Adjustment of dipyramidal-surface enveloping worm emery cutters

A technology of toroidal worm and adjustment method, which is applied in the direction of worms, components with teeth, belts/chains/gears, etc., and can solve problems such as the inability to realize the tooth surface processing of toroidal worms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

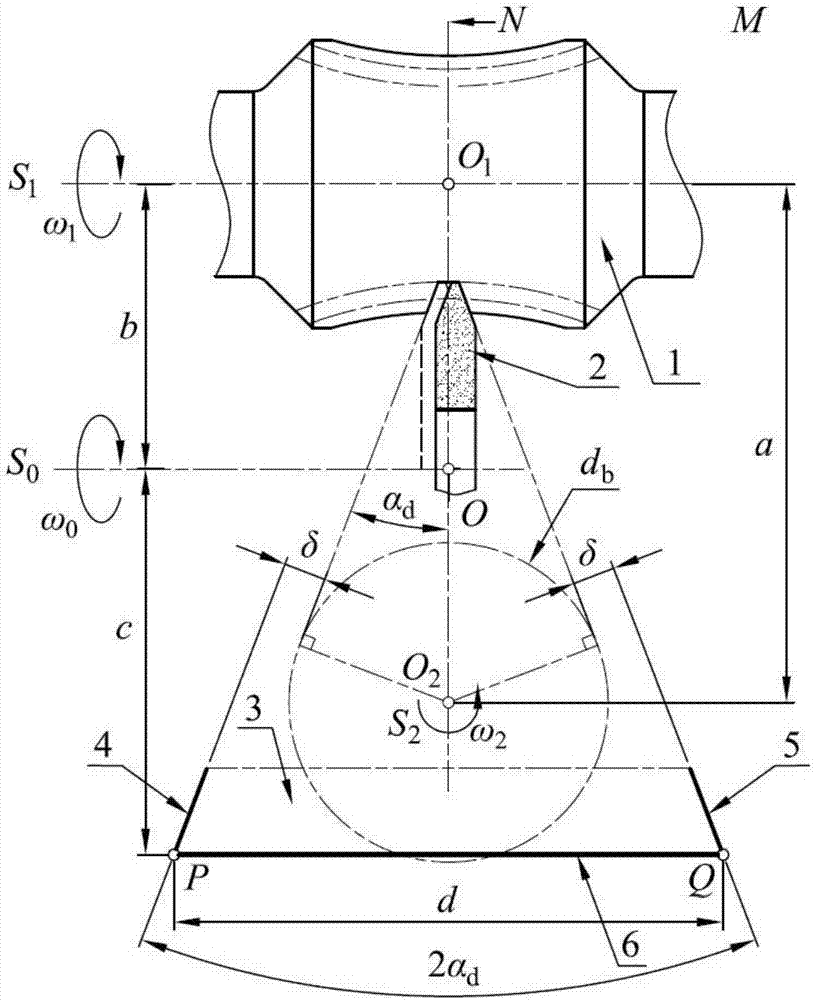

[0023] Embodiment 1: the center distance of the toroidal worm pair a=240mm, the transmission ratio i 12 =40, the number of heads of the toroidal worm (1) Z 1 =1, the direction of rotation is right-handed, the diameter of the root circle of the throat is d f1 =61mm, the normal alveolar width e of the partial annulus of throat n1 =17.58mm, the number of worm gear teeth meshing with it Z 2 =40, end modulus m t =10mm, diameter of main base circle d b =153.20mm, the diameter of the indexing circle is d 2 =400mm, tooth profile angle α of double cone grinding wheel (2) d =20°, diameter d d =160mm;

