Steel pipe machining method

A processing method and technology for steel pipes, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inability to realize automatic connection of flow water, and achieve the effect of compact structure, low cost and money saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

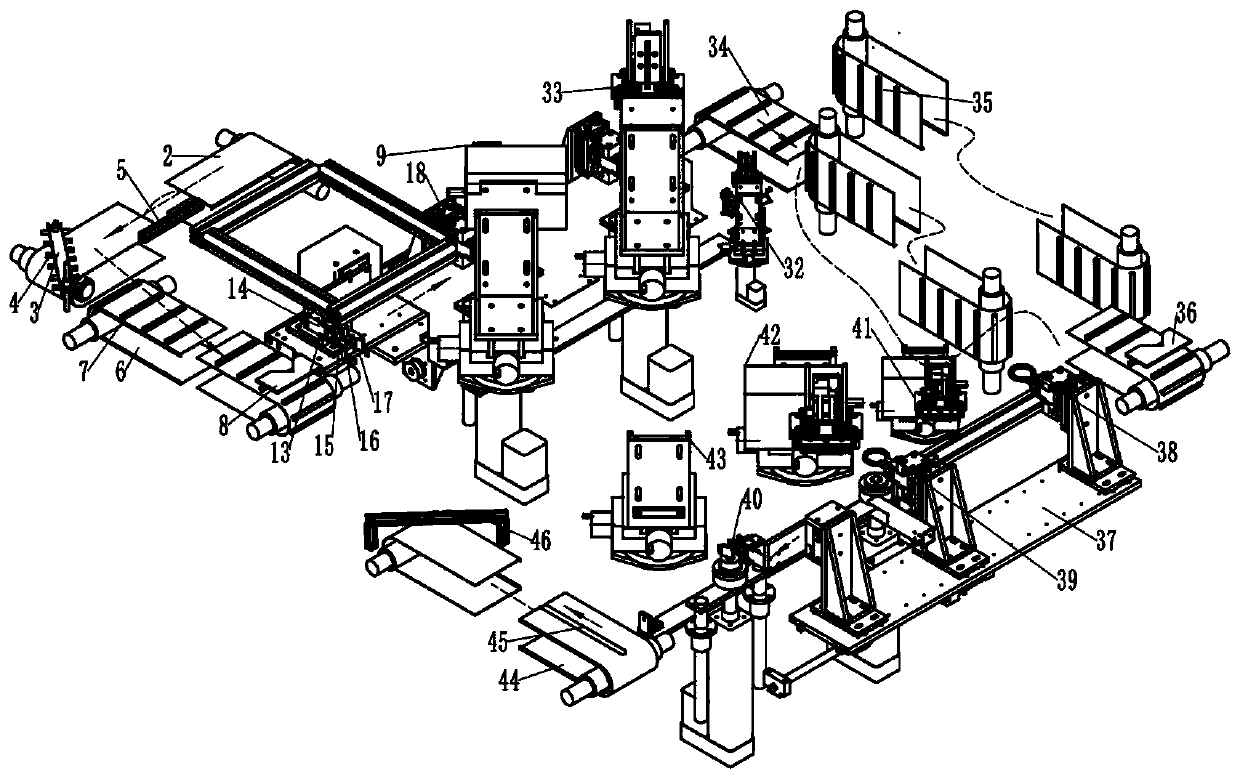

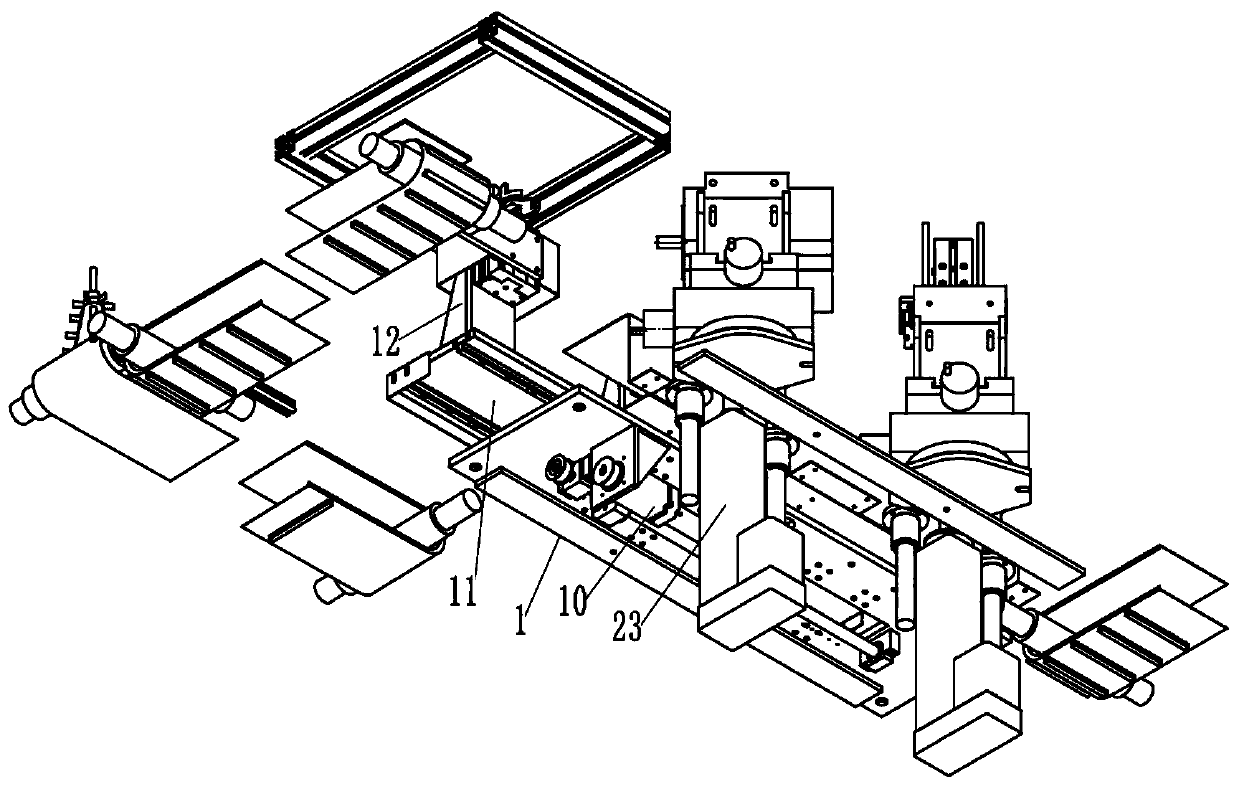

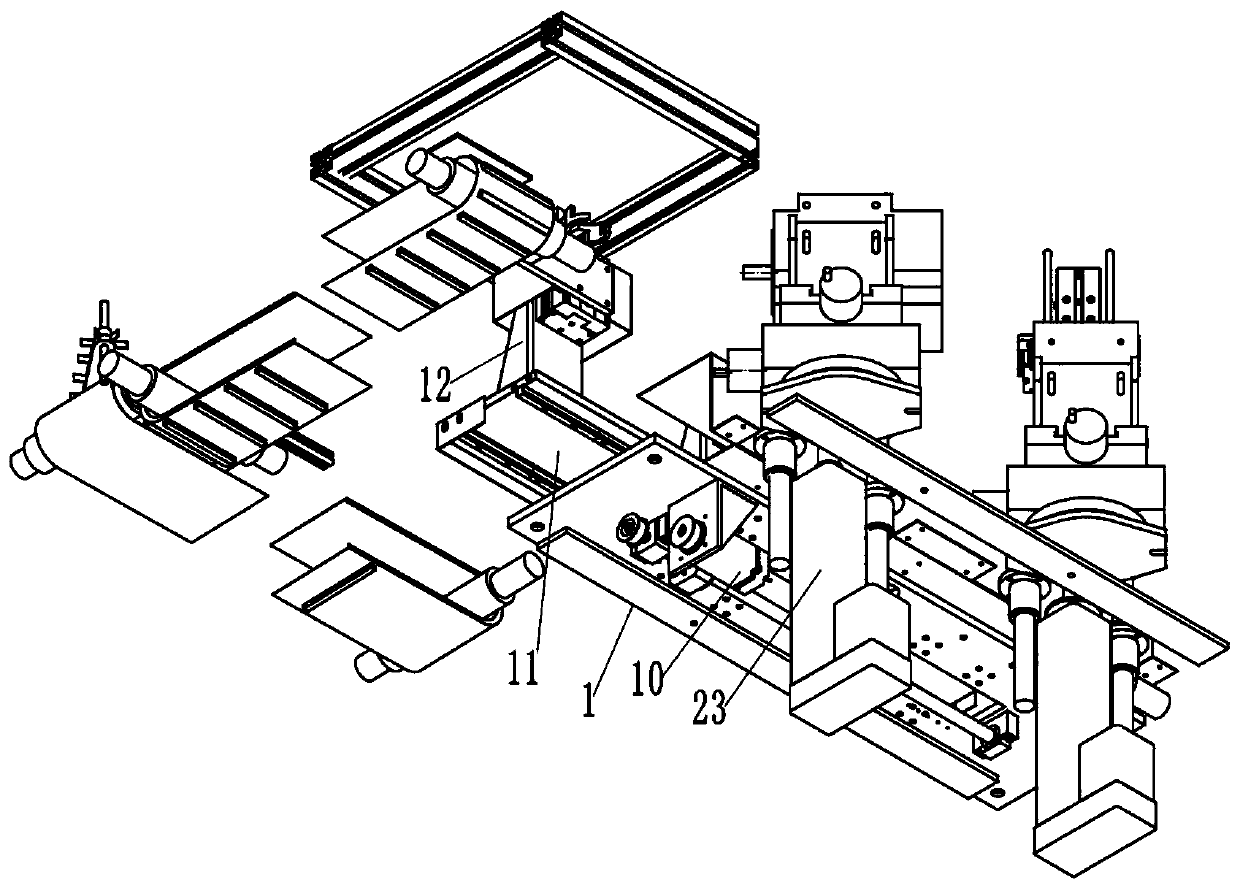

[0029] like Figure 1-8 As shown, the steel pipe processing method of the present embodiment, by means of a steel pipe processing system, includes a frame assembly 1, a feeding conveyor belt 2 arranged on the frame assembly 1, and an inclined connection between the input end and the output end of the feeding conveyor belt 2. Conveyor belt 3, an inclined side conveyor belt 5 arranged on one side of the output end of the feeding conveyor belt 2, an inclined side conveyor belt 5 arranged on the inclined side conveyor belt 5 and used for horizontally pulling out the steel pipe fittings on the feeding conveyor belt 2. The input end The input conveyor belt 6 connected to the output end of the inclined conveyor belt 3, the input cross arm 7 distributed on the input conveyor belt 6, the V-shaped centering block 8 arranged at the output end of the input cross arm 7 and used for centering the steel pipe fittings, is arranged on The first end surface processing device on one side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com