Patents

Literature

60results about How to "Reduce the number of annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

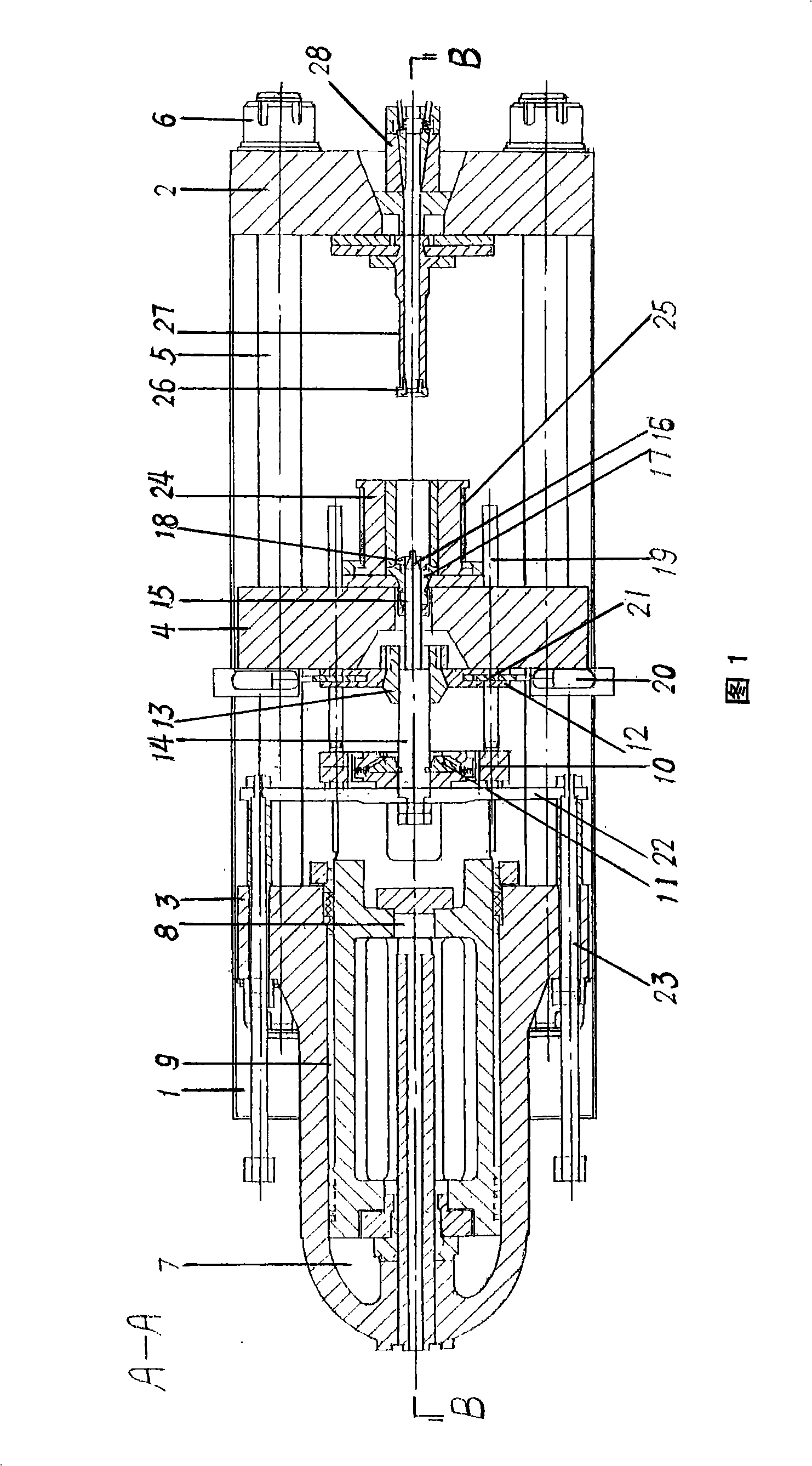

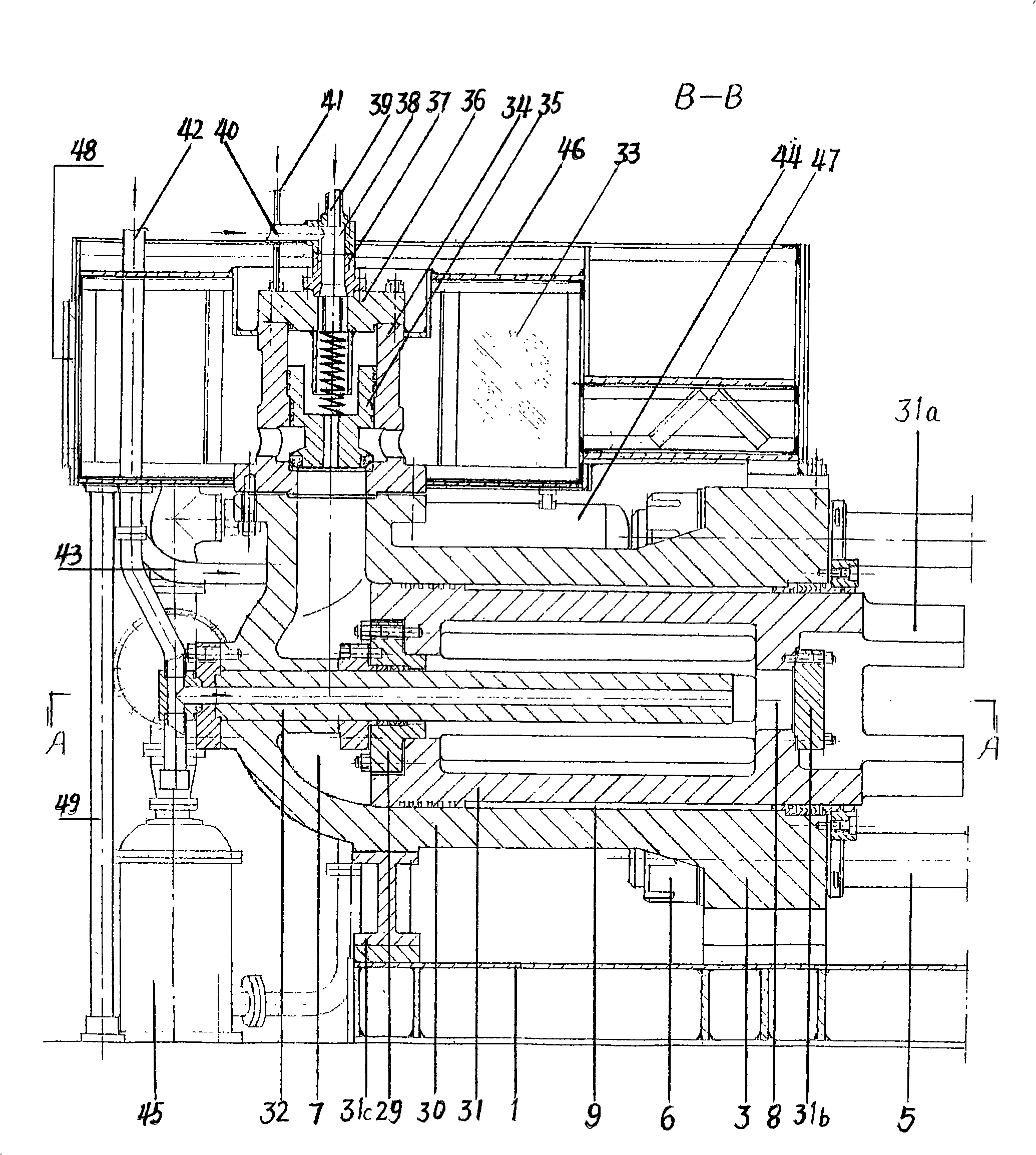

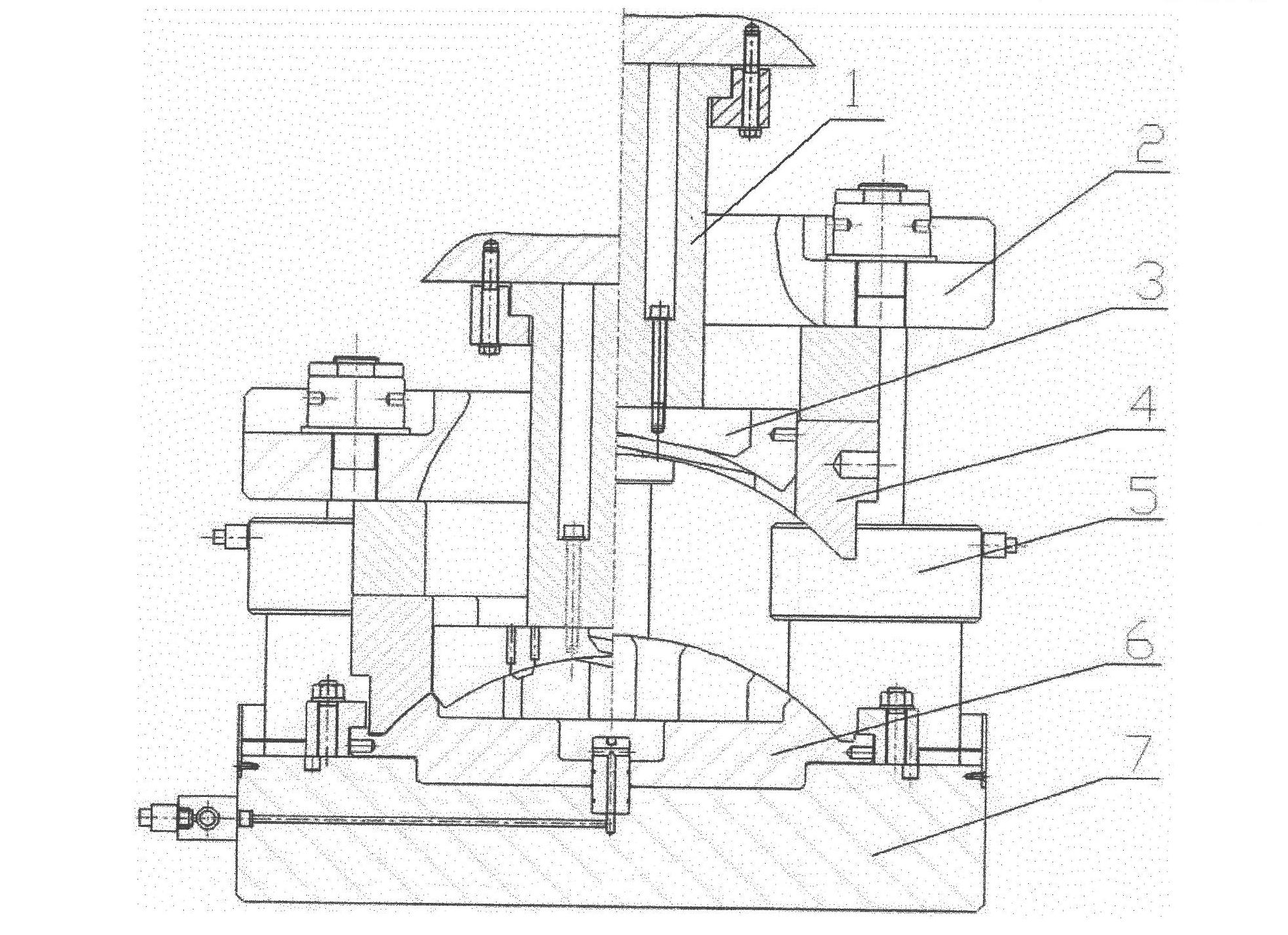

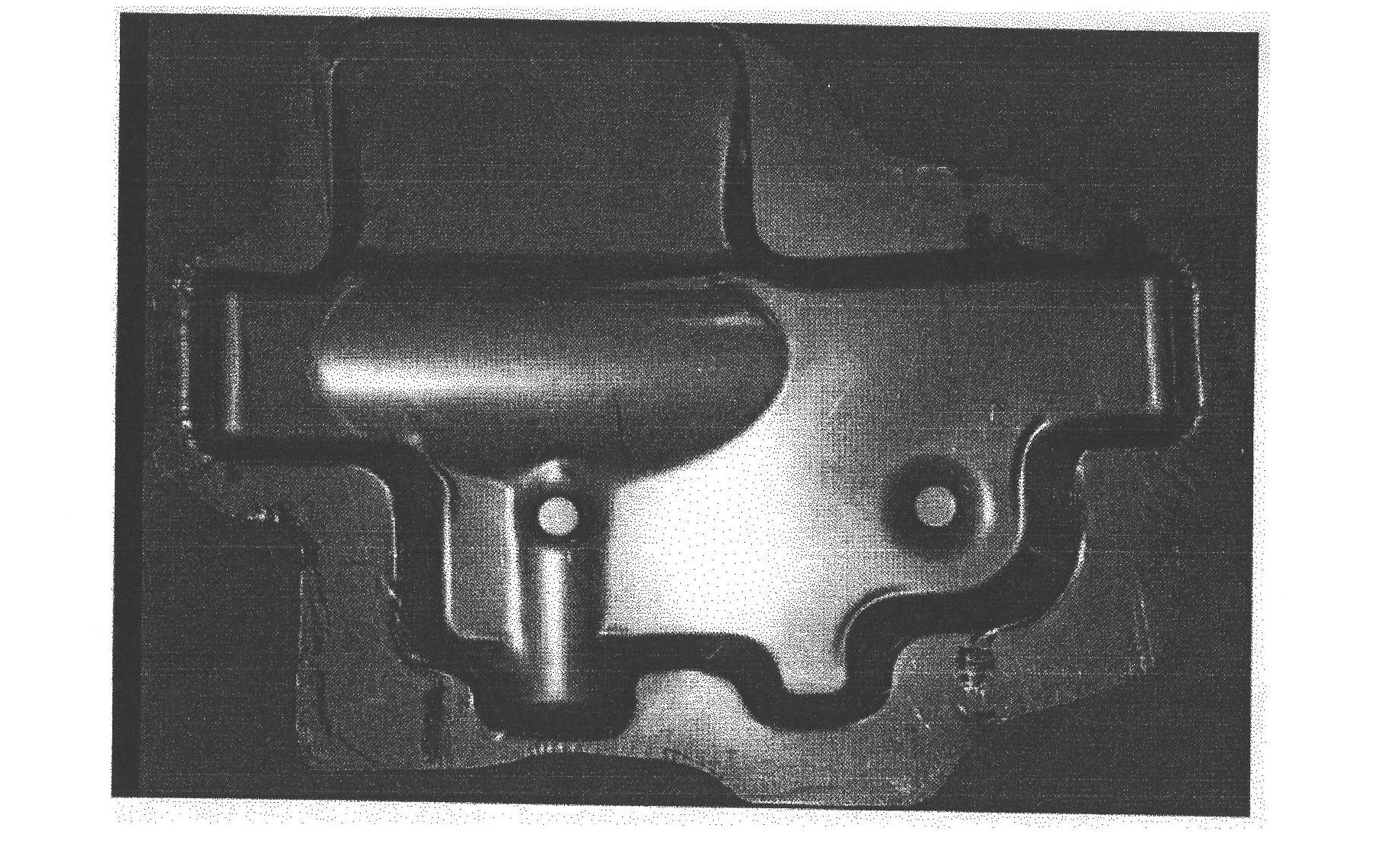

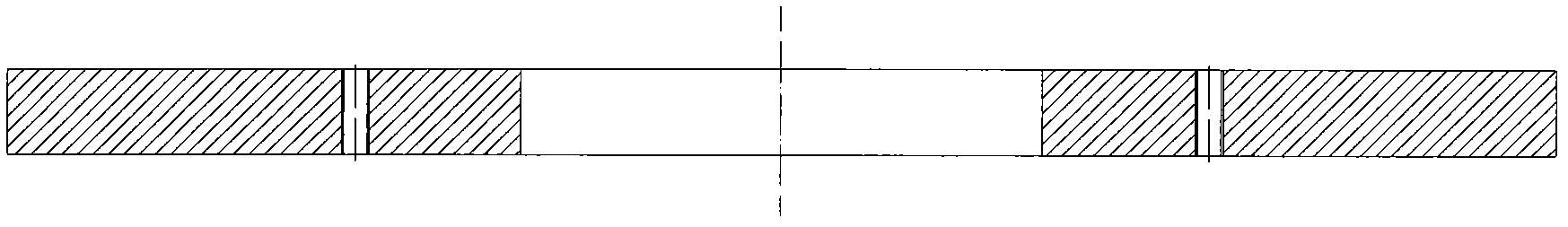

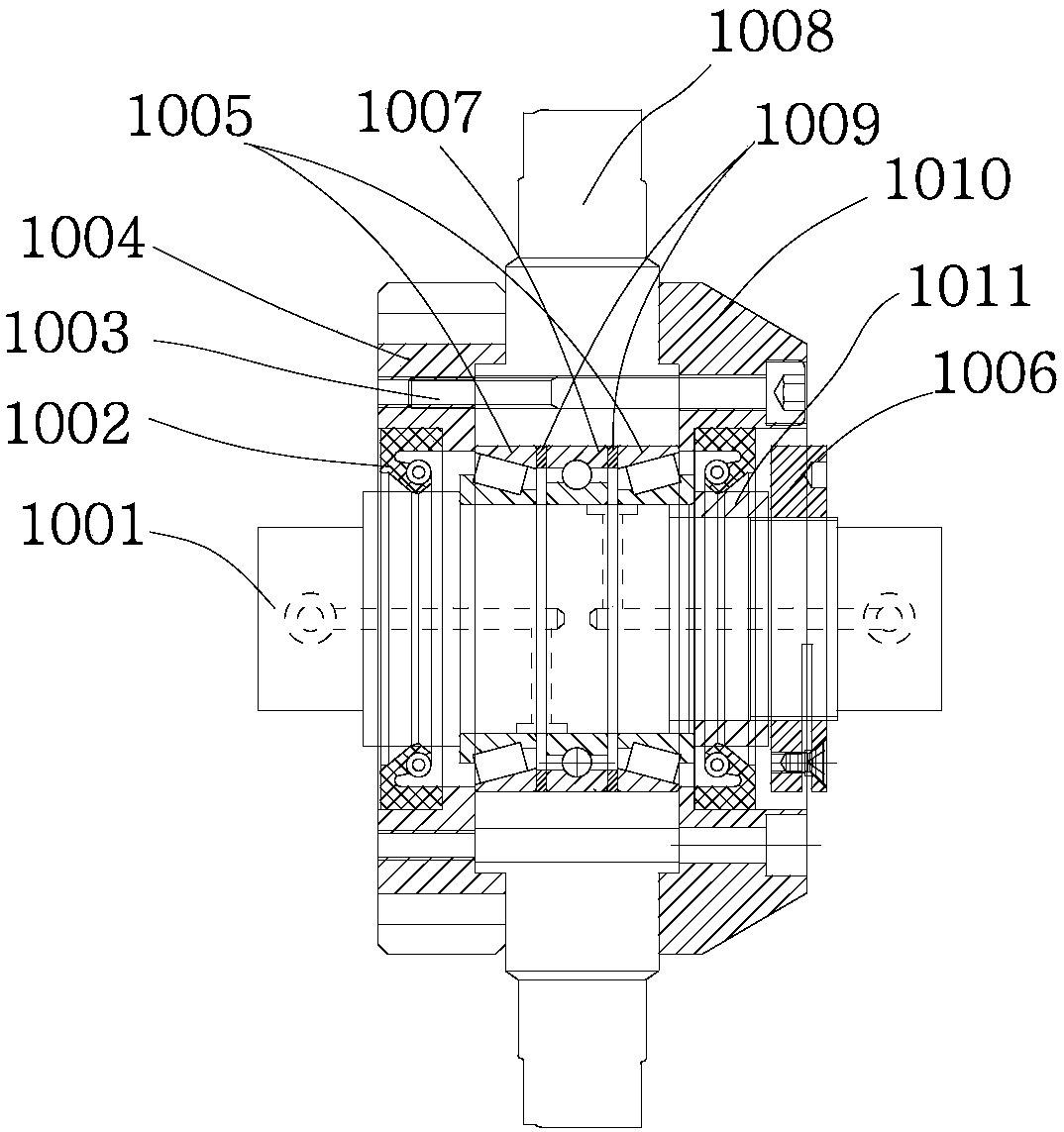

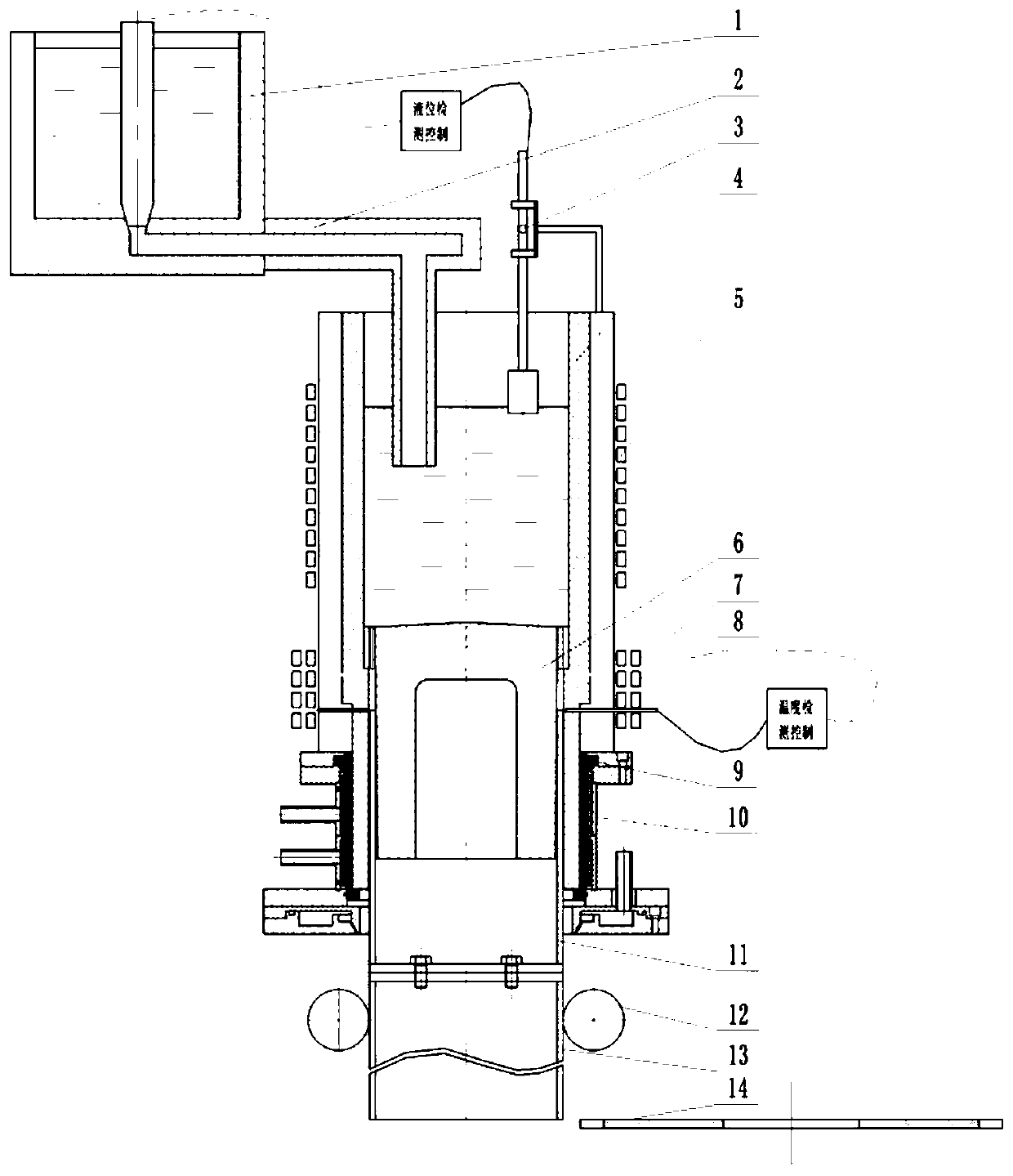

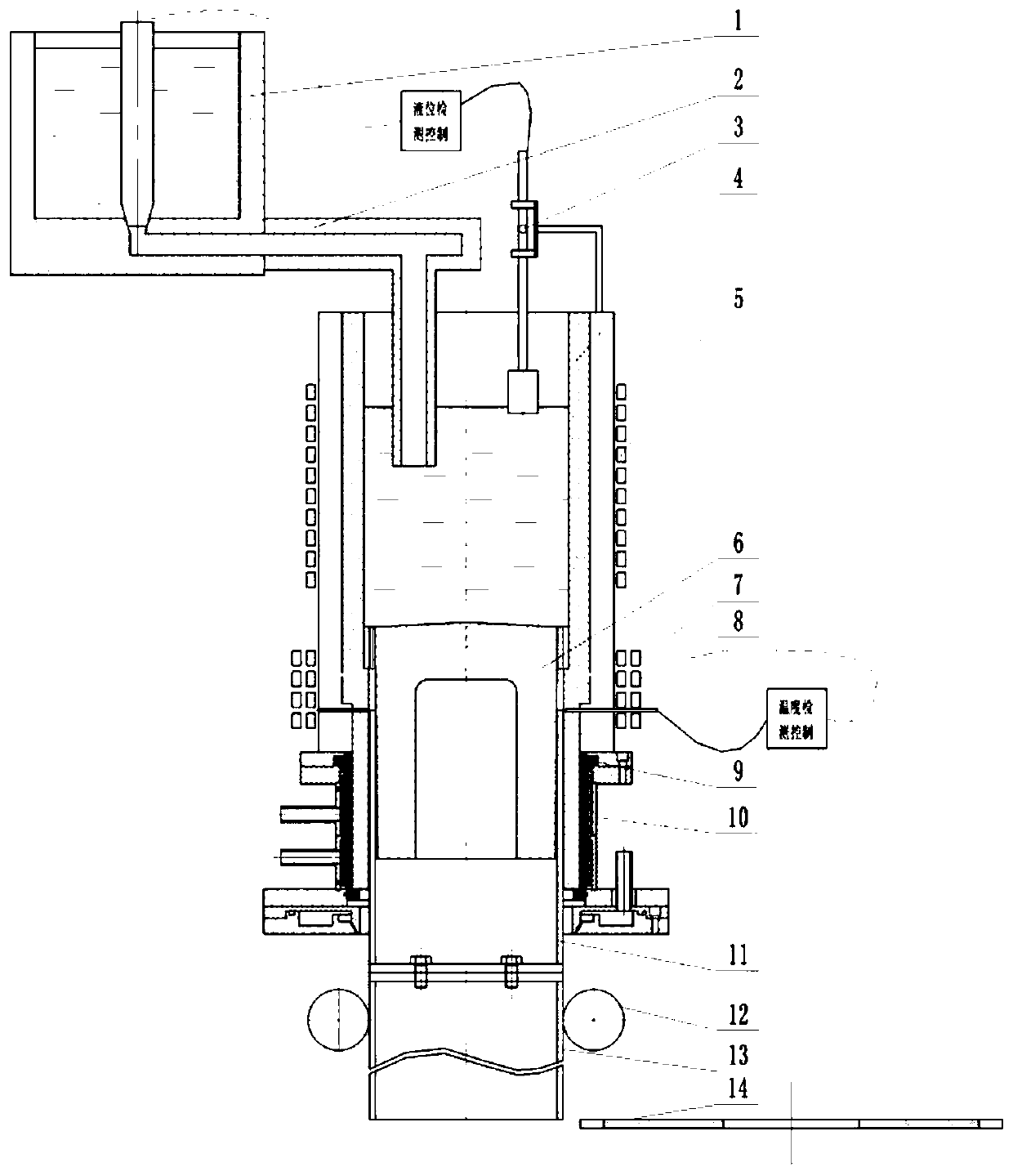

