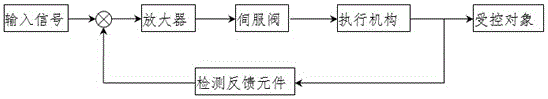

Patents

Literature

69results about How to "Guaranteed work pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

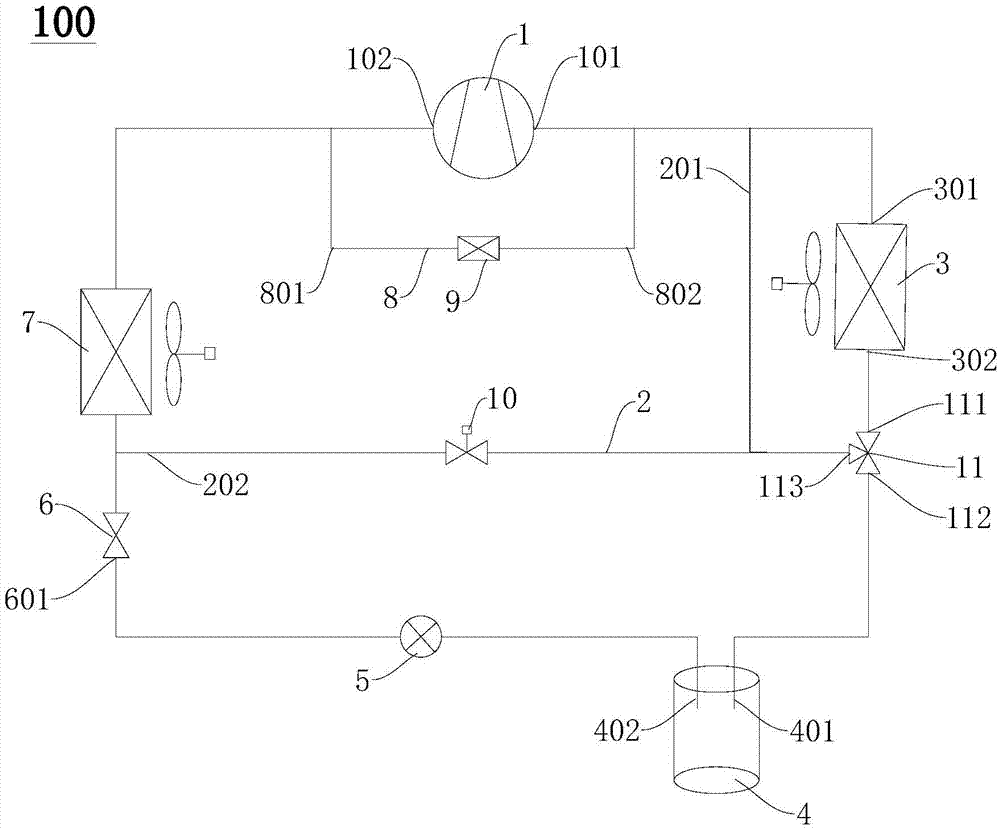

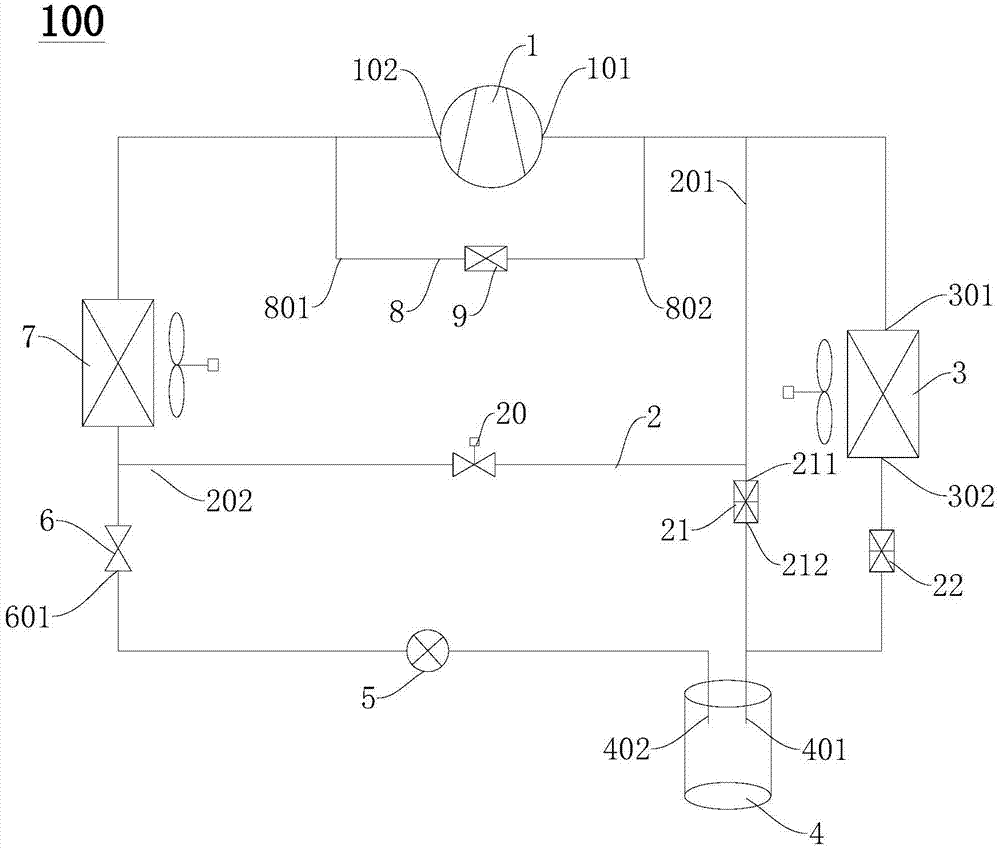

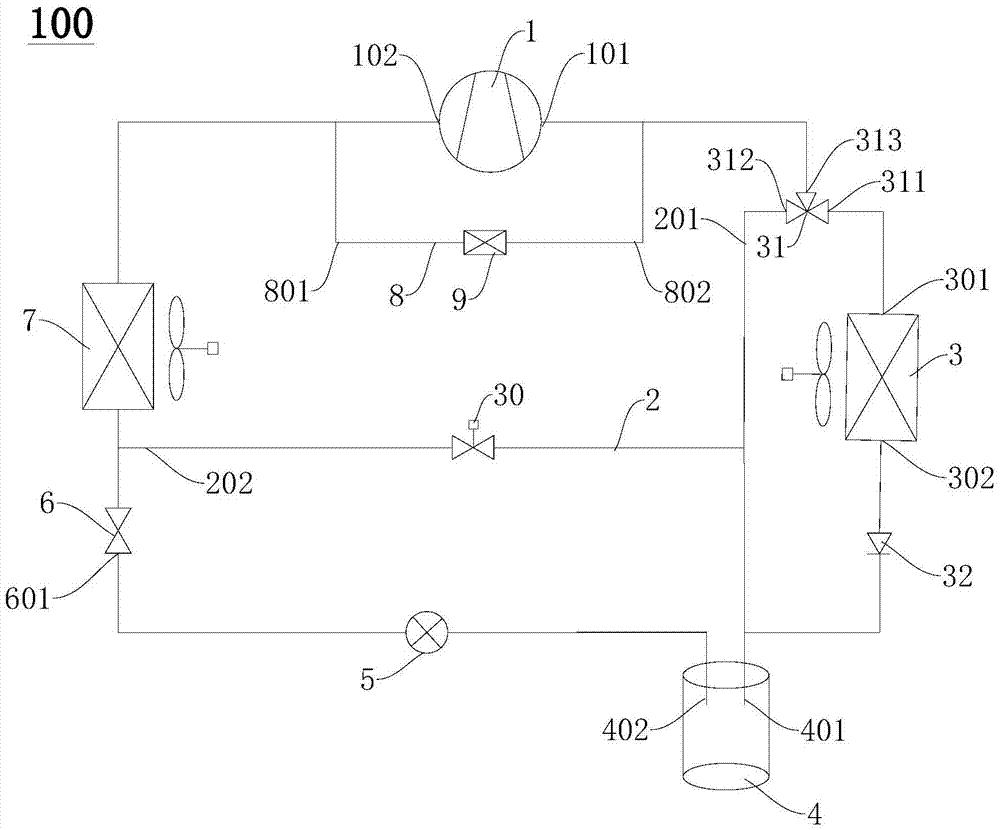

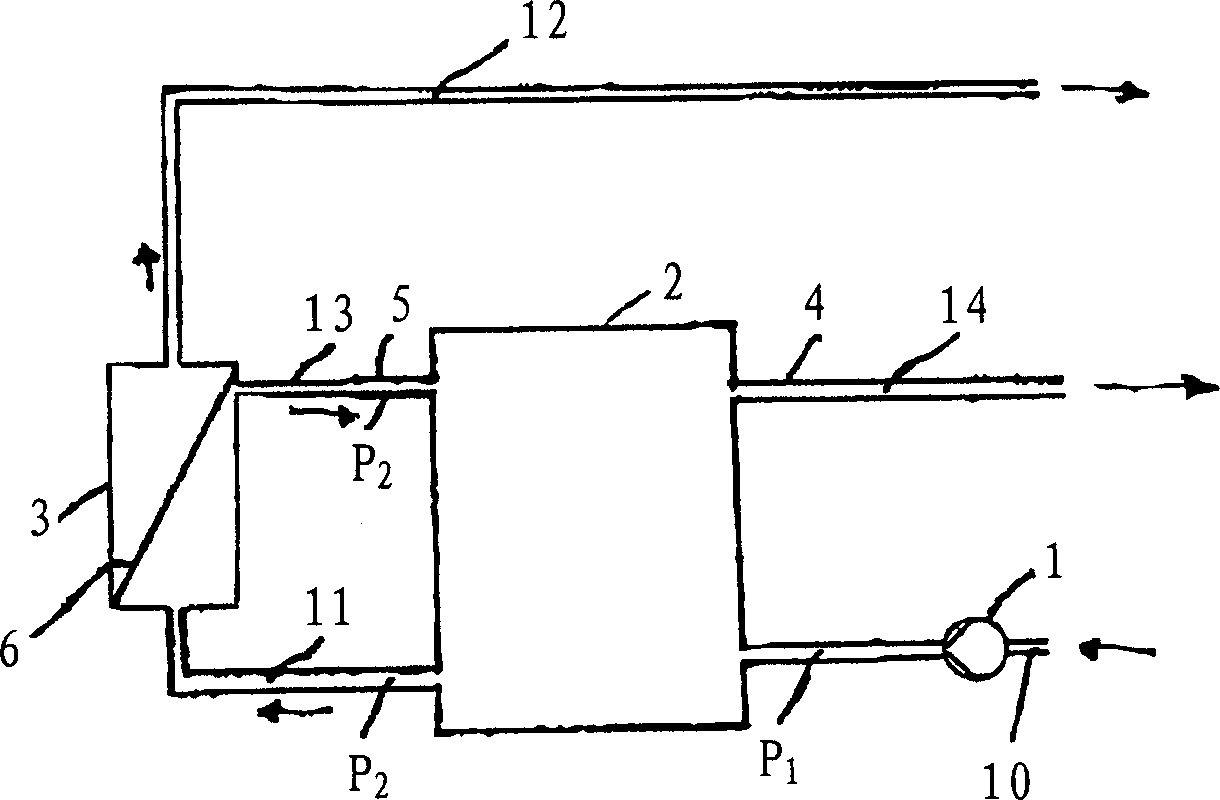

Refrigeration system and control method thereof

ActiveCN105444448AGuaranteed uptimeGuaranteed work pressureMechanical apparatusCompression machines with non-reversible cycleControl valvesRefrigeration

The invention discloses a refrigeration system and a control method thereof. The refrigeration system comprises a compressor, a condenser, a throttle device and an evaporator which are connected end to end in sequence to form a loop, a bypass loop and a control valve group, wherein a first end of the bypass loop is connected between an exhaust port of the compressor, and the condenser, and a second end of the bypass loop is connected between the throttle device and the evaporator; and the control valve group is used for controlling exhaust gas of the compressor to selectively flow through one of the bypass loop and the condenser. The refrigeration system disclosed by the invention can be preheated through the arranged bypass loop to normally start, and the exhaust gas of the compressor can be controlled to selectively flow through one of the bypass loop and the condenser through the control valve group according to an external environment temperature, thus the refrigeration system is enabled to start in a low-temperature environment, and run stably and reliably.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

