Patents

Literature

124results about How to "Reduce process flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

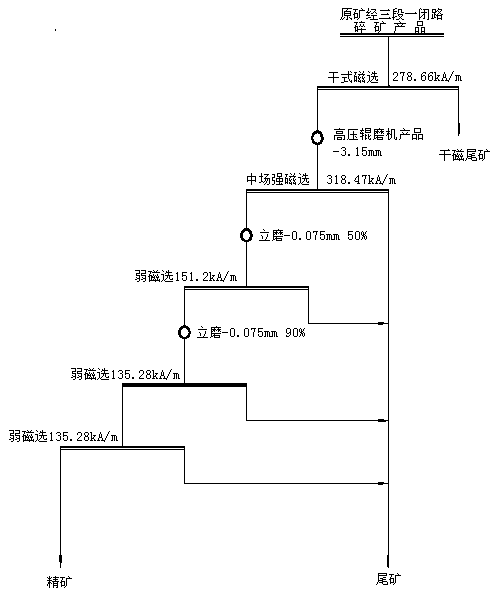

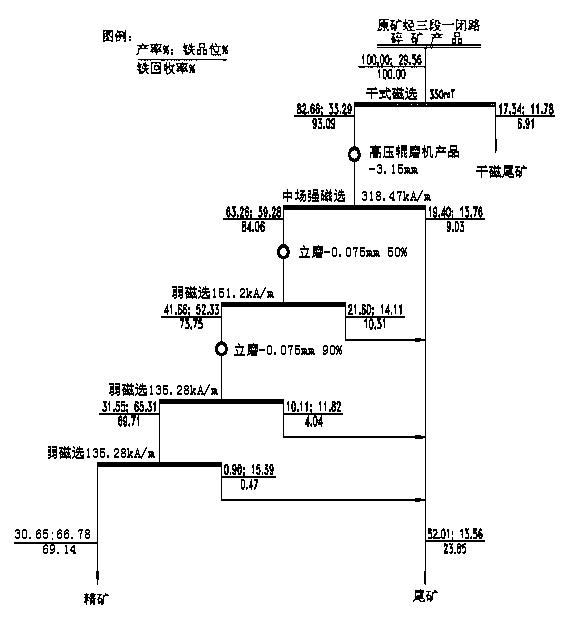

High-efficiency and energy-saving new lean magnetite combined milling magnetic separation method

ActiveCN104162475AReduce consumptionReduce energy consumptionMagnetic separationGrain treatmentsMagnetiteSteel ball

The invention discloses a high-efficiency and energy-saving new lean magnetite combined milling magnetic separation method. A high pressure roller mill is used as an ultrafine crushing device, and a vertical mill substitutes a ball mill. The method comprises the following steps: crushing, screening, carrying out dry pre-concentration, milling through the high pressure roller mill, carrying out medium field intensity wet magnetic separation, carrying out vertical coarse milling, carrying out weak magnetic roughing, carrying out vertical fine milling, and carrying out low intensity magnetic separation. The method allows a large number of coarse grain waste ores to be abandoned before milling, so the milling amount is reduced, the over milling problem during mineral liberation is effectively solved, and the consumption of steel balls and lining plates of the ball mill is significantly reduced, thereby the operation cost of the whole process is reduced. The method improves the grade of raw ores by above 2% after the weak magnetic dry separation, improves the relative grindability of roller mill products by above 30%, and reduces the energy consumption by 35-50% by adopting the vertical stirred mill to substitute the ball mill; and the power consumption of per unit of the raw ores and the consumption of the steel balls and the lining plates of the method in the invention are 65.37% and 59.26% lower than those of with routine three stage closed loop + two stage ball milling + two stage weak magnetic separation milling technologies in ore separation work respectively.

Owner:马钢集团设计研究院有限责任公司

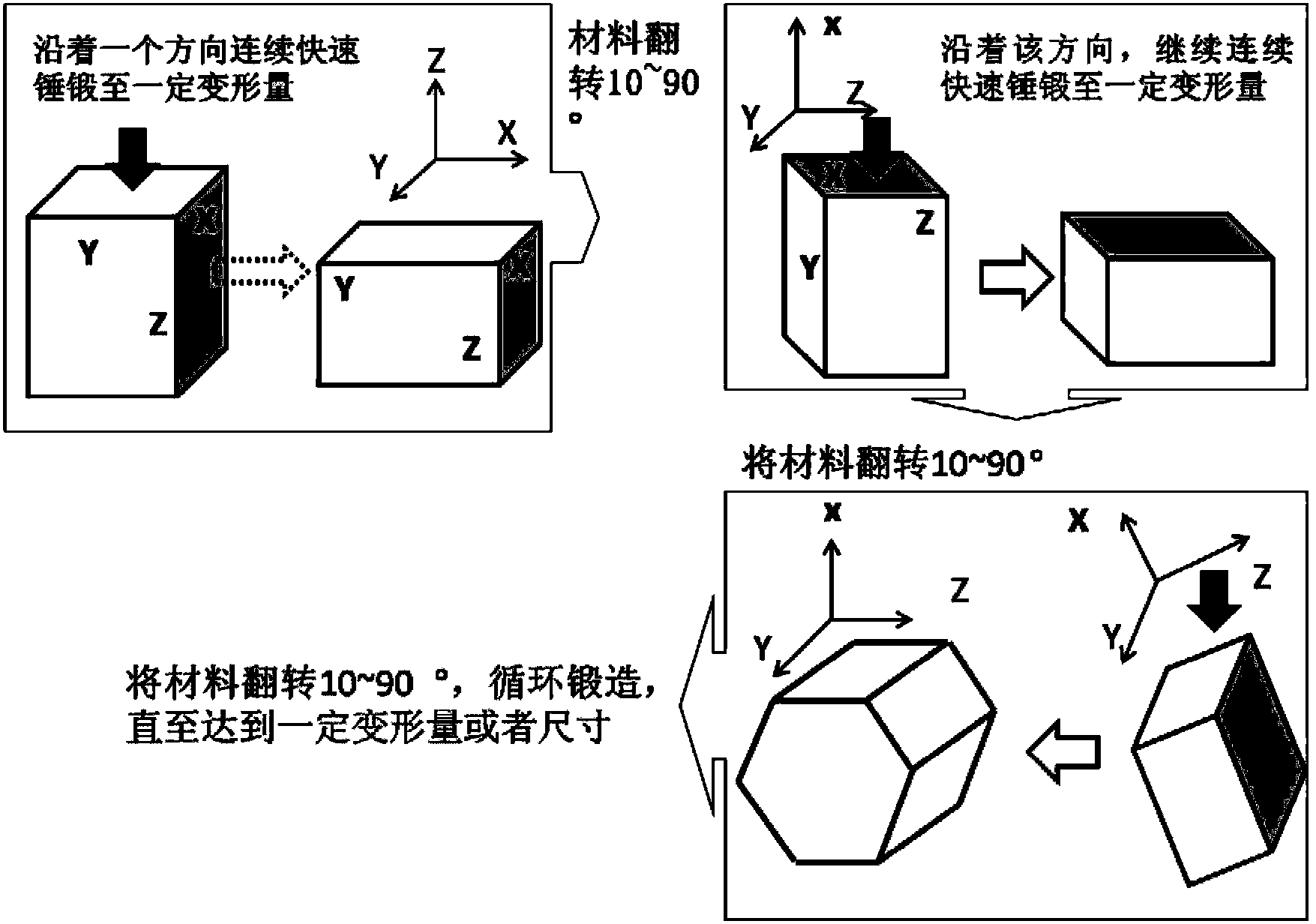

Forging method for multi-direction, circulatory and high-speed hammer forging of magnesium alloy

ActiveCN103805923AOvercome the shortcomings of poor plastic processing performanceLess slipHigh velocityHeat treated

The invention relates to a magnesium alloy plastic processing technology, and relates to a forging method for multi-direction, circulatory and high-speed hammer forging of a magnesium alloy. The method comprises the specific steps: after carrying out homogenization annealing of a casting-state or deformation-state magnesium alloy, carrying out continuous high-speed hammer forging along one direction of the bulk material at a certain temperature; after a certain deformation amount is reached, overturning the material, and continuing to carry out continuous high-speed hammer forging along another direction to reach a certain deformation amount; then overturning the material to another direction, and carrying out such circulatory hammer forging until the material reaches a predetermined deformation amount and size; and finally, carrying out heat treatment on the material. The method utilizes the textured micostructure formed during the processes of high-speed hammer forging of the magnesium alloy to be combined to change the hammer forging direction, thereby improving the ultimate deformation amount that the magnesium alloy can withstand and is not cracked during forging, and improving the plastic processing performance of the magnesium alloy. The method is suitable for magnesium and the alloy material thereof, and improves the forging processing production efficiency of magnesium and the alloy material thereof.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

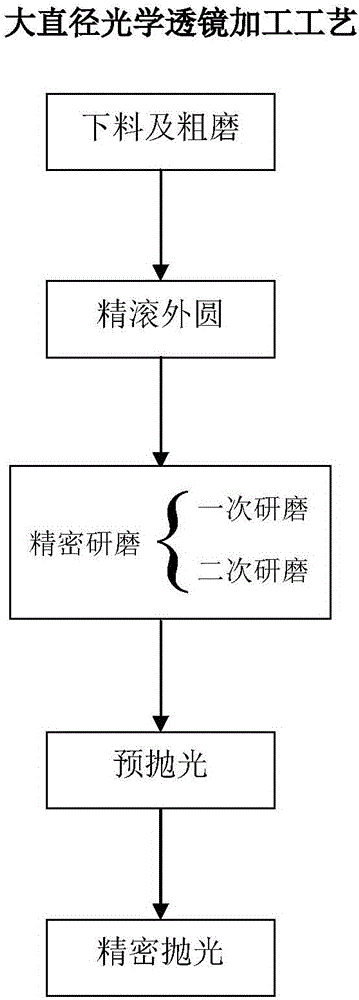

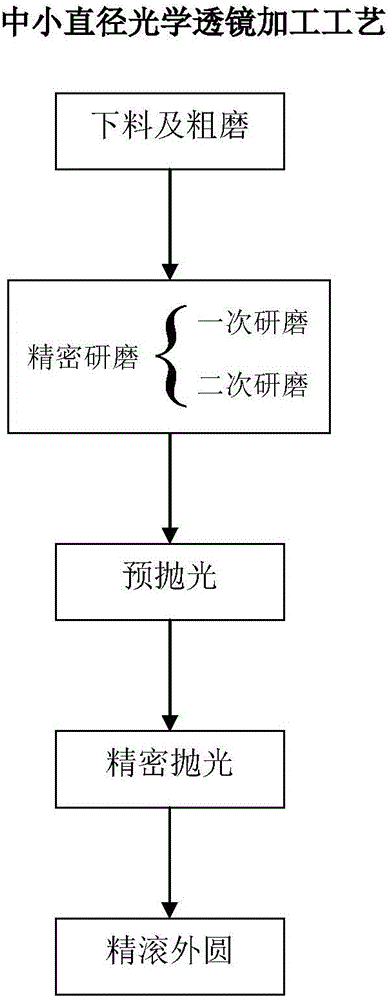

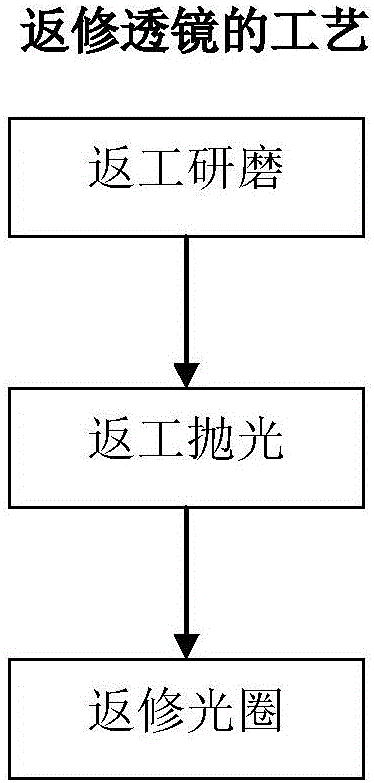

Cold-machining technology for high-precision optical lenses

InactiveCN105834859AGuarantee processing qualityIncrease productivityOptical surface grinding machinesHobbingLow speed

The invention discloses a cold-machining technology for high-precision optical lenses. The cold-machining technology for high-precision optical lenses includes the following steps that S1, blanking and rough grinding are conducted, specifically, a material is cut into a square, the thickness is modified, and the outer ring is subjected to rough grinding; S2, the outer ring is subjected to precise hobbing, specifically, the outer ring is subjected to precise hobbing till meeting the requirement of a drawing, the radius portion is subjected to milling and grinding, and the face form and center thickness are controlled; S3, precise grinding is conducted, specifically, the lens material is placed in a grinding clamp and is grinded on a high-speed horizontally-swinging fine grinder through a diamond pellet; S4, pre-polishing is conducted, specifically, the lens is subjected to pre-polishing on a high-speed horizontally-swinging polishing machine through a polyurethane chip; and S5, precise polishing is conducted, specifically, the workpiece is subjected to precise polishing, aperture modification and detection on a low-speed polishing machine so that the lens can meet the requirements for the center thickness, surface form and degree of roughness finally. The process of the cold-machining technology for high-precision optical lenses is designed for high-precision optical lenses, and the high-speed fine grinder, the high-speed polishing machine and the low-speed polishing machine are combined for machining. The optical lens obtained through machining has the characteristics of being few in surface defect, high in degree of finish, good in surface form and low in degree of surface roughness.

Owner:THE OPTICAL ELEMENT FACTORY OF THE INST OF OPTICS & ELECTRONICS THE CHINESE ACADEMY OF SCI

Wear-resistant steel with high resistance to tempering and manufacturing method thereof

ActiveCN101555574AEasy access to strengthGuaranteed StrengthTemperature control deviceMetal rolling arrangementsTemperingHardness

The invention relates to wear-resistant steel with high resistance to tempering and a method for manufacturing steel plates made of the same. The wear-resistant steel with high resistance to tempering comprises the following components according to the weight percent: 0. 10 to 0.24 of C, 0.15 to 1.40 of Si, 1.20 to 2.00 of Mn, 0.40 to 1.60 of Cr, 0.15 to 0.50 of Mo, not more than 0.30 of Ni, not more than 0.12 of V, not more than 0.03 of Ti, not more than 0.05 of Al, not more than 0.015 of P, not more than 0.010 of S and the balanced Fe and inescapable impurities. The wear-resistant steel with high resistance to tempering can keep the strength and the rigidity at higher temperature, remarkably improves the use temperature, has simple process and saves the cost.