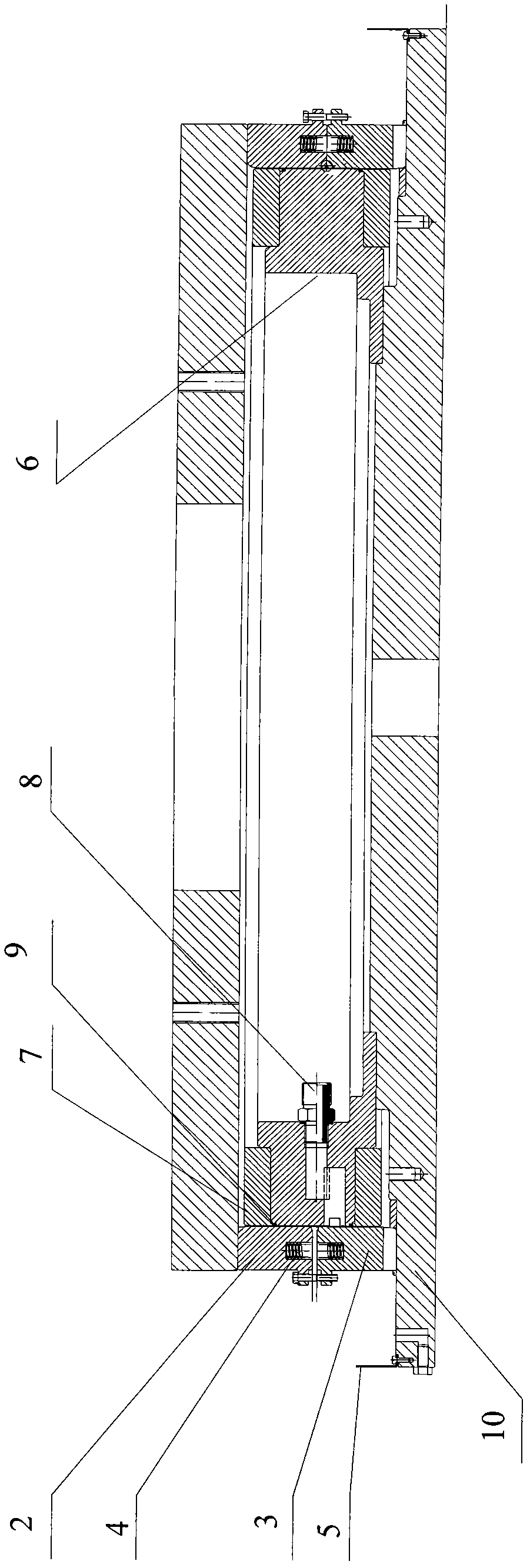

Alloyed steel horizontal type indirect extrusion machine

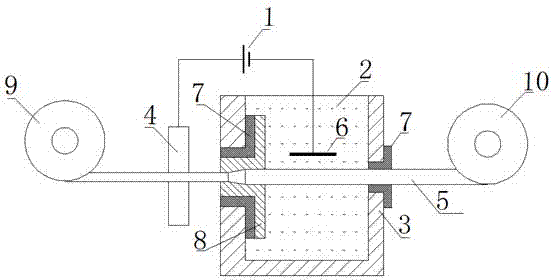

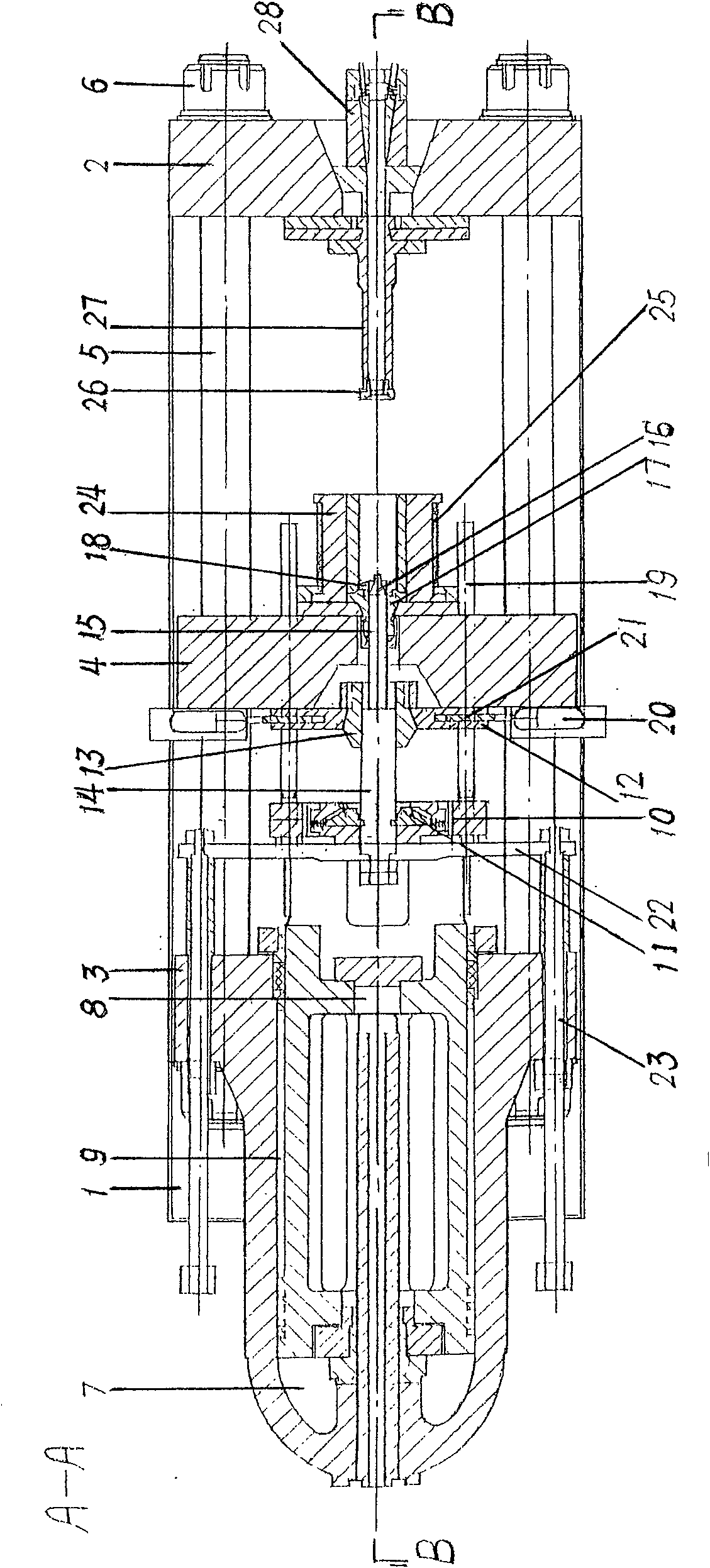

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation and extrusion and automatic switching system, a hot extrusion / molding system and a die removal and disengaging and residual extrusion and cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

