Dislocation corrosion detecting method of single germanium wafer

A germanium single wafer, corrosion detection technology, applied in the field of germanium single wafer dislocation corrosion detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

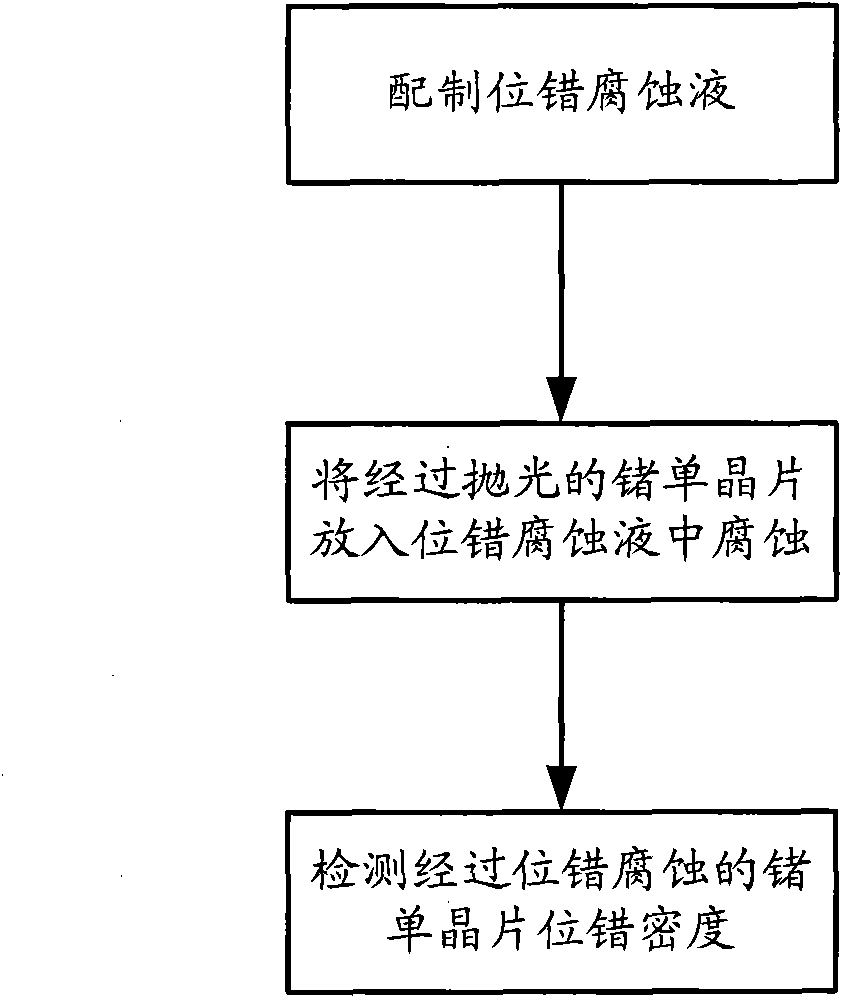

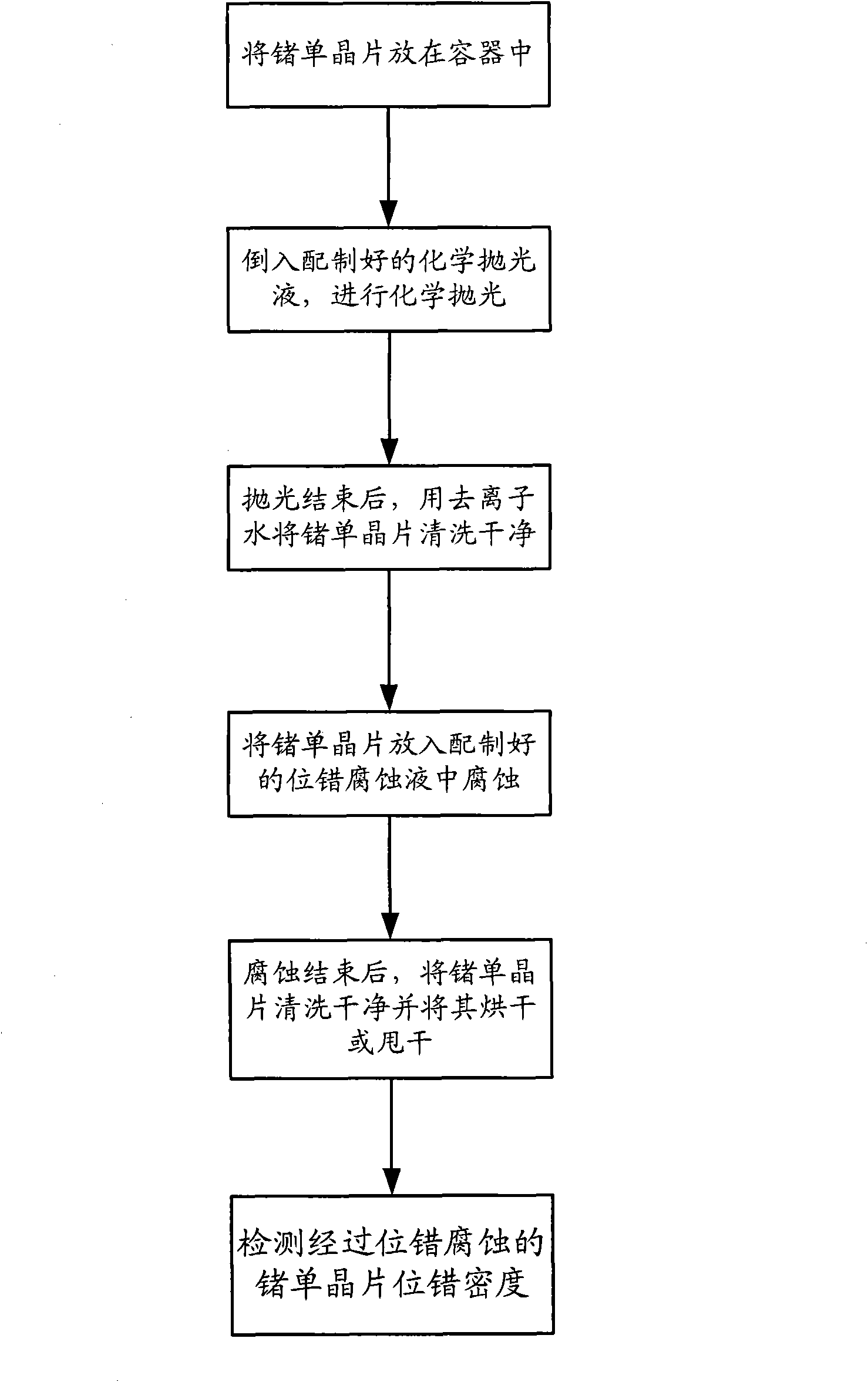

[0029] combine figure 1 , figure 2 , the following are the specific implementation steps of the germanium single wafer dislocation corrosion detection method deviated from the crystal orientation 9° of the present embodiment:

[0030] The first step is to place a polished germanium single crystal wafer with a thickness of not less than 150 μm in an acid and alkali resistant container.

[0031] In the second step, hydrofluoric acid (HF) and nitric acid (HNO 3 ) according to the volume ratio of 1:3 to 4 (ratio of 1:3 to 1:4) to prepare chemical polishing liquid, the concentration of hydrofluoric acid used is 40%, and the concentration of nitric acid is 65% to 68%. The process is as follows:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com