Owner:BAOSHAN IRON & STEEL CO LTD

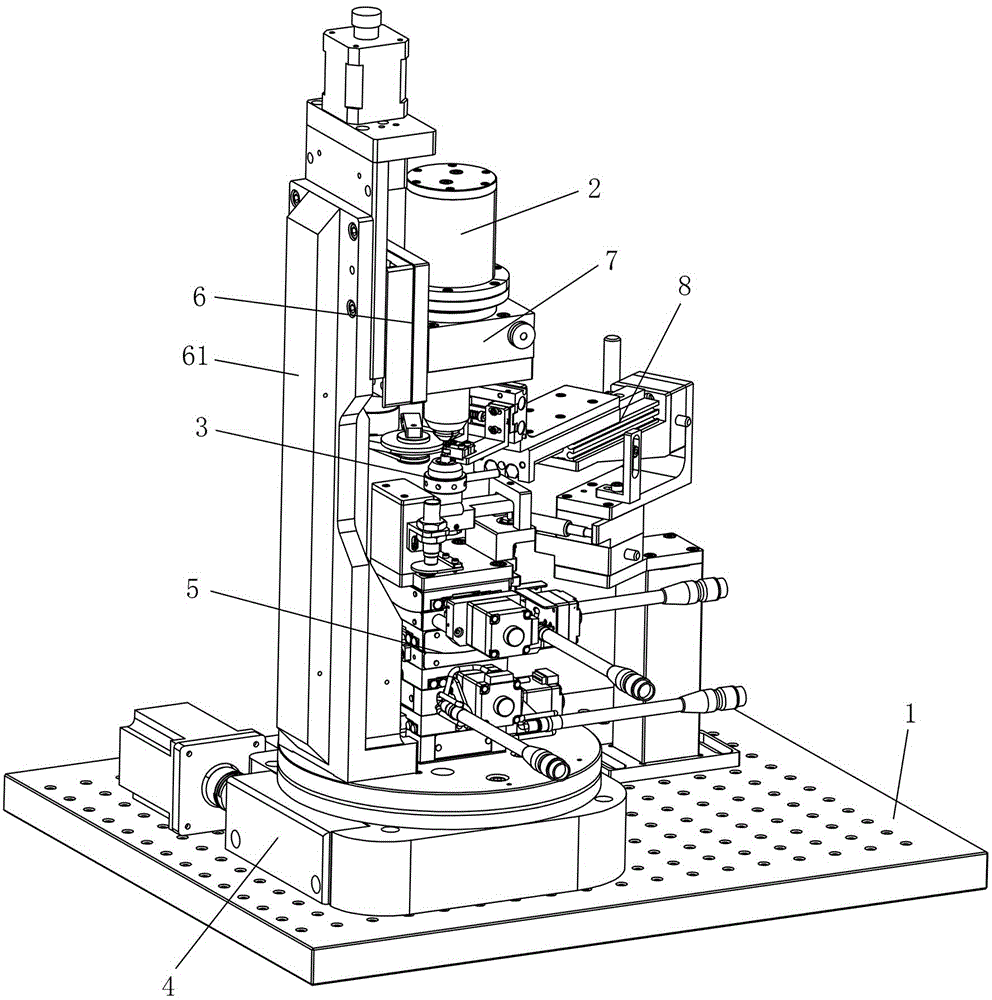

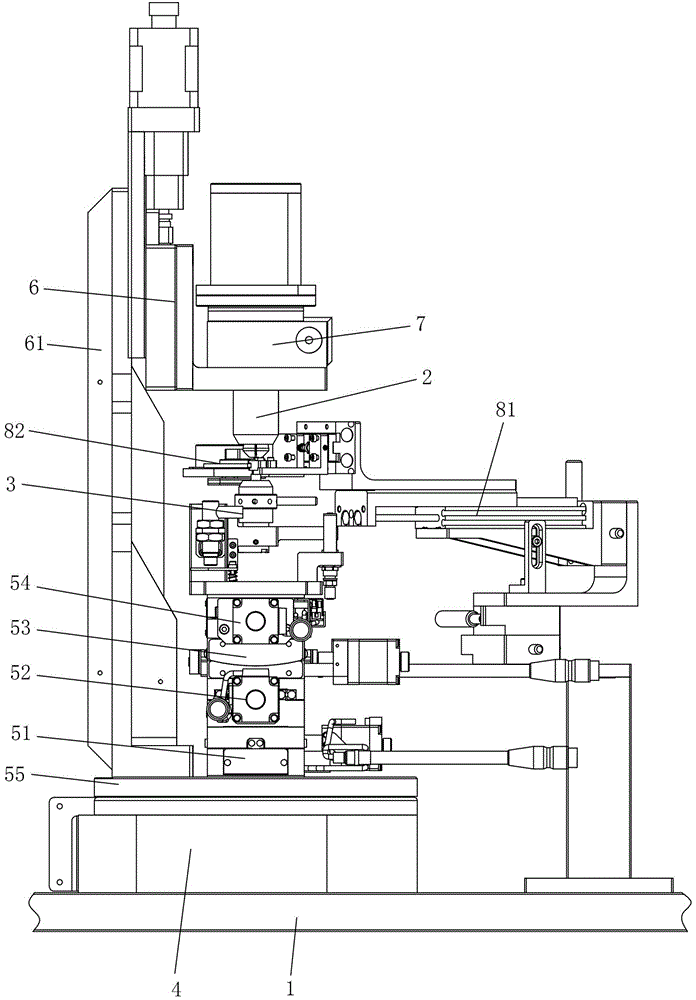

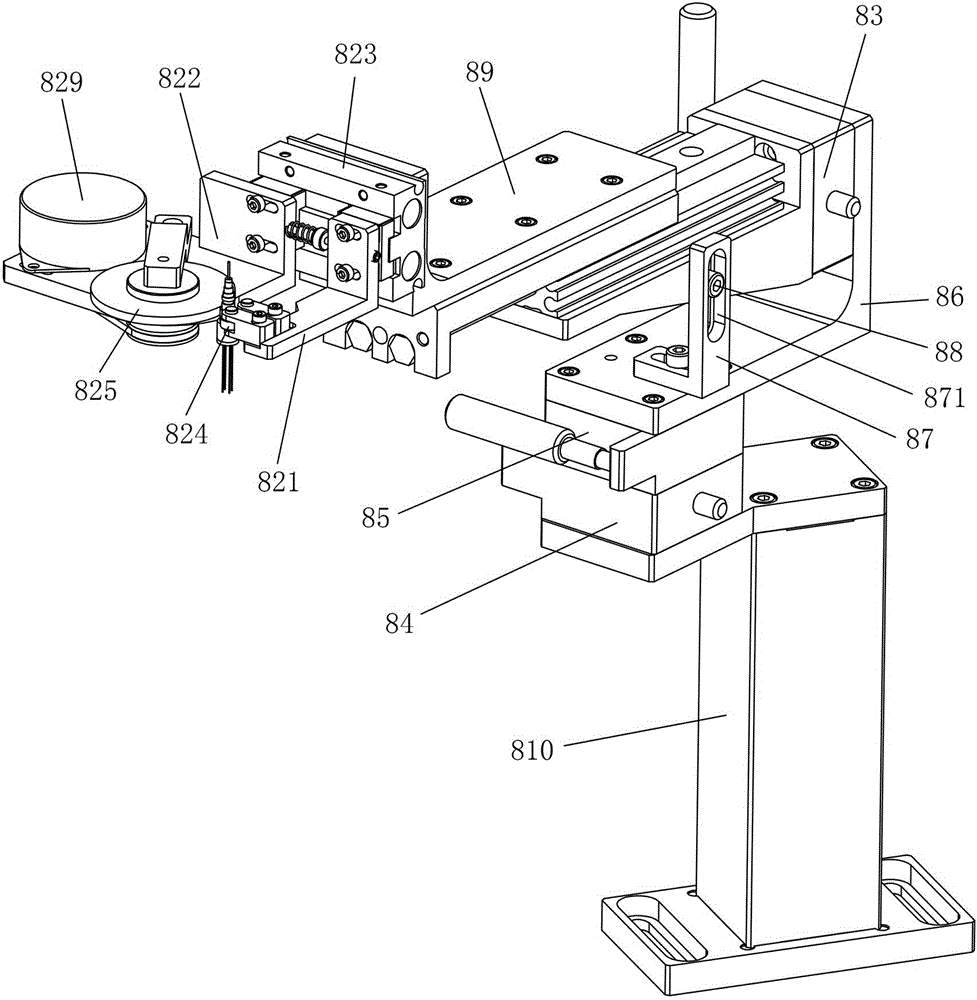

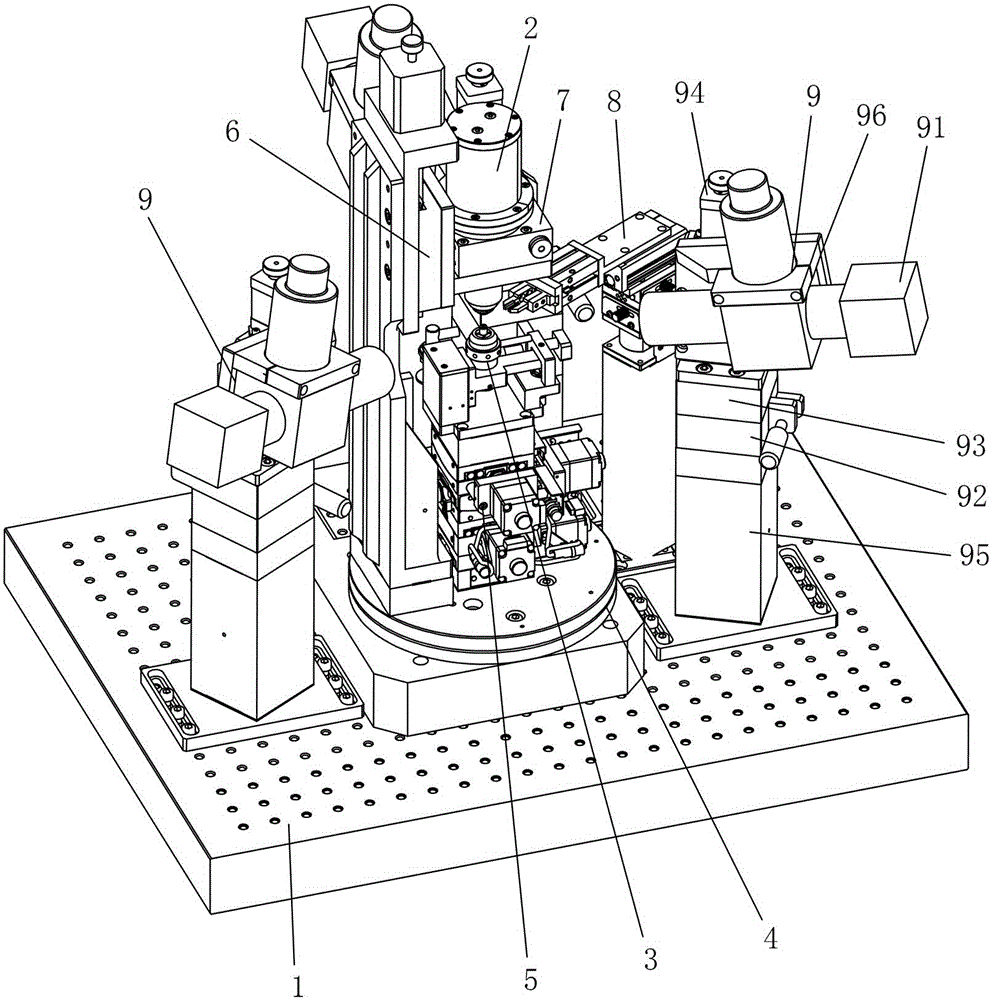

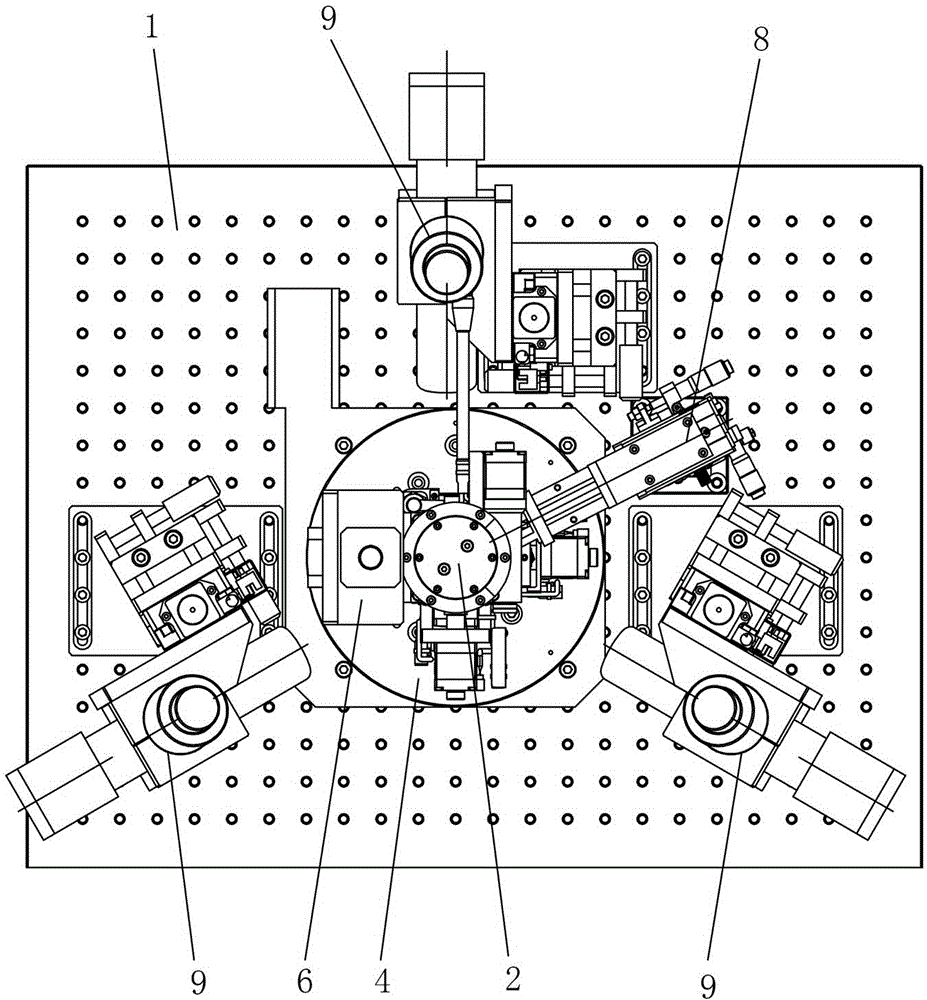

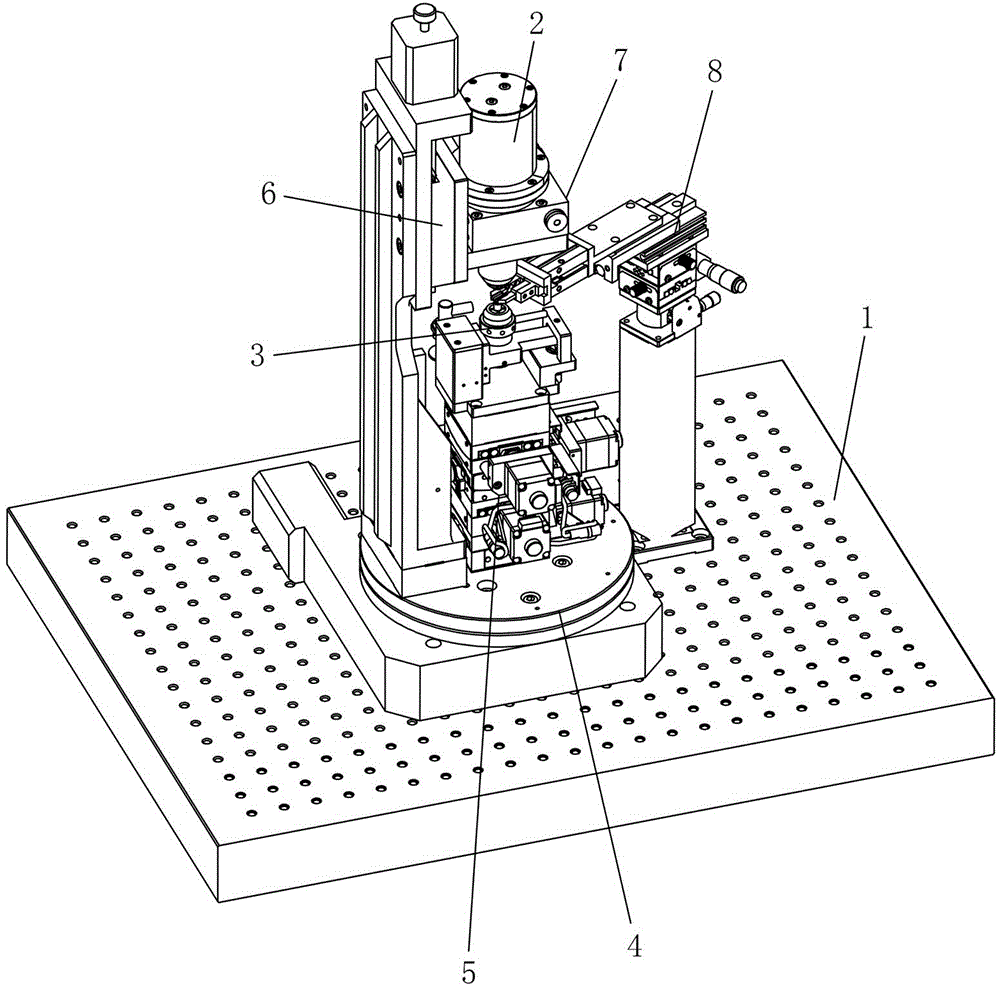

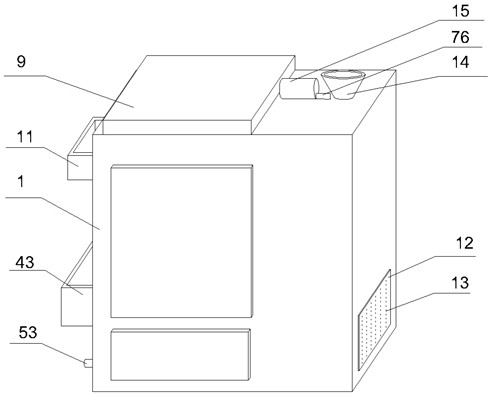

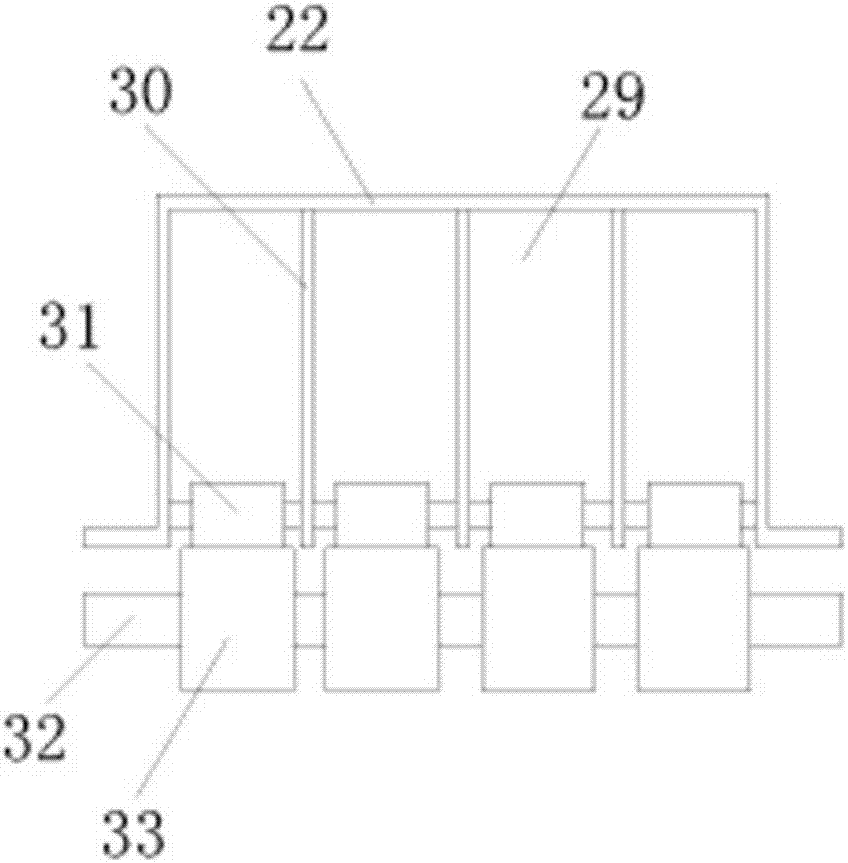

Automatic coupling device of three-in-one coaxial type photoelectronic device

ActiveCN104914520APrecise adjustment of polarization angleEnsure consistencyCoupling light guidesCouplingEngineering

The invention discloses an automatic coupling device of a three-in-one coaxial type photoelectronic device. The automatic coupling device comprises a rack, an upper fixture, a lower fixture and an automatic rotating platform, wherein the automatic rotating platform is assembled on the rack and can rotate around a Z axis; the lower fixture is assembled on the automatic rotating platform through an alignment device, and can be driven to move along an X axis and a Y axis as well as swing around the X axis and the Y axis by the alignment device; a lifting device is arranged on the automatic rotating platform, and a rotating device is installed at a lifting end of the lifting device; the upper fixture is installed at a rotary driving end of the rotating device; and a polarization angle adjusting device used for driving the isolator to rotate is assembled on the rack. The automatic coupling device has the advantages of reasonable structural design, high degree of automation, high production efficiency, low production cost, stable product quality, wide application range and the like.

Owner:CENT SOUTH UNIV

Automatic coupling device of three-in-one coaxial type photoelectronic device

ActiveCN104914522AHigh degree of automationIncrease productivityCoupling light guidesMountingsCouplingEngineering

The invention discloses an automatic coupling device of a three-in-one coaxial type photoelectronic device. The automatic coupling device comprises a rack, an upper fixture, a lower fixture and an automatic rotating platform, wherein the automatic rotating platform is assembled on the rack and can rotate around a Z axis; the lower fixture is assembled on the automatic rotating platform through an alignment device, and can be driven to move along an X axis and a Y axis as well as swing around the X axis and the Y axis by the alignment device; a lifting device is arranged on the automatic rotating platform, and a rotating device is installed at a lifting end of the lifting device; the upper fixture is installed at a rotary driving end of the rotating device; and a clamping device used for clamping an optoisolator is assembled on the rack. The automatic coupling device has the advantages of reasonable structural design, high degree of automation, high production efficiency, low production cost, stable product quality, wide application range and the like.

Owner:湖南中南鸿思自动化科技有限公司

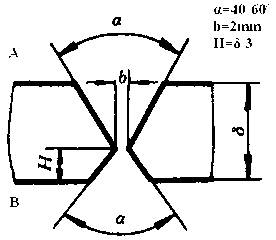

Easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process

InactiveCN103231155AImprove welding working conditionsImprove welding productivityArc welding apparatusHeat-affected zoneSemi automatic

The invention relates to an easy-welding high-strength large-thickness steel plate preheating-free gas shielded welding process which mainly comprises the following contents that: the large-thickness easy-welding 700MPa-level high-strength steel plate with the thickness of 40-80mm is matched with a high-strength high-toughness welding wire with high deoxidation element content, a 80 percent Ar+20 percent CO2 active mixed gas shielded semi-automatic or automatic welding method is adopted, due to the preheating-free treatment before welding and heating-free treatment after welding, the welding process parameters are strictly controlled, the welding sequence is reasonably arranged, the asbestos cloth coated weldment is used for heat insulation, the defect-free excellent-performance welding joint is obtained, the tensile strength of the joint is not lower than the base metal standard requirement due to mechanical performance detection, the welding line and heat affected zone are good in texture, low-temperature charpy impact absorption work (KV2) is high in surplus amount, and the application environments of the low-temperature environment can be completely met. According to the method, the production process is reduced, the labor conditions of workers are improved, the production cost is saved, and the production efficiency is improved.

