Equipment used for automatic feeding, film pasting and discharging of aluminum products and operating method thereof

An automatic feeding and feeding technology, applied in packaging and other directions, can solve problems such as large labor and time costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

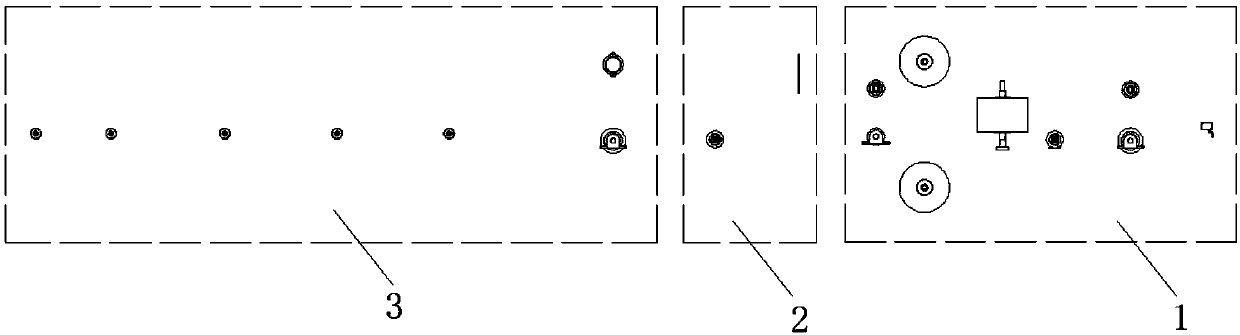

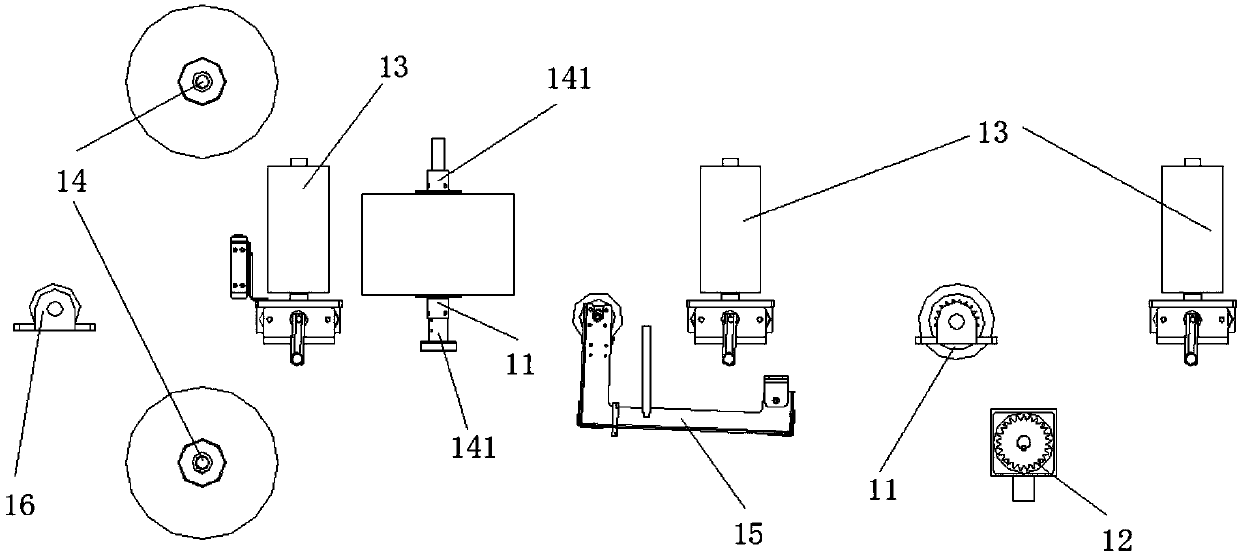

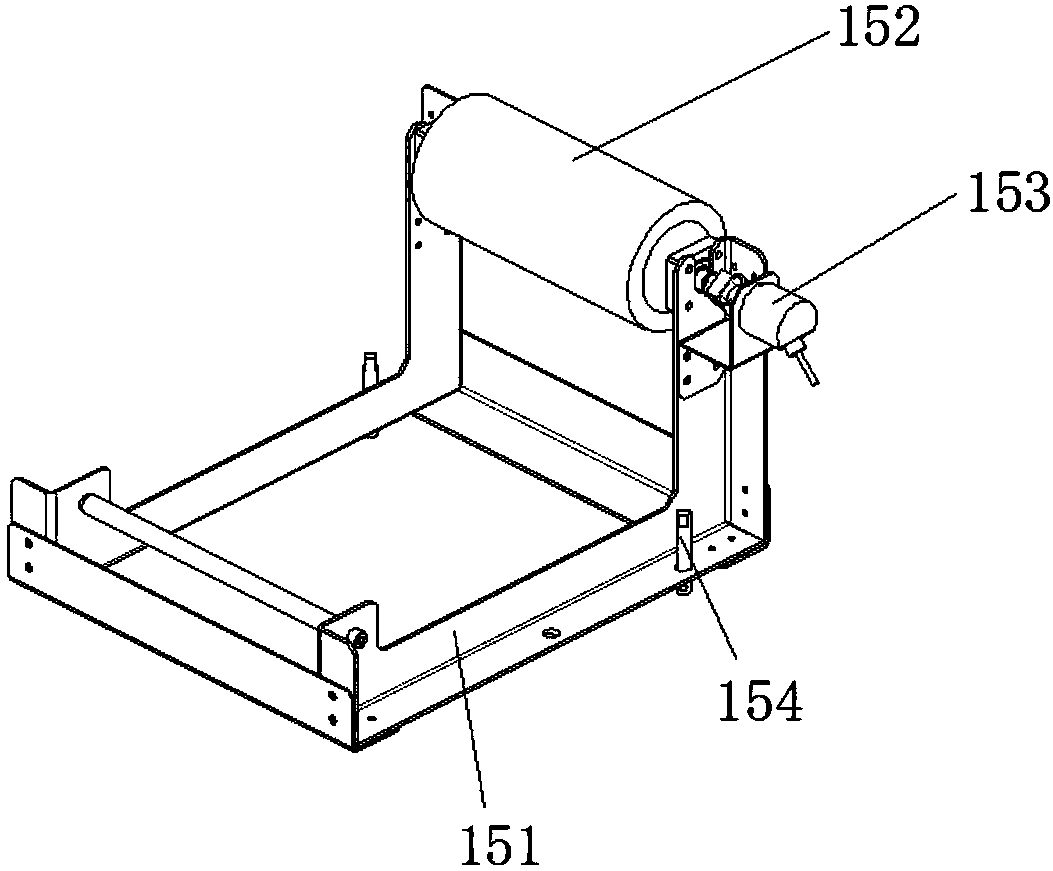

[0045] The invention provides a device for automatic feeding, film sticking and discharging of aluminum materials, such as figure 1 As shown in the schematic diagram of the model, the equipment of the present invention mainly consists of three major mechanism parts, which are respectively a feeding film sticking mechanism 1, a film cutting mechanism 2 and a discharging mechanism 3, and they divide labor and cooperate with each other to complete aluminum (or other equivalent needs) Incoming material for pasting film) integrated processing of feeding, filming and discharging. The present invention is an integral fixing seat (which can also be spliced or welded), but for the convenience of description, it is divided into the fixing seats required by three major mechanism parts, which are respectively the feeding support, the film cutting fixing seat and the discharging Fixed seat; since there is no improvement point on the fixed seat, it is a very mature existing technology, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com