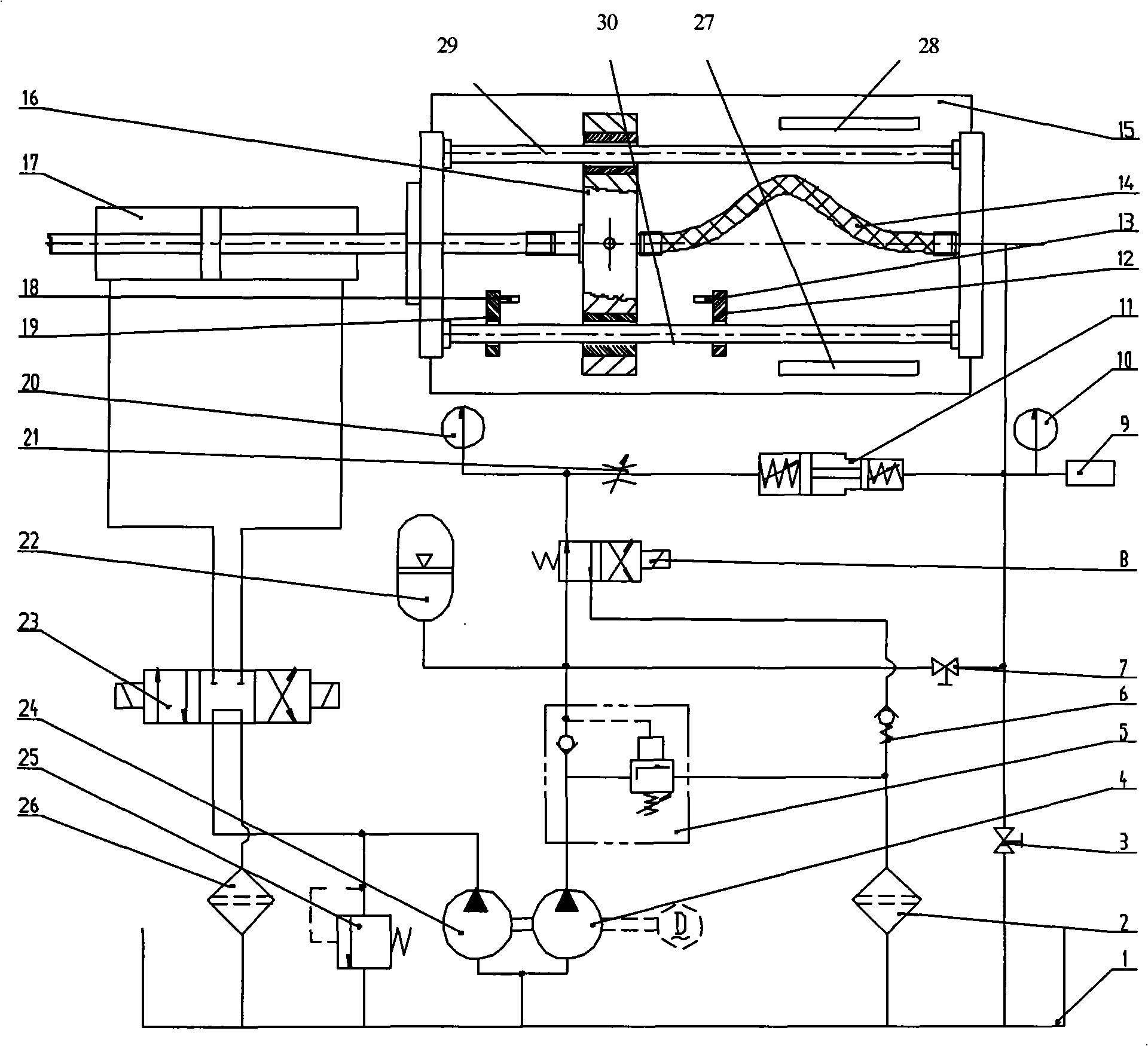

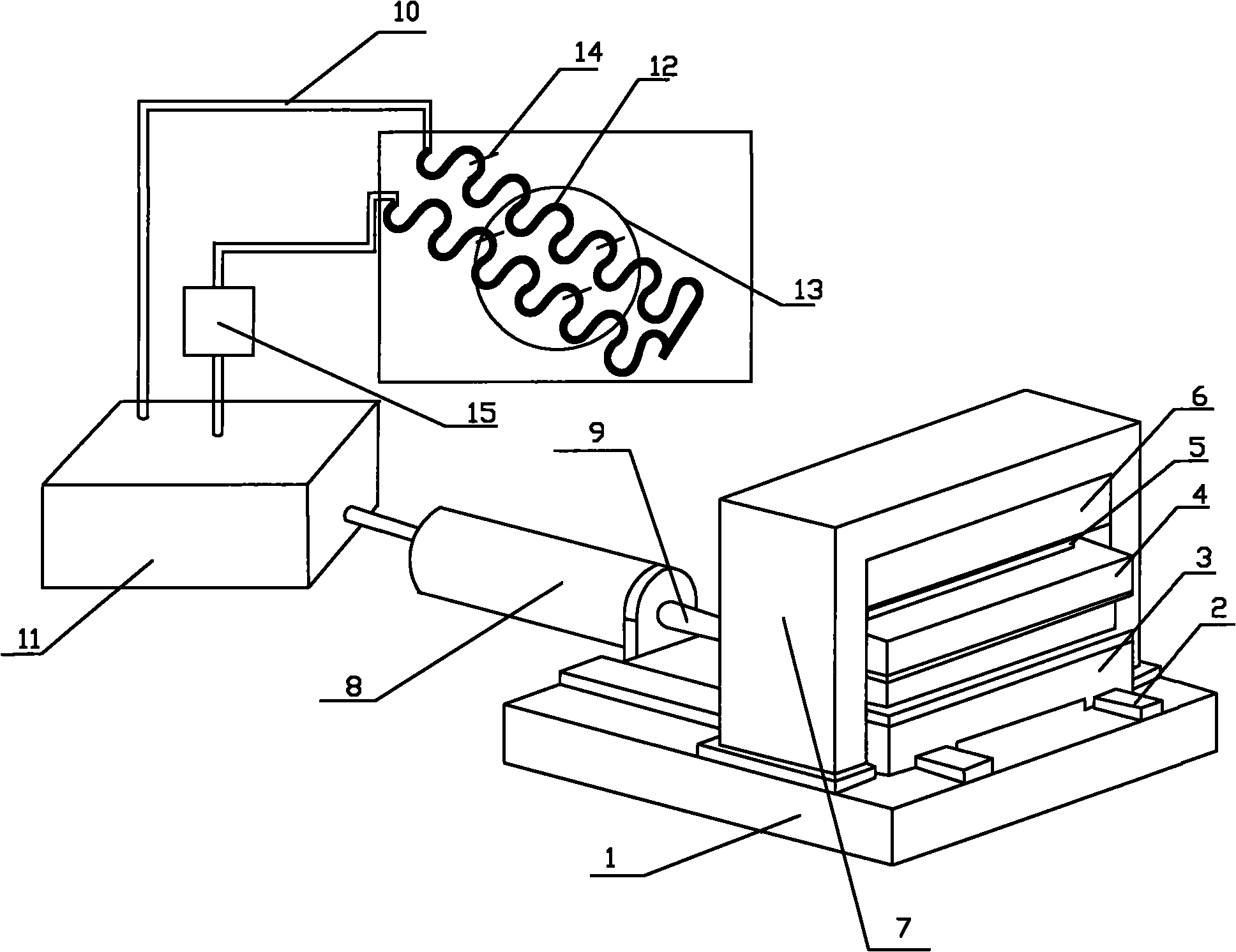

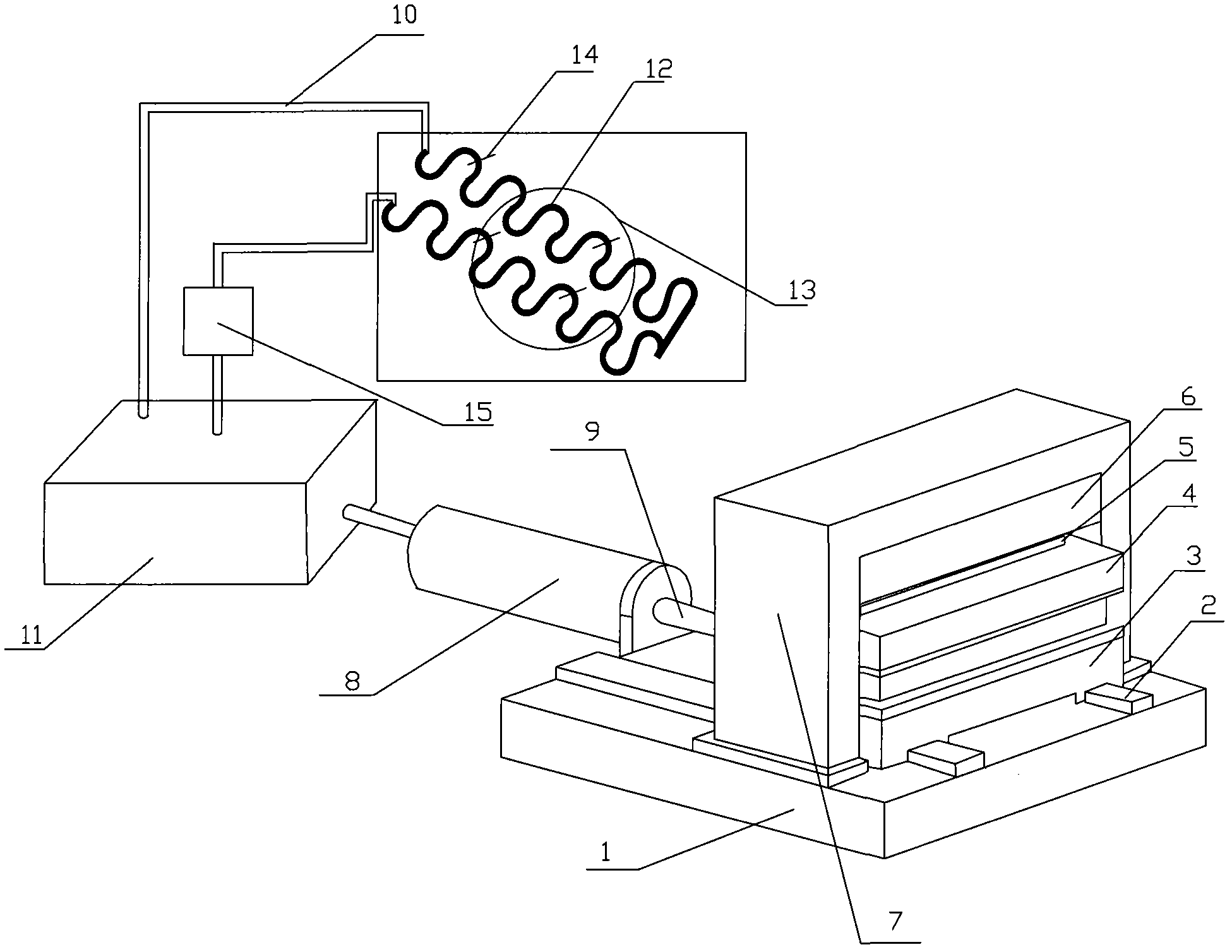

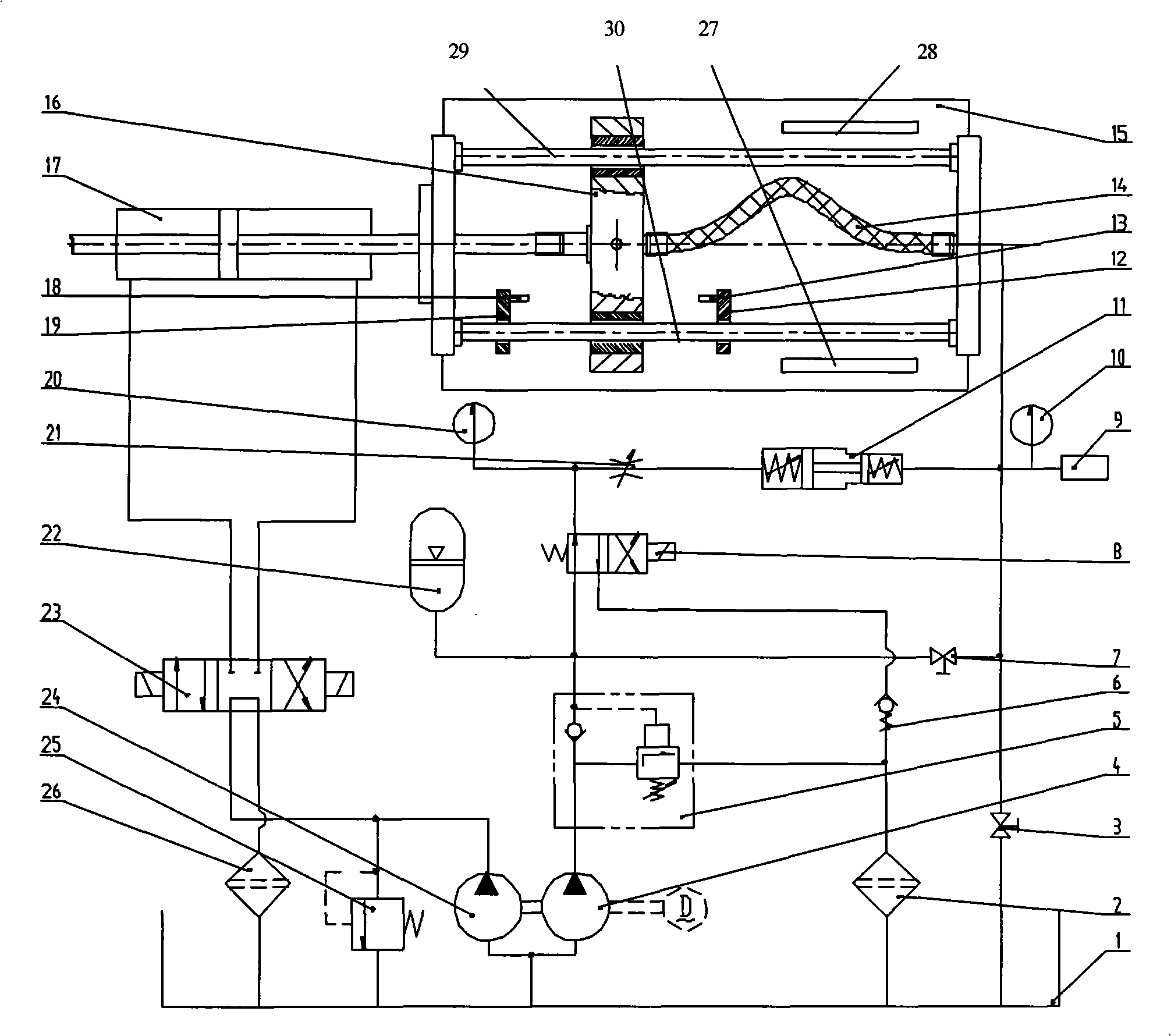

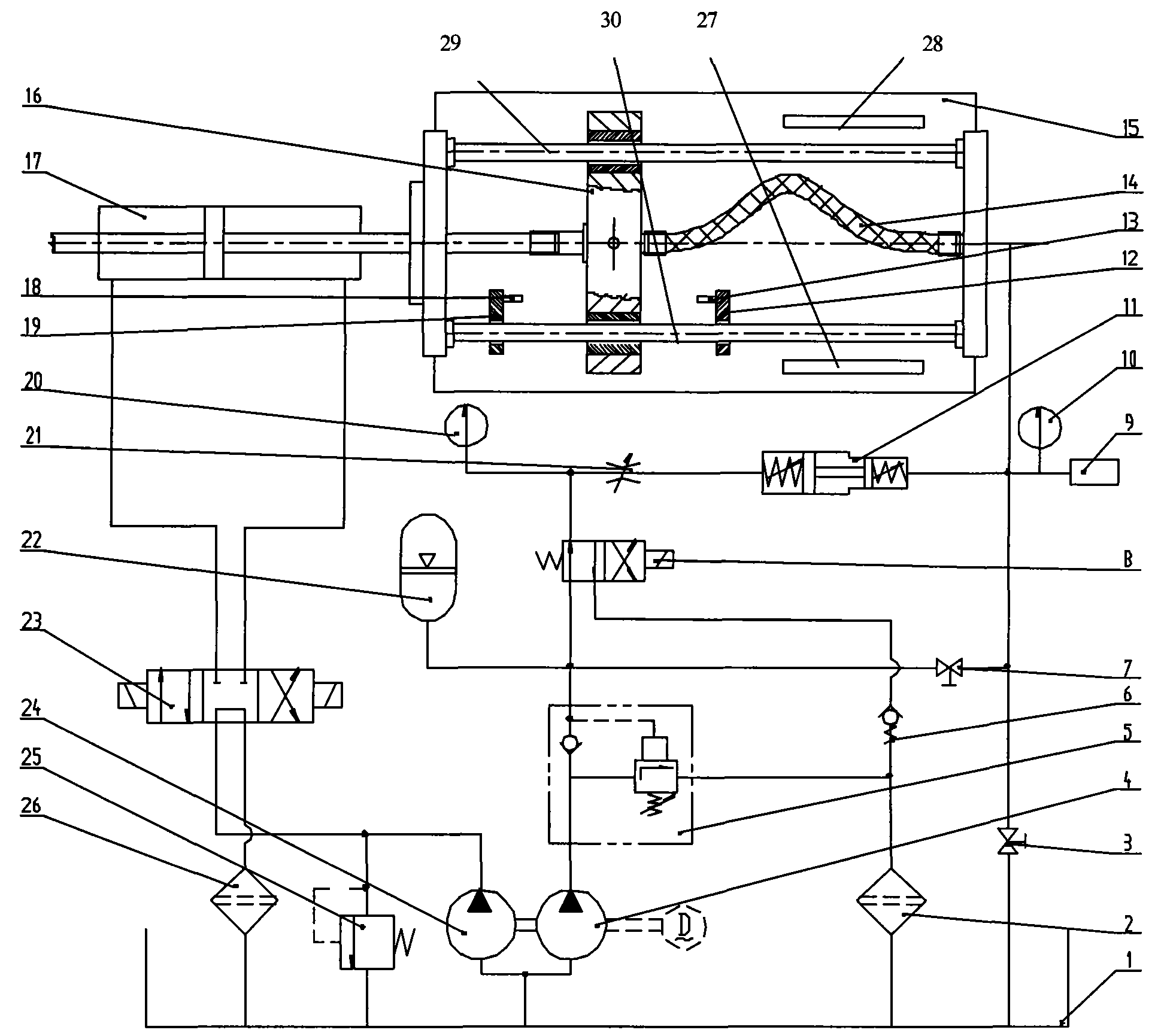

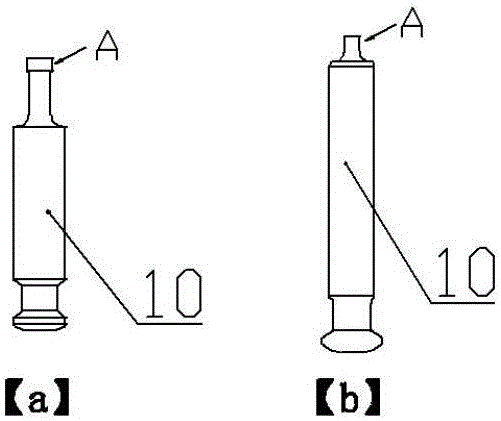

Hydraulic hose performance test experiment table

InactiveCN101672747AAdjustable bendGuaranteed temperature requirementsWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesHydraulic cylinderHydraulic pump

The invention relates to a hydraulic hose performance test experiment table mainly comprising an electric control system, an impact load system, a bending driving system of a hose to be tested, and anenvironmental simulator which are connected mutually, wherein the impact load system mainly comprises a hydraulic oil pump I, an unloading spillover valve, an accumulator, a two-position four-way magnet valve, a throttle , a pressure booster, a stop valve, a counterbalance valve, an oil return filter I, a pressure gauge, a pressure sensor, an oil tank, a connection oil pipe, a joint, and the like; the bending driving system of a hose to be tested mainly comprises a hydraulic oil pump II, a safety valve, an oil return filter II, a three-position four-way magnet valve, a hydraulic oil cylinder,a connection oil pipe, a joint, and the like; and the environmental simulator mainly comprises an environmental chamber body and an electric heater, an ultraviolet emitter and a bending degree controller of a hose to be tested, which are arranged in the environmental chamber body. The experiment table can test a plurality of hoses simultaneously, test the experimental pressure wave shape of the hoses to be tested on line and estimate the fatigue lifetime of the hoses to be tested; and the invention has simple structure, easy operation, little energy consumption and high reliability.