Owner:JIGANG GRP

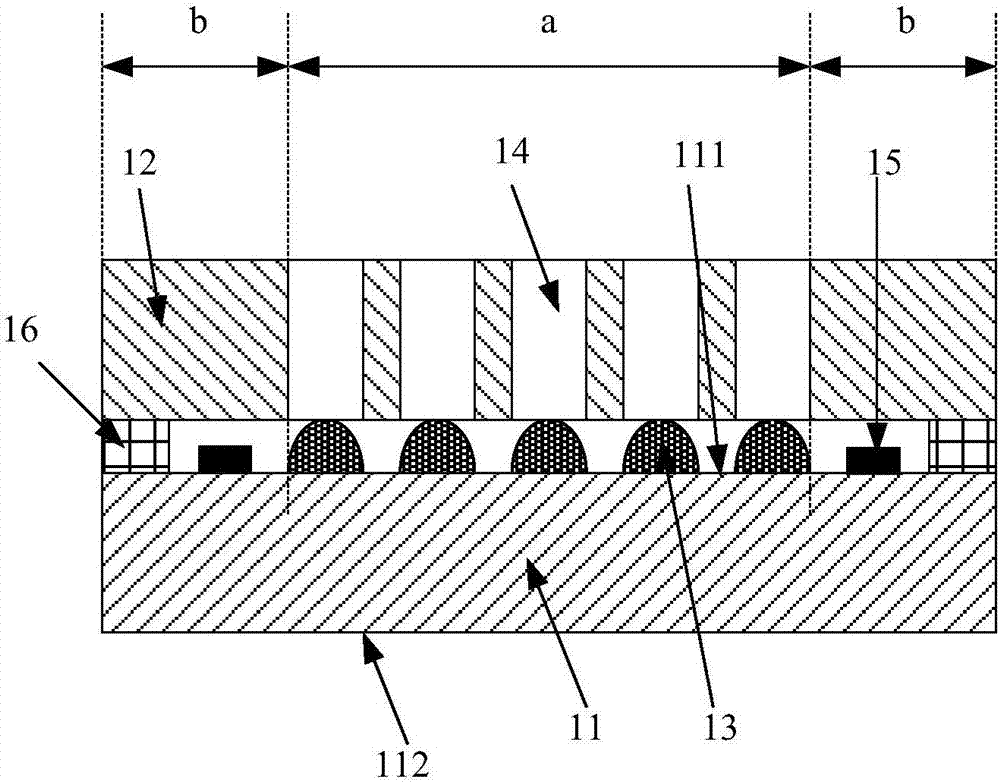

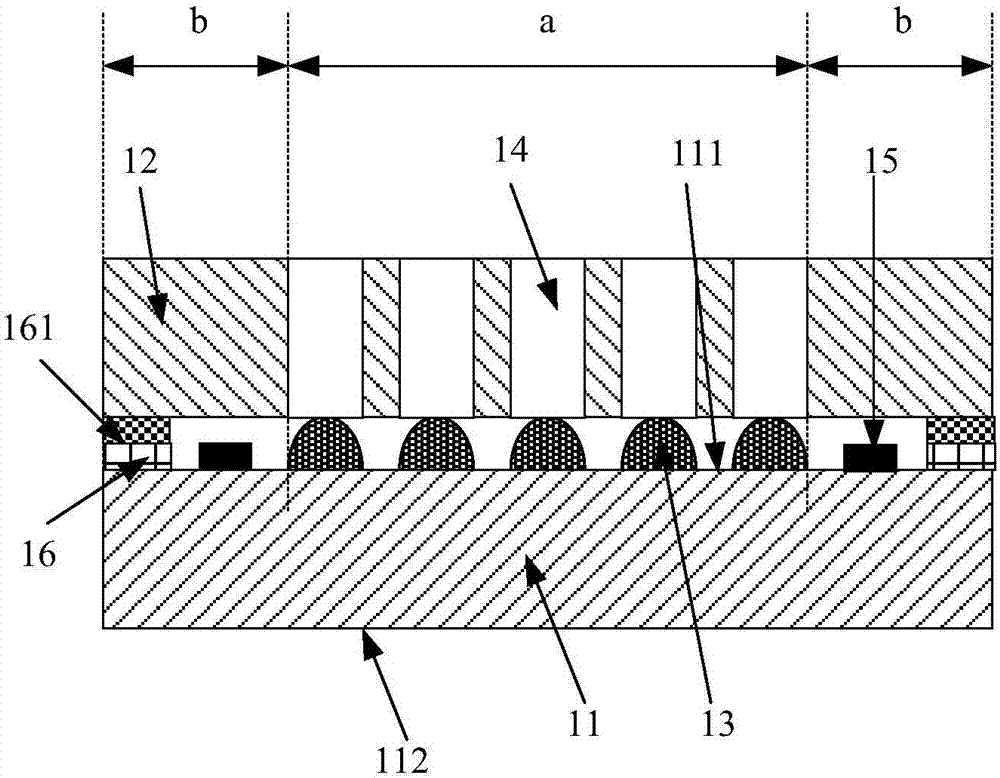

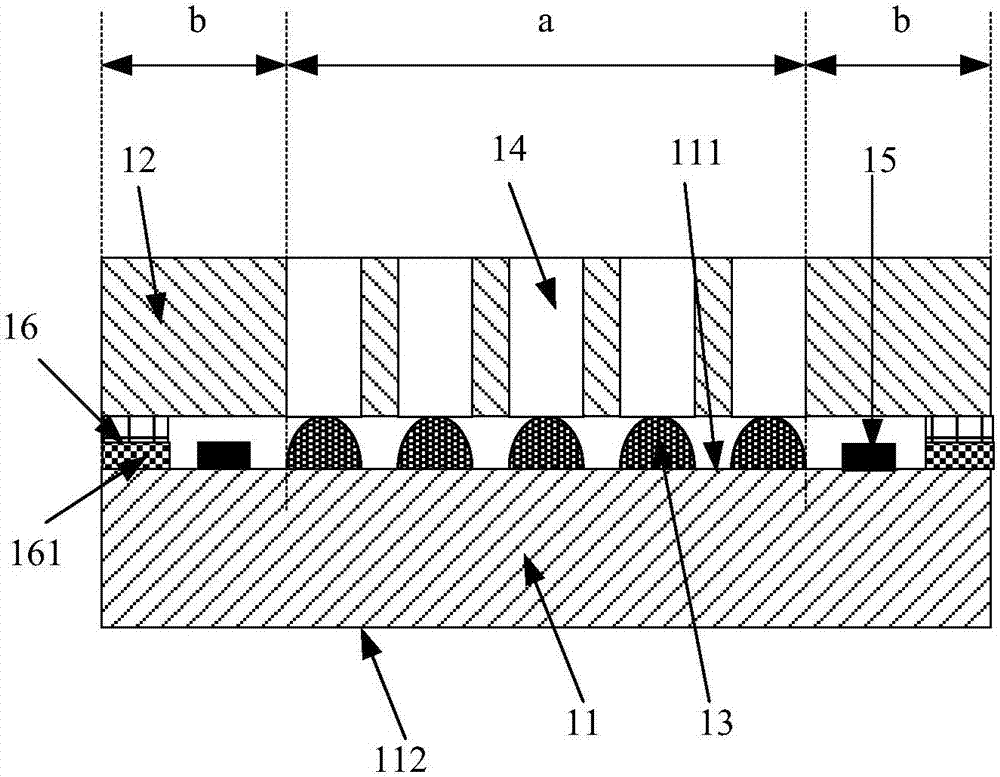

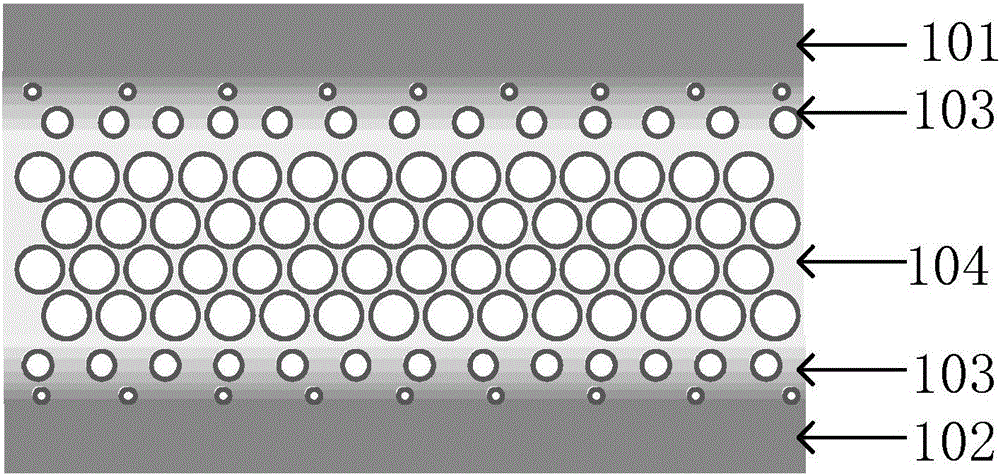

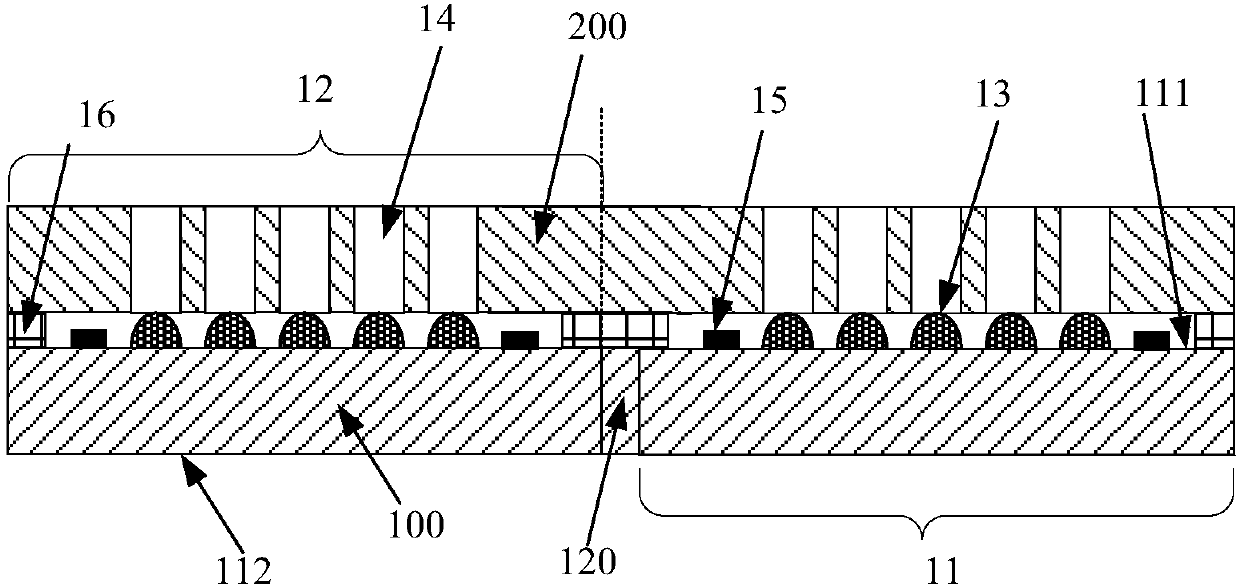

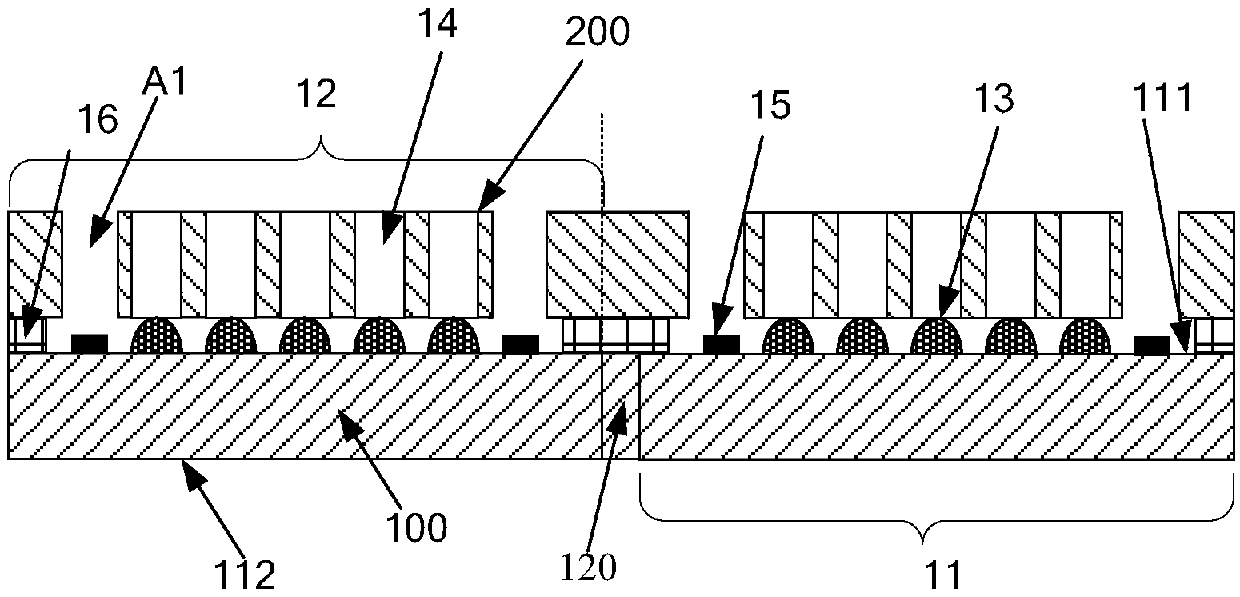

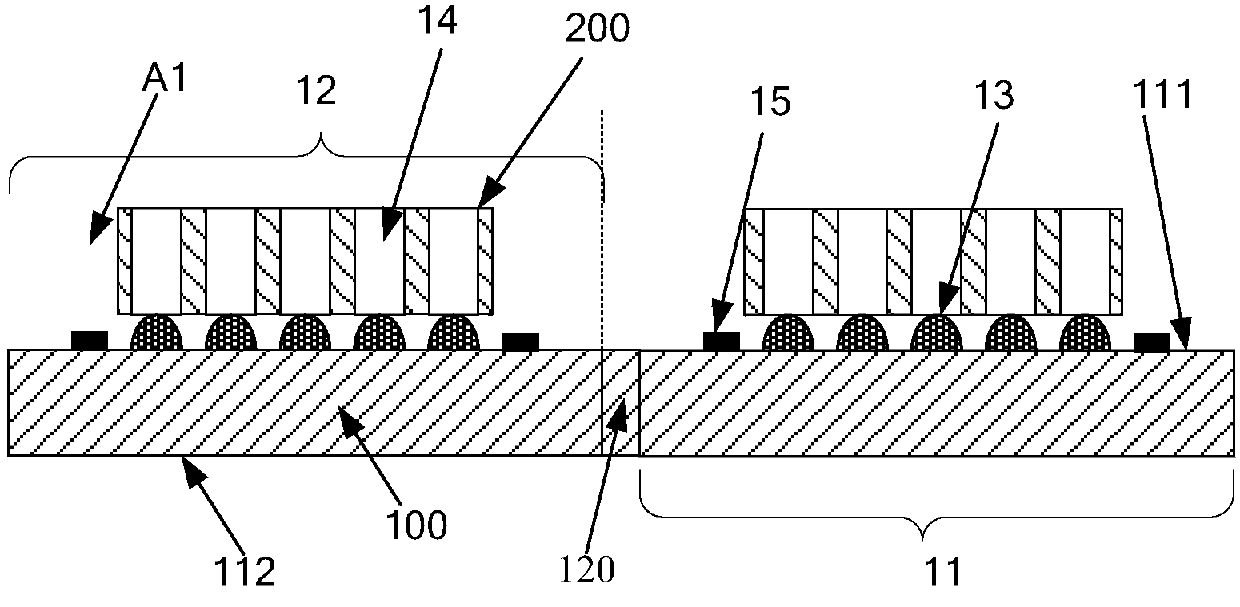

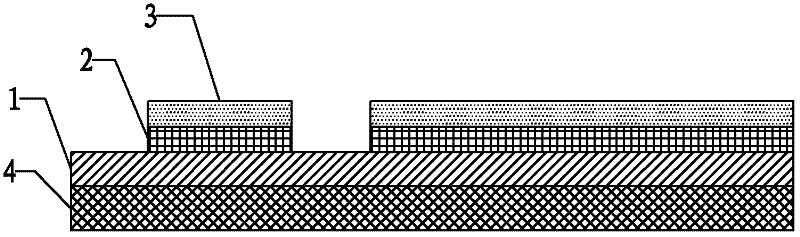

Packaging structure and packaging method of fingerprint identification chip

InactiveCN107046008AImprove accuracyLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesSemiconductorCrosstalk

The invention discloses a packaging structure and a packaging method of a fingerprint identification chip. The packaging structure comprises the fingerprint identification chip and a semiconductor cover plate for covering the first surface; fingerprint identification chip comprises a first surface and a second surface which are arranged oppositely; a plurality of pixel points used for collecting fingerprint information are on the first surface; a plurality of through holes are formed in the semiconductor cover plate; and the pixel points are exposed from the bottoms of the corresponding through holes. According to the technical scheme, the semiconductor cover plate is arranged on the first surface of the fingerprint identification chip; multiple through holes, in one-to-one correspondence with the pixel points of the fingerprint identification chip, are formed in the semiconductor cover plate; and the through holes are used for exposing the corresponding pixel points, so that the problem of crosstalk between adjacent pixel points can be lowered, and accuracy of fingerprint identification is improved.

Owner:CHINA WAFER LEVEL CSP

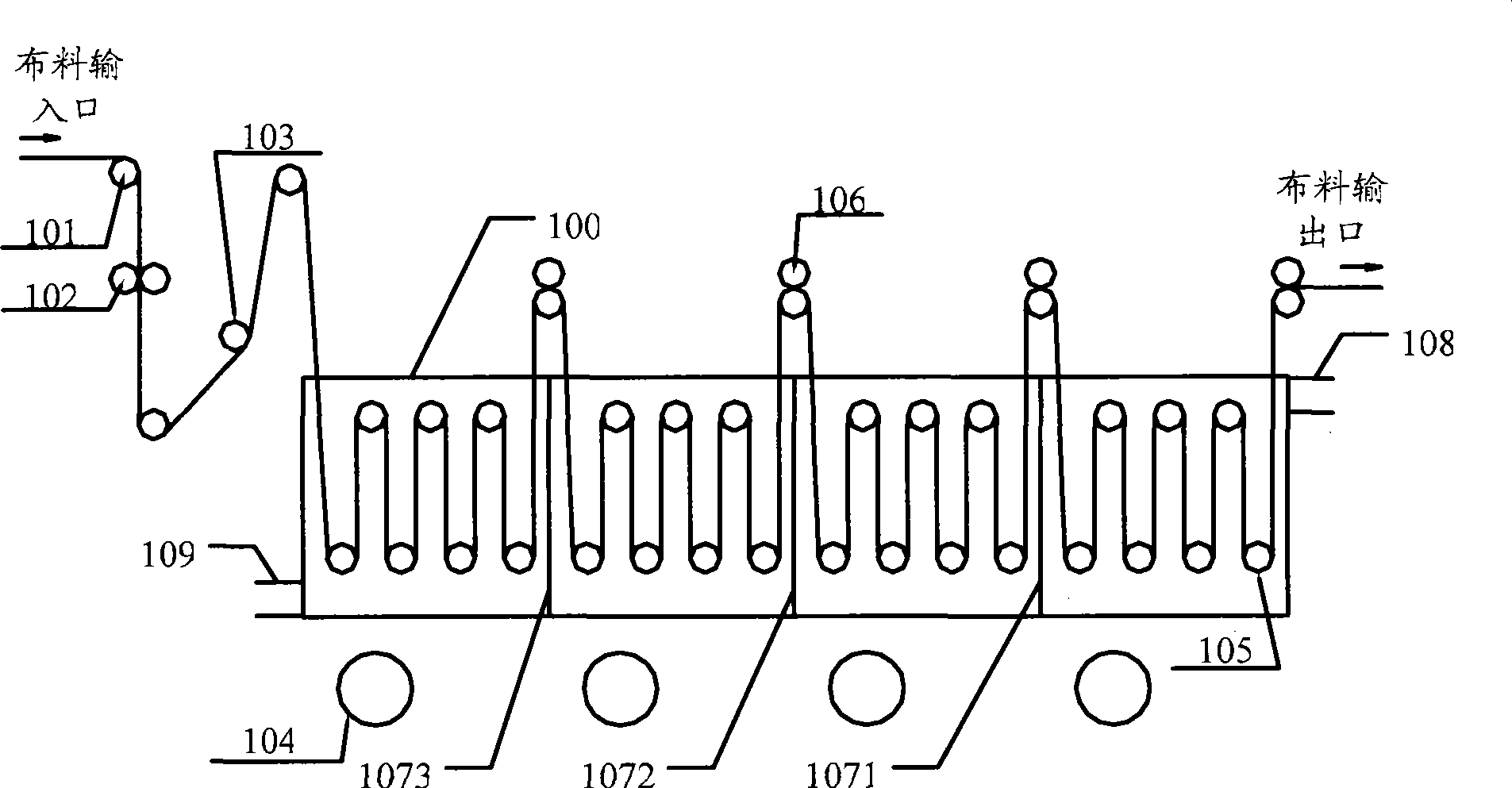

Cloth cleaning machine

ActiveCN101476221ARealize continuous online cleaningReduce process flowLiquid/gas/vapor textile treatmentSlagEngineering

The invention discloses a cloth cleaning machine for realizing cloth continuous on-line cleaning. The cloth cleaning machine of the invention comprises: a cloth inputting port, a guiding device, a cleaning device and a cloth outputting port; the cloth inputting port is connected with the slag-cloth separator in production line for conveying the slag removed cloth to the guiding device; the guiding device is used for guiding the cloth inputted from the cloth inputting port to the cleaning device; the cleaning device is used for cleaning the conveyed cloth and conveying the cleaned cloth to the outputting port; the cloth outputting port is connected with the filtered cloth stacking device in production line for conveying the cleaned cloth to the filtered cloth stacking device to stack. The invention can increase production efficiency effectively.

