Helical type cold cathode fluorescence lamp

A cold cathode fluorescent lamp, a spiral type technology, applied in the field of fluorescent lamps, can solve the problems of high activation temperature, the need for expensive additional equipment, and insufficient suction capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

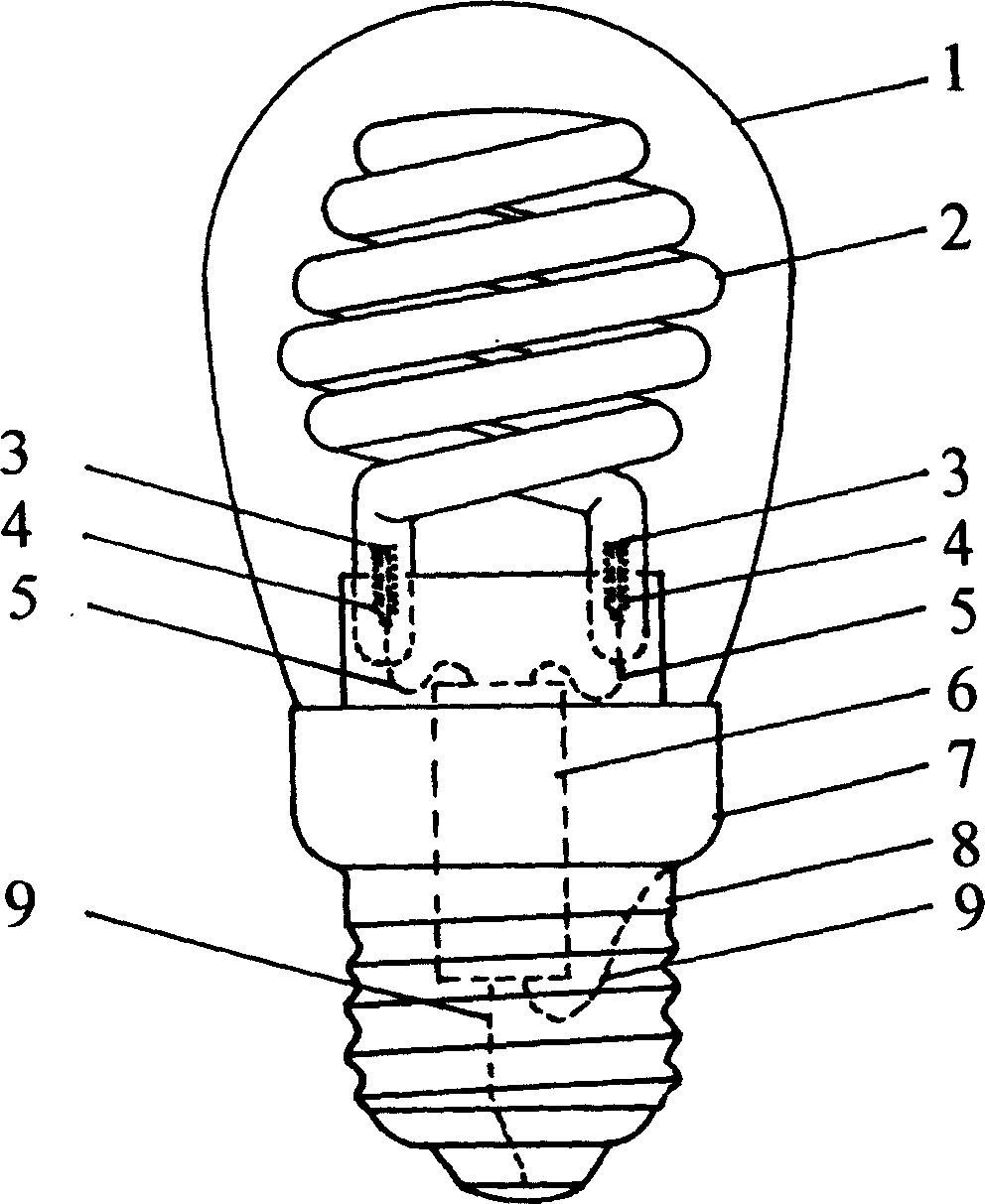

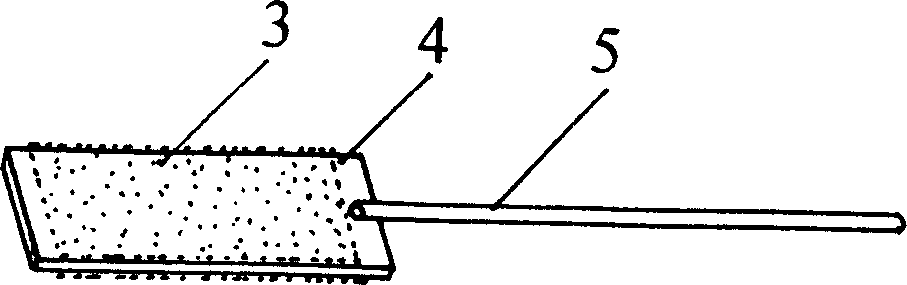

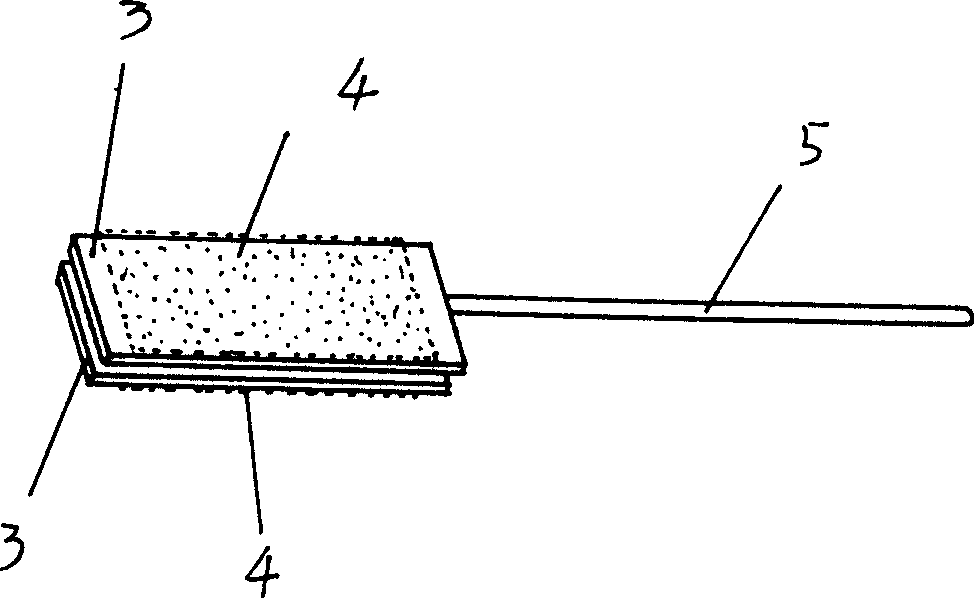

[0016] In the figure: 1 is the bulb, 2 is the lamp tube, 3 is the cathode, 4 is the getter, 5 is the guide wire, 6 is the driver, 7 is the driver shell, 8 is the lamp cap, and 9 is the electrical connection wire between the driver and the lamp cap.

[0017] refer to figure 1 , the utility model consists of a bulb 1, a lamp tube 2, a cathode 3, a getter 4, a guide wire 5, a driver 6, a driver shell 7, a lamp holder 8, a driver 6 and a lamp holder electric connection wire 9, and is characterized in that: There is a getter 4 on the cathode 3, and the getter 4 is zirconium-vanadium-iron. The zirconium-vanadium-iron cathode getter has a strong air-absorbing ability and a low activation temperature (about 390°C), which can be activated during the normal exhaust process of the lamp tube. , does not require additional equipment to be heated at a high temperature, thereby shortening the process flow, omitting additional equipment, and reducing production costs.

[0018] The cathode of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com