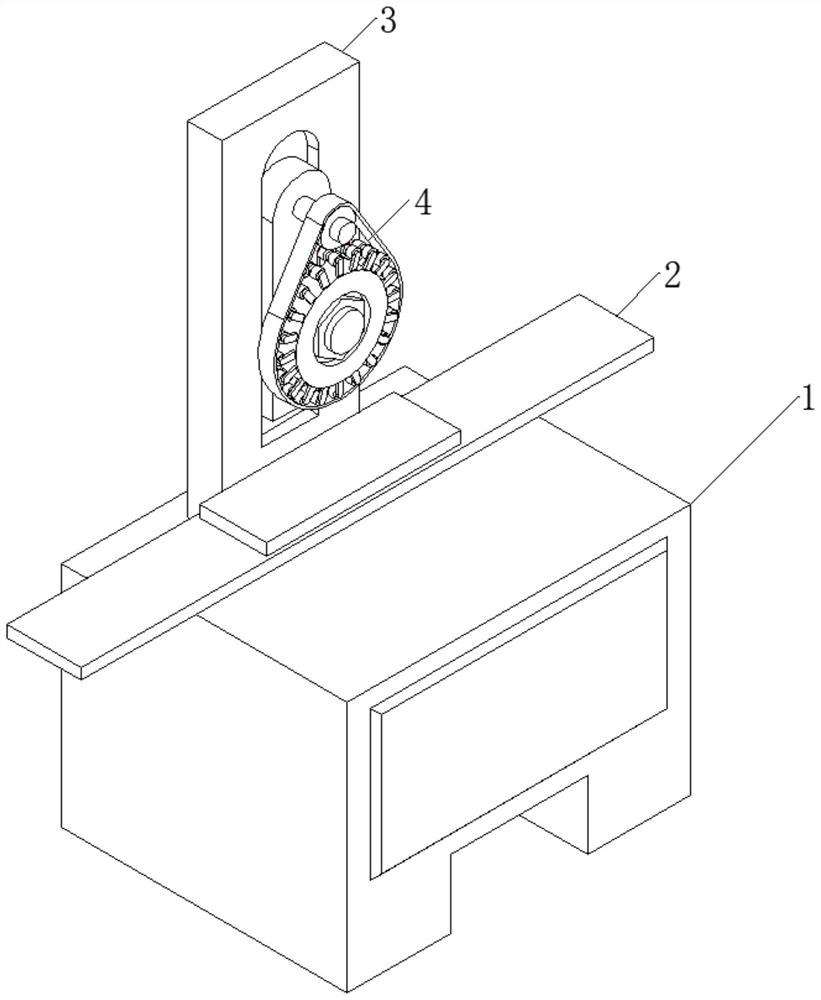

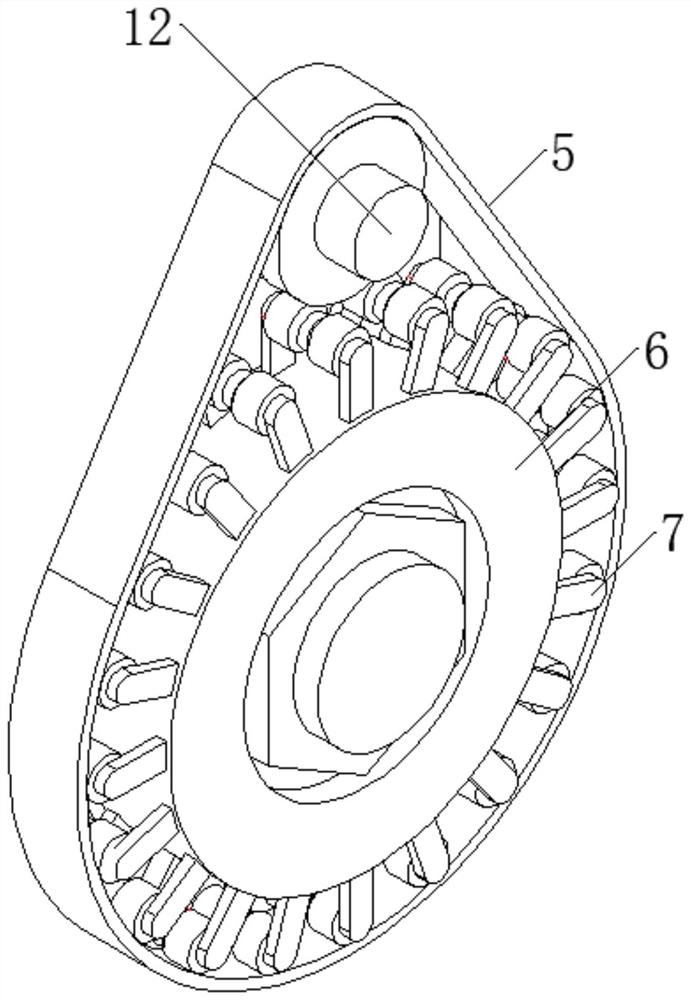

Grinding method for starwheel oval straight channel

InactiveCN102975100ARealize grindingHigh precision indexing capabilityGrinding machinesGear grindingMachined surface

The invention relates to a grinding method for a starwheel oval straight channel. A numerically controlled forming gear grinding machine is adopted as high-precision starwheel straight channel grinding equipment, and a high-precision starwheel straight channel grinding process method is provided through customizing a special starwheel fixture and using a coordinate fitting forming method, so as to implement grinding machining on the aerial high-precision starwheel straight channel. The correcting capability, the high-precision scale division capability and the size precision stability of the numerically controlled forming gear grinding machine are utilized; meanwhile, the cooling oil can dissipate the grinding heat in the grinding process, as a result, the machining deformation is reduced, the roughness of the machined surface is improved, so that various indexes of the grinded starwheel straight channel meet the precision requirements of the aerial high-precision starwheel.

