Patents

Literature

40results about How to "Realize automatic layout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

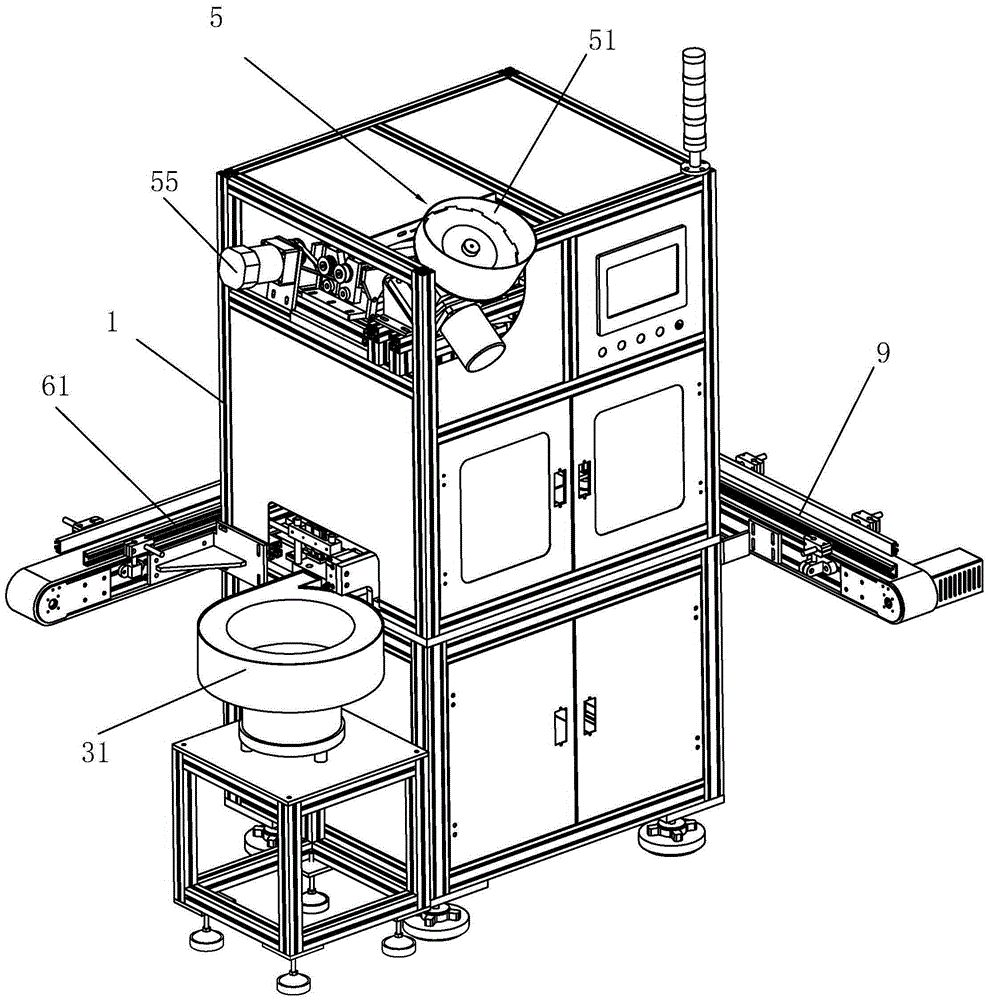

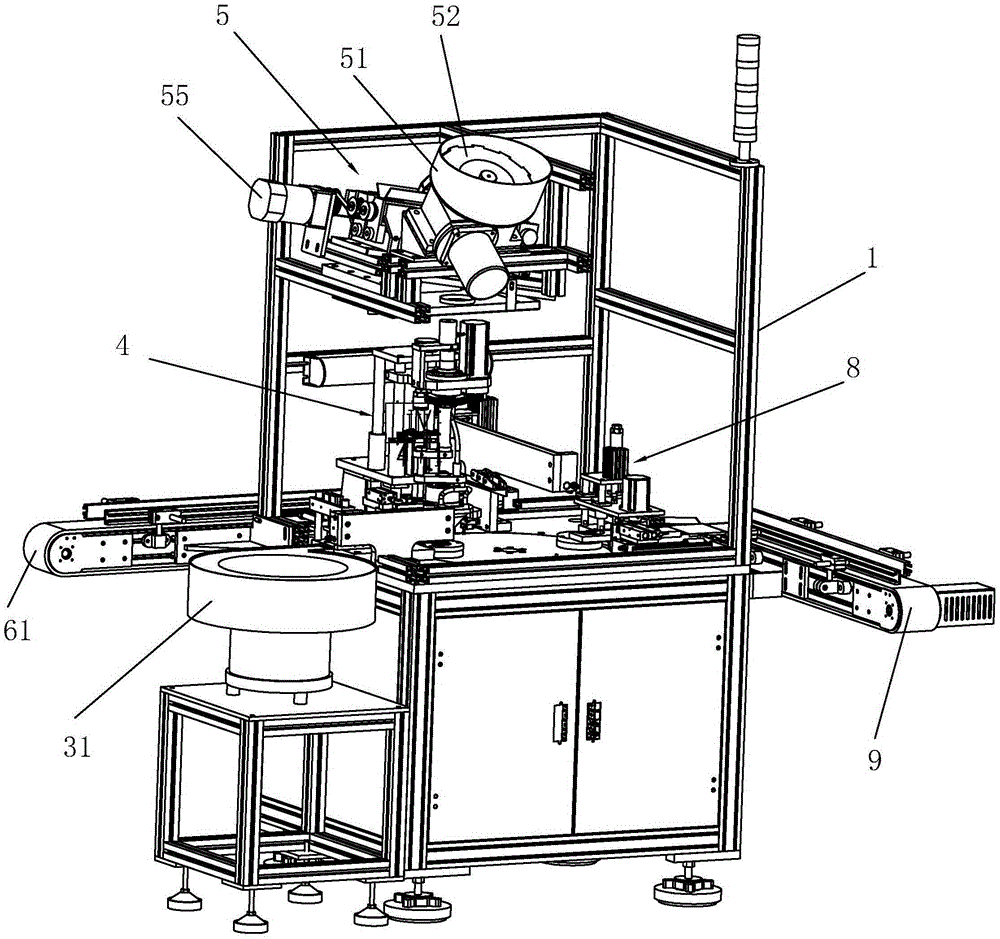

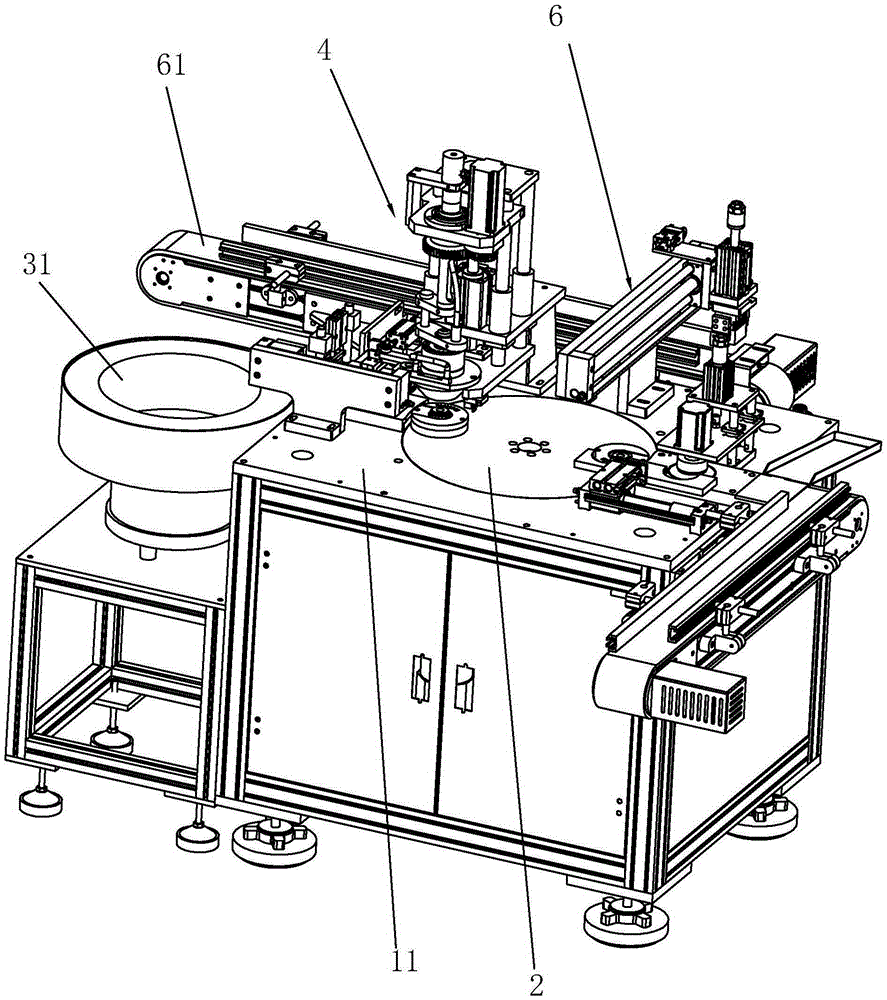

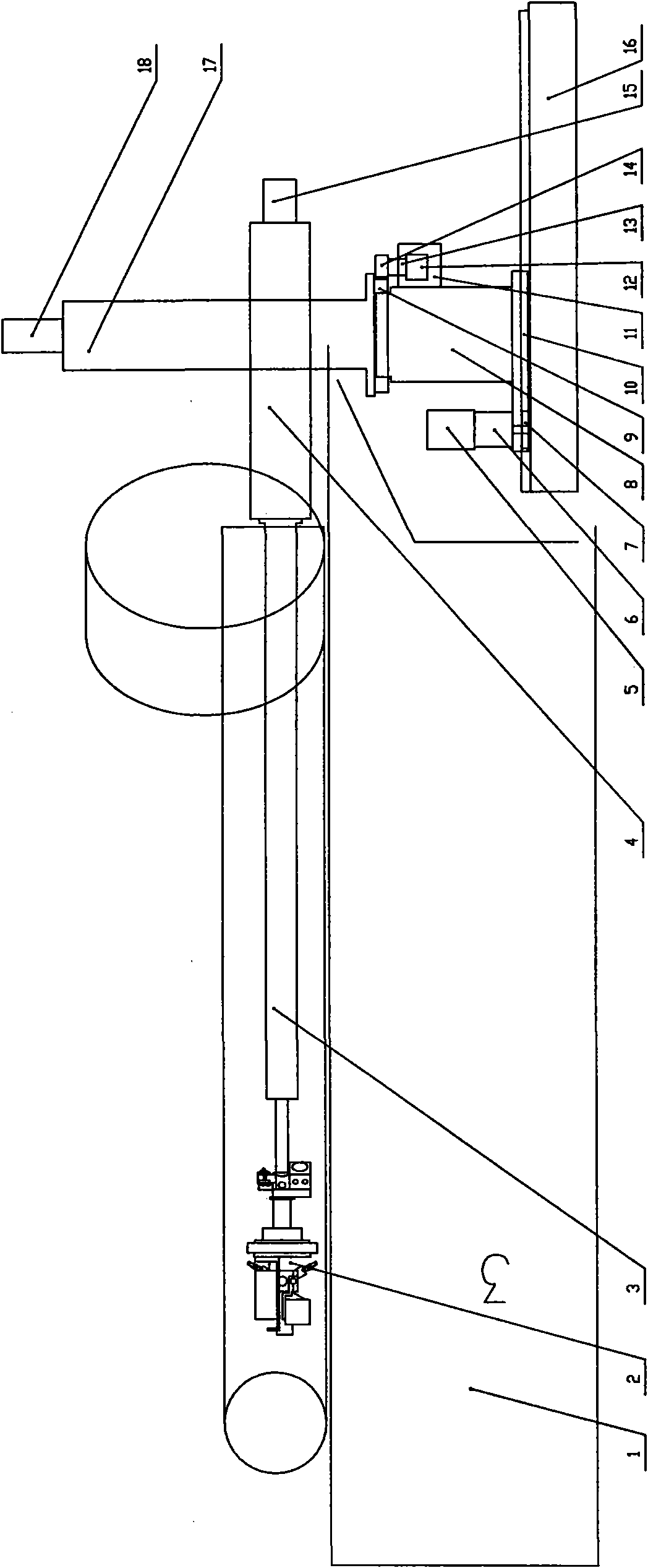

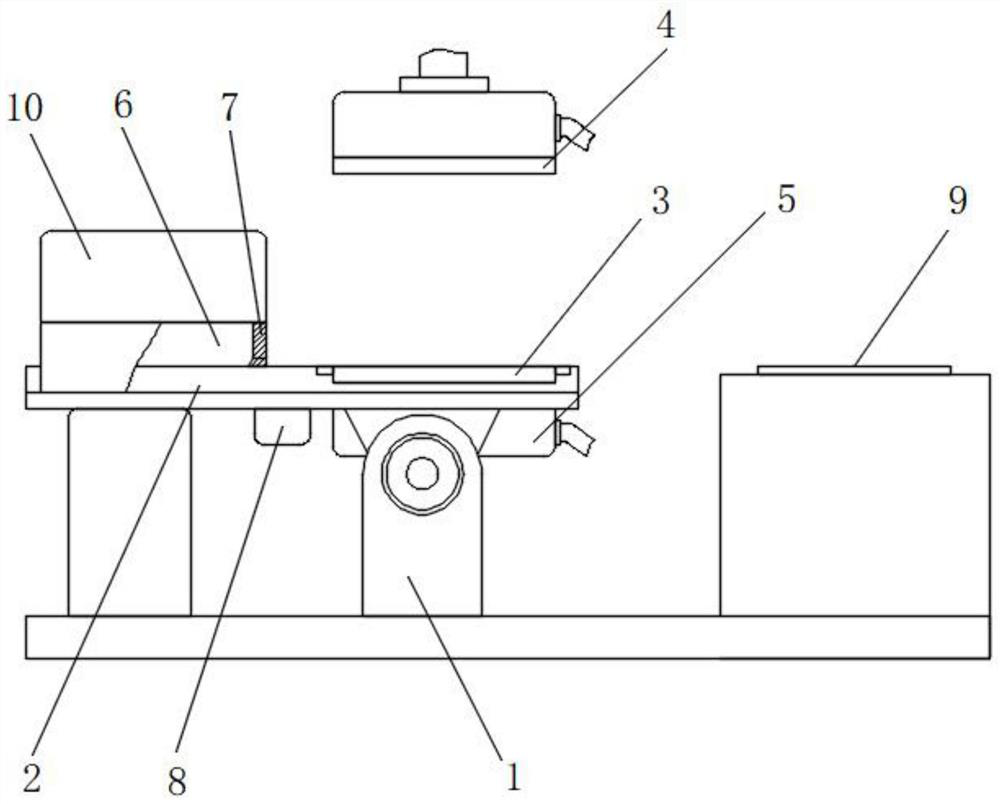

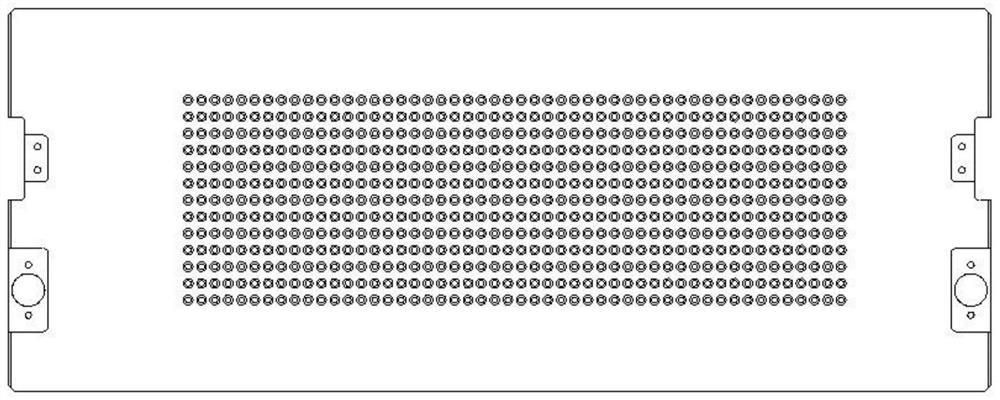

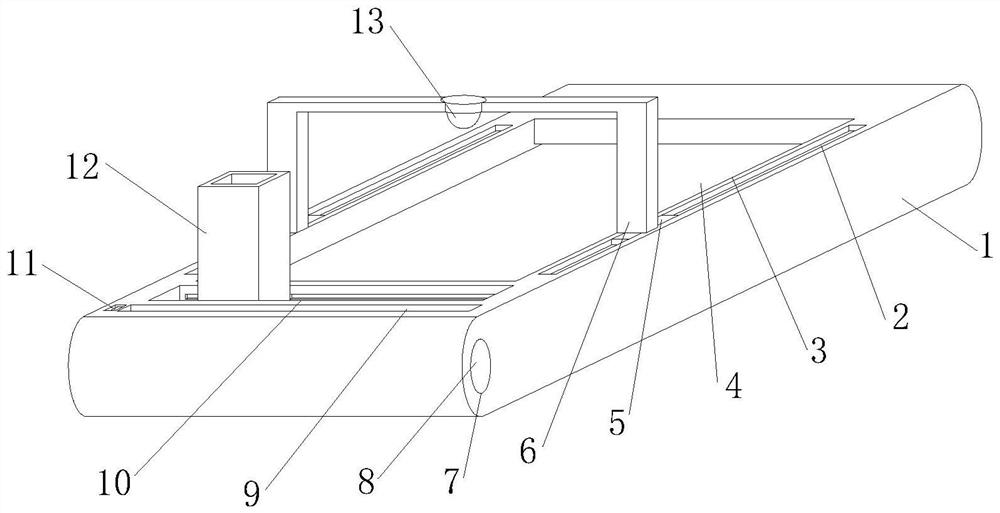

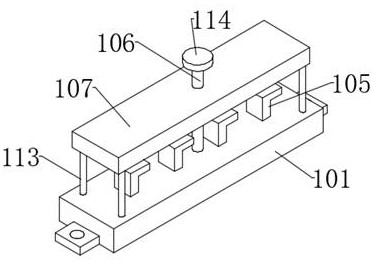

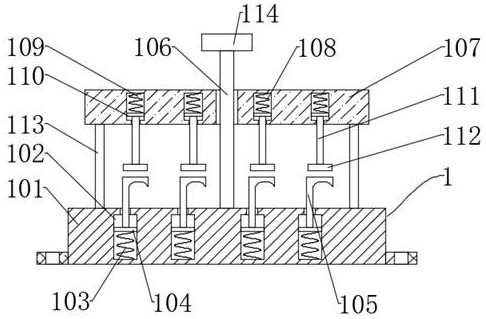

Two-station bearing assembly machine

ActiveCN105402258ARealize automatic layoutAchieve installationBearing componentsEngineeringWorkbench

The invention discloses a two-station bearing assembly machine, the key points of a technical scheme are that the two-station bearing assembly machine comprises a rack, wherein a workbench is arranged on the rack, a rotary plate is arranged on the workbench in a rotating manner, a bearing tooling for installing a bearing is arranged on the rotary plate, the two-station bearing assembly machine also comprises a holder feeding device used for placing a holder on the bearing tooling, a tapered roller unloading device used for installing tapered rollers into the holder, a mounting plate arranged on the rack in a slipping manner, wherein a material storage barrel for storing the tapered rollers is arranged on the mounting plate, a plurality of material storage holes for storing the tapered rollers are formed in the circumference of the material storage barrel an array way, and a bearing inner race feeding device used for placing a bearing inner race on the bearing tooling, the two-station bearing assembly machine disclosed by the invention has the advantages that the structure is compact, the degree of automation is high, the assembly of the tapered rollers can be automatically implemented, the bearing assembly efficiency is greatly improved, a detection device is arranged, the number of the assembled tapered rollers can be detected, and the product quality of the bearing can be guaranteed.