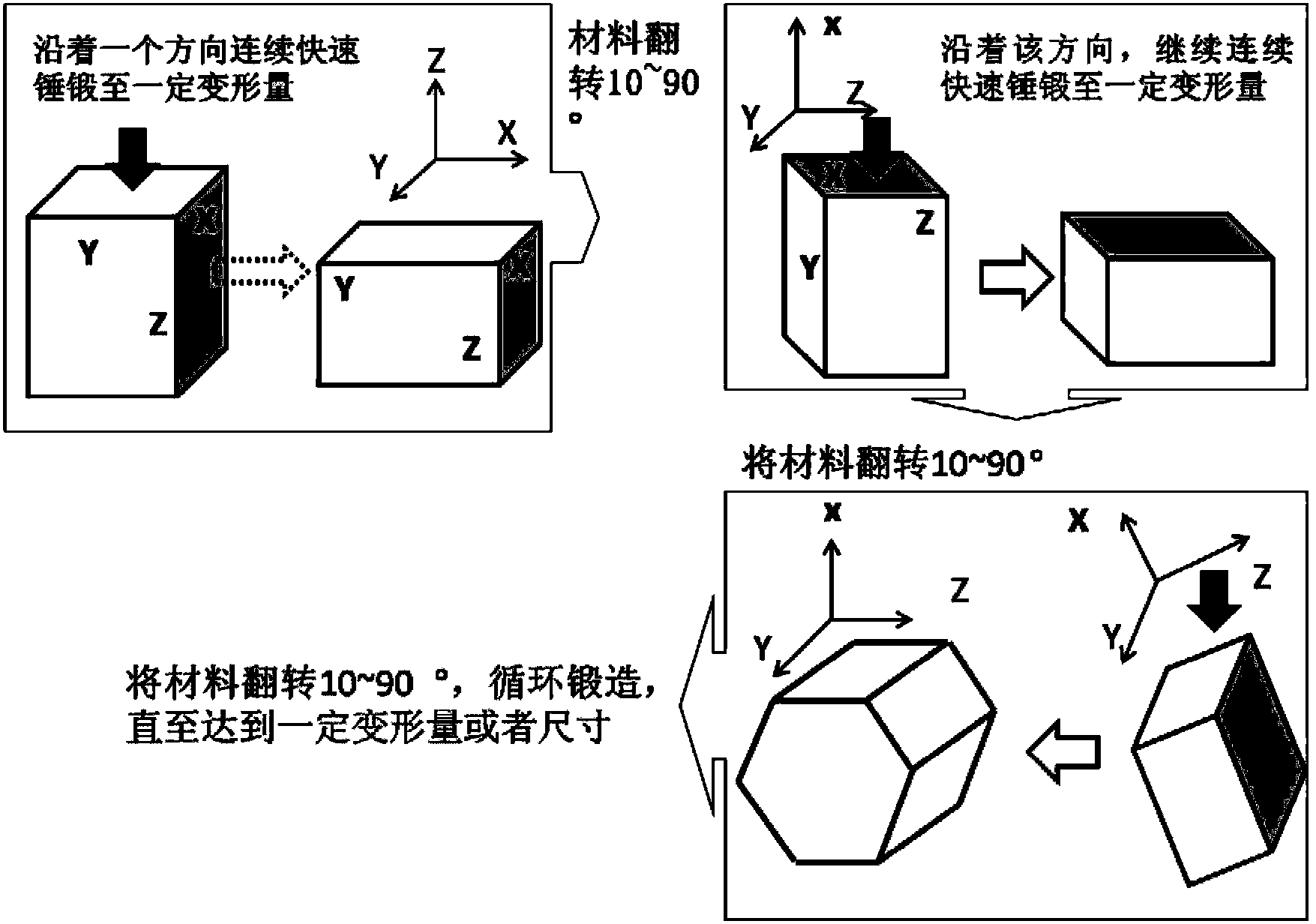

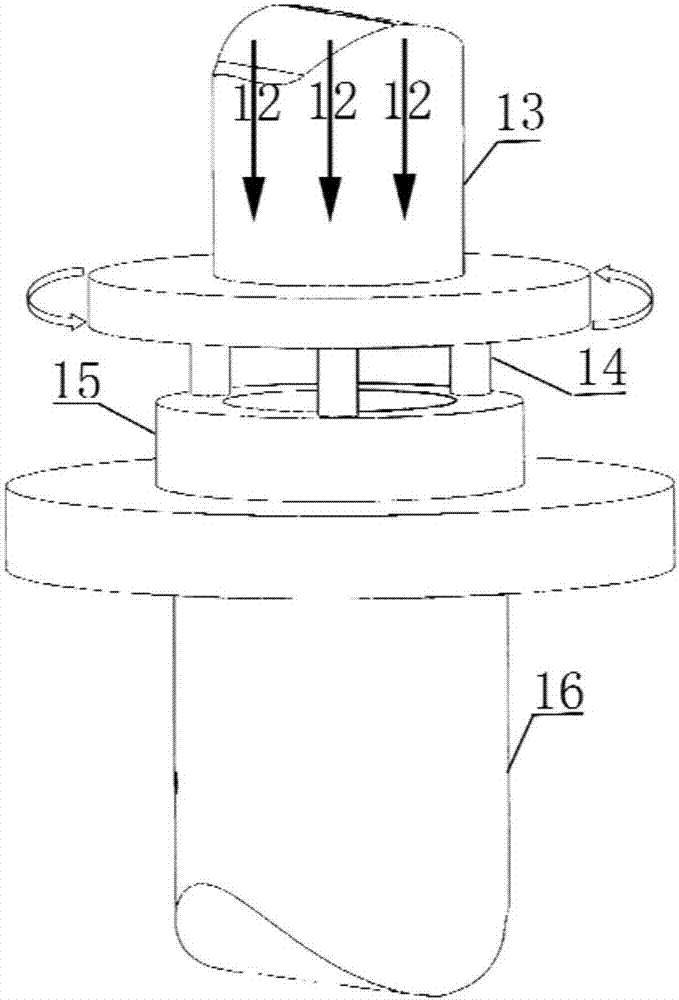

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

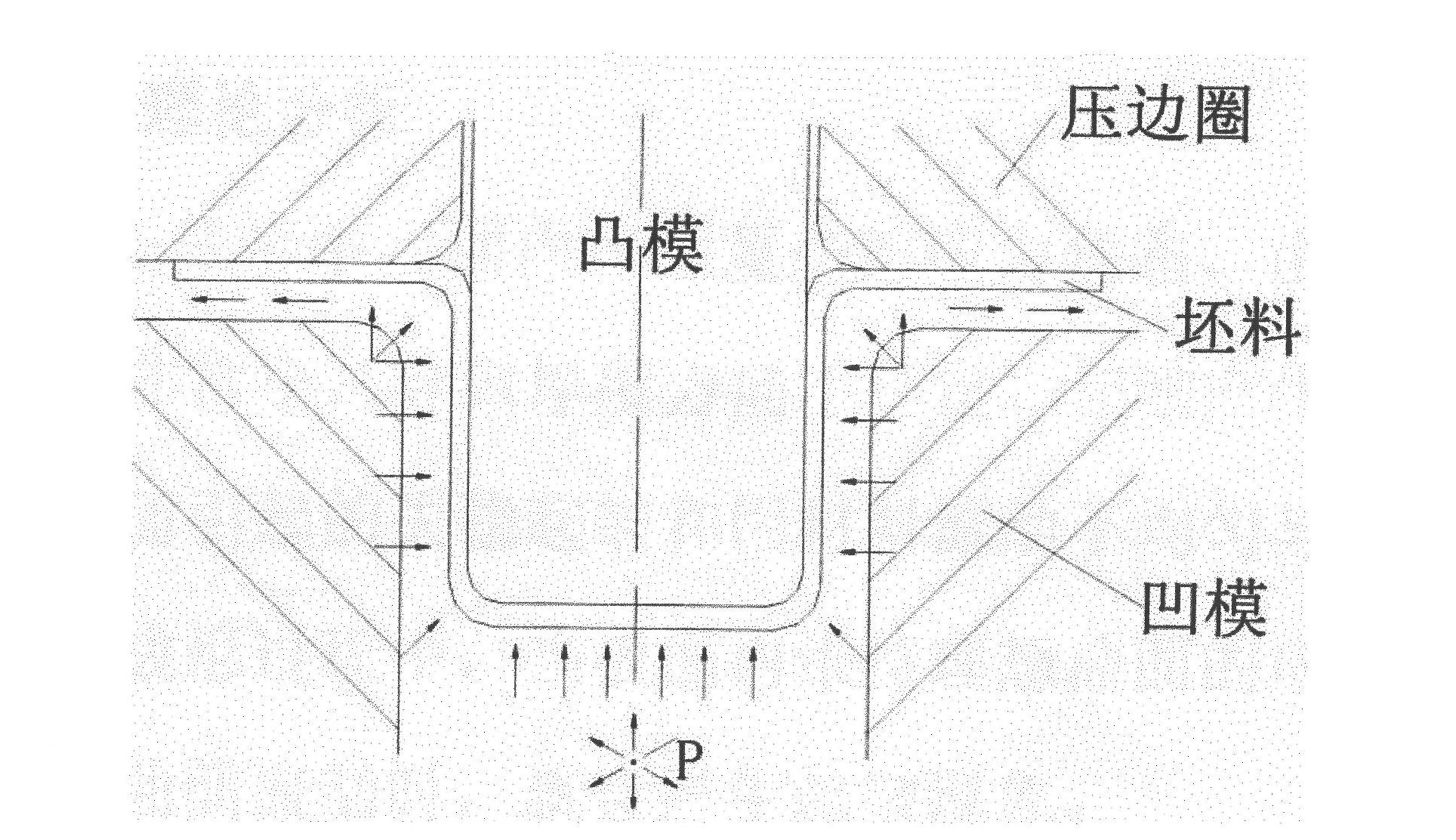

Method for forming thin-walled parts through stamping and drawing

The invention discloses a method for forming thin-walled parts through stamping and drawing, which is used for reducing the thicknesses (0.4-2mm) of raw materials to 50-100% of the original thicknesses the raw materials; the raw materials comprise magnesium alloys, aluminum alloys, titanium alloys, high temperature alloys and complex splice-welded plates; and the method specifically comprises the following steps that: a flexible forming technique is adopted with the aid of moulds and a hydraulic machine, wherein the moulds are in concave-convex fit with the hydraulic machine; upper and lower blank holders and concave and convex moulds are respectively subjected to hydraulic pressure exertion control; the nominal pressure of a main hydraulic cylinder exerted on the concave and convex moulds is 25000-4500 KN, and the nominal pressure of a side-pressing hydraulic cylinder accounts for 50-67% of the nominal pressure of the main hydraulic cylinder; and the maximum operating pressure of a liquid chamber is 150MPa. By using the method disclosed by the invention, an expected effect is obtained, and the qualification rates and efficiencies of parts are obviously improved; and meanwhile, the hydroforming technology fills in the gaps in industry application, and lays a solid foundation for the thorough solving of technical bottlenecks existing in actuating cylinder cover forming and the research and preparation of future novel thin-wall parts and sheet metal forming parts.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Short-flow high-efficiency production method for white brass alloy pipes

The invention relates to a short-flow high-efficiency production method for white brass alloy pipes, belonging to the field of metal materials. In the method, a white brass pipe produced by virtue of a hot-cold-combined casting-mould horizontal continuous casting process is used as a blank; in a straight white brass pipe production process, the pipe blank is directly subjected to cold rolling with the total deformation amount of 50-90% and the single-pass deformation amount of not more than 20-25%; in a white brass coiled pipe production process, the pipe blank is subjected to the cold rolling deformation with the total deformation amount of not more than 50-70% and the single-pass deformation amount of not more than 20-25%, low-temperature recovery annealing is carried out at the temperature of 300-550 DEG C for 1-2 hours after the rolling is completed, an annealing protection atmosphere is formed by 2% of H2 and the balance of N2, and the annealed coiled pipe is bound to be subjected to once finishing in a serial continuous drawing way or triple continuous drawing before coil drawing; and in a subsequent coil drawing process, an average pass lengthening coefficient is 1.2-1.5, and the coil drawing speed is 1-1,000m / min. Compared with the traditional casting and rolling drawing method for producing the white brass pipes, the method provided by the invention has the advantages of short process flow, obviously decreased annealing frequency and low annealing temperature, and is beneficial to energy conservation and production efficiency improvement.

