Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

A magnesium alloy, multi-directional technology, applied in high-speed hammer forging magnesium alloy forging, multi-directional, magnesium alloy processing, circulation field, can solve the problem that it is not suitable for the production of bulk magnesium alloy final products, high equipment stability requirements, It is not suitable for production and other problems, and achieves the effect of facilitating large-scale industrial production and application, inhibiting dynamic recrystallization, and inhibiting grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

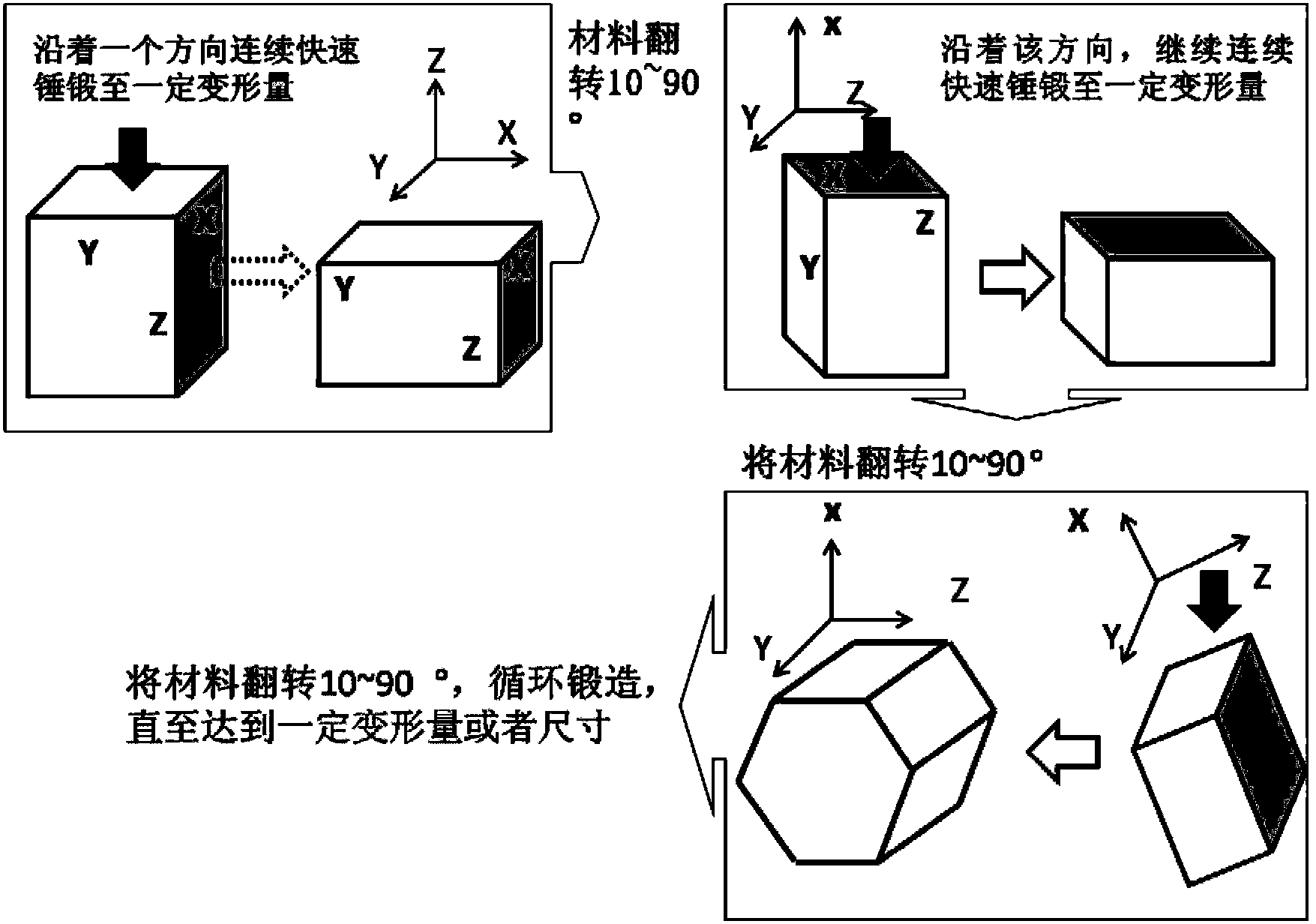

Method used

Image

Examples

Embodiment 1

[0031] 1) Select AZ80 as-cast material, cut into 80mm×80mm×100mm squares, homogenize at 400°C for 2 hours, then carry out continuous hammer forging on a 250Kg industrial air hammer forging machine. First, hammer forging 3 times continuously along the height direction of the sample (Z direction), the hammering frequency is 20 times / min, the hammering speed is 1m / s, and the strain rate is 10s -1 , each time the strain is 5%, and the total strain in the height direction reaches 15%; the sample is rotated at 90°C, continuously forged 4 times along the width direction (Y direction) of the sample, and the hammering frequency is 50 times / min. The impact speed is 10m / s, and the strain rate is 10s -1, each time the strain is 6%, and the total strain in this direction reaches 24%; the sample is then rotated at 90°C, and continuously forged 2 times along the length direction of the sample (X direction), the hammering frequency is 60 times / min, The hammering speed is 10m / s, and the strai...

Embodiment 2

[0033] Select Mg-2.0Zn-0.8Gd-0.4Zr as-cast material, cut into 50mm×50mm×60mm squares, homogenize at 500°C for 24 hours, and then carry out continuous hammer forging on a 250Kg industrial hammer forging machine. First, hammer forging 4 times continuously along the height direction of the sample (Z direction), the hammering frequency is 30 times / min, the hammering speed is 15m / s, and the strain rate is 50s -1 The strain amount is 6% each time, and the total strain amount in the height direction reaches 24%; the sample is rotated at 90°C, forged 2 times along the length direction (X) of the sample, and the hammering frequency is 70 times / min (Supplementary), The hammering speed is 70m / s (supplementary) and the strain rate is 100s -1 , the strain amount is 20%, and the total strain amount in this direction is 20%; the sample is then rotated 90°C, continuously forged 5 times along the width direction (Y) of the sample, the hammering frequency is 200 times / min, and the hammering spe...

Embodiment 3

[0035] AZ31 rolled material was selected, cut into 50mm×55mm×60mm squares, after homogenization treatment at 420°C for 0.5 hours, continuous hammer forging was carried out on a 250Kg industrial hammer forging machine. First, hammer forging 5 times continuously along the length direction of the sample (X direction), the hammering frequency is 70 times / min, the hammering speed is 40m / s, and the strain rate is 40s -1 , each strain is 4%, and the total strain in the height direction reaches 20%; the sample is rotated at 90°C, continuously forged 10 times along the height direction (Z) of the sample, and the hammering frequency is 100 times / min. The speed is 60m / s and the strain rate is 100s -1 , each strain is 2%, and the total strain in this direction reaches 20%; the sample is then rotated at 90°C, and continuously forged 8 times along the width direction (Y) of the sample, with a hammering frequency of 300 times / min. The impact speed is 100m / s, and the strain rate is 45s -1 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com