Owner:淮安辰锟科技有限公司

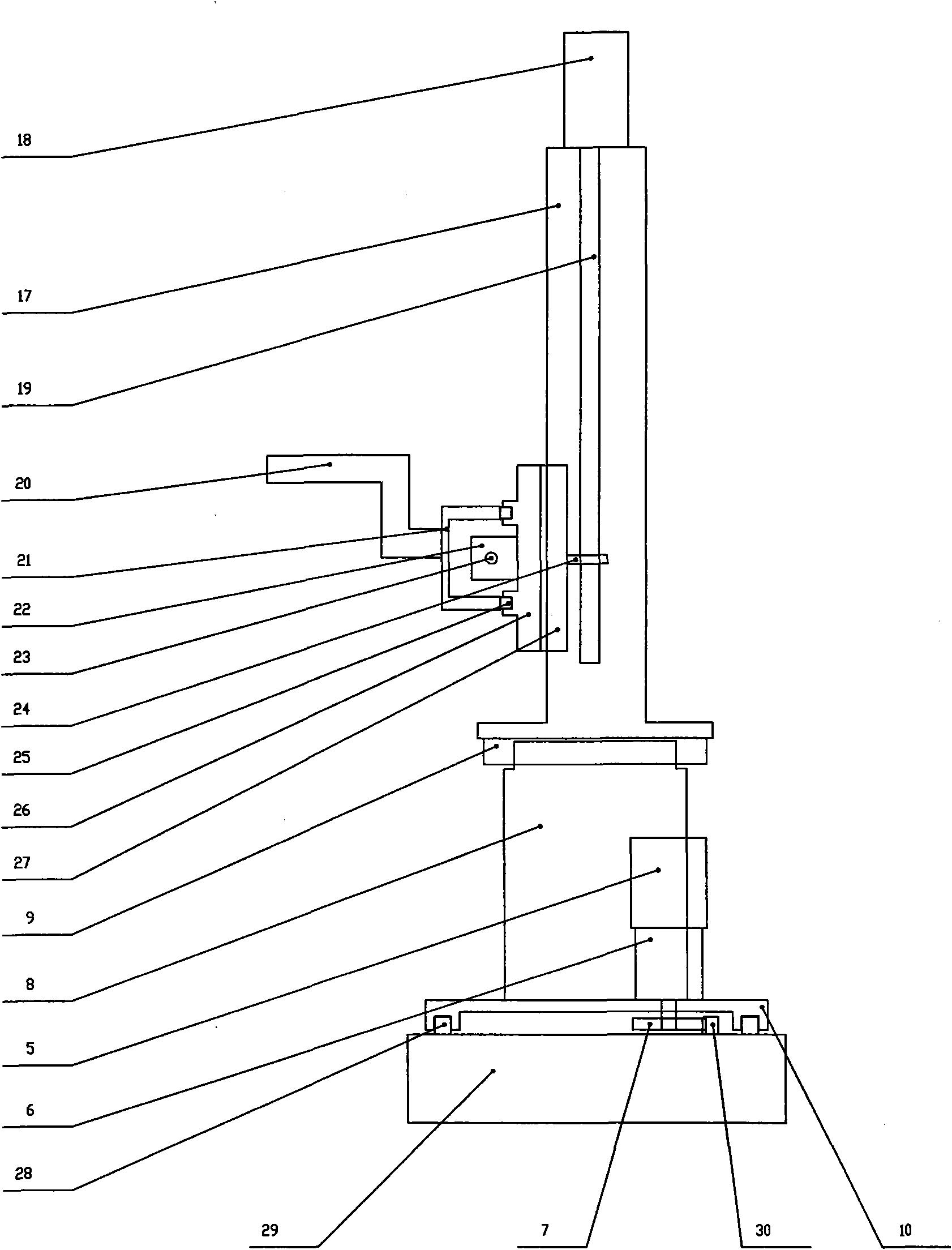

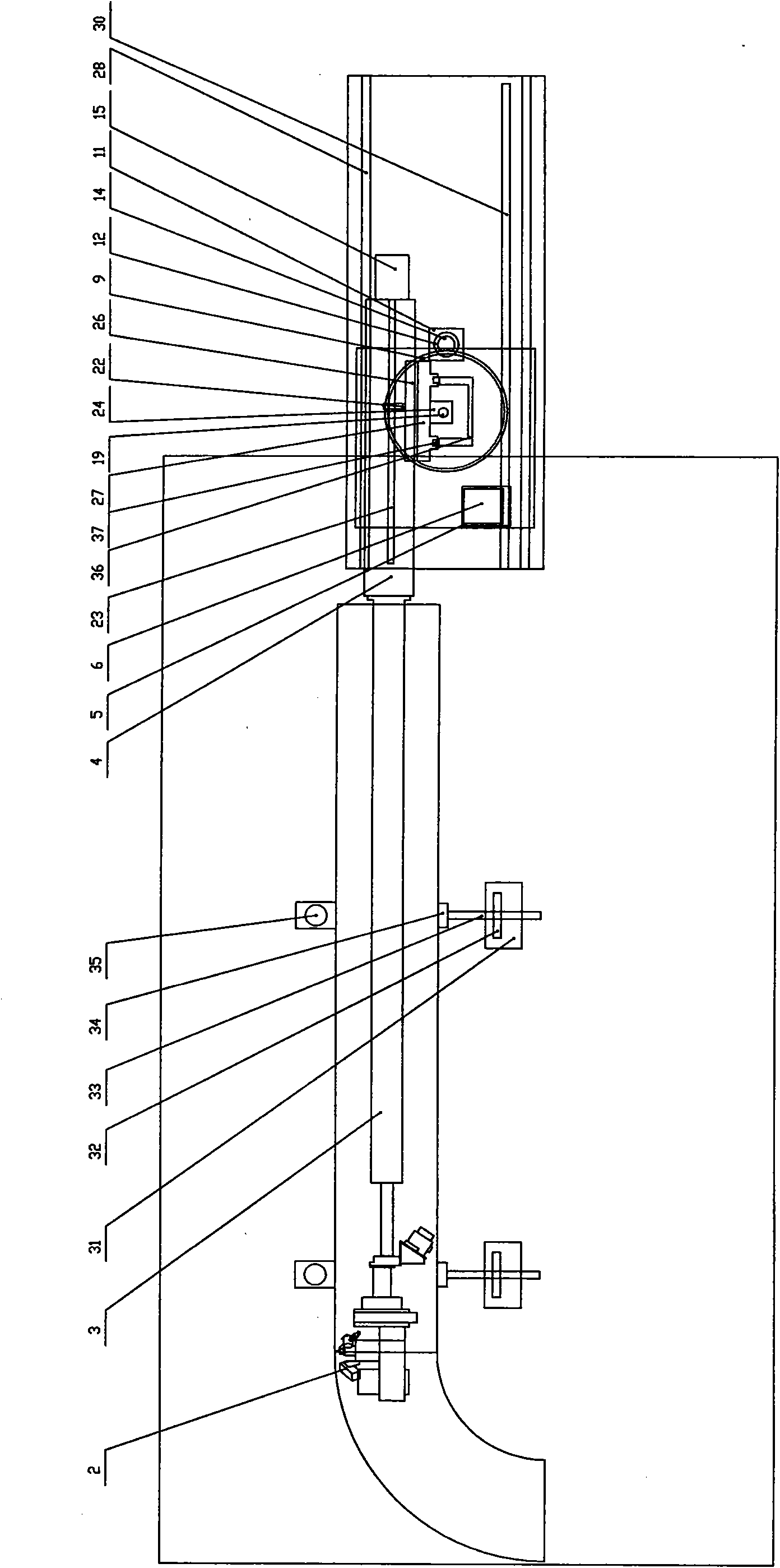

Inner wall overlaying system for 90-degree elbow

InactiveCN101885120APerfect 90° elbow welding solutionPerfect welding solutionWelding/cutting auxillary devicesAuxillary welding devicesSlide plateElbow

The invention relates to welding equipment, in particular to an overlaying system of an inner wall overlaying machine for a 90-degree elbow. The system comprises a platform, a clamp assembly, an upright post assembly, a cross arm assembly, a rotary assembly and a translation guide rail assembly, wherein the translation guide rail assembly is integrally and transversely fixed at one sides of the platform and the clamp assembly and provided with the rotary assembly capable of moving on a linear guide rail of the translation guide rail assembly; the upright post assembly is fixed on a rotary support on the rotary assembly; a vertical guide rail of the upright post assembly is provided with a vertical move sliding plate, a transverse guide rail of the cross arm assembly is provided with a transverse move sliding plate, and the vertical move sliding plate and the transverse move sliding plate are connected and fixed; and the cross arm assembly is provided with a welding nose through a connecting arm. The system can realize circumferential annular all-position overlaying and has the oscillating function of a welding gun, and the oscillating amplitude gradually enlarges from inside to outside along with the radius of the elbow so as to guarantee that the overlaying thicknesses of all points of the inner wall are consistent. The system not only can be used for welding 90-degree elbows, but also can be used for welding combinations of straight pipes and elbows, thereby improving the utilization rate of welding systems.

Owner:TANGSHAN KAIYUAN ROBOT SYST

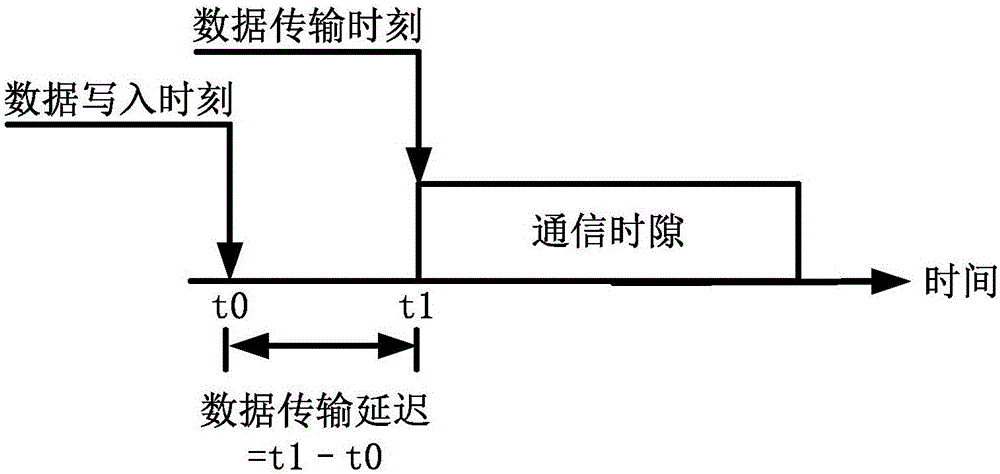

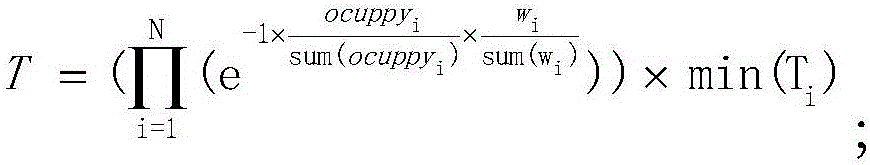

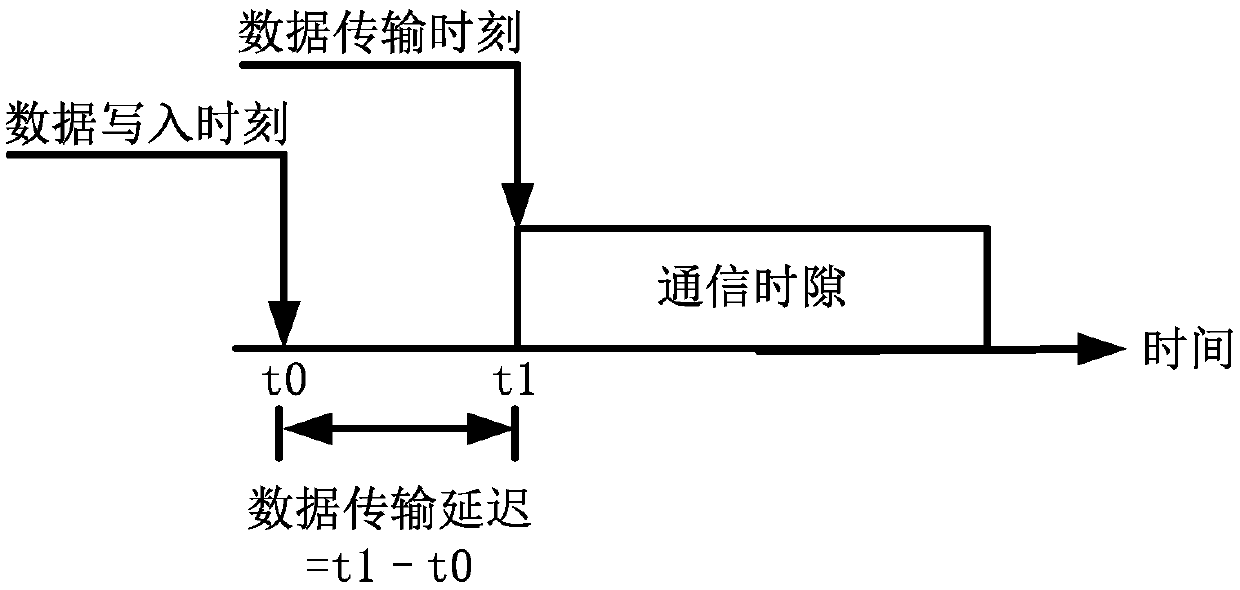

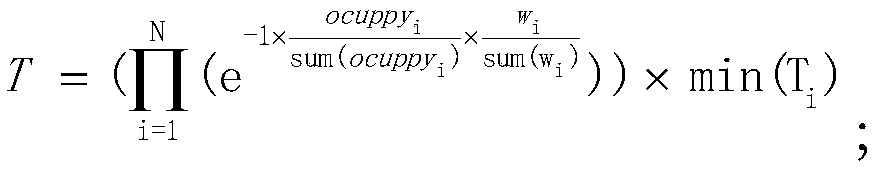

Communication time slot arrangement method based on time trigger bus

ActiveCN106302062AThe time delay requirement is metRealize automatic layoutBus networksSelf adaptiveComputing systems

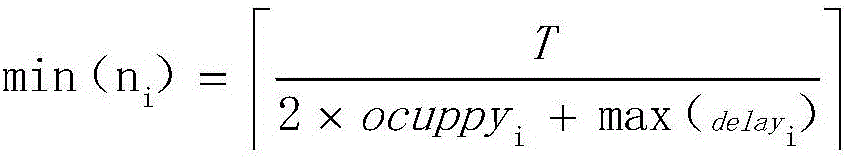

The invention discloses a communication time slot arrangement method based on a time trigger bus. The method specifically comprises the following steps of setting the number of nodes in a system as n, wherein a time duration of a communication time slot occupied by a node i is ocuppyi, a weight value is wi and a communication period is Ti for the node I, and computing a total communication period T of a network of the system; establishing a constraint condition equation set for the node i according to the real-time requirements for functional communication of the node i, solving multiple groups of solutions related to n1-nN, selecting any group as a distribution scheme of the number of communication time slots of each node, and arranging the nodes to a queue A from big to small or from small to big according to the distributed number of the communication time slots; selecting the nodes from the queue A in sequence and uniformly arranging the communication time slots corresponding to the selected nodes on a time shaft according to the distributed number of the communication time slots; and if the time arranged by the communication time slot corresponding to the node is occupied, arranging the communication time slot after the occupied time. According to the method, the communication frame period can be periodically and adaptively adjusted according to the functions of each node of the time trigger bus.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

