Preparation method of high-strength and high-toughness Cu-Nb-Cu composite wire

A cu-nb-cu, composite wire technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of limiting material properties, difficult to make new breakthroughs in tensile strength, etc., to improve processing efficiency , high-intensity, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

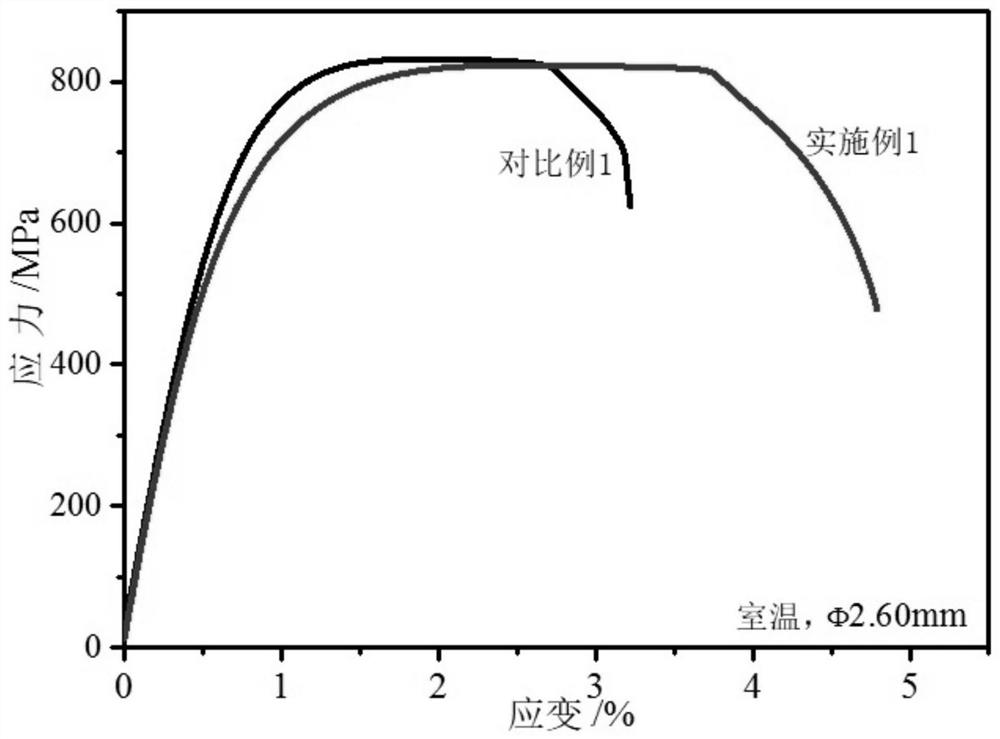

Embodiment 1

[0028] This embodiment includes the following steps:

[0029] Step 1. Anneal the Nb tube reinforced Cu-Nb with a diameter of Φ7.74mm prepared by the cluster drawing method, that is, the Cu-Nb-Cu tertiary composite wire. The temperature of the annealing treatment is 650°C and the time is 4h, and then the hole is drilled. The shape is rolled to a diameter of Φ4.35mm, and the total deformation of the pass rolling is 68%;

[0030] Step 2: Immerse the Cu-Nb-Cu tertiary composite wire rod after pass rolling in step 1 in a foam tank equipped with liquid nitrogen for cooling for 1 min;

[0031] Step 3: The Cu-Nb-Cu tertiary composite wire that has been cooled in step 3 is plastically drawn to a diameter of Φ2.60 mm through a drawing die in turn to obtain a high-strength and high-toughness Cu-Nb-Cu composite wire; The processing rate of drawing passes is 8%, and the diameters of the drawing die used are: Φ4.35mm, Φ4.12mm, Φ4.08mm, Φ3.95mm, Φ3.64mm, Φ3.35mm, Φ3.12mm, Φ3. 08mm, Φ2.95mm...