Owner:FOSHAN HAITIAN FLAVOURING & FOOD CO LTD +1

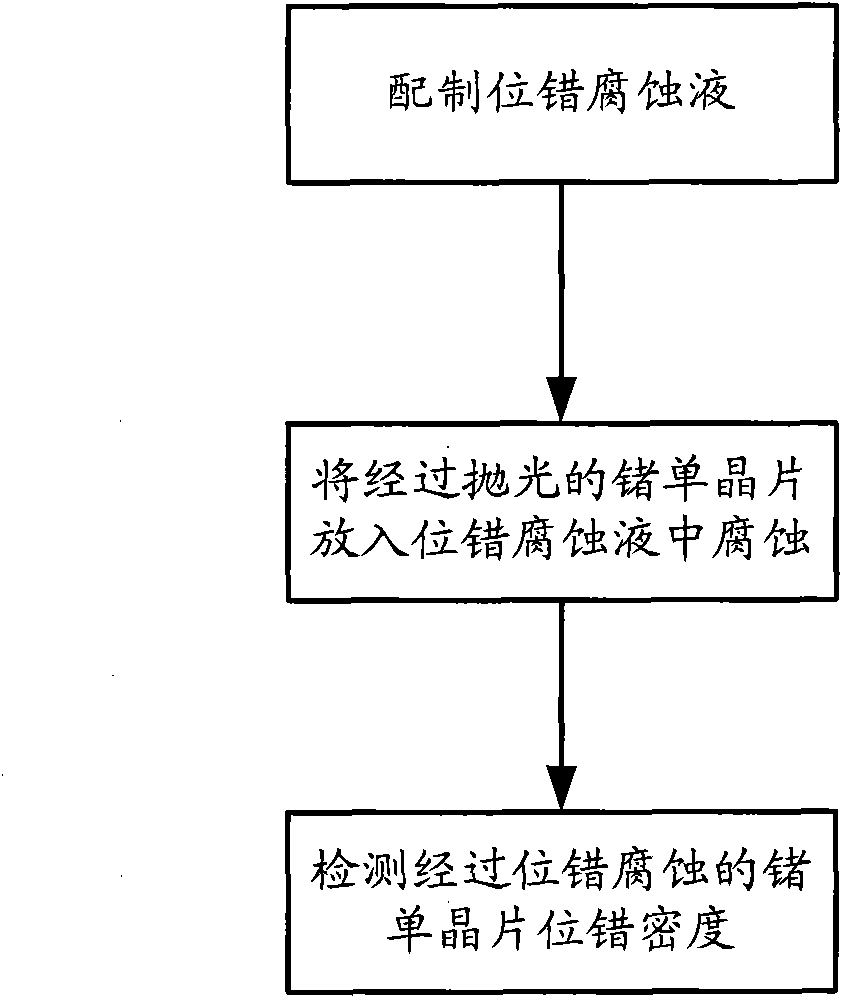

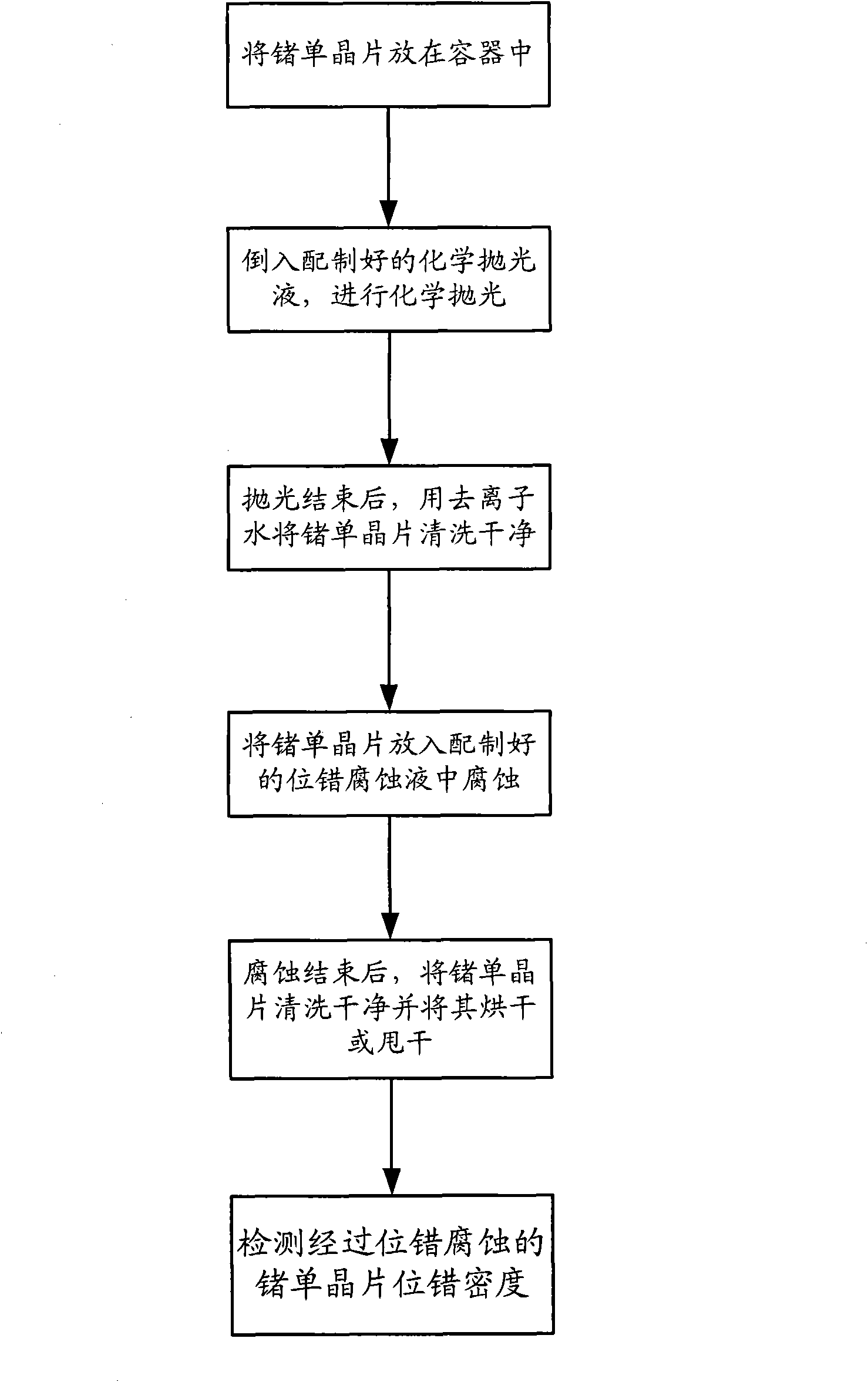

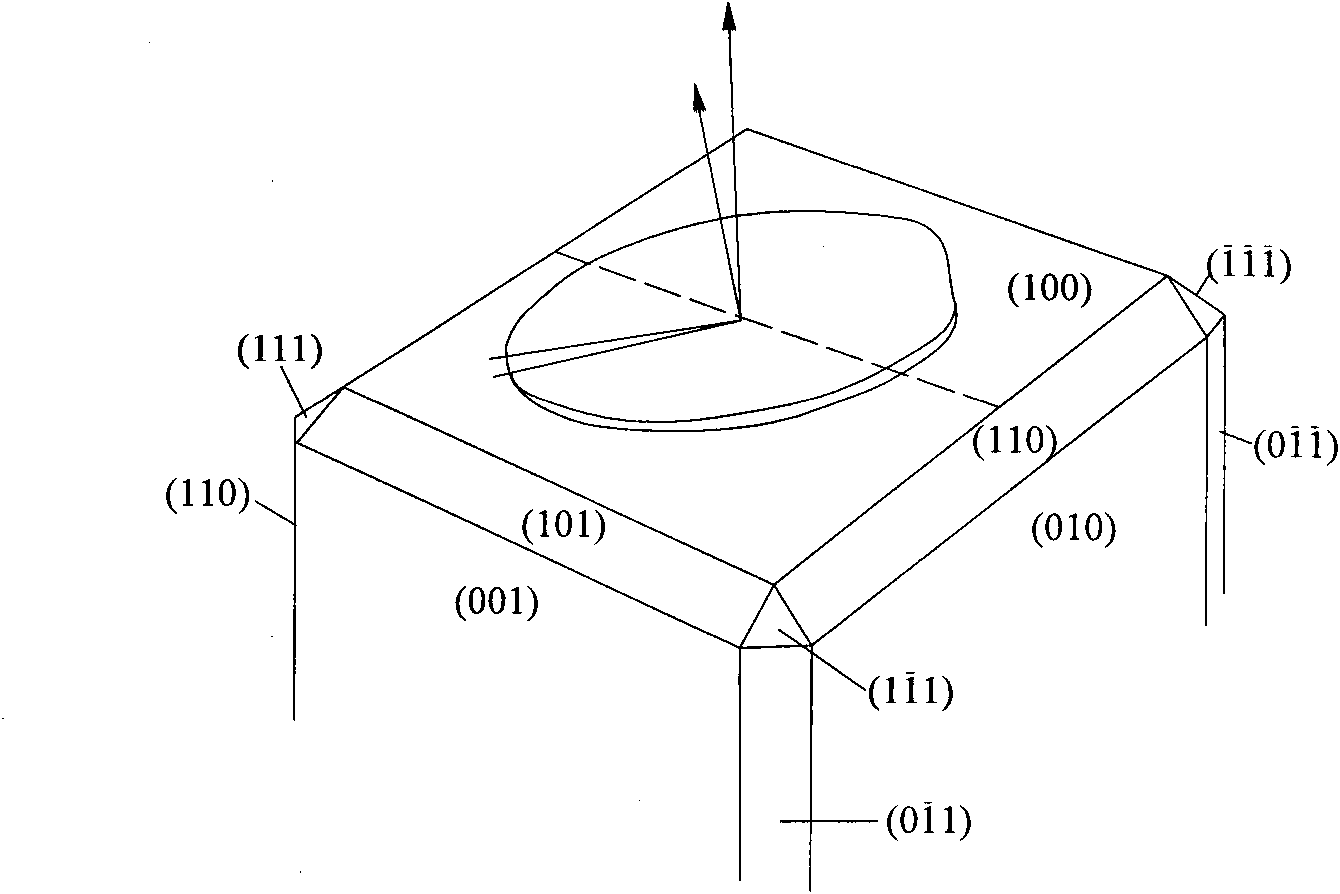

Dislocation corrosion detecting method of single germanium wafer

InactiveCN101655427AReduce lossesReduce process flowPreparing sample for investigationHydrofluoric acidWafering

The invention discloses a dislocation corrosion detecting method of a single germanium wafer, comprising the following steps: putting a polished single germanium wafer into dislocation corrosion solution formed by mixing the water solution of hydrofluoric acid, nitric acid and copper nitrate to corrode, and detecting the dislocation density after the corrosion. In the invention, dislocation diction is carried out on the single germanium wafer, and can be used for directly detecting a cutting wafer, a grinding wafer and a polishing wafer of the single wafer cutting the wafers into wafers with dislocation <100> wafer direction of 6 degrees in a wafer direction, thereby reducing the lose of the single wafer and shortening working procedures. By adopting the method for the dislocation detection of the single germanium wafer, a product of the single germanium wafer in any working procedure can be detected by the dislocation, thereby the method avoids the condition that dislocation detectioncan be carried out only by cutting the single germanium wafer in a special mode in single wafer detection, ensures that the dislocation detection of the single germanium wafer can be carried out at any moment and is beneficial to executing quality control.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

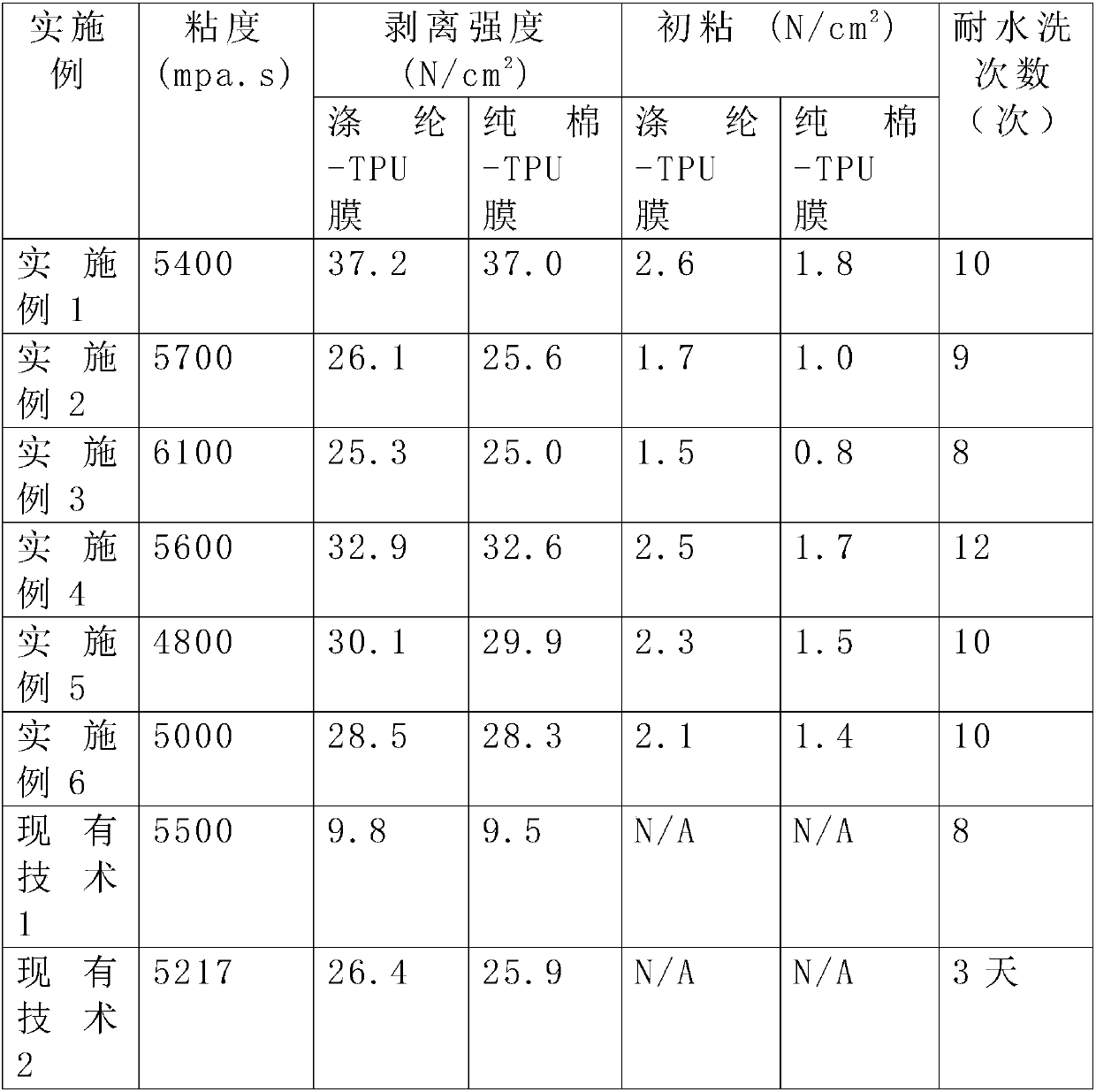

Hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and preparation method thereof

InactiveCN108084948AHighlight cohesionOutstanding initial tackNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses a hyperbranched polyester hot-melt-type polyurethane adhesive for weaving and a preparation method thereof. The hyperbranched polyester hot-melt-type polyurethane adhesive comprises polyether polyol, hyperbranched polyester polyol, MDI and an additive. The preparation method comprises preheating hyperbranched polyester polyol at 100-150 DEG C until melting to obtain hyperbranched polyester polyol pre-melt, checking the hermeticity of a reactor, removing water through replacing with nitrogen gas, carrying out preheating to 50 DEG C, orderly adding MDI and polyether polyol into the reactor, carrying out stirring in vacuum under control of a jacket temperature to 60-80 DEG C for a reaction for 1-3h, fast cooling the reaction system to 55 DEG C to obtain a polyurethaneprepolymer, orderly adding polyester polyol and the hyperbranched polyester polyol pre-melt into the polyurethane prepolymer in vacuum, heating the mixture to 60-80 DEG C, carrying out stirring for areaction for 1-3h, breaking vacuum after the reaction, and removing air bubbles to obtain the hyperbranched polyester hot-melt-type polyurethane adhesive for weaving.

Owner:黄子昕

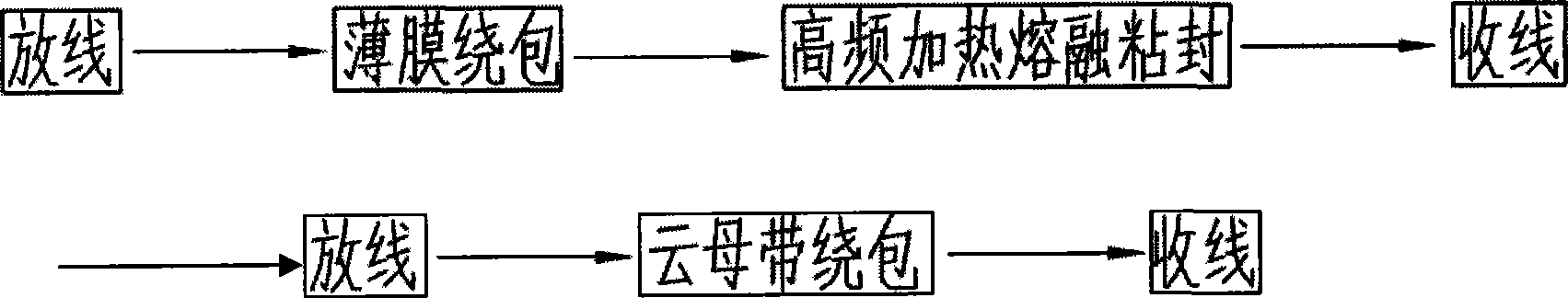

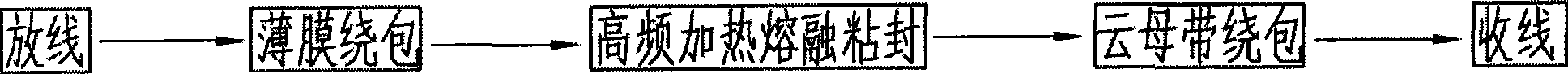

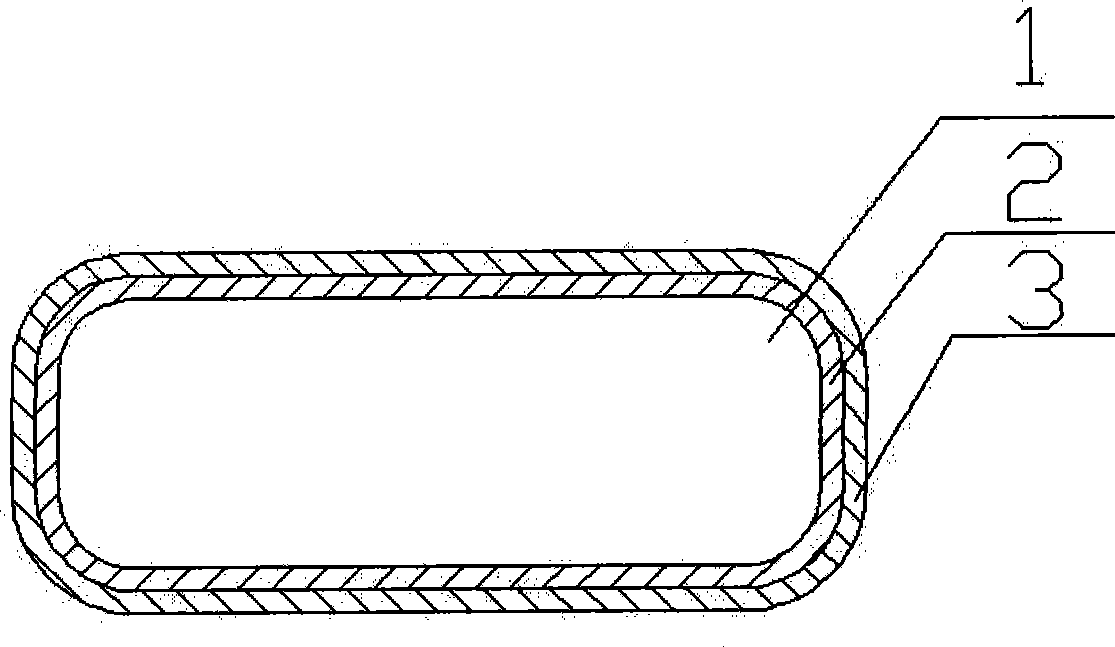

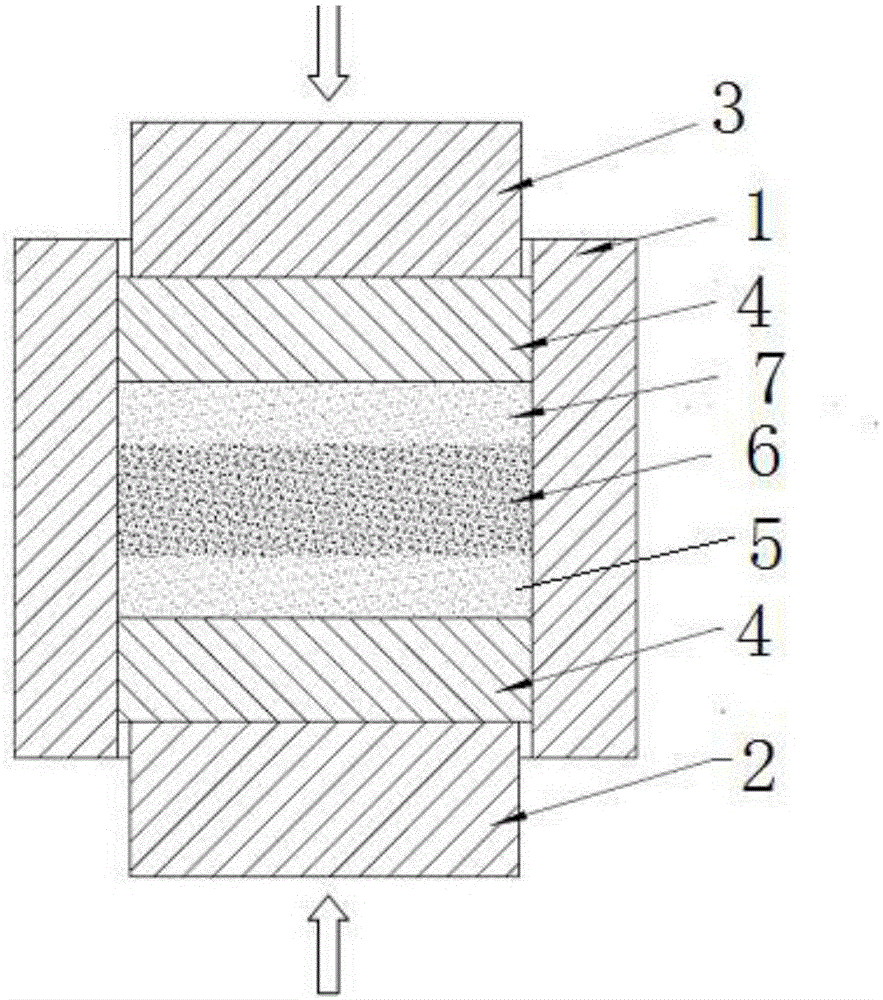

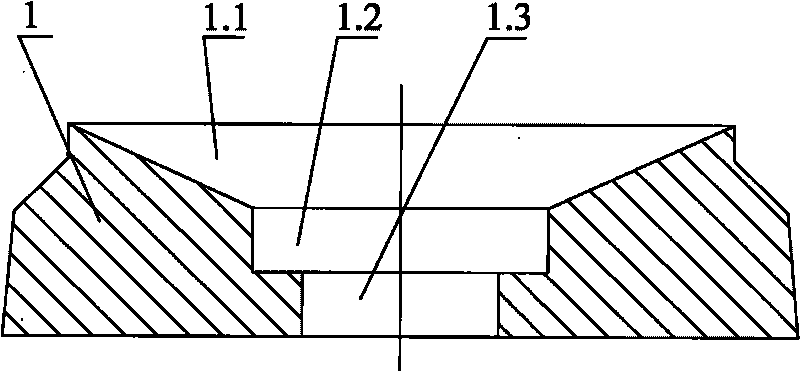

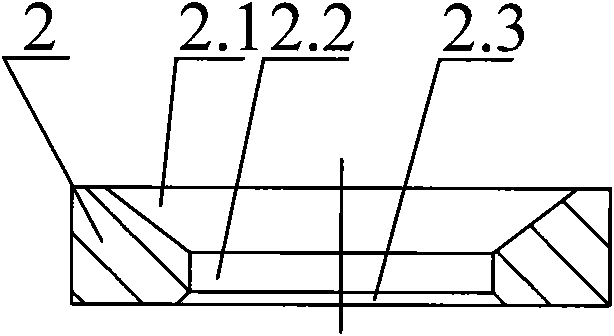

Polyimide film sintered powder mica bend coated flat copper cord and manufacturing process thereof

ActiveCN101383198AAvoid degradation of mechanical propertiesMeet the use requirementsPlastic/resin/waxes insulatorsInsulated cablesWind drivenElectrical conductor

The invention relates to a polyimide film sintering powder and mica tape winding copper flat wire and a preparation method thereof. Two layers of insulation materials are wound outside a metal wire, the inner layer is a sintered polyimide film, and the outer layer is a mica tape. The electromagnetic wire has good voltage and heat resistance, high mechanical strength and strong corona resistance. The preparation method comprises the following technical routes: conductor straightening, conductor polishing, film winding, high-frequency heating, melting, adhesive sealing, mica tape winding and rolling. The invention integrates the production technical routes by improving a high-frequency device, a mica winding device and other devices, the quality of the copper flat wire is ensured, meanwhile, the mechanical property of the copper flat wire is increased, the production flow is shortened, and the production efficiency is increased. The invention is suitable for composite insulation winding coils of large-sized motors and electric appliances, such as wind driven generators, and the like.