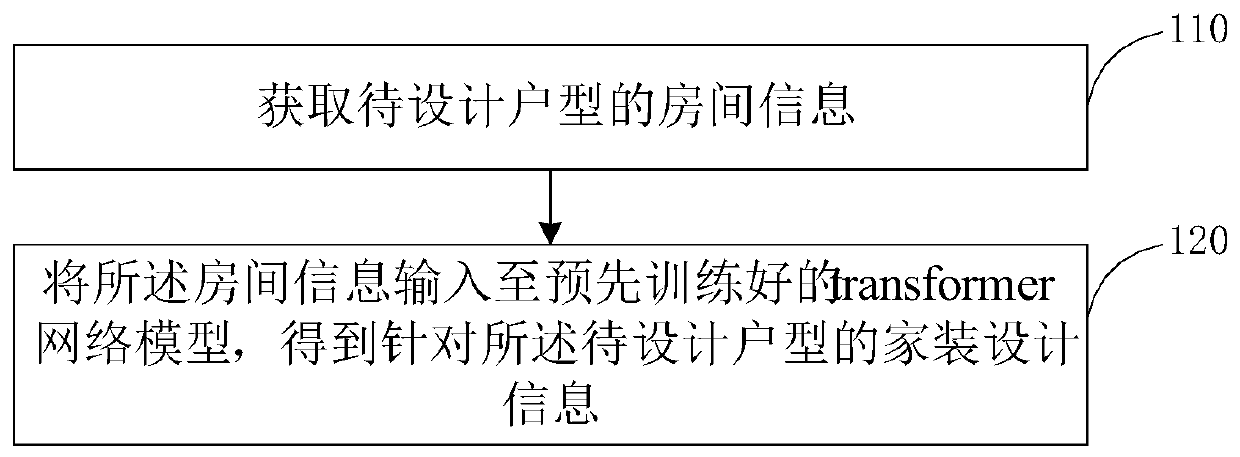

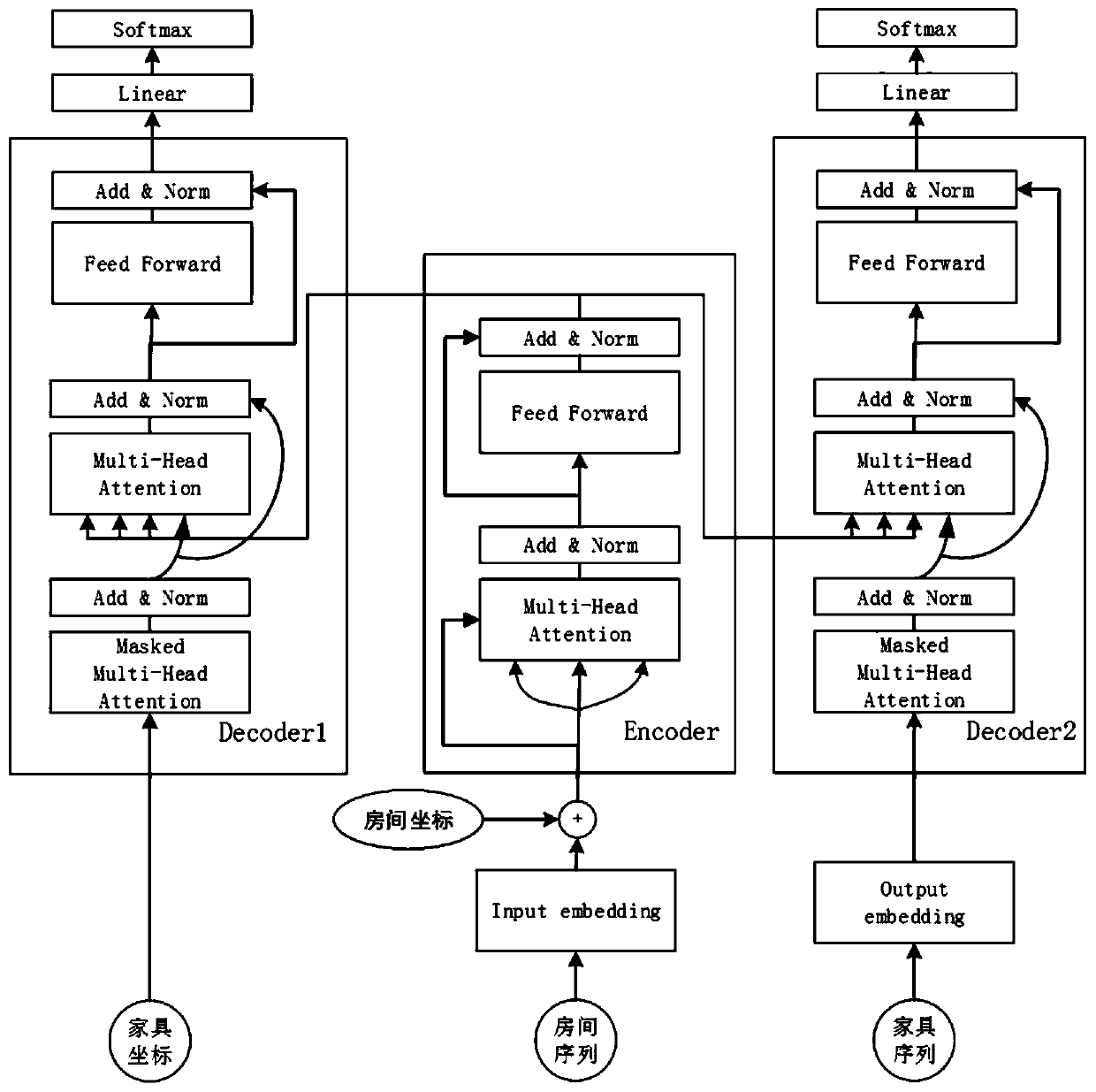

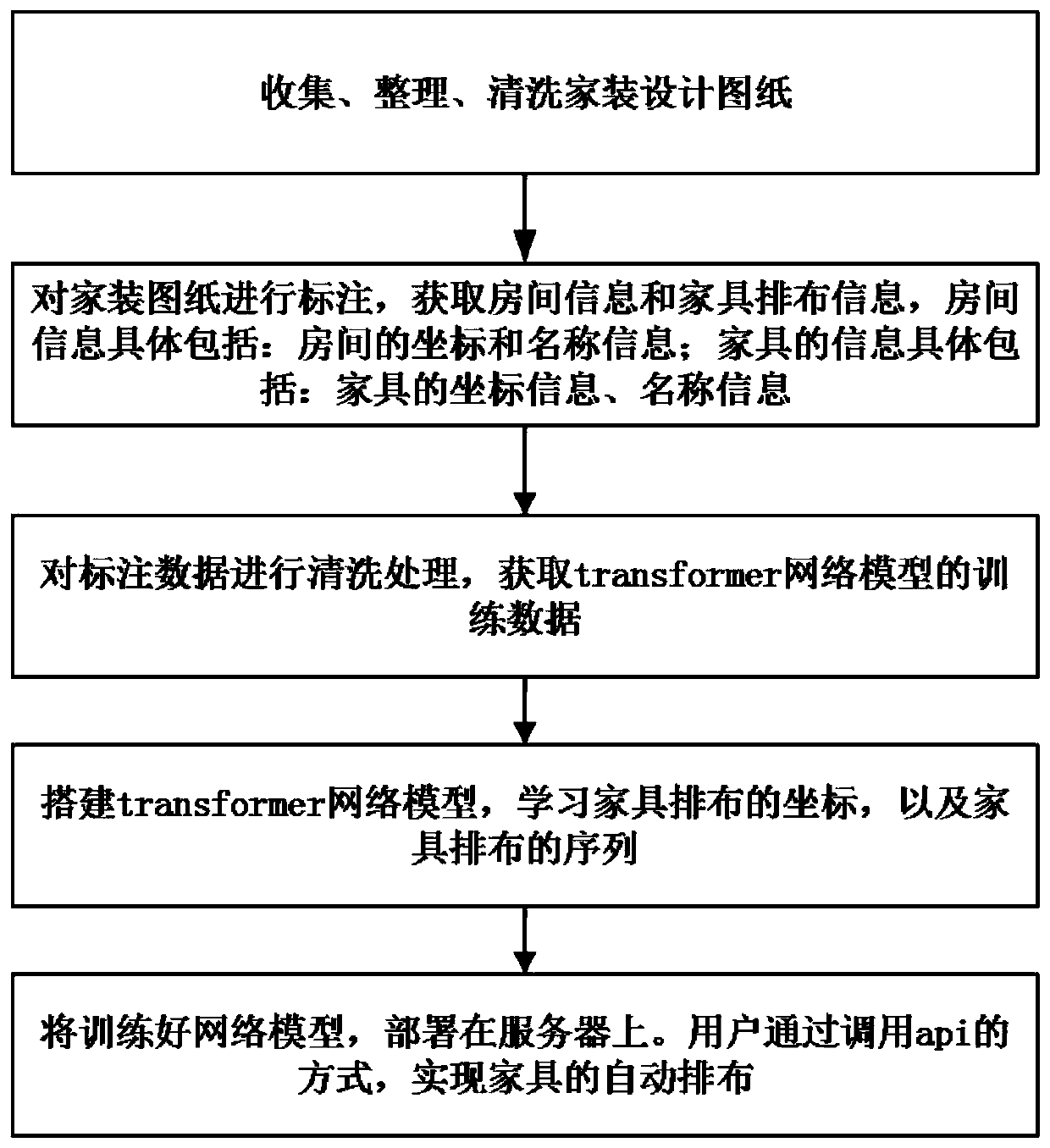

Home decoration design method and device, electronic equipment and storage medium

PendingCN111553012AImprove design efficiencySimple designGeometric CADDesign optimisation/simulationTransformerSoftware engineering

Embodiments of the invention disclose a home decoration design method and device, electronic equipment and a storage medium, wherein the method comprises the steps of obtaining room information of a to-be-designed house type; inputting the room information into a pre-trained transformer network model to obtain home decoration design information for the house type to be designed, wherein the home decoration design information comprises category information of at least one piece of furniture and placement position information of the furniture. According to the technical scheme of the embodimentof the invention, the intelligent design of home decoration is realized; the purpose of automatically arranging furniture is further realized; and the intelligent degree of home decoration design is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

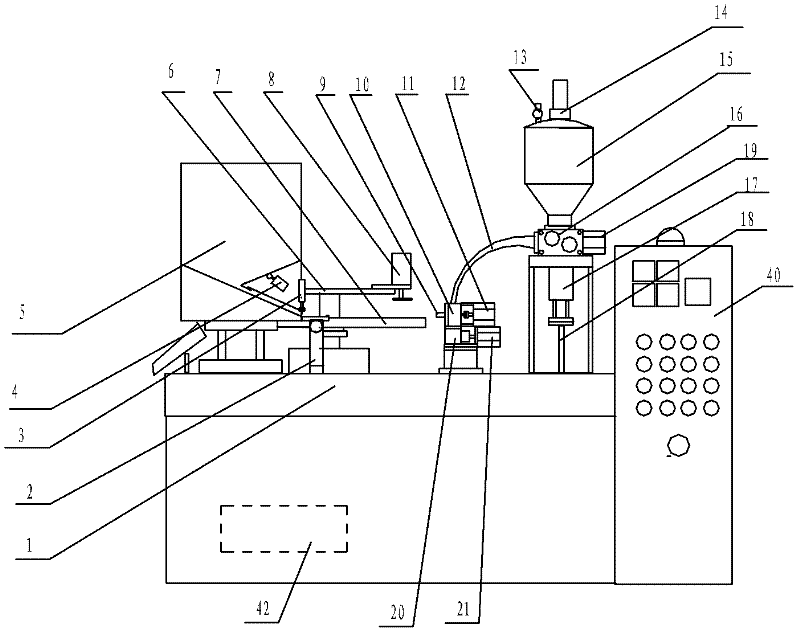

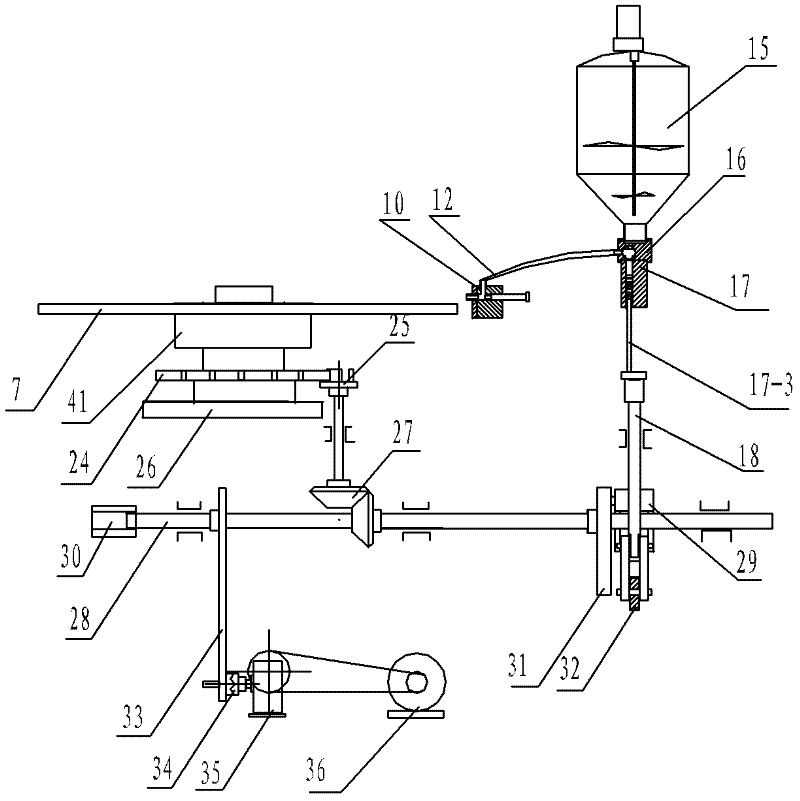

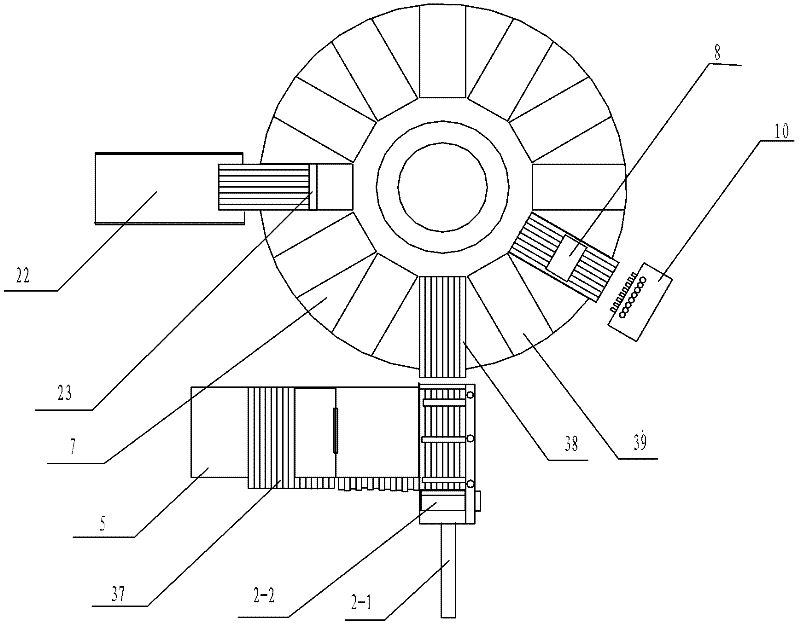

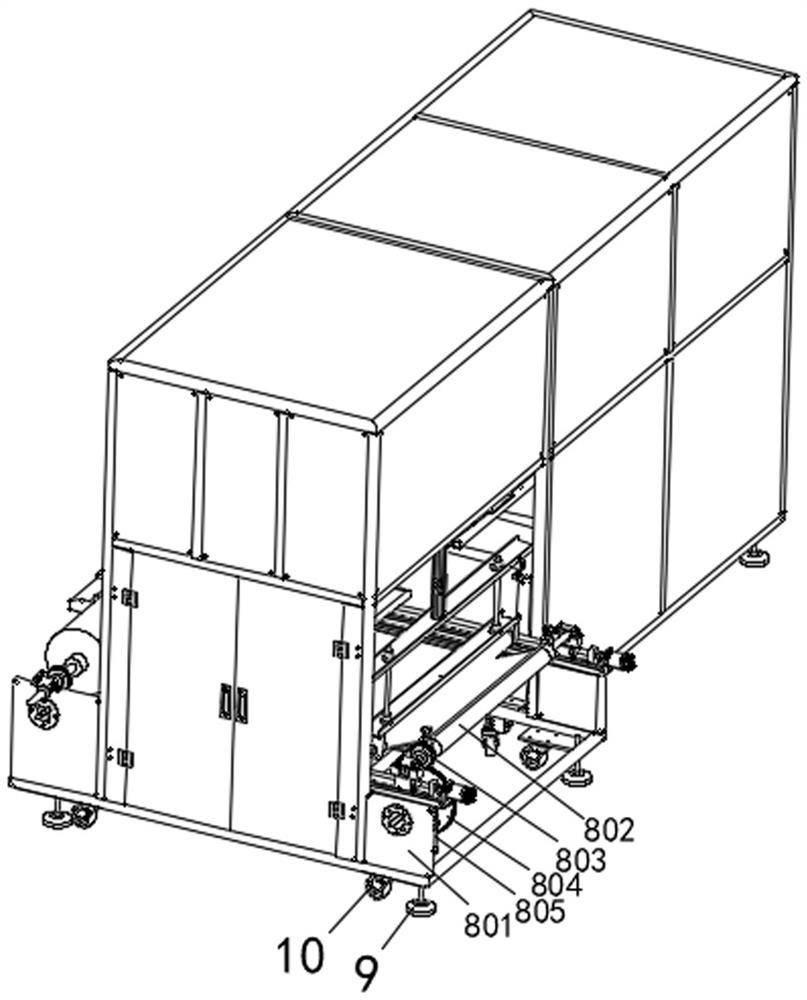

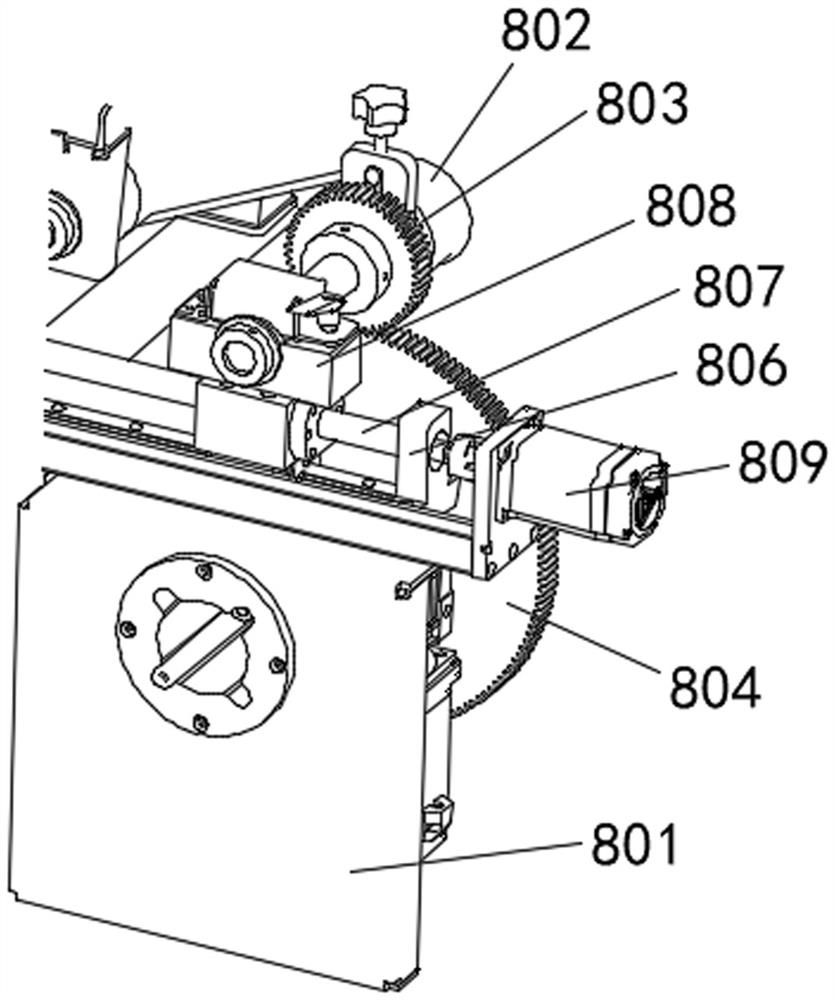

Full-automatic eyebrow pencil core filling machine

ActiveCN102641036AEase of modern managementReduce the use of areaPackaging toiletriesPackaging cosmeticsMechanical driveEyebrow

The invention discloses a full-automatic eyebrow pencil core filling machine which comprises an automatic quantitative rod feeding system, a quantitative filling system, a multi-station rotary disk system and a mechanical driving system and is characterized in that the quantitative filling system comprises a storing tank, a big valve body assembly, a small valve body assembly, a piston cylinder sleeve assembly and a piston rod driving system; an outlet of the storing tank is connected with an upper opening of the big valve body assembly; a lower opening of the big valve body assembly is connected with the upper end of the piston cylinder sleeve assembly; a piston rod of the piston cylinder sleeve assembly is connected with the piston rod driving system; inlets of the big valve body assembly and the small valve body assembly are connected through a hose assembly; the outlet of the small valve body assembly is provided with a discharge port assembly; the big valve body is a T-shaped valve body; and the small valve body is an L-shaped valve body. The full-automatic eyebrow pencil core filling machine disclosed by the invention has the advantages of breaking through traditional processes of pen making industrials, changing intensive manual labour to mechanization production, reducing the labor cost and increasing the labor efficiency and the product qualification ratio.