Owner:UNIV OF SCI & TECH BEIJING

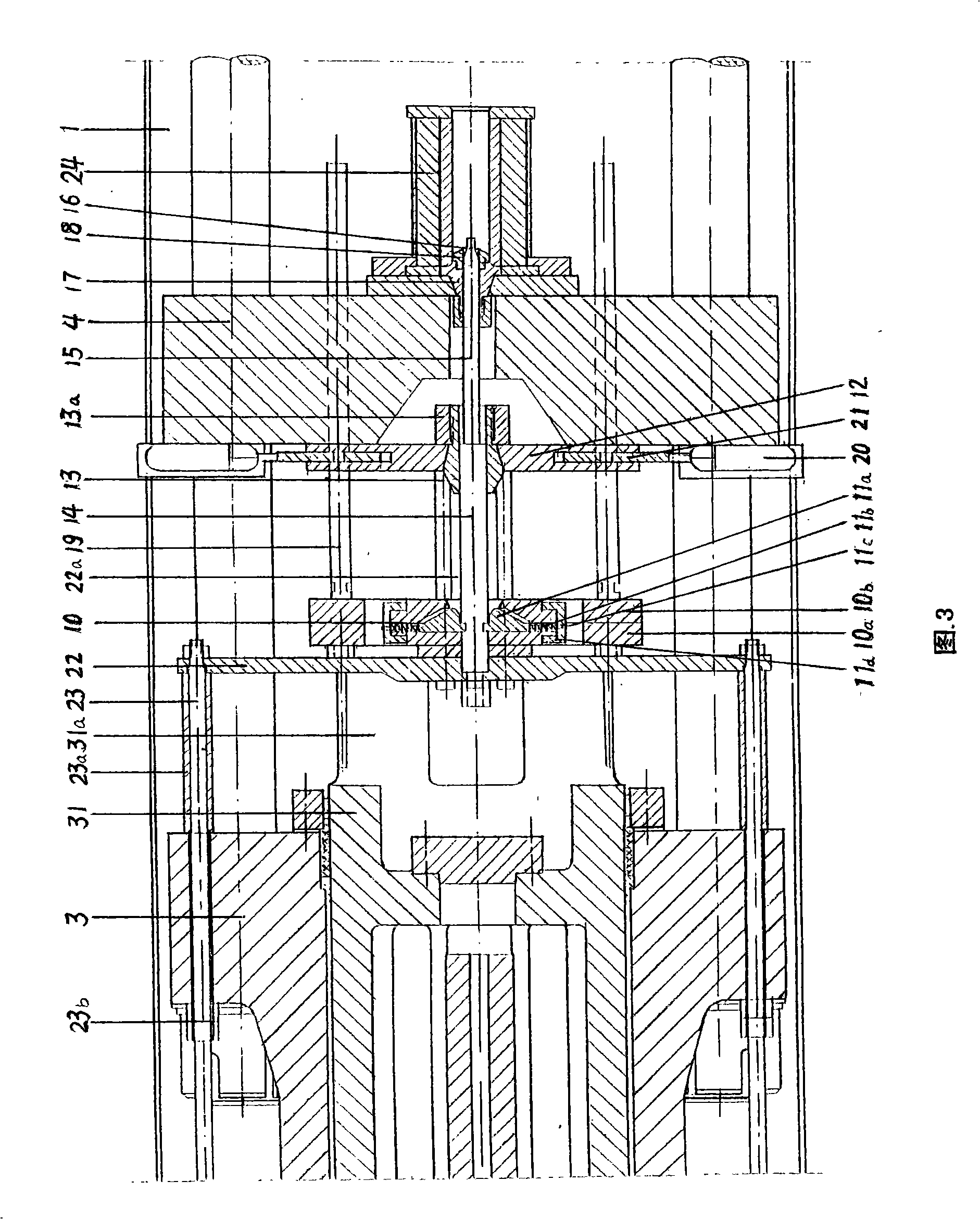

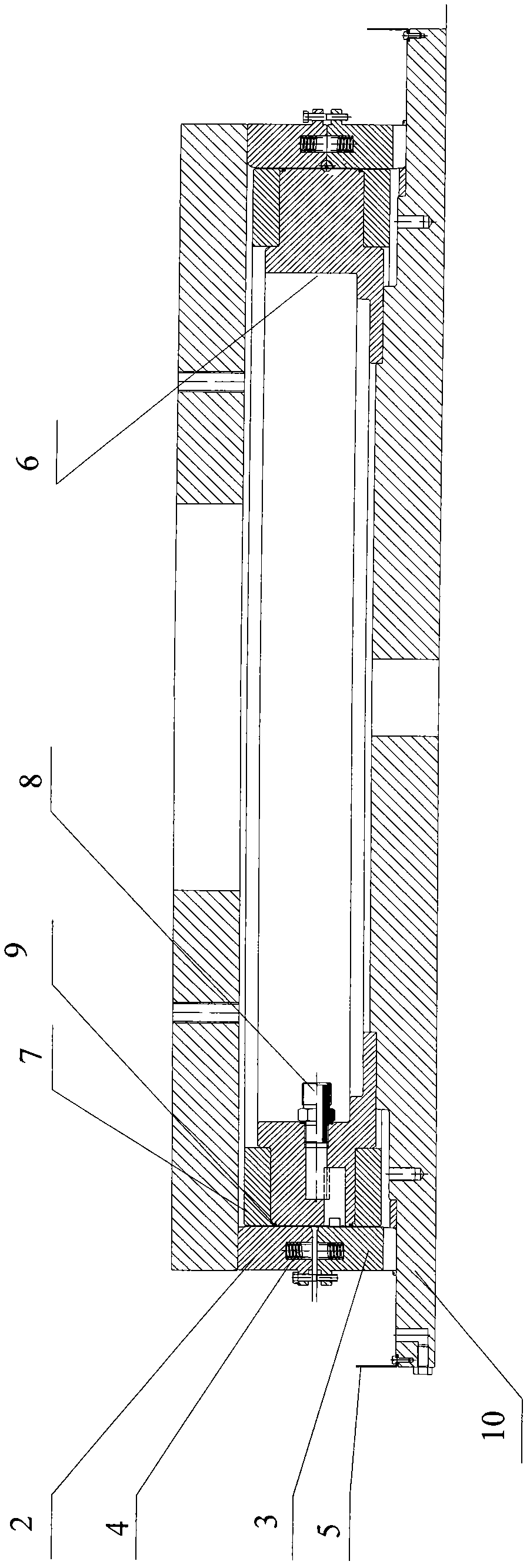

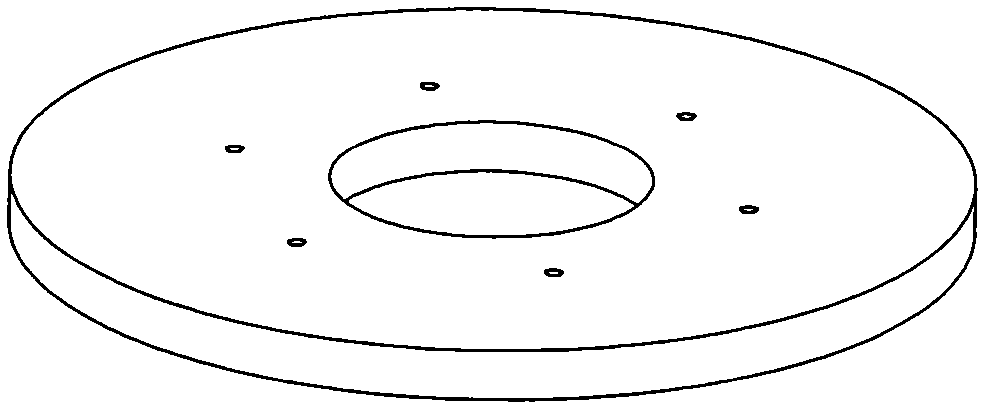

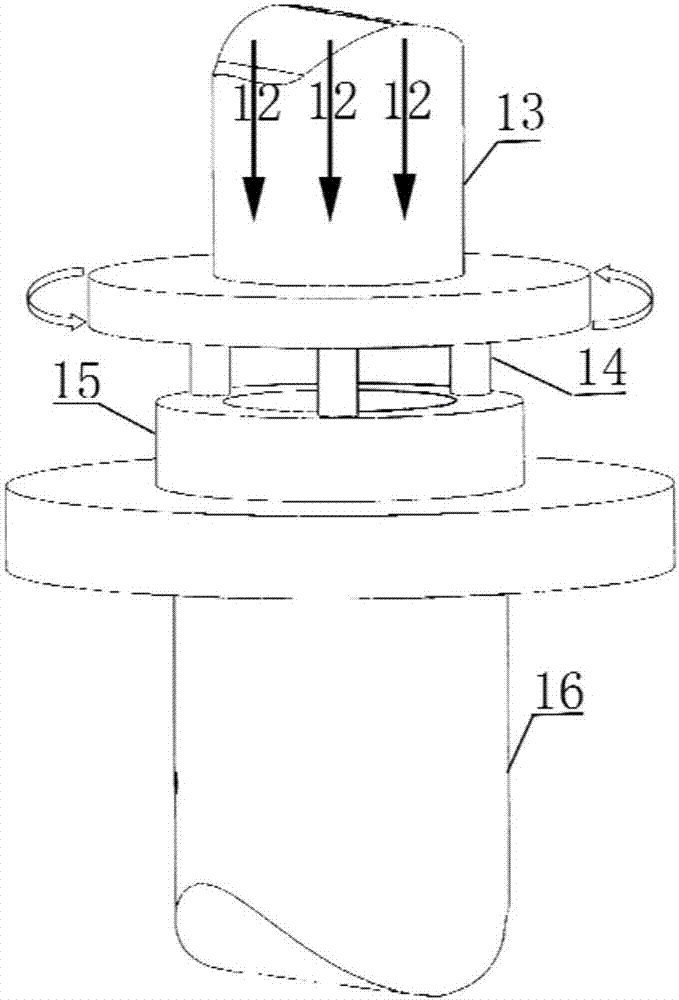

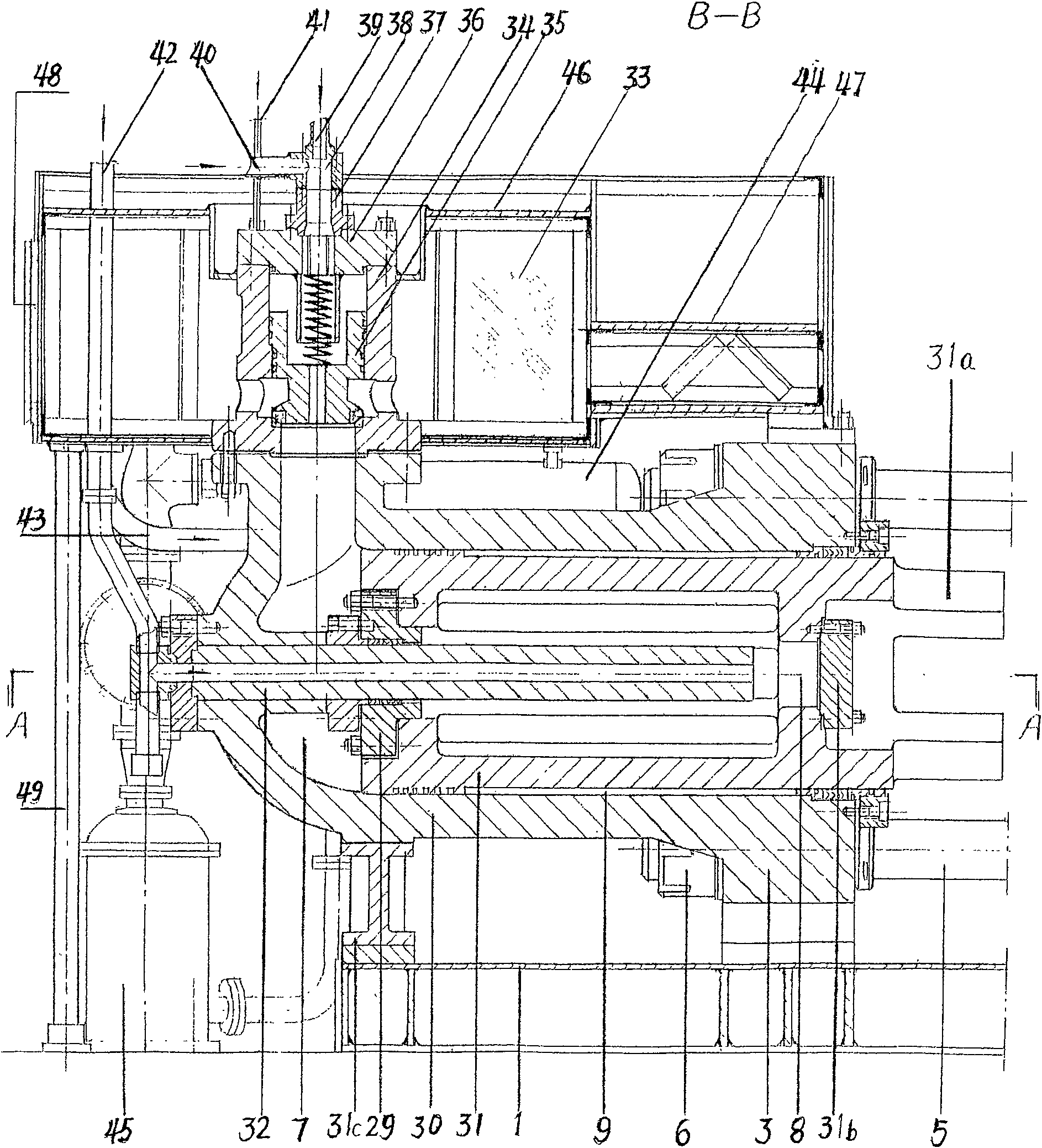

Forming method and forming die device for sealing ring used in engine

The invention relates to a forming die device for a sealing ring used in an engine. The device comprises a primary forming die and a final forming die, wherein the primary forming die specifically comprises a pressure plate, a first upper die, a first lower die, a supporting spring, an oil baffle pan, a base, an internal mold column, a sealing end cover, an oil guide pipe adapter, and the like; and the final forming die specifically comprises a pressure plate, a second upper die, an upper locking lantern ring, a lower locking lantern ring, a second lower die, an oil baffle pan, an intermediate model, a base, an internal mold column, a sealing end cover, and the like. The forming method for the sealing ring used in the engine comprises the following two steps of primary forming and final forming.

Owner:BEIHANG UNIV

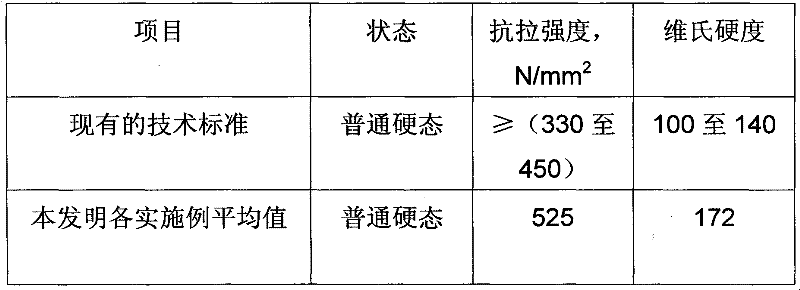

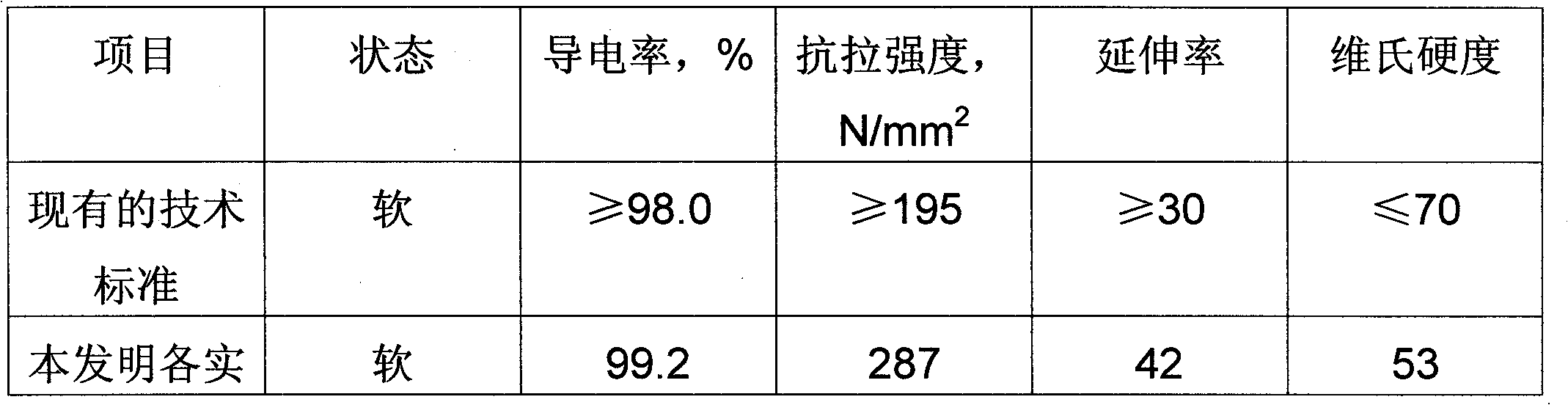

Copper cladded aluminum composite thin flat wire and its preparation method

ActiveCN101169987AReduce weightIncrease slot fill rateSingle bars/rods/wires/strips conductorsFlat/ribbon cablesFine lineAluminum composites

The invention relates to a copper-clad aluminum composite thin flat wire and a preparation method thereof. The copper-clad aluminum composite thin flat wire is composed of a core aluminum body and a pure copper cladding layer, and the pure copper cladding area ratio is 10% to 30%. , the thickness of the copper layer is evenly distributed, the minimum width of the cross-sectional dimension can reach 0.08mm, and the minimum thickness can reach 0.02mm. It is beneficial to reduce the volume and weight of the coil, and can meet the use requirements of micro-motor enameled wires for various precision micro-electrical appliances. The copper-clad aluminum composite thin flat wire is prepared by cold liquid extrusion to prepare copper-clad aluminum wire billet, combined with subsequent cold deformation strong processing (drawing, rolling) to prepare copper-clad aluminum composite thin flat wire, the prepared copper-clad aluminum composite thin The preparation process of the flat wire greatly reduces the number of annealing times, lowers the annealing temperature, and even does not need annealing according to needs, simplifies the production process, and reduces the production cost.

Owner:UNIV OF SCI & TECH BEIJING

Magnesium alloy as well as preparation method and application thereof

The invention relates to a magnesium alloy as well as a preparation method and application thereof, in particular relates to an abrasive-resistant magnesium alloy, magnesium alloy surfacing welding rod and preparation method thereof, and belongs to the technical field of techniques and metallurgies of metal materials. The magnesium alloy comprises the following chemical components in percentage by mass: 7.98 to 9.31 percent of Al, 0.19 to 1.52 percent of Zn, 0.10 to 0.61 percent of Mn, 0.80 to 1.89 percent of Gd, 0.40 to 1.49 percent of Y, and the balance of Mg. Under a condition of a dry friction abrasion test at a room temperature, after the Mg-Al-Zn-Gd-Y magnesium alloyx welding rod is subjected to surfacing, the relative abrasion property can reach 3.09.

Owner:NORTHEASTERN UNIV

High-strength high-surface anodic oxidation appearance aluminum alloy strip and preparation method thereof

InactiveCN108149091ADoes not affect oxidation appearanceReduce the number of annealingSolid solution strengtheningHigh surface

The invention relates to the field of preparation of aluminum and aluminum alloy strips, in particular to a high-strength high-surface anodic oxidation appearance aluminum alloy strip and a preparation method thereof. The high-strength high-surface anodic oxidation appearance aluminum alloy strip and the preparation method thereof mainly solve the technical problems of incapability of synchronously achieving high surface appearance and high strength because an aluminum profile in the prior art can achieve high strength through quenching and ageing after extrusion but an aluminum alloy strip can achieve strength through solid solution strengthening of solid solution elements and hardening given by cold rolling. The aluminum alloy strip comprises the following components in percentage by mass: 3.0-5.0 wt% of Mg, 0.1-1.0 wt% of Zn, no more than 0.05 wt%of Si, no more than 0.10 wt%of Fe, no more than 0.05 wt%of Mn,no more than 0.1 wt%of Cr, no more than 0.05 wt%of Ti, nomore than 0.10 wt%of Cu, and the balance Al, wherein Fe / Si=1-3.

