Low-temperature air-source heat pump system adopting two-stage air supply

A technology of low-temperature air and source heat pumps, applied in heat pumps, lighting and heating equipment, compressors with reversible cycles, etc., can solve problems such as high exhaust temperature of compressors, high coefficient of performance of heating supply, and contradiction between heat supply and demand, etc., to achieve Reduced design power, improved safety and stability, and improved operating economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described below.

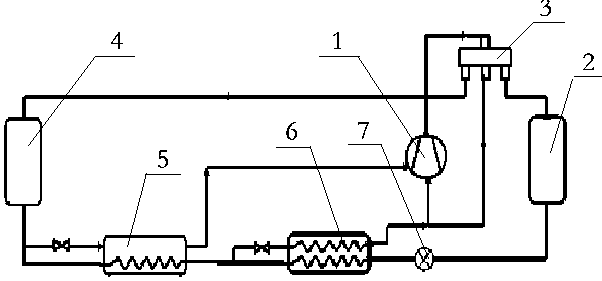

[0025] As shown in the accompanying drawings, a two-stage supplementary low-temperature air source heat pump system is implemented, including a compressor 1, an evaporator 2, a four-way reversing valve 3, a condenser 4, an economizer 5, a phase change heat accumulator 6 and Expander 7; its composition is that the outlet refrigerant pipeline of the evaporator 2 is connected with the suction port of the compressor 1 through the four-way reversing valve, and the exhaust port of the compressor 1 is connected with the condenser through the four-way reversing valve The inlet refrigerant pipelines of 4 are connected, and part of the outlet refrigerant liquid of condenser 4 is throttled and enters the economizer 5, and the other part flows through the heat exchange tube in the economizer 5; the outlet refrigerant vapor of the economizer passes through the pipeline It is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com