Owner:株洲兆源机电科技有限公司

Aluminum foam sandwich plate with gradient interface and manufacturing method thereof

The invention discloses an aluminum foam sandwich plate with a gradient interface and a manufacturing method thereof, which belong to the technical field of porous metallic materials and laminar composite materials. The manufacturing method comprises the steps of firstly, uniformly mixing aluminite powder or aluminum alloy powder and foaming agent titanium hydride powder to obtain mixed powder; then sequentially filling lower panel alloy powder, the mixed powder and upper panel alloy powder into a steel mold, wherein the three powder is distributed in a layered way; then putting the steel mold into a hot press machine so as to be hot-press densified to obtain a foamable sandwich plate prefabricated member; and finally heating and foaming the prefabricated member to obtain the foam sandwich plate with the gradient interface. According to the method, the densification of the aluminum foam prefabricated member and a compounding process of aluminum foam and panels are completed at the same time within one working procedure, so that the process flow is short, and the manufacturing cost is low; commercially available metal sheets have no need to be used, so that a material selection range and a design space are wide; and the aluminum foam sandwich plate with the gradient interface prepared through the invention is hopefully applied widely in the fields of automobiles, rail trains, buildings, electronics and national defense and military industry.

Owner:有研金属复材技术有限公司

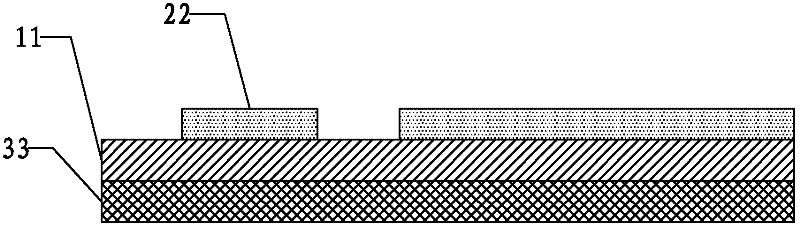

Fingerprint recognition chip packaging structure and method

InactiveCN106684052AImprove accuracyLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesPattern recognitionSilicon

The invention provides a fingerprint recognition chip packaging structure and method. The structure comprises a fingerprint recognition chip and a silicone cover plate. The fingerprint recognition chip comprises a front face and a rear face opposite to the front face. The front face of the fingerprint recognition chip is provided with a fingerprint recognition region and multiple welding pads located on the periphery of the fingerprint recognition region. The welding pads are electrically coupled with the fingerprint recognition region. The fingerprint recognition region is composed of multiple pixel points arranged in an array mode, and the pixel points are used for acquiring fingerprint information. The silicone cover plate is pressed on the front face of the fingerprint recognition chip, multiple through holes are formed in the portion, corresponding to the fingerprint recognition region, of the silicone cover plate, the through holes correspond to the pixel points one to one, and the pixel points are exposed at the bottoms of the through holes. The welding pads are exposed on the silicone cover plate. The silicone cover plate has the low dielectric constant, the crosstalk problem between the adjacent pixel points can be reduced, and the accuracy of fingerprint recognition is improved.

Owner:CHINA WAFER LEVEL CSP

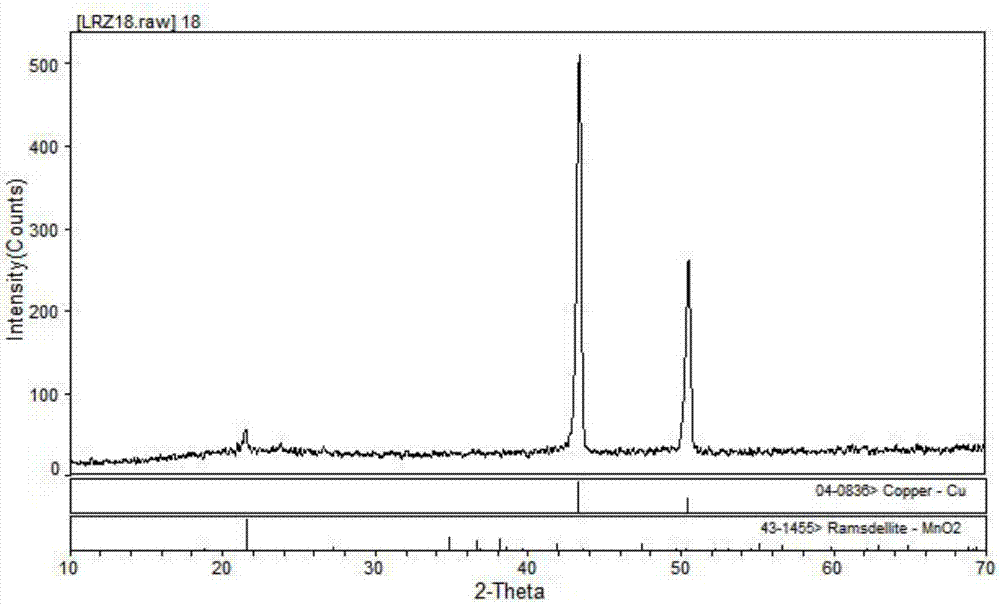

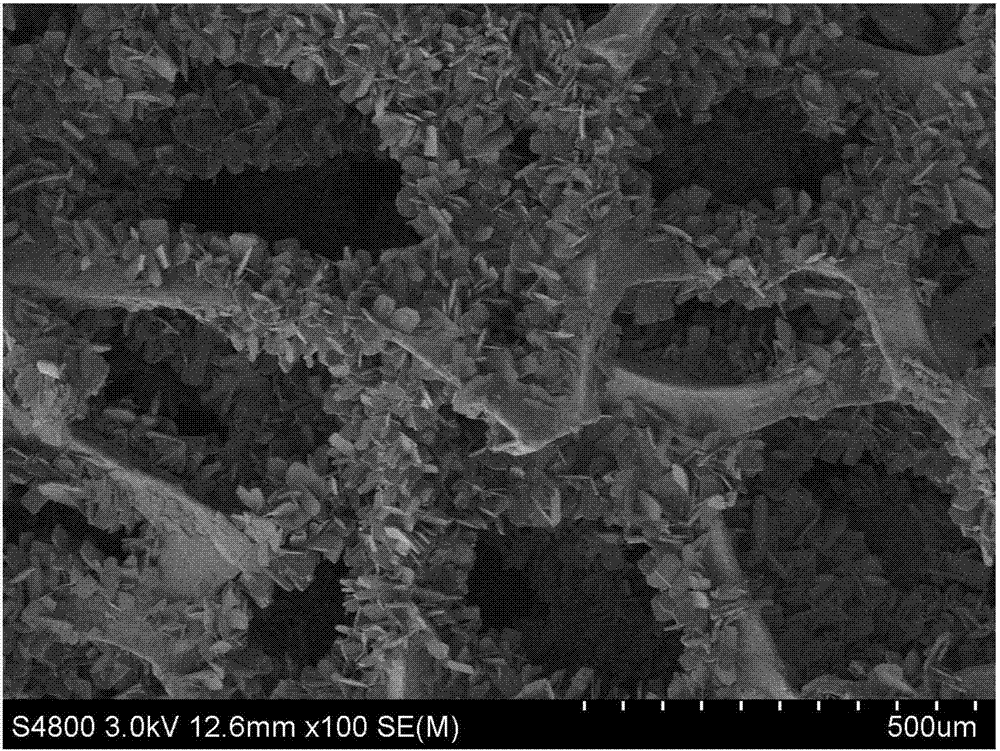

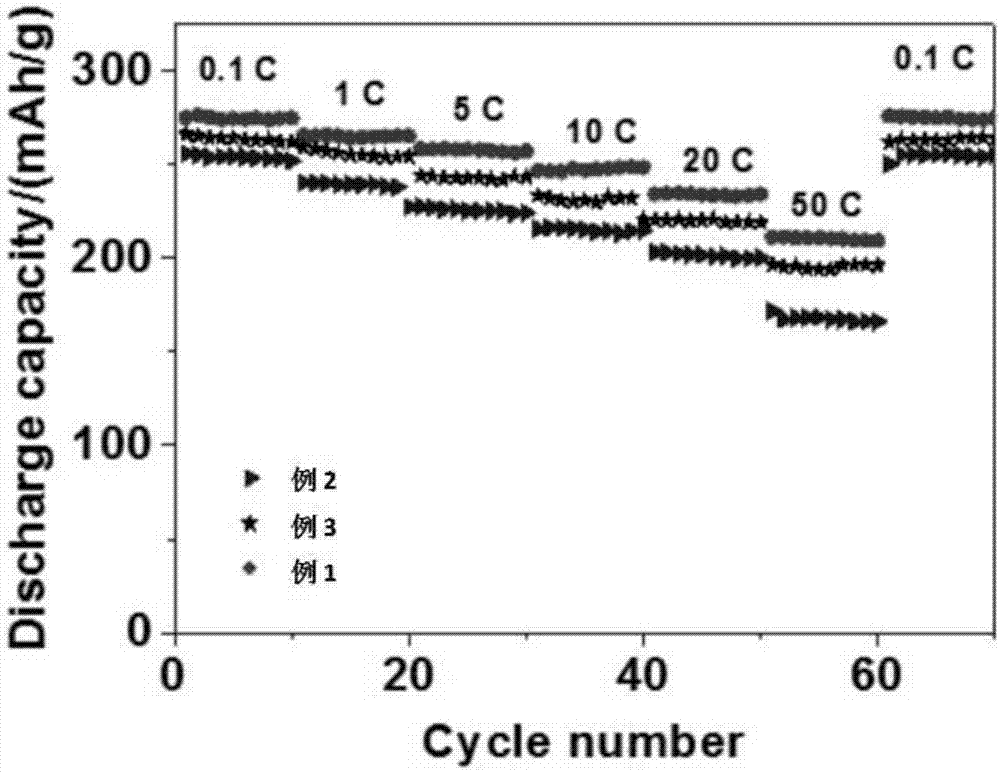

Manganese dioxide/copper foam sodium ion battery self-supporting negative pole preparation method

ActiveCN107093703ACapacity does not affectExcellent rate performanceElectrode carriers/collectorsSecondary cellsAlcoholSulfate

The invention discloses a manganese dioxide / copper foam sodium ion battery self-supporting negative pole preparation method. The method comprises the steps that flake copper foam is treated with absolute ethyl alcohol, washed to be clean and dried, and an electrode substrate is obtained; a manganese sulfate solution of a certain concentration is prepared; the obtained solution and a copper foam sheet are put into a hydrothermal reaction kettle, heating and heat preservation are conducted for a certain time through hydrothermal induction heating equipment, and then the manganese dioxide / copper foam sodium ion battery self-supporting negative pole with a three-dimensional porous communicating frame-shaped structure is obtained.

Owner:SHAANXI UNIV OF SCI & TECH

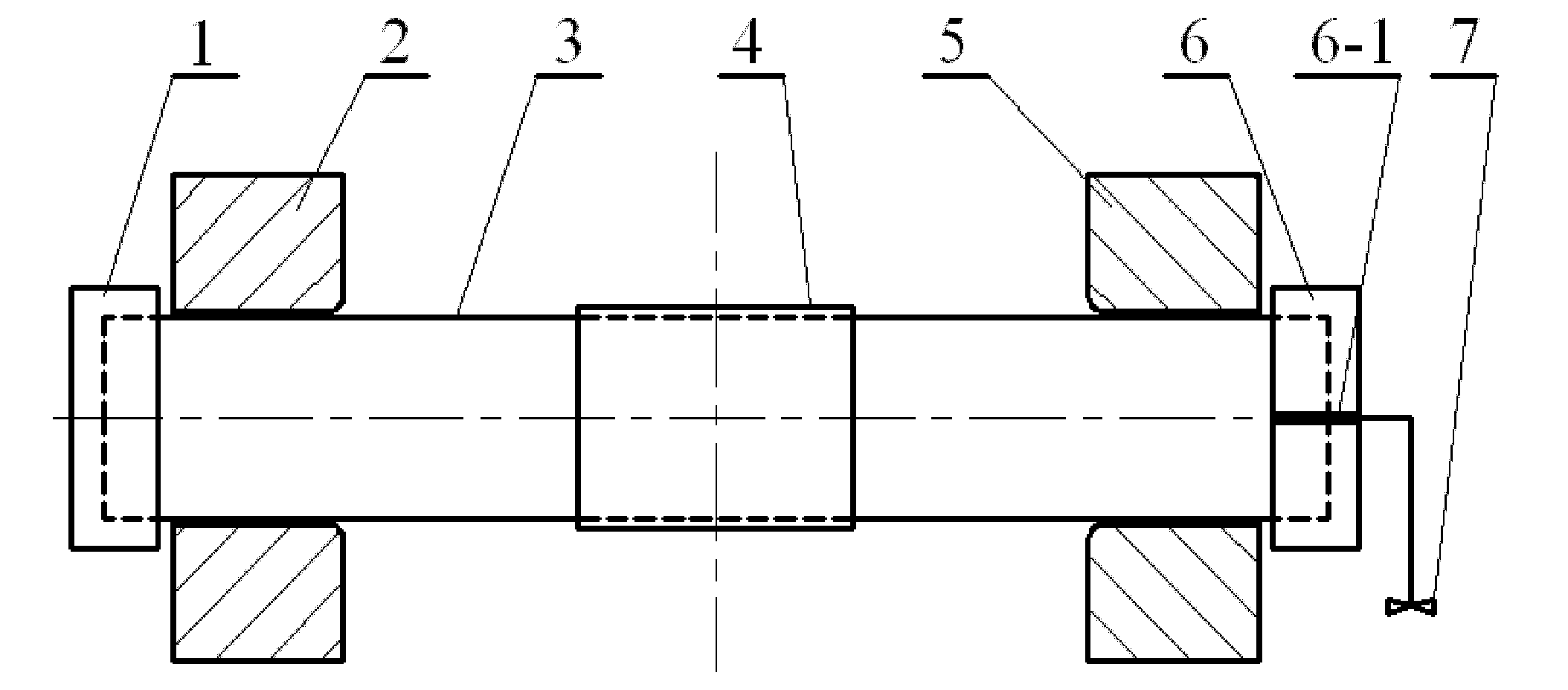

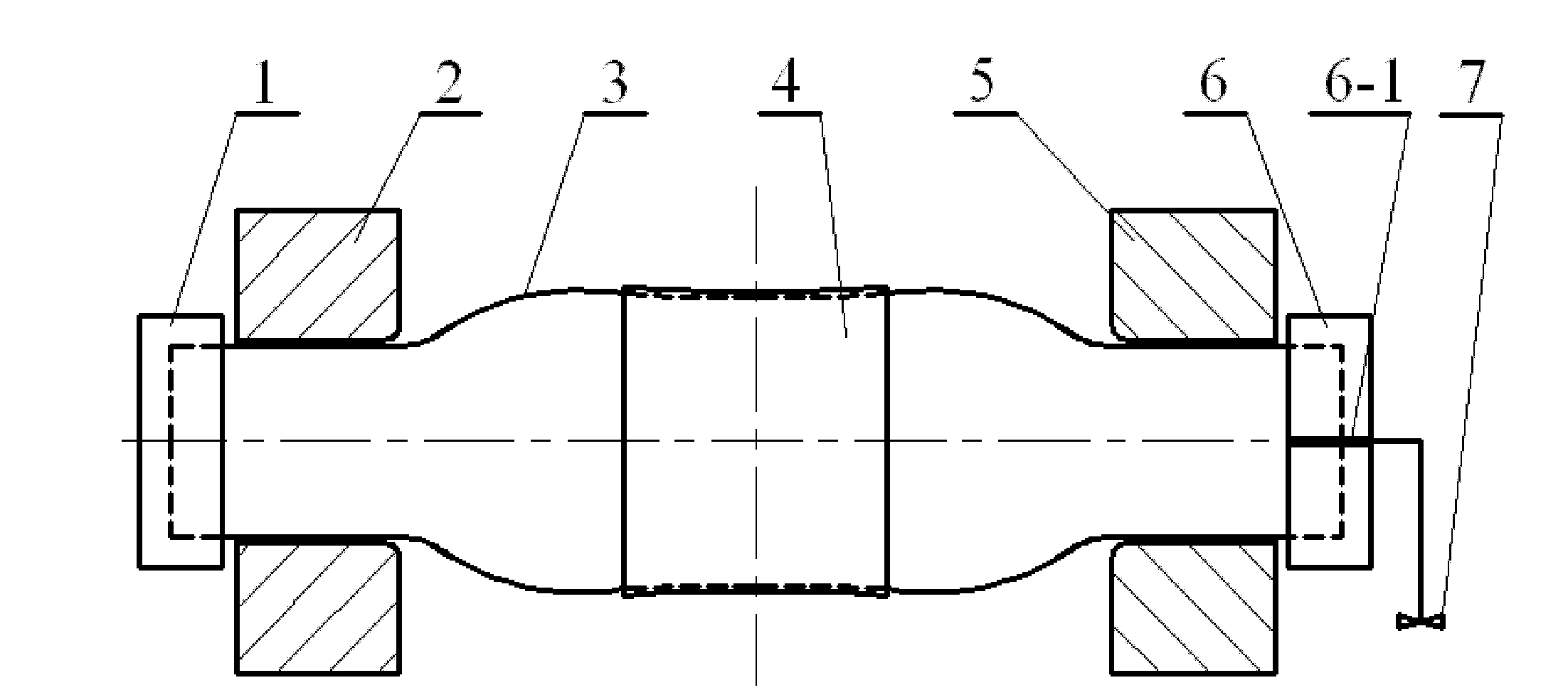

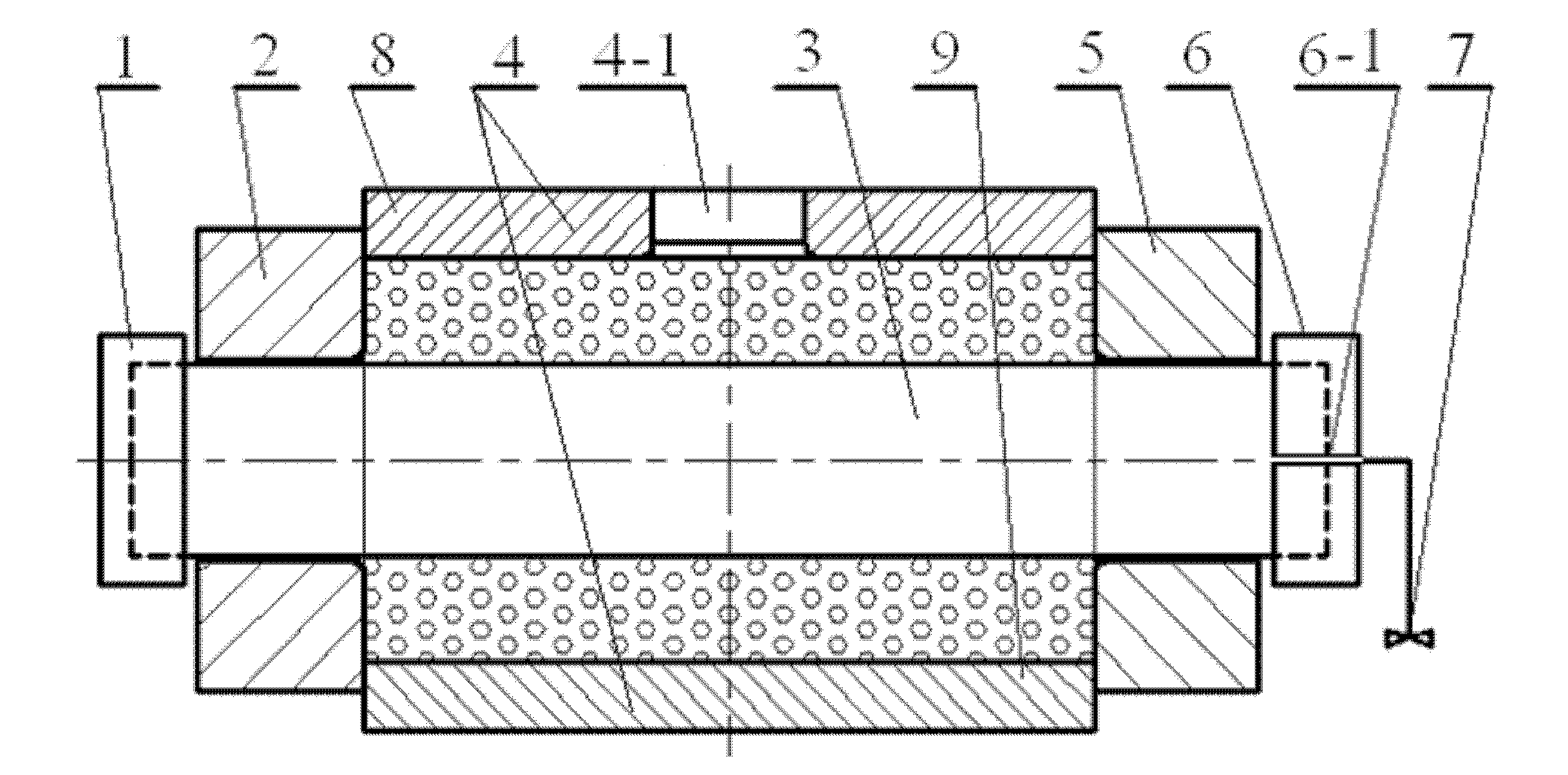

Device for improving pipe internal-pressure forming limit and method for improving pipe internal-pressure forming limit by utilizing same