Owner:HARBIN DONGAN ENGINE GRP

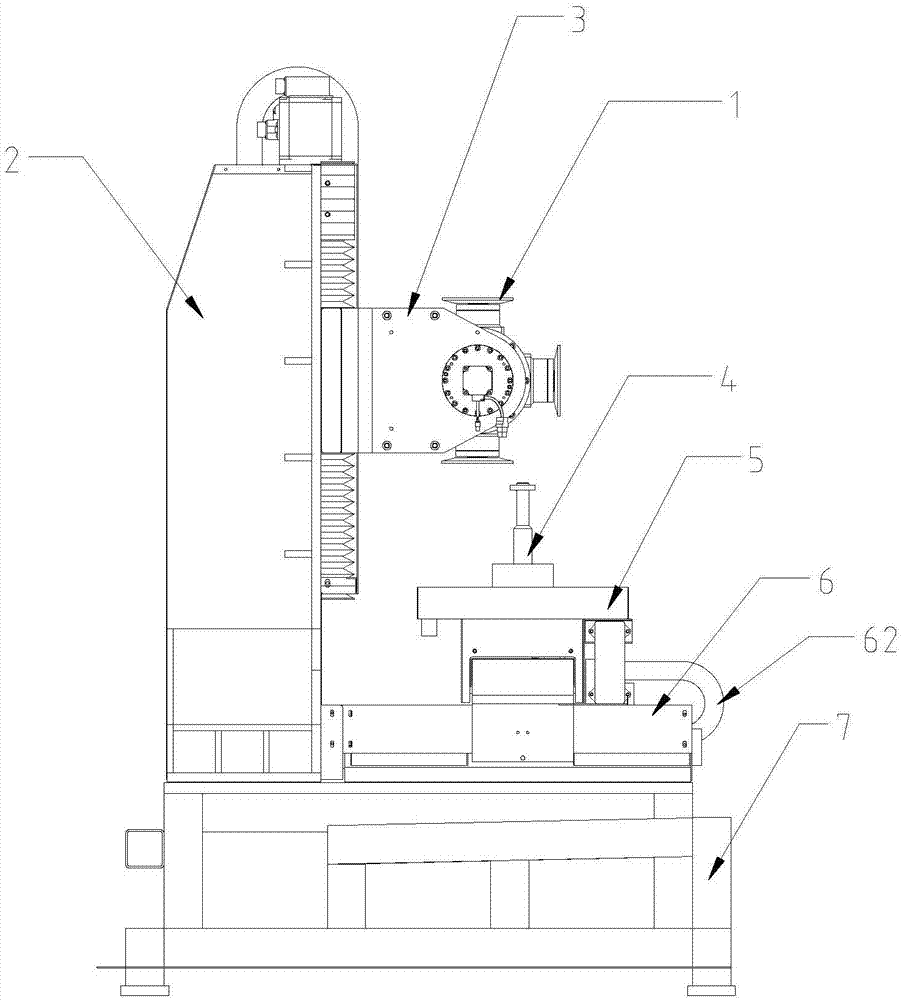

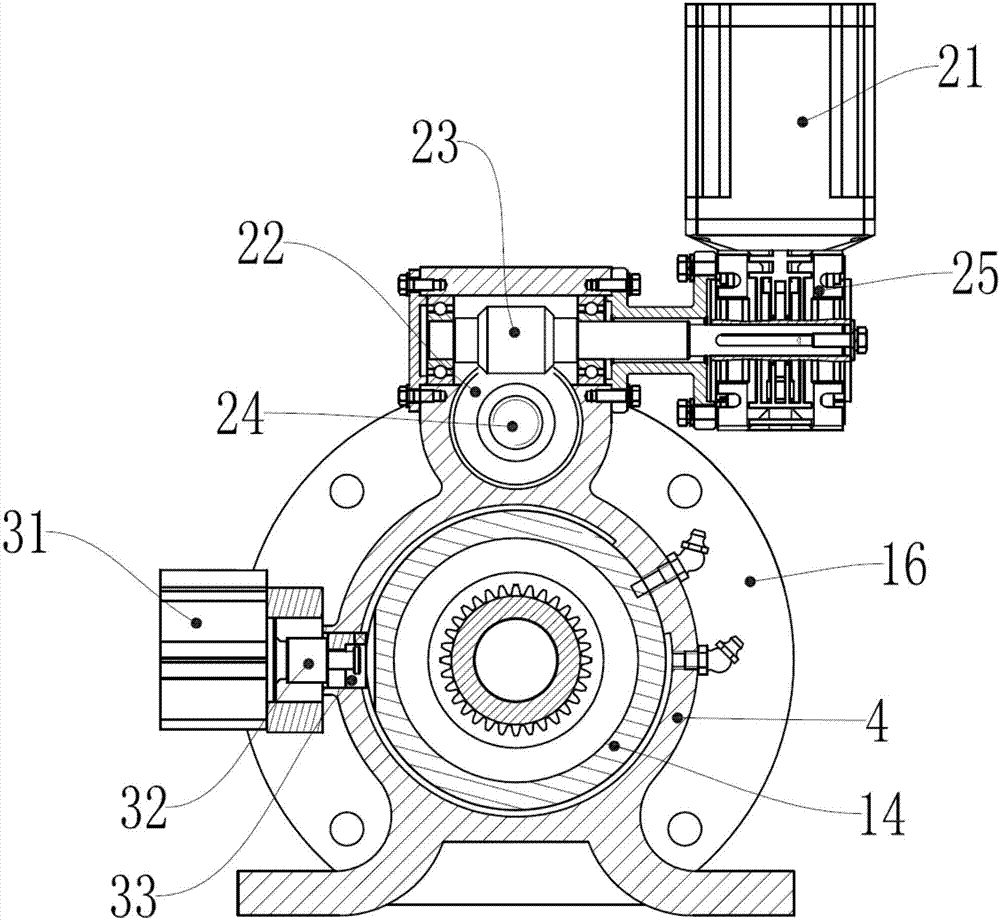

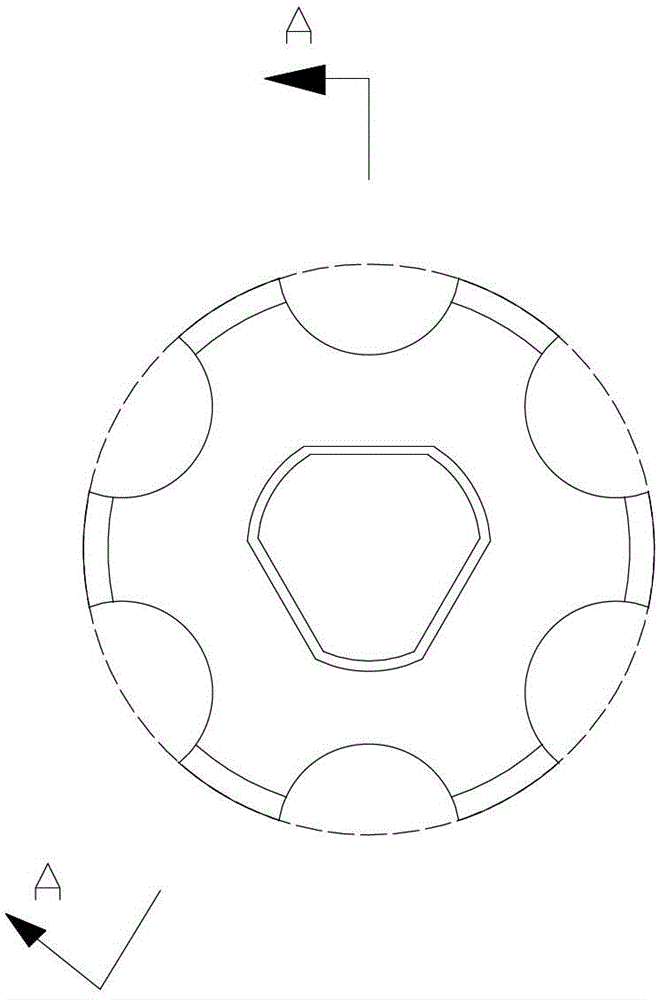

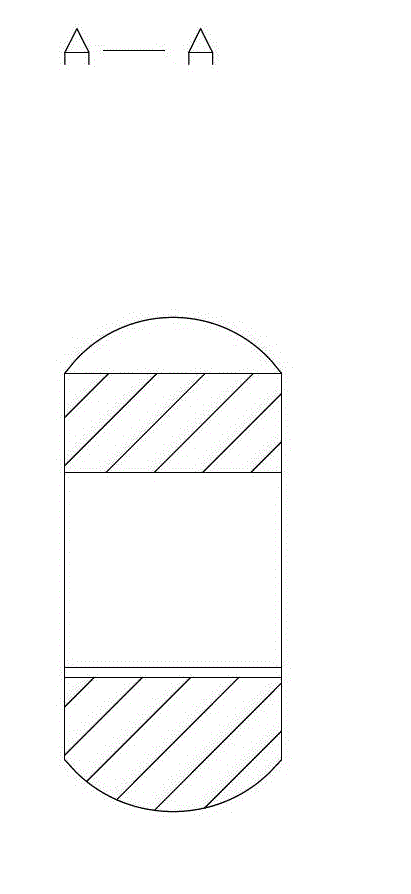

Numerically controlled grinder with rotatable grinding wheel head

InactiveCN106180917ARealize grindingAchieve rotationThread cutting machinesGear-cutting machinesBall screwGear wheel

The invention discloses a numerically controlled grinder with a rotatable grinding wheel head, which has the advantage that a grinding wheel can be tilted and turned to grind a thread and a tooth and can also swing left and right to grind a circular conical surface. According to the numerically controlled grinder, a first servo motor on a grinding wheel head base drives a sliding plate fixing plate to slide on a first guide rail via a first ball screw; a first direct-drive motor is mounted on the sliding plate fixing plate; a grinding wheel connecting seat is mounted on the first direct-drive motor; a second direct-drive motor is mounted on the grinding wheel connecting seat; a motorized spindle fixing seat is connected with the second direct-drive motor; a motorized spindle is mounted on the motorized spindle fixing seat; and the motorized spindle is connected with the grinding wheel to drive the grinding wheel to realize grinding machining. The first direct-drive motor and the second direct-drive motor can rotate respectively to control the grinding wheel on the motorized spindle to rotate left and right or tilt, and the grinding wheel can grind an external circular conical surface, gear or thread of a workpiece after being trimmed.

Owner:广东豪特曼机床股份有限公司

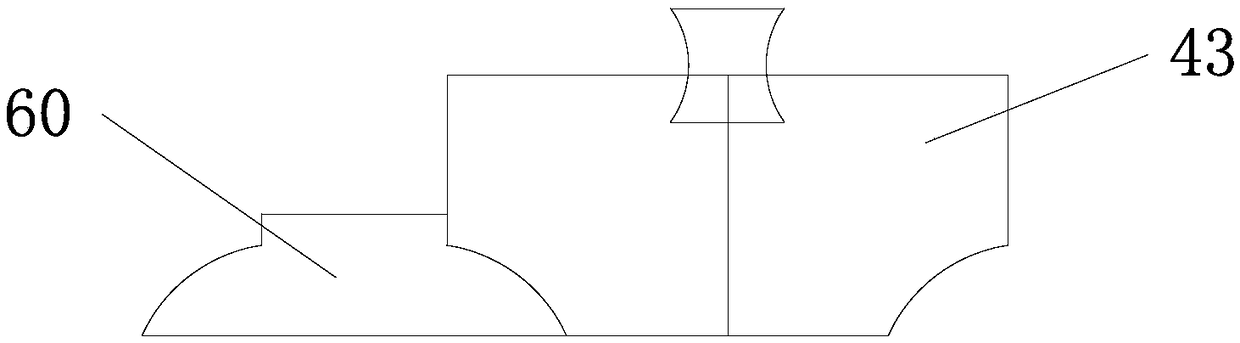

Rotary type stone processing equipment

PendingCN109397031ARealize station changeIncrease productivityGrinding drivesGrinding machinesTransmission beltEngineering

The invention provides rotary type stone processing equipment. The equipment comprises a base, wherein a rotating disc is rotationally connected to the base, and rotating assemblies are arranged on the rotating disc; each rotating assembly comprises a rotating rod and a rotating motor; the upper end of each rotating rod is in transmission connection with a supporting disc, and the lower end of each rotating rod is in transmission connection with a driven belt wheel; the output shaft of each rotary motor is in transmission connection with a driving belt wheel, parts of the driving belt wheels and the driving belt wheels are wound around a transmission belt, and each driven belt wheel and each driving belt wheel are located in a space defined by the transmission belt; and the upper part and / or the side part of the rotating disc are provided with a plurality of grinding assemblies. According to the equipment, the rotating assemblies are arranged, so that the equipment is suitable for a cylindrical stone of a rotary body structure; and meanwhile, the rotary disc is arranged, the corresponding cooperation between different grinding assemblies and different rotating assemblies is realized by utilizing the rotating disc, so that the station transformation is realized without replacing grinding heads or repeatedly loading and unloading the stone, and the production efficiency is relatively high.

Owner:QUANZHOU JIANENG MACHINERY MFG

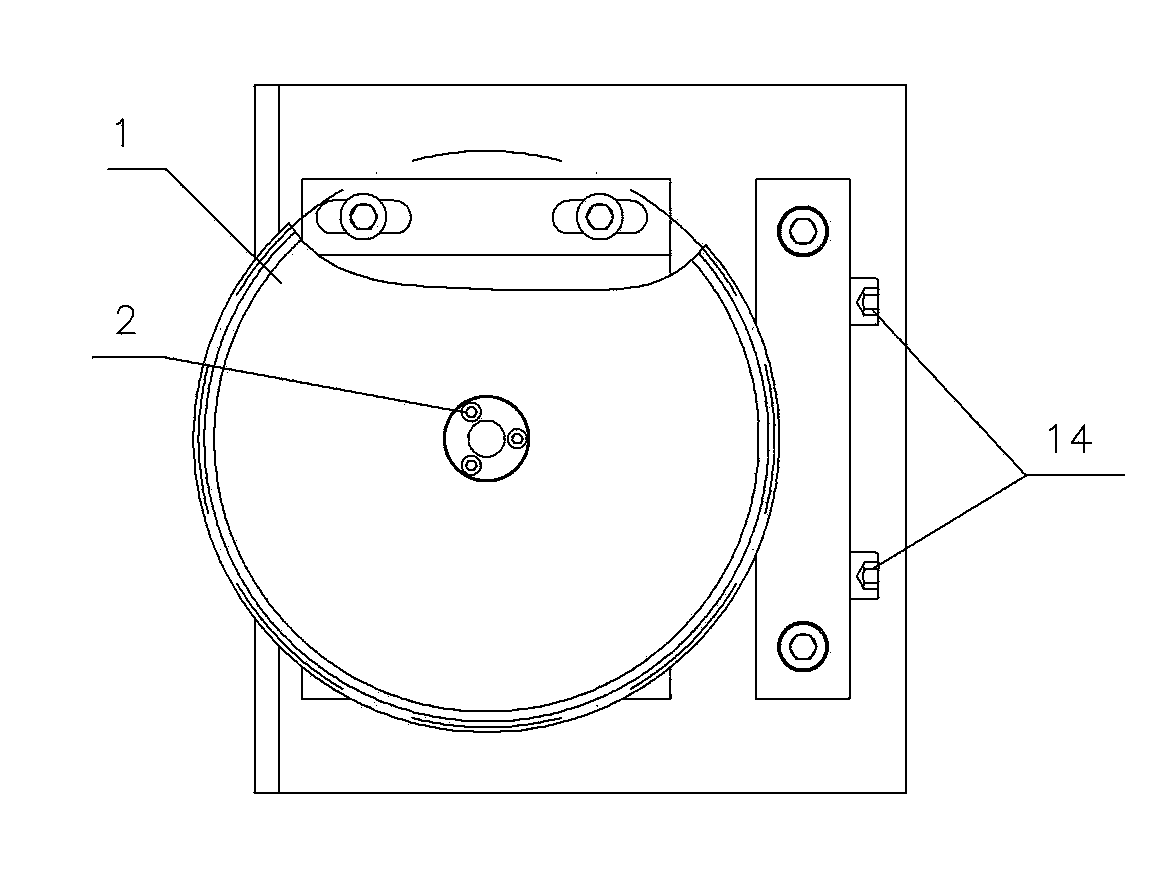

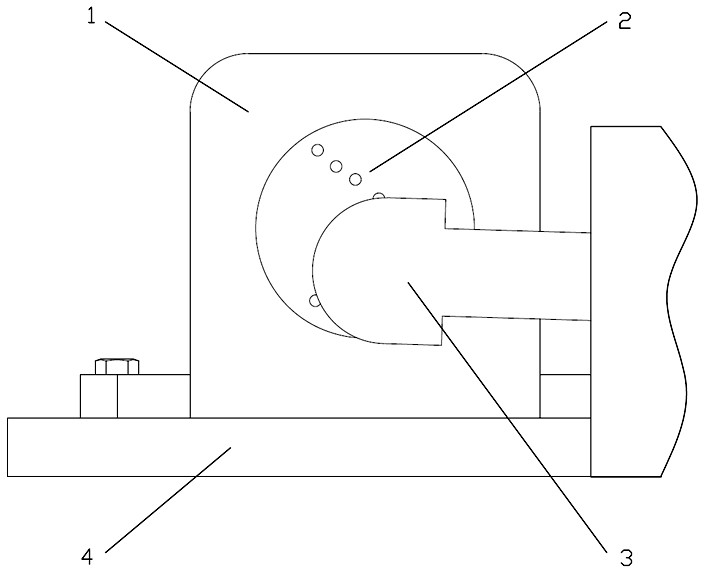

Grinding device for machining for insulation bushings and loops of solar cell array substrate