Owner:ZHEJIANG YONGJIE ALUMINUM CO LTD

Method for quickly preparing magnesium alloy fine crystalline wire and superfine magnesium alloy wire based on drawing process

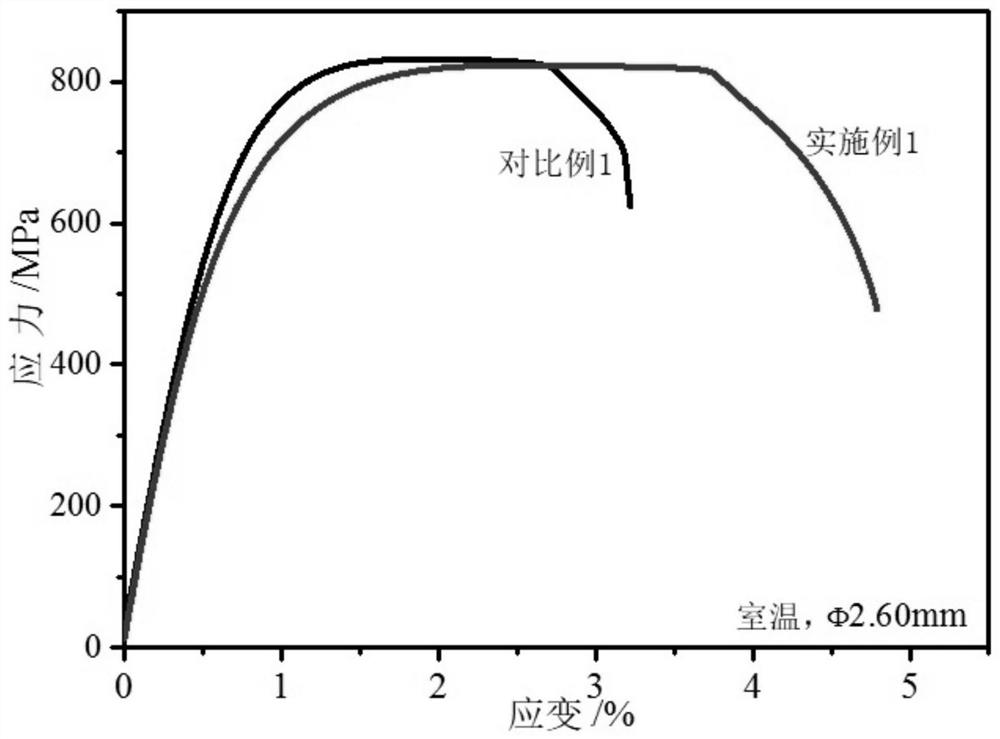

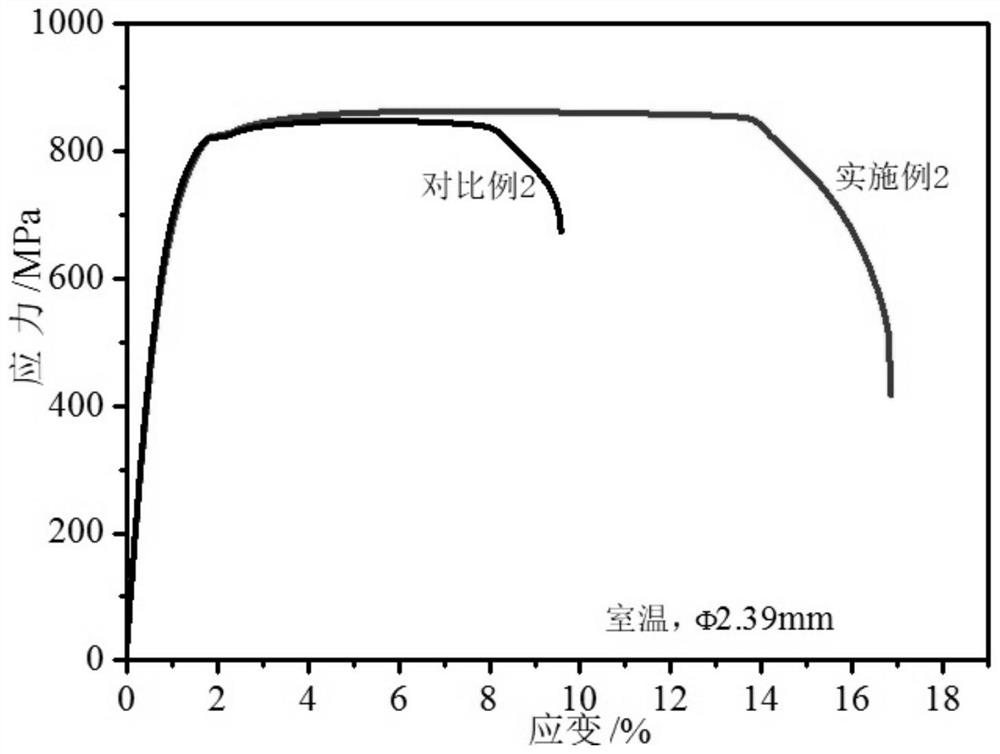

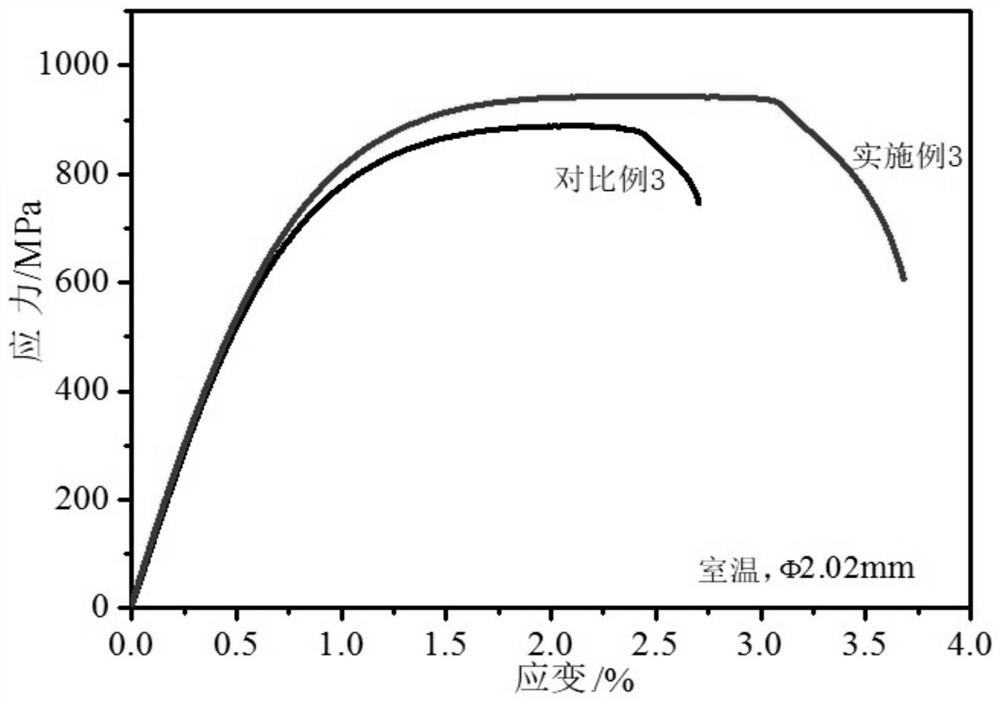

ActiveCN110193525AIncrease the degree of deformationReduce the temperatureNonferrous metalRoom temperature

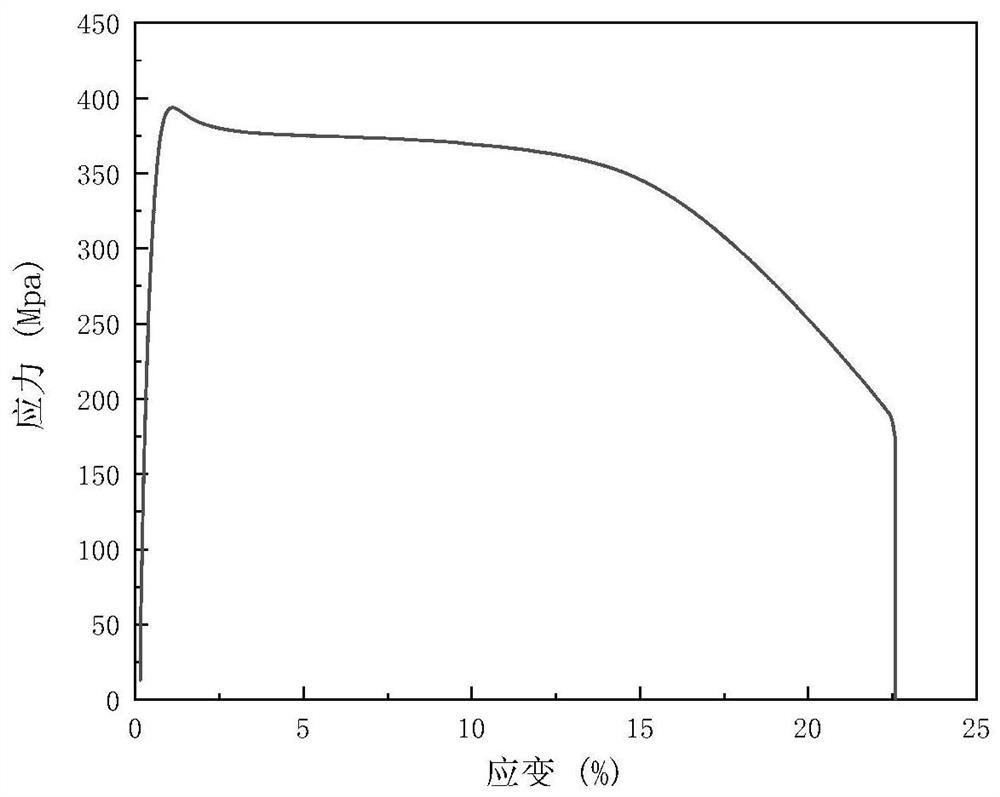

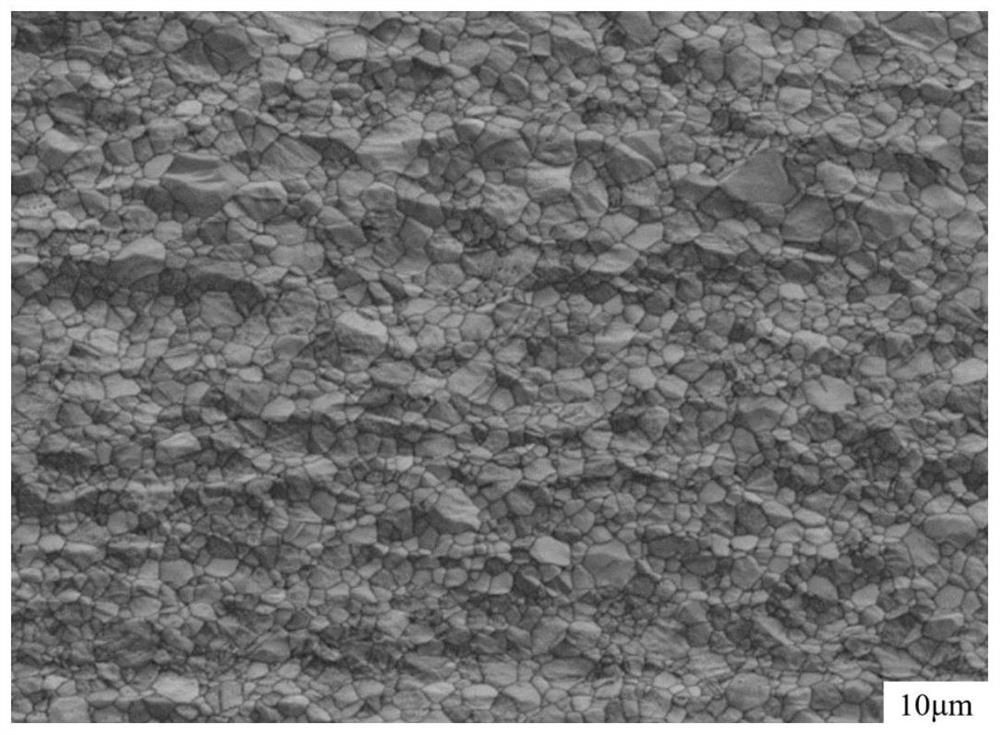

The invention discloses a method for quickly preparing a magnesium alloy fine crystalline wire and a superfine magnesium alloy wire based on a drawing process, belongs to the field of nonferrous metalplastic forming, and aims to solve the technical problem that an existing magnesium alloy drawing process is liable to have wire breakage, and is not ideal in crystalline grain size. The method for preparing the magnesium alloy fine crystalline wire comprises the following steps: thermally extruding magnesium alloy cast ingots into bars with diameters Phi being 6mm-10mm, and annealing the bars; II, performing thermal drawing on the bars, and immediately water-cooling the bars to the room temperature after each-pass thermal drawing; III, performing continuous cold-drawing on the bars, and air-cooling the bars to the room temperature; and IV, repeating operations of steps II to III until the diameters Phi of the bars are 1.0mm-1.5mm. The method for preparing the superfine magnesium alloy wire comprises the following steps: step 1, performing continuous cold-drawing on the magnesium alloy fine crystalline wire until the diameter Phi of the wire is lower than 1.0 mm, and air-cooling the wire to the room temperature after annealing; and step 2, repeating the operation of step 1 until the diameter Phi of the wire is 0.10mm. The Phi 0.10mm wire prepared by the method has an average crystalline grain size of 1[mu]m.

Owner:HARBIN UNIV OF SCI & TECH

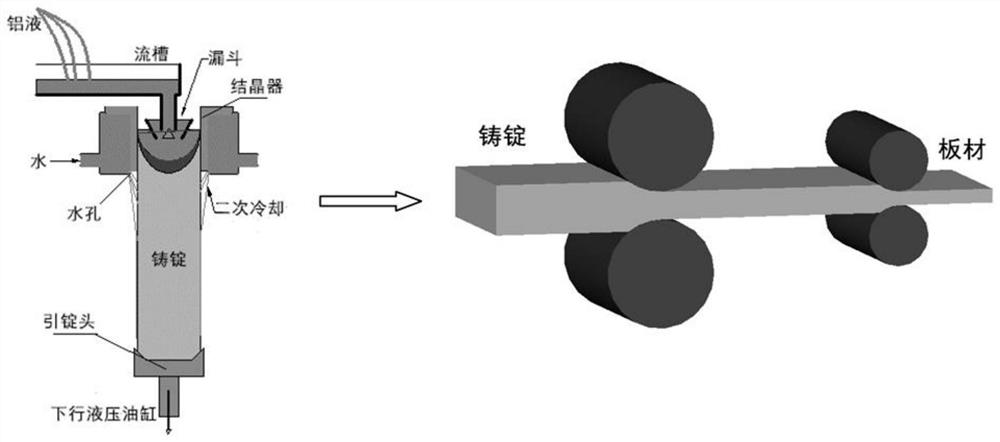

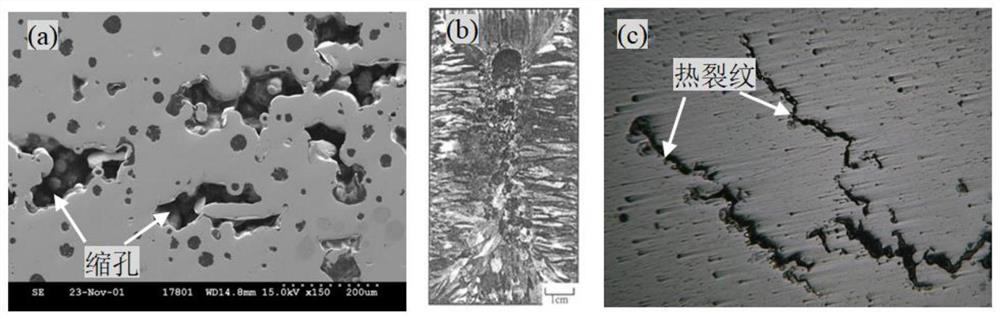

Aluminum alloy plate strip preparation method based on vacuum centrifugal casting and vacuum centrifugal casting device

The invention relates to an aluminum alloy plate strip preparation method based on vacuum centrifugal casting and a vacuum centrifugal casting device. The preparation method comprises the following steps that raw materials are prepared according to components of a target aluminum alloy; a cast pipe blank is cast in a vacuum centrifugal casting manner; the cast pipe blank prepared through vacuum centrifugal casting is split, the split cast pipe blank is leveled, and an aluminum alloy cast plate blank is obtained; and the aluminum alloy casting plate blank is rolled, and an aluminum alloy plate strip is obtained. According to the preparation method, under the action of centrifugal force, the feeding environment in the solidification process of aluminum alloy melt liquid can be obviously improved, and casting defects such as shrinkage porosity and shrinkage cavities can be effectively bridged under the action of the centrifugal force. Due to the fact that vacuum centrifugal casting is completed under the vacuum condition, a melt does not make contact with air, melt oxidation can be effectively avoided, the defect of oxide inclusion in the cast pipe blank is greatly reduced, and the quality of the pipe blank is improved.