The invention provides a device for improving pipe internal-pressure forming limit and a method for improving pipe internal-pressure forming limit by utilizing the same, which relate to a device and method for improving pipe internal-pressure forming limit and solve the problems of poor deformation uniformity, cracking due to the excessive thinning of a local part and low room-temperature forminglimit in the traditional pipe internal-pressure forming process. In the device provided by the invention, a constraint sleeve is arranged at the middle part of the outer side wall of a pipe or a die is arranged outside the pipe; in the method provided by the invention, the constraint sleeve is arranged at the middle part of the outer side wall of the pipe or the die is arranged outside the pipe, a filler is added into the gap between the die and the pipe, the pipe is fixed on a die frame with the two ends sealed, an internal pressure is introduced into the inner cavity of the pipe, and forming is finally carried out. In the invention, a back pressure is applied to the outer side of the pipe, so that the stress state of the pipe at a sectional part subjected to the maximum deformation is changed into a two-pulling and one-pressing mode from a two-pulling mode, thereby avoiding the possibility that a cracking defect is caused as the wall thickness of the part is excessively thinned, improving the room-temperature forming limit, and increasing the expansion ratio to 30-45%.

Owner:HARBIN INST OF TECH

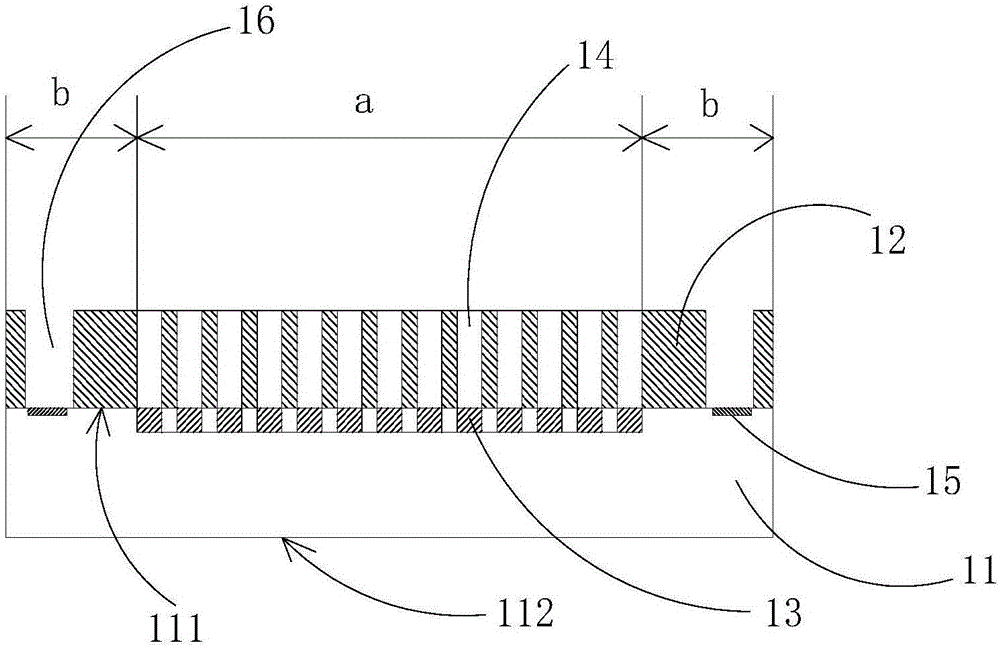

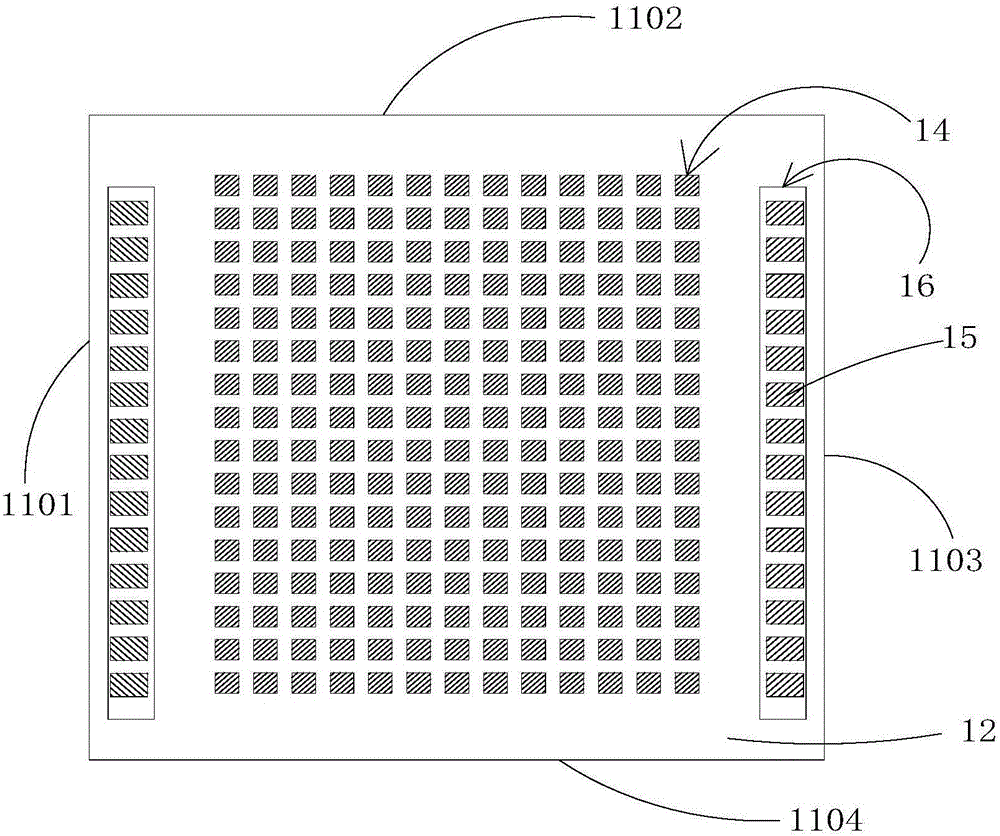

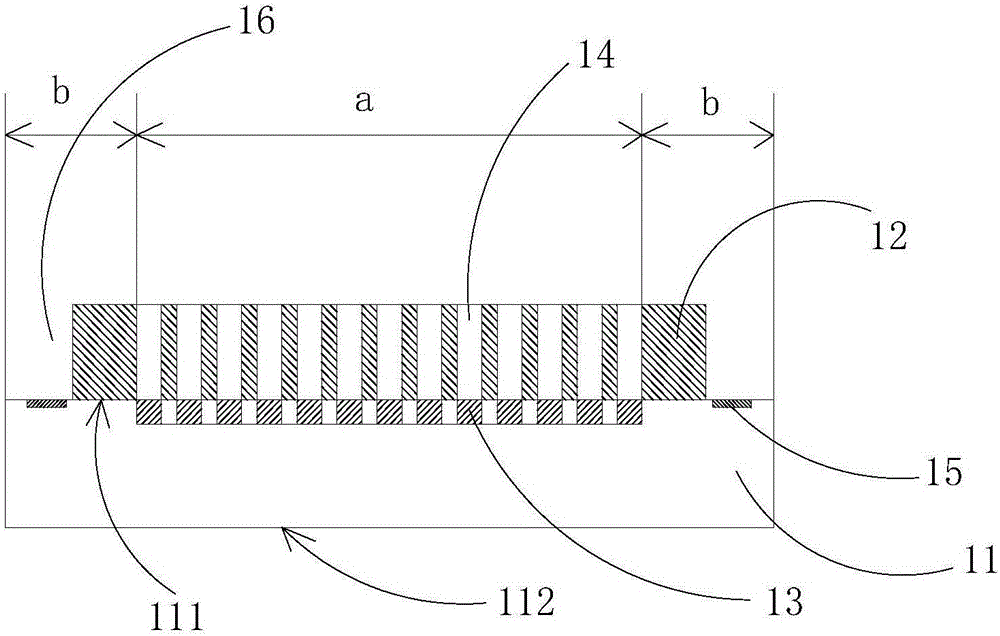

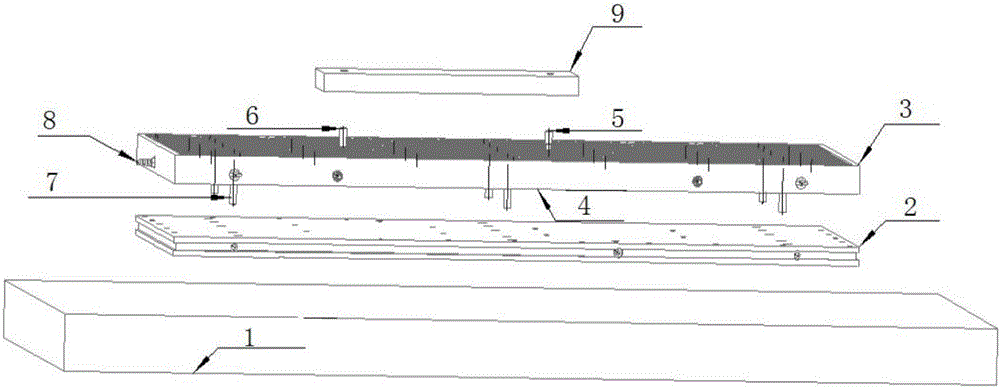

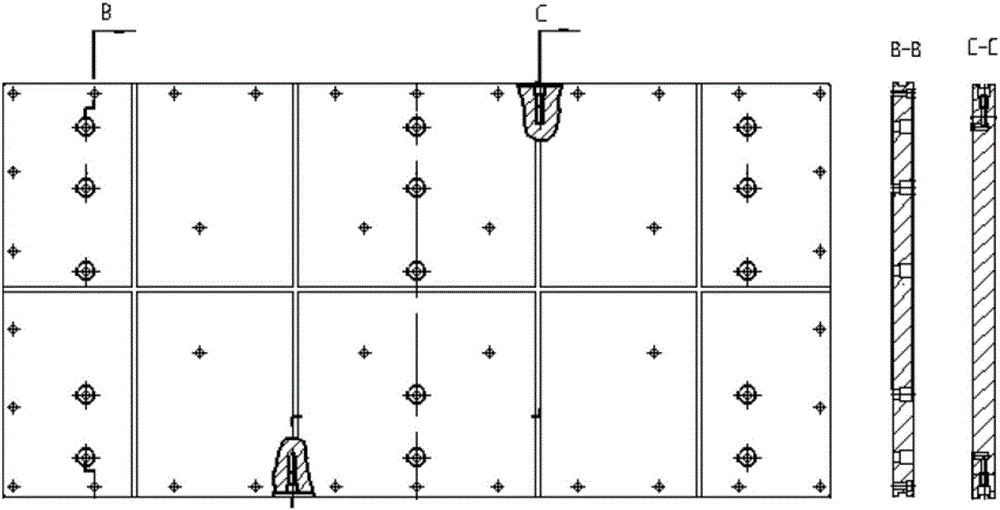

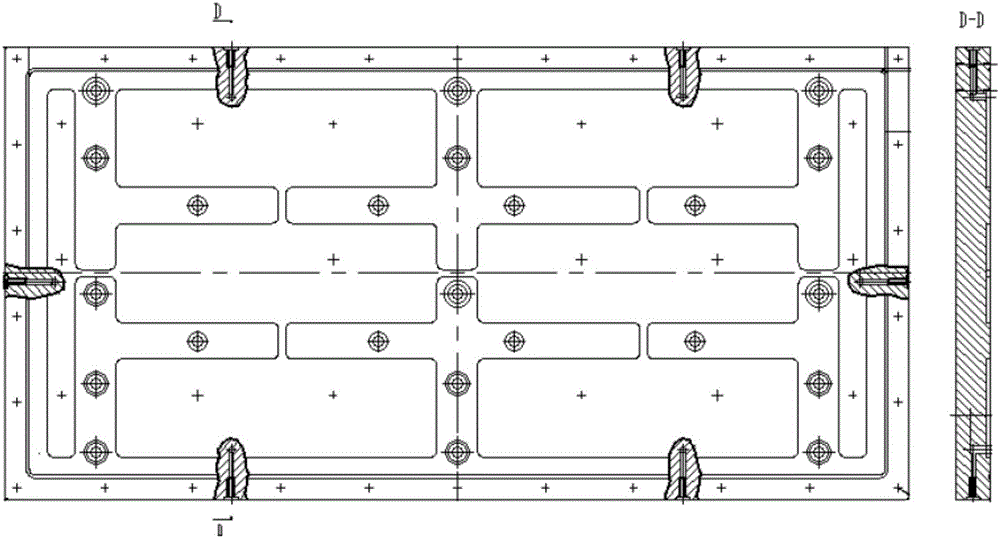

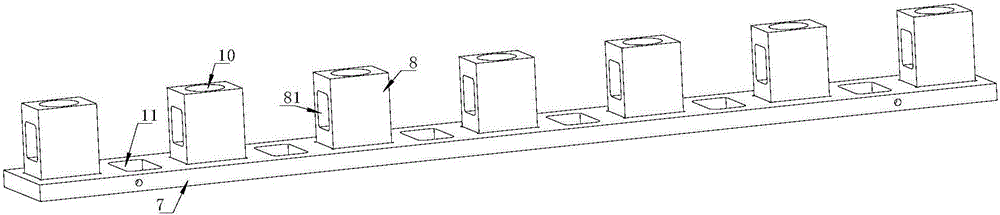

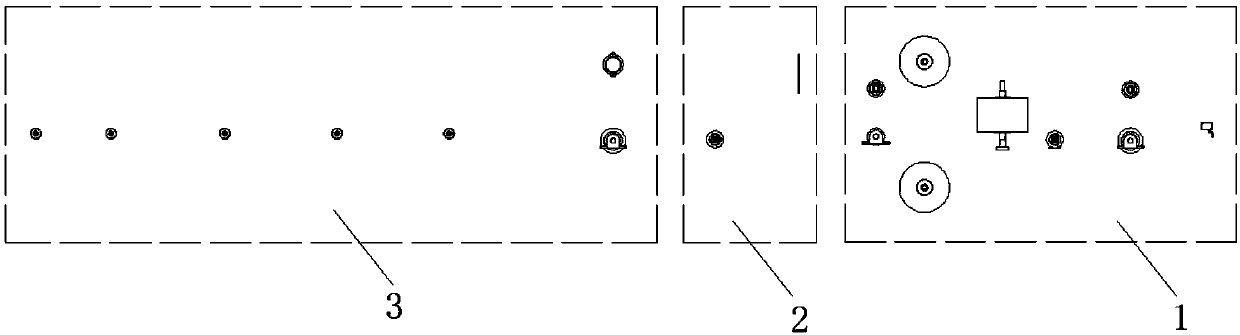

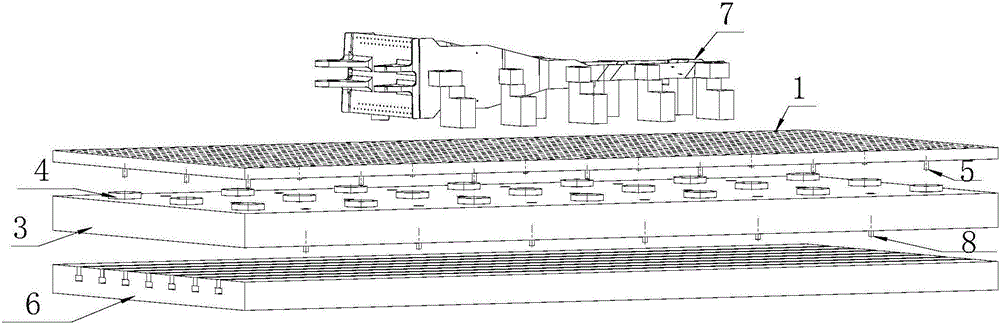

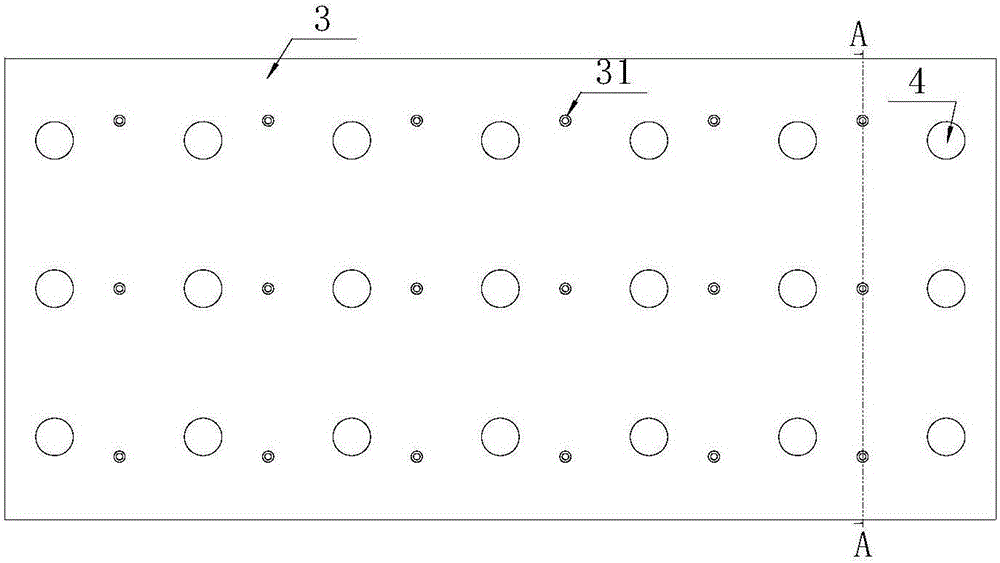

Multi-station quick positioning device and method applicable to aviation sheet metal parts

InactiveCN105922043AQuick changeQuick clampingPositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a multi-station quick positioning device and method applicable to aviation sheet metal parts. The device comprises a general vacuum platform arranged on a machine tool workbench. An aspirating chamber is arranged on a bottom face part of a body of the general vacuum platform, aspirating holes are formed in the aspirating chamber, sealing grooves are formed in the periphery of the bottom face, and after sealing strips are installed in the sealing grooves, the general vacuum platform is fixedly assembled with a base sealing plate; and the surface of the body of the general vacuum platform is partitioned into boxes by sealing grooves, a steel bush is installed in the center of each box, and sealing strips are installed in the sealing grooves. According to the multi-station quick positioning device and method, the maximum performance of a machine tool is brought into full play on the premise that equipment and a tool run safely, the time for process preparing and part installing and replacing is shortened, a part of aviation parts can be machined in an assembly line manner through the vacuum platform, operation standards are unified, the technical process is unified, machining information is detected digitally, human operation errors are reduced, the quality stability is improved, and meanwhile, modernized auxiliary tools are used for improving the machining efficiency.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

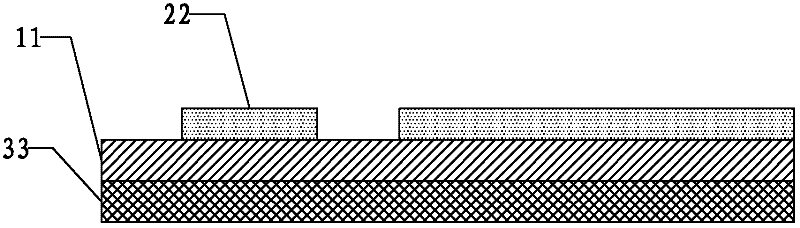

Fingerprint identification chip package structure and packaging method

InactiveCN108022904AImprove accuracyLow dielectric constantSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor

The invention discloses a fingerprint identification chip package structure and a packaging method. The package structure comprises a fingerprint identification chip, wherein the fingerprint identification chip comprises a first surface and a second surface, which are opposite, the first surface having a plurality of pixel points for collecting fingerprint information; and a semiconductor cover plate covered on the first surface, wherein the semiconductor cover plate has a plurality of through holes, the bottom portions of the through holes exposing the pixel points respectively. According tothe technical scheme, the first surface of the fingerprint identification chip is provided with the semiconductor cover plate, the semiconductor cover plate has the plurality of through holes in one-to-one correspondence with the pixel points of fingerprint identification chip respectively, and the through holes are used for exposing the pixel points, so that the problem of crosstalk between adjacent pixel points can be reduced, and fingerprint identification accuracy is improved.