InactiveCN108044501ARealize flat cutting processRealize grindingFinal product manufactureLapping toolsEngineeringSolar cell

The invention discloses a grinding device for machining for insulation bushings and loops of a solar cell array substrate. The grinding device comprises a grinding head, a circular shaft, an adjustment gasket, a handle, an upper cover plate, a lower cover plate and an adjustment nut, wherein the upper cover plate and the lower cover plate are assembled through a location pin and a connection bolt;the grinding head is a diamond grinding head, and installed at the lower end of the circular shaft through a screw; the upper end of the circular shaft sequentially penetrates through a pin hole of the upper cover plate and the adjustment gasket, and then is connected with the handle; the upper surface and the lower surface of the adjustment gasket form mechanical contact with the handle and theupper cover plate separately; the adjustment nut is connected to the lower cover plate through a thread; and adjustment the height of the device in a product can be realized through rotating the adjustment nut, so as to control the machining thickness of the product. The grinding device disclosed by the invention is capable of rapidly and effectively realizing grinding for the planeness of the insulation bushings and the loops at a hinged support seat of the solar cell array substrate; the planeness of a plane composed of the bushings at the same side of the hinged support seat can be within 0.02mm; the planeness of a single bushing of the hinged support seat can be within 0.01mm; and machining and production can be rapidly and effectively completed.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

Stroke control device of grinding machine working table

InactiveCN104325403ARealize automatic fixed distance reversingEasy to operateGrinding drivesHydraulic cylinderControl system

The invention discloses a stroke control device of a grinding machine working table, and relates to the technical field of manufacturing of mechanical equipment. The stroke control device comprises a machine tool control system and the movable working table driven by a hydraulic cylinder; the movable working table is arranged on a machine tool body. The stroke control device is characterized in that a rotary encoder electrically connected with the machine tool control system is arranged on the machine tool body; a rotary shaft of the rotary encoder is connected with a gear; the gear is in meshing connection with a rack arranged on the movable working table; the rack is arranged in the straight-line motion direction of the movable working table. Compared with the prior art, the gear and the rack transmit to drive the encoder to rotate, and the straight-line motion process of the grinding machine working table is fed back to the machine tool control system in real time through the coaxial rotary encoder; therefore, the machining precision is improved, and grinding machining of a concave-convex curve on the surface of a part and automatic distance-fixed reversing of the working table can be achieved; a machine tool is easy, convenient and rapid to operate.

Owner:柳州金盛重型数控机床有限责任公司

Swing type filament grinding device for chemical fiber filaments

The invention provides a swing type filament grinding device for chemical fiber filaments and belongs to the technical field of chemical fiber filament processing. The swing type filament grinding device comprises a filament grinding guide mechanism and a filament grinding mechanism and is characterized in that the filament grinding mechanism comprises filament grinding roller components, filamentgrinding drive components and a filament grinding roller swing component, the U-shaped filament grinding roller supports of the filament grinding units of the filament grinding roller components areclamped to the upper clamping sections of rotary shafts, filament grinding roller support shafts are mounted on the U-shaped filament grinding roller supports in a clamped manner, filament grinding rollers are rotatably arranged on the filament grinding roller support shafts, the filament grinding O-shaped belts are arranged on the drive belt grooves of filament grinding drive rollers and the driven belt grooves of the filament grinding rollers in a surrounding manner, one end of the rotary block of the filament grinding roller swing component is connected with a rotary block support through arotary support shaft, and the other end of the rotary block is hinged to one swing crossbeam through a rotary pin. The swing type filament grinding device has the advantages that grinding of the chemical fiber filaments can be achieved efficiently through the swing type filament grinding rollers, effective hairness removing can be achieved, and the fiber tension of the chemical fiber filaments can be increased.

Owner:桐乡市恒达经编股份有限公司

Double-head type efficient grinding mechanism for semiconductor crystal bar

PendingCN109746803AGuaranteed Stability and ReliabilityRealize grindingGrinding carriagesGrinding drivesVertical motionSurface grinding

The invention discloses a double-head type efficient grinding mechanism for a semiconductor crystal bar. The mechanism comprises two grinding feeding assemblies which are structured the same, whereinthe two grinding feeding assemblies are oppositely arranged in the same plane and are not symmetric to each other; each grinding feeding assembly comprises a vertical moving assembly, a main shaft rotating assembly and a transverse feeding assembly; each main shaft rotating assembly comprises a main shaft rotating motor, a transmission shaft, a bearing box and an adapting plate; one end of each transmission shaft is connected to the output end of the corresponding main shaft rotating motor through a coupling, and the other end of each transmission shaft is connected to the corresponding adapting plate; a grinding wheel is mounted on each adapting plate; the main shaft rotating assemblies are mounted on the vertical moving assemblies in an up-down sliding manner; and the vertical moving assemblies can be mounted on the transverse feeding assemblies in opposite directions of the two grinding feeding assemblies by a reciprocating sliding manner. According to the grinding mechanism, the grinding wheels can be controlled to horizontally and vertically upwards move so as to realize rolling grinding and OF surface grinding of crystal bars with different diameter.

Owner:QINGDAO GAOCE TECH CO LTD

Grinding machine for curved surface machining

ActiveCN112847058ASolve the problem that it is not convenient to grind irregular surfacesRealize grindingBelt grinding machinesGrinding/polishing safety devicesCircular discMachine

The invention discloses a grinding machine for curved surface machining, and relates to the technical field of grinding machine equipment. The grinding machine comprises a box body, a loading table and a moving frame are installed on the box body, the moving frame is located at one side of the loading table, meanwhile, a grinding part located at the upper side of the loading table is installed on the moving frame, the grinding part comprises a grinding belt, a wheel disc and a guide wheel, and the wheel disc and the guide wheel are in transmission connection through the grinding belt, wherein a plurality of telescopic supporting arms are evenly distributed on the circumferential side face of the wheel disc, and the grinding belt is connected to the outer sides of the supporting arms in a sleeving manner. According to the grinding machine, the multiple telescopic supporting arms are installed on the wheel disc in a matched manner, when the surface of a workpiece with a curved surface structure is ground, the corresponding supporting arms stretch out and draw back, the grinding belt connected with the outer sides of the telescopic supporting arms in the sleeving manner are attached to the surface of the workpiece, and grinding machining of the curved surface is achieved; and the problem that an existing disc millstone cannot conveniently grind irregular surfaces is solved.

Owner:东莞市启航精密五金制品有限公司

Swing device for eccentric arc grinding

PendingCN111993224ASimple structureEasy to useGrinding carriagesGrinding drivesElectric machineryEngineering

The invention discloses a swing device for eccentric arc grinding. The swing device comprises a driving part, a transmission structure and a swing structure, wherein the transmission structure is connected with the driving part and the swing structure; the transmission structure comprises a transmission wheel, a transmission rod and a connecting rod; the transmission wheel sleeves an output shaftof the driving piece, and a notch is formed in the transmission wheel; the swing structure comprises a deflection frame, a deflection frame fixing piece and a wedge block fixing piece. The swing device disclosed by the invention is simple in structure and convenient to use, the purpose of concentricity by eccentric adjustment is achieved through the deflection frame; a motor is started to do cam motion; the swing arc length is adjusted through the arc length of up-down deflection, and grinding machining of the eccentric arc of the wedge block is achieved; the small ends of the two ends of thewedge block and the deflection frame are fastened and clamped through the wedge block fixing piece, and the positioning precision of the swing device is guaranteed.

Owner:JINGJI TECH JIAXING CO LTD

Irregular stone multifunctional composite processing center with double five-axle linkage system

ActiveCN101357490BEngraving and milling realizationRealize the processing effectGrinding machinesStone-like material working toolsEngineeringMachining

The invention relates to a special shaped stone high-speed high-efficiency combined machining center with the functions of double five-axis linkage and synchronous cutting by double working heads, and relates to a device for processing stones. Active gantry structure is adopted in the machining center, the double-motor synchronous driving technology is adopted on the gantry beam, and synchronous high-speed driving is realized by the screw bar pair at the two sides; a milling working head component and a turning working head component are respectively arranged on the saddle of the beam, the vertical feeding mechanism thereof is formed by a suit of screw bar pair and a hydraulic pressure auxiliary mechanism; wherein, the milling working head can carry out rotation and scales division aroundthe axis B, and the turning working head facilitates the same servo motor to realize rotation and scale division of axis A and cutting movement; the turning working head and the milling working head are arranged alternately, and both the turning process and the grinding processing can be carried out on stone articles at the same time. The machining center is provided with a numerical control system with the function of double five-axis linkage, and horizontal five-axis linkage machining and vertical five-axis linkage machining can be realized.