Owner:烟台盖恩机械设备有限公司

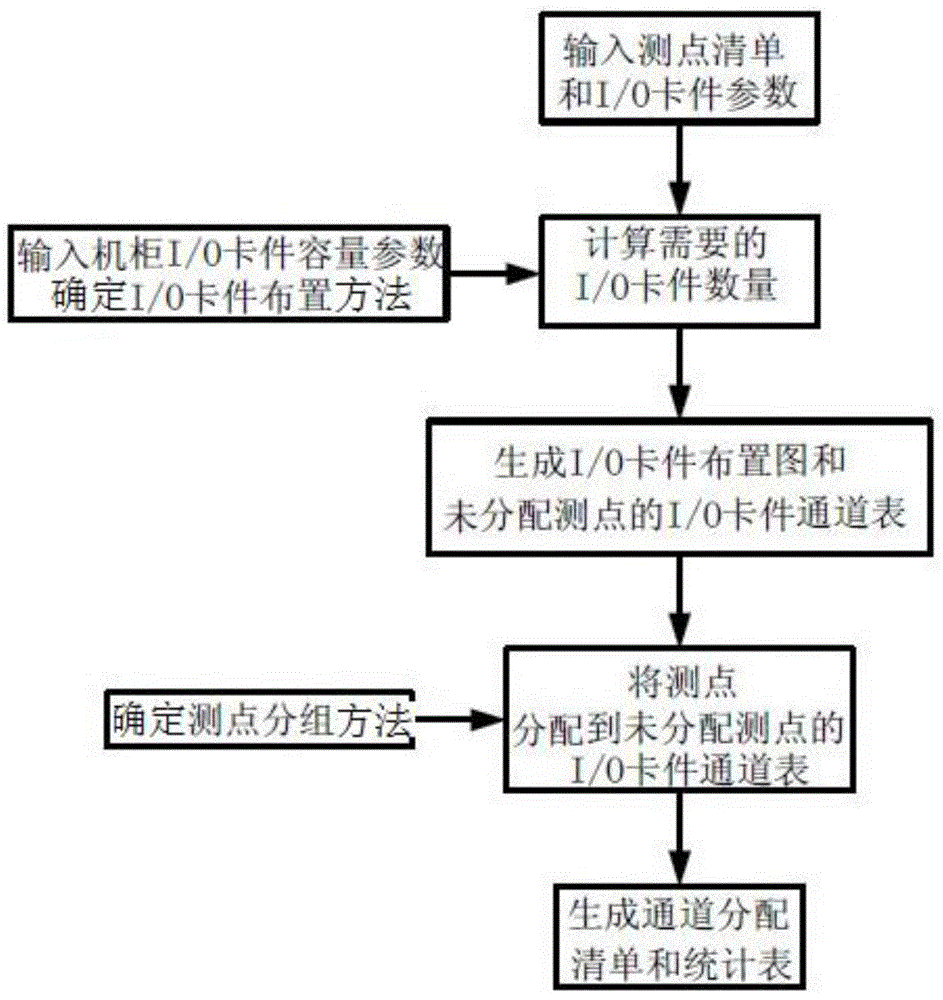

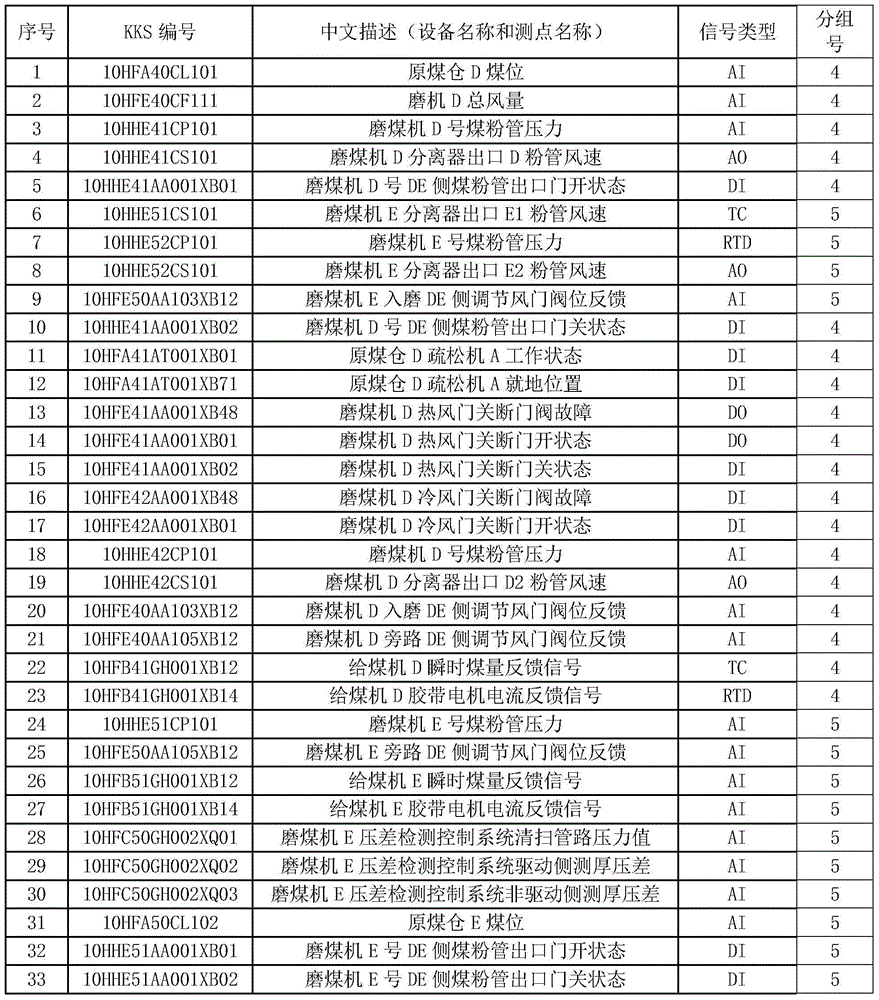

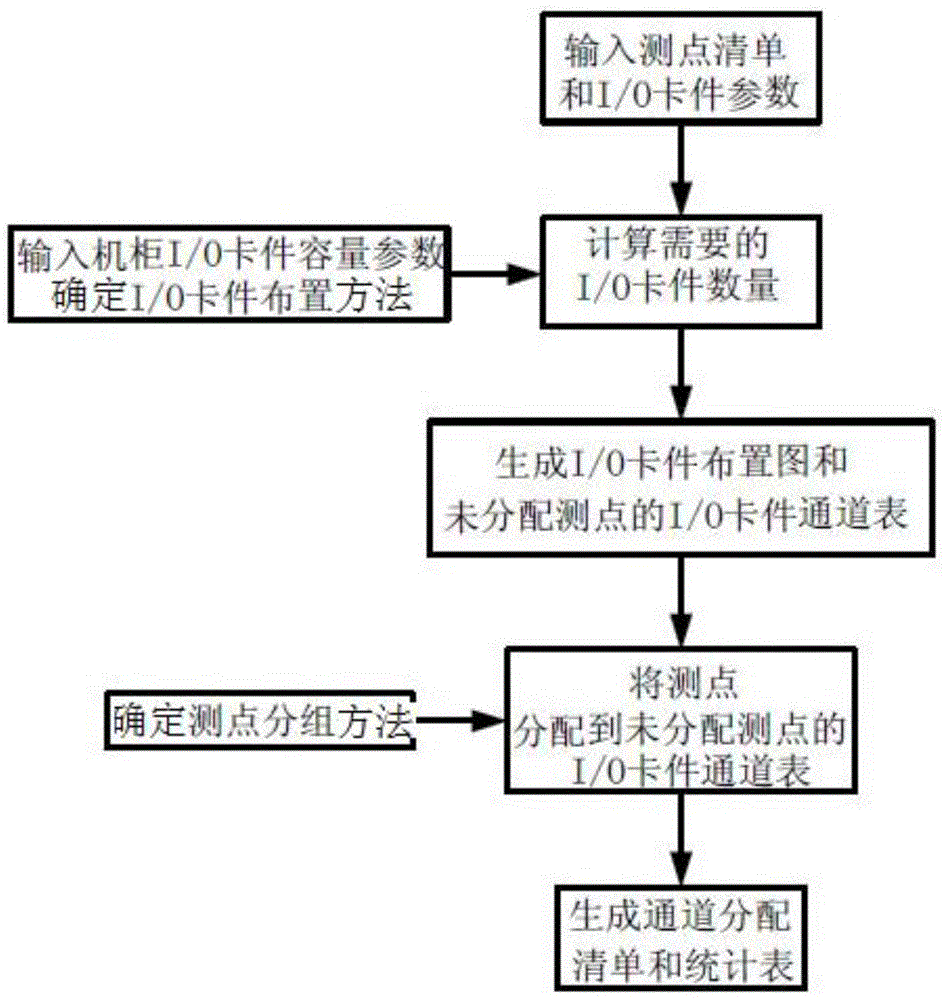

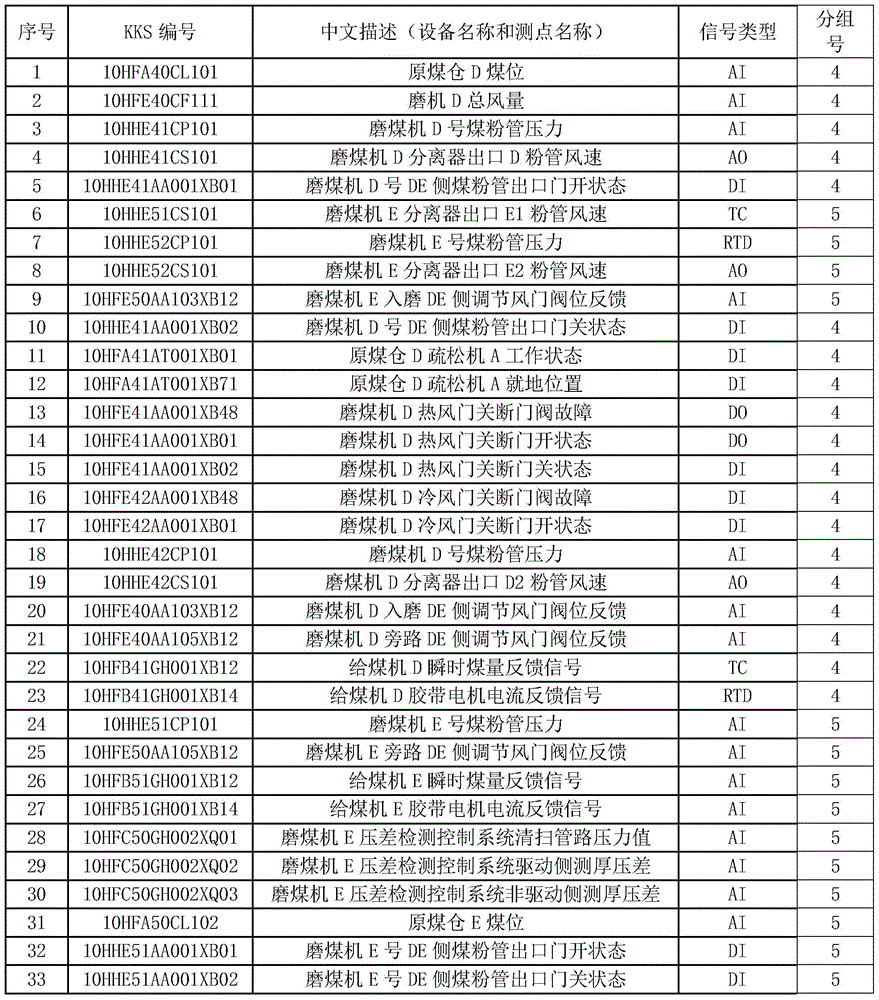

Method for distributing I/O cards for DCS (Data Communication System)

ActiveCN104091000AImprove work efficiencyReduce construction costsSpecial data processing applicationsDevice nameComputerized system

The invention discloses a method for distributing I / O cards for DCS (Data Communication System). The method is characterized in that the EXCEL VBA technology is utilized. The method comprises the following steps: a, inputting a measurement point list into a computer system, wherein the measurement point list includes number of each measurement point, name of each device, name of each measurement point, type of signal and group number; b, inputting the type of the I / O cards and the number of point, and calculating the quantity of the I / O cards of different types; c, inputting capacity parameters of I / O cards in a cabinet, and generating a layout and a list of the I / O cards in the cabinet; d, creating a list of I / O card channels without the distributed measurement points according to the measurement point list; e, grouping the measurement points according to the keywords; f, distributing the grouped measurement points to the channels of different cards, and creating an I / O card channel distribution sheet. With the adoption of the method for distributing the I / O cards for the DCS, the automatic arrangement of the cabinet and the automatic distribution of the measurement points are realized, the cards can be accurately an automatically arranged, thus the accuracy of the obtained channel sheet is ensured, and good guide can be brought to production.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

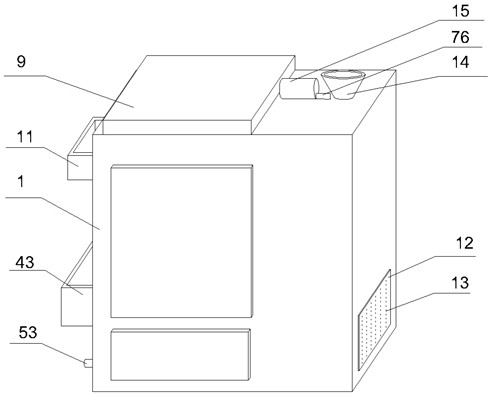

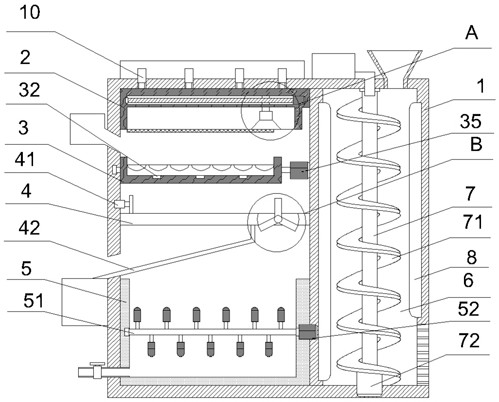

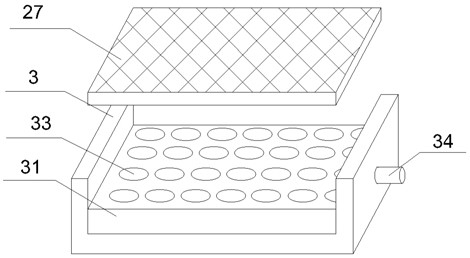

Dried shiitake mushroom production equipment with sterilization action

ActiveCN112385866ARealize automatic layoutRealize automatic de-handlingSievingScreeningBiotechnologyEngineering

The invention relates to the technical field of food processing equipment and discloses dried shiitake mushroom production equipment with a sterilization action. The dried shiitake mushroom productionequipment comprises a box body, wherein a top seat is arranged at the internal upper end of the box body, a cutting box is arranged at the lower end of the top seat, a screen plate is arranged at thelower end of the cutting box, a cleaning tank is arranged at the lower end of the screen plate, a drying chamber is arranged at one side, far away from the cleaning tank, inside the box body, supporting columns are arranged inside the drying chamber, and ultraviolet sterilizing lamps are arranged on internal walls of the drying chamber. According to the dried shiitake mushroom production equipment with the sterilization action, through matching between the cutting box and the screen plate, shiitake mushrooms can be subjected to automatic stem removing and automatic screening separation; the shiitake mushrooms are cleaned through rubber sleeves, and thus, damage to appearance of the shiitake mushrooms is reduced; and the ultraviolet sterilizing lamps are arranged in the drying chamber, sothat uniform baking and sterilizing of the shiitake mushrooms are facilitated, the space usage of the equipment is saved, and procedure flows of manual transferring are also reduced.