Owner:徐州沃土资产管理有限公司

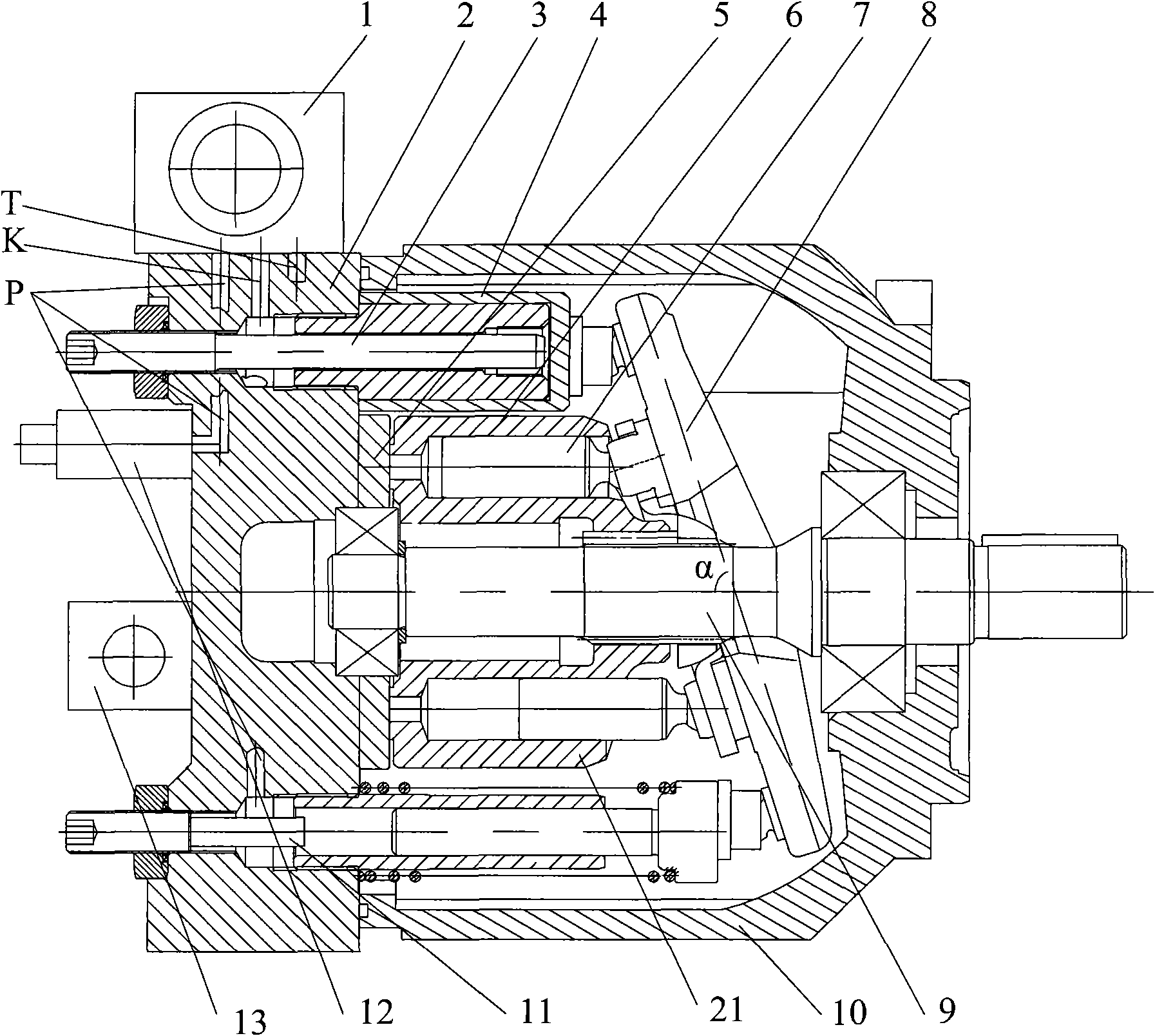

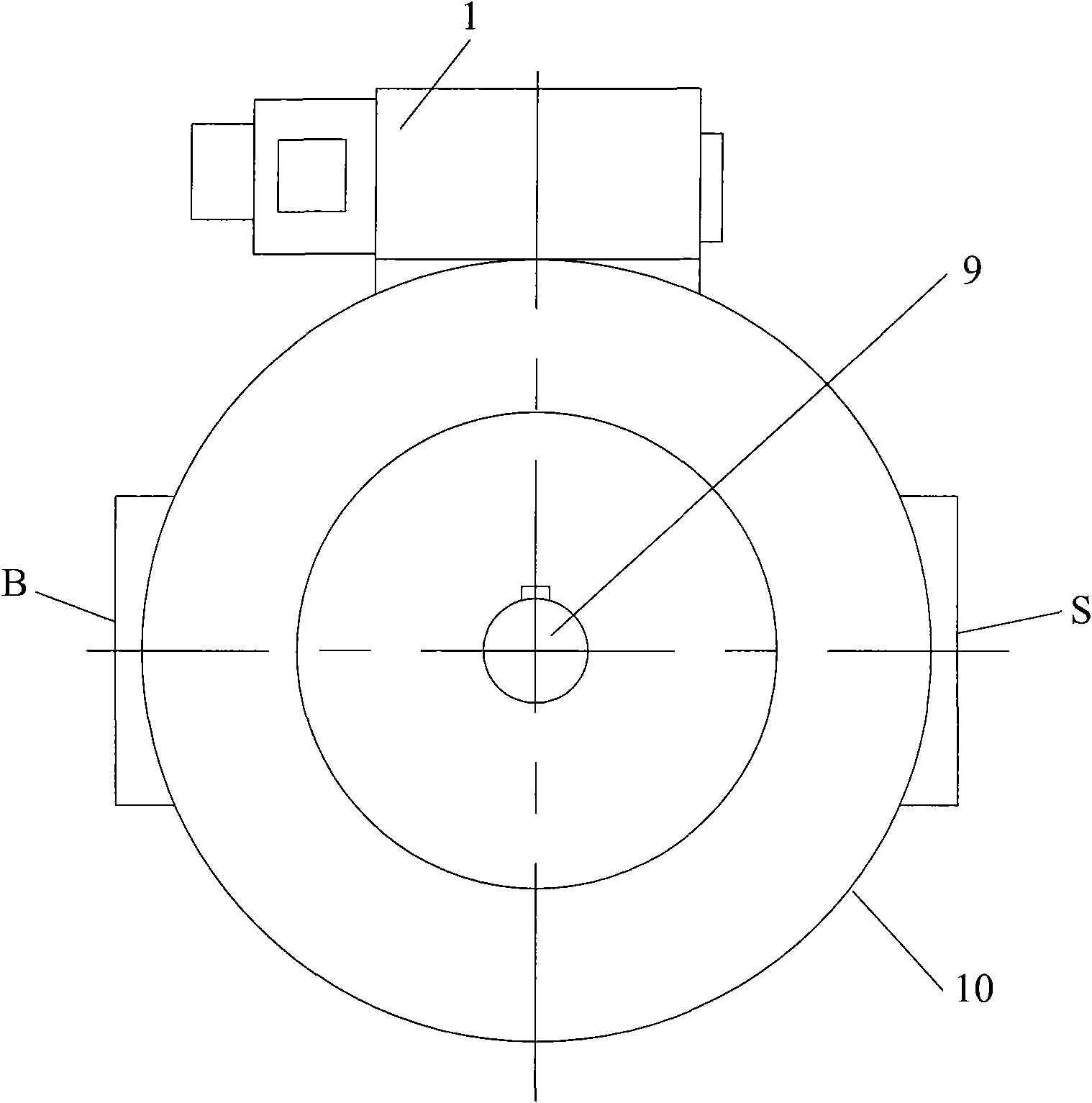

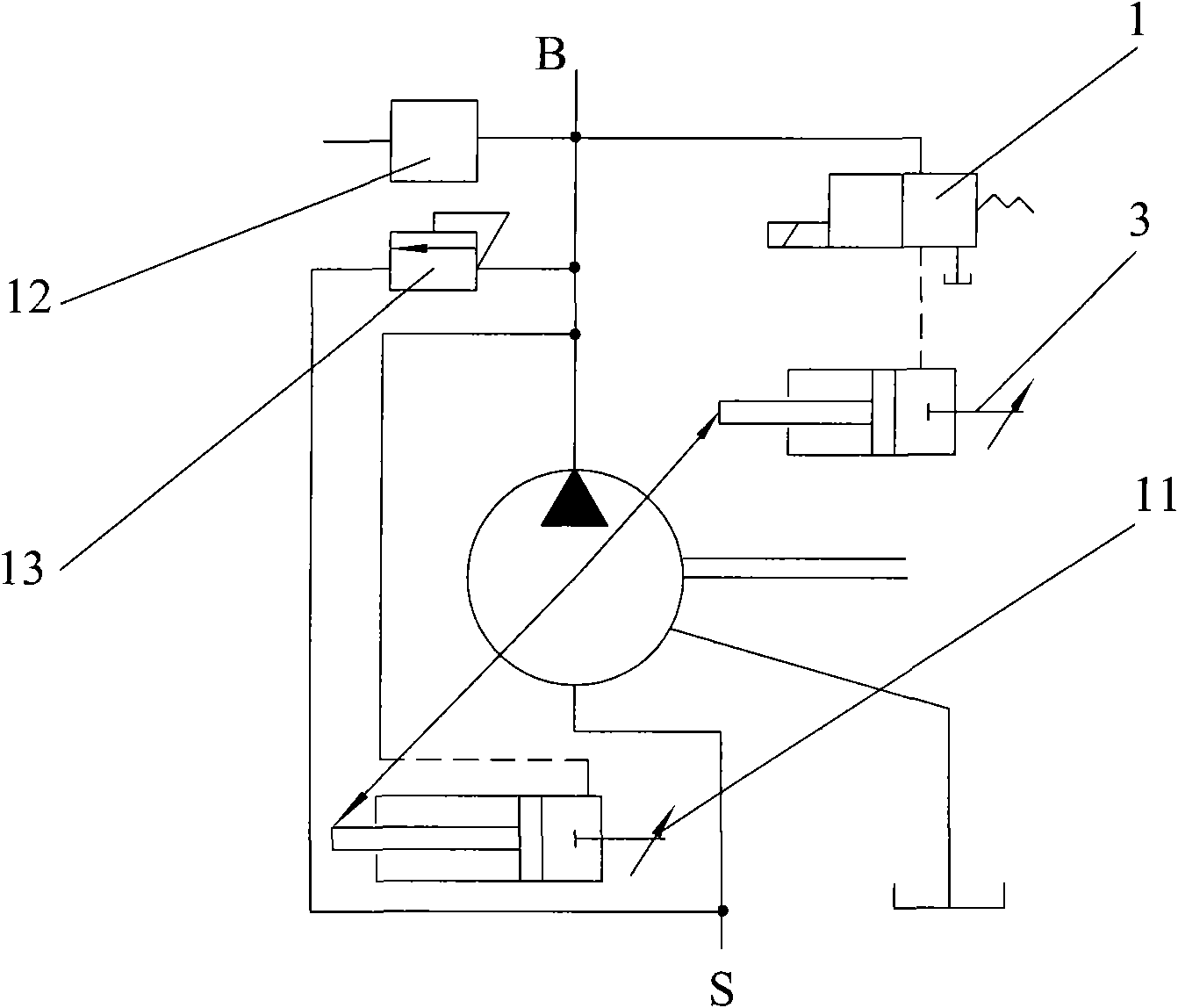

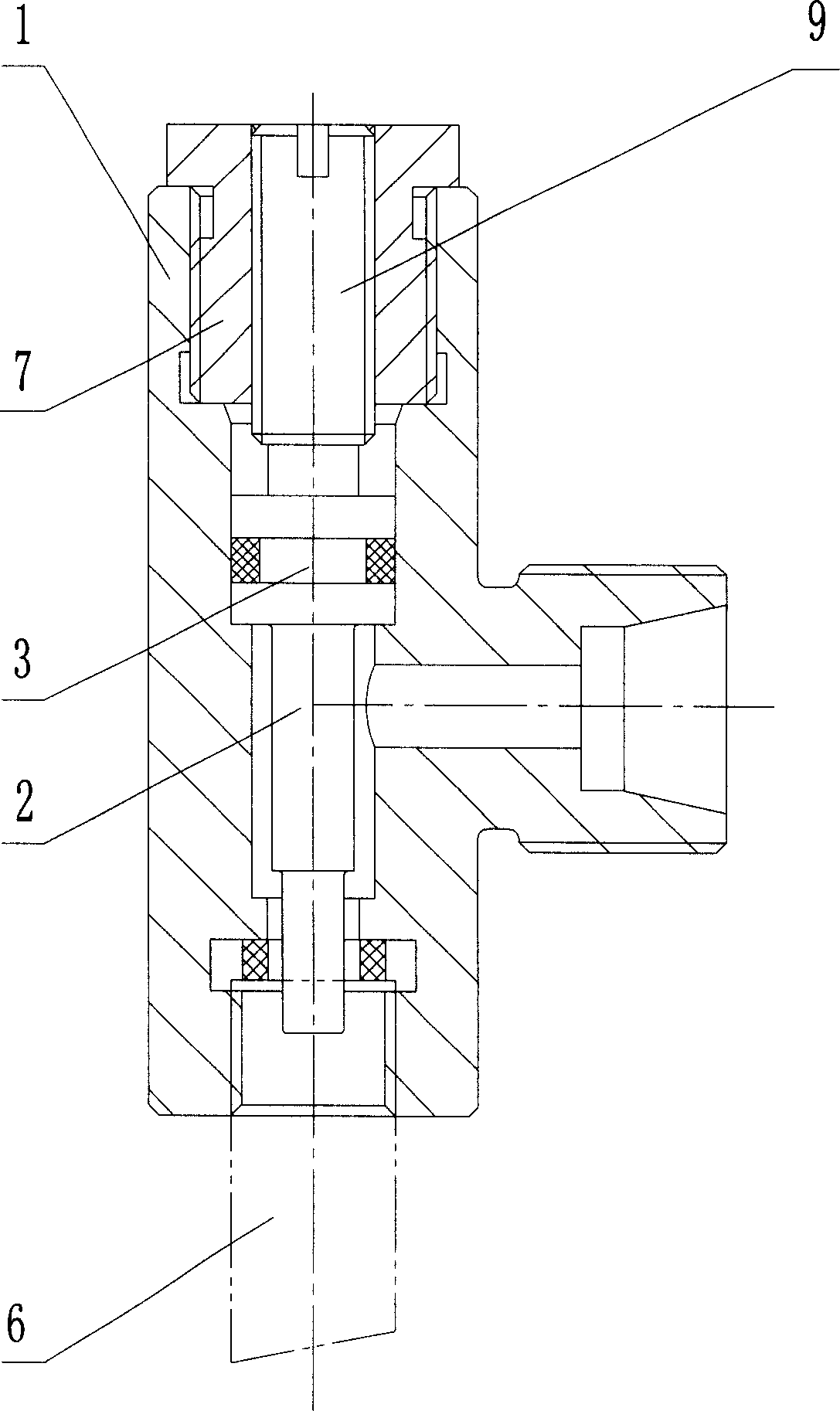

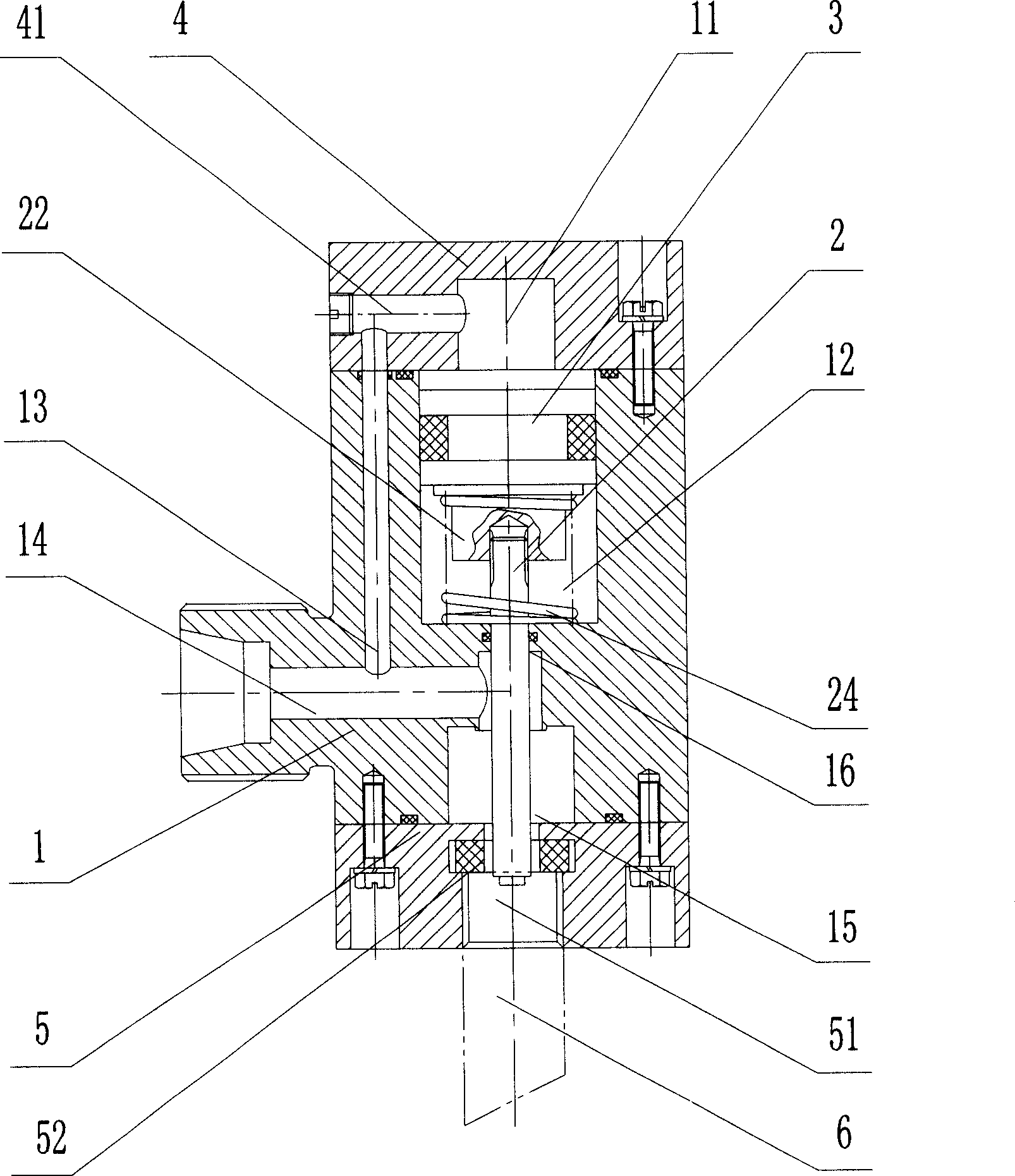

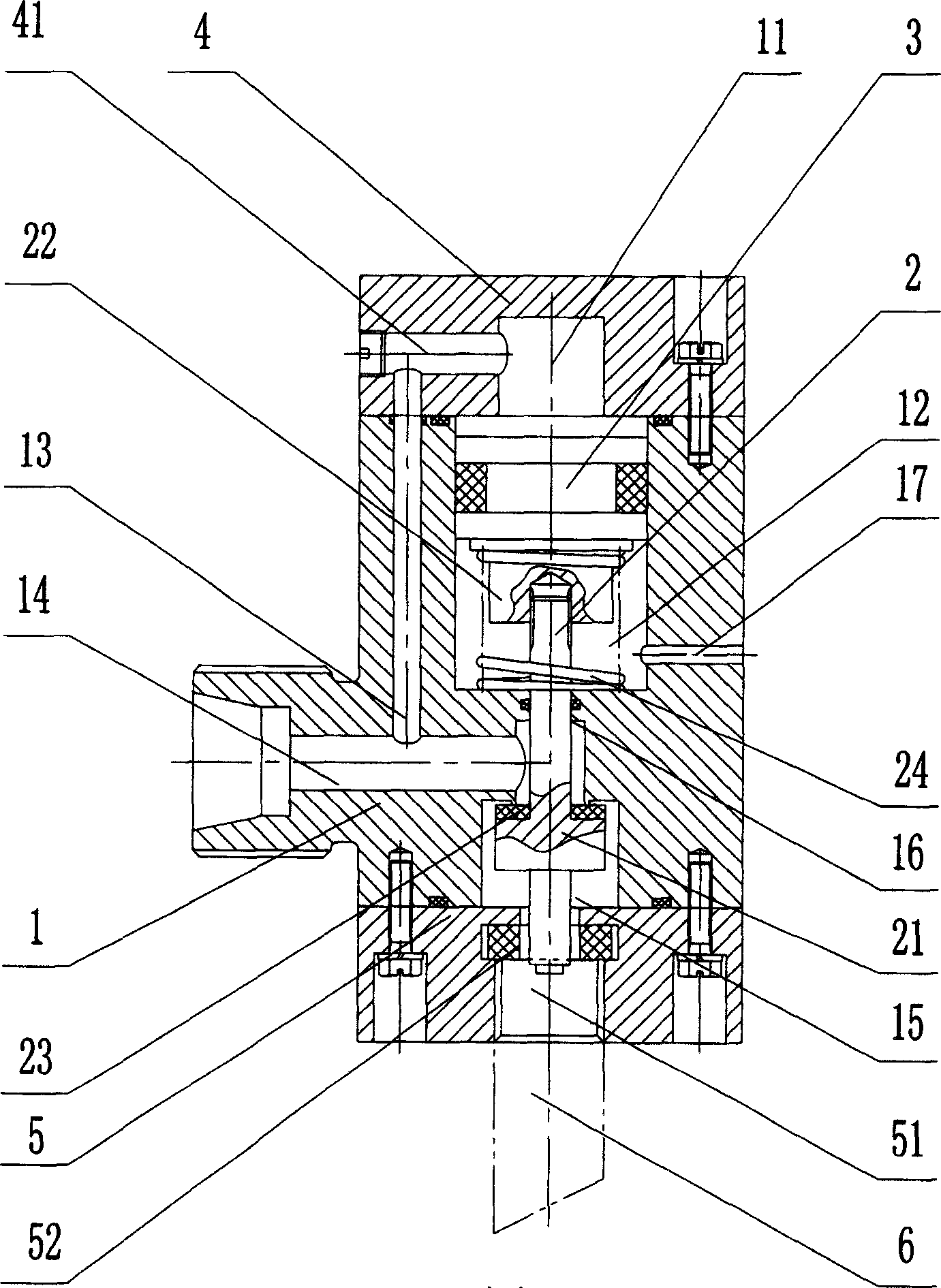

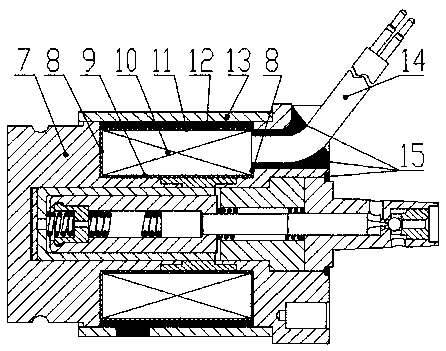

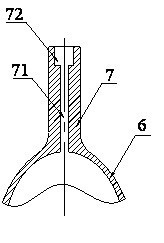

Plunger pump

InactiveCN101684783AQuick release pressureGuaranteed work pressurePositive-displacement liquid enginesMulti-cylinder pumpsElectricityDrive shaft

The invention discloses a plunger pump, which comprises a pump shell, a rear cover, an oil outlet, an oil inlet and an axial hydraulic plunger machine. The hydraulic plunger machine comprises a transmission shaft and a cylinder axially sleeved on the transmission shaft; one side of the cylinder is provided with nine cylinder holes; a plunger-skid shoe assembly is arranged in each cylinder hole; aswing component is movably pivoted to one side, exposed out of the cylinder hole, of the plunger-skid shoe assembly, and an oil distribution disc is fixedly arranged on the other side of the cylinder;the rear cover is parallel to the transmission shaft, and a small-displacement regulating device and a large-displacement regulating device are arranged on the rear cover and the transmission shaft symmetrically in equal distance; the small-displacement regulating device and the large-displacement regulating device penetrate the rear cover into the pump shell to be separately connected with the end margin of a swing component and flexibly adjust an included angle between the swing component and the transmission shaft through a control cylinder component; and the rear cover is also provided with an electric-hydraulic valve electrically connected with the large-displacement regulating device and a safety pressure valve. Therefore, the plunger pump has the characteristics of small vibration,stable pressure, energy saving, improvement on production efficiency, low cost and long service life.

Owner:HIGH TECH FLUID POWER CO LTD

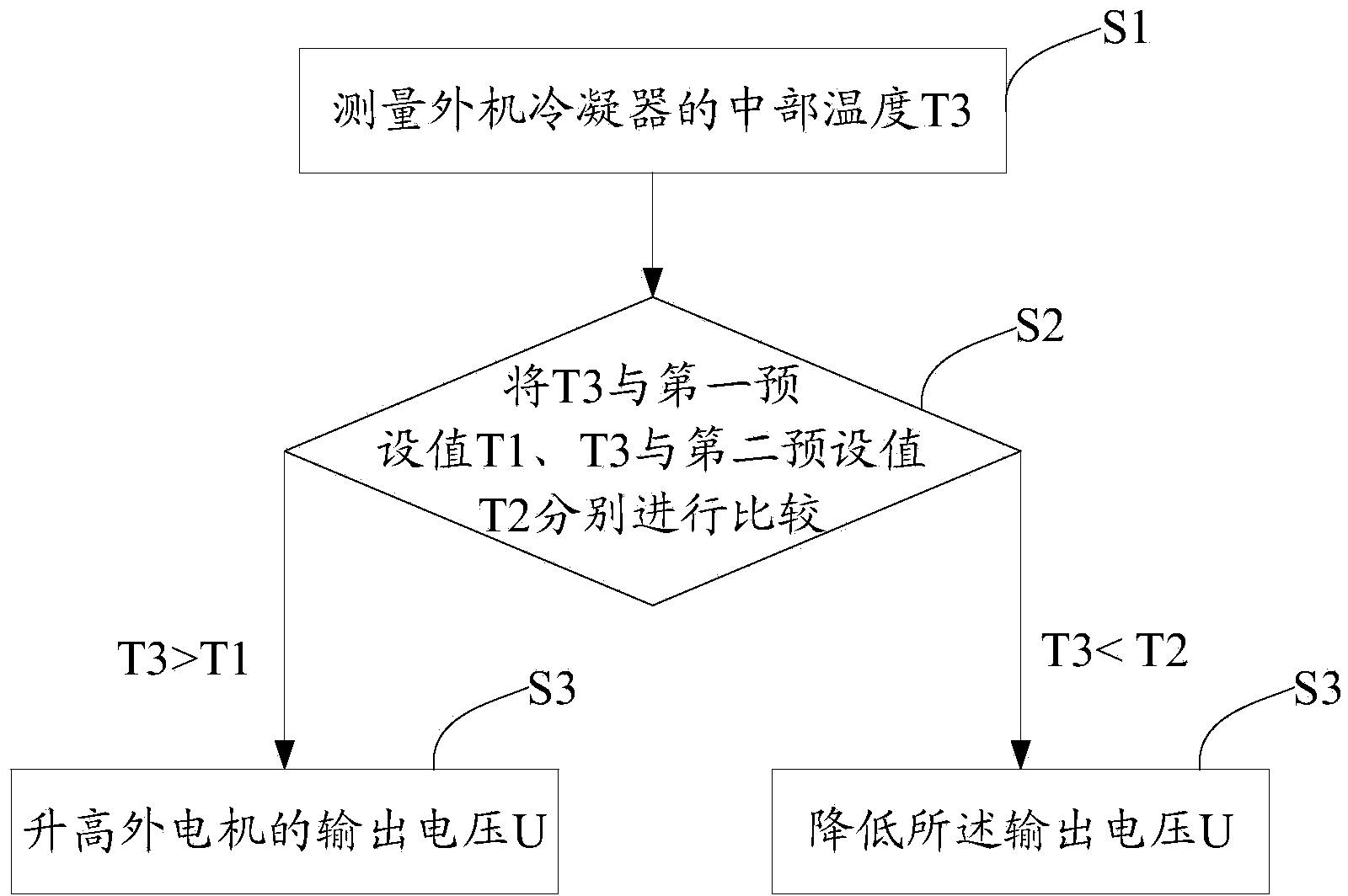

Method for controlling low temperature refrigeration of air conditioner

ActiveCN103411292AIncrease speedReduce speedSpace heating and ventilation safety systemsLighting and heating apparatusElectric machineWorking pressure

The invention provides a method for controlling low temperature refrigeration of an air conditioner. The method comprises the following steps: (1) measuring middle temperature T3 of an outer unit condenser; (2) comparing T3 with first preset values T1 and T3 and a second preset value T2 respectively, wherein T1 is greater than T2; (3) when T3 is greater than T1, raising output voltage U of an external motor so as to increase the rotating speed of an external fan; when T3 is smaller than T2, decreasing the U so as to reduce the rotating speed of the external fan. According to the method for controlling the low temperature refrigeration of the air conditioner, the output voltage U of the external motor is adjusted according to the middle temperature T3 of the condenser so as to adjust the rotating speed of the external fan, and then the T3 is stabilized in a range of T2 to T1. The T3 can reflect the system operation pressure of the air conditioner better, thus the T3 stabilized in the certain range can ensure the working pressure of the condenser, thus the system operation pressure is controlled better; therefore, stable operation of the system is ensured during the low temperature refrigeration of the air conditioner, thus the start and stop times of a compressor are reduced, and the comfort of room is improved.

Owner:GUANGDONG CHIGO HEATING & VENTILATION EQUIP CO LTD

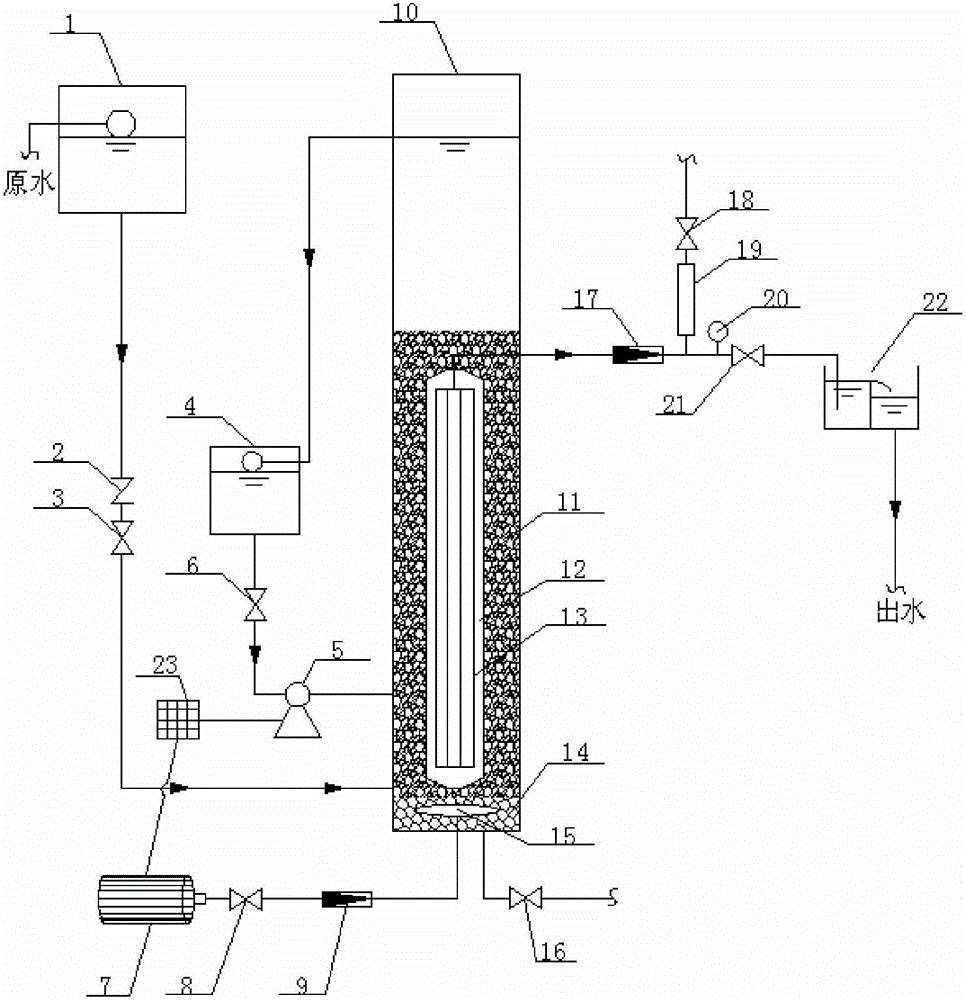

Filler/ultrafiltration membrane integrated water purifying device and application method thereof

ActiveCN105712589AAvoid wastingGuaranteed work pressureWater treatment parameter controlSpecific water treatment objectivesUltrafiltrationWater quality

The invention relates to a filler / ultrafiltration membrane integrated water purifying device and an application method thereof and belongs to the technical field of drinking water treatment. The filler / ultrafiltration membrane integrated water purifying device can be used for solving the problems that an existing ultrafiltration water purifying device and an application method thereof are high in working pressure, high in energy consumption, high in operating cost, complex in operation management, high in operation technical requirements and poor in effluent quality. The filler / ultrafiltration membrane integrated water purifying device comprises a constant-level raw water tank, a lift water tank, a lift water pump, an air pump, a gas flowmeter, an ultrafiltration membrane tank, filler, a perforation isolation cover, an ultrafiltration membrane component, a supporting layer, an aeration device, an air exhausting device and an overflow weir. The filler / ultrafiltration membrane integrated water purifying device is characterized in that the filler and the ultrafiltration membrane component are arranged in one system, a low-pressure low-energy-consumption medicament-free filler / ultrafiltration membrane component integrated water purifying device is constructed, a dual water purification effect is achieved, the working pressure is low, and hydraulic cleaning and chemical cleaning are not required, so that the filler / ultrafiltration membrane integrated water purifying device has the advantages of good effluent quality, stable water yield, small occupied area, low working pressure, low operating cost, simple operation management, small maintenance load, low requirements on operation technological level of workers and the like.

Owner:NAT ENG RES CENT OF URBAN WATER RESOURCE

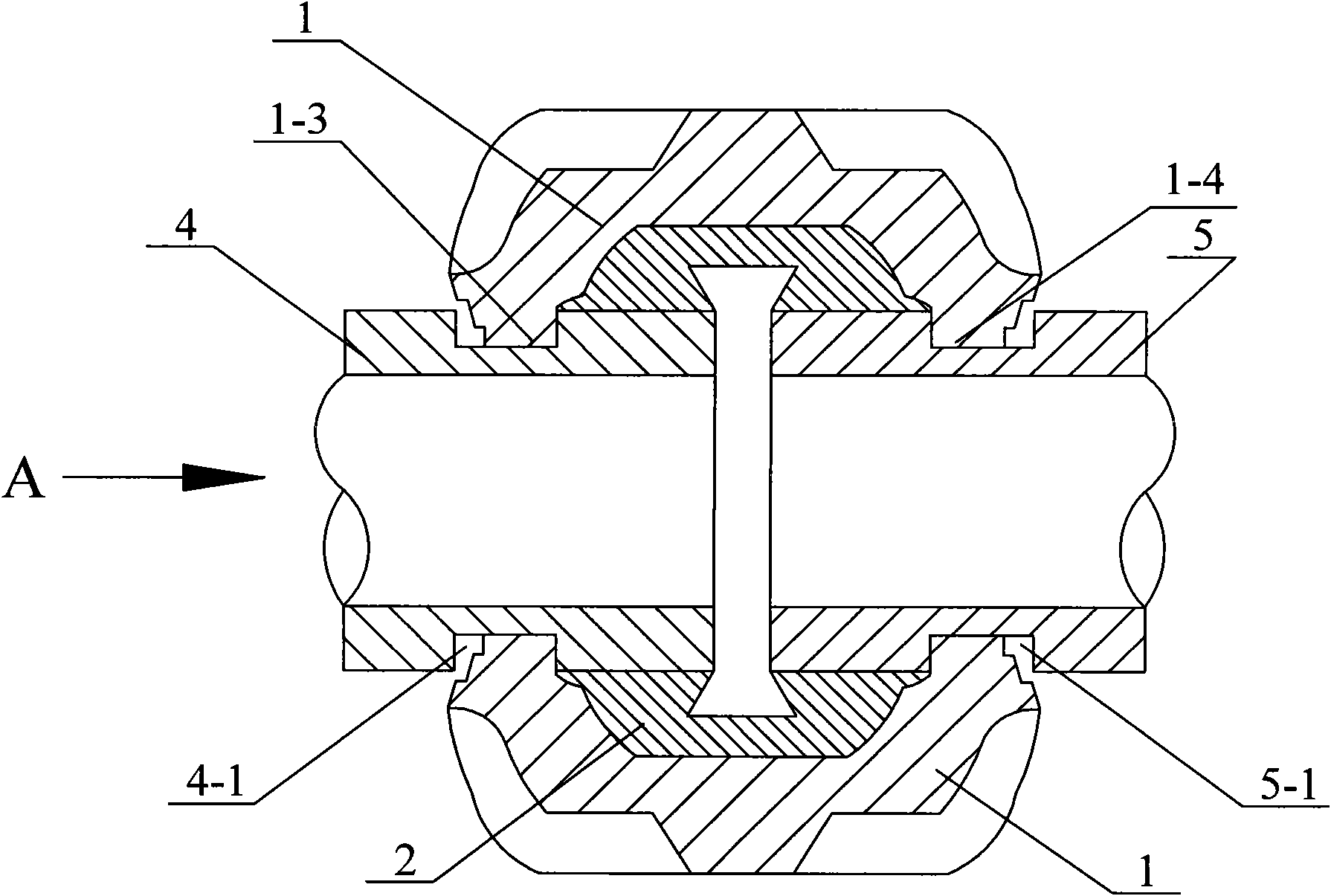

Groove clamping hoop type pipeline joint

The invention discloses a groove clamping hoop type pipeline joint in the technical field of pipe joints. When used for connecting pipe fittings, the groove clamping hoop type pipeline joint has the advantages of quickness, simplicity and convenience, reliability, safety, economy, vibration isolation, no pollution and convenient maintenance. The groove clamping hoop type pipeline joint comprises two semicircle arciform clamping hoops, and two ends of each semicircle arciform clamping hoop are provided with a fastening bolt connecting lug protruding outwards respectively; the lower edges along the two lateral faces of the semicircle arciform clamping hoops are provided with flanges extending downwards respectively; a groove is arranged between the two flanges, and the two semicircle arciform clamping hoops are jogged with each other to form a seal washer mounting groove; a seal washer can be mounted in the seal washer mounting groove in a matching mode; and two fastening pieces are used for fastening tightly the lugs of the two semicircle arciform clamping hoops.