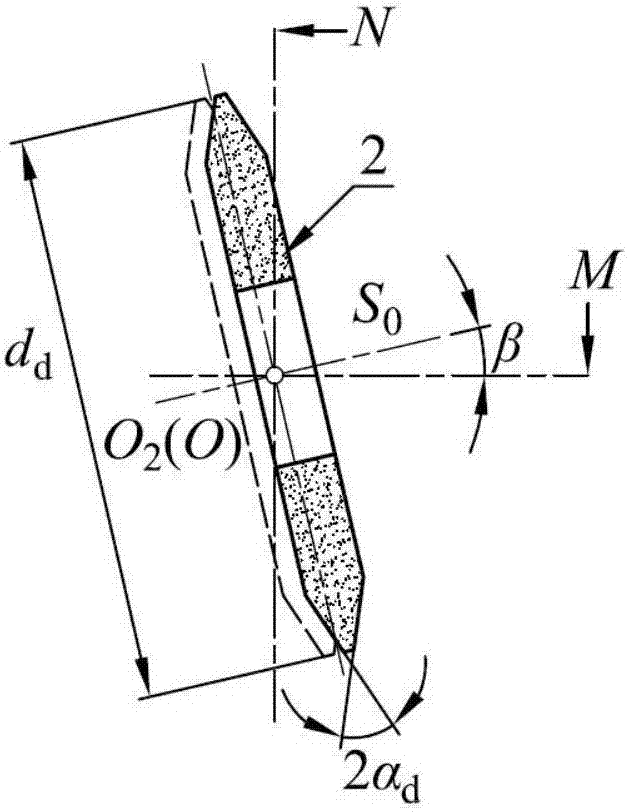

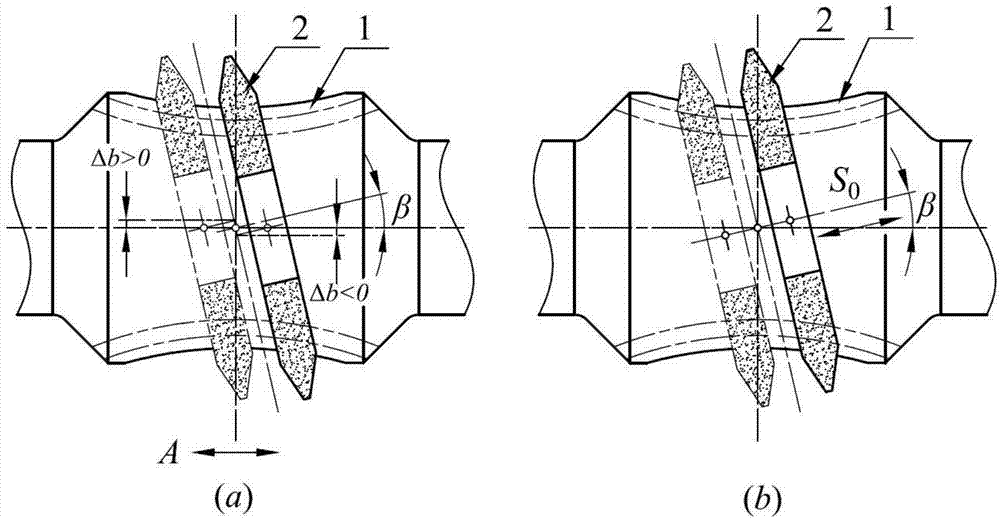

[0024] Set the rotation axis of the toroidal worm (1) as S 1, the rotation axis of the double-cone grinding wheel (2) is S 0 , by two parallel axes S 0 and S 1 Determine the base surface M, the main base circle of the worm gear meshed with the toroidal worm (1) is located in the base surface M, and the center of the circle is O 2 , over O 2 point and perpendicular to the base...

Embodiment 2

[0035] Embodiment 2: Increase the center distance a=400mm and transmission ratio i of the toroidal worm pair 12 =40, the number of heads of the toroidal worm (1) Z 1 =1, the direction of rotation is right-handed, the diameter of the root circle of the throat is d f1 =110.3mm, the number of worm gear teeth meshing with it Z 2 =40, end modulus m t =16.5mm, the diameter of the indexing circle is d 2 =660mm, tooth profile angle α of double cone grinding wheel (2) d =20°, diameter d d = 350mm, select the inclination angle β of the double-cone grinding wheel (2) = 10°, and calculate the normal slot width e n1 =28.59mm, diameter of main base circle of worm gear d b =259.50mm, parameter 2α of reference table (3) d , c and d remain unchanged, calculate the grinding wheel distance b = 169.85mm, offset distance δ = 1.889mm, according to the same adjustment method as above, by adjusting the grinding wheel distance b, offset distance δ and inclination β, determine the double cone gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Center distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com