Owner:河南天中亿龙食品有限公司

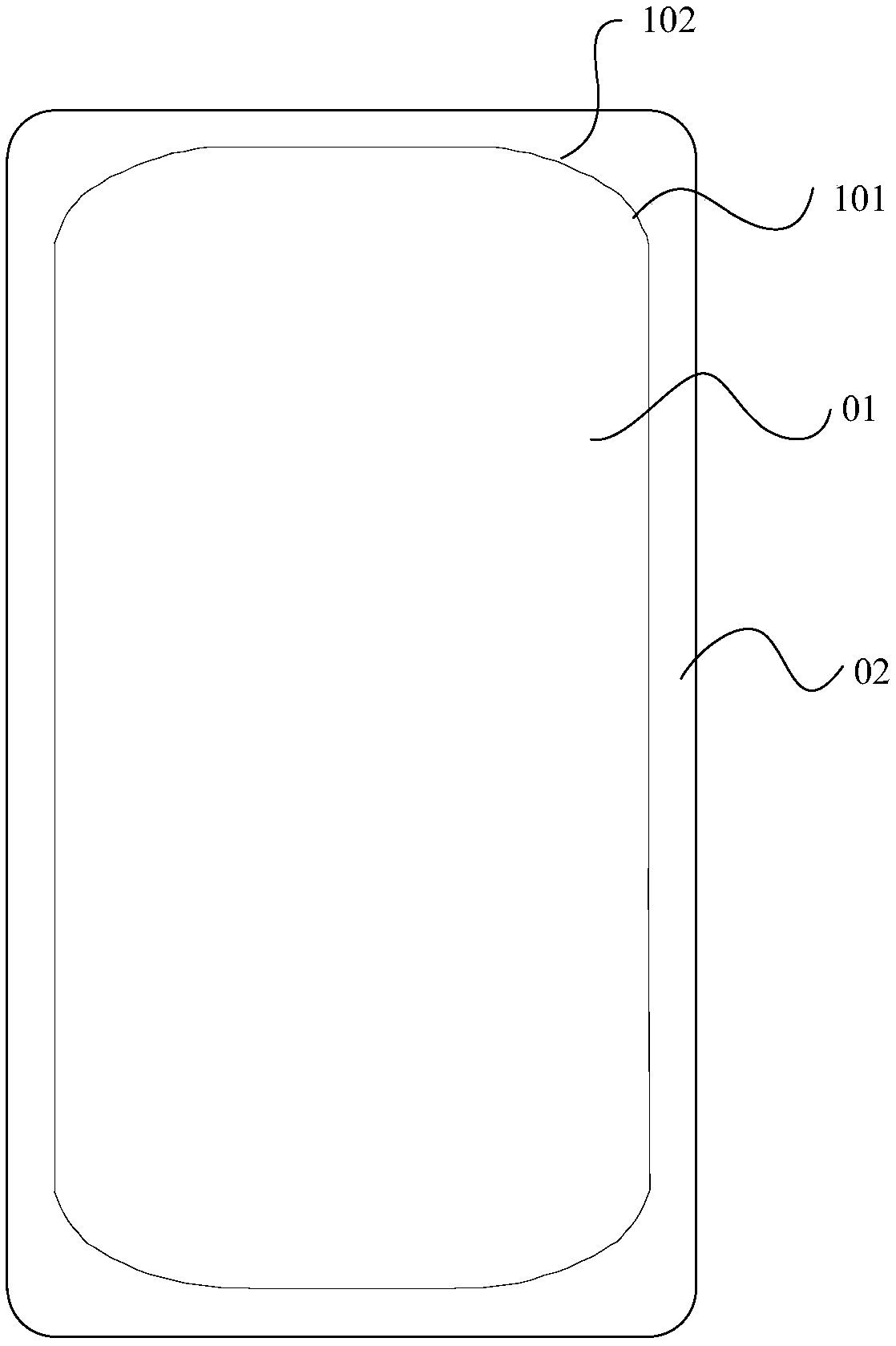

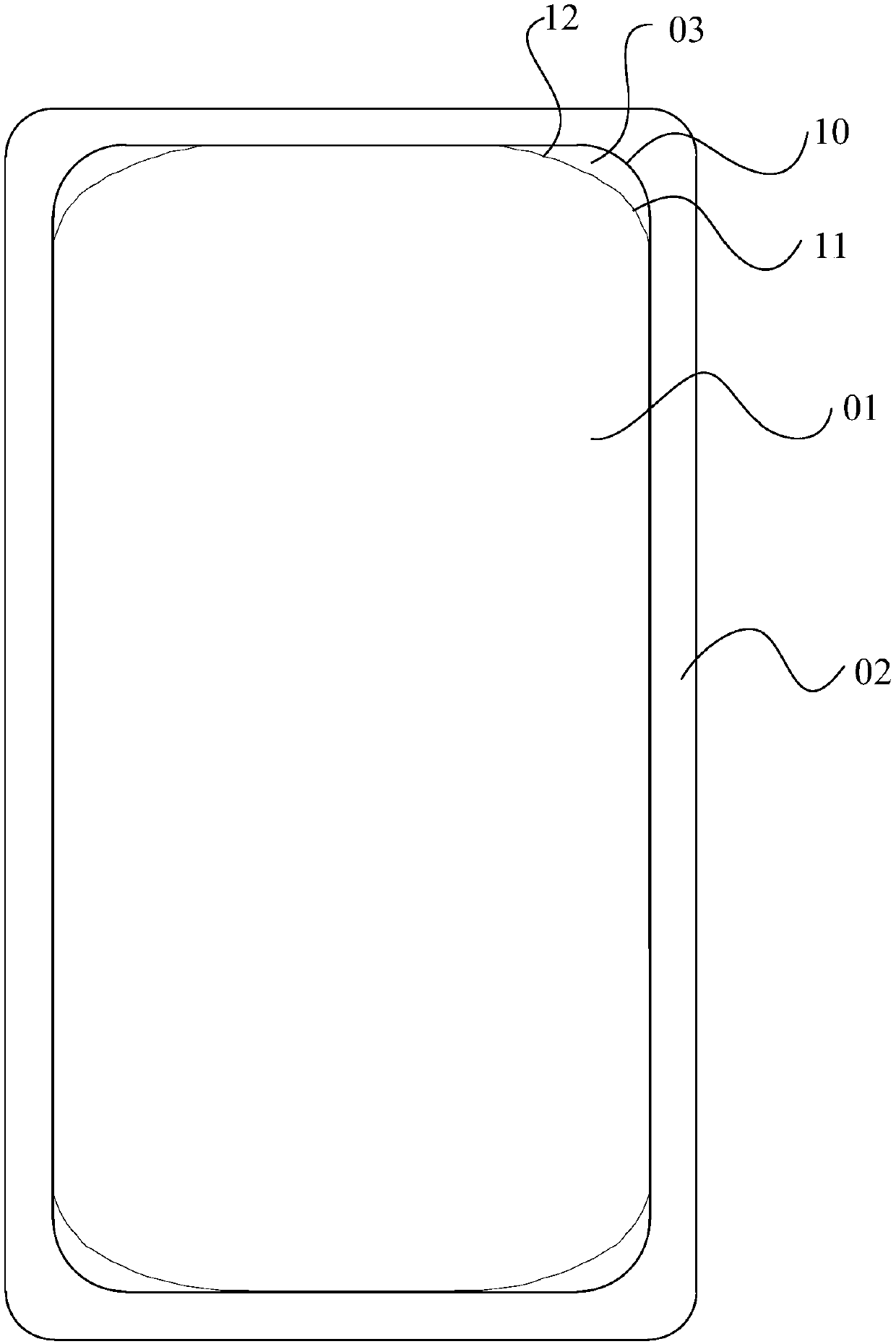

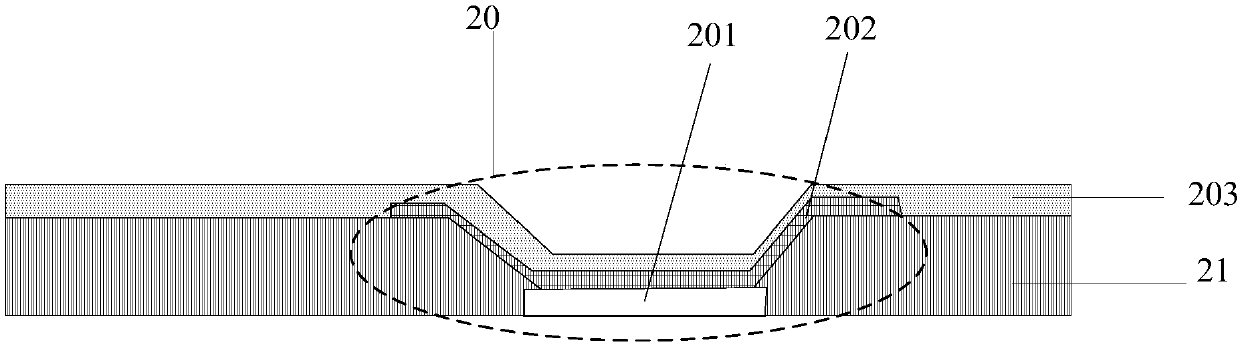

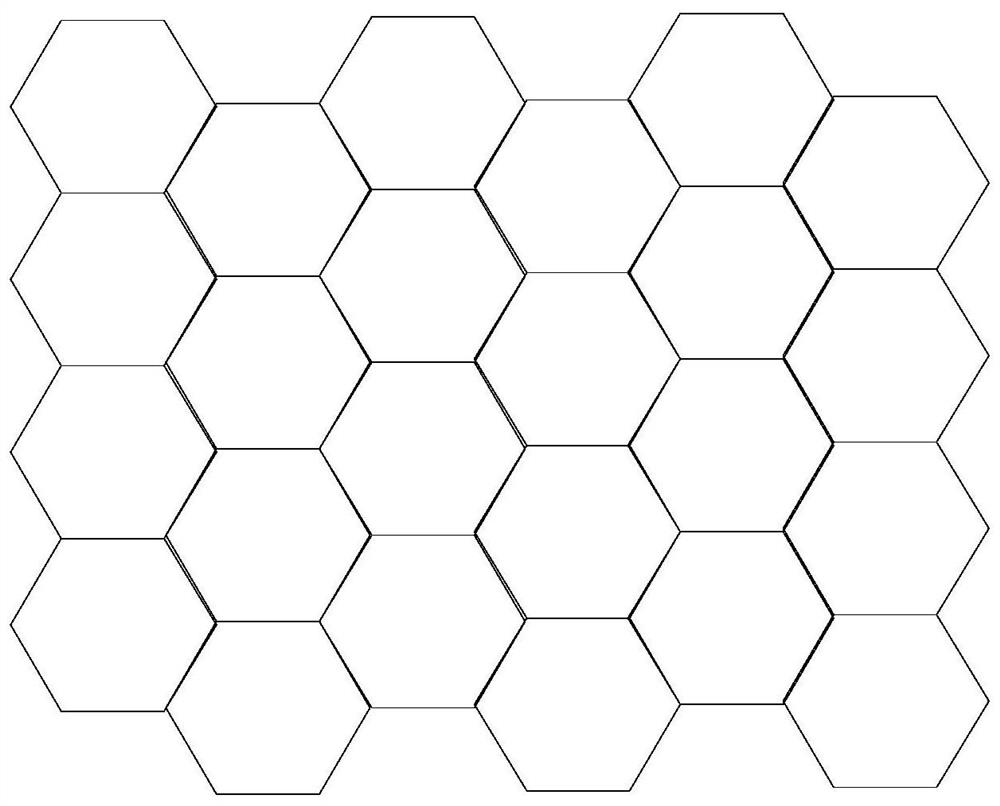

Display panel and display device

ActiveCN108039358ARealize automatic layoutReduce design difficultySolid-state devicesSemiconductor devicesRADIUSDisplay device

The invention discloses a display panel and a display device to solve the problem in the prior art that it is difficult to design the masks of all the layers in a special-shaped display area. The display panel includes a display area, a peripheral area, and at least one middle area between the display area and the peripheral area. The edge of each middle area away from the display area includes afirst fillet having a first curvature radius. The edge of each middle area near the display area includes a first arc having a second curvature radius and a second arc having a third curvature radius.The display area and the middle areas include light emitting units arranged in an array and a pixel definition layer. Each light emitting unit includes a first electrode, a light emitting layer and asecond electrode, and the light emitting layer is between the first electrode and the second electrode. In the display area, the pixel definition layer is used for limiting the light emitting units.In each middle area, the pixel definition layer covers the first electrodes of the light emitting units.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

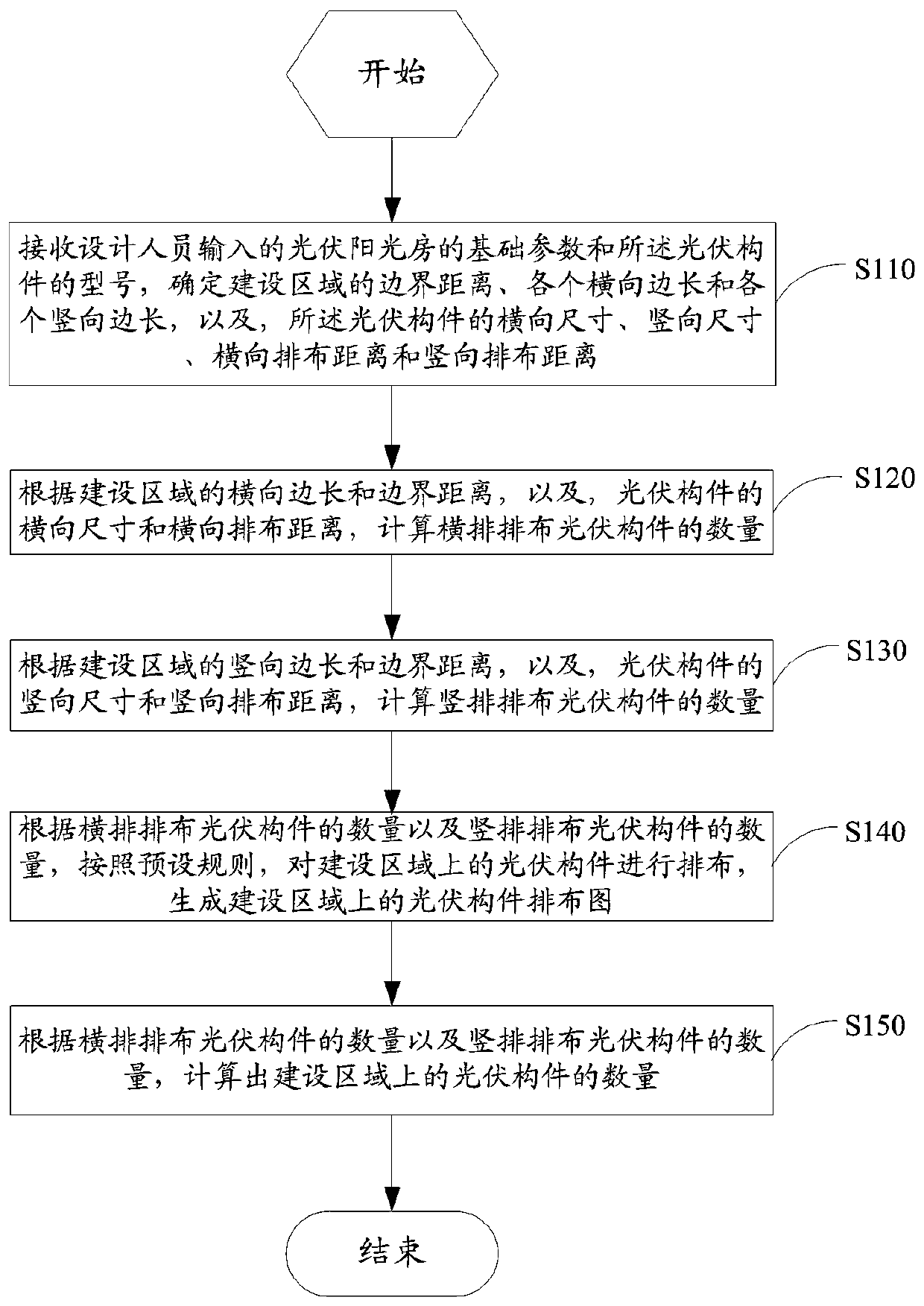

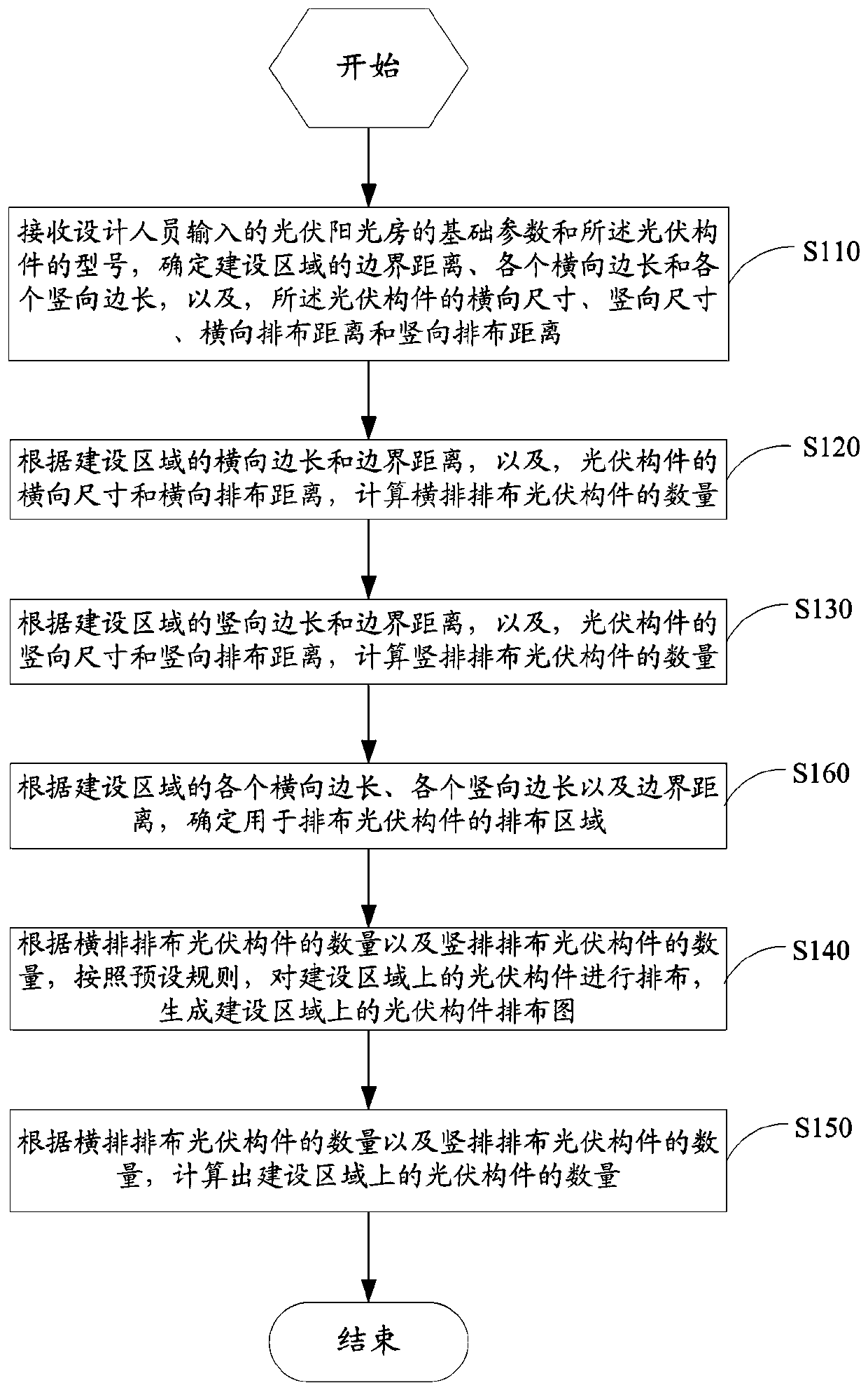

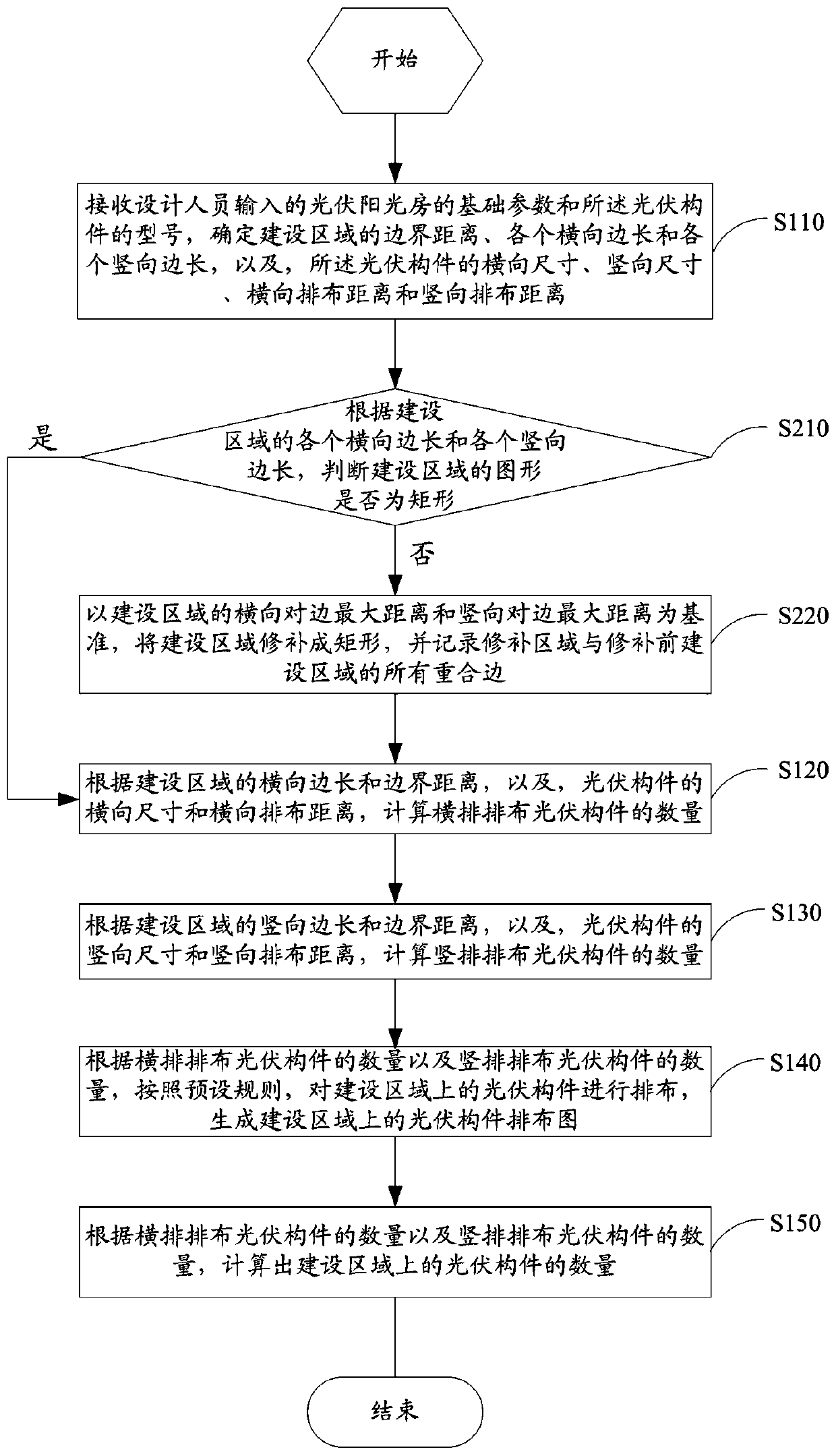

Photovoltaic component arrangement method and photovoltaic array construction determination method