Owner:NORTHEASTERN UNIV

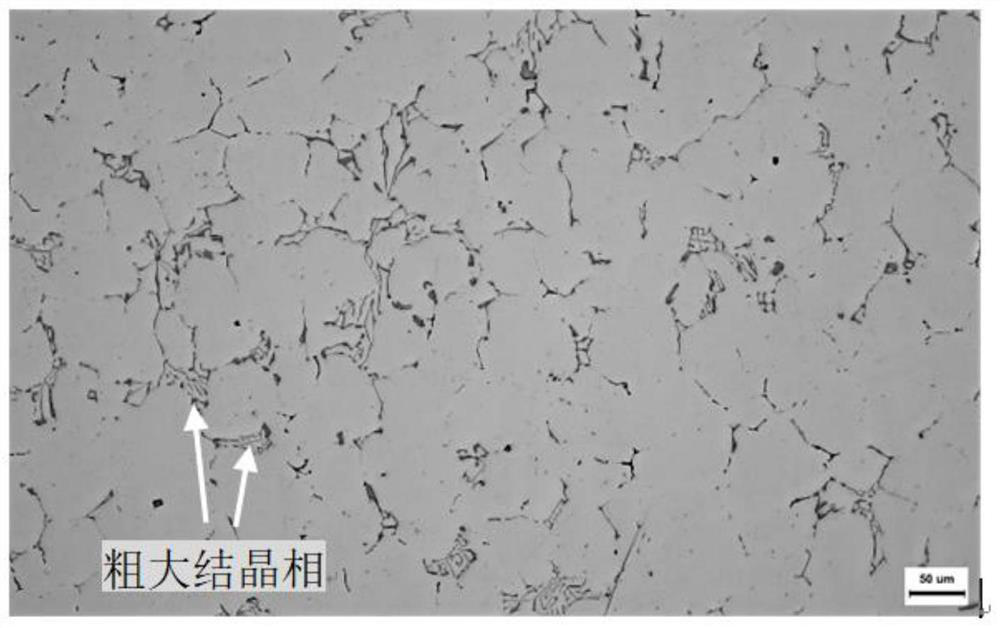

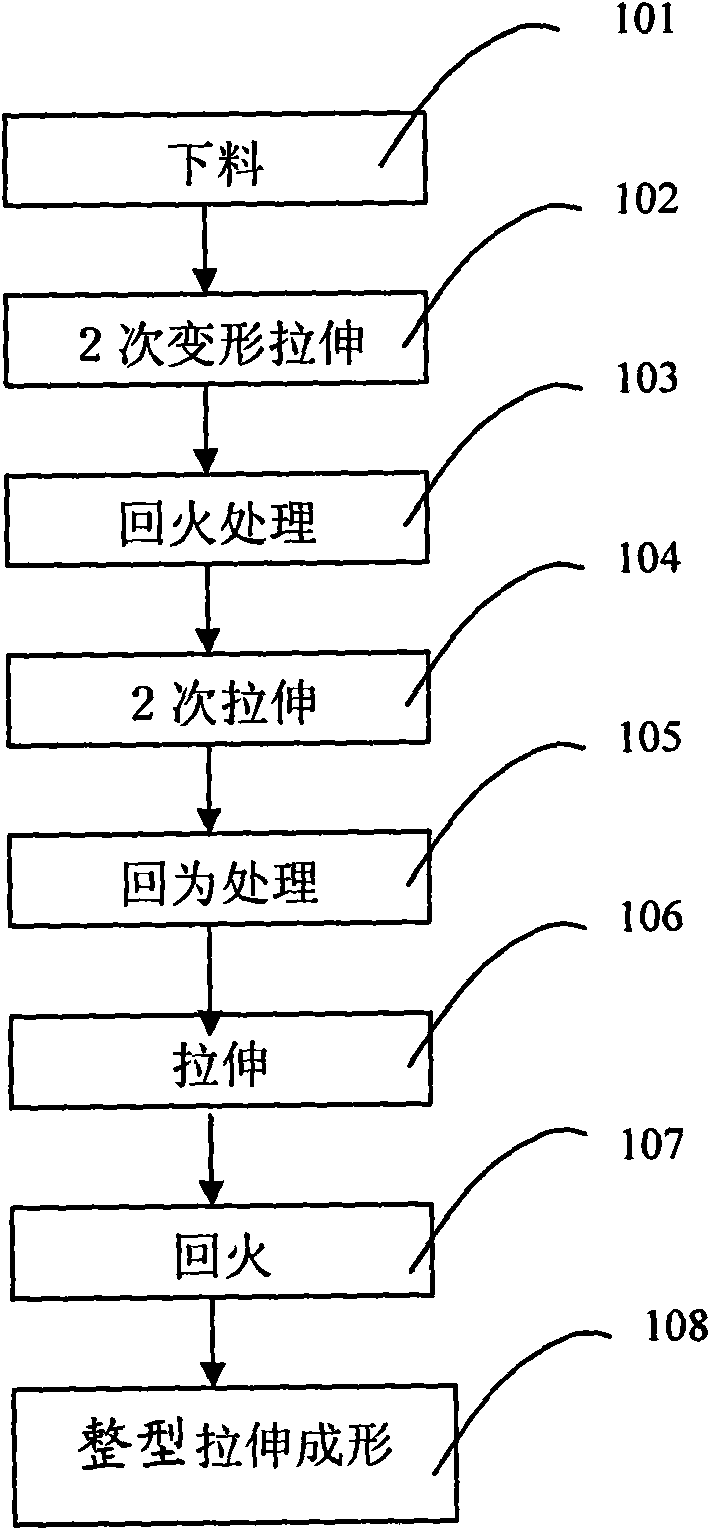

Stainless steel thin-walled member, processing method thereof and die for processing

InactiveCN101612635AReduce the number of annealingReduce processing stepsShaping toolsFurnace typesMetallurgyThin walled

The invention provides a processing method for processing a stainless steel thin-walled member applied in the field of processing of stainless steel thin-walled members. The method comprises: a step of continuous stretching for N times, a step of tempering treatment, and a step of alternated treatment of stretching for K-N times and tempering. By adopting twice continuous deformation stretching and then carrying out a process of once annealing treatment, the processing method reduces the annealing times so as to reduce the processing procedure, save the processing time and improve the processing efficiency.

Owner:郭赞琼

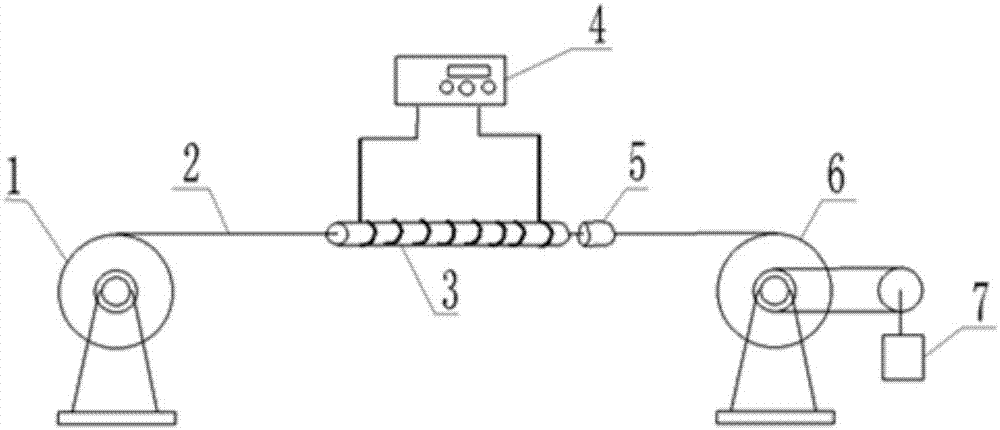

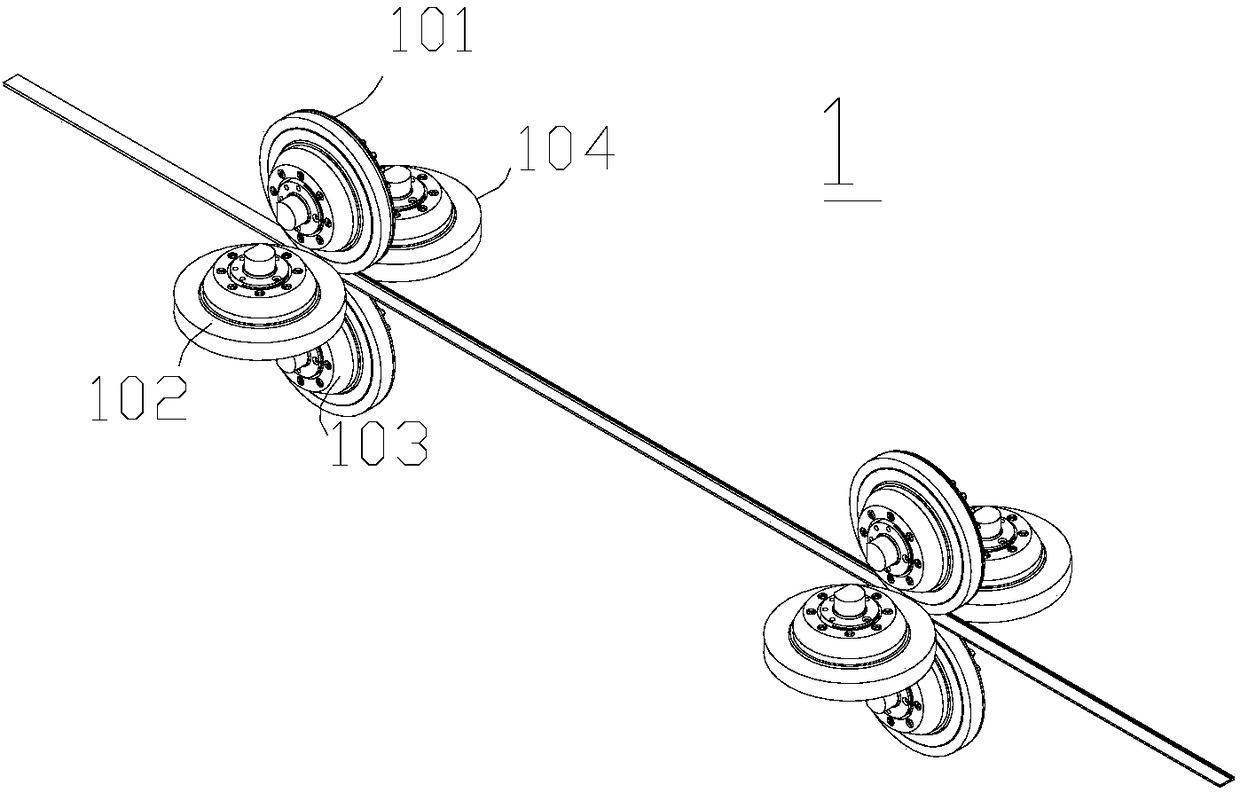

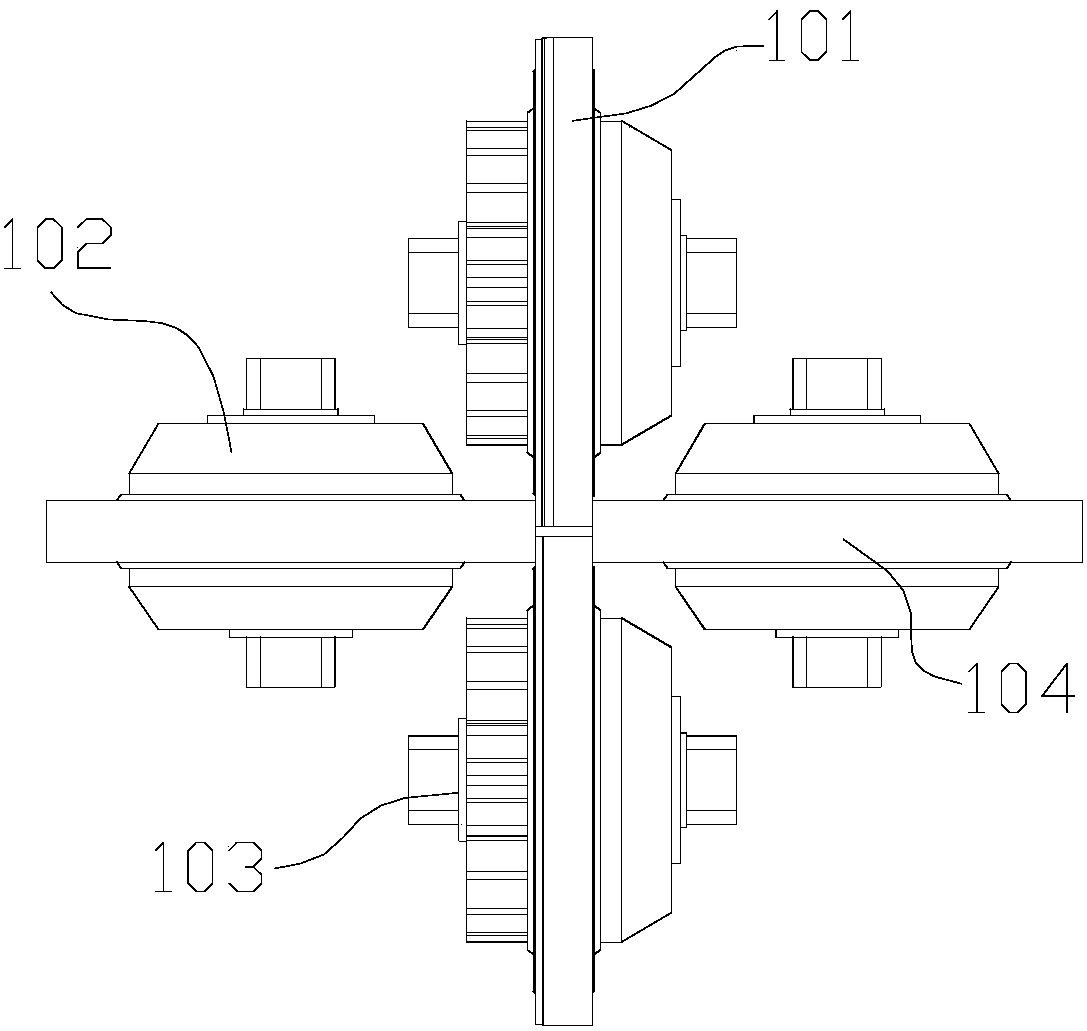

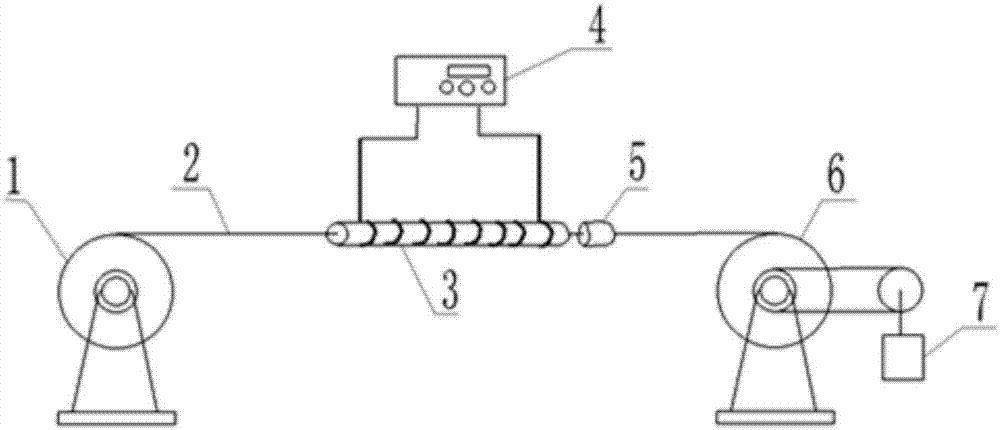

Rolling and drawing joint production equipment for profiled material products, and rolling and drawing production technology thereof

InactiveCN108296303AReduce the number of annealingShorten the production cycleMetal rolling arrangementsContinuous rollingMaterials science

The invention discloses rolling and drawing joint production equipment for profiled material products, and a rolling and drawing production technology thereof. The production equipment comprises a guiding device, a rolling mill, a drawing machine and an auxiliary device, and the rolling mill is a two-pass continuous rolling mill, and comprises a first rolling group, a second rolling group, a thirdrolling group and a fourth rolling group, wherein a first rolling pass is formed by the first rolling group and the second rolling group, and a second rolling pass is formed by the third rolling group and the fourth rolling group; and the prototype of a workpiece is controlled by the rolling mill; the drawing machine is a continuous drawing machine, and comprises a first drawing group and a second drawing group which are located at a first drawing pass and a second drawing pass separately; and the drawing machine further comprises front and rear drawing trolleys and a box body. The rolling and drawing production technology comprises the steps of two times of continuous rolling by the first pass, annealing, two times of continuous rolling by the second pass, annealing, drawing on the firstpass, drawing on the second pass and so forth, so that the profiled material products are obtained.

Owner:广州众山金属科技有限公司

Mg-Al-Zn-Gd-Ce alloy and preparing method and application thereof

ActiveCN107164674ALower requirementExtended service lifeWelding/cutting media/materialsSoldering mediaRoom temperatureMagnesium alloy

The invention relates to an Mg-Al-Zn-Gd-Ce alloy and a preparing method and application thereof, in particular to an abrasion-resisting Mg-Al-Zn-Gd-Ce alloy, an Mg-Al-Zn-Gd-Ce alloy surfacing welding stick and a preparing method of the welding stick, and belongs to the technical field of metal material technologies and metallurgy. The Mg-Al-Zn-Gd-Ce alloy comprises magnesium alloy chemical components including, by mass percent, 2.47%-3.55% of Al, 0.29%-1.50% of Zn, 0.26%-0.56% of Mn, 0.80%-2.54% of Gd, 0.49%-2.38% of Ce, and the balance Mg. Under the room temperature dry friction abrasion test conditions, after the Mg-Al-Zn-Gd-Ce magnesium alloy welding stick is subjected to surfacing, the relative abrasion resistance of the Mg-Al-Zn-Gd-Ce magnesium alloy welding stick can reach 3.29.

Owner:NORTHEASTERN UNIV

Short-flow efficient production method of pure copper tube

The invention belongs to the metal material field and relates to a short-flow efficient production method of a pure copper tube. The technical scheme of the invention is as follows: the hot-cold combined moulding and continuous casting technology is adopted to efficiently produce the pure copper tube blank with an axial orientation structure and good inner surface quality and outer surface quality; subsequent shape processing is performed to the tube blank without adopting surface planing treatment; and intermediate annealing is not required in the processing process or little low-temperatureannealing is only required, so as to efficiently produce the pure copper tube. The hot-cold combined moulding and continuous casting technology is characterized in that a continuous casting crystallizer is combined by a heated hot moulding section and a cold moulding section which is forced to be cooled by the circulating water, and the solidification interface position of the tube is controlled to be near the borderline of the hot moulding section and the cold moulding section to efficiently prepare the tube blank with high surface quality and an axial orientation structure. The method has the advantages of short production process, low energy consumption, low cost, high yield and high production efficiency.

