Automatic coupling device of three-in-one coaxial type photoelectronic device

An optoelectronic device and automatic coupling technology, which is applied in the coupling of optical waveguide, optical components, installation, etc., can solve the problems of unguaranteed accuracy and low efficiency, achieve improved stability and pass rate, simple and convenient operation, and simplified operation interface and the effect of operating procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

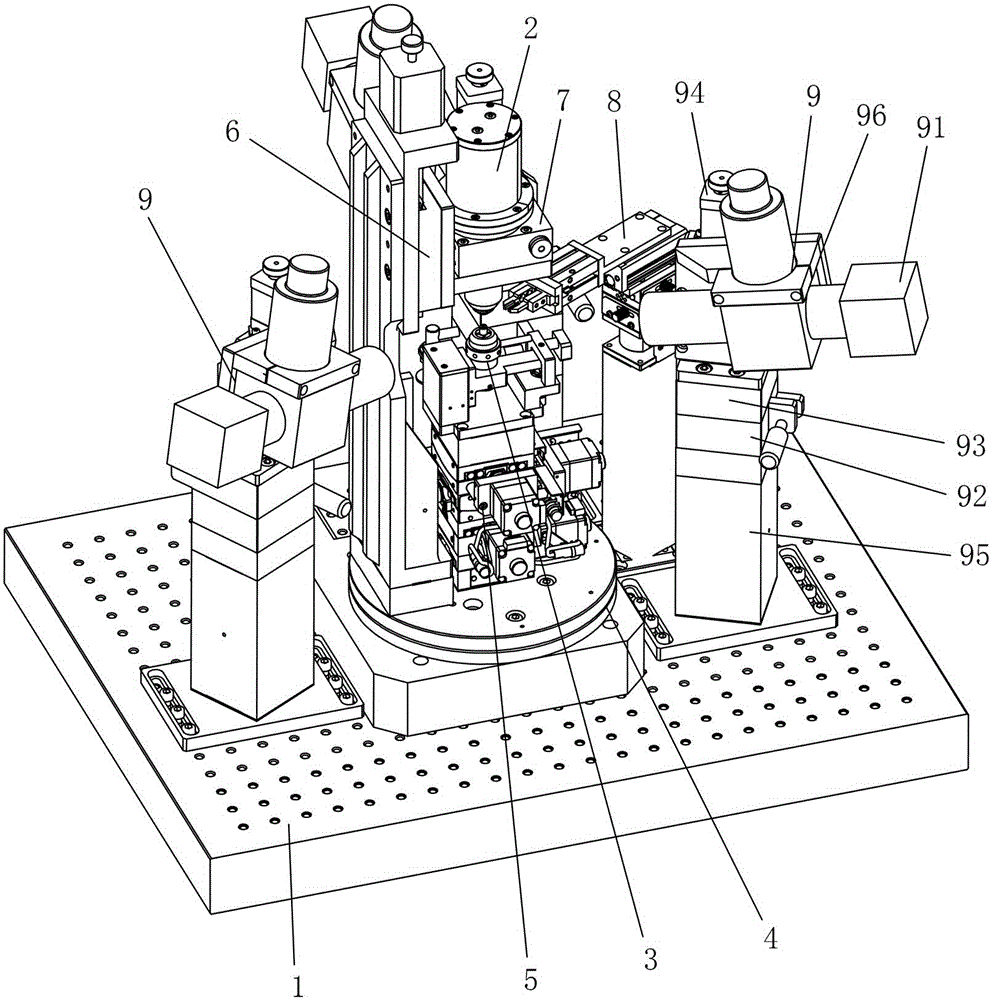

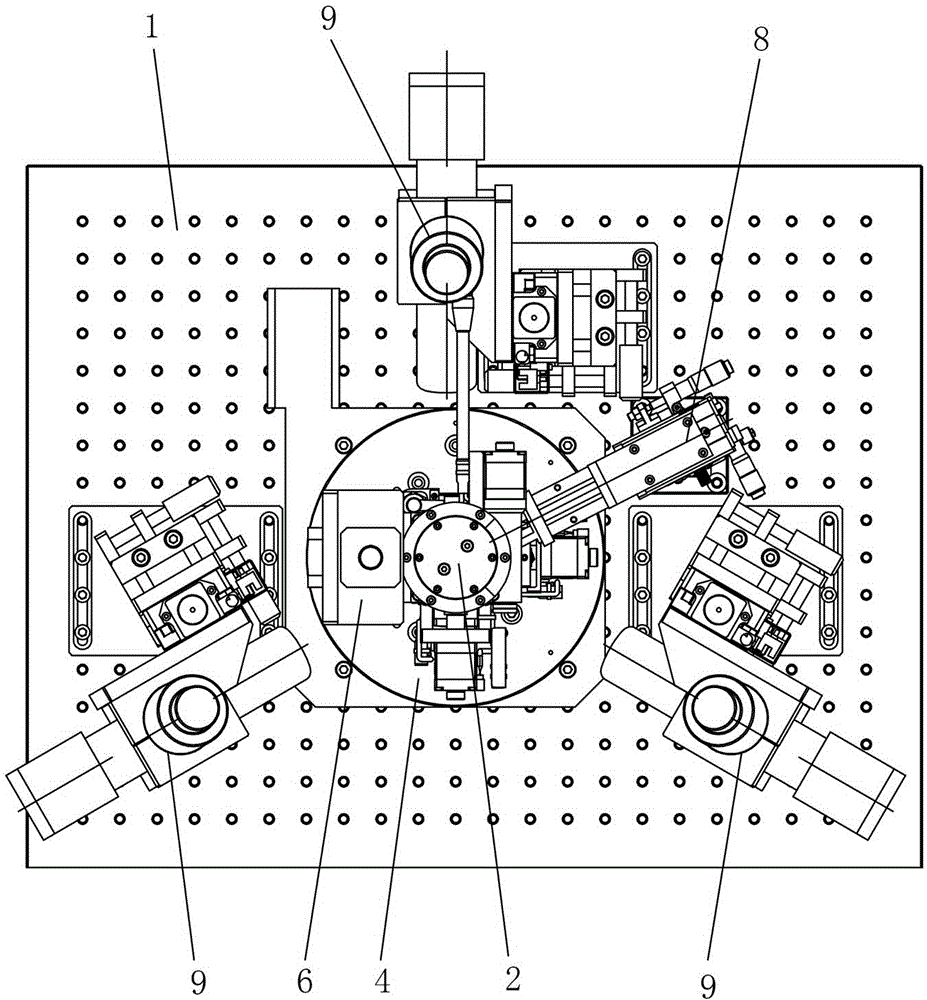

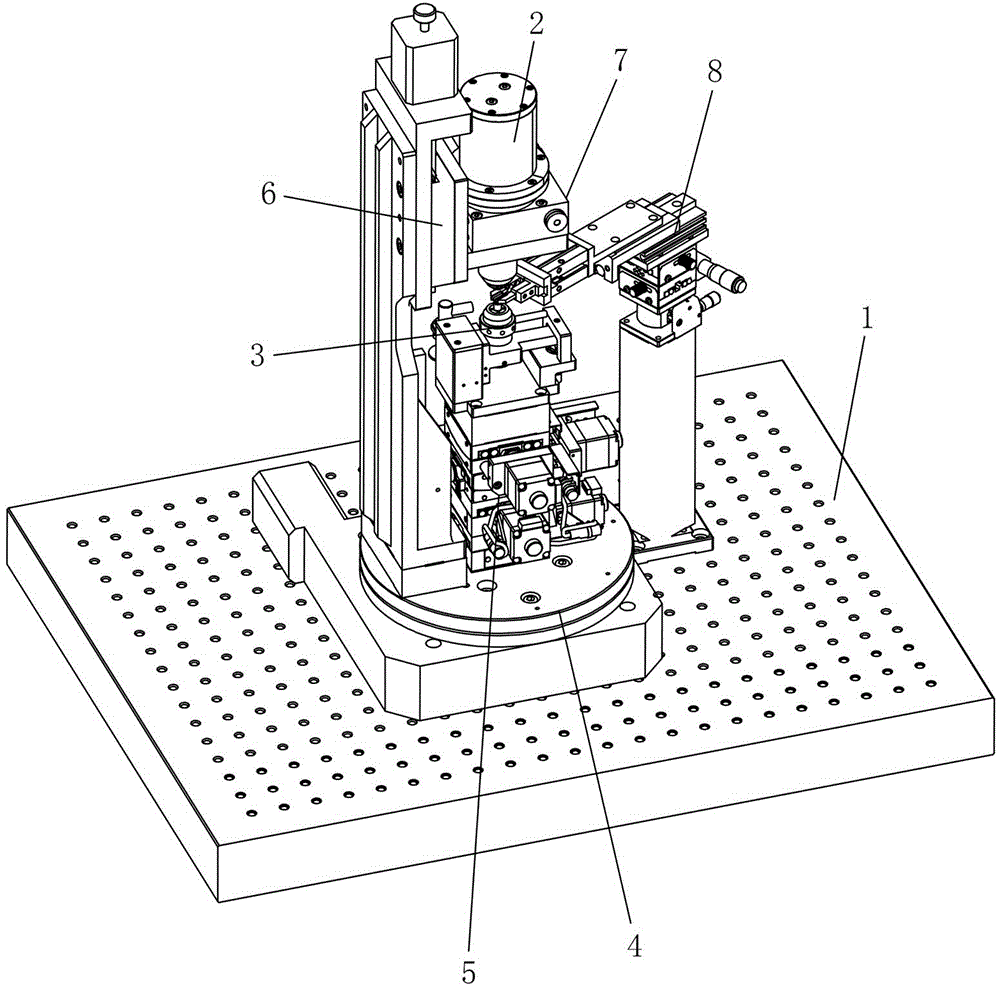

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0033] like image 3 and Figure 4As shown, the automatic coupling device of the three-body coaxial optoelectronic device of the present invention includes a frame 1 (optical breadboard), an upper fixture 2, a lower fixture 3, and an automatic coupling device mounted on the frame 1 and capable of rotating around the Z axis. Rotating platform 4, wherein the upper fixture 2 is used to clamp the upper device 102 (optical fiber), the lower fixture 3 is used to clamp the lower device 100 (laser), and the lower fixture 3 is installed on the automatic rotating platform 4 through the alignment device 5 And it can be driven by the alignment device 5 to move along the X axis, move along the Y axis, swing around the X axis and swing around the Y axis. The automatic rotating platform 4 is provided with a lifting device 6, and the lifting end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com