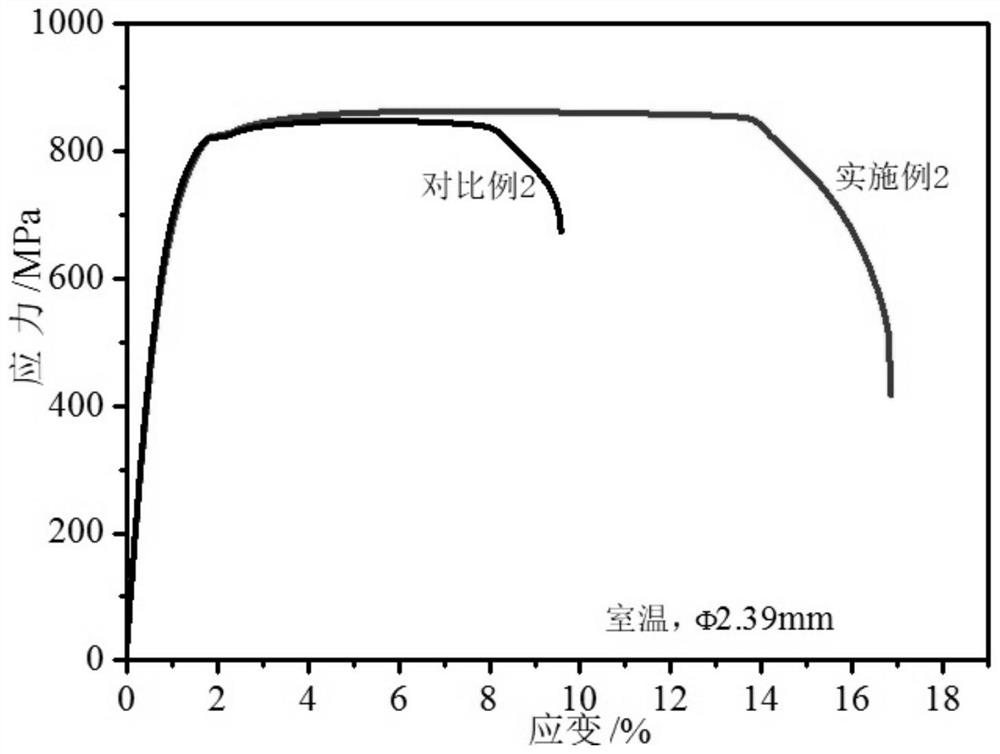

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step 1. Anneal the Nb tube reinforced Cu-Nb with a diameter of Φ7.74mm prepared by the cluster drawing method, that is, the Cu-Nb-Cu tertiary composite wire. The temperature of the annealing treatment is 700°C and the time is 4h. The shape is rolled to a diameter of Φ4.35mm, and the total deformation of the pass rolling is 68%;

[0038] Step 2: Immerse the Cu-Nb-Cu tertiary composite wire rod after pass rolling in step 1 in a foam tank equipped with liquid nitrogen for cooling for 1 min;

[0039] Step 3: The Cu-Nb-Cu tertiary composite wire after cooling in step 3 is plastically drawn to a diameter of Φ2.39mm through a drawing die in turn to obtain a high-strength and high-toughness Cu-Nb-Cu composite wire; The processing rate of drawing passes is 7%, and the diameters of the drawing die used are: Φ4.12mm, Φ4.08mm, Φ3.95mm, Φ3.64mm, Φ3.35mm, Φ3.12mm, Φ3.08mm, Φ2. 95mm, Φ2.83mm, Φ2.71mm, Φ2.60mm, Φ2.49mm, Φ2.39mm, ...

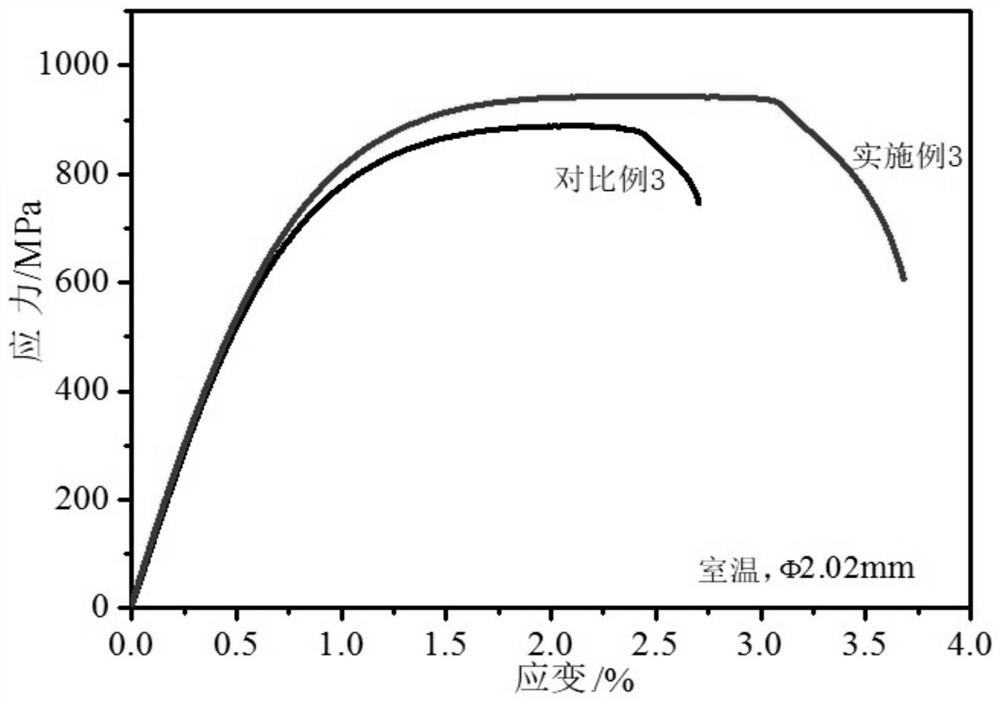

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1. The Nb tube reinforced Cu-Nb with a diameter of Φ8.66mm prepared by the cluster drawing method, that is, the Cu-Nb-Cu tertiary composite wire, is annealed. The shape is rolled to a diameter of Φ4.35mm, and the total deformation of the pass rolling is 72%;

[0046] Step 2, soaking the Cu-Nb-Cu tertiary composite wire rod after pass rolling in step 1 in a foam tank equipped with liquid nitrogen for cooling for 2min;

[0047] Step 3: The Cu-Nb-Cu tertiary composite wire that has been cooled in step 3 is plastically drawn to a diameter of Φ2.02 mm through a drawing die in turn to obtain a high-strength and high-toughness Cu-Nb-Cu composite wire; The processing rate of the drawing passes is 9%, and the diameters of the drawing die used are: Φ4.12mm, Φ4.08mm, Φ3.95mm, Φ3.64mm, Φ3.35mm, Φ3.12mm, Φ3.08mm, Φ2. 95mm, Φ2.83mm, Φ2.71mm, Φ2.60mm, Φ2.49mm, Φ2.39mm, Φ2.12mm, Φ2.02mm, and the wire to be drawn must be plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com