Owner:UNIV OF SCI & TECH BEIJING

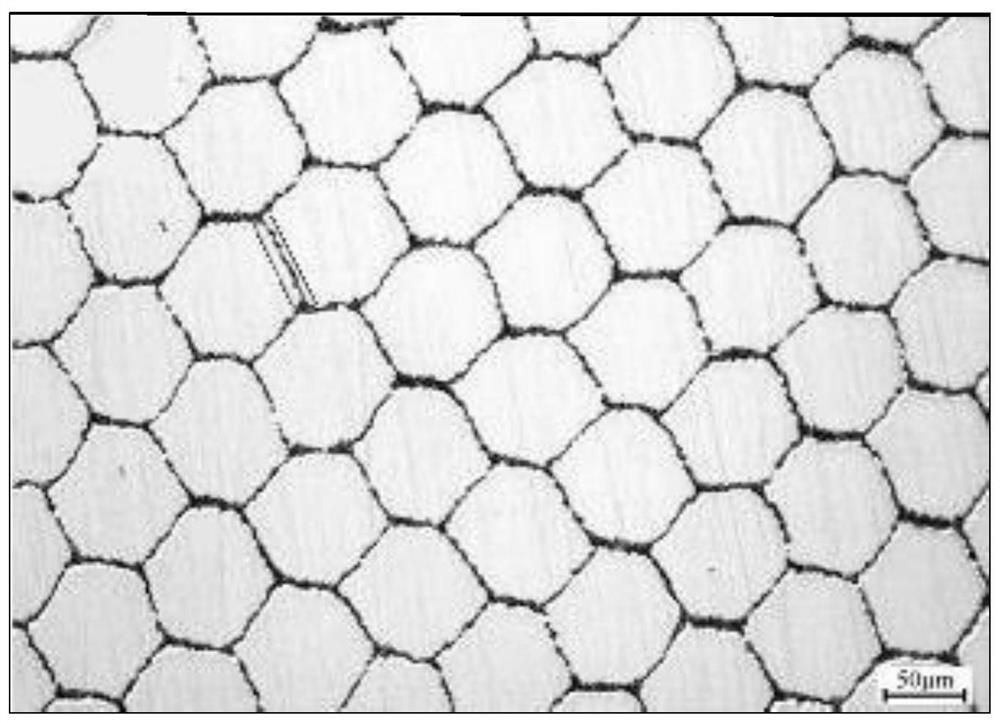

A new type of solid welding wire processing and manufacturing method

ActiveCN103286481BHigh strengthImprove plasticityWelding/cutting media/materialsSoldering mediaNonferrous metalMegasonic cleaning

The invention relates to the field of welding material manufacturing, in particular to a manufacturing method of novel solid welding wires. The method starting from wire rod machining sequentially includes: forging, annealing, continuously wire drawing, scraping, and ultrasonic wave cleaning to obtain the solid welding wires which are bright and fine-grain. The solid welding wires include various non-ferrous metal and non-ferrous metal alloy welding wires. The manufactured solid welding wires have fine and even equiaxed grains on the transverse end faces and the longitudinal end faces, product strength and plasticity are increased evidently compared with other manufacturing methods, and excellent mechanical property is achieved. In addition, the manufacturing method is simple in process, low in waste material, high in yield and the like.

Owner:抚顺东工冶金材料技术有限公司

Cross rolling method of molybdenum-copper alloy foil

InactiveCN102489508ARolling suitable forSolve the problem of surface crackingMetal rolling arrangementsHigh densityHigh volume manufacturing

The invention discloses a cross rolling method of a molybdenum-copper alloy foil, cold rolling is performed on a molybdenum-copper alloy sintered plate billet in the thickness of 0.8-4mm multiple times, when the rolling deformation is 60-90%, 90-degree cross rolling is performed, the deformation is still controlled within 60-90%, and then annealing is performed on the cross-rolled foil, wherein the annealing temperature is 600-850 DEG C. The cross rolling can be continuously performed on the billet after annealing according to the requirement of the thickness of a product, and the cross rolling is performed once before every annealing. According to the cross rolling method disclosed by the invention, the surface cracking problem during the one-way rolling process can be effectively solved, the times of annealing can be reduced, and the high-density molybdenum-copper alloy foil in the thickness of 0.02-0.1mm can be prepared. The method has the advantages of low requirements on equipment, high production efficiency, low energy consumption and the like, and is suitable for mass production and rolling of the molybdenum-copper alloy foil.

Owner:无锡乐普金属科技有限公司

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Cross rolling method for tungsten-copper alloy foil

InactiveCN102489504ASolve the problem of surface crackingReduce the number of annealingMetal rolling arrangementsHigh densityHigh volume manufacturing

The invention discloses a cross rolling method for a tungsten-copper alloy foil. The method comprises the following steps of: performing multi-pass cold rolling on a tungsten-copper alloy sintering plate blank with the thickness of 0.8 to 3mm; when the rolling deformation amount is about 40 percent, performing 90-degree cross rolling, wherein the deformation amount is still controlled to be less than or equal to 40 percent; annealing the blank which is subjected to cross rolling at the temperature of between 700 and 900 DEG C; and performing cross rolling on the annealed blank continuously according to the thickness requirement of a product, wherein cross rolling is performed once every time before annealing. By the method, the problem that the surface is cracked in a one-way rolling process can be effectively solved, the annealing frequency is reduced, and the high-density tungsten-copper alloy foil with the thickness of 0.05 to 2mm can be prepared. The method has the advantages of low requirement on equipment, high production efficiency, low energy consumption and the like, is suitable for batch production, and tungsten-copper alloy of which the mass percentage of tungsten is 50 to 95 percent.

Owner:无锡乐普金属科技有限公司

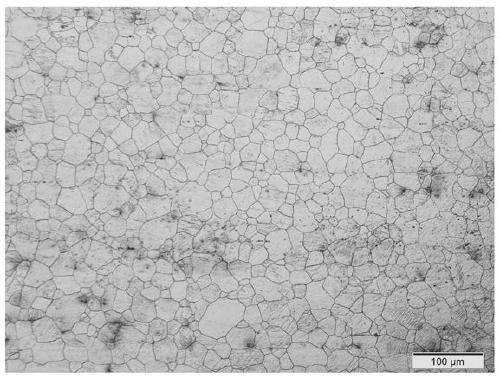

Machining process of high-precision thin-walled pure aluminum or aluminum alloy pipes

The invention provides a machining process of high-precision thin-walled pure aluminum or aluminum alloy pipes, and the machining process aims to solve the problems that in a traditional extrusion production process of high-precision aluminum or aluminum alloy pipes, the size precision and the yield are low, and in horizontal continuous casting, the wall thickness uniformity is poor and mold sticking is prone to happening. The method adopts a vertical continuous casting technology to prepare the high-precision thin-walled pure aluminum or aluminum alloy pipe blanks, the solid-liquid interfaceposition is located at the transition area of a heat section and a cold section by controlling the continuous casting and molding, the formed pipe blanks have columnar crystal structures with high inner and outer surface quality and high orientation degree in the continuous casting direction, axial extending deformation of subsequent cold machining like rolling and drawing is facilitated, the continuous cast pipe blanks can be directly subjected to large-deformation cold machining and molding without face milling, short-process production of the high-precision thin-walled pure aluminum or aluminum alloy pipes is achieved, and the problems that in a traditional process of the high-precision thin-walled pure aluminum or aluminum alloy pipes, the investment is large, the process is long, theyield is low and the cost is high are solved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Production method of T2 copper strap used for automobile radiator

The invention discloses a production method of a T2 copper strap used for an automobile radiator, which belongs to the field of material processing, and solves the problems of the prior art that the process flow of the T2 copper strap production process is longer and the required equipment is expensive. The production method of the T2 copper strap used for the automobile radiator comprises the following steps: batching and melting raw material, and covering dry wood coal on liquid raw material; transferring the liquid raw material covered with the dry wood coal into a heat preserving furnace with the temperature of 1100 DEG C to 1150 DEG C for 30 to 45 minutes, then performing horizontal continuous casting, the casting temperature being 1220 DEG C to 12050 DEG C, and adopting drawing, stopping and returning process; milling and cold rolling cogging, then performing intermediate annealing and rough rolling to reduce-second intermediate annealing-surface cleaning and passivating-cold finish rolling-low temperature heat treatment on finished product-surface cleaning and passivating-bending and flattening, and obtaining the required T2 copper strap. With the invention, the existing homogenizing anneal procedure can be omitted, the additionally arranged expensive equipment can be avoided, the complexity of the process is reduced, and the cost can be saved.

Owner:宁波市鄞州锡青铜带制品有限公司

Method for preparing high-electric-conductivity pure copper strips for transformer

InactiveCN102321810AShort production processHigh cold working rateProcess efficiency improvementSurface cleaningTransformer

The invention discloses a method for preparing high-electric-conductivity pure copper strips for a transformer, belonging to the field of material manufacturing, for solving problems of longer preparation process and expensive required devices of the high-electric-conductivity pure copper strips in the prior art. The preparation method of the high-electric-conductivity pure copper strips for the transformer comprises the following steps of: distributing materials, melting materials, adding a copper phosphor intermediate alloy, and covering dry charcoal on liquid raw materials; transferring the liquid raw materials covered with dry charcoal in a heat preservation furnace at the temperature of 1180 DEG C-1280 DEG C, and keeping the temperature for 25-30 minutes; then carrying out horizontal continuous casting at the casting temperature from 1100 DEG C to 1200 DEG C by adopting pulling, stopping and returning technologies; and carrying out face milling, intermediate annealing after cold rolling and cogging, as well as roughing and reduction, secondary intermediate annealing, surface cleaning and passivation, cold finishing rolling, low-temperature thermal treatment for finished products, surface cleaning and passivation, stretch bending leveling, thus the required high-electric-conductivity pure copper strips are obtained. According to the invention, the existing uniform annealing working procedure is omitted, expensive devices are not required to be purchased additionally, the technology complexity is lowered, and the cost is lowered.

Owner:宁波市鄞州锡青铜带制品有限公司

Preparing method of stainless steel/copper multi-core composite wire

InactiveCN110788159AImprove coordination and deformation abilityHigh tensile strengthWire rodSS - Stainless steel

The invention discloses a preparing method of a stainless steel / copper multi-core composite wire. The method comprises the following steps that firstly, a copper bar is loaded in a stainless steel sheath, and two ends are subjected to sealing welding; secondly, through hot extrusion, a stainless steel / copper single-core composite bar is obtained; thirdly, multi-pass drawing is carried out to obtain a stainless steel / copper single-core composite wire; fourthly, straightening, sizing, cutting off, acid pickling and drying are carried out in sequence; and fifthly, bundling assembling is carried out to obtain a stainless steel / copper multi-core composite body, the sealing welding process, the hot extrusion process and the multi-pass drawing process are sequentially repeated, and through in-order putting, the a stainless steel / copper multi-core composite wire is obtained. Through the bundling assembling drawing method and in combination with hot extrusion, the excellent physical and chemical characteristics of the stainless steel are used, through design of the machining process and parameters, the synchronous coordinated deforming capacity of a stainless steel base body and a copper core wire can be greatly improved, the good stainless steel / copper interface combination effect can be formed, and the tensile strength and the conductive property of the stainless steel / copper multi-core composite wire can be improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

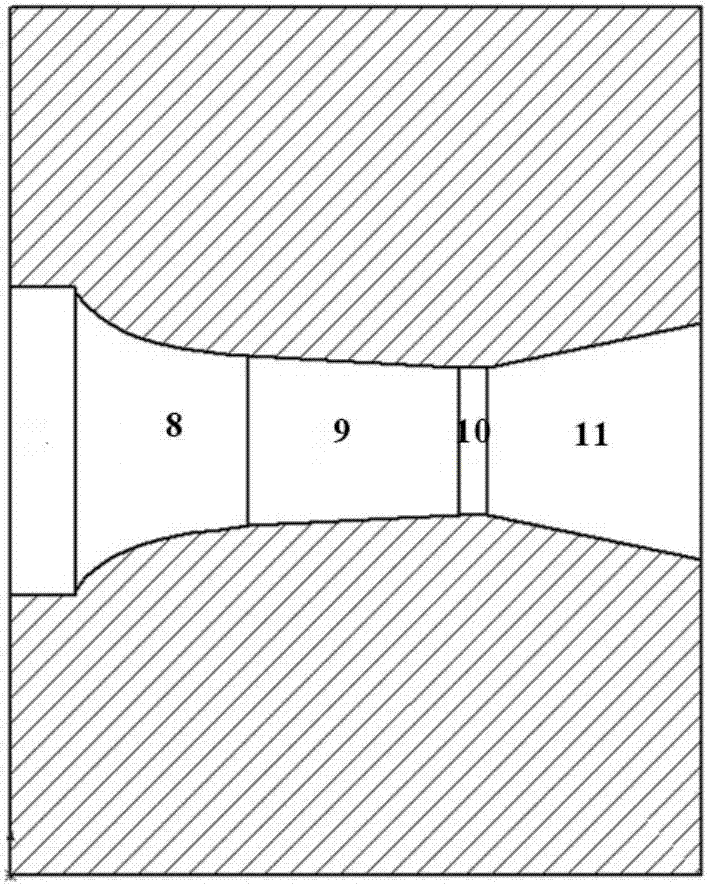

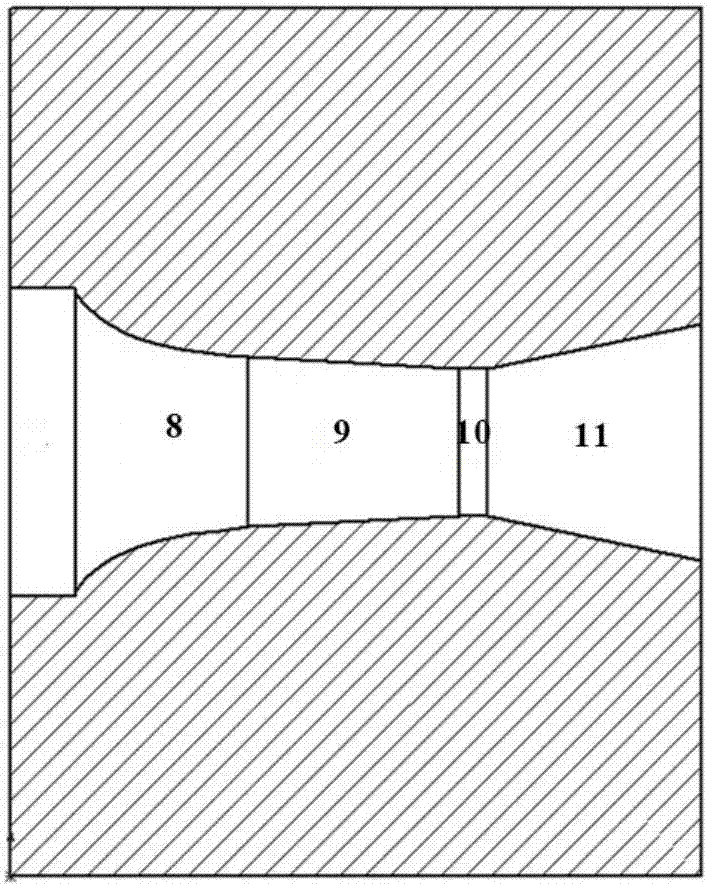

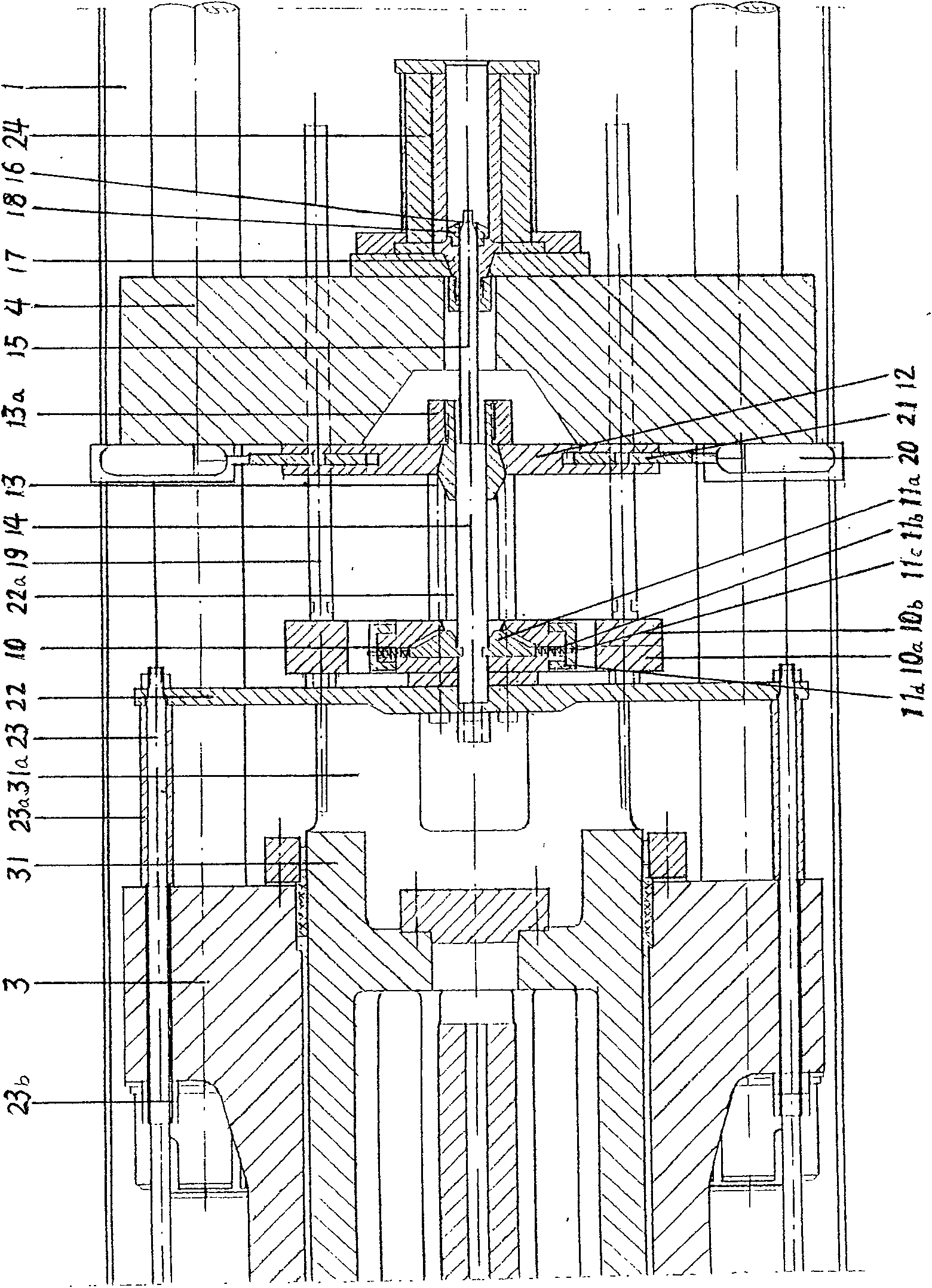

Electrochemical drawing process and electrochemical drawing device for metal wire material

ActiveCN104722590AReduce surface hardnessReduce the number of annealingElectrolytic agentMetal filament

The invention discloses an electrochemical drawing device for a metal wire material. According to the electrochemical drawing device, a direct-current power supply 1 and an electrolytic cell 3 in which an electrolyte 2 is contained are additionally arranged, wherein a positive electrode of the direct-current power supply is connected to the metal wire material 5 through a power connection post 4; a negative electrode of the direct-current power supply is communicated with the electrolyte 2 through a cathode stainless steel sheet 6; insulation blocks 7 are respectively arranged at the two ends of the electrolytic cell 3 and used for insulating and separating a wiredrawing mould 8 from the electrolytic cell 3, and insulating and separating the metal wire material 5 from the electrolytic cell 3. Compared with the conventional drawing, the electrochemical drawing process has the advantages that the surface hardness of the wire material can be reduced, the surface quality is improved, various scratches and cracks on the surface of the material are effectively reduced, the middle annealing times of the wire material are reduced, and the wire material preparation efficiency is improved; under the same process condition, the surface-layer hardness of the aluminum alloy material is reduced by 10%-20%, the drawing force is reduced by 8%-18%, and the drawing force of the copper alloy is reduced by 10%-27%.