Owner:SHENYANG JIANZHU UNIVERSITY

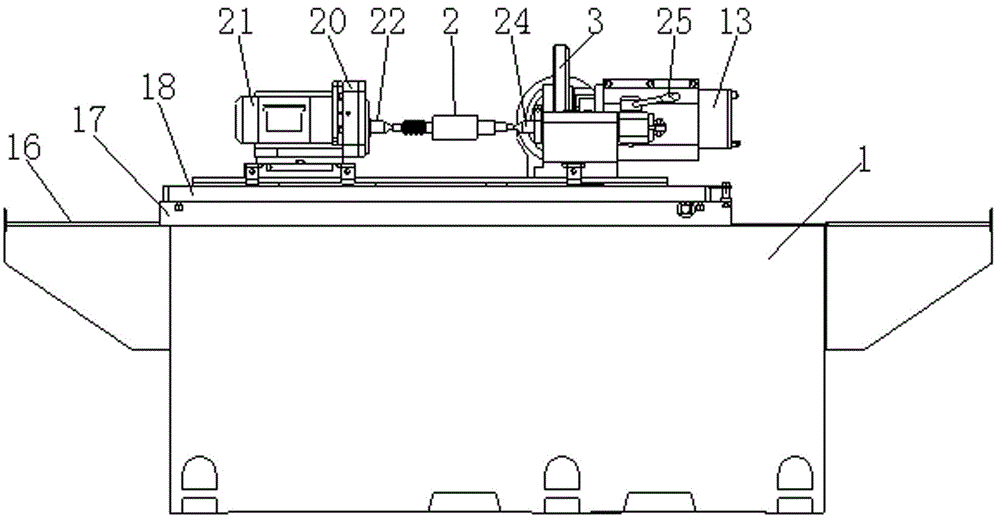

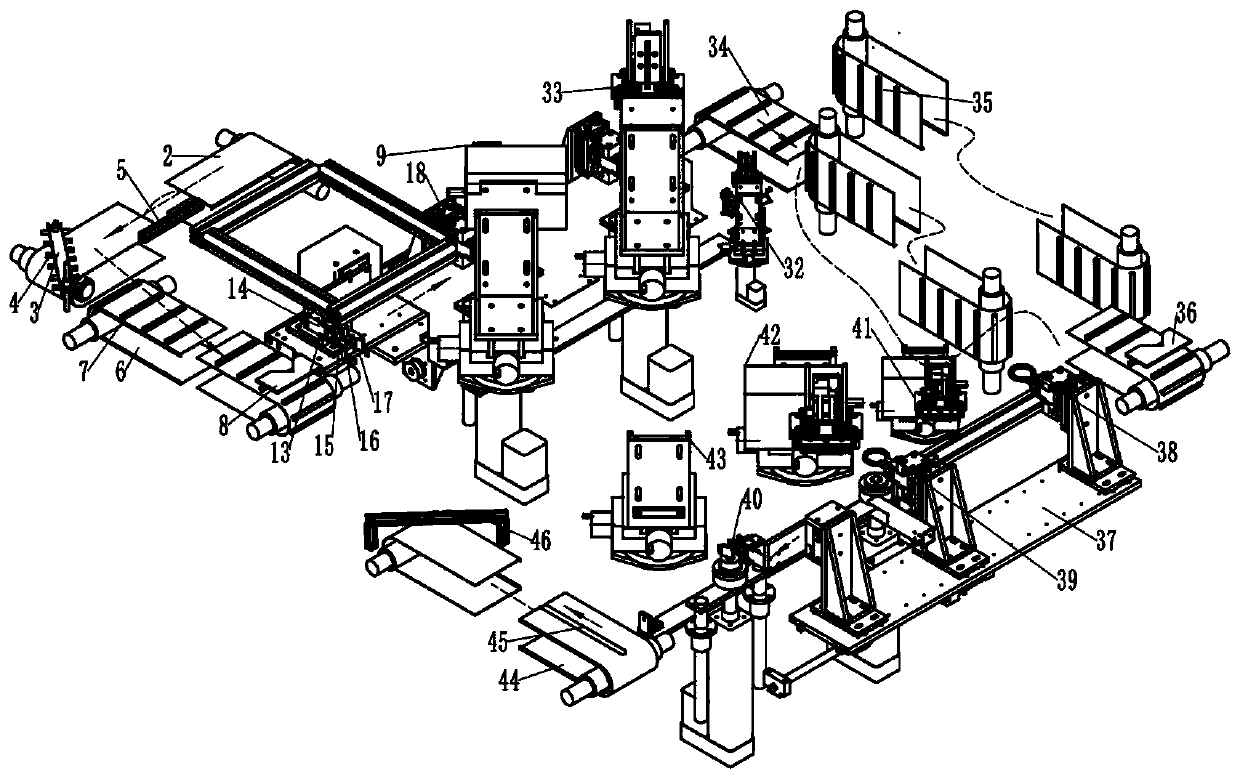

Steel pipe machining system

InactiveCN111098143ARealize automatic feeding processRealize grindingOther manufacturing equipments/toolsMetal working apparatusClassical mechanicsEngineering

The invention relates to a steel pipe machining system. The steel pipe machining system comprises a machine frame assembly, a feeding conveyor belt arranged on the machine frame assembly, an inclinedconveyor belt with the input end linked with the output end of the feeding conveyor belt, an inclined side conveyor belt arranged on one side of the output end of the feeding conveyor belt, inclined pulling arms distributed on the inclined side conveyor belt and used for transversely pulling out steel pipes on the feeding conveyor belt, an input conveyor belt with the input end linked with the output end of the inclined conveyor belt, input cross arms distributed on the input conveyor belt, a V-shaped centering block arranged at the output ends of the input cross arms and used for centering the steel pipes, and a first end face machining device arranged on one side of the V-shaped centering block. The steel pipe machining system is reasonable in design, compact in structure and convenientto use.