Owner:CHINA WAFER LEVEL CSP

A kind of surface protection method of flexible printed circuit board

ActiveCN102271466AGood solder resistanceImprove flexibilityNon-metallic protective coating applicationFlexible circuitsQuality control

The invention relates to a method for protecting surface of a flexible printed circuit board. The method comprises the following steps of: a, manufacturing a silk printing screen plate; b, aligning and regulating, so that a pattern on the silk printing screen plate is just opposite to a surface-protecting area of the circuit board; c, uniformly coating liquid polyimide (PI) on the surface-protecting area of the circuit board through the pattern on the silk printing screen plate; and d, drying the circuit board. In the method for protecting the surface of the flexible printed circuit board, the liquid PI is uniformly coated on the surface-protecting area of the flexible circuit board (FPC), and dried and cured at high temperature to form a protecting layer with excellent solder resistance and flexibility, so that the liquid PI has the same function of protecting the copper surface of a substrate as a common covering film, the working processes are reduced, the product producing time isshortened, manpower is saved, raw materials are saved, and production cost is reduced; and in the aspect of quality control, quality problems such as air bubbles generated in the process of manufacturing the common covering film, poor creases and the like are avoided, and the qualified rate of products is improved.

Owner:SHENZHEN JINGCHENGDA CIRCUIT TECH

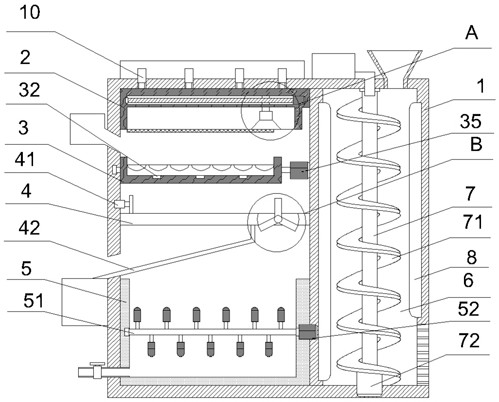

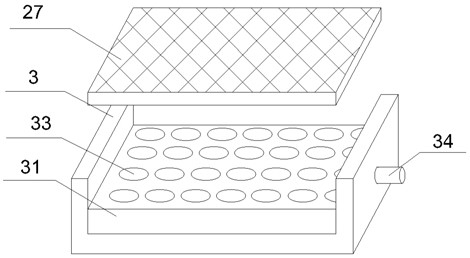

Dried shiitake mushroom production equipment with sterilization action

ActiveCN112385866ARealize automatic layoutRealize automatic de-handlingSievingScreeningBiotechnologyEngineering

The invention relates to the technical field of food processing equipment and discloses dried shiitake mushroom production equipment with a sterilization action. The dried shiitake mushroom productionequipment comprises a box body, wherein a top seat is arranged at the internal upper end of the box body, a cutting box is arranged at the lower end of the top seat, a screen plate is arranged at thelower end of the cutting box, a cleaning tank is arranged at the lower end of the screen plate, a drying chamber is arranged at one side, far away from the cleaning tank, inside the box body, supporting columns are arranged inside the drying chamber, and ultraviolet sterilizing lamps are arranged on internal walls of the drying chamber. According to the dried shiitake mushroom production equipment with the sterilization action, through matching between the cutting box and the screen plate, shiitake mushrooms can be subjected to automatic stem removing and automatic screening separation; the shiitake mushrooms are cleaned through rubber sleeves, and thus, damage to appearance of the shiitake mushrooms is reduced; and the ultraviolet sterilizing lamps are arranged in the drying chamber, sothat uniform baking and sterilizing of the shiitake mushrooms are facilitated, the space usage of the equipment is saved, and procedure flows of manual transferring are also reduced.

Owner:河南天中亿龙食品有限公司

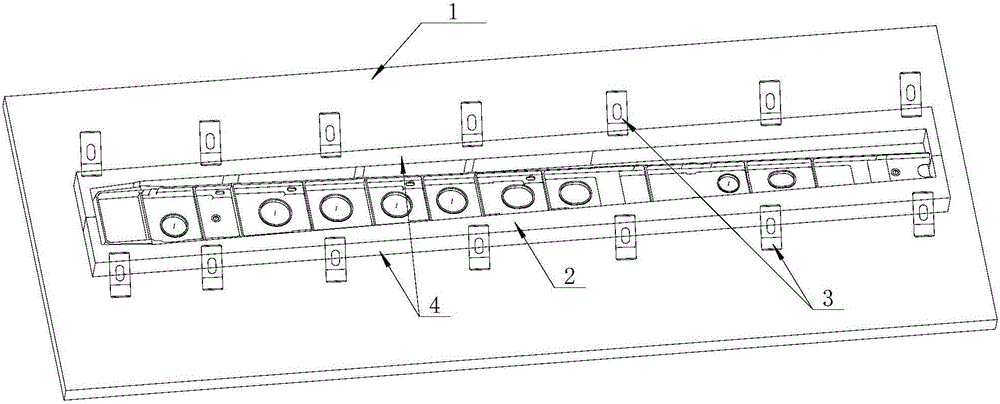

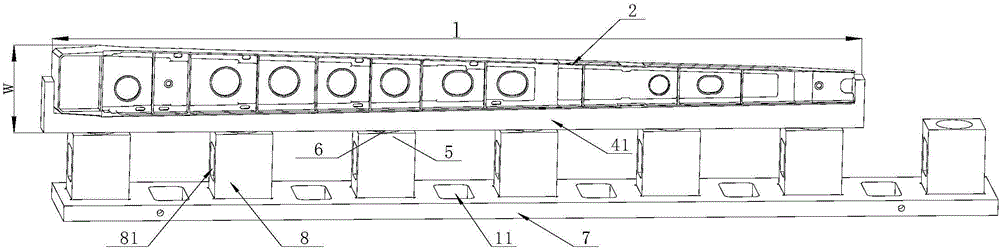

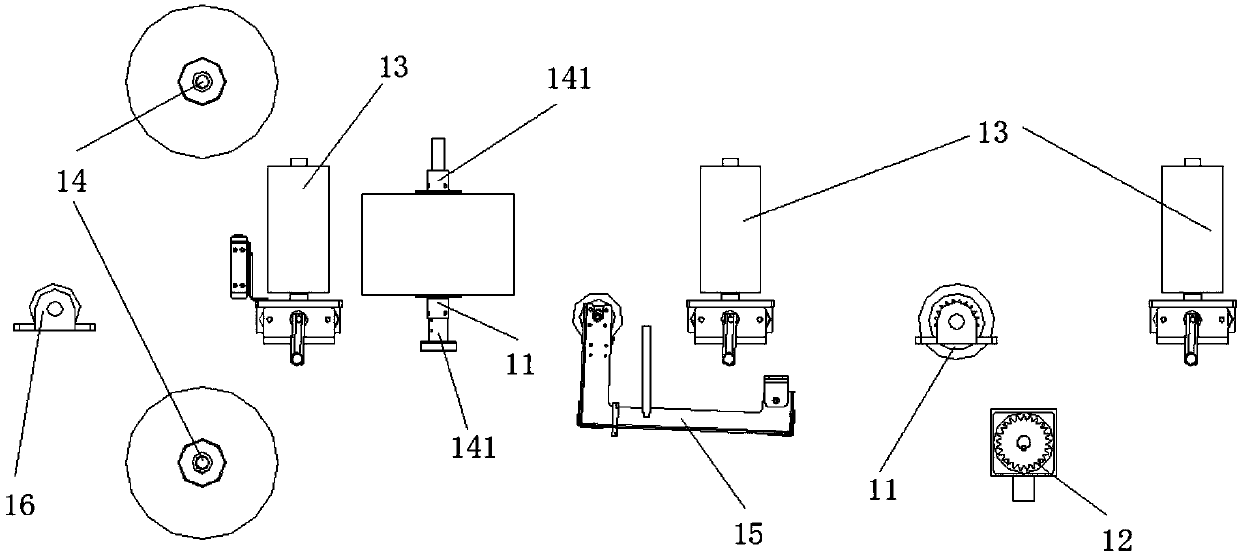

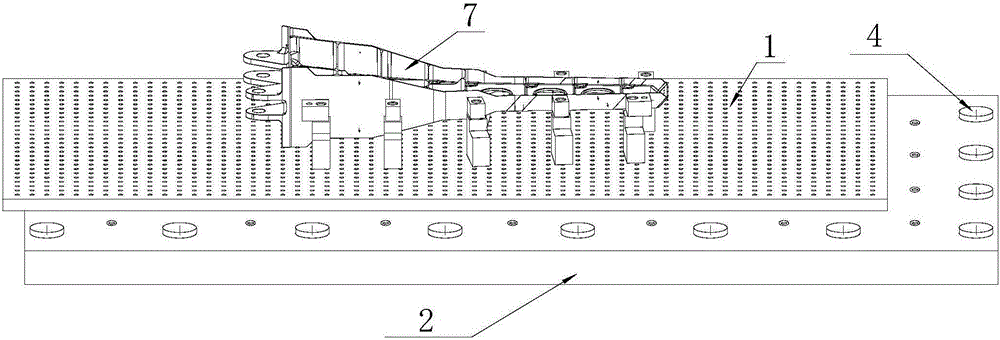

Method for rapidly improving machining efficiency of aviation beam type products and device of method

InactiveCN106141581AReduce process flowImprove processing efficiencyPositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a method for rapidly improving the machining efficiency of aviation beam type products and a device of the method, and belongs to the field of aviation product machining. A zero point positioning device is used for conducting vertical clamping on a to-be-machined aviation beam type component, and machine tool machining is conducted in a vertical clamping state; in vertical clamping, a clamping tool is used for clamping and fixing the to-be-machined aviation beam type component in the states of the horizontal length direction and the vertical width direction of the to-be-machined aviation beam type component, wherein the clamping tool comprises the zero point positioning device and a positioning fixing device, and the positioning fixing device comprises a bottom plate and a plurality of supporting blocks fixed to the bottom plate; and a plurality of positioning connectors are arranged on the bottom edge, in the length direction, of the to-be-machined aviation beam type component, the position below each positioning connector corresponds to one supporting block, and zero point locators are arranged on the top faces of the supporting blocks. According to the method, the process procedures are reduced, and the machining efficiency is improved; the machining period is shortened, and cost is reduced; clamping and positioning are accurate, and product loading and unloading are rapid; and repeated clamping work is reduced.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

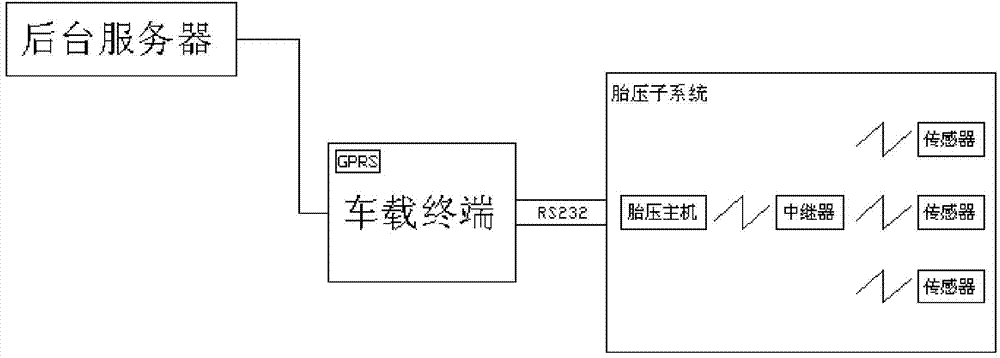

Automatic pairing method applied to tire pressure monitoring

InactiveCN103921628AMake a paired connectionPracticalTyre measurementsComputer terminalTire-pressure monitoring system

The invention discloses an automatic pairing method applied to tire pressure monitoring. The automatic pairing method comprises the following steps: (1) when a tire pressure sensor goes out of a warehouse, a worker needs to fill out an outgoing list that in which the tire pressure sensor is arranged the position of a wheel of a vehicle, a background server automatically acquires data and then forms a new configuration list, and the new configuration list is stored in a cache of the background server; (2) the tire pressure sensor is installed on the corresponding vehicle recorded in the outgoing list; (3) the vehicle is started, a vehicle-mounted terminal is on-line and is in communication with the background server through wireless signals, and the background server transmits the configuration list to the vehicle-mounted terminal; (4) after a handshake protocol is established between the vehicle-mounted terminal and a tire pressure host, and the configuration list in the vehicle-mounted terminal is decomposed into multiple configuration commands which can be recognized by the tire pressure host, so that the pairing connection between the tire pressure host and the tire pressure sensor is completed. The automatic pairing method is simple, reliable and practical, procedures are reduced, and the working efficiency is improved.

Owner:NINGBO KINYOUNG CHEM LOGISTICS

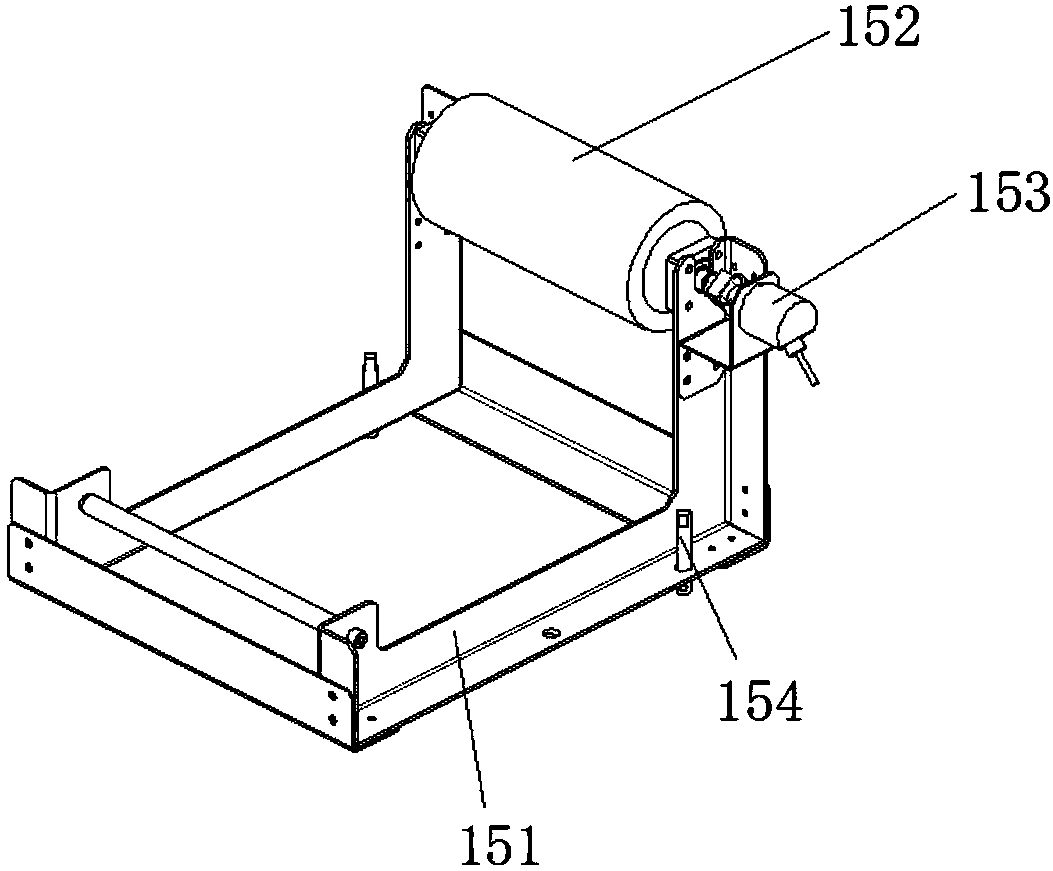

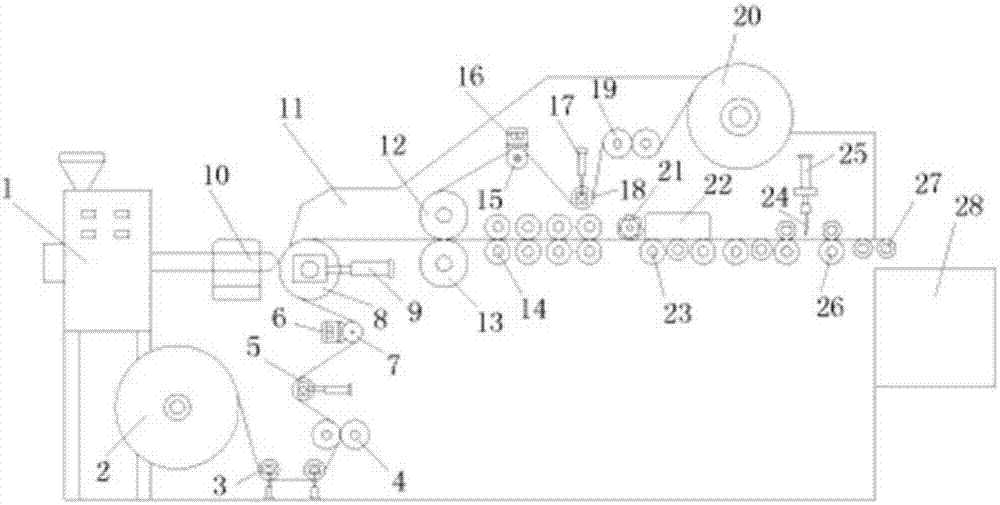

Equipment used for automatic feeding, film pasting and discharging of aluminum products and operating method thereof

The invention discloses a device for automatic feeding, film-sticking and discharging of aluminum materials and an operation method thereof. The incoming materials are automatically transported, aligned and film-attached; the press-cut film mechanism is used to press the film-attached incoming materials to make the film more closely attached to the incoming materials, and is used to adjust the end of the film-attached incoming materials. The film is cut to separate the next incoming material from the previous incoming material; the discharge mechanism is used to automatically output the incoming material after the film is pasted, and push it to the side of the discharge mechanism for stacking. The present invention solves the need for a large amount of manpower and huge time cost in the existing film sticking process, so that all processes in the film sticking process of aluminum materials are automatically processed, reducing labor intensity, saving time and effort, and facilitating large-scale production of aluminum materials.