Owner:LANZHOU WEITE WELDING MATERIAL FURANCE BURDEN

Alloyed steel horizontal type indirect extrusion machine

The invention discloses a horizontal reverse alloy steel extrusion machine, which belongs to the novel technical field of seamless steel pipe and relates to a seamless steel pipe manufacturing facility. The purpose is to settle the problems of complex process, inefficiency, high energy consumption and pollution of the environment with the prior domestic cold drawing techniques of small-bore seamless alloy steel tube. The machine consists of a rigid framework, a liquid-filled combined hydraulic cylinder and a die assembly, wherein, the rigid framework consists of an anterior fixed beam, a posterior fixed beam and an intermediate moving beam on the frame, which are connected in series by a four tensile columns; the liquid-filled combined hydraulic cylinder has a compact structure and is capable of executing the operations of die displacement, material feeding, perforation, extrusion and die removal; the die assembly consists of a perforation & extrusion & automatic switching system, a hot extrusion / molding system and a die removal & disengaging & residual extrusion & cutting system. The machine is capable of achieving once-and-for-all heating and once-and-for-all molding to directly produce finished products of small-bore seamless alloy steel pipes. Compared with forward extrusion, the deviations of the displacement of the piercing mandril and the dies are small, and no friction occurs between the billets and the internal wall of the container, thereby the machine can directly adopt continuous casting billets to extrude small-bore pipes, and has the advantages of simple process, high quality, high efficiency, low energy consumption, etc.

Owner:周家镳

Preparation method of zinc alloy pipe for degradable cardiovascular stent

PendingCN113416867AIncrease the amount of deformation in a single passImprove processing efficiencyStentsSurgeryCardiovascular stentZinc alloys

The invention relates to a preparation method of a zinc alloy pipe for a degradable cardiovascular stent, and belongs to the technical field of material preparation. The zinc alloy pipe comprises the following alloy components in percentage by weight: 0.05% of Mg, 0.2-0.5% of Mn, 0.1-0.5% of Cu, 0.02-0.05% of P, less than or equal to 10ppm of inevitable impurities and the balance of Zn. The preparation method comprises the following steps: (1) heating pure zinc to 550 + / -5 DEG C, adding other metals after melting, uniformly stirring, cooling the molten metal to 480 + / -10 DEG C, and casting; (2) preserving heat at 380 DEG C for 10-24 hours, and then cooling to room temperature in water; (3) conducting heat preservation for 30 min at the temperature of 150 DEG C, and then conducting hot extrusion forming at the temperature of 100 DEG C, wherein the extrusion speed is 0.2-1 mm / s; (4) conducting multi-pass hot drawing, wherein the accumulated deformation is 75-95%, the drawing speed is 0.2-10 mm / s, the drawing temperature is 100 DEG C, and the deformation of each pass is 10-15%; and (5) conducting cold drawing finishing and annealing treatment, and finally conducting air cooling to the room temperature. The preparation method of the zinc alloy pipe for the degradable cardiovascular stent is suitable for forming of various zinc alloy pipes so as to meet different use requirements.

Owner:NORTHEASTERN UNIV

A method for forming a sealing ring in an engine and a mold device

The invention relates to a forming die device for a sealing ring used in an engine. The device comprises a primary forming die and a final forming die, wherein the primary forming die specifically comprises a pressure plate, a first upper die, a first lower die, a supporting spring, an oil baffle pan, a base, an internal mold column, a sealing end cover, an oil guide pipe adapter, and the like; and the final forming die specifically comprises a pressure plate, a second upper die, an upper locking lantern ring, a lower locking lantern ring, a second lower die, an oil baffle pan, an intermediate model, a base, an internal mold column, a sealing end cover, and the like. The forming method for the sealing ring used in the engine comprises the following two steps of primary forming and final forming.

Owner:BEIHANG UNIV

Short-flow rolling preparation process of high-strength and high-plasticity AlN/AZ91D magnesium base composite material plate

ActiveCN107747071AQuality improvementHigh quality and high performanceMagnesium matrix compositeIngot

The invention relates to a short-flow rolling preparation process of a high-strength and high-plasticity AlN / AZ91D magnesium base composite material plate; solid solution and water quenching processesof a cast ingot before rolling are formulated; subsequent rolling and annealing processes are optimized; and a set of cold rolling process for preparing a high-strength and high-plasticity magnesiumbase composite material rolled plate is provided. The cold rolling process is high in reduction in pass, few in annealing times among passes and short in annealing time, and can realize industrial short-flow preparation. In particular, through the patent technology, namely the optimal ratio of solid solution process parameters to water quenching process parameters to rolling process parameters toannealing process parameters, the edge cracking problem in the cold rolling process is solved when the high-strength and high-plasticity cold-rolled plate is obtained, and finally, the high-quality and high-performance magnesium alloy composite material cold-rolled plate can be obtained with high efficiency.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

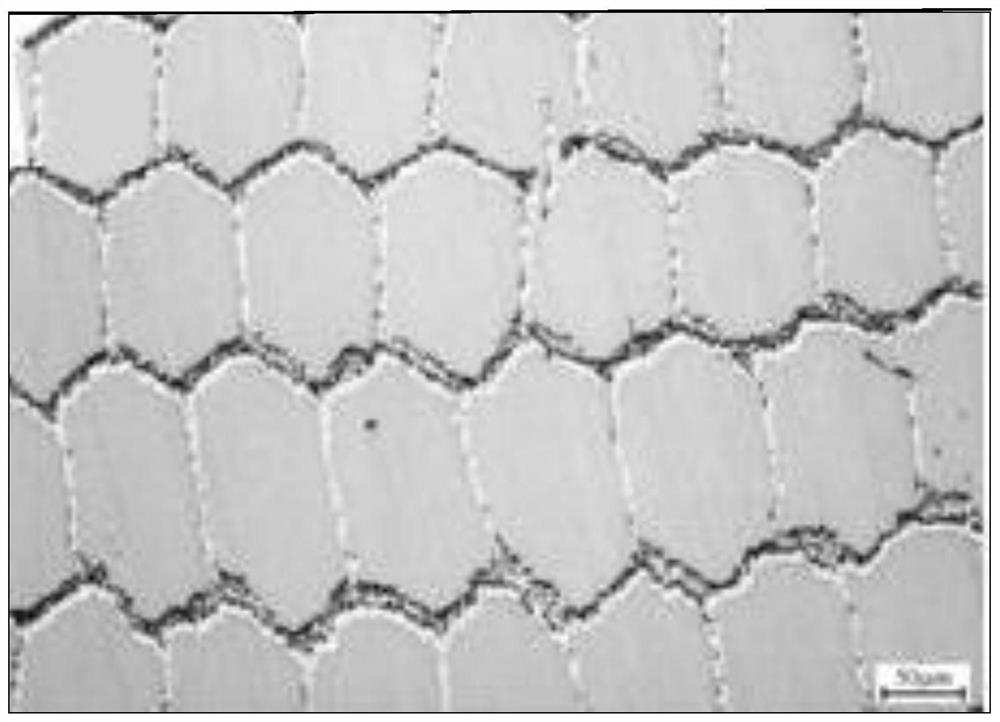

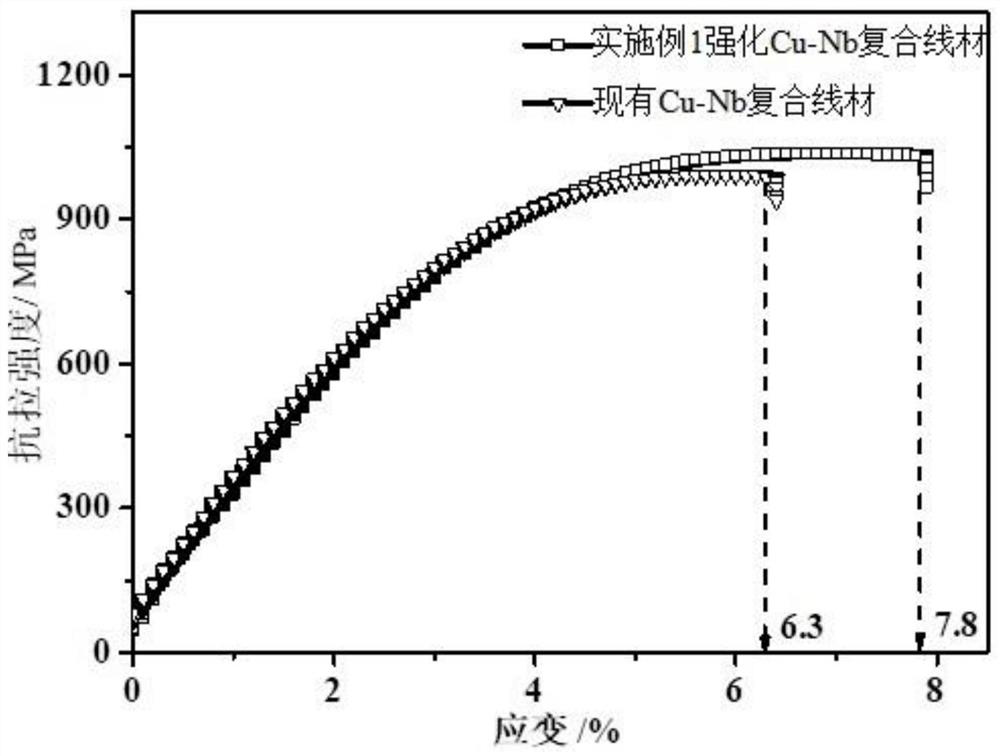

Preparation method of reinforced Cu-Nb composite wire

ActiveCN112007949AFacilitates longitudinal deformationQuality improvementMetal rolling arrangementsWire rodContinuous rolling

The invention discloses a preparation method of a reinforced Cu-Nb composite wire. The method comprises the following steps: 1, carrying out plastic drawing processing on a Cu-Nb three-time compositewire prepared by adopting a bundling drawing method, and then carrying out annealing treatment; 2, carrying out continuous multi-roll pass rolling on the annealed Cu-Nb three-time composite wire to obtain a Cu-Nb composite wire intermediate; and 3, carrying out plastic drawing processing on the Cu-Nb composite wire intermediate to obtain the reinforced Cu-Nb composite wire. According to the preparation method, a multi-roll pass rolling process is adopted for continuous rolling; the longitudinal deformation of the Cu-Nb three-time composite wire is promoted. Compared with the prior art, the plastic deformation is promoted to be improved, the plastic deformation amount is increased, the obtained reinforced Cu-Nb composite wire is more uniform in core wire distribution and deformation, and more obvious in core wire refinement, plastic deformation capacity is enhanced, the quality and performance of the reinforced Cu-Nb composite wire are improved, good matching of the mechanical propertyand the conductivity is achieved, and the engineering application requirement is met.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

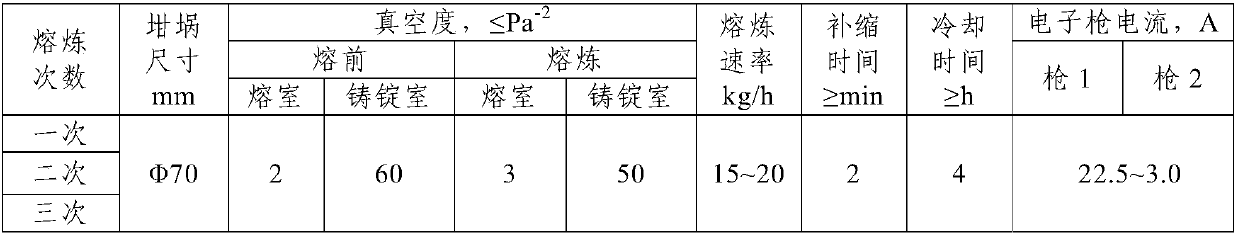

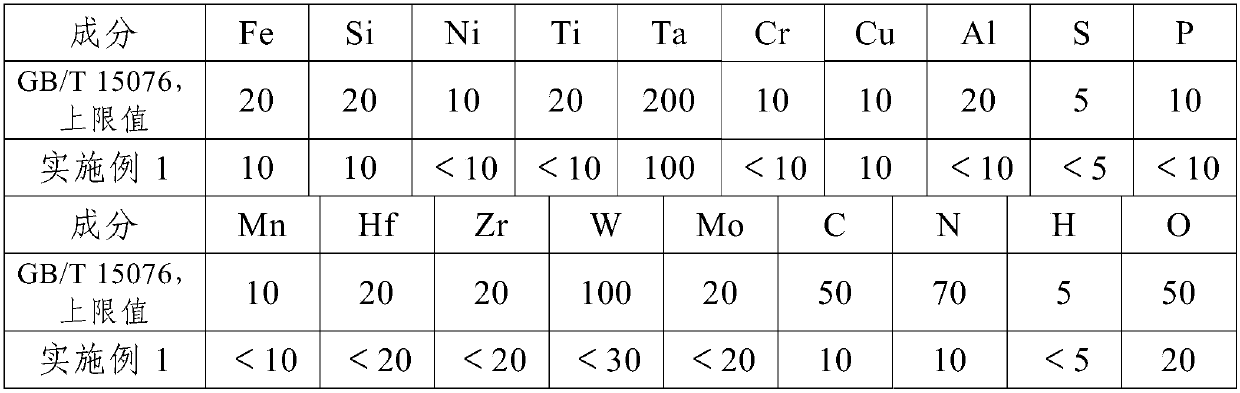

Method for preparing high-purity niobium wire for nuclear fuel from general industrial niobium rod as raw material

ActiveCN106391747BAccelerate evaporationMelting rate is slowSurface reaction electrolytic coatingNuclear energy generationWork in processIngot

The invention provides a method for preparing high-purity niobium wire for nuclear fuel using niobium bars for general industrial use as raw materials, which includes the following steps: 1. Electron beam melting of niobium bars for general industrial use to obtain ingots; 2. Turning processing; 3. Extrusion, to obtain the extruded bar blank; 4. Carry out the first stage annealing treatment after turning; 5. Rotating, to obtain the swaged bar blank; 6. Carry out the second stage annealing treatment, and then perform surface sanding to obtain Sanding the rod blank; 7. Roller die stretching to obtain a rough wire material; 8. After surface treatment, perform fixed mold stretching and shaping to obtain semi-finished wire material; 9. After surface treatment, straighten to obtain a diameter of 1.5mm~ 3.0mm, high purity niobium wire for nuclear fuel with straightness <3mm / m. The invention has fewer heat treatment fires, less hot processing, and a high yield. The size, surface inspection, and composition of the high-purity niobium wire prepared by this method all meet the requirements for nuclear-grade materials, and can be directly used for the preparation of uranium-niobium alloys for nuclear fuel.

Owner:西安诺博尔稀贵金属材料股份有限公司

Preparation method of high-strength and high-toughness Cu-Nb-Cu composite wire

PendingCN114643296AImprove plastic deformation abilityExhibit toughening propertiesWork treatment devicesFurnace typesWire rodUltimate tensile strength

The invention discloses a preparation method of a high-strength and high-toughness Cu-Nb-Cu composite wire, which comprises the following steps of: 1, carrying out annealing treatment on an Nb tube reinforced Cu-Nb, namely a Cu-Nb-Cu three-time composite wire prepared by adopting a bundling drawing method, and then carrying out groove rolling; 2, soaking the Cu-Nb-Cu three-time composite wire subjected to pass rolling in a foam tank filled with liquid nitrogen for cooling; and thirdly, the cooled Cu-Nb-Cu tertiary composite wire is subjected to plastic drawing, and the high-strength and high-toughness Cu-Nb-Cu composite wire is obtained. According to the method, the process of combining groove rolling with liquid nitrogen temperature zone drawing is adopted, the plastic deformation capacity of the Cu-Nb-Cu composite wire is improved, the superfine Cu-Nb-Cu composite wire is obtained, high strength is obtained, meanwhile, high toughness is achieved, the inversion relation between the material strength and plasticity is regulated and controlled, the process cost is saved, and batch production is easy to achieve.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com