Owner:ZHEJIANG ZHONGWU STEEL TUBE MFG CO LTD

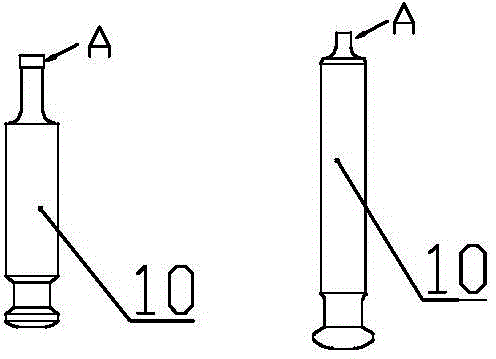

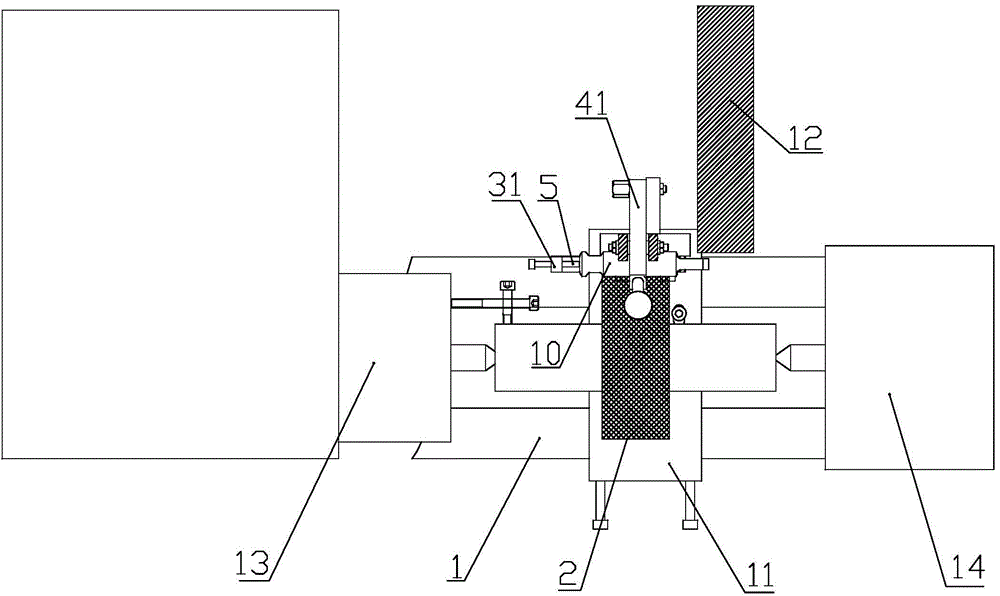

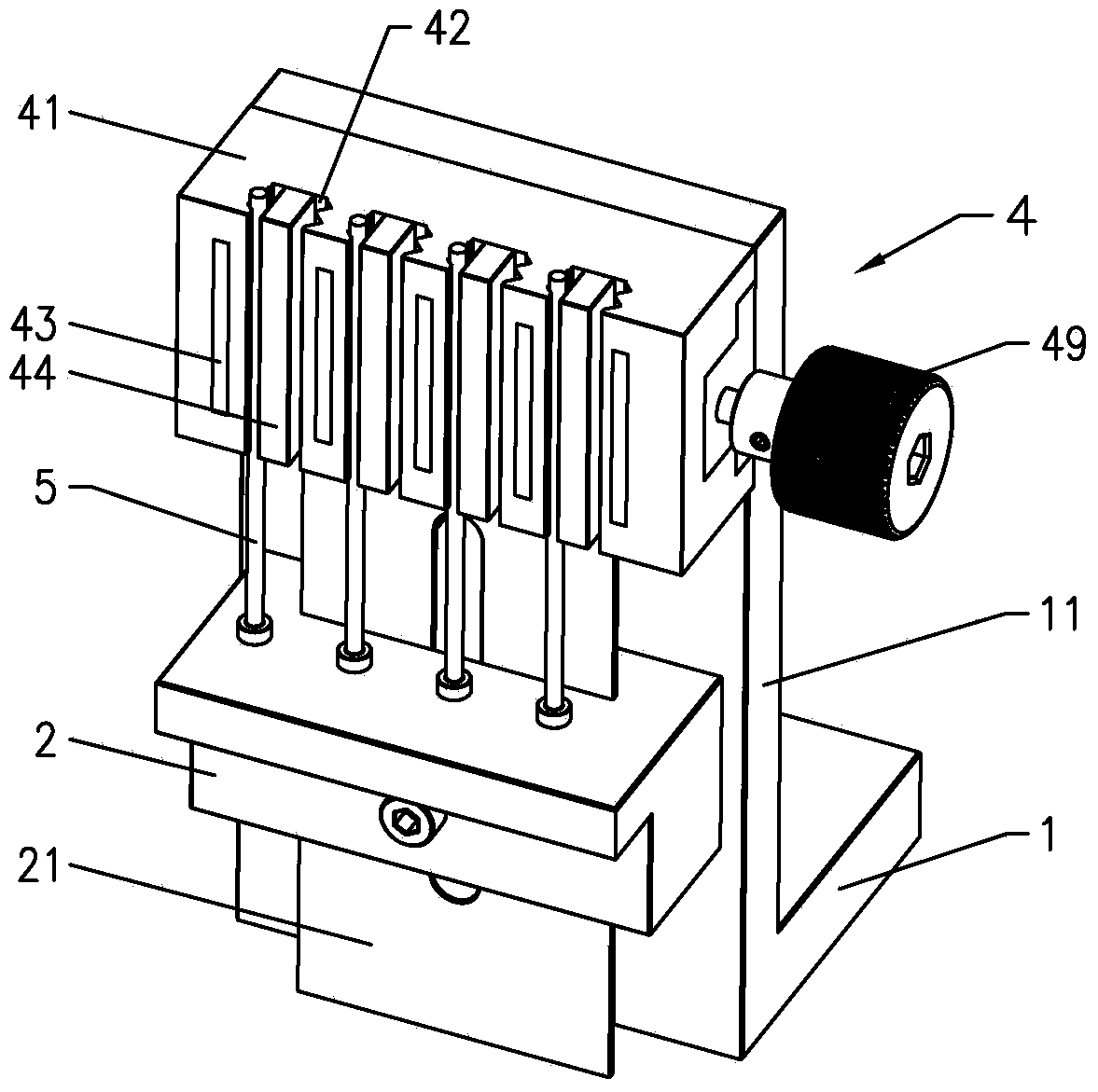

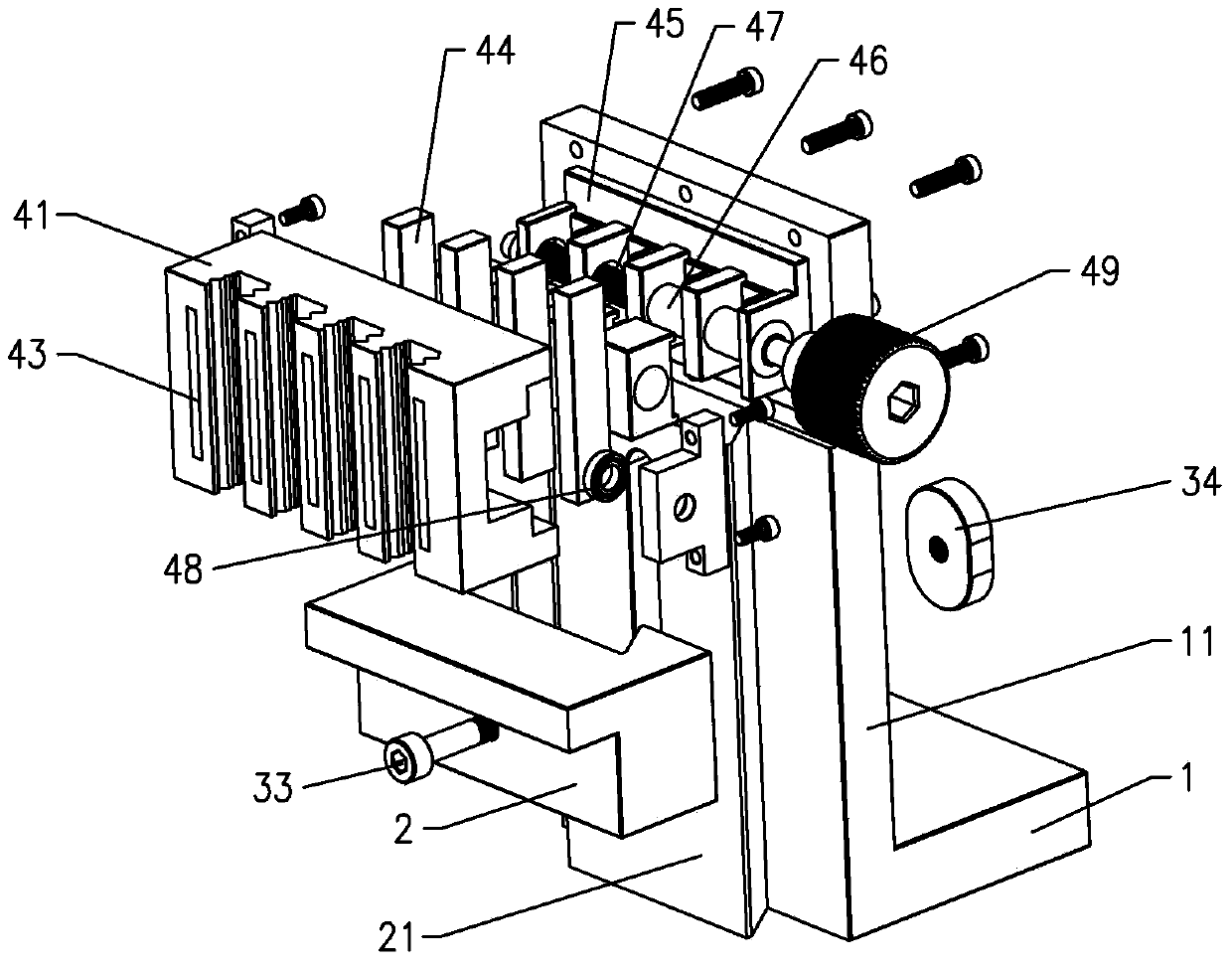

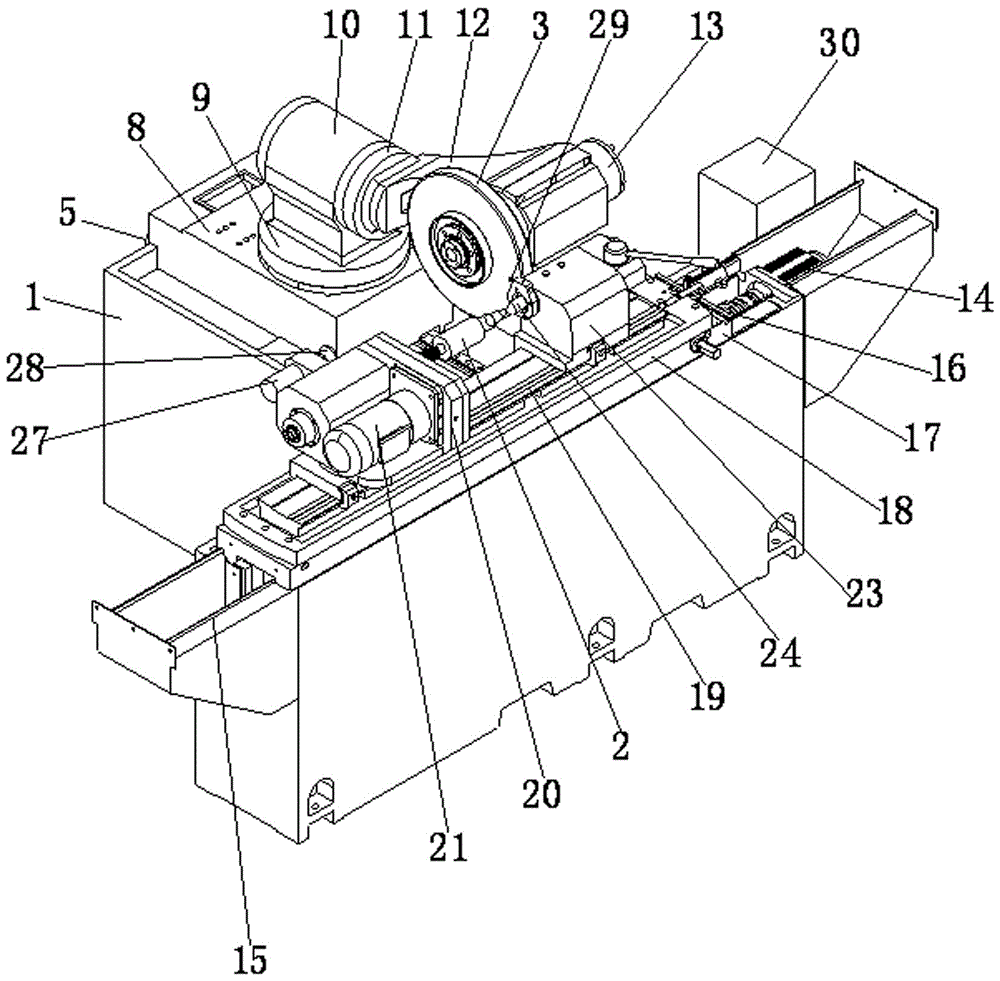

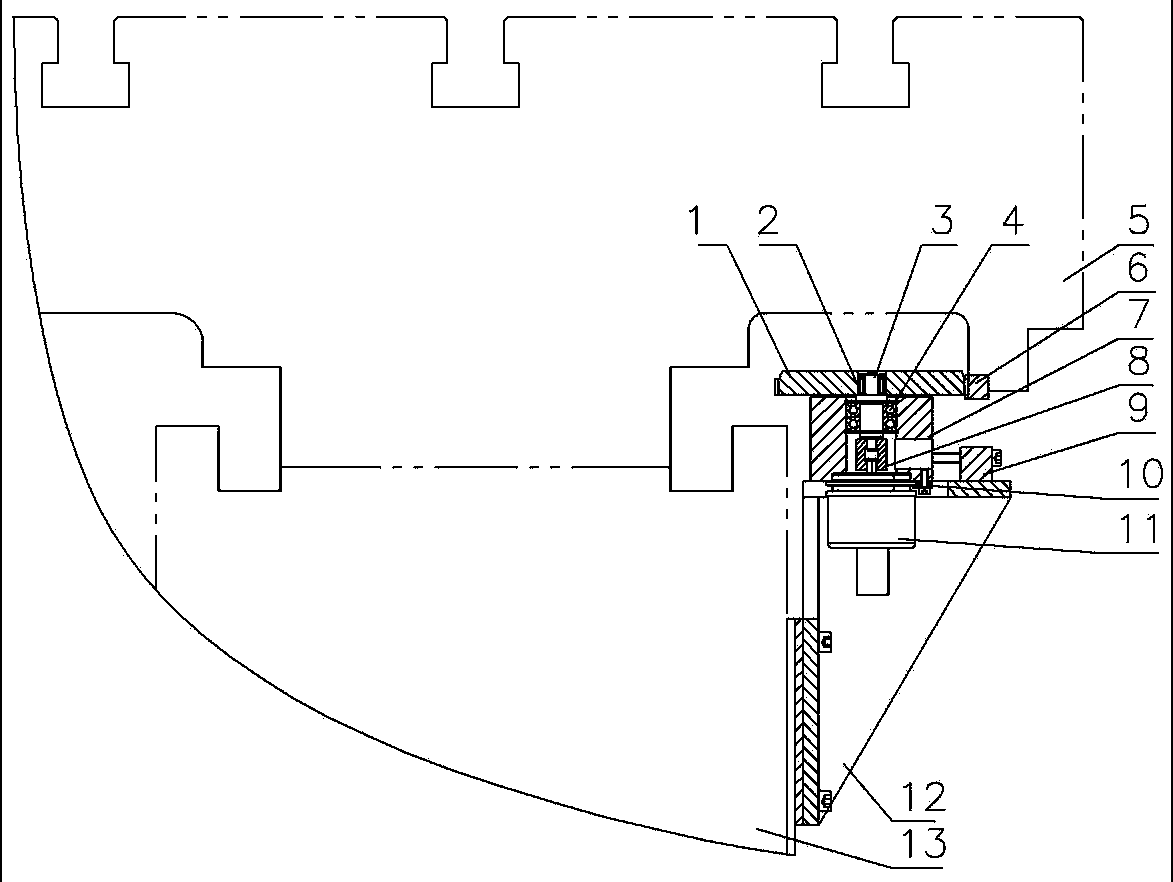

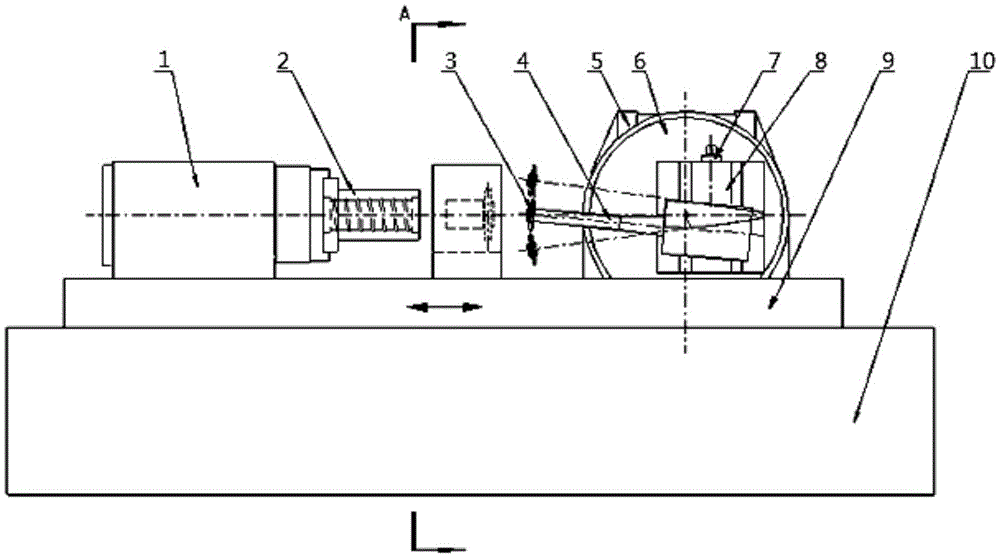

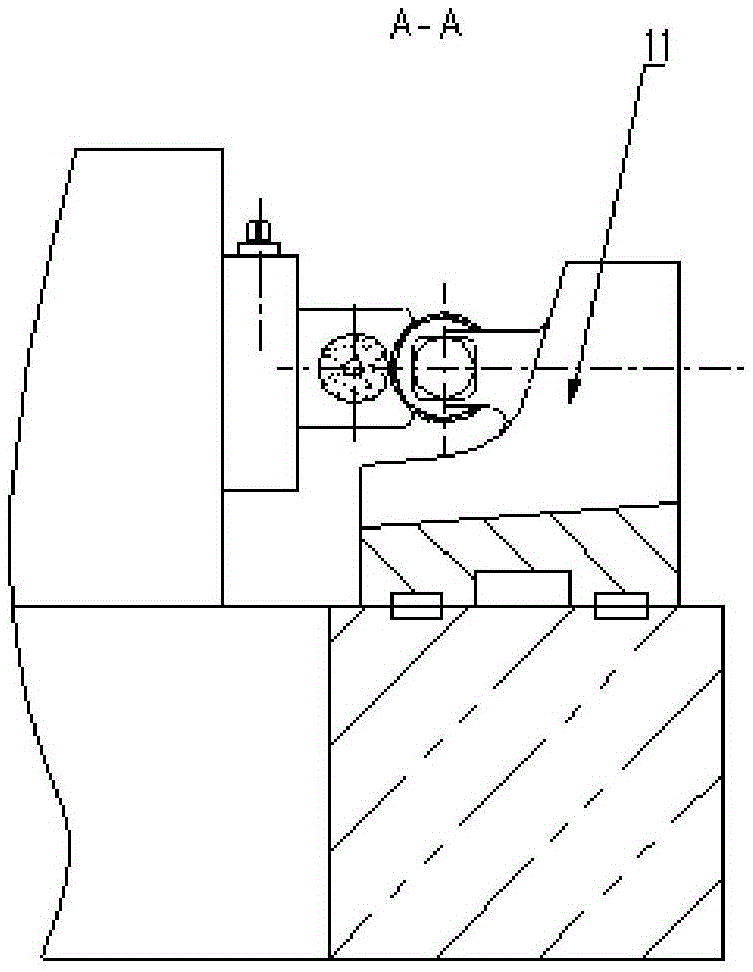

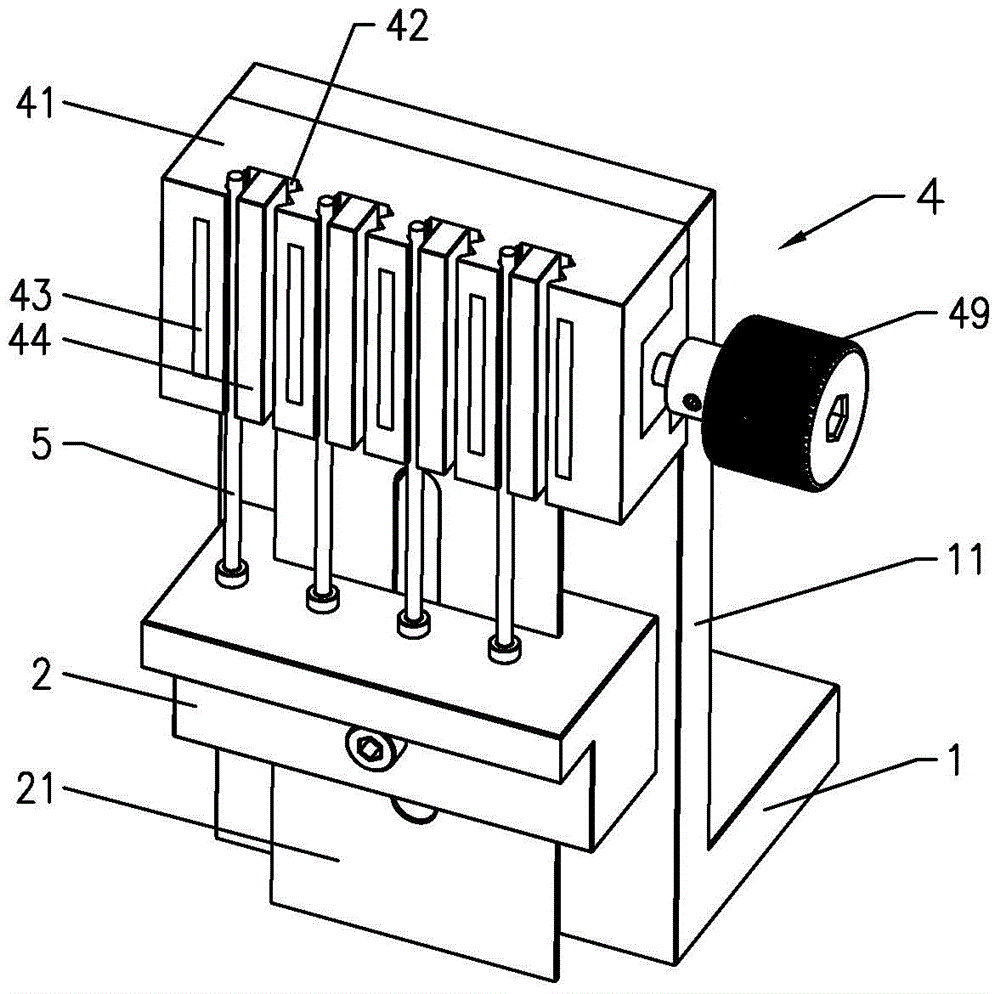

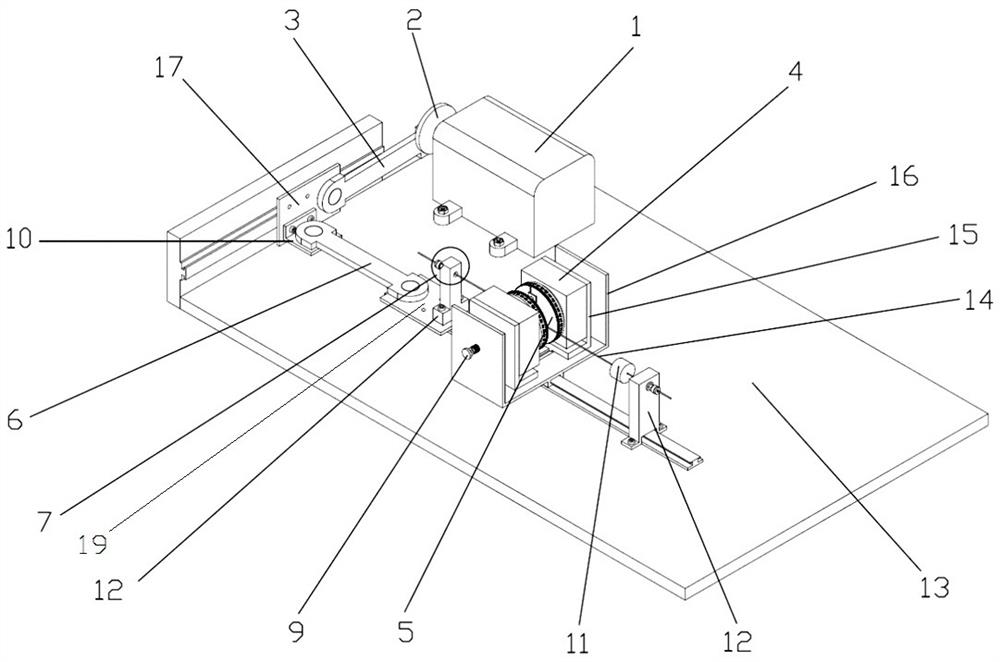

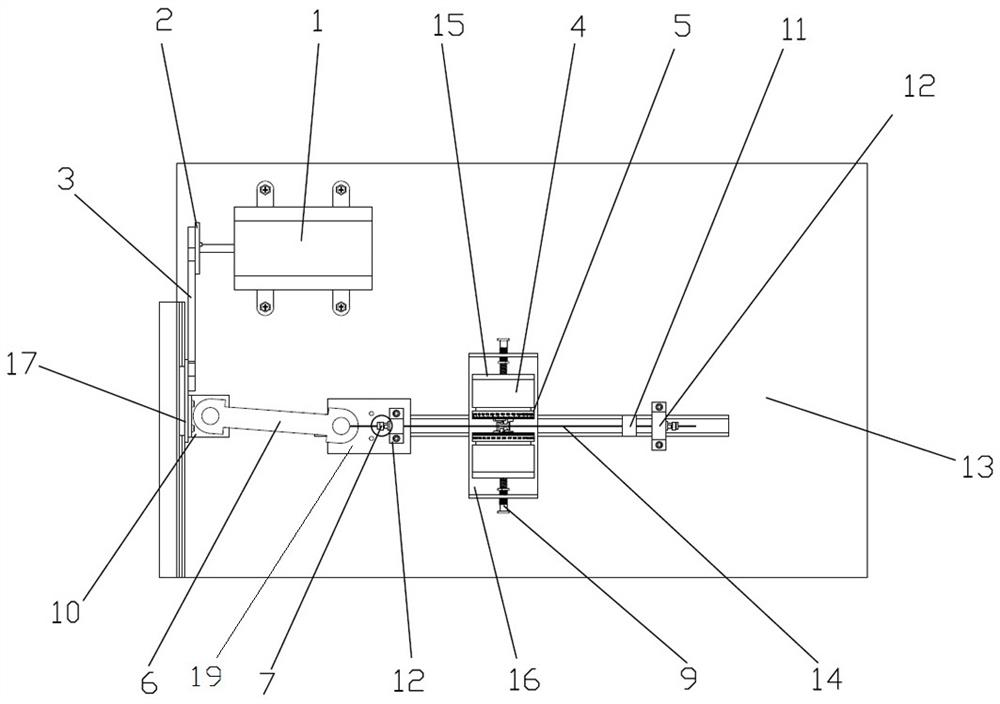

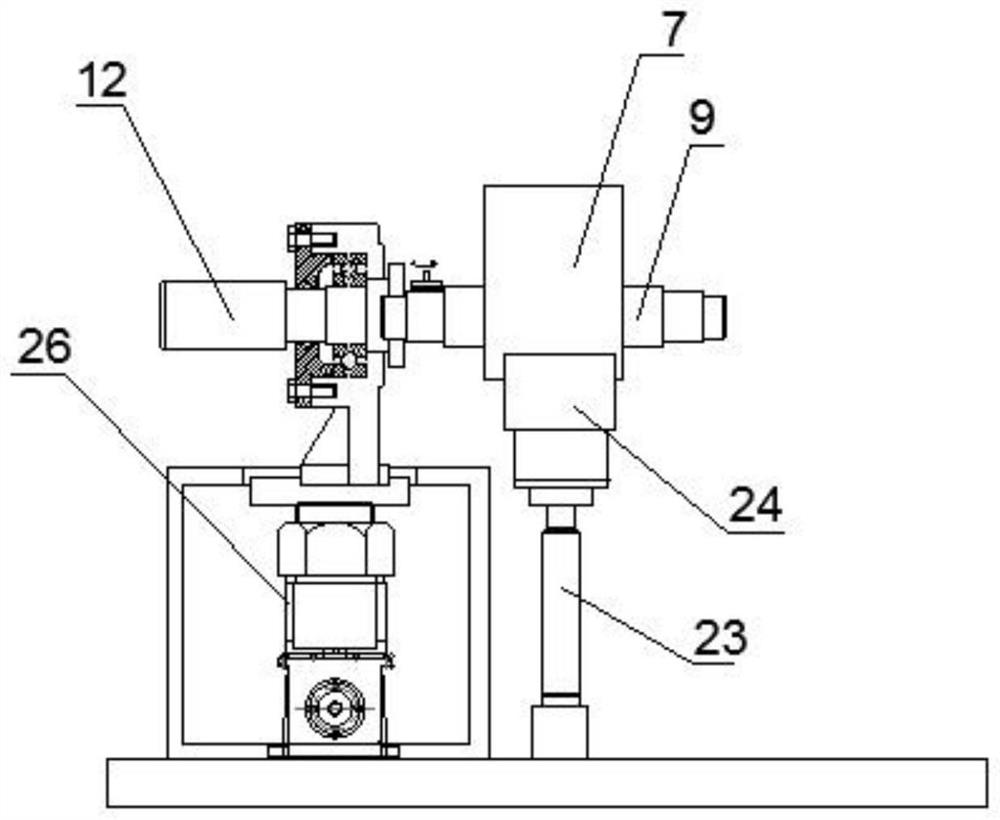

Nut Internal Thread Grinding Device with Replaceable Grinding Rod

ActiveCN103737129BRealize grindingImprove processing efficiencyThread cutting machinesEngineeringScrew thread

The invention provides a nut internal thread grinding device with a replaceable grinding rod. The internal thread grinding device with the replaceable grinding rod comprises a headstock 1, an internal thread grinding tool 3, the grinding rod 4, a grinding wheel carriage base 5, a grinding wheel carriage rotary drum 6, a supporting board feeding device 7, a supporting board 8, a workbench 9, a lathe bed 10 and a grinding tool finishing device 11. The workbench 9 is arranged on the lathe bed 10 and the headstock 1, the grinding tool finishing device 11 and the grinding wheel carriage base 5 are arranged on the workbench 9; the headstock 1 is used for driving a workpiece with the internal thread characteristic to rotate and the grinding wheel carriage base 5 and the grinding wheel carriage rotary drum 6 can relatively rotate so that a spiral angle required by grinding of internal threads can be obtained; the supporting board feeding device 7 can drive the supporting board 8 to move and drive the internal thread grinding tool 3 to move through the grinding rod 4. Through replacement of the grinding device and adjustment of the position of the grinding rod, nuts of various lengths can be ground on one device, the machining range is enlarged, the machining efficiency and flexibility of the internal threads of the nuts can be improved, and particularly, an ultra-long nut can be ground.