Owner:佛山市嘉荣智能机械有限公司

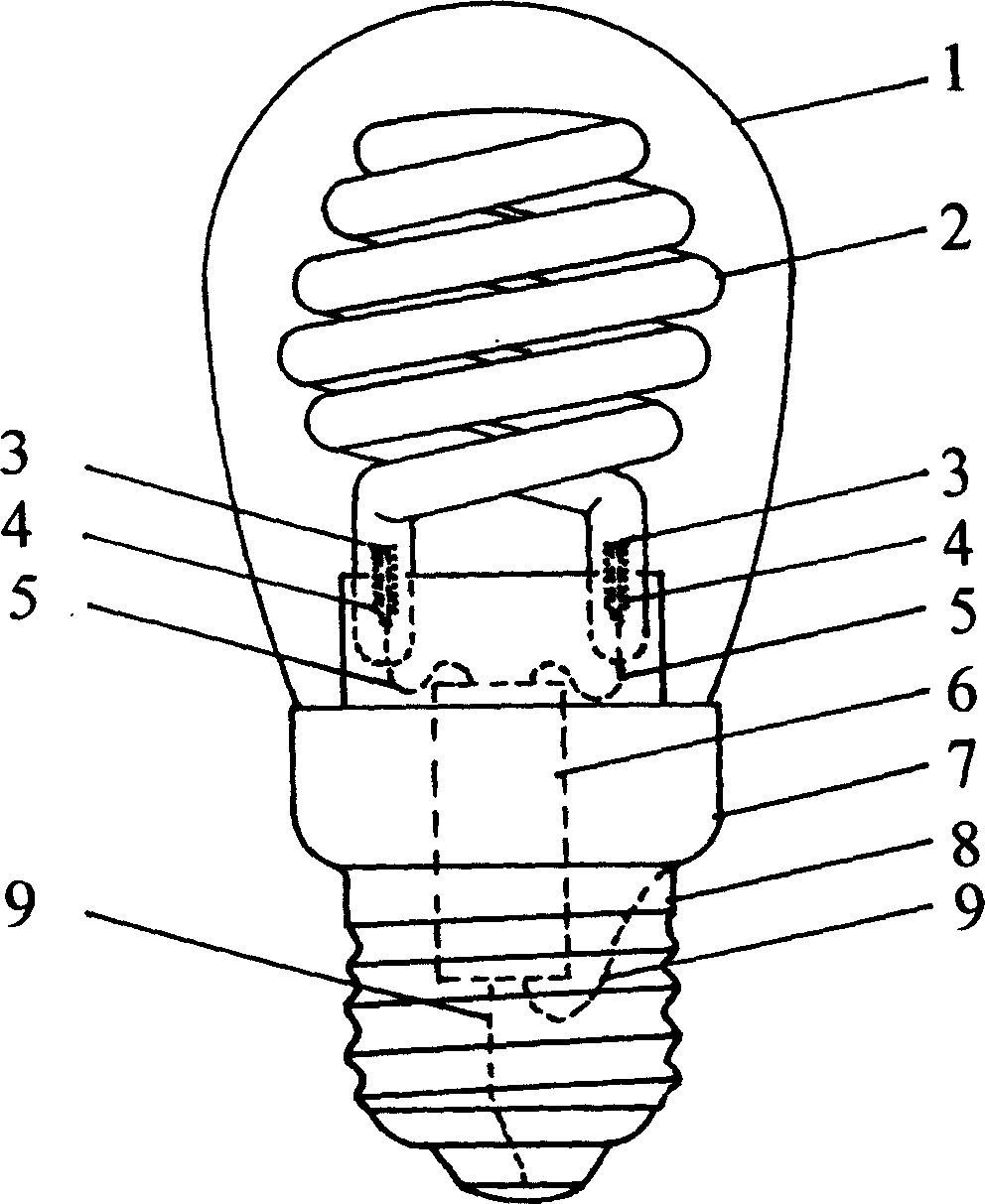

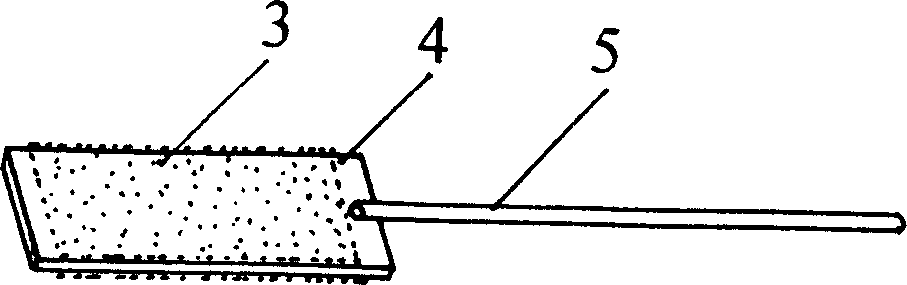

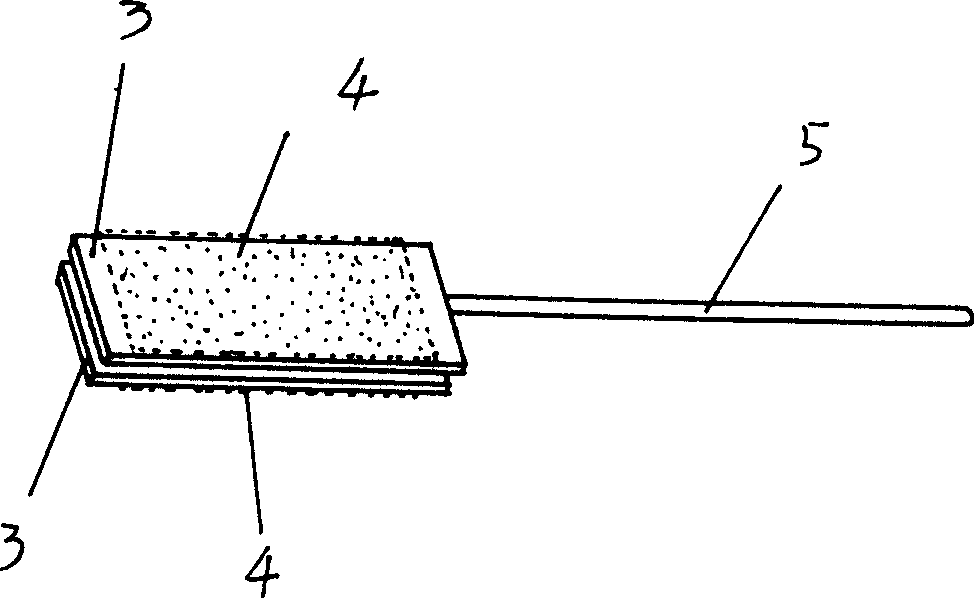

Helical type cold cathode fluorescence lamp

InactiveCN1627471AImprove inhalation capacityStrong activation temperatureGas discharge lamp detailsFluorescenceCold cathode

The disclosed lamp includes bulb shell, luminous tube, cathode of tube, guiding thread, actuator as well as casing, lamp base and connecting line. Characters are that luminous tube is a double helix tube, and a getter layer of zirconium vanadium iron is coated on cathode of tube. The said double helix tube can be as following forms: two helix tubes are embedded and spiraled along axial direction, and their ends are connected; external diameters of two helixes are identical, or external diameters are gradual changed to larger from smaller or vice versa etc. Bulb shell is made from transparent, milky or frosted glass, or plastic. There is light reflection layer on inner wall of bulb shell. Colors of bulb shell include colorless, blue, red etc. Advantages are: the getter layer of zirconium vanadium iron provides high capability of air intake, thus activation can be completed in conventional exhaust process so as to save additional equipment.

Owner:SHANGHAI XIANG SHAN IND LIABILITY

Rapid clamping method and device suitable for discrete multi-station production mode

InactiveCN106112587AImprove processing efficiencyImprove machining accuracyPositioning apparatusMetal-working holdersAviationEngineering

The invention discloses a rapid clamping method and device suitable for the discrete multi-station production mode, and belongs to the field of machining of aviation structural components. After clamping alignment is conducted through an outside-machine clamping work station, machining is conducted on a processing machine tool. The outside-machine clamping work station comprises a working table, a zero point positioning device, a supporting plate and an outside-machine clamping base plate. The zero point positioning device comprises zero positioning devices and positioning connectors. Workpiece clamping fixing holes are formed in the supporting plate. The multiple positioning connectors are arranged on the bottom face of the supporting plate. The multiple matched zero point positioning devices are arranged on the top face of the outside-machine clamping base plate. Multiple installation holes for being detachably fixed to the working table are further formed in the outside-machine clamping base plate. The outside-machine clamping base plate and a machine tool base plate on the processing machine tool have the united zero point positioning reference. The center distances of the zero point positioning devices of the outside-machine clamping base plate and the machine tool base plate on the processing machine tool are completely consistent. By means of the rapid clamping method and device, the machine tool halt time is shortened, the halt time caused by clamping is shortened, the process flow is shortened, and the production efficiency is improved.

Owner:SICHUAN FUTURE AEROSPACE IND LLC

Production method for packaging bag with various traceability codes

ActiveCN106144173AReduce process flowIncrease productivityContainer decorationsLevel indicationsFilm materialEngineering

The invention discloses a production method for a packaging bag with various traceability codes and belongs to the technical field of soft packaging. The production method includes the following steps that firstly, a transparent film material is provided, the film material comprises a front face and a back face, the back face is subjected to inner printing and meanwhile printed with decorative patterns and an explanatory text of the packaging bag, and multiple blank regions are reserved; secondly, corona treatment is conducted on the blank regions; thirdly, the blank regions obtained in the second step are printed with the traceability codes; fourthly, wind iron heating treatment is conducted on the film material obtained in the third step; fifthly, the back face of the film material obtained in the fourth step is covered with a bottom layer, and then a bag body material is obtained; sixthly, curing and cooling treatment are conducted on the bag body material; and seventhly, the bag body material obtained in the sixth step is made into the packing bag or cut into roll films.

Owner:安徽独秀包装科技有限公司

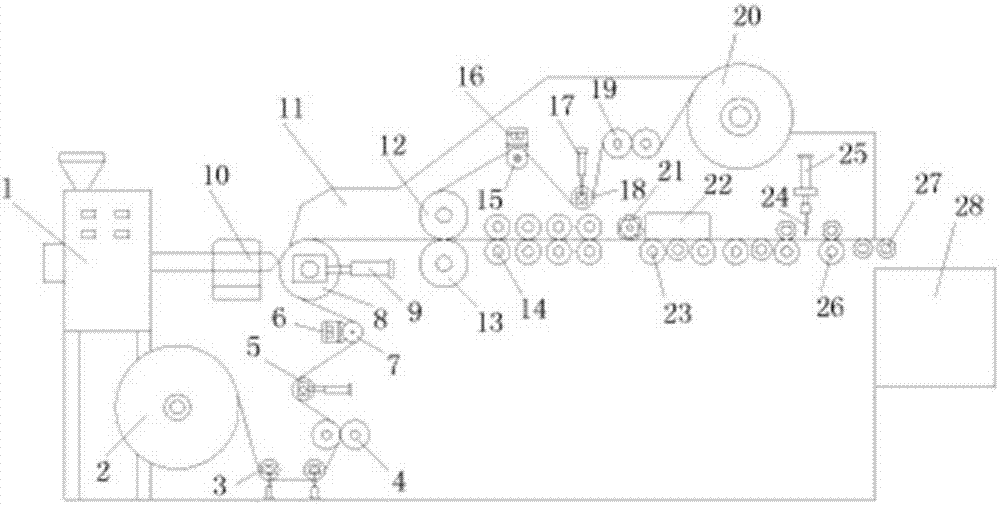

Butyl adhesive tape production line device used for automobiles

PendingCN108003811AReliable moldingReduce process flowFilm/foil adhesivesFlat articlesL&D processEngineering

The invention discloses a butyl adhesive tape production line device used for automobiles. The device comprises a rack, a backing unreeling and feeding mechanism, a top film paper unreeling and feeding mechanism, a gumming mechanism, a compound mechanism, a cutting mechanism, a detaching mechanism and a trimming mechanism, wherein the backing unreeling and feeding mechanism comprises a backing unreeling roller and a backing clamping roller; the top film paper unreeling and feeding mechanism comprises a top film paper unreeling roller and a top film paper clamping roller; the gumming mechanismcomprises a butyl rubber extruding machine; the butyl rubber extruding machine is communicated with a gumming die head through a gum conveying pipe; a gumming roller corresponding to the gumming die head is mounted on the rack; an electric gumming telescopic rod for driving the gumming roller to get close to the gumming die head is mounted on the rack; and the compound mechanism is provided with apressure roller mechanism, the cutting mechanism, the detaching mechanism and the trimming mechanism in sequence. According to the device, the process flow is greatly reduced, the production efficiency is improved, the production process is carried out by adopting automatic equipment, extra manpower is not needed, and the manpower cost is reduced.

Owner:江苏新长宜科技有限公司

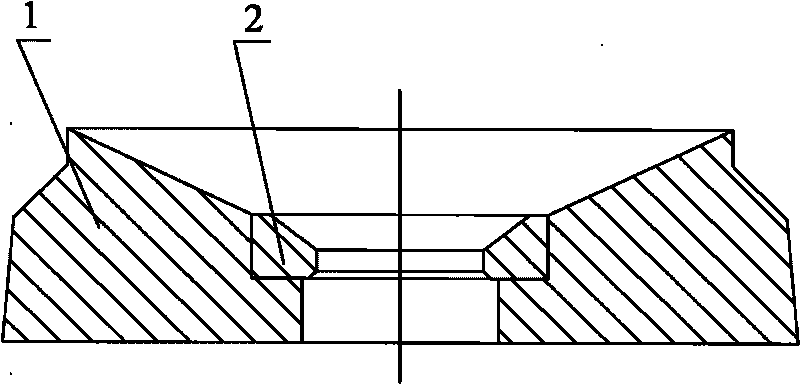

Bipyramid copper alloy extrusion die

ActiveCN101695721AExtended service lifeReduce direct manufacturing costsExtrusion diesHigh intensitySizing

The invention relates to a bypyramid copper alloy extrusion die which is mainly used on extruding high-strength copper alloy tubes. An outer die is provided with an outer die taper cavity arranged in an inverse taper shape, an outer die below the outer die taper cavity is internally provided with a columnar installing excess cavity, an outer die below the installing excess cavity is internally provided with a columnar outlet cavity, an inner die is provided with an inner taper cavity arranged in an inverse taper shape, an inner die below the inner die taper cavity is internally provided with a columnar sizing belt, an inner die below the sizing belt is internally provided with an outlet taper arranged in a positive taper shape, an extrusion liner is arranged on the upper end face of the outer die, the bottom end of the inner hole of the extrusion liner covers the taper top of the outer die taper cavity, an extrusion pad is connected into the extrusion liner in a sealing and sliding way, and the inner hole of the extrusion pad is used for positioning a hole forming pin. The invention can improve the liquidity of metals, reduces the extrusion force, relatively improves the product density, increases the product quality and greatly prolongs the service life.

Owner:江苏隆达超合金股份有限公司

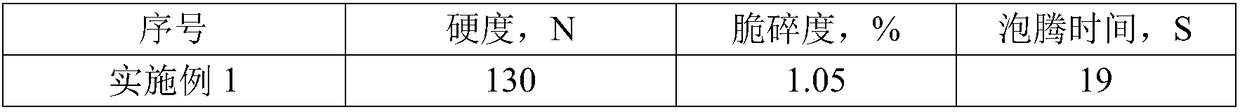

Vitamin C effervescent tablet

InactiveCN108157975AImprove effervescenceImprove stabilityFood shapingFood ingredient functionsDiseaseVitamin C

The present invention relates to an effervescent tablet, and particularly relates to a vitamin C effervescent tablet. The invention belongs to the technical field of health food tablet formulation. Vitamin C, one of the essential vitamins of the human body, has a preventive effect on many diseases. Vitamin C can also be used in combination with many other drugs in the treatment of certain diseases. Effervescent tablet is a novel tablet developed and applied abroad in recent years, and the effervescent tablet is usually prepared by acid and alkali separate wet granulation, followed by being mixed with other raw materials for tablet compressing. In order to shorten the production process and further improve the product stability, the invention adopts the mixed use of alpha- and beta-crystalform D-mannitol, which reduces the fragility of the tablets on the basis of ensuring the effervescent effect of the tablets. The formula of the invention is suitable for the direct tablet compressingprocess, free of the addition of water or other wetting agents in the production process and capable of reducing the occurrence of material pollution, improving the production efficiency, reducing theprocess flow and decreasing and reducing the energy consumption. In addition, the addition of sodium caseinate can improve the effervescent effect of the tablets.

Owner:SHANDONG TIANLI PHARMA

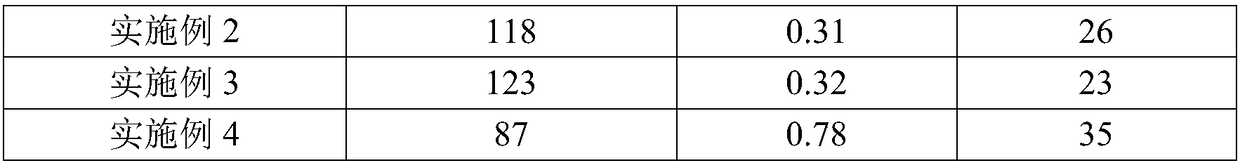

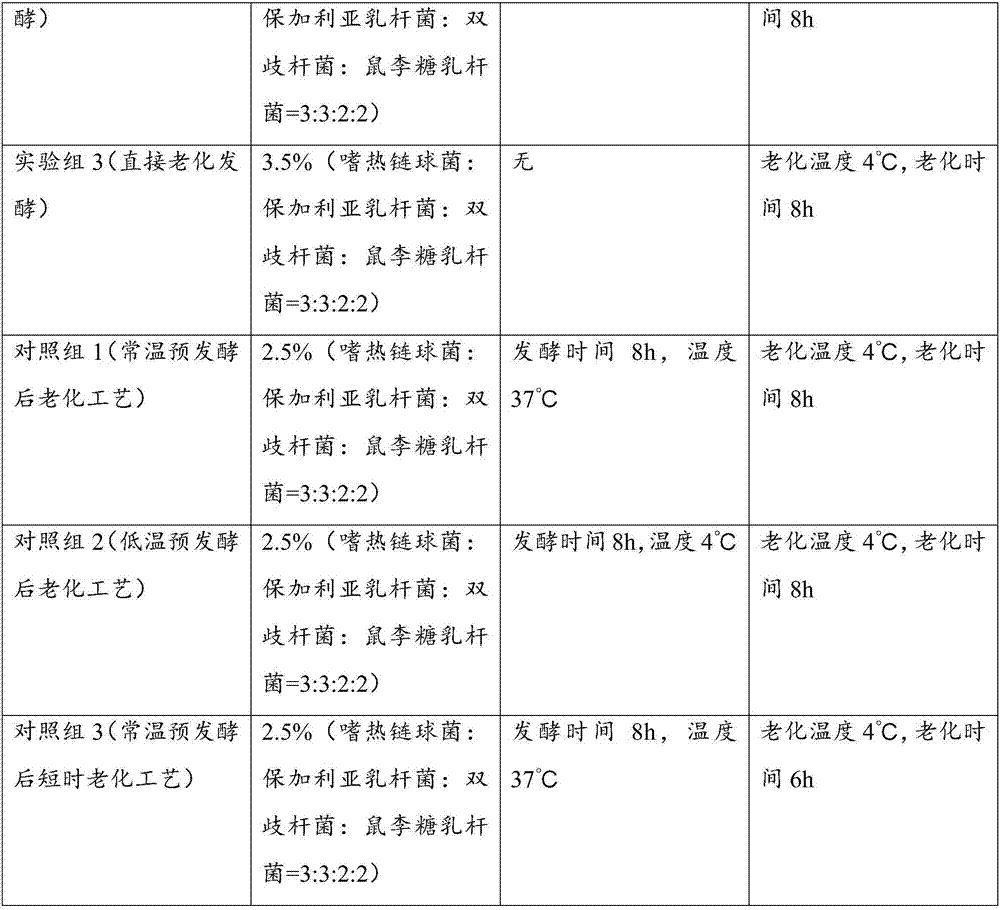

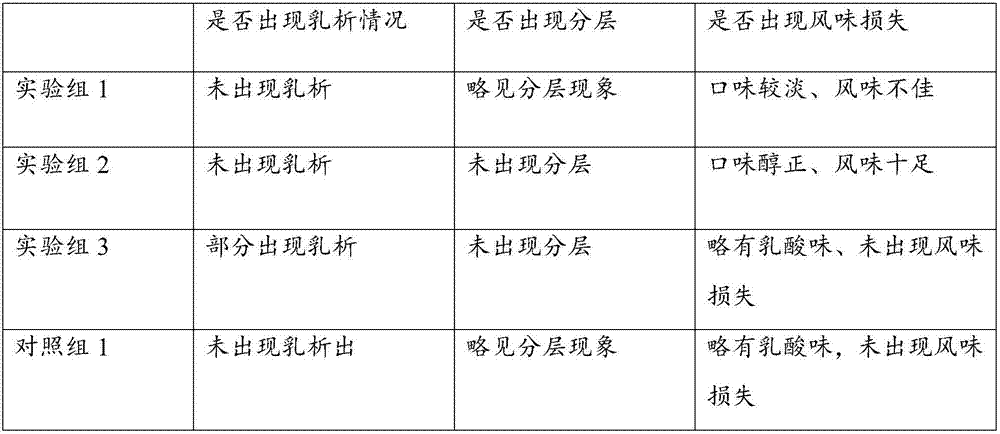

Probiotics ice cream and preparation method thereof

InactiveCN107173516AMeet your own health needsAvoid destructionFrozen sweetsFood ingredient functionsFlavorIce cream

The invention discloses probiotics ice cream and a preparation method thereof and belongs to the technical field of probiotics ice cream. The probiotics ice cream is prepared by mixing and sterilizing non-probiotics materials and sequentially performing homogenization, inoculation with probiotics, aging, congelation and hardening. The probiotics ice cream has stable quality, cannot prone to creaming, layering, flavor loss and the like in the aging and congelation processes and is suitable for production of the probiotics ice cream.

Owner:大庆市红宝石冰淇淋有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com