Owner:JIANGSU JIANGDU CONSTR GRP

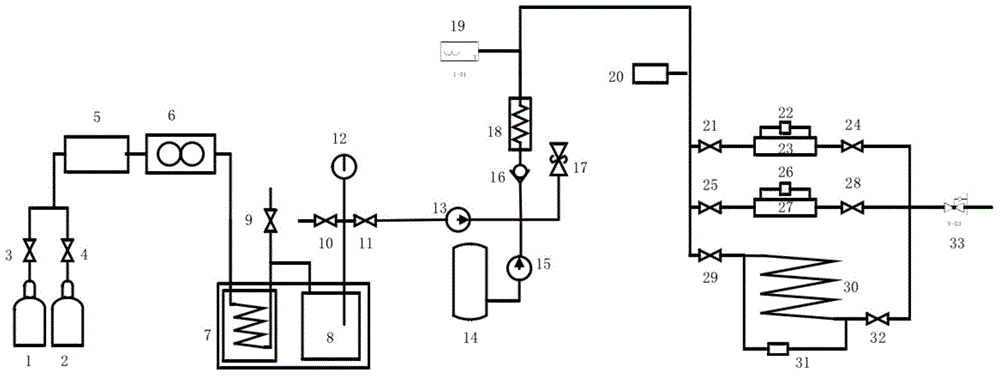

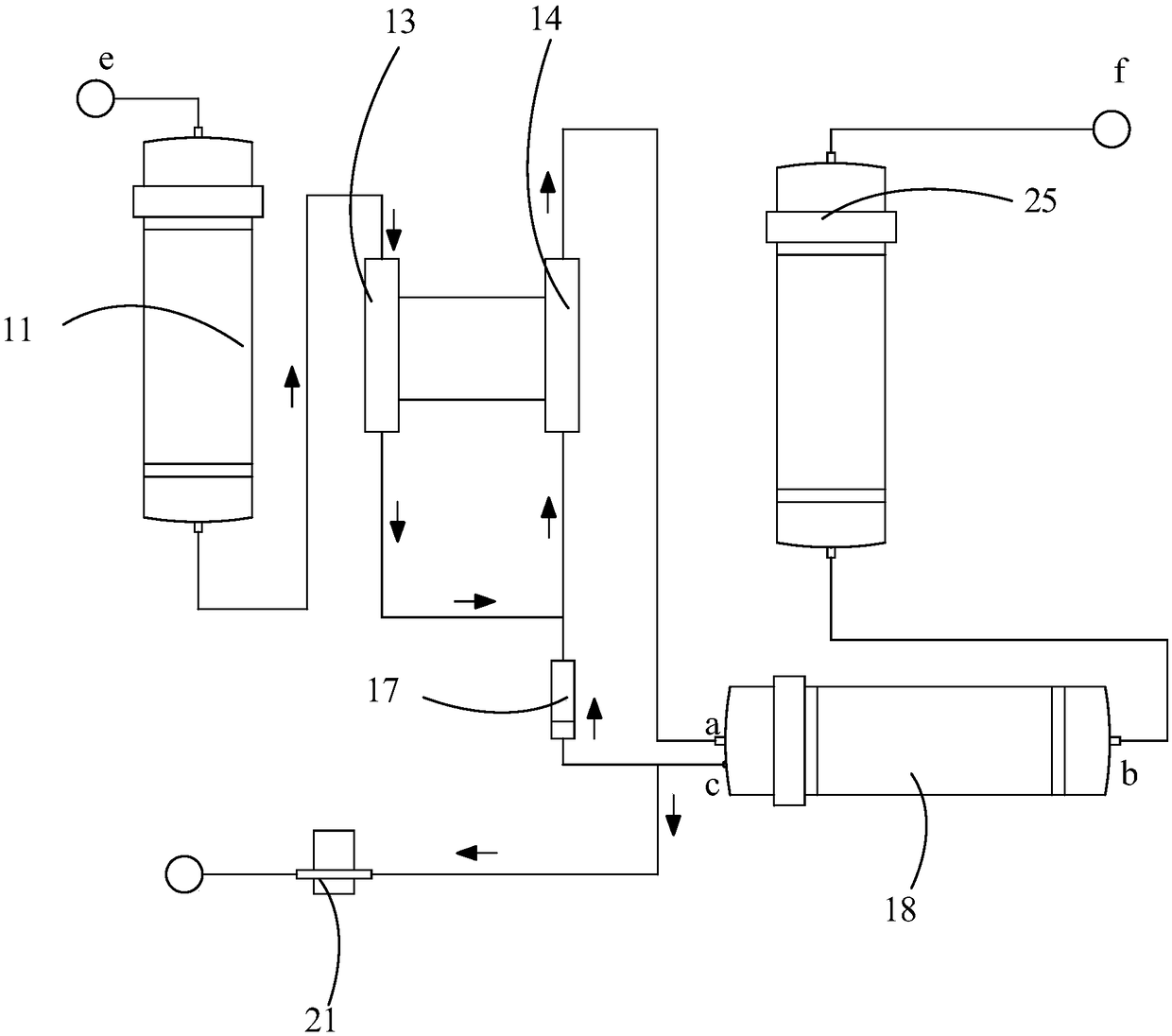

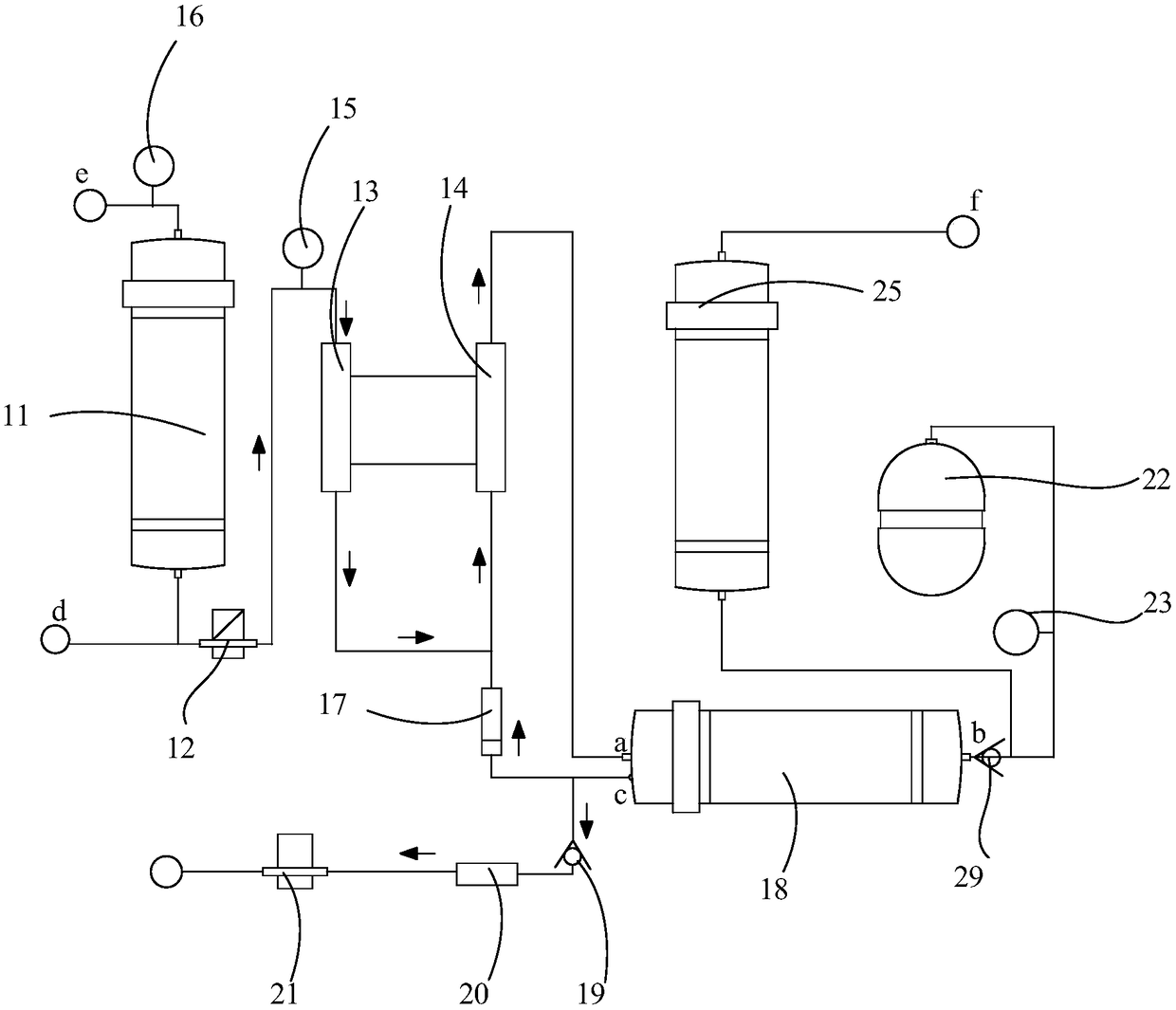

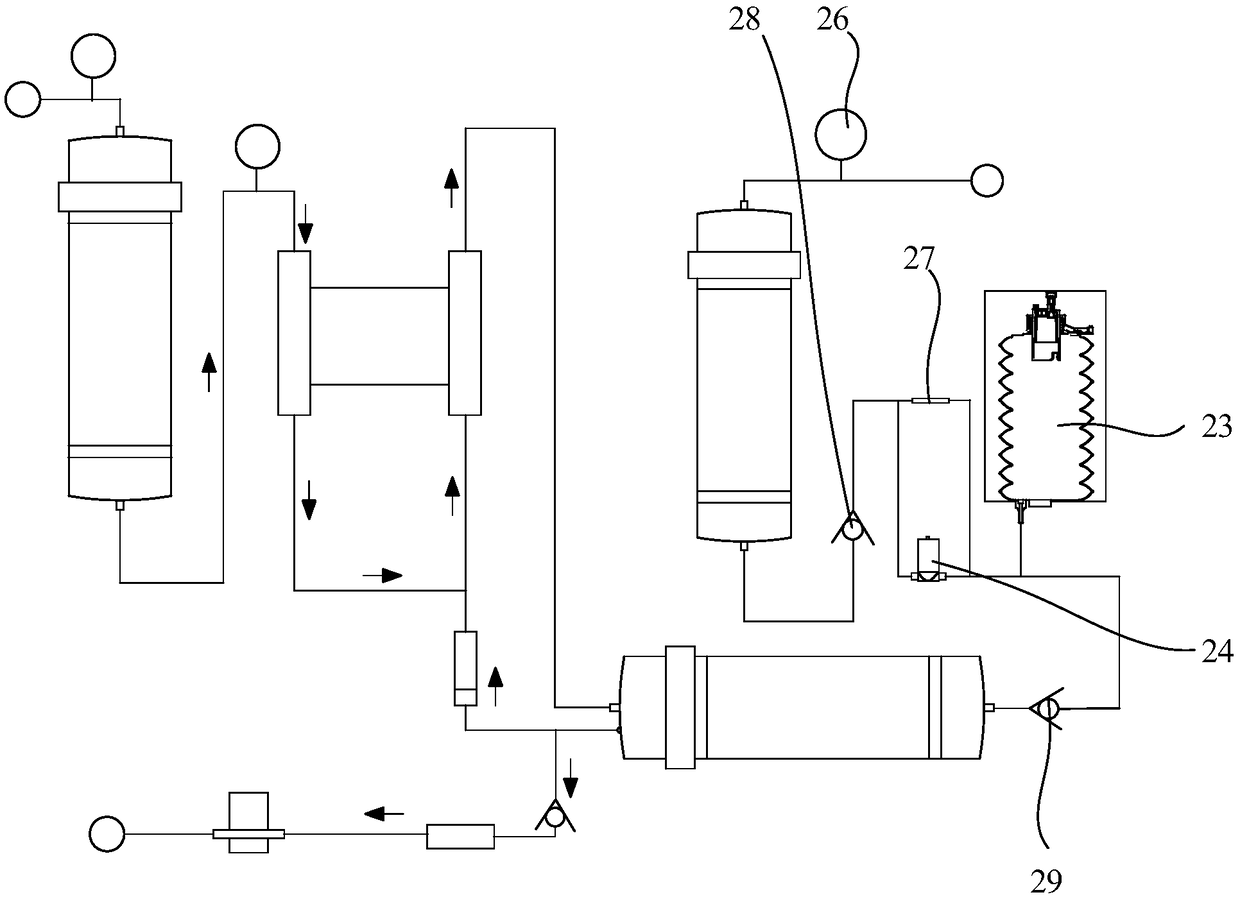

System for testing friction resistance of carbon dioxide anhydrous fracturing fluid

InactiveCN104880386AControl ratioTemperature controlFlow propertiesDifferential pressureFracturing fluid

The invention provides a system for testing the friction resistance of a carbon dioxide anhydrous fracturing fluid, and specifically provides a device for especially testing the friction resistance of the carbon dioxide anhydrous fracturing fluid at different temperatures and under different pressures. The system is also applicable to testing the rheological properties of a carbon dioxide dry fracturing fluid at different temperatures and under different pressures; firstly, the CO2 gas is refrigerated and liquefied; next, the liquefied CO2 is injected into a pipeline by use of a CO2 pump under a high pressure and mixed with a reagent injected by use of a reagent pump to form the carbon dioxide anhydrous fracturing fluid; the frequency and the proportion can be adjusted according to requirements, and meanwhile, the fracturing fluid in the pipeline can be heated to a desired temperature by use of a preheater and then discharged via a thin straight pipe or a thick straight pipe or a coiled pipe selected flexibly by use of a valve; the pressure of the pipeline system is adjusted by use of a back pressure valve; a recovery treatment device is connected to the outlet of the pipeline; meanwhile, the pressure difference between the two ends of the straight pipe or the coiled pipe is measured by use of a differential pressure sensor, and the differential pressure value is the friction resistance value to be measured; in addition, the rheological properties are measured according to a thin-tube pheometer principle.

Owner:HUANENG CLEAN ENERGY RES INST +1

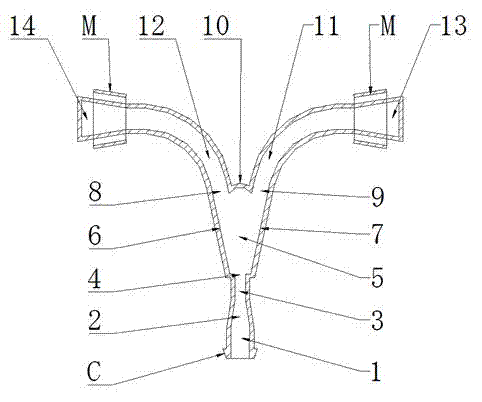

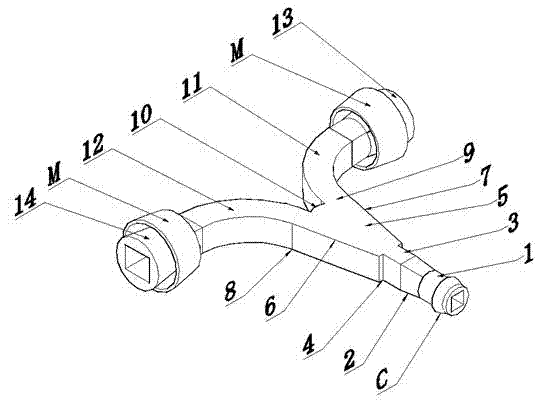

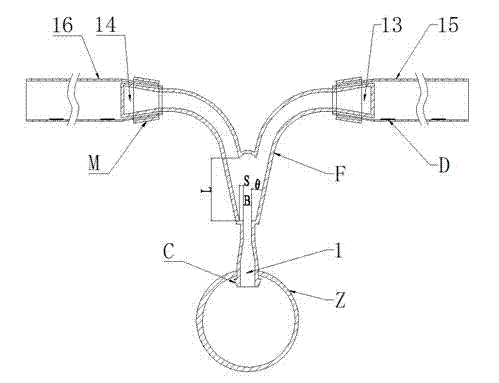

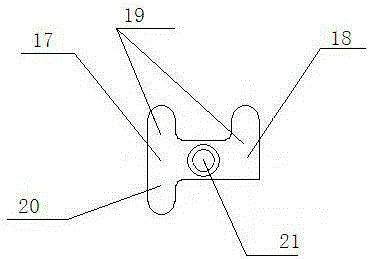

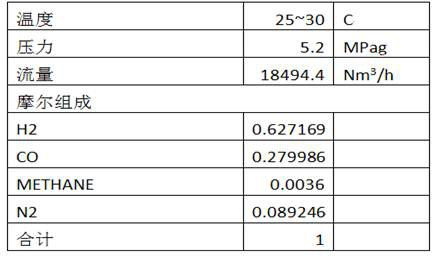

Jet tee joint

InactiveCN103203293AGuaranteed work pressureImprove anti-clogging performanceWatering devicesSpray nozzlesFeedback effectWater flow

The invention discloses a jet tee joint for micro-irrigation. The jet tee joint comprises an inlet section, a jet element and two outlet sections. When the jet tee joint is applied to a micro-irrigation system, the inlet section is connected with a branch tube, the jet element is positioned between the inlet section and the outlet sections, each of the two outlet sections is connected with a capillary tube, water flow passes the inlet section via the branch tube to enter the jet element so as to generate jet wall attachment effect, and under the feedback effect of water pressure load in the capillary tubes, wall-attached water flow generates intermittent deflection to enable the water flow to flow in the two capillary tubes alternately according to certain frequency, pulse water flow is formed in the capillary tubes and then enters an irrigation emitter, and strong turbulent and impacting water flow is formed in the irrigation emitter so as to improve anti-clogging capacity and irrigation uniformity of the irrigation emitter. The jet tee joint has the advantages of simple structure, reliability and high durability, can be formed by one-step injection molding, and is simple in machining process, low in manufacturing cost, convenient to mount and use, and applicable to various micro-irrigation systems for field crops, vegetables, forestry and fruit industry and the like.

Owner:JIANGSU UNIV

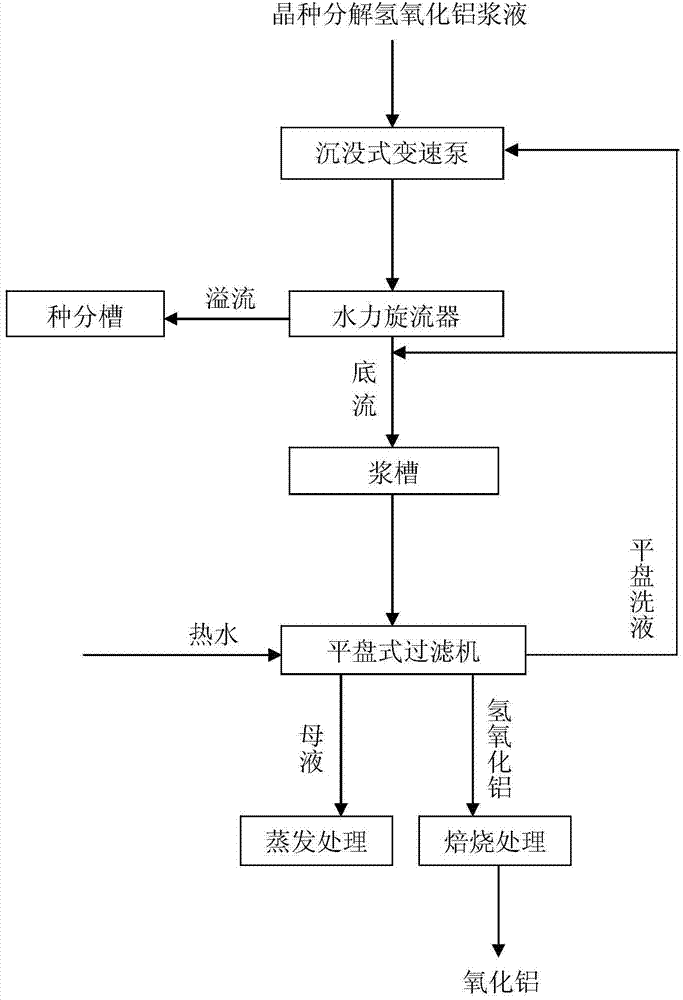

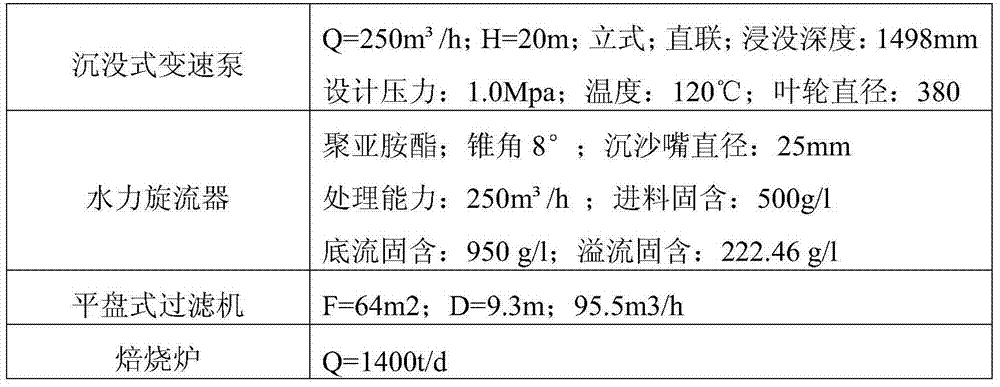

Method for treating seed precipitated aluminum hydroxide size

The invention provides a method for treating seed precipitated aluminum hydroxide size. The method comprises the following steps: pumping seed precipitated aluminum hydroxide size into a hydrocyclone by utilizing a submersible variable-speed pump in the process of producing alumina by a Bayer process; performing stage treatment on the seed precipitated aluminum hydroxide size by utilizing the hydrocyclone to obtain overflow aluminum hydroxide size and underflow aluminum hydroxide size; introducing the underflow aluminum size into a size tank for temporary storage; introducing the underflow aluminum hydroxide in the size tank into a flat-plate type filter for filtering and washing treatment to obtain mother liquor, flat-plate washing liquor and aluminum hydroxide; and roasting the aluminum hydroxide to obtain aluminum oxide, wherein the flat-plate washing liquor is returned to the submersible variable-speed pump and / or returned and mixed with the underflow aluminum hydroxide size. By adopting the method, the classification effect can be effectively improved, the product quality can be improved, vapor consumption and electricity consumption of Bayer process produced aluminum oxide can be reduced, and cost can be reduced.

Owner:YUNNAN WENSHAN ALUMINUM

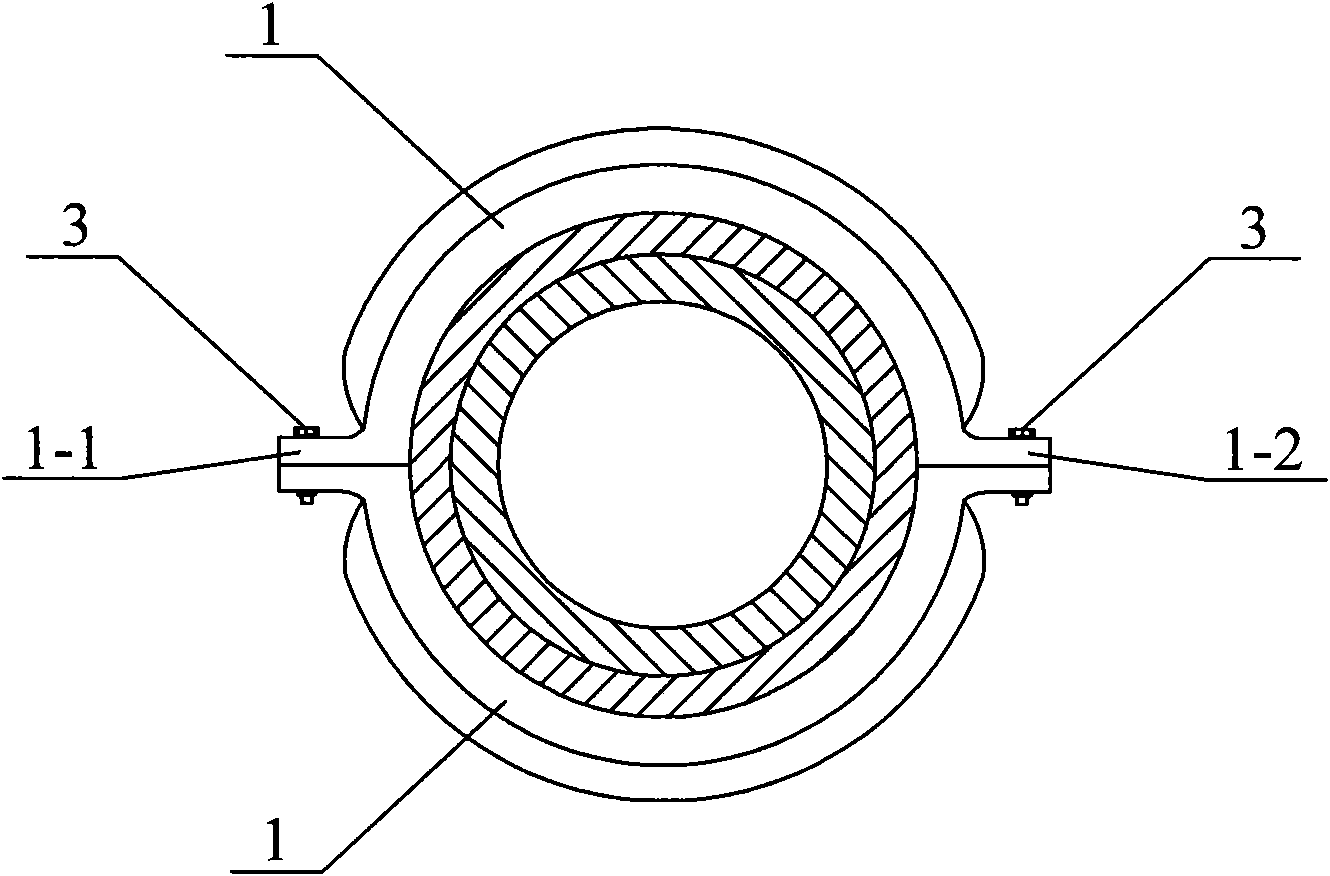

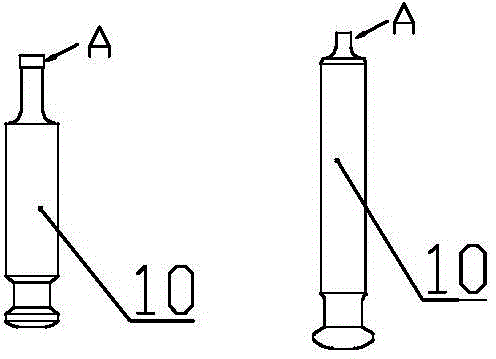

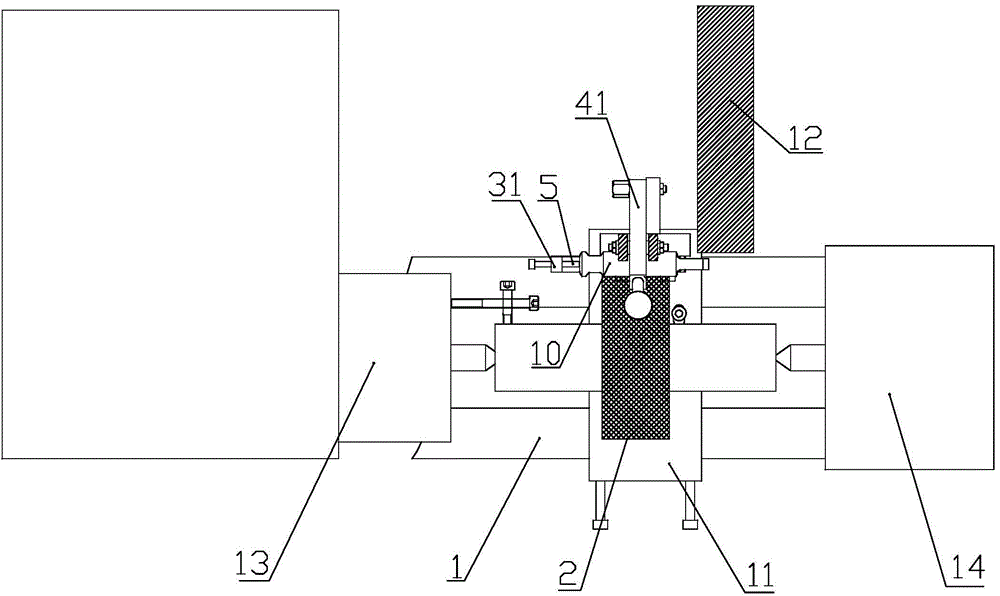

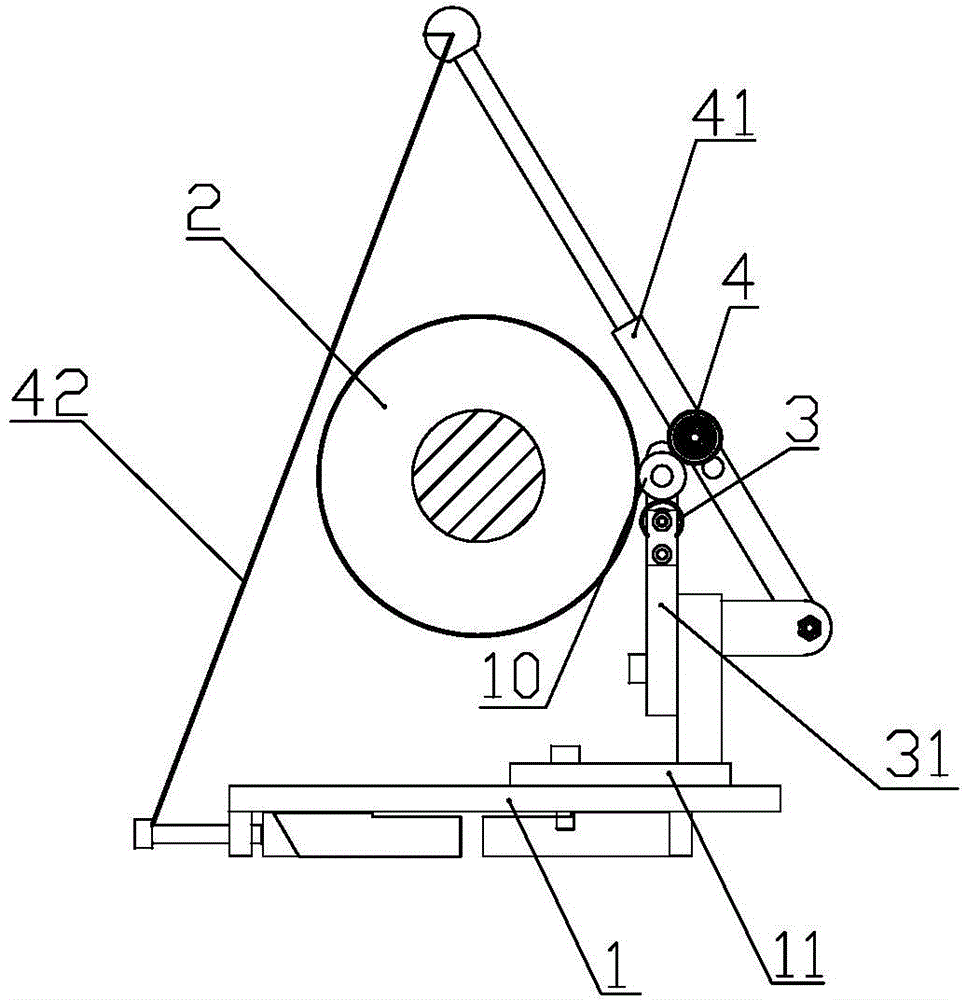

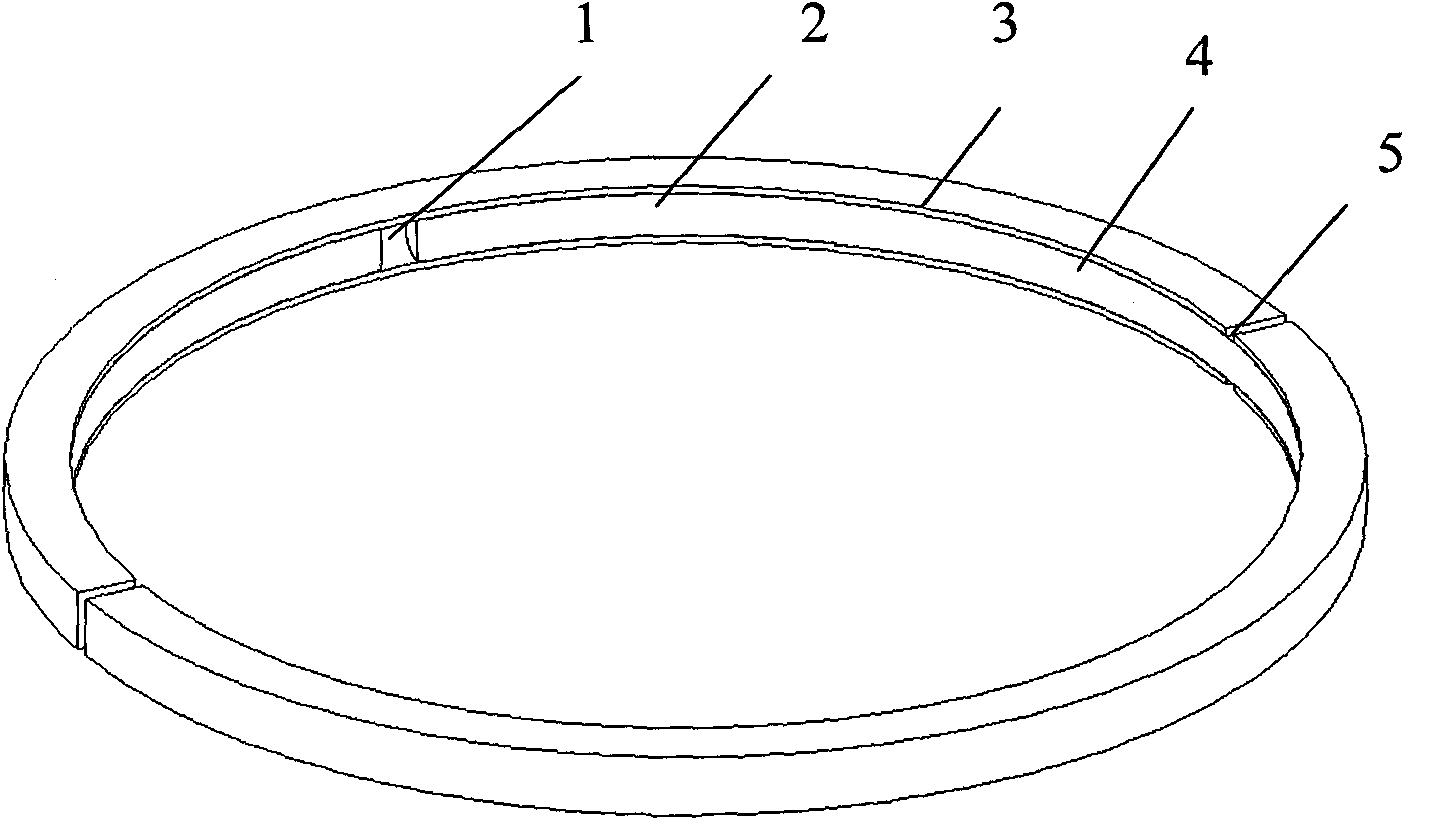

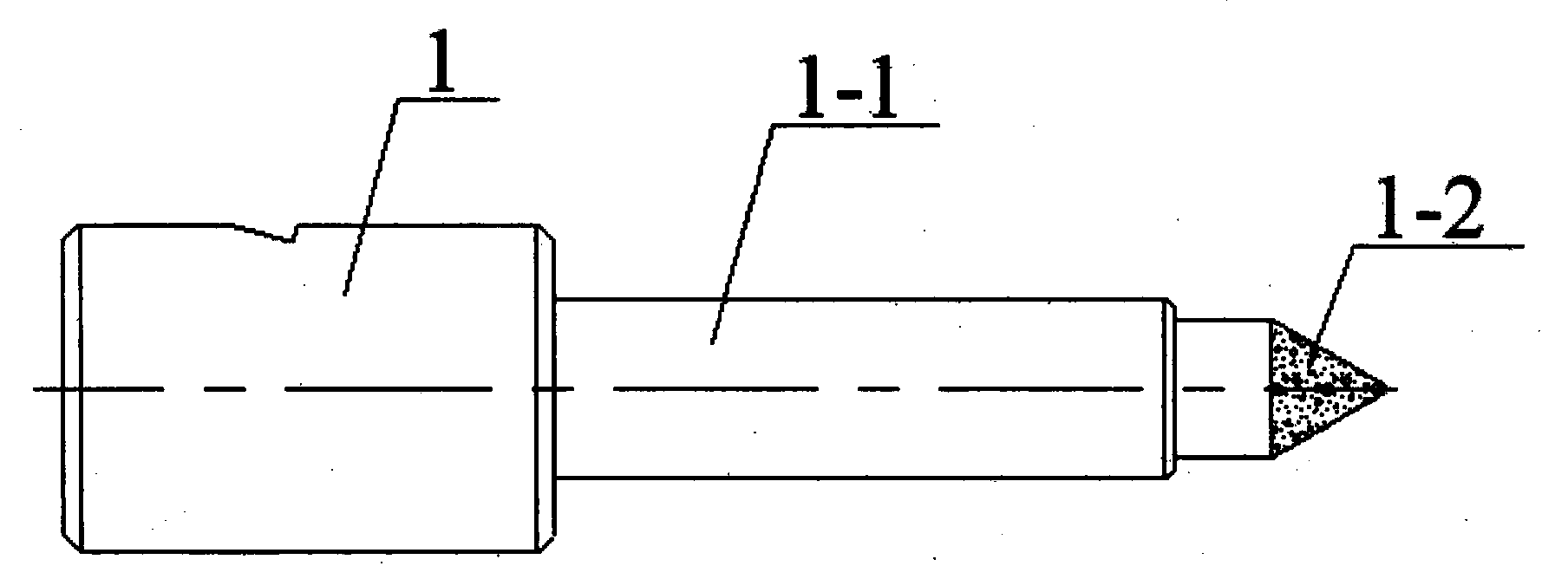

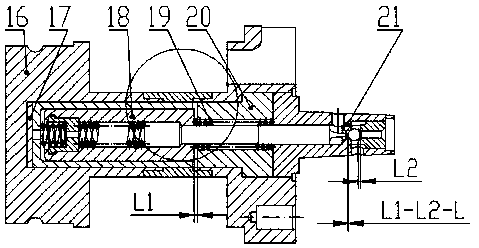

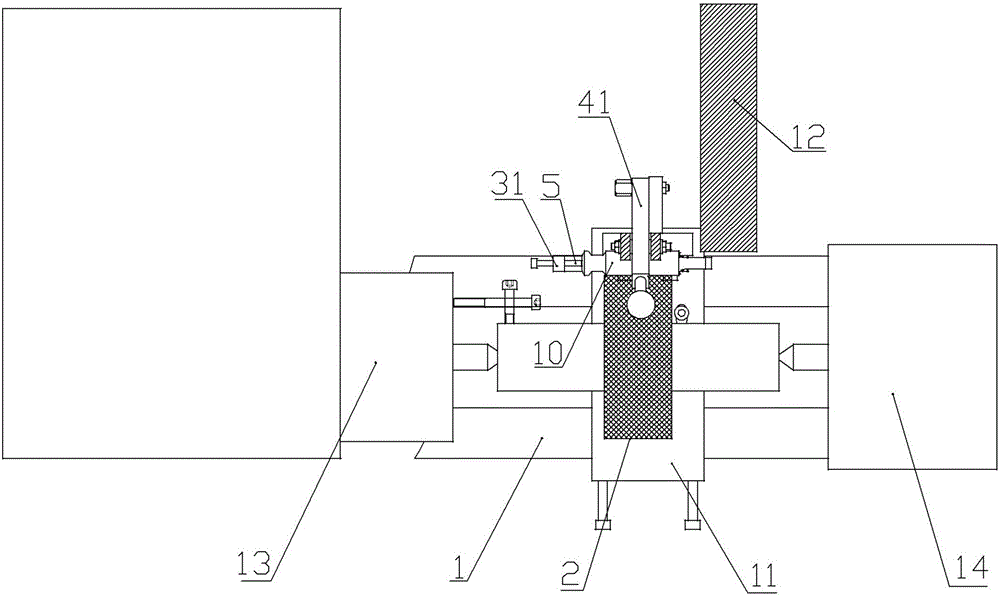

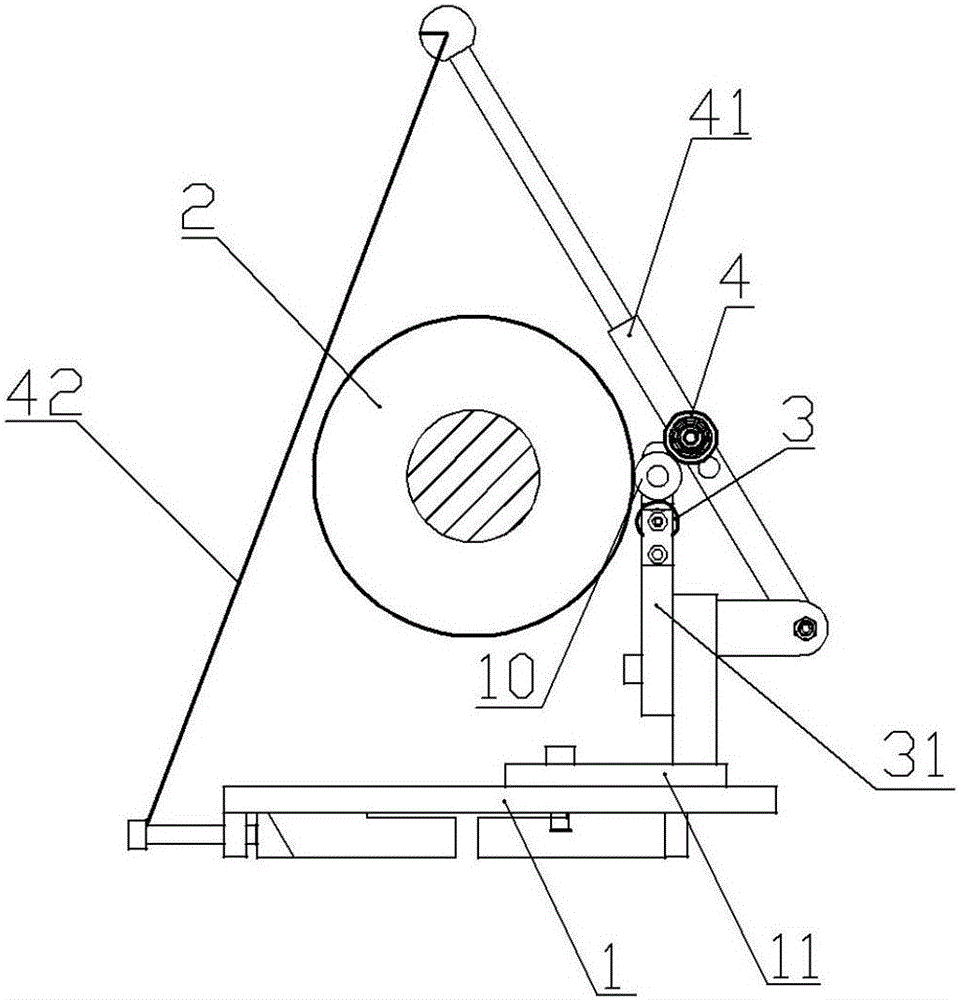

Centerless fixture for cylindrical grinding machine

InactiveCN104669080AGuaranteed axisGuaranteed working pressureRevolution surface grinding machinesEngineeringCylindrical grinding

The invention discloses a centerless fixture for a cylindrical grinding machine. The centerless fixture comprises a driving wheel, a supporting wheel and a pressing wheel, wherein the driving wheel is arranged on a rotating shaft of a grinding machine; the supporting wheel is arranged at the slanting lower part of the rear side of the driving wheel; the outer side of a support of the supporting wheel is hinged to one end of a pressing rod; the pressing wheel is arranged at the middle of the pressing rod; the other end of the pressing rod is connected with one end of a spring; the other end of the spring is connected onto a grinding machine rack; a positioning part is arranged at one end face side, which is away from a grinding wheel of the grinding machine, of the supporting wheel, on the support of the supporting wheel; a punch rod clamped among the driving wheel, the supporting wheel and the pressing wheel can be axially positioned by the positioning part; the punch rod is fixed by line contact matching between the circumferential surfaces of the driving wheel, the supporting wheel and the pressing wheel and the circumferential surface of a punch body of the punch rod; after the punch rod is fixed, the axiality of the punch rod can be directly guaranteed; the acting pressure of the pressing wheel on the punch rod is guaranteed by the pretightening force of the spring; the driving wheel is driven by the rotating shaft to rotate and drives the punch rod to rotate; the grinding processing is realized by contacting a circumferential section of the upper end to be ground of the punch rod with the grinding wheel.

