A Composite Getter Device at Room Temperature for Vacuum Insulation Panels

A technology of vacuum insulation panels and getters, which is applied in the direction of heat preservation, heat exchange equipment, and pipeline protection through heat insulation, etc. It can solve the problems of difficult gas extraction, explosion, negative impact of vacuum degree, etc., and achieve good suction capacity, Excellent performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

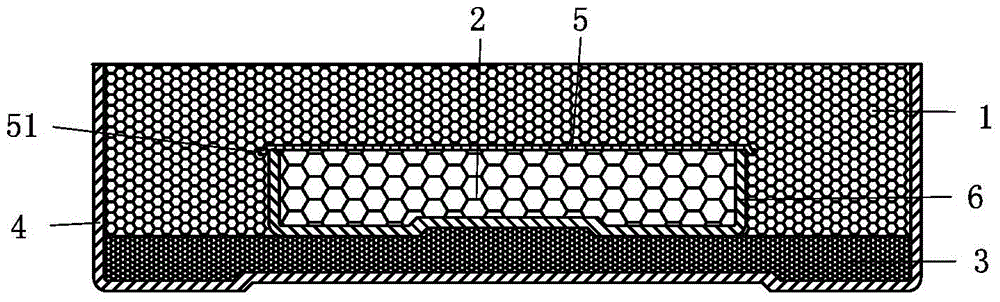

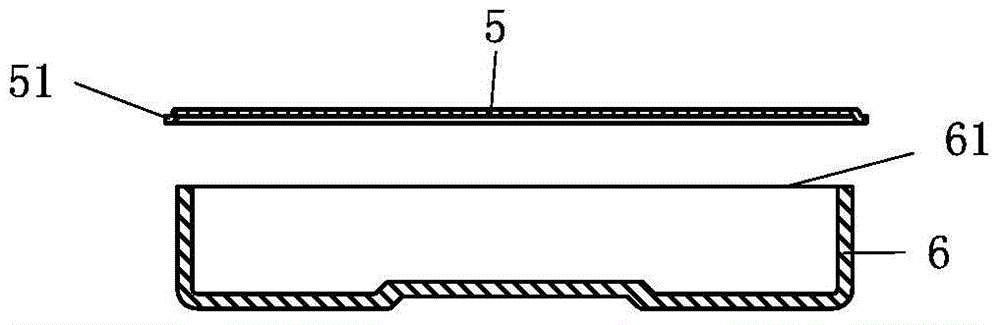

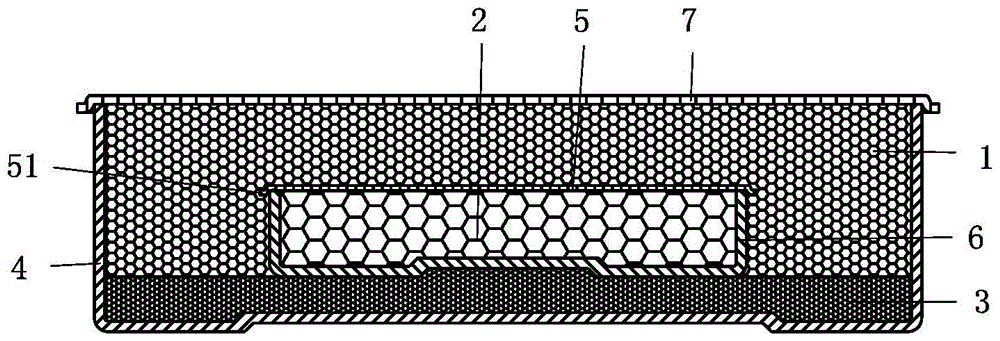

[0017] The present invention is used for the room temperature compound getter device of vacuum insulation panel, as figure 1 As shown, it includes desiccant powder 1 , getter alloy powder 2 , metal oxide powder 3 , first metal yu 4 , metal protective net 5 and second metal yu 6 .

[0018] The upper end of the first metal bowl 4 is open, and in its internal space, the metal oxide powder 4 with an average particle size of 2-20 microns is spread on the bottom, and the second metal bowl 6 with the open upper end is placed on the metal oxide powder layer. The second metal bowl 6 is filled with getter alloy powder 2 with a particle size of 100-200 microns, and the metal protective net 5 with a mesh size of 10-100 microns covers the opening of the second metal bowl 6 with an average particle size of 10-100 microns. The micron desiccant 1 surrounds the second metal bowl 6 from the sides and above and is compacted in the inner space of the first metal bowl 4 .

[0019] The getter all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com