Owner:SHANGHAI JIAO TONG UNIV

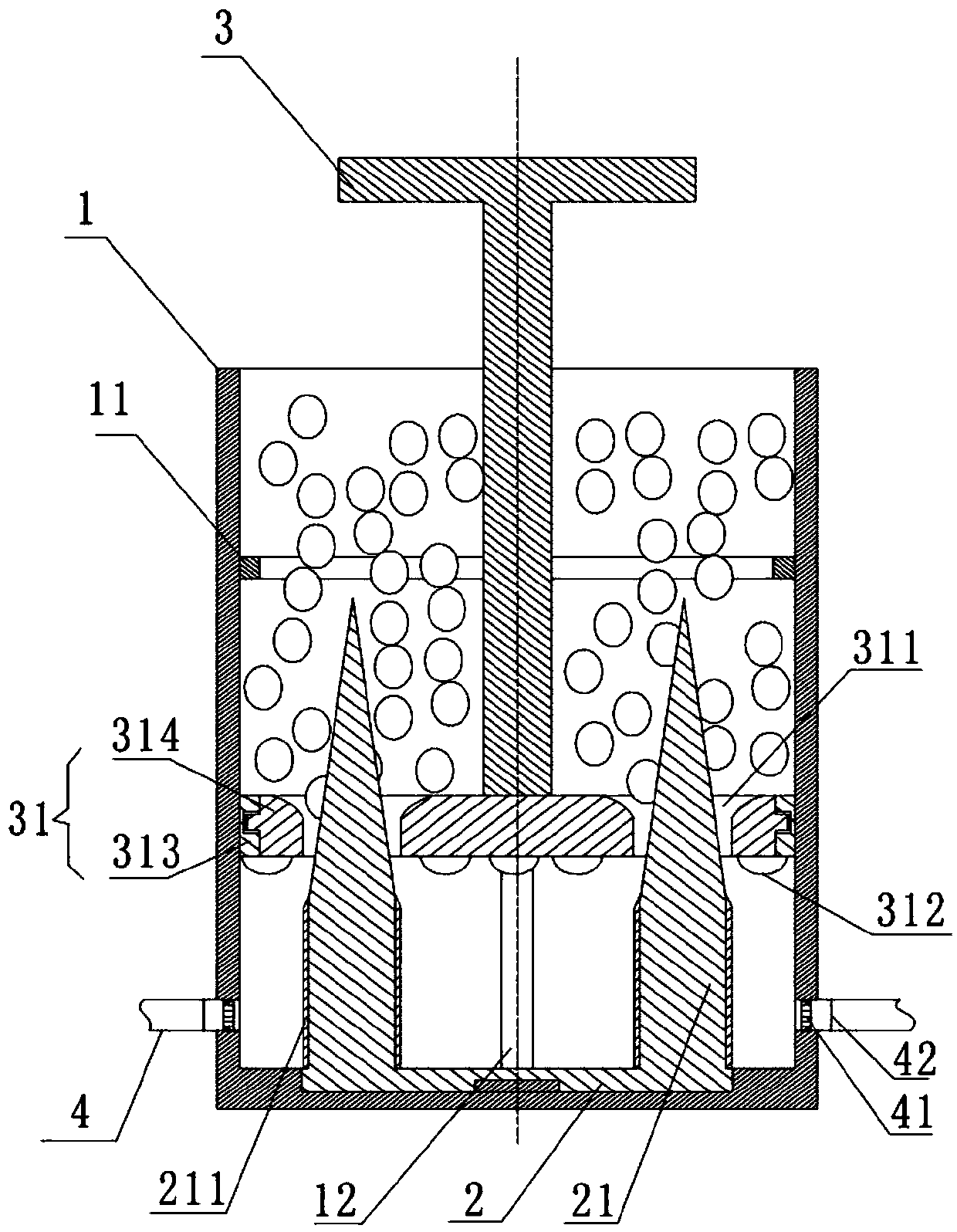

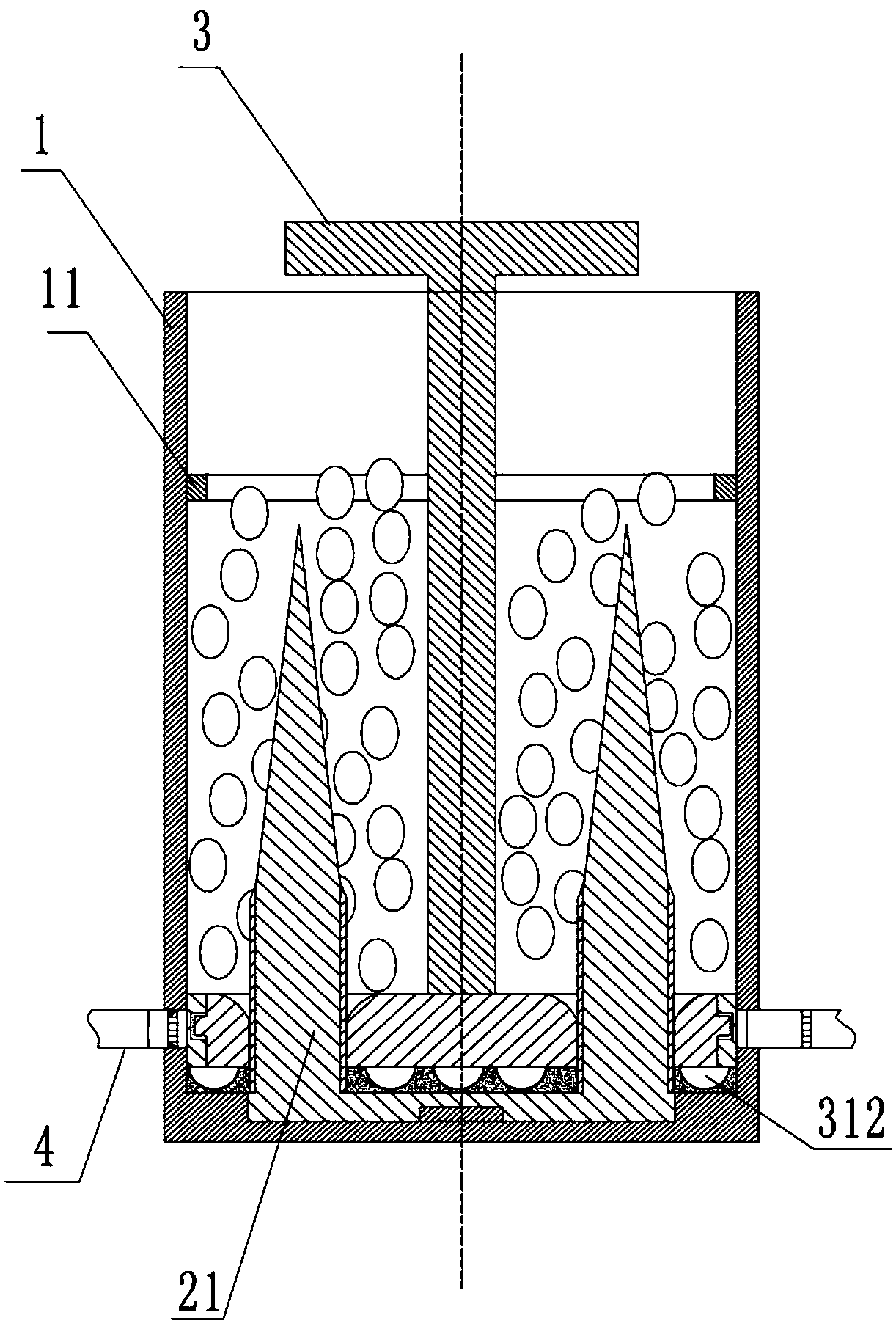

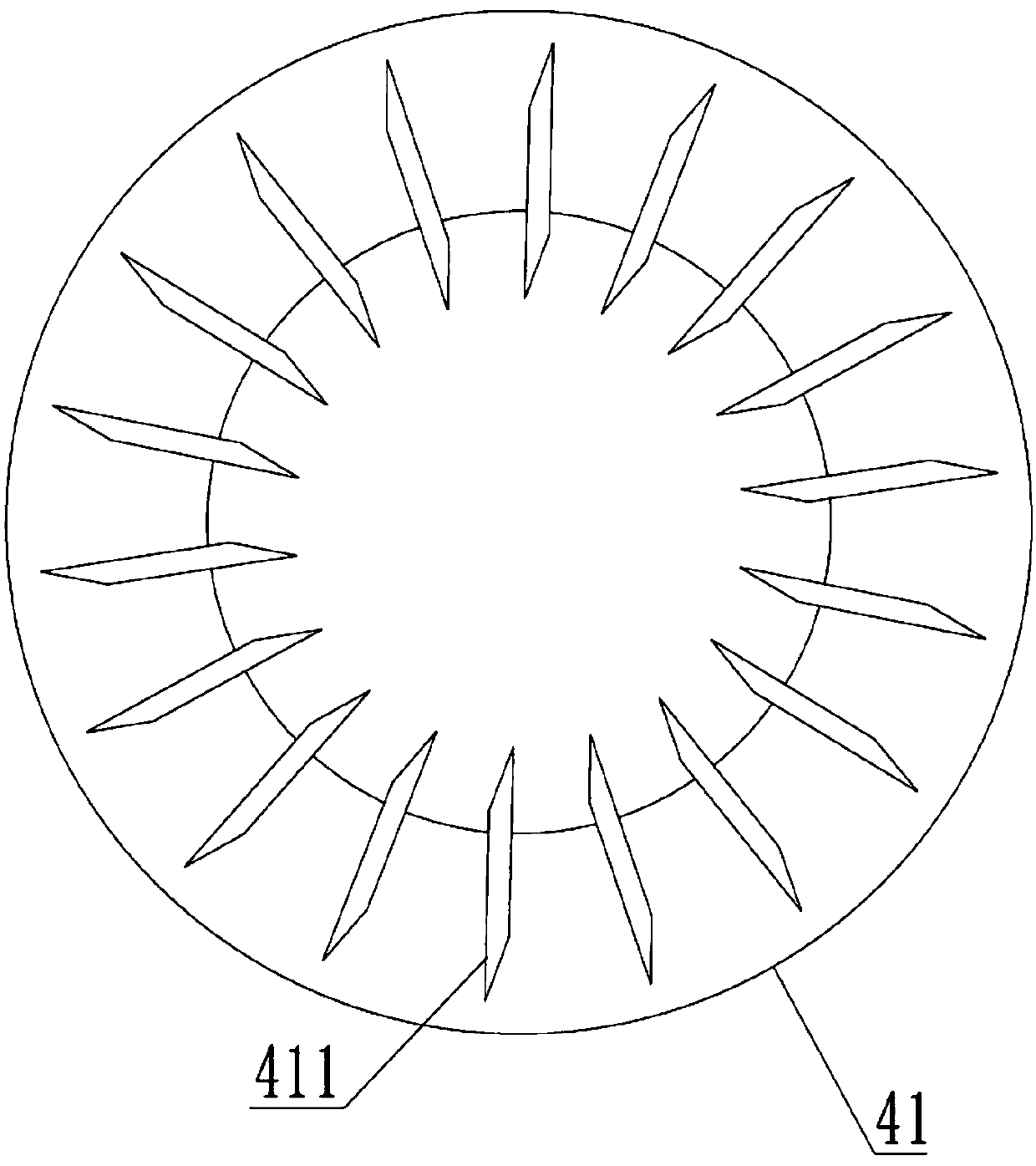

Olive oil deep processing equipment

ActiveCN107866299BFall into realizationPrevent fallingFatty-oils/fats productionGrain treatmentsEngineeringOlive oil

The invention relates to the technical field of processing of vegetative raw materials, in particular to olive oil deep processing equipment. The olive oil deep processing equipment comprises a processing barrel, a rotating structure and a pushing and pressing structure used for pushing and pressing olives. The rotating structure comprises a rotating disc and guiding rods located on the rotating disc, and the rotating disc is rotatably connected with the inner bottom face of the processing barrel; the pushing and pressing structure comprises push rods and push discs, charging holes used for allowing the guiding rods to extend out are formed in the push discs, balls are arranged on the bottom faces of the push discs, and the upper portions of the guiding rods are in taper shapes; and sealing layers capable of being in contact with the hole walls of the charging holes are arranged on the outer walls of the lower portions of the guiding rods, discharging pipes are arranged on the lower portion of the processing barrel, secondary processing rings and hard filter screens are sequentially arranged on the discharging pipes in the pipe outlet direction, and blades are arranged on the innerwalls of the secondary processing rings. According to the scheme of the olive oil deep processing equipment, charging is convenient, and the olives can be very simply and repeatedly rolled and crushed.

Owner:重庆江源油橄榄开发有限公司

Plastic mold thimble grinding fixture

ActiveCN103722491BChange distanceAchieve positioningGrinding work supportsLocking mechanismEngineering

Owner:GOERTEK INC

A Centerless Fixture Used on Cylindrical Grinding Machine

InactiveCN104669080BGuaranteed axisGuaranteed work pressureRevolution surface grinding machinesDrive wheelEngineering

The invention discloses a centerless fixture for a cylindrical grinding machine. The centerless fixture comprises a driving wheel, a supporting wheel and a pressing wheel, wherein the driving wheel is arranged on a rotating shaft of a grinding machine; the supporting wheel is arranged at the slanting lower part of the rear side of the driving wheel; the outer side of a support of the supporting wheel is hinged to one end of a pressing rod; the pressing wheel is arranged at the middle of the pressing rod; the other end of the pressing rod is connected with one end of a spring; the other end of the spring is connected onto a grinding machine rack; a positioning part is arranged at one end face side, which is away from a grinding wheel of the grinding machine, of the supporting wheel, on the support of the supporting wheel; a punch rod clamped among the driving wheel, the supporting wheel and the pressing wheel can be axially positioned by the positioning part; the punch rod is fixed by line contact matching between the circumferential surfaces of the driving wheel, the supporting wheel and the pressing wheel and the circumferential surface of a punch body of the punch rod; after the punch rod is fixed, the axiality of the punch rod can be directly guaranteed; the acting pressure of the pressing wheel on the punch rod is guaranteed by the pretightening force of the spring; the driving wheel is driven by the rotating shaft to rotate and drives the punch rod to rotate; the grinding processing is realized by contacting a circumferential section of the upper end to be ground of the punch rod with the grinding wheel.

Owner:LIAOCHENG WANHE IND MFR

Metal rubber metal wire fretting wear and fatigue test device and test method thereof

PendingCN114878388ARealize clampingRealize grindingInvestigating abrasion/wear resistanceMetal rubberStructural engineering

The invention relates to a metal rubber metal wire fretting wear and fatigue test device and a test method thereof.The metal rubber metal wire fretting wear and fatigue test device comprises a base, a clamp mounting table is arranged on the base, and a micro-amplitude vibration plate is arranged beside the clamp mounting table; a first metal wire clamp and a second metal wire clamp or two first metal wire clamps which are oppositely arranged front and back are mounted on the clamp mounting table; fatigue connecting blocks are arranged on the left side and the right side of the clamp installation table, fatigue metal wire locking mechanisms are arranged on the fatigue connecting blocks, one fatigue connecting block is detachably connected to the base, and the other fatigue connecting block is detachably connected to the micro-amplitude vibration plate. And the second metal wire clamp is provided with a fretting wear connecting seat which is detachably connected with the micro-amplitude vibration plate. The whole device adopts a horizontal arrangement structure, is convenient to use and high in practicability, has fretting fatigue and fretting wear test functions, and can meet the fretting wear and fatigue test requirements of various metal wires, and the fretting fatigue module and the fretting wear module can be replaced with each other.

Owner:FUZHOU UNIV

High-precision milling machining method for hob of hard alloy granulator

ActiveCN113118885ARealize grindingImprove milling efficiencyGrinding carriagesGrinding drivesElectric machineryStructural engineering

The invention relates to a high-precision milling machining method for a hob of a hard alloy granulator. The high-precision milling machining method comprises the following steps that a grinding knife with a required size is selected; two positioning plates are mounted on a milling table, a distance adjusting mechanism for adjusting the distance between the two positioning plates is arranged on the milling table, and locking mechanisms are mounted on the side walls of the positioning plates; the distance between the two positioning plates is adjusted through the distance adjusting mechanism, and the hob is fixed through the locking mechanisms; gear motors are mounted on the side walls of the positioning plates, and the locking mechanisms are driven by the gear motors to rotate, so that a to-be-milled blade on the hob is aligned with the grinding knife; a base used for bearing the milling table is arranged below the milling table, a lifting mechanism is arranged on the base, and the lifting mechanism is used for driving the grinding knife to move downwards; a sliding mechanism for driving the milling table to slide is arranged on the base, the sliding mechanism is used for driving the milling table to slide in the axial direction of the hob, and the hob is milled through the grinding knife. The angle of the hob is not required to be manually adjusted, time and labor are saved, and the milling efficiency is improved.

Owner:南京南洋机械有限公司

Steel pipe machining method

ActiveCN111098097ARealize automatic feeding processRealize grindingPositioning apparatusMetal-working holdersPipe fittingTransmission belt

The invention relates to a steel pipe machining method. A steel pipe machining system is used for assistance and comprises a rack assembly, a feeding conveying belt arranged on the rack assembly, an inclined conveying belt with the input end connected with the output end of the feeding conveying belt, an inclined side conveying belt arranged on one side of the output end of the feeding conveying belt, an inclined stirring arm distributed on the inclined side conveying belt and used for transversely stirring out a steel pipe fitting on the feeding conveying belt, an input conveying belt with the input end connected with the output end of the inclined conveying belt, an input cross arm distributed on the input conveying belt, a V-shaped centring block arranged at the output end of the inputcross arm and used for centring the steel pipe fitting and a first end face machining device arranged on one side of the V-shaped centring block. According to the steel pipe machining method, design is reasonable, the structure is compact, and use is convenient.

Owner:ZHEJIANG ZHONGWU STEEL TUBE MFG CO LTD

A double-station grinding tool for cam machining

InactiveCN111251130BRealize grindingEasy to processGrinding carriagesGrinding drivesCamGrinding wheel

The invention discloses a double-position grinding tool for cam machining. Through double positions, the double-position grinding tool for cam machining can realize grinding machining on a cam surface, can also carry out grinding machining on the circumferential surface of a rotary shaft of a cam and effectively improves the cam machinability. The controller can control a cam surface machining andlocating mechanism and a rotary shaft circumferential surface machining and locating mechanism to realize automatic lifting adjustment according to the shape of the cam surface of the cam to be machined, effectively drives a grinding wheel to carry out grinding machining on the surface of the cam to be machined and improves the grinding capability. The grinding wheel does not need to carry out feeding according to the shape of the cam in a tool feeding mode. The problem that big errors occur under unbalanced force caused by complex feeding of the grinding wheel can be effectively prevented. The grinding precision is improved. Meanwhile, the double-position grinding tool for cam machining can carry out machining on a supporting rotary shaft and improve the machinability.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com