Device for improving pipe internal-pressure forming limit and method for improving pipe internal-pressure forming limit by utilizing same

A technology of forming limit and pipe material, which is applied in the field of devices for improving the forming limit of pipe internal pressure, which can solve the problems of poor deformation uniformity, low room temperature forming limit, cracking, etc. little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

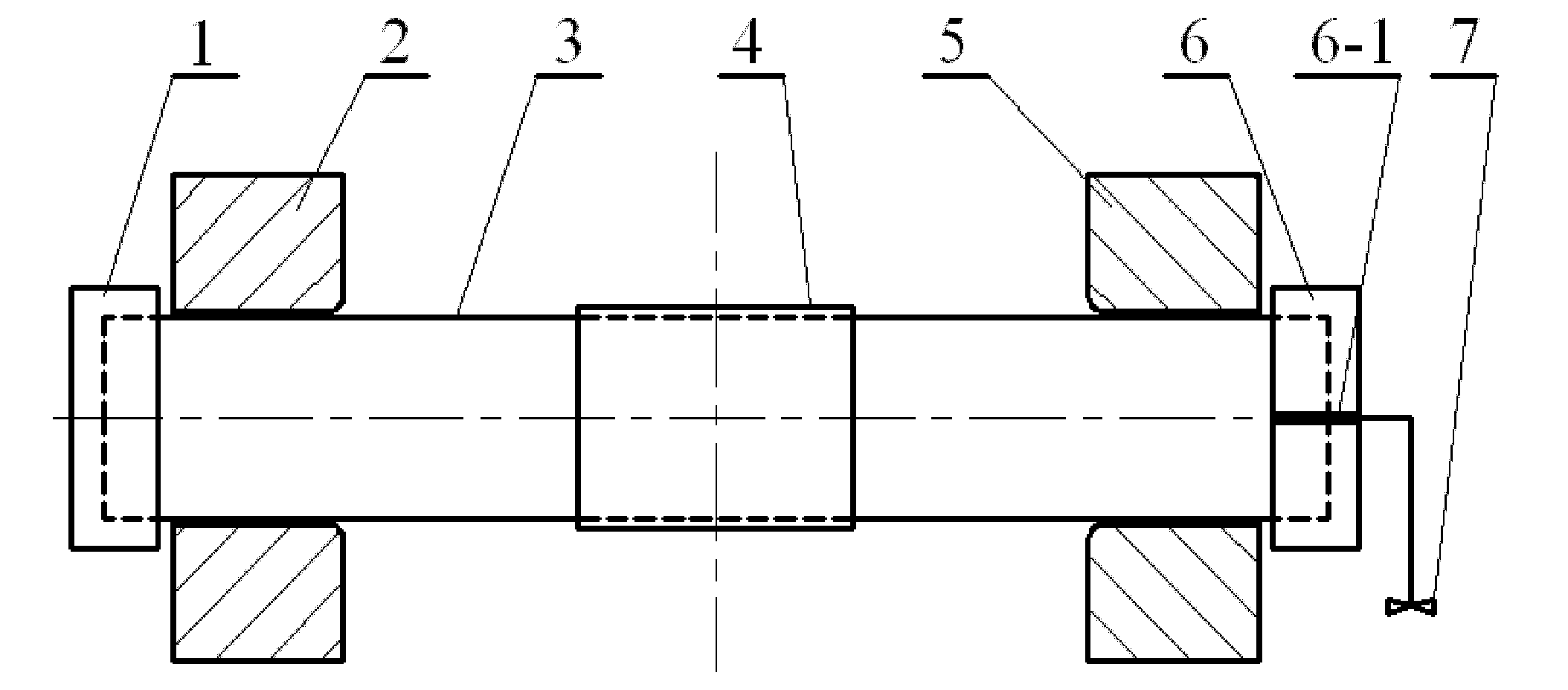

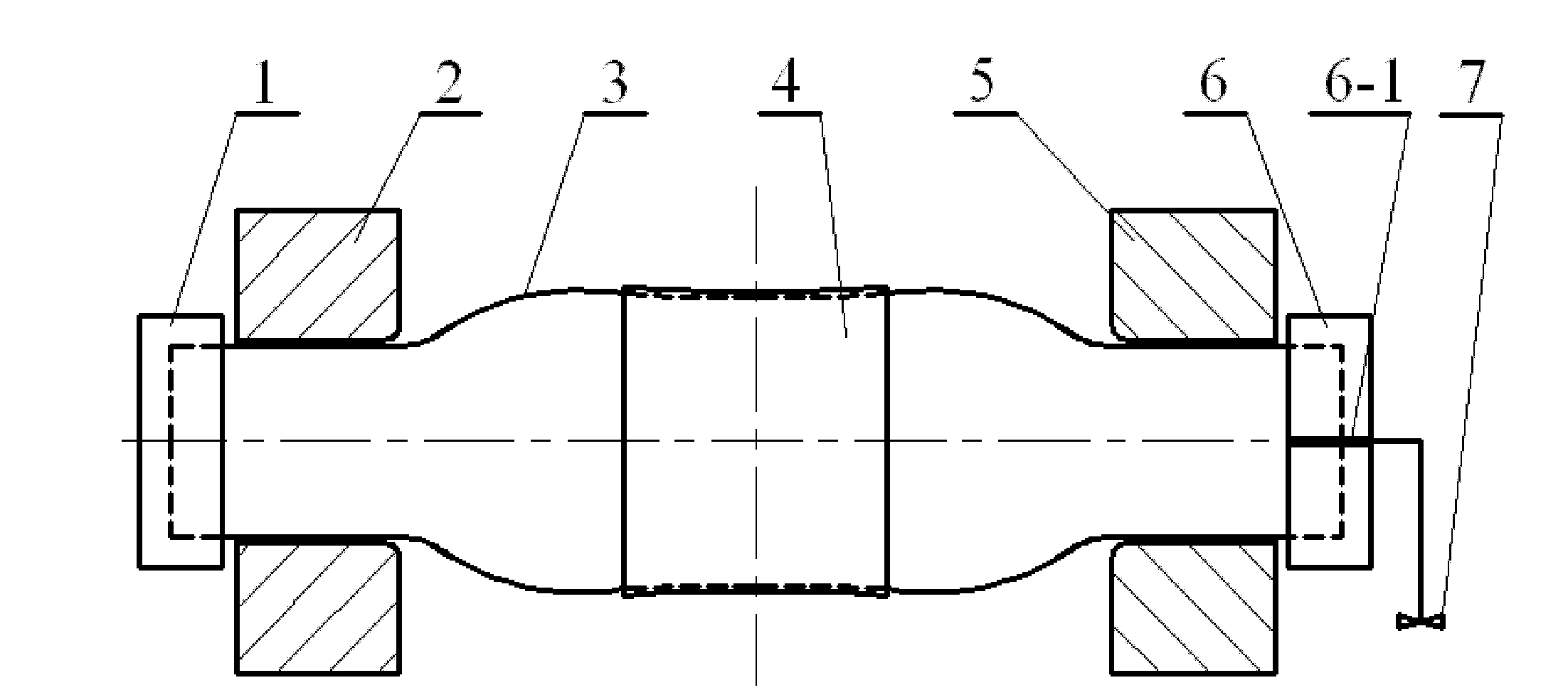

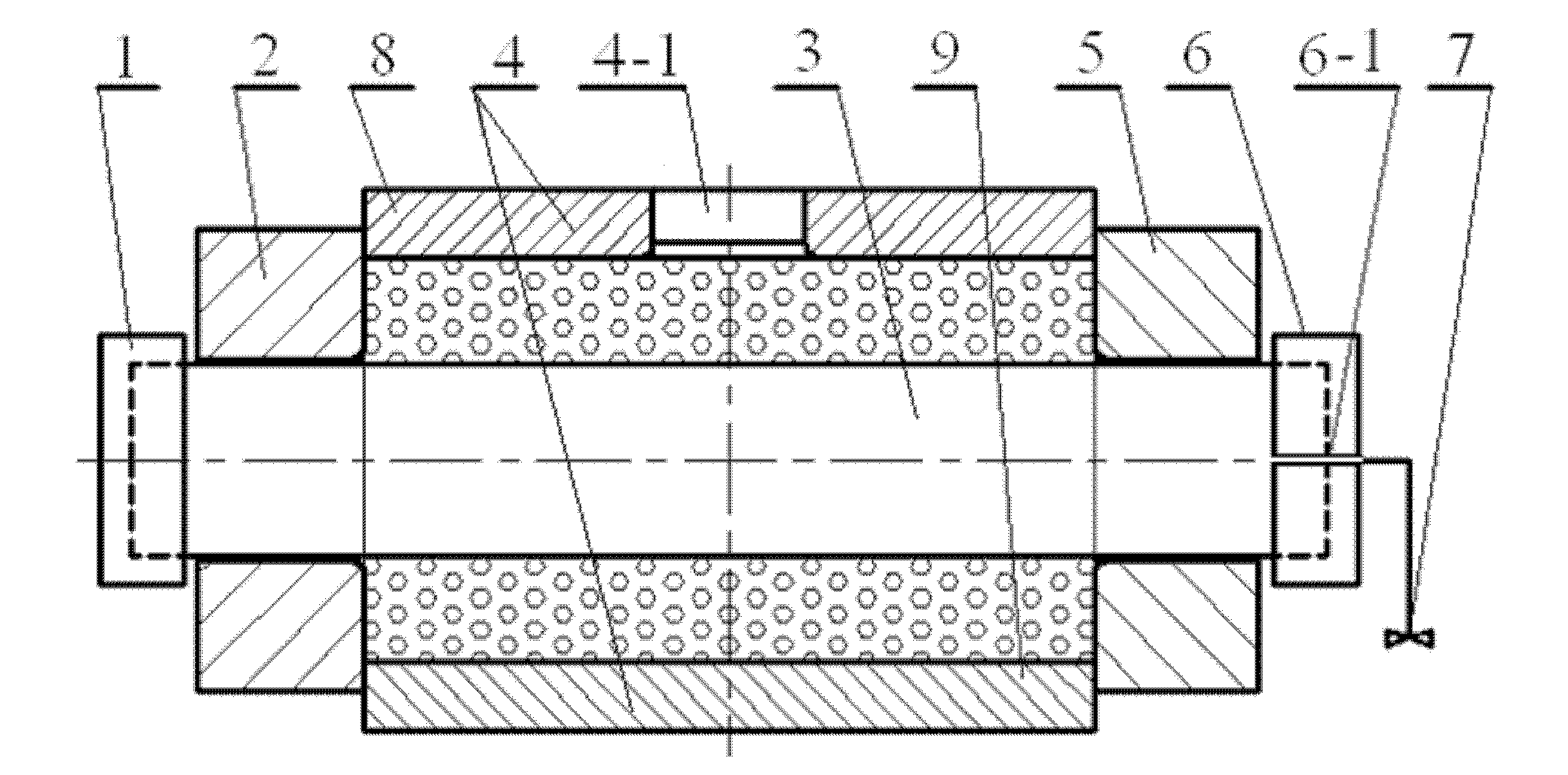

[0018] Specific implementation mode one: combine figure 1 , to illustrate the first device for increasing the limit of internal pressure forming of pipes in this embodiment. The device for increasing the limit of internal pressure forming of pipes includes a first sealing device 1, a first mold frame 2, a second mold frame 5, a first Two sealing devices 6 and pressure regulating valves 7, the first formwork 2 and the second formwork 5 fix the pipe material 3, the first sealing device 1 seals one end of the pipe material 3, and the second sealing device 6 seals the other end of the pipe material 3 A passage 6-1 is provided on the axis of the second sealing device 6, and the output end of the pressure regulating valve 7 is connected to the passage 6-1 on the second sealing device 6 through a pipeline, and the passage 6-1 connects the pipe 3 The inner cavity communicates with the output end of the pressure regulating valve 7, wherein a restraint sleeve 4 is provided in the middle...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that the length of the restraining sleeve 4 is preferably 1 / 4 to 1 / 3 of the pre-formed length of the pipe 3 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the inner diameter of the constraint sleeve 4 is 0.6 mm to 0.9 mm larger than the outer diameter of the pipe 3 . Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com