High-conductivity medium-strength all-aluminum alloy energy-saving guide wire and manufacturing method thereof

A technology of aluminum alloy wire and high conductivity, which is applied in the field of aluminum-based alloys and can solve the problems of reducing the tensile strength, strength, and conductivity of wires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

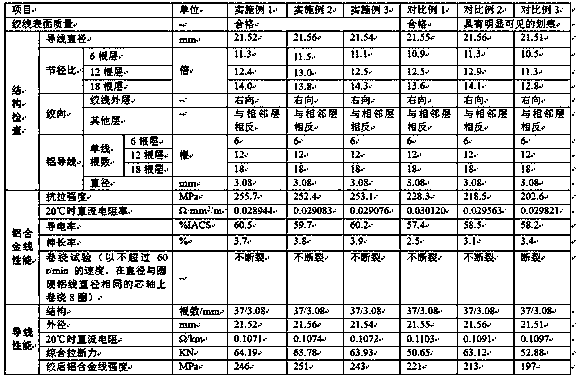

Examples

Embodiment 1

[0028] High-conductivity medium-strength all-aluminum alloy energy-saving conductor is made of twisted multi-layer aluminum alloy monofilament. The multi-layer aluminum alloy monofilament consists of a core layer, a first layer, a second layer and a third layer. Aluminum alloy monofilament, the first layer is 6 aluminum alloy monofilaments, the second layer is 12 layers of aluminum alloy monofilament, the third layer is 18 layers of aluminum alloy monofilament, and the aluminum alloy monofilament is composed of the following mass percentage: Mg0. 40, Si0.38, Zr0.12, Ti0.08, V0.05, La0.04, Ce0.06, B0.09, Mg / Si=1.05, the rest are Al and unavoidable impurities, unavoidable impurities The total amount is less than 0.05%.

[0029] Among them, unavoidable impurities include Mn, Cr, Fe and other elements, and the mass percentage of a single impurity is less than 0.03%.

[0030] A method for preparing a medium-strength all-aluminum alloy energy-saving wire with high conductivity, inc...

Embodiment 2

[0044] The high-conductivity medium-strength all-aluminum alloy energy-saving wire described in this embodiment is different from the embodiment 1 in that: the aluminum alloy monofilament is composed of the following components in mass percentage: Mg0.60, Si0.45, Zr0.15, Ti0.10, V0.06, La0.05, Ce0.08, B0.10, Mg / Si=1.33, the rest are Al and unavoidable impurities, the total amount of unavoidable impurities is less than 0.05%.

[0045] A method for preparing a medium-strength all-aluminum alloy energy-saving wire with high conductivity, including:

[0046] 1) Melting Al source, Mg source, Si source, Zr source, Ti source, V source, La source, Ce source and B source to obtain alloy liquid;

[0047] 2) Casting the alloy liquid to obtain an aluminum alloy ingot;

[0048] 3) Roll the aluminum alloy ingot, the rolling temperature is 520°C, and the rod output temperature is 90°C to obtain the rod;

[0049] 4) The rod is subjected to solution treatment at 400°C for 2 hours, and then w...

Embodiment 3

[0057] The high-conductivity medium-strength all-aluminum alloy energy-saving wire described in this example is different from Example 1 in that: the aluminum alloy monofilament is composed of the following components in mass percentage: Mg0.50, Si0.35, Zr0.13, Ti0.06, V0.07, La0.06, Ce0.07, B0.08, Mg / Si=1.43, the rest are Al and unavoidable impurities, the total amount of unavoidable impurities is less than 0.05%.

[0058] A method for preparing a medium-strength all-aluminum alloy energy-saving wire with high conductivity, including:

[0059] 1) Melting Al source, Mg source, Si source, Zr source, Ti source, V source, La source, Ce source and B source to obtain alloy liquid;

[0060] 2) Casting the alloy liquid to obtain an aluminum alloy ingot;

[0061] 3) Roll the aluminum alloy ingot, the rolling temperature is 530°C, and the rod output temperature is 90°C to obtain the rod;

[0062] 4) The rod is subjected to solution treatment at 420°C for 1 hour, and then water quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com