Indirect heat exchange type supercritical water oxidization system and control method

A supercritical water oxidation, indirect technology, applied in chemical instruments and methods, oxidation treatment of sludge, oxidation water/sewage treatment, etc., can solve the problems of high temperature and pressure matching requirements, high process parameters, etc., to achieve low design power and guarantee Safety, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

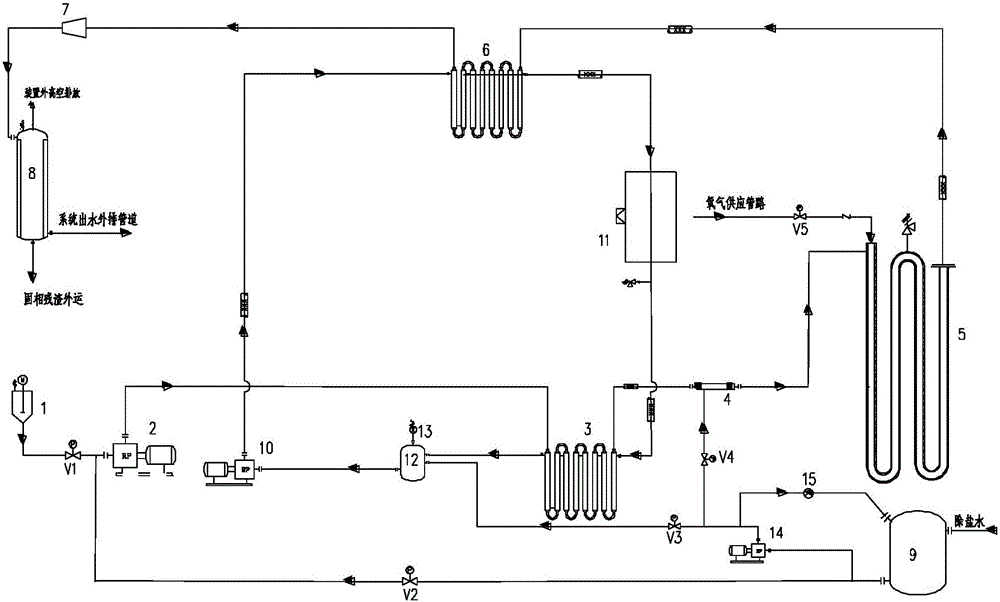

[0039] The present invention is described in further detail below in conjunction with accompanying drawing:

[0040] see figure 1 , the indirect heat exchange supercritical water oxidation system of the present invention mainly includes the main process of supercritical water oxidation reaction, the intermediate medium process and other auxiliary pipelines, the main process of supercritical water oxidation reaction includes a material buffer tank 1 connected to a material pump 2, and the two There is a material buffer tank outlet control valve V1 between them, the material pump 2 is connected to the inner pipe of the preheater 3, the outlet of the inner pipe of the preheater 3 is connected to the inlet 1 of the desuperheater 4, and the outlet of the desuperheater 4 is connected to the inlet 1 of the reactor 5 The outlet of the reactor 5 is connected to the inner pipe of the regenerator 6, the outlet of the inner pipe of the regenerator 6 is connected to the pressure reducer 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com