Owner:LIAOCHENG WANHE IND MFR

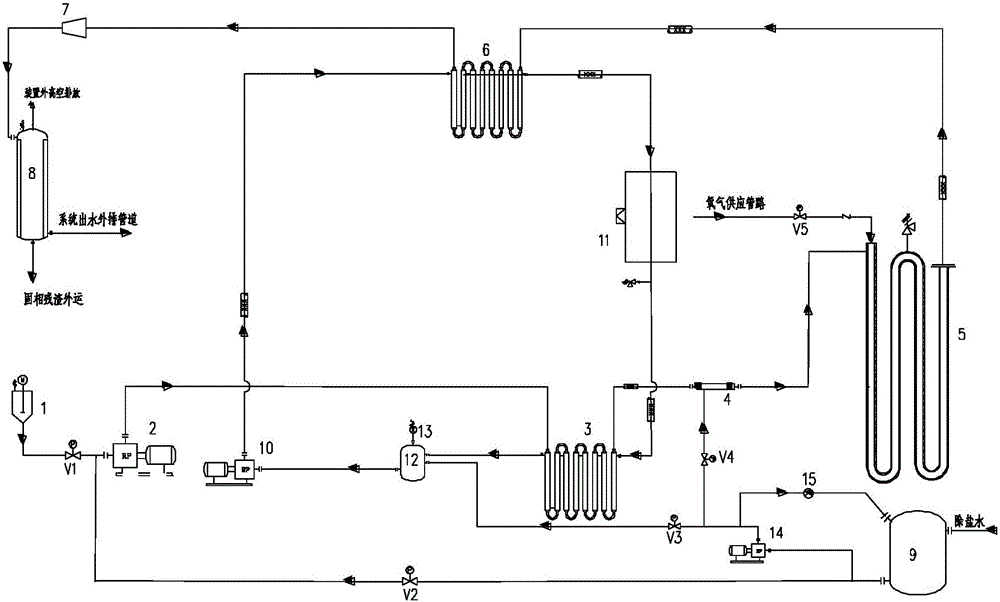

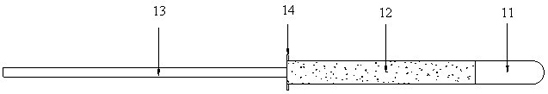

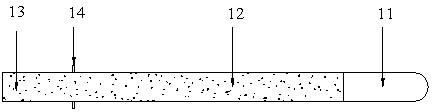

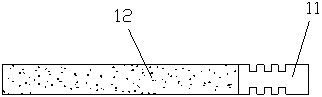

Indirect heat exchange type supercritical water oxidization system and control method

ActiveCN105776492AReduce design powerLess investmentSludge treatment by oxidationSpecific water treatment objectivesAutomatic controlSystem safety

The invention discloses an indirect heat exchange type supercritical water oxidization system and a control method. The system mainly comprises a main supercritical water oxidization reaction flow and an intermediate medium loop. The control method comprises two-flow pressure and temperature increasing control, temperature and pressure reduction control and normal running control. The invention aims at an automatic control strategy for engineering practices of the indirect heat exchange type supercritical water oxidization system, and the concept of cyclic heating is adopted for a temperature increasing process of the system, so that investment in heating equipment is effectively reduced; mismatch between working pressure of two flows is avoided, and effectiveness of heat exchange between supercritical pressure fluids in an inner pipe and an outer pipe of a preheater / heat exchanger of a temperature increasing or temperature reduction stage of the system is ensured; process effects and system safety are ensured by effective control over reaction temperature and over-temperature protection over key equipment.

Owner:XI AN JIAOTONG UNIV +1

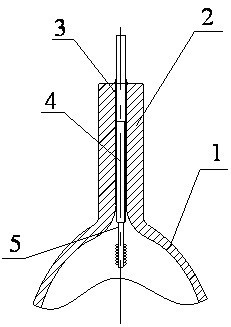

Electrode assembly

InactiveCN101901735ASolve unfavorable problemsSolving Consistency IssuesGas discharge lamp detailsLead structureAssembly structure

The invention discloses an electrode assembly structure. The structure comprises a tungsten mandril, a metal ceramic rod and a lead structure which are connected in turn, wherein one end of the tungsten mandril is a discharge end, the other end of the tungsten mandril is connected with one end of the metal ceramic rod, and the other end of the metal ceramic rod is connected with the lead or the metal ceramic rod directly used as the structure of a leading-out wire; and the outer diameter of the tungsten mandril is equivalent to that of the metal ceramic rod. The electrode assembly structure can effectively prevent the excessive conduction of heat to a tail end of the electrode assembly and ensure the excellent performance of a finished lamp in all aspects.

Owner:CHAOZHOU AUBADE LIGHTING

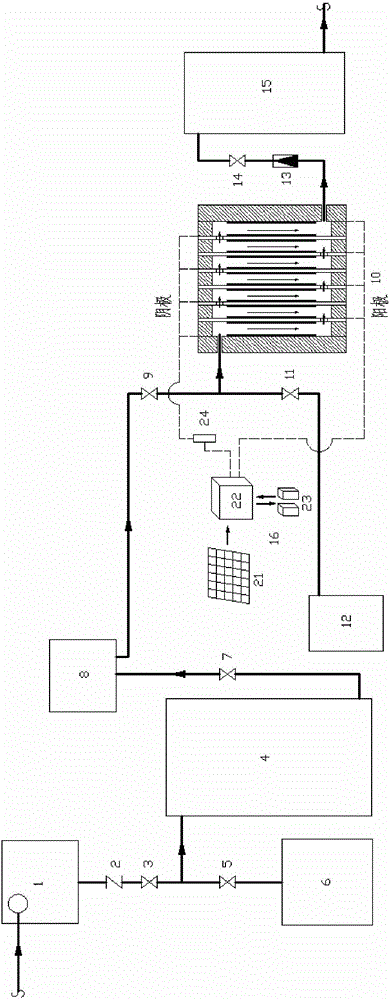

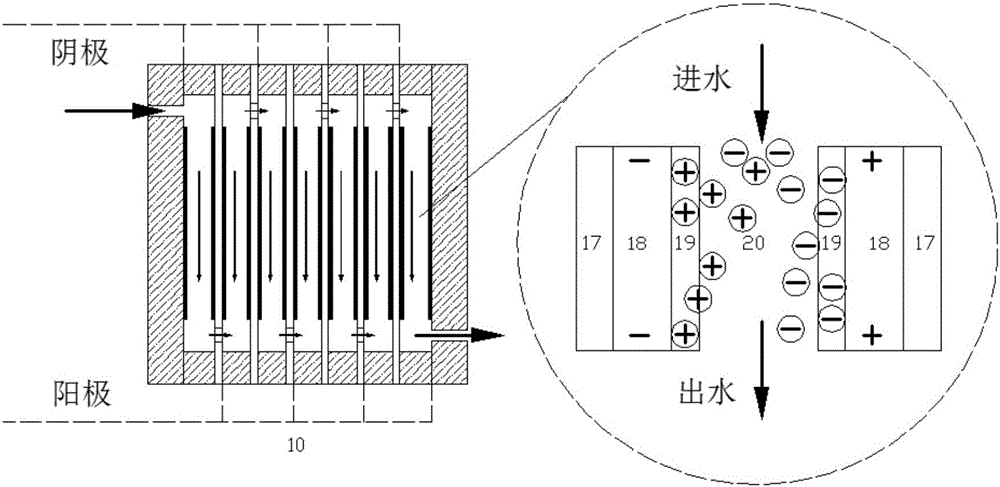

Activated carbon filter coupling solar energy driven device for treating bitter salty water through membrane capacitive deionization and application method thereof

InactiveCN105948187AAvoid wastingConstant water levelSpecific water treatment objectivesDispersed particle separationCapacitanceDihydrogen oxide

The invention discloses an activated carbon filter coupling solar energy driven device for treating bitter salty water through membrane capacitive deionization and an application method thereof, and belongs to the technical field of bitter salty water treatment. The problems that MCDI electrode organic pollution is serious, effluent quality is poor and non-renewable energy resources are used for supplying power of an existing method for treating bitter salty water through MCDI are solved. The device comprises a raw water tank, a check valve, a raw water inlet valve, an activated carbon filter, a drainage valve, a back washing water storage tank, a back washing valve, intermediate water tank, an MCDI water inlet valve, an MCDI assembly, a regeneration valve, a concentrated brine storage tank, a fluid flowmeter or water meter, a water outlet valve, a clean water tank and a solar power supply system. According to the device, gravity flow exists in the whole application process, the water supply power cost is saved, meanwhile, working pressure is low, clean and renewable solar energy is used as the power supply, and power saving and environmental protection are achieved; effluent quality is improved, and MCDI organic pollution is avoided; operation is easy, the maintenance rate is low, and no chemical agent exists.

Owner:NAT ENG RES CENT OF URBAN WATER RESOURCE

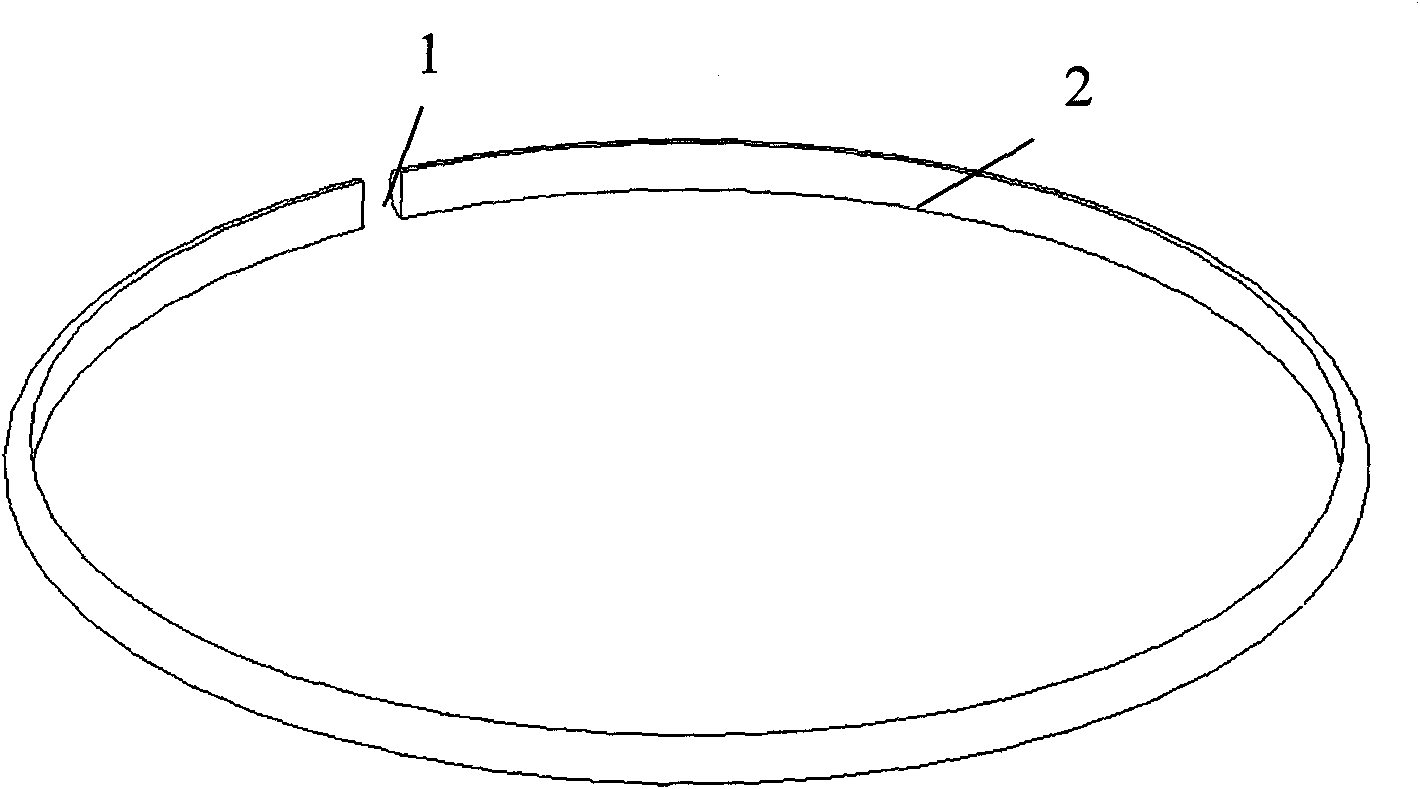

Piston ring for optical controlled engine

InactiveCN101813034AImprove sealingGuaranteed self-lubricationPiston ringsMachines/enginesCombustion chamberBiochemical engineering

The invention discloses a piston ring for an optical controlled engine, which comprises an outer ring which is made of graphite and an inner ring with elasticity, wherein the inner circumferential surface of the outer ring is provided with an arc groove, the inner ring is provided with an internal ring opening, and the inner ring is arranged inside the arc groove. The piston ring for the optical controlled engine consists of the outer ring and the inner ring, the inner side of the graphite outer ring is provided with the arc groove, and the outer ring is attached onto the inner ring through the groove, so the leak tightness of the piston ring is greatly improved, and the work pressure of the combustion chamber is effectively ensured. At the same time, the graphite has self-lubrication effect and good heat conduction, so the lubrication between the piston ring and a transparent cylinder sleeve is ensured, and the temperature of the transparent cylinder sleeve caused by the friction can be reduced.

Owner:CHERY AUTOMOBILE CO LTD

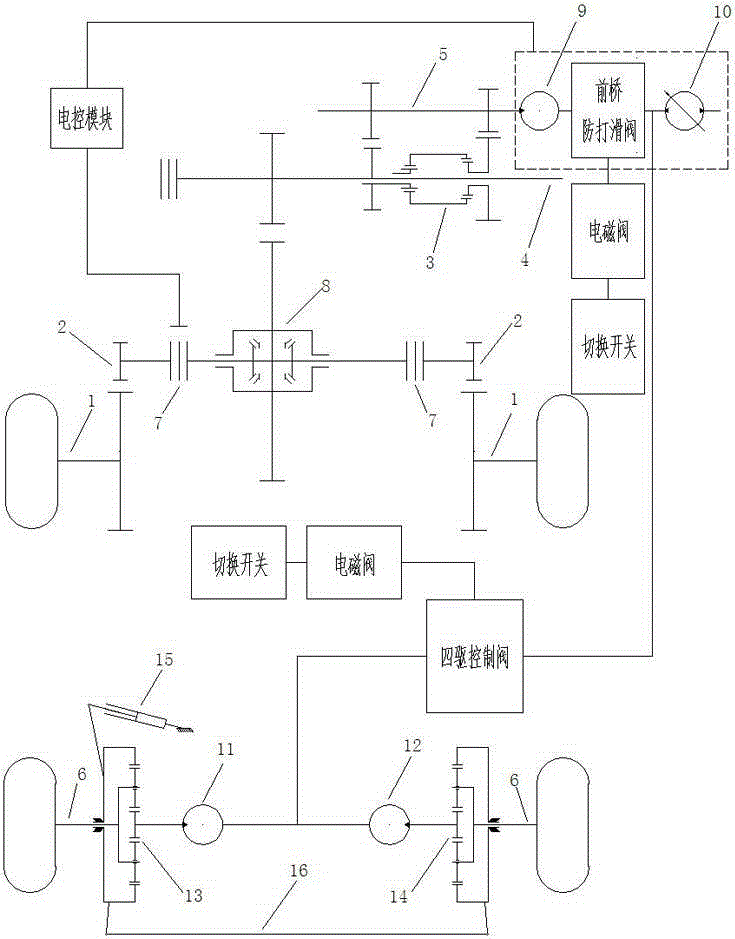

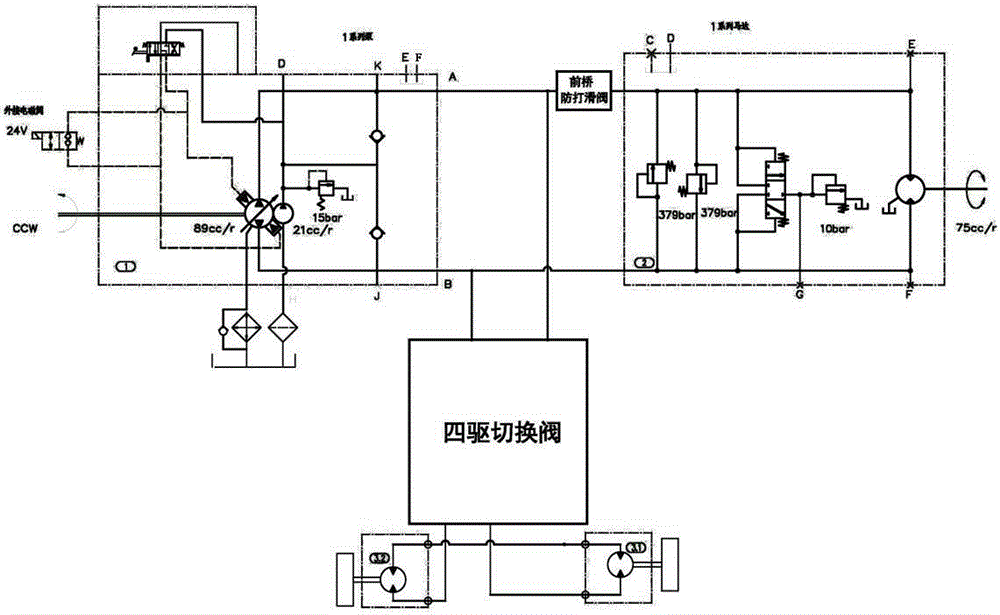

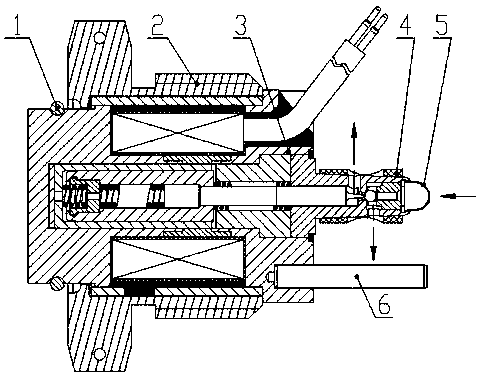

Two-gear four-wheel hydraulic stepless variable speed drive axle assembly for large harvester

ActiveCN105235508AGuaranteed work pressureEasy to operate and controlControl devicesHydraulic motorWorking pressure

The invention relates to a two-gear four-wheel hydraulic stepless variable speed drive axle assembly for a large harvester. The two-gear four-wheel hydraulic stepless variable speed drive axle assembly comprises a hydraulic variable pump located on a front axle and used for driving a quantitative hydraulic motor. A quantitative motor output shaft is connected with a gearbox power input shaft. A gearbox power output shaft is connected with a wheel edge speed reducer input shaft through a differential mechanism assembly. A hydraulic brake assembly is arranged on a transmission shaft in the middle of a gearbox. The two-gear four-wheel hydraulic stepless variable speed drive axle assembly is characterized in that the hydraulic variable pump is connected with the quantitative hydraulic motor through a front axle antiskid valve, the front axle antiskid valve is connected with a switch through an electromagnetic valve, and the hydraulic variable pump is connected with a cycloid motor of a rear axle through a four-drive control valve. The two-gear four-wheel hydraulic stepless variable speed drive axle assembly is easy, reliable and timely to operate and control, the stepless speed change and reverse drive of two drive axle assemblies can be achieved, the hydraulic system is kept at certain working pressure, and therefore rear wheels of the harvester can still drive the whole harvester to walk.

Owner:青岛科瑞特传动科技有限公司

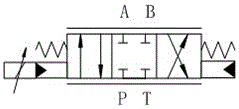

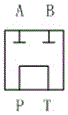

Two-position four-way rotary reversing valve

ActiveCN105736500AReliable designFlexible commutationServomotor componentsEngineeringMechanical engineering

The invention discloses a two-position four-way rotary reversing valve. The two-position four-way rotary reversing valve comprises a valve body, a valve element arranged in the valve body, a valve cover for fixing the valve element in the valve body, and a pressing spring; the valve body includes a baseplate, and a valve element mounting cylinder projected from a mounting surface of the baseplate to be far from the mounting surface; four oil ports P, T, A and B are formed in the baseplate; a large end of the valve element is inserted in the valve element mounting cylinder, and a small end is exposed out of the valve element mounting cylinder; a blocking convex block is arranged on the large end surface of the valve element; the outer diameter of the middle section of the valve element is smaller than the outer diameter of the large end thereof for annularly coating the pressing spring on the middle section; a limiting convex block is outwards projected on the outer wall of the small end of the valve element; the valve cover covers the valve element mounting cylinder for axially fixing the valve element in the valve element mounting cylinder; the valve cover is provided with a through hole for penetrating through the small end of the valve element; and the inner wall of the through hole is outwards projected with an arc limiting space corresponding to the limiting convex block.

Owner:CHONGQING HUAYU HEAVY IND ELECTROMECHANICAL CO LTD

Tyre air inflating device of tyre road pressing machine

InactiveCN1903626AGuaranteed work pressureEasy to useVehicle servicing/repairingPistonInternal cavity

The present invention relates to a tyre inflation unit of tyre street roller. It includes valve body and valve stem and piston which are mounted in the interior of valve body, the piston is positioned in the upper end of valve stem. The described piston can be used for dividing upper portion of internal cavity of valve body into pressure accumulating cavity and elastic force cavity. Two ends of said valve body are equipped with an upper end cover and a lower end cover, and said valve body has a valve body air guide channel, one end of said valve body air guide channel is communicated with air inlet set on the valve body, and its another end is communicated with pressure accumulating cavity by means of end cover air guide channel set on the upper end cover, the lower end of the valve stem is extended to air outlet set on the lower end cover.

Owner:SANY HEAVY IND CO LTD (CN)

Machining method of valve seat of relief valve

The invention discloses a machining method of a valve seat of a relief valve. The machining method of the valve seat of the relief valve is characterized by comprising performing turning machining on the valve seat of the relief valve through a numerical control lathe, wherein the turning machining comprises drilling a rough hole in the valve seat of the relief valve through a drilling bit, machining a thread bottom hole at the bottom of the rough hole through a tapping bit and forming an expanded hole in the middle section of the rough hole through boring cutter machining; performing finish machining on the top of the rough hole through a milling cutter to form a tapered hole; performing grinding machining on the expanded hole through internal and external circular grinding machines; machining the top of the tapered hole through a self-made grinding tool and performing grinding and polishing processing in a low rotating speed and rapid feeding mode and a low rotating speed and slow feeding mode to form a small frustum. The machining method of the valve seat of the relief valve has the advantages of being wide in applicable range, high in machining accuracy, low in production cost, high in production efficiency and the like.

Owner:龙工(上海)精工液压有限公司

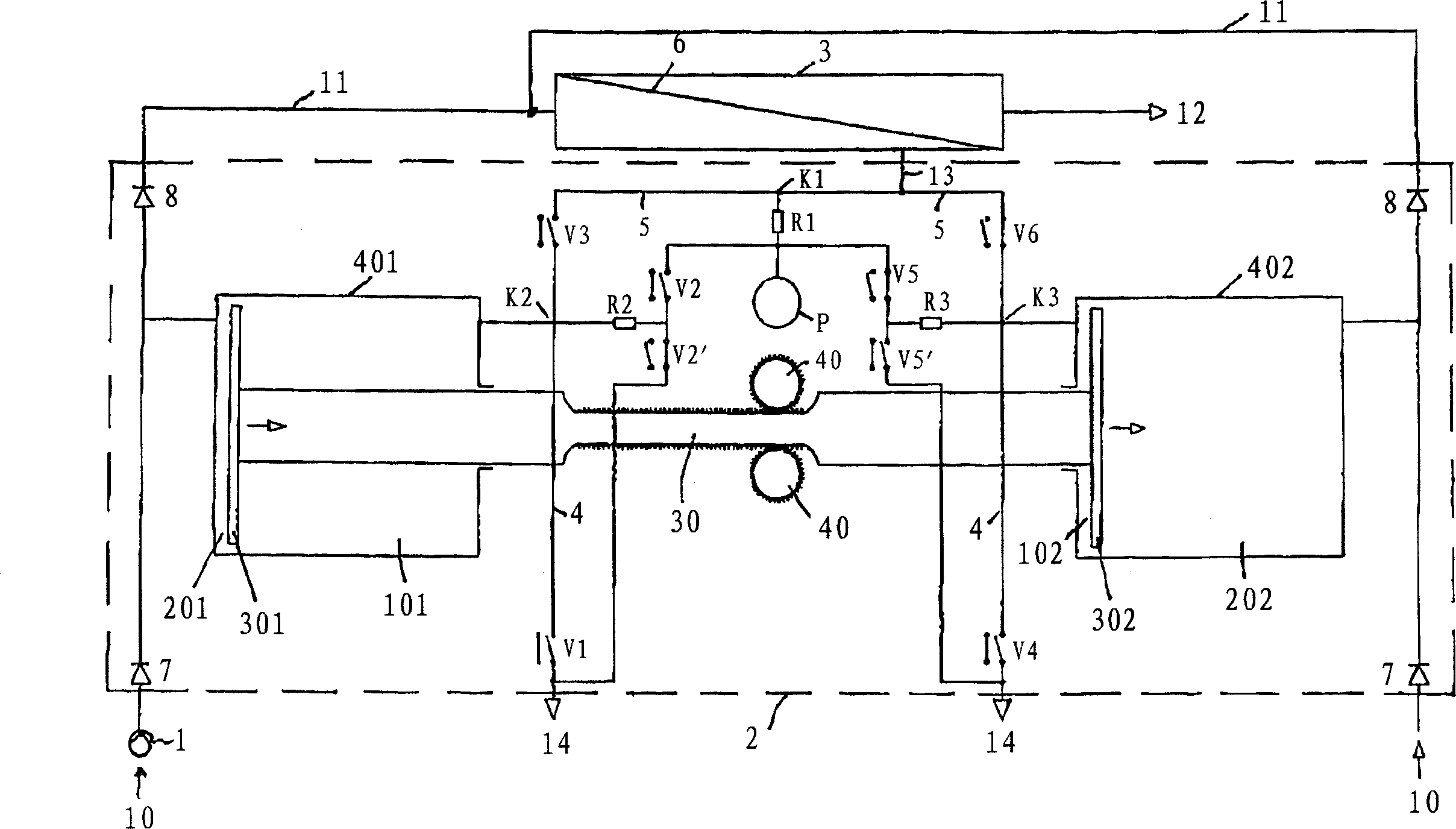

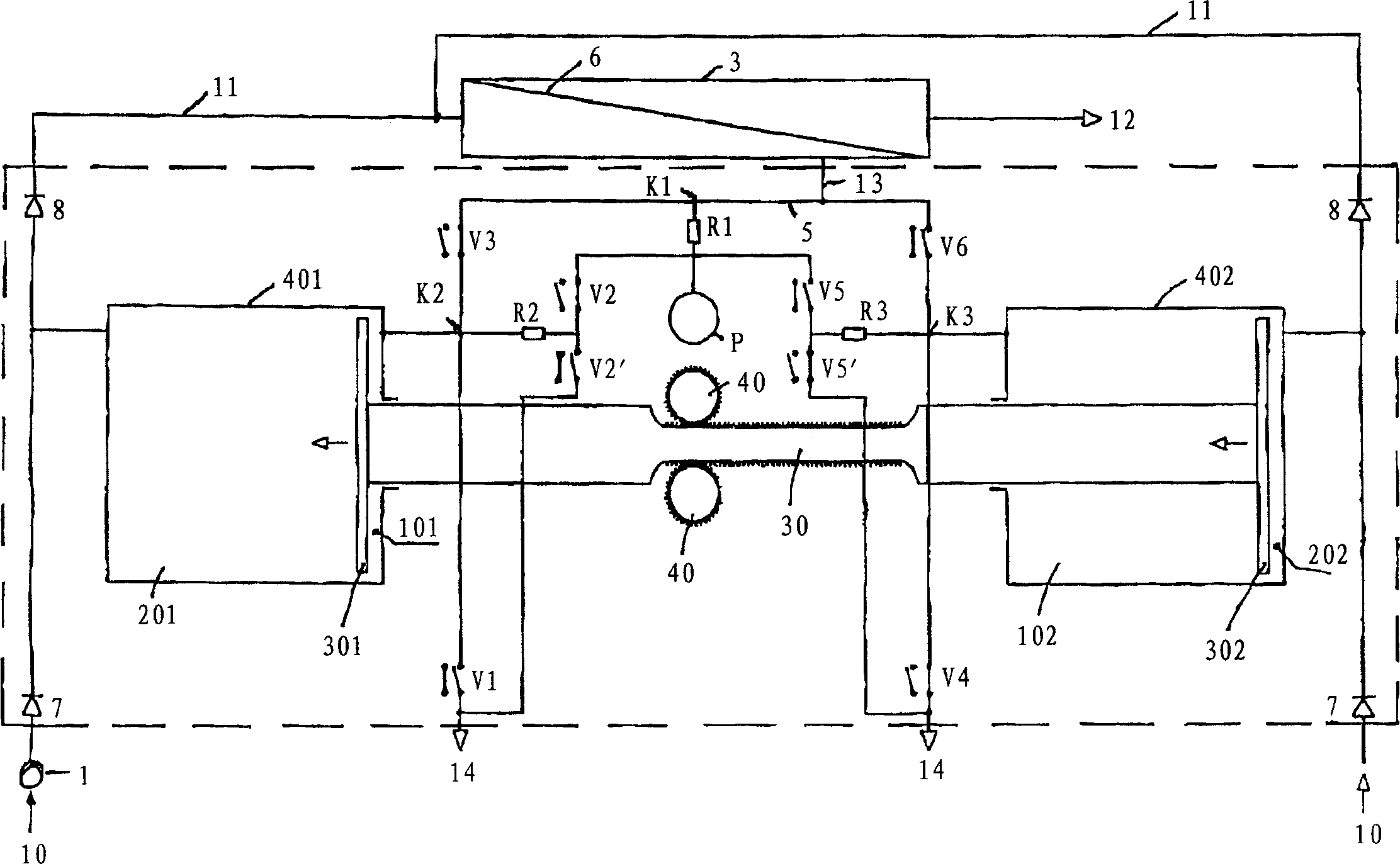

Method and device for desalting water

InactiveCN1486214AGuaranteed work pressureDependent Claims ImprovementGeneral water supply conservationSeawater treatmentSaline waterDesalination

The invention pertains to a method and a device for desalting water by reverse osmosis, particularly for desalting seawater, in which saltwater is introduced under a first pressure into a pressure-compensation device and conducted from pressure-compensation device at a second, higher pressure into a membrane module, wherein desalted water and concentrated saltwater are conducted out of membrane module, wherein the concentrated saltwater conducted out of membrane module is continuously introduced at roughly second pressure into pressure-compensation device and used there to apply roughly second pressure to saltwater introduced into pressure-compensation device and to introduce saltwater into membrane module, and wherein the introduction of concentrated saltwater into pressure-compensation device and the conduction of concentrated saltwater out of pressure-compensation device are accomplished by means of controlled main valves. The main valves are subject to high mechanical stresses, particularly during the opening and closing of the valves. To reduce or avoid these, it is provided according to the invention that secondary valves arranged in parallel with main valves are controlled such that load peaks during opening and / or closing of main valves are reduced.

Owner:阿洛伊斯沃本

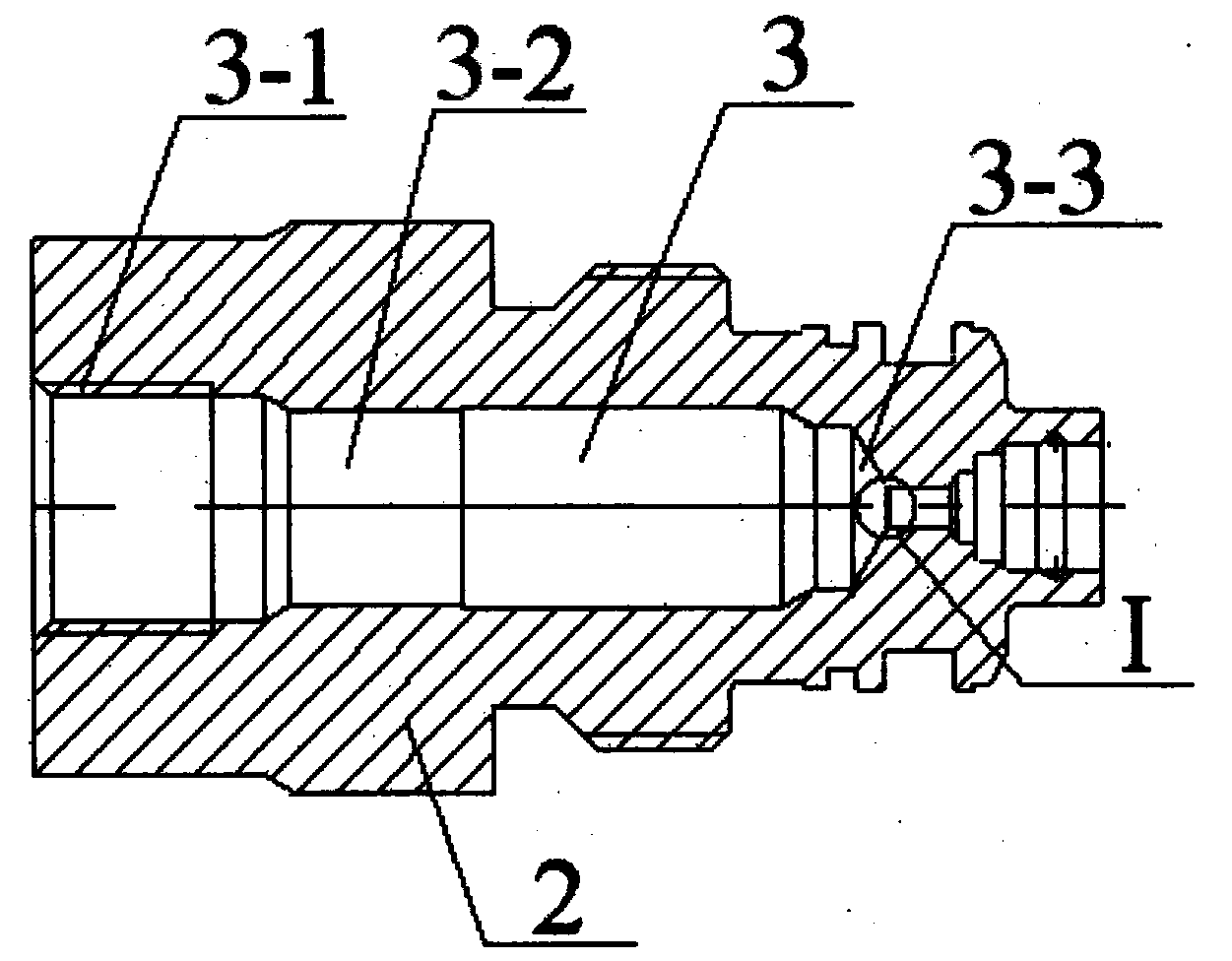

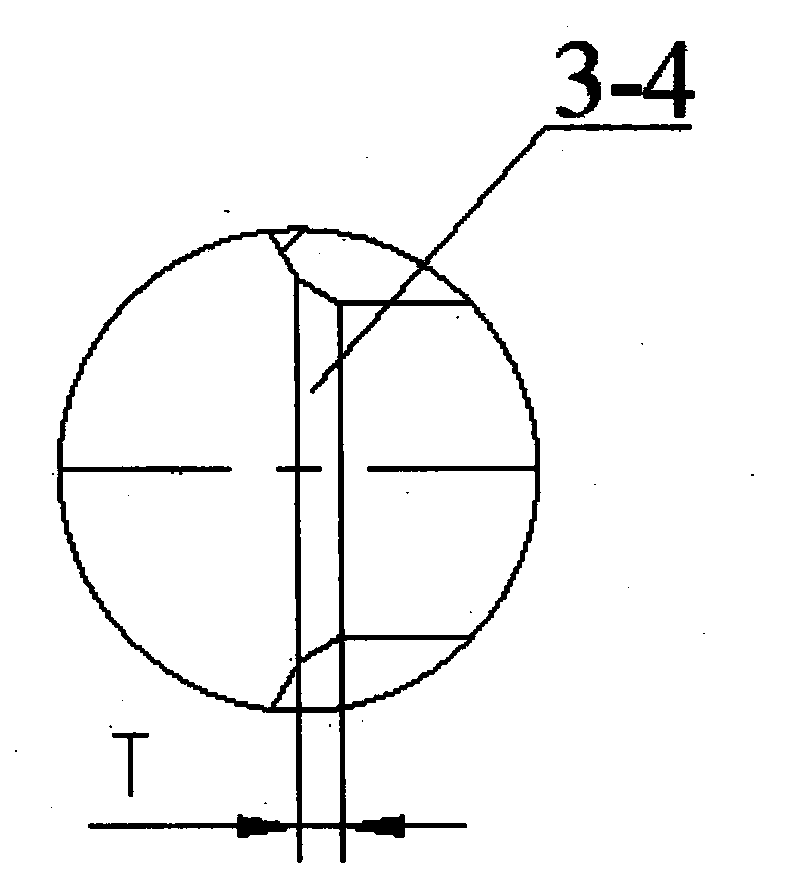

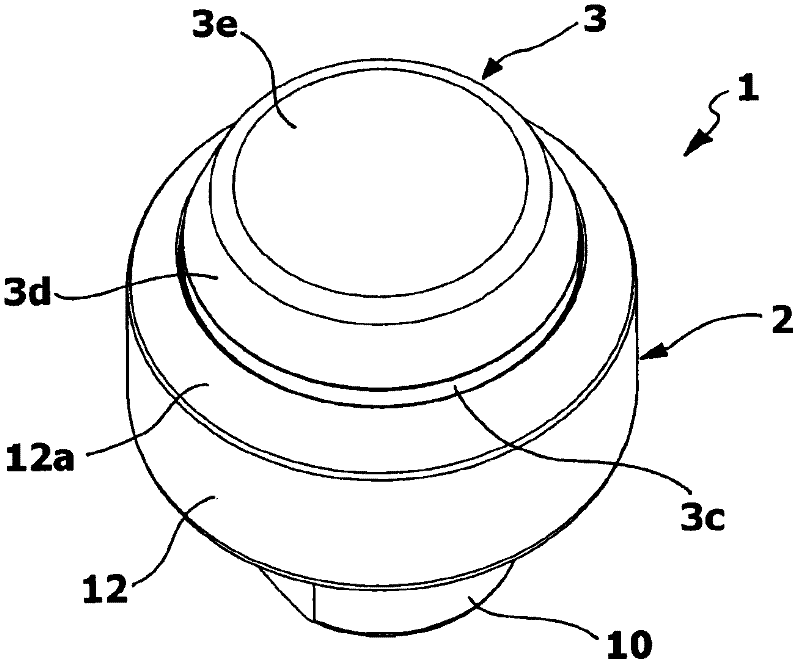

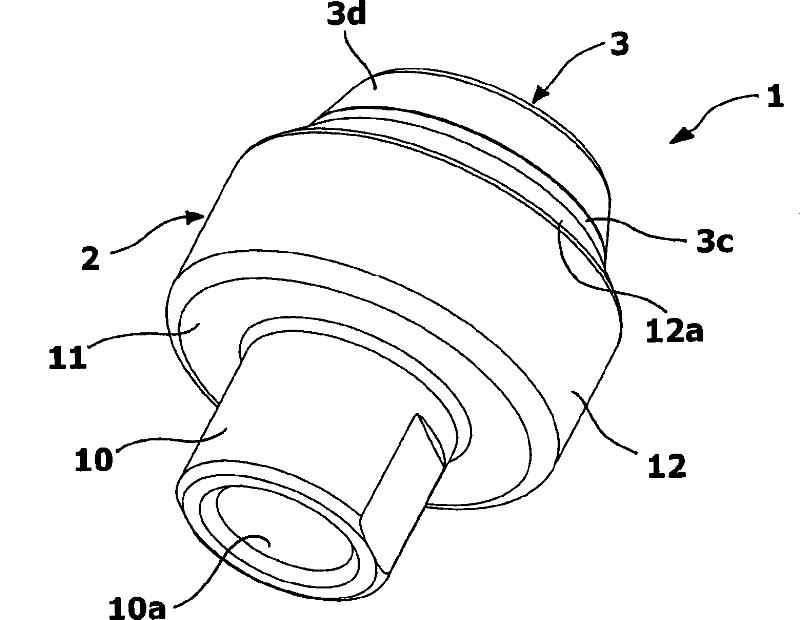

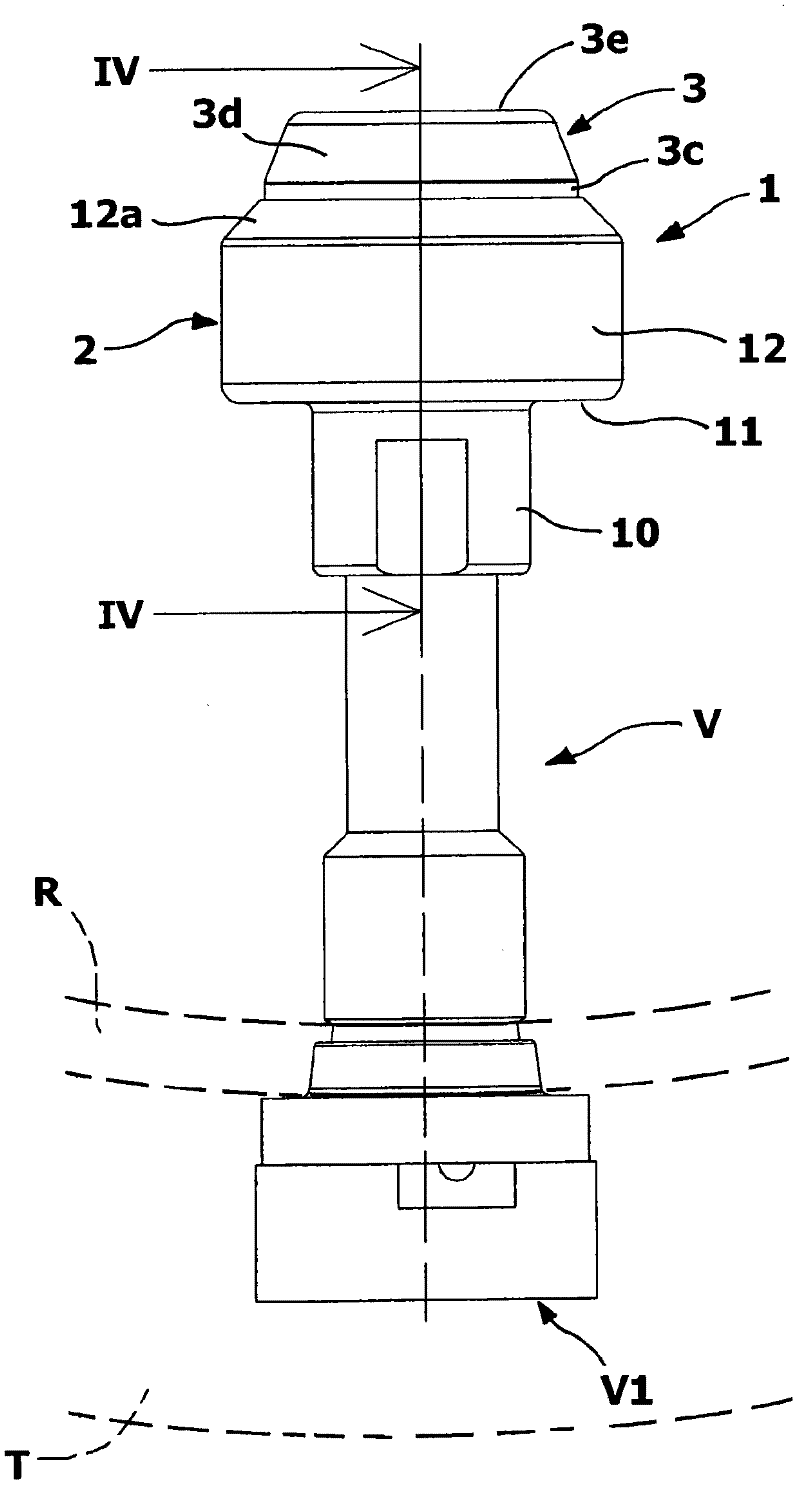

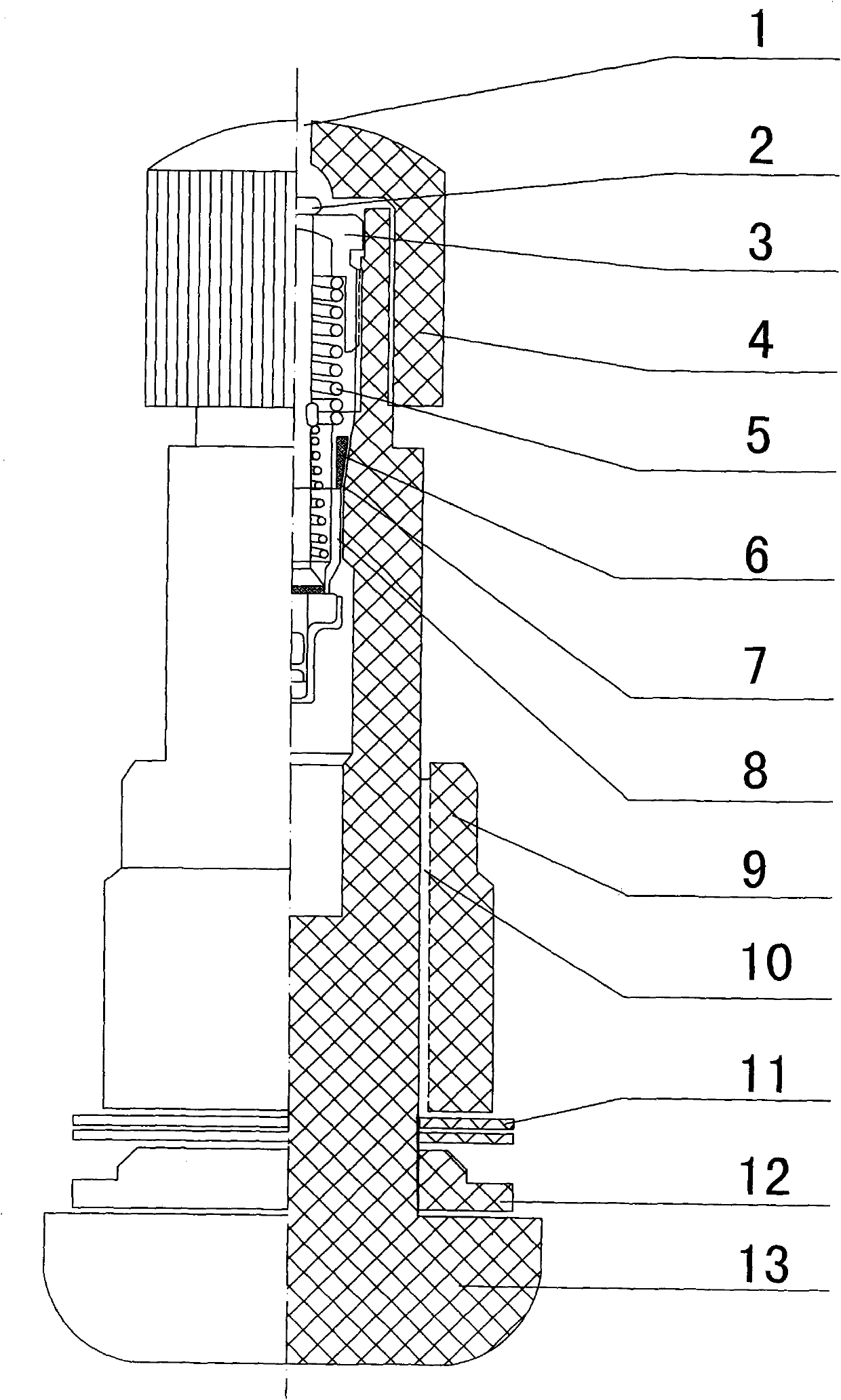

Device for monitoring a vehicle wheel

InactiveCN102666145AReduce deliveryImprove efficiencyTyre measurementsPolyphthalamideSynthetic materials

A device (1) for monitoring the tyre of a wheel of a vehicle is configured for detecting and transmitting to a receiver, through a wireless connection, information regarding at least one characteristic quantity of the state of the tyre, in particular its inflating pressure. The monitoring device (1) has a body (2, 3) for housing a circuit (16-18) designed to transmit the aforesaid information to the receiver at at least one substantially predetermined radiofrequency. The body (2, 3) is prearranged for being fixed to the rim of the wheel in a position external to the tyre and so as to face at least partly towards the outside of the rim. The body (2, 3) comprises a first body part (2), made of a first material, and a second body part (3) made of a second material, the first and second body parts (2, 3) defining between them a housing (4) for the circuit (16-18). At least the second material is a synthetic material having an electrical permittivity that is substantially constant at said at least one predetermined frequency. Preferably the first and second body parts (2, 3) are rigid and are fixed together by clinching or local mechanical deformation of the first body part (2) on the second body part (3). The synthetic material is preferably a polyphthalamide or PPA based resin.

Owner:ELTEK

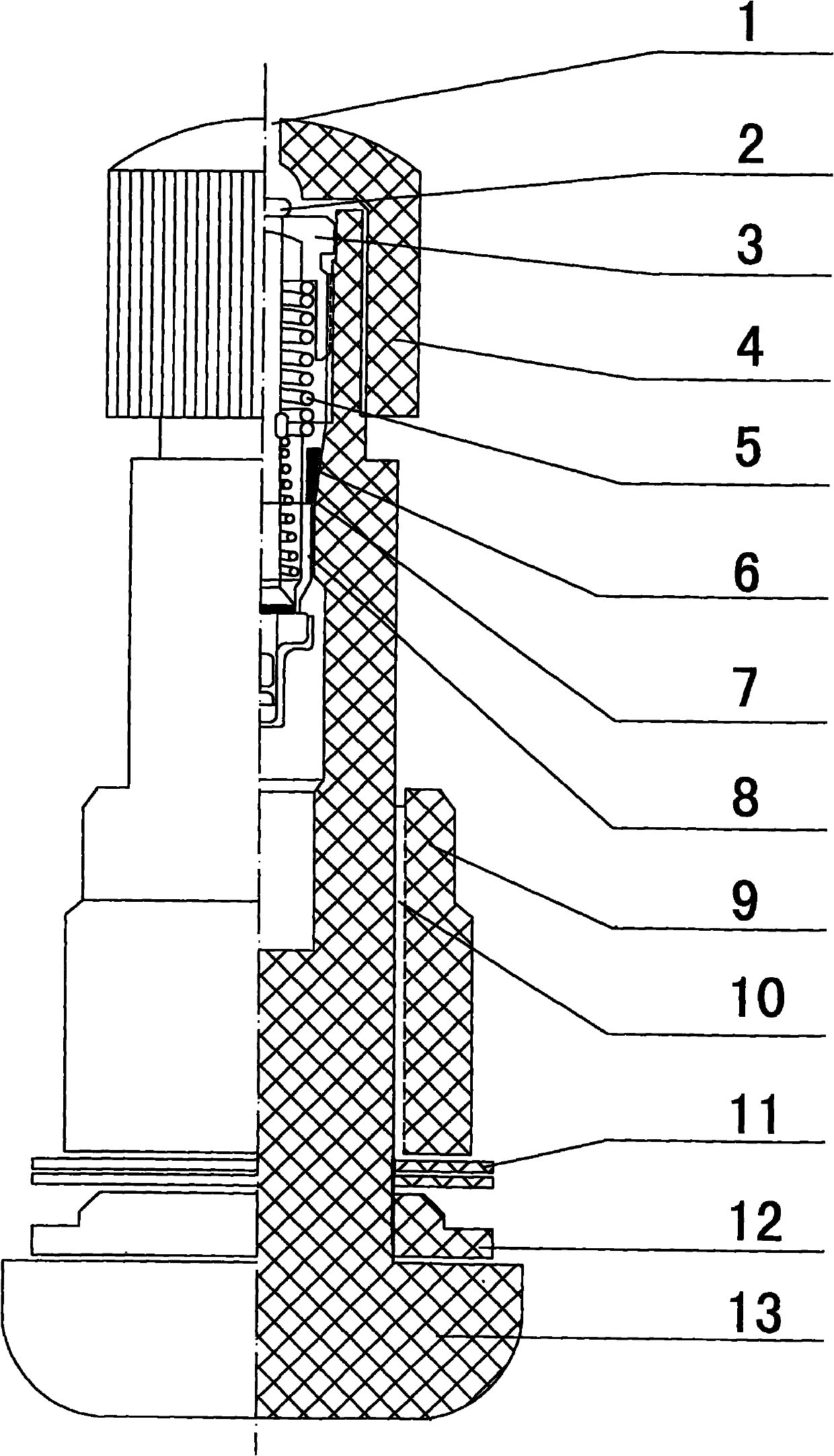

Pressure-regulating dual anti-burst tire safety valve

InactiveCN101994863AMake up for the shortcomings of burstingGuaranteed work pressureCheck valvesEqualizing valvesWorking pressureEngineering

The invention discloses a pressure-regulating dual anti-burst tire safety valve, relating to the improvement of a tire inflating valve. The safety valve is characterized in that the valve body is fixedly matched with a dust-proof cap in a thread mode; the dust-proof cap is provided with a vent hole; a core is installed in a ventilation channel in the valve body through a limit groove; a core cap with the limit groove is fixed on the upper part in the valve body through the threads; a core bar is fixed on the center line of the inner cavity of the core; the core bar penetrates through the core cap and is matched with the core cap in a sliding mode; a pressure limiting spring is arranged outside the core bar and in the limit groove of the core cap; and top end of the core cap is provided with transversely protruded cap outer edge. The safety valve has the beneficial effects of making up the anti-burst tire function which the existing inflating valve does not have and overcoming the defect that the inflating valve bursts under the action of pressure, thereby not only inflating tires, but also regulating and discharging pressure for the tires to ensure the normal working pressure of the tires, prolonging the service life of the tires, saving fuels, and preventing accidents due to tire burst and valve burst.

Owner:孔春花 +3

Improved straightening machine

InactiveCN102380522AReduce high oil temperatureGuaranteed work pressureShaping safety devicesCamFuel tank

The invention relates to an improved straightening machine, comprising a base, a sliding platform, a lower template, an upper template and a hydraulic oil cylinder; the base is provided with a pair of guide rails; the sliding platform is embedded between the guide rails; the upper part of the sliding platform is provided with the lower template; the lower template is provided with a cam shaft contacted with the upper template; the upper template is fixedly arranged on the beam of a gantry frame; the gantry frame is fixed on the base; the sliding platform is connected with the hydraulic oil cylinder by using a central shaft fixedly arranged at one end of the base; the hydraulic oil cylinder is connected with an oil tank by using a pipeline; the outlet of the oil tank is connected with the inlet of the oil tank; the oil return port of an oil path is connected with the inlet of an oil-temperature reducing device; the outlet of the oil-temperature reducing device is connected with the inlet of the oil tank. The improved straightening machine has the advantages that: the oil-temperature reducing device can be used for reducing the high oil-temperature in the straightening machine and prevents an electromagnetic valve from being damaged; the working pressure is guaranteed and the working efficiency is improved.

Owner:施成新

Two-position three-way normally opened type micro fuel oil electromagnetic valve with buffer mechanism

ActiveCN109185541AGuaranteed work pressureImprove reliabilityOperating means/releasing devices for valvesFuel oilEngineering

The invention discloses a two-position three-way normally opened type micro fuel oil electromagnetic valve with a buffer mechanism. The electromagnetic valve comprises an armature assembly. The armature assembly comprises an outer armature of a cup body structure. An inner armature is sleeved into the outer armature; a first ejector rod, a third spring and a spring seat are successively sleeved into an inner cavity of the inner armature; a second spring is placed in the inner cavity of the spring seat; the other end of the second spring is in contact with the inner bottom surface of the outerarmature; the spring seat, the third spring, the inner armature and the first ejector rod form an inner armature assembly, wherein the outer armature and the inner armature and the first ejector rod and the inner armature are in clearance fit. The electromagnetic valve has the advantages of being small in size, light in weight, high-temperature-resistant, low in power consumption, high in reliability, long in service life and the like, and solves the problems that an existing electromagnetic valve is large in size, heavy in weight, high in starting energy consumption and the like.

Owner:GUIZHOU HONGLIN MACHINERY

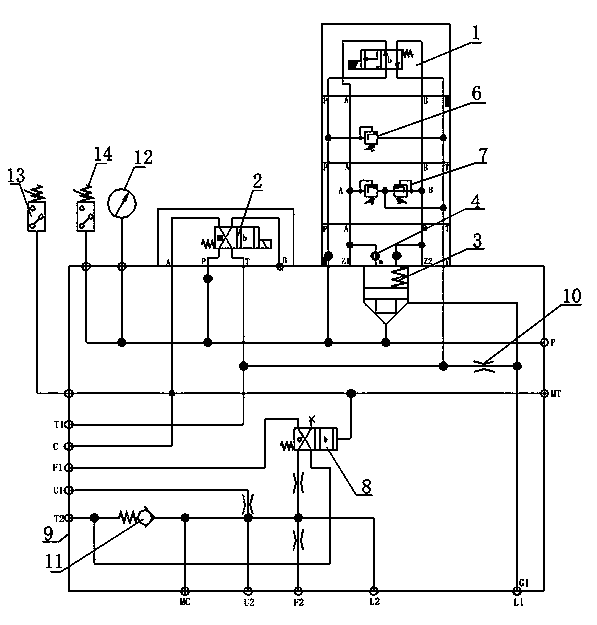

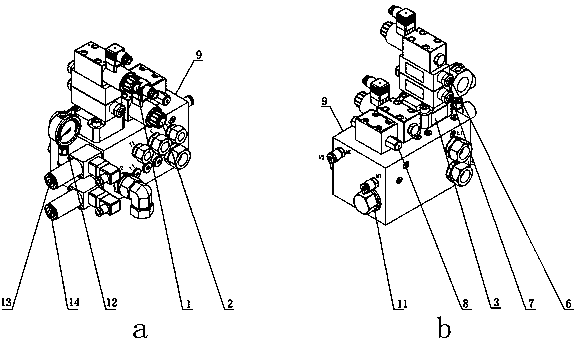

Control valve group of hydraulic clutch

ActiveCN103953661AImprove the lubrication effectGuaranteed work pressureFluid actuated clutchesLubrication check valvesControl valvesHigh voltage

The invention discloses a control valve group of a hydraulic clutch. The control valve group comprises a valve body, wherein a functional valve core is mounted on the valve body; the valve body is provided with connection openings; an oil duct is arranged in the valve body; the functional valve core comprises a first electromagnetic exchange valve, a second electromagnetic exchange valve, a P opening overflow valve, an AB opening overflow valve, a pilot operated directional control valve, an inserting valve and a one-way valve; the connection openings comprise a high voltage input opening P, a hydraulic clutch driving connection opening C, a hydraulic clutch lubricating connection opening F1, a functional valve core oil return opening T1, a lubricant passage way oil return opening T2, a cooler oil inlet connection opening L1 and a cooler oil outlet connection opening L2. The control valve group can meet the flow requirement of a system during normal operation, meanwhile can obtain more lubricant, properly lubricates the fully rotating control valve group and other parts, guarantees certain operating pressure in a lubricant passage way, balances oil pressure in all oil ducts, ensures that the fluctuation is relatively small, and simultaneously and effectively cools the system while lubricating the system.

Owner:NANJING HIGH ACCURATE MARINE EQUIP CO LTD

Water purifying device and water purifier

PendingCN108623025AReduce loadReduce differential pressureTreatment involving filtrationMultistage water/sewage treatmentWater flowWastewater

The invention discloses a water purifying device and a water purifier. The water purifying device comprises a membrane filter core, a first booster pump and a second booster pump, wherein the membranefilter core is provided with a water inlet, a purified water outlet and a wastewater outlet; the water inlet end of the first booster pump is connected with a raw water port, and the water outlet endof the first booster pump is connected with the water inlet of the membrane filter core; the second booster pump is serially connected to a pipeline between the first booster pump and the membrane filter core, and the water inlet end of the second booster pump is further connected with the wastewater outlet; a wastewater discharging pipe is further arranged on the wastewater outlet. According tothe technical scheme, a phenomenon of excessive reflux water flow due to excessive pressure difference between the water inlet end of the second booster pump and the wastewater outlet can be prevented.

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

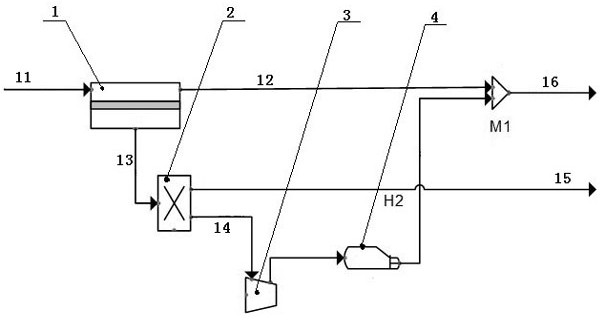

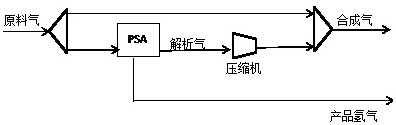

System for adjusting hydrogen-carbon ratio of synthesis gas and simultaneously producing byproduct hydrogen through coupling of membrane separation and pressure swing adsorption

PendingCN113735060AReduce dosageSmall scaleHydrogen separation using solid contactHydrogen/synthetic gas productionEngineeringHydrogen production

The invention discloses a system for adjusting the hydrogen-carbon ratio of synthesis gas and simultaneously producing a byproduct hydrogen by coupling membrane separation and pressure swing adsorption, wherein raw material gas firstly enters a membrane separator, permeate gas and impermeable gas are obtained under the pushing of the pressure difference of two sides of a separation membrane, the permeate gas is subjected to pressure swing adsorption to purify high-concentration product hydrogen and desorption gas with higher carbon monoxide concentration, the desorption gas is pressurized by a compressor and then is mixed with the membrane separation impermeable gas to form the synthesis gas with the hydrogen-carbon ratio meeting the requirement. The amount of permeate gas entering pressure swing adsorption is adjusted by adjusting the operation pressure of membrane separation or the membrane separation area, so that the hydrogen production amount of pressure swing adsorption is adjusted, and the hydrogen-carbon ratio of the synthesis gas is adjusted. The advantages of two gas separation methods of membrane separation and pressure swing adsorption are fully utilized, the whole set of system is low in energy consumption, no exhaust waste gas is generated, and the purposes of adjusting the hydrogen-carbon ratio of the synthesis gas and producing high-concentration hydrogen as a byproduct are achieved at the same time.

Owner:TIANBANG NAT ENG RES CENT OF MEMBRANE TECH

Ceramic metal halide lamp shell

InactiveCN101916711AExtend your lifeImprove coaxialityGas discharge lamp detailsHermetic sealLamp shell

The invention belongs to the field of ceramic light sources, and in particular relates to a ceramic metal halide lamp shell. The ceramic metal halide lamp shell comprises a discharging cavity and capillary tubes arranged at the two ends of the discharging cavity, wherein each capillary tube comprises an inner tube section and a welding groove which are connected with each other; the inner tube section is close to the discharging cavity; the welding groove is positioned on the end face; the inside diameter of the welding groove is greater than that of the inner tube section; the welding grooverealizes air-tight seal of the discharging cavity by padding a welding flux; part of the outer surface of the discharging groove is provided with a light reflecting material layer; and a glass transparent glaze layer is covered on the outer surface, not provided with the light reflecting layer, of the discharging cavity. The ceramic metal halide lamp shell has the advantages of simple encapsulation, good sealing effect, high luminous efficiency and the like.

Owner:杨潮平

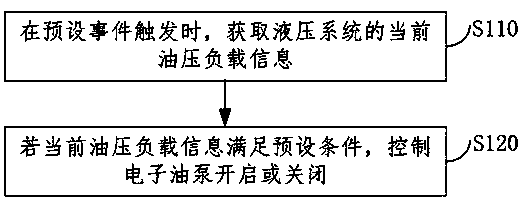

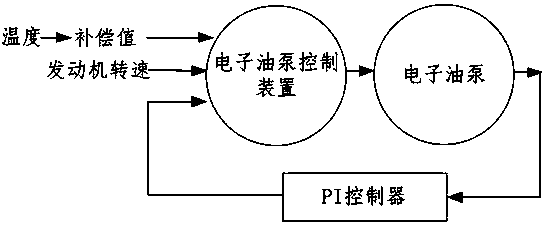

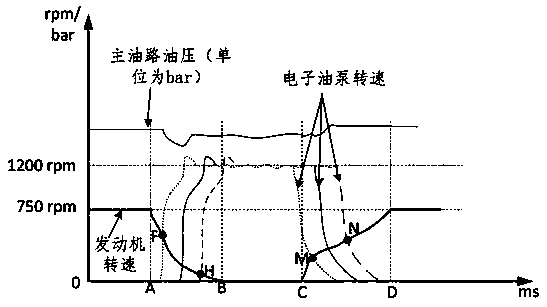

Control method and device of electronic oil pump, electronic equipment and storage medium

ActiveCN111425381ABad phenomena that affect the service lifeGuaranteed work pressurePump controlPositive-displacement liquid enginesWorking pressureProcess engineering

The invention relates to a control method and device of an electronic oil pump, electronic equipment and a storage medium. The control method of the electronic oil pump comprises the following steps that current oil pressure load information of a hydraulic system is obtained during triggering of a preset event, and the electronic oil pump is controlled to be opened or closed if the current oil pressure load information meets the preset conditions. By means of the control method, the essence is to control the opening or closing time of the electronic oil pump based on the current oil pressure load of the hydraulic system in real time, and the purpose that the adverse phenomenon that the service life of an electronic oil pump is affected due to the excessive load of the electronic oil pump is also avoided while the working pressure of a gearbox is ensured is achieved.

Owner:SHENGRUI TRANSMISSION

Hydraulic hose performance test experiment table

InactiveCN101672747BAdjustable bendGuaranteed temperature requirementsWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesHydraulic pumpFuel tank

The invention relates to a hydraulic hose performance test experiment table mainly comprising an electric control system, an impact load system, a bending driving system of a hose to be tested, and an environmental simulator which are connected mutually, wherein the impact load system mainly comprises a hydraulic oil pump I, an unloading spillover valve, an accumulator, a two-position four-way magnet valve, a throttle , a pressure booster, a stop valve, a counterbalance valve, an oil return filter I, a pressure gauge, a pressure sensor, an oil tank, a connection oil pipe, a joint, and the like; the bending driving system of a hose to be tested mainly comprises a hydraulic oil pump II, a safety valve, an oil return filter II, a three-position four-way magnet valve, a hydraulic oil cylinder, a connection oil pipe, a joint, and the like; and the environmental simulator mainly comprises an environmental chamber body and an electric heater, an ultraviolet emitter and a bending degree controller of a hose to be tested, which are arranged in the environmental chamber body. The experiment table can test a plurality of hoses simultaneously, test the experimental pressure wave shape of the hoses to be tested on line and estimate the fatigue lifetime of the hoses to be tested; and the invention has simple structure, easy operation, little energy consumption and high reliability.

Owner:徐州沃土资产管理有限公司

A Centerless Fixture Used on Cylindrical Grinding Machine

InactiveCN104669080BGuaranteed axisGuaranteed work pressureRevolution surface grinding machinesDrive wheelEngineering

The invention discloses a centerless fixture for a cylindrical grinding machine. The centerless fixture comprises a driving wheel, a supporting wheel and a pressing wheel, wherein the driving wheel is arranged on a rotating shaft of a grinding machine; the supporting wheel is arranged at the slanting lower part of the rear side of the driving wheel; the outer side of a support of the supporting wheel is hinged to one end of a pressing rod; the pressing wheel is arranged at the middle of the pressing rod; the other end of the pressing rod is connected with one end of a spring; the other end of the spring is connected onto a grinding machine rack; a positioning part is arranged at one end face side, which is away from a grinding wheel of the grinding machine, of the supporting wheel, on the support of the supporting wheel; a punch rod clamped among the driving wheel, the supporting wheel and the pressing wheel can be axially positioned by the positioning part; the punch rod is fixed by line contact matching between the circumferential surfaces of the driving wheel, the supporting wheel and the pressing wheel and the circumferential surface of a punch body of the punch rod; after the punch rod is fixed, the axiality of the punch rod can be directly guaranteed; the acting pressure of the pressing wheel on the punch rod is guaranteed by the pretightening force of the spring; the driving wheel is driven by the rotating shaft to rotate and drives the punch rod to rotate; the grinding processing is realized by contacting a circumferential section of the upper end to be ground of the punch rod with the grinding wheel.

Owner:LIAOCHENG WANHE IND MFR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com