The invention provides a photovoltaic component arrangement method and a photovoltaic array construction determination method. The method comprises the following steps: firstly, determining a boundary distance, each transverse side length and each vertical side length of a construction area, and determining a transverse size, a vertical size, a transverse arrangement distance and a vertical arrangement distance of a photovoltaic component from basic parameters on the construction area and the model of the photovoltaic component received by a designer; then, according to the parameters, respectively calculating the number of the horizontal row of photovoltaic components and the number of the vertical row of distributed photovoltaic components; finally, calculating the number of the photovoltaic components, arranging the photovoltaic components according to a preset rule, and generating a photovoltaic component arrangement diagram. The arrangement of the photovoltaic components on the construction area is realized; professional technicians do not need to depend on professional design software to carry out arrangement design, and therefore the problems that in the prior art, a skylight, a photovoltaic module, a stand column of the photovoltaic module and a light-transmitting plate of the photovoltaic module have high requirements for professionals and technical foundations of the designers, and consumed time is long are solved.

Owner:HEFEI SUNGROW RENEWABLE ENERGY SCI & TECH CO LTD

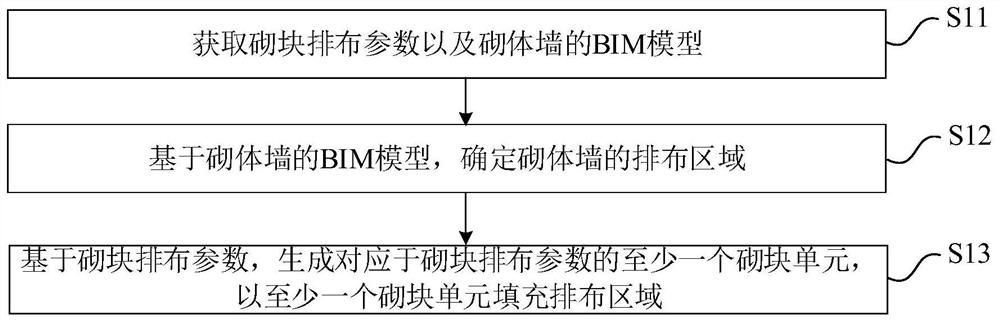

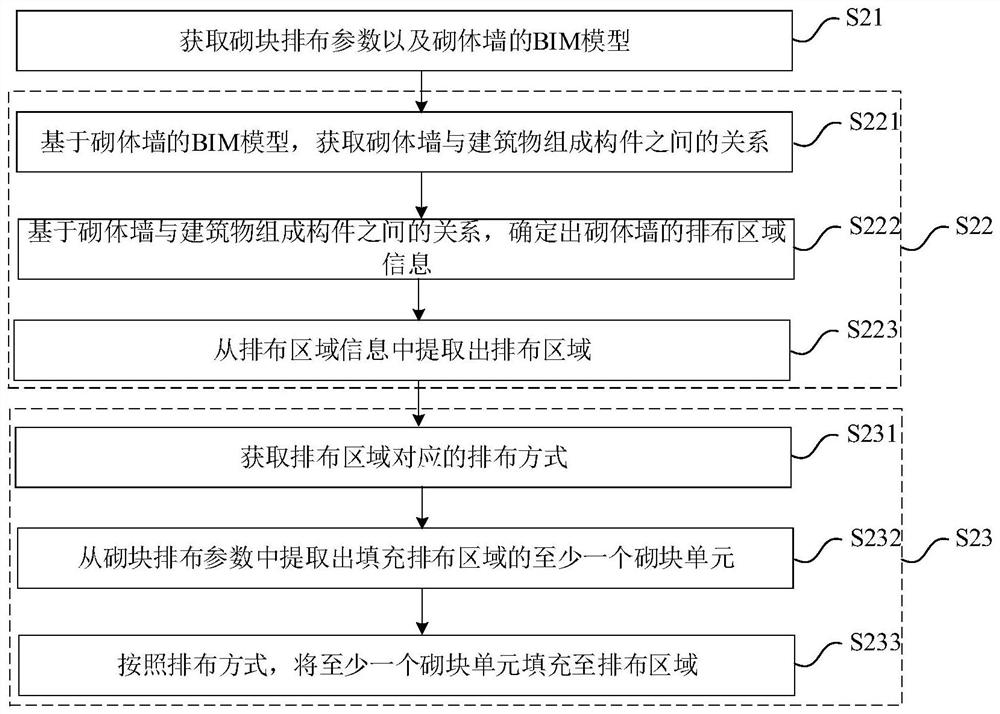

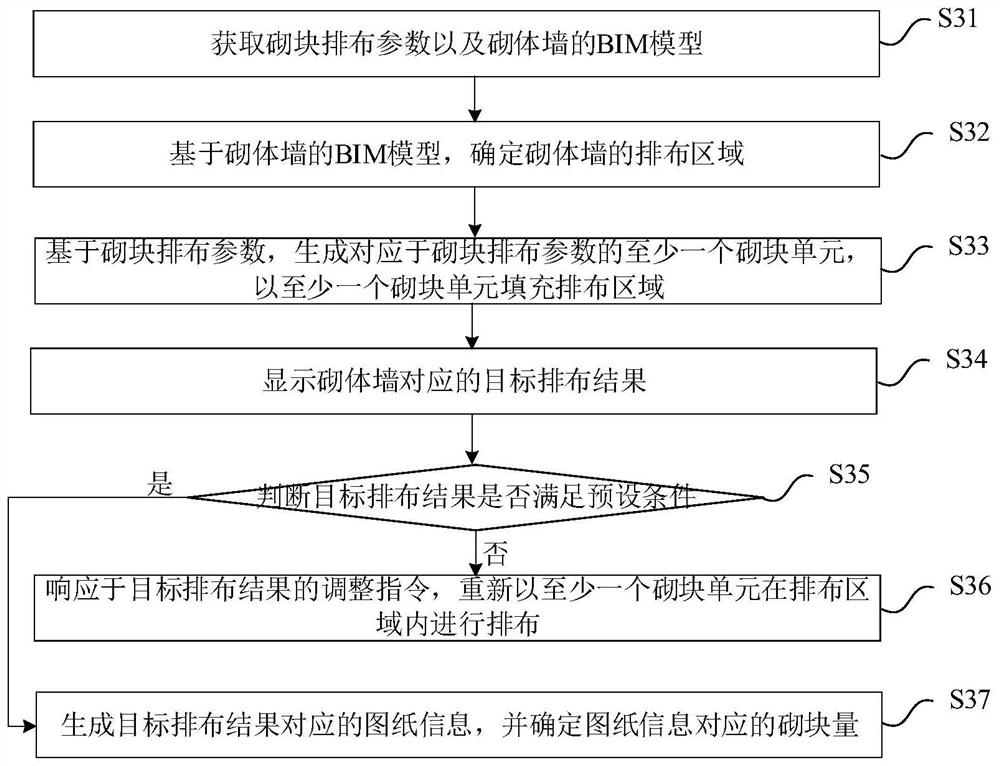

Masonry arrangement method and device, electronic equipment and readable storage medium

PendingCN113553640AReduce cuttingSave human effortGeometric CADDesign optimisation/simulationElectronic equipmentArchitectural engineering

The invention relates to the technical field of engineering construction, and discloses a masonry arrangement method and device, electronic equipment and a readable storage medium. The method comprises the steps: acquiring building block arrangement parameters and a BIM model of a masonry wall; based on the BIM model of the masonry wall, determining an arrangement area of the masonry wall; and on the basis of the building block arrangement parameters, generating at least one building block unit corresponding to the building block arrangement parameters, and filling the arrangement area with the at least one building block unit. By means of the automatic arrangement method and device, automatic arrangement of the masonry wall is achieved, meanwhile, the arrangement area is filled according to at least one building block unit, standard building blocks are used for arrangement as much as possible, cutting of the standard building blocks is reduced, and therefore manpower is saved, and the construction cost is reduced.

Owner:GLODON CO LTD

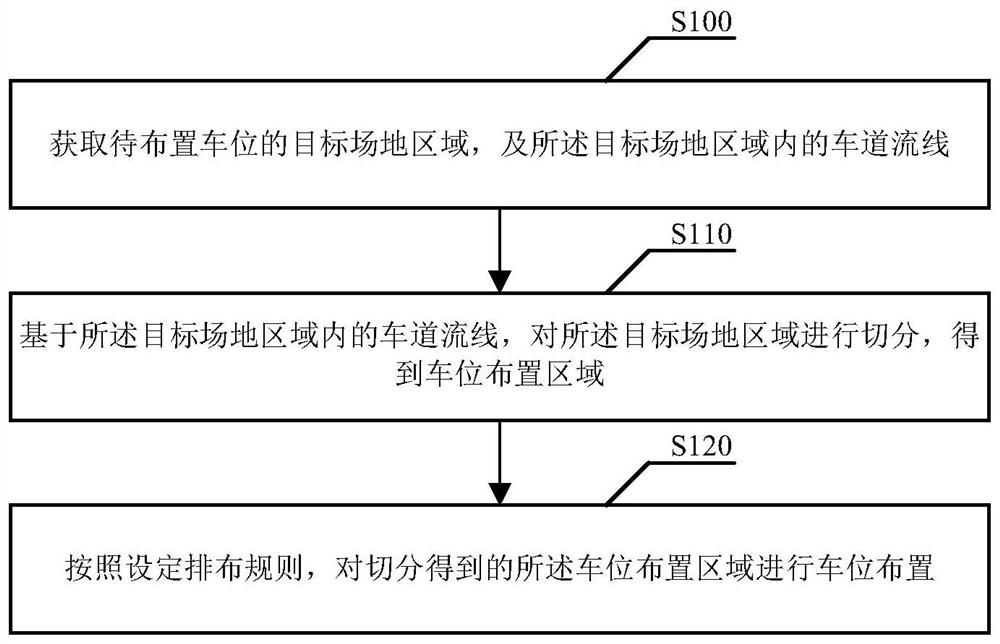

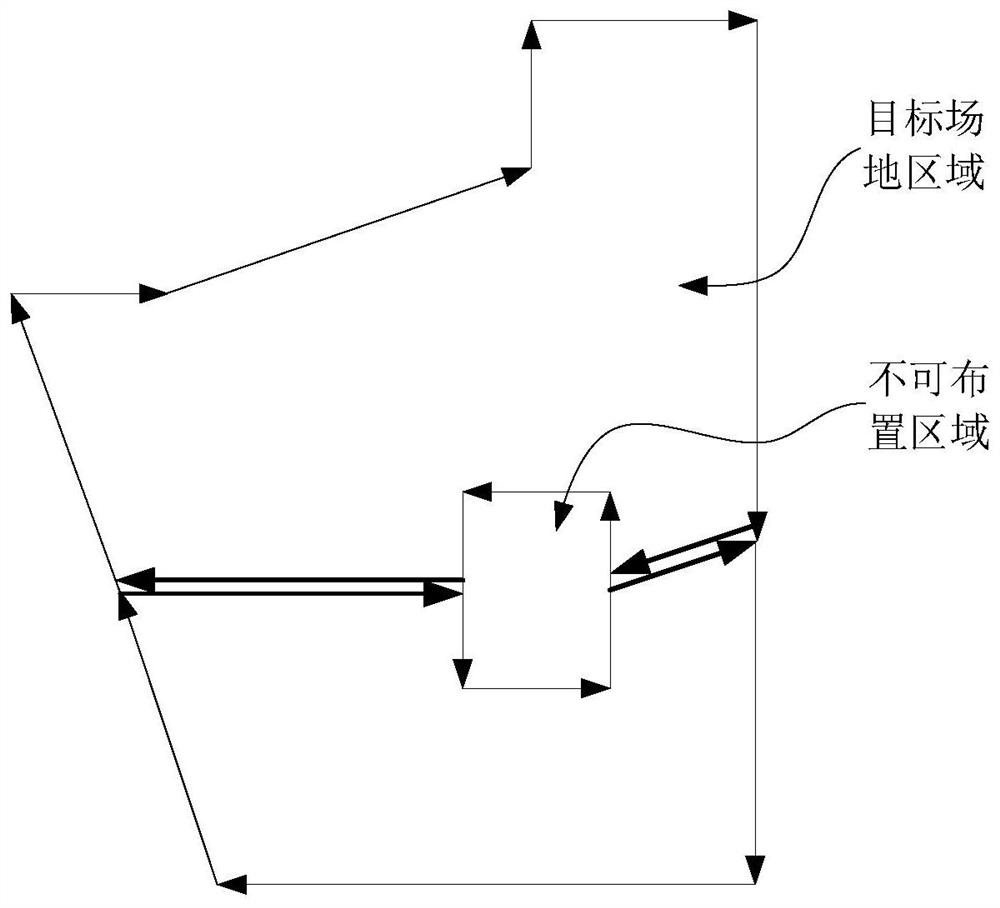

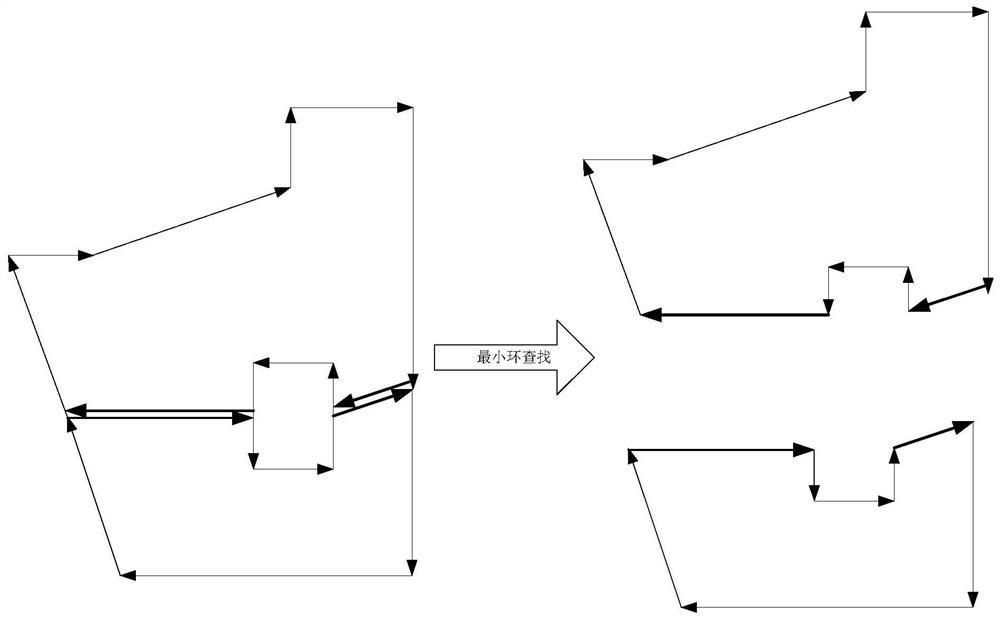

Parking space arrangement method, device and equipment and storage medium

PendingCN113158296ARealize automatic layoutFast layout efficiencyGeometric CADSpecial data processing applicationsAutomotive engineeringParking space

The invention discloses a parking space arrangement method and device, equipment and a storage medium, and the method comprises the steps: obtaining a lane streamline in a target site region of a to-be-arranged parking space, enabling the lane streamline to be used for indicating the center line of a lane, and carrying out the segmentation of the target site region based on the lane streamline; obtaining the parking space arrangement areas used for arranging the parking spaces after segmentation, carrying out parking space arrangement on the parking space arrangement areas according to the set arrangement rule, and achieving automatic parking space arrangement of the target site area. Compared with the mode that the parking spaces are manually arranged one by one by a designer, the scheme is higher in automation degree, higher in parking space arrangement efficiency and shorter in consumed time.

Owner:合肥量圳建筑科技有限公司

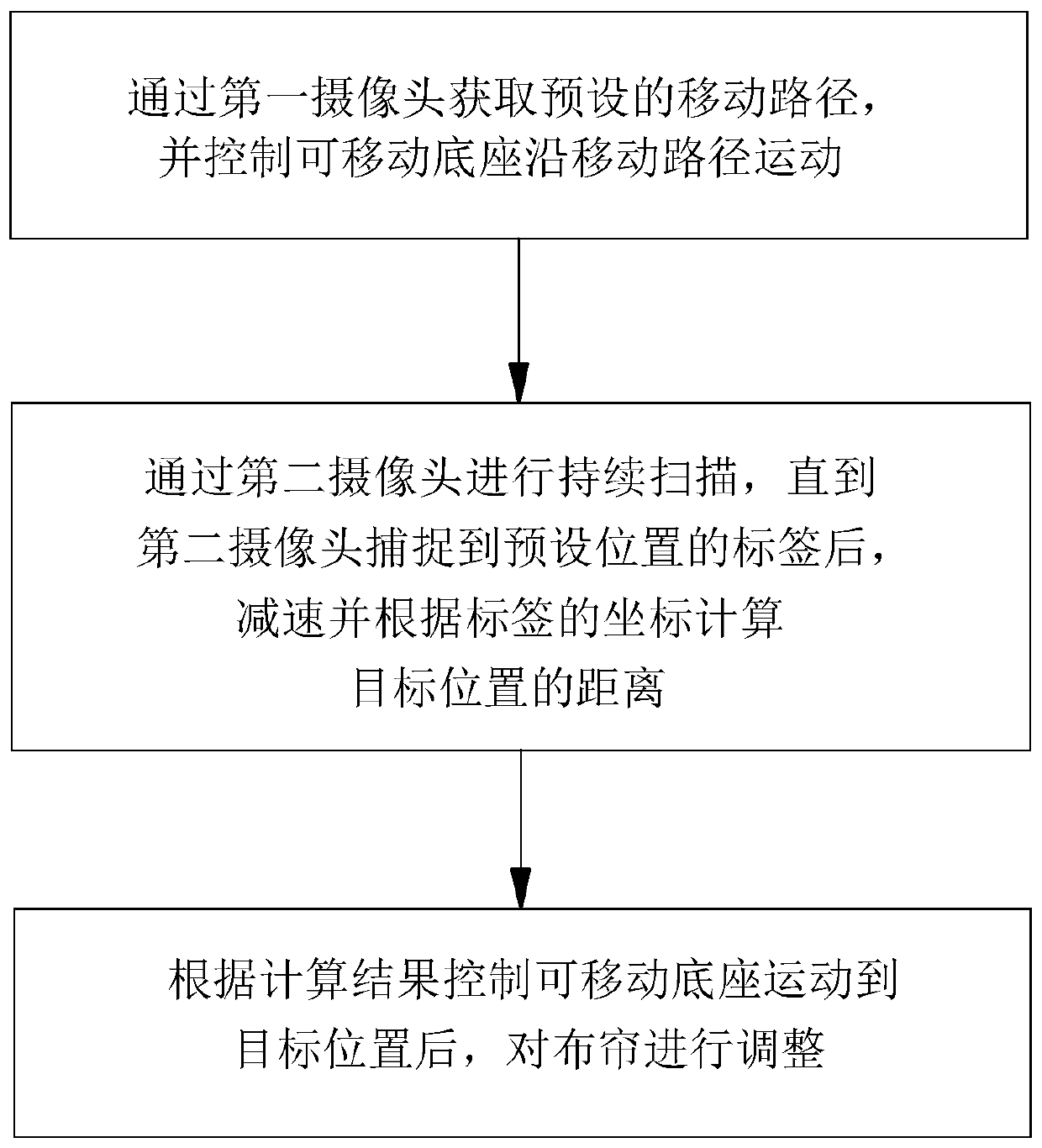

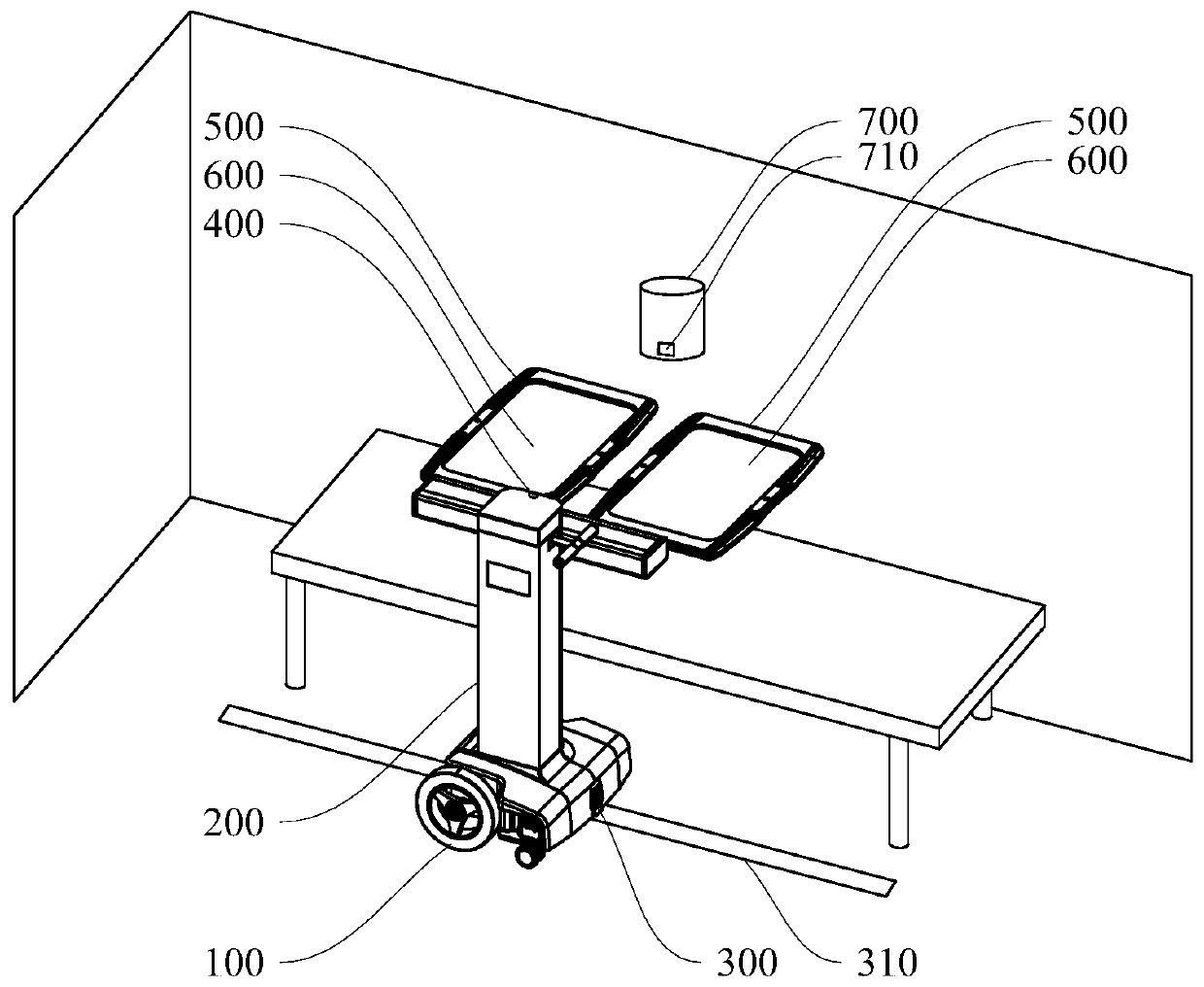

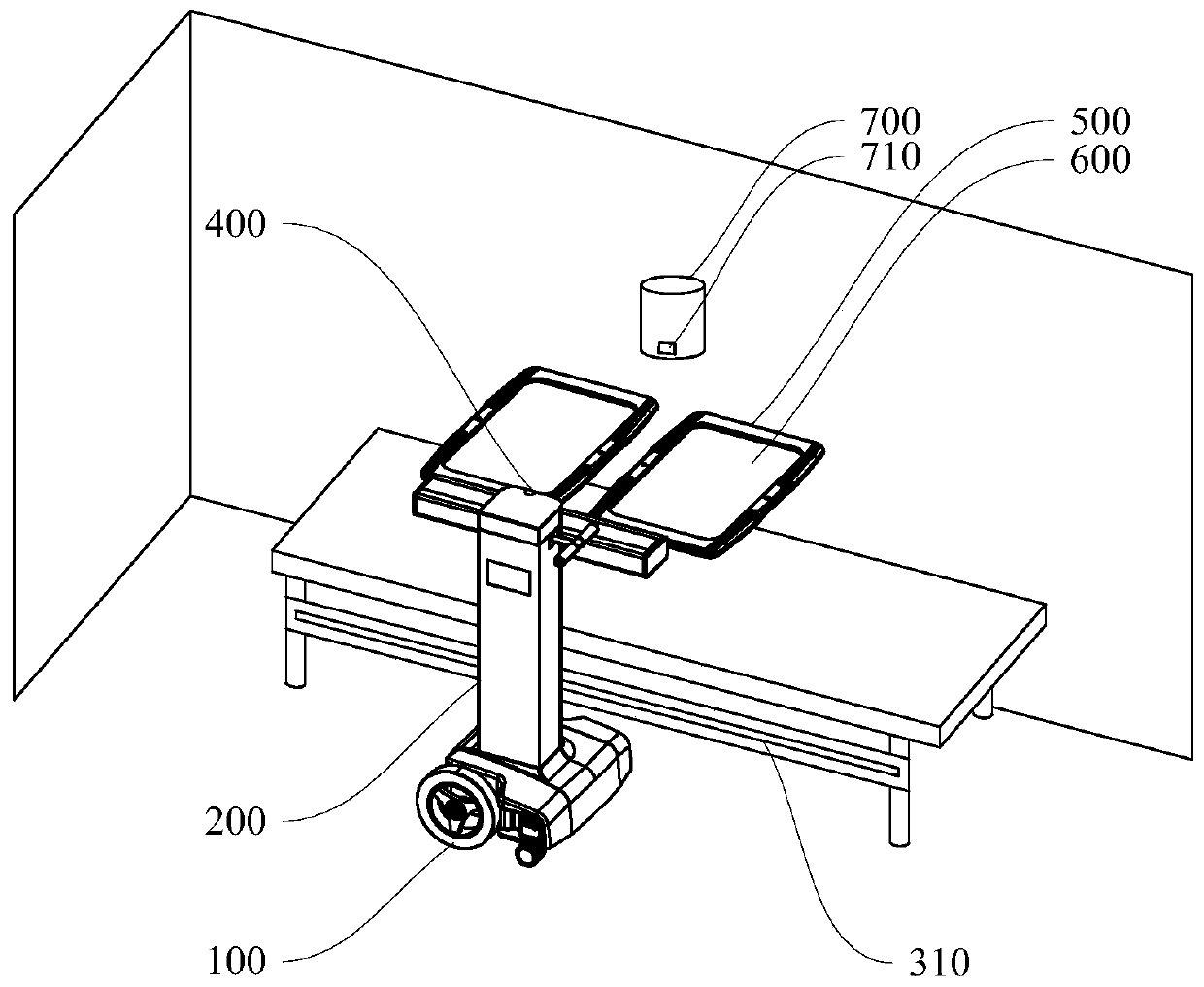

X-ray protection device control method and X-ray protection device

ActiveCN111110266ARealize automatic layoutSave installation spaceRadiation diagnostic device controlRadiation safety meansComputer hardwareContinuous scanning

The invention discloses an X-ray protection device control method and an X-ray protection device. The method comprises the following steps of obtaining a preset moving path through a first camera, andcontrolling a movable base to move along the moving path; performing continuous scanning through a second camera until the second camera captures a label in a preset position; performing deceleration, and calculating the distance to a target position according to the coordinate of the label; and after the movable base is controlled to move to the target position according to the calculation result, regulating a cloth curtain. The moving path is obtained through the first camera; the automatic tracking is realized in an image processing mode, so that entity tracks can be omitted; the cost andthe installing space of the entity tracks can be saved; the label of the preset position is captured through the second camera; the fixed-point placement is realized; the cloth curtain is regulated after the target position is reached; the automatic arrangement of the X-ray protection device can be realized; and the time and the labor are favorably saved.

Owner:珠海威瑞医疗科技有限公司

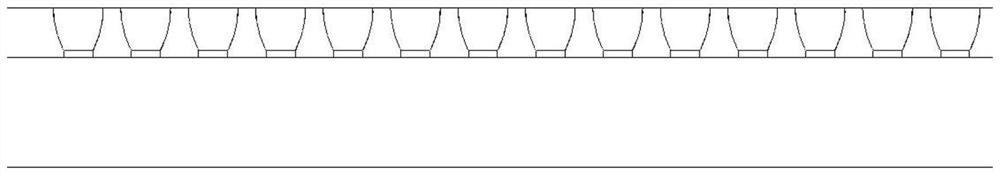

Small-hole gravity type solder ball array method and process

InactiveCN112289693ARealize automatic layoutIncrease production capacitySolid-state devicesSemiconductor/solid-state device manufacturingSolder ballEngineering

The invention discloses a small-hole gravity type solder ball array method and process, and the method comprises the following steps: arranging a solder ball discharging plate on an operation platformwhich can achieve the inclination and turnover control, and arranging a ball taking and feeding plate which can move left and right and up and down above the solder ball discharging plate, processingarray type cup-shaped miniature small holes in the upper solder ball taking plate and a lower solder ball taking plate, the cup-shaped miniature small holes in the upper solder ball taking plate corresponding to the cup-shaped miniature small holes in the lower solder ball plate, and installing vacuum cavity supporting plates at the bottom of the lower solder ball plate and the top of the upper solder ball taking plate. And the vacuum cavity in a vacuum cavity support plate is communicated with the cup-shaped micro small holes in the solder ball lower ball plate and the ball taking upper ballplate. The solder ball bin is controlled to enable the solder balls to fall onto the ball discharging plate under the action of gravity and negative pressure, then the solder balls are controlled toreset and close the negative pressure of the ball discharging plate, the redundant solder balls are taken away under the dual action of gravity and a scraper, the ball taking and feeding plate is controlled to transfer the solder balls into the solder balls, and the capacity of full-automatic BGA packaging production is improved. And the implantation precision and the ball mounting efficiency of the solder balls are improved.

Owner:深圳市立可自动化设备有限公司

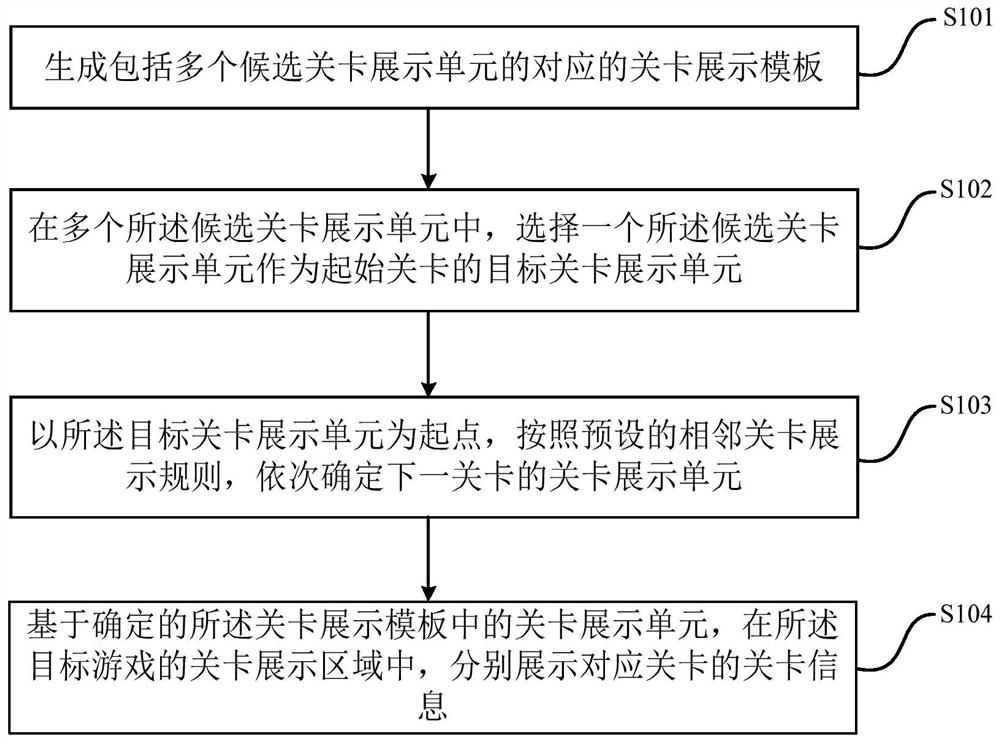

Display method and device of level information, computer equipment and storage medium

ActiveCN113713396AIncrease flexibilityRealize automatic layoutVideo gamesComputer hardwareEngineering

The invention provides a level information display method and device, computer equipment and a storage medium. The method comprises steps of generating a level display template comprising a plurality of candidate level display units; selecting one candidate level display unit from a plurality of candidate level display units as a target level display unit of the starting level; sequentially determining the level display unit of the next level according to a preset adjacent level display rule by taking the target level display unit as a starting point; and based on the level display unit in the determined level display template, respectively displaying the level information of the corresponding level in the level display area of the target game. According to the method, automatic arrangement of levels can be realized, and flexibility of the arrangement position can be realized while the arrangement of the levels meets a certain regularity.

Owner:BEIJING ZITIAO NETWORK TECH CO LTD

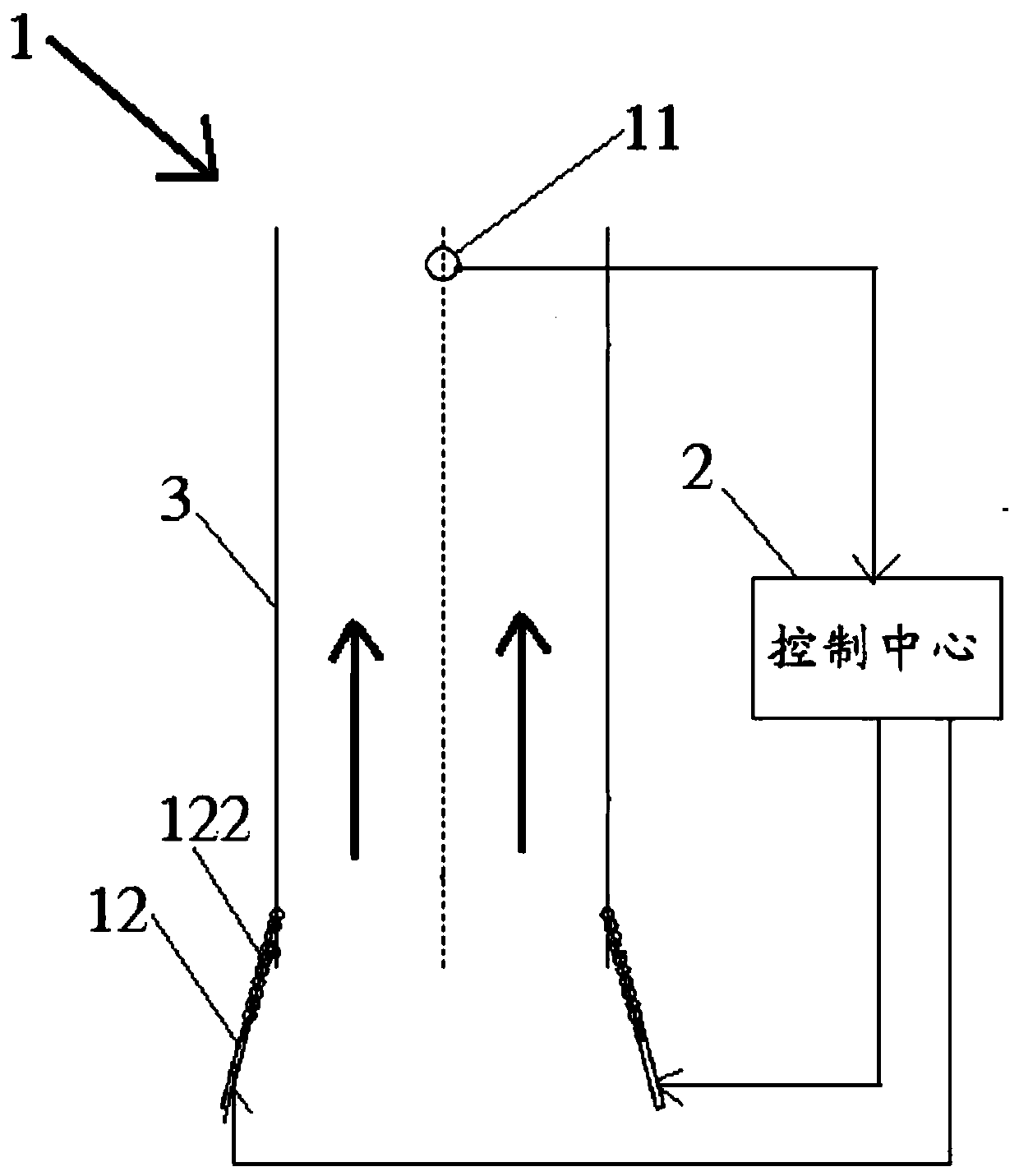

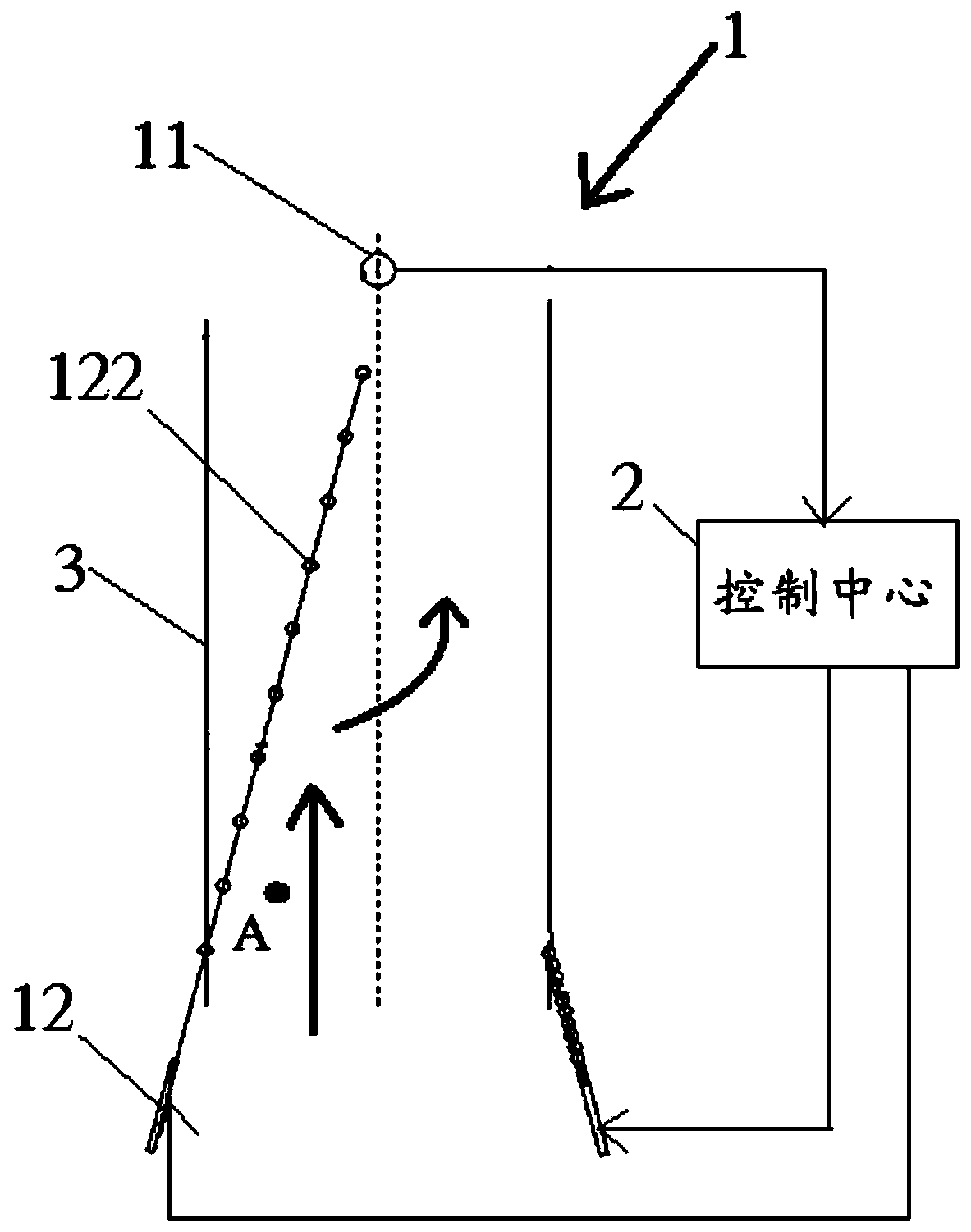

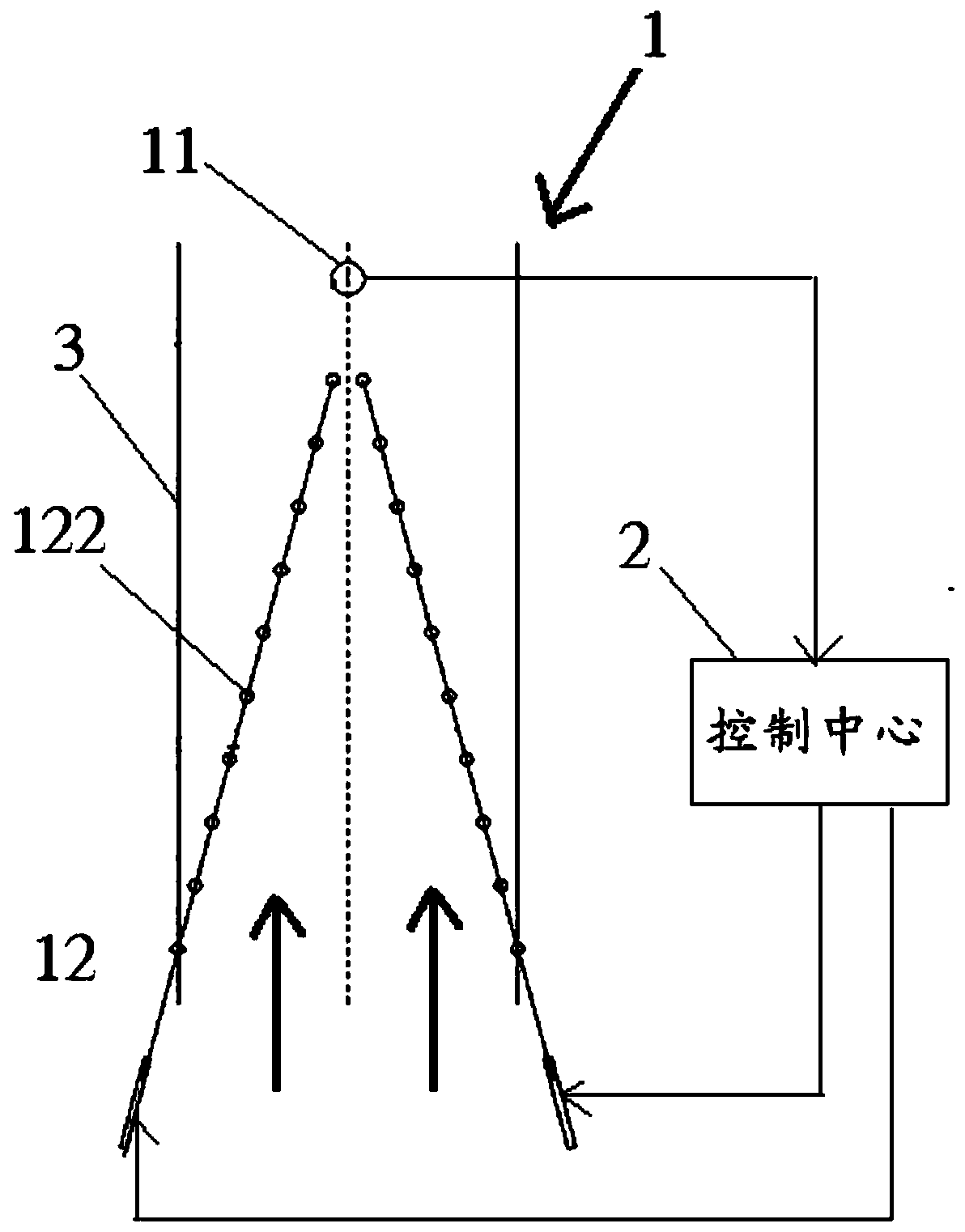

Automatic retracting and releasing device and method for traffic cone isolation belt

PendingCN110765959AAvoid the risk of secondary traffic accidentsSolve potential safety hazardsImage enhancementImage analysisRoad traffic safetyStructural engineering

The invention discloses an automatic retracting and releasing device and method for a traffic cone isolation belt, and belongs to the technical field of traffic safety. The device comprises a plurality of groups of automatic folding and unfolding units arranged along the driving direction and a control center. Each group of automatic retracting and releasing unit comprises a multi-stage hydrauliccylinder and a laser radar. When the multi-stage hydraulic cylinder is in a contraction state, each stage of oil cylinder is provided with an extending section on which a traffic cone is fixed. The multi-stage hydraulic cylinder is obliquely arranged relative to the roadside line in a contraction state. The laser radar is arranged in the center of the top of the tunnel, detects road surface pointcloud data and transmits the information to the control center, and the control center judges whether a fault occurs or not according to the received road surface point cloud data and transmits a judgment result to the multi-stage hydraulic cylinder to control the multi-stage hydraulic cylinder to stretch out or draw back. Automatic releasing of the traffic cone isolation belt is achieved, and potential safety hazards caused by manual arrangement are avoided. The response time is short, the layout is timely, and secondary accidents can be effectively avoided.

Owner:CHANGAN UNIV

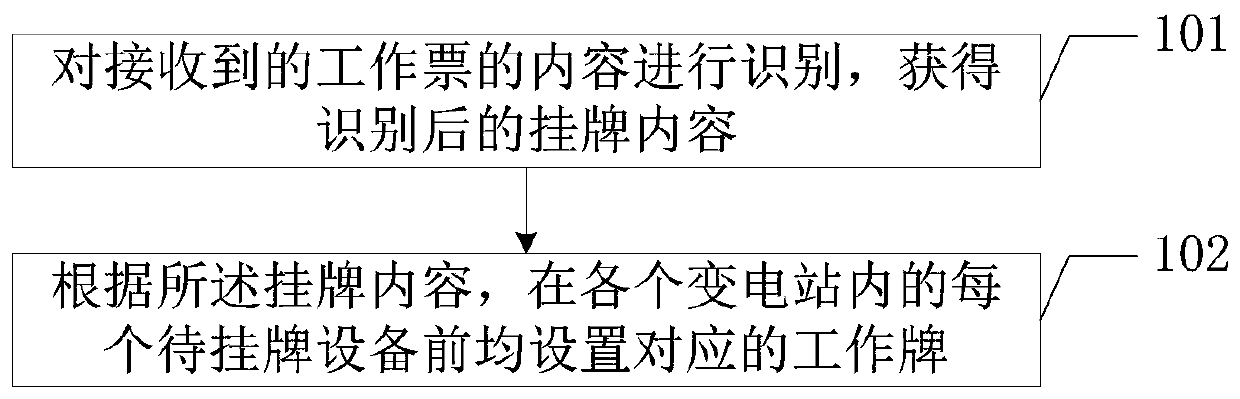

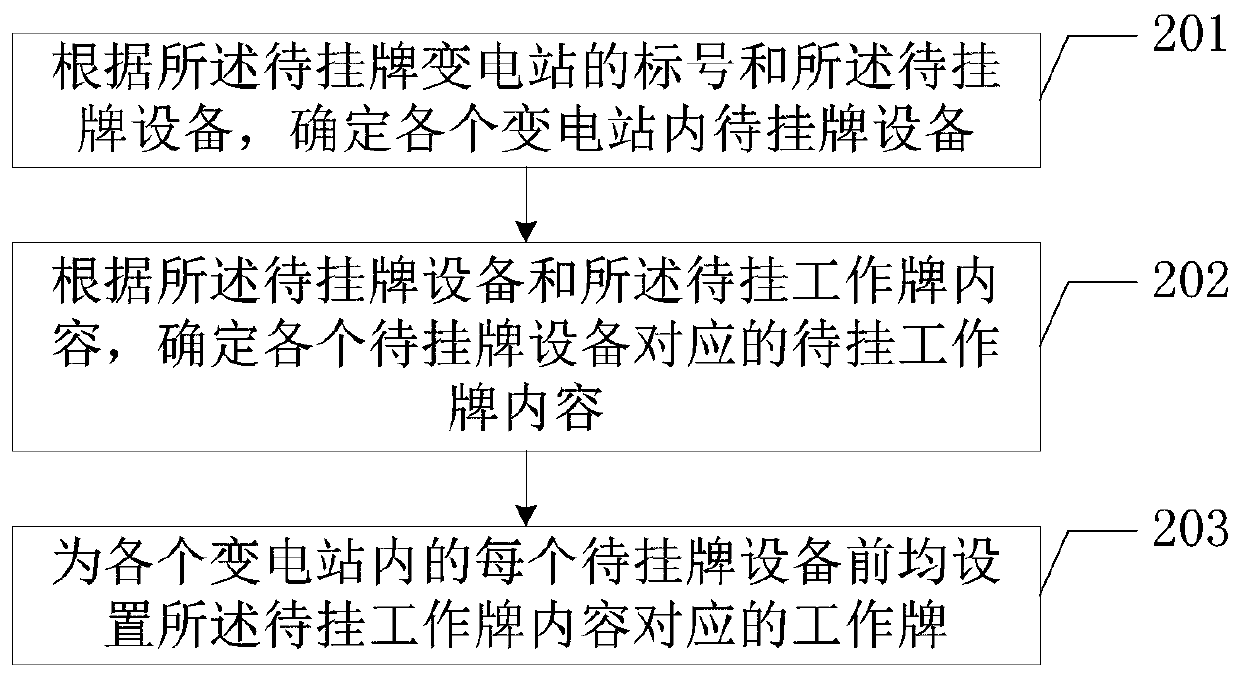

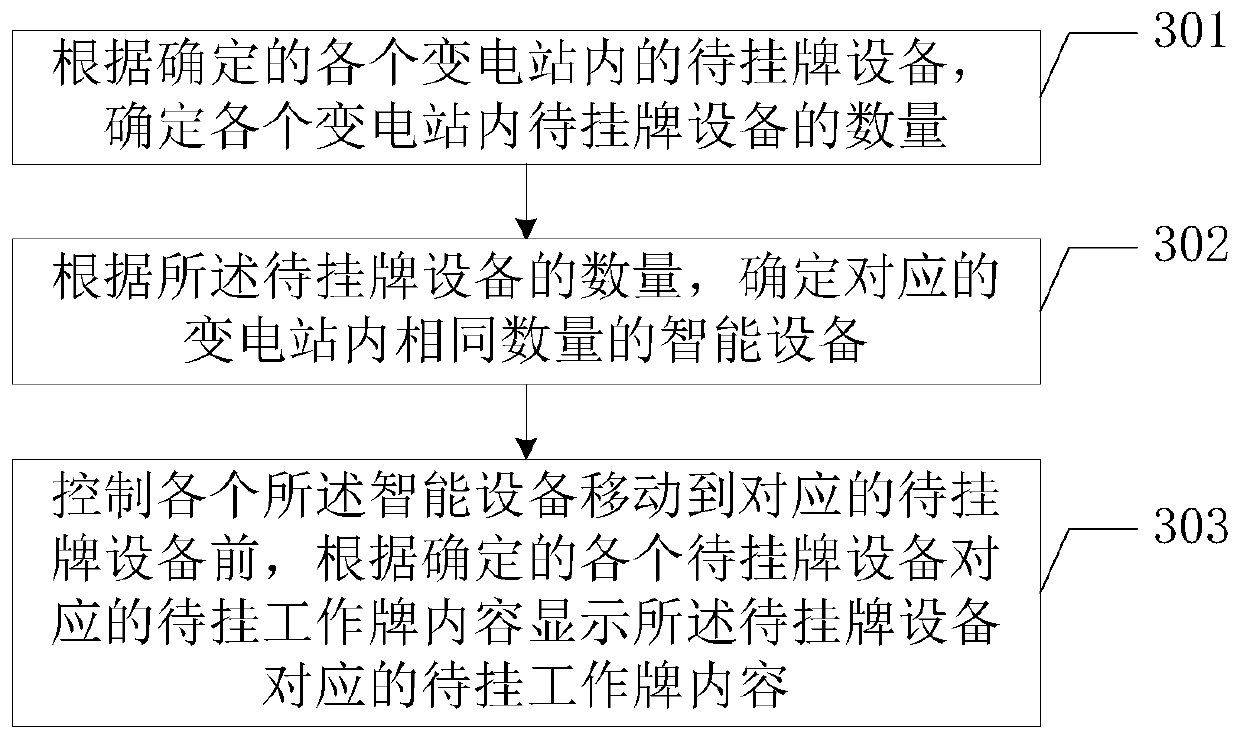

Substation primary equipment work card arrangement method and terminal equipment

InactiveCN110288316ARealize automatic layoutEasy to operateOffice automationTerminal equipmentEmbedded system

The invention is applicable to the technical field of work card setting, and provides a substation primary equipment work card arrangement method and terminal equipment, and the method comprises the steps: identifying the content of a received work ticket, and obtaining identified listing content; and then, according to the listing content, a corresponding work card is arranged in front of each to-be-listed device in each substation, so that automatic arrangement and recovery operation of the work cards in the substations can be realized, the time is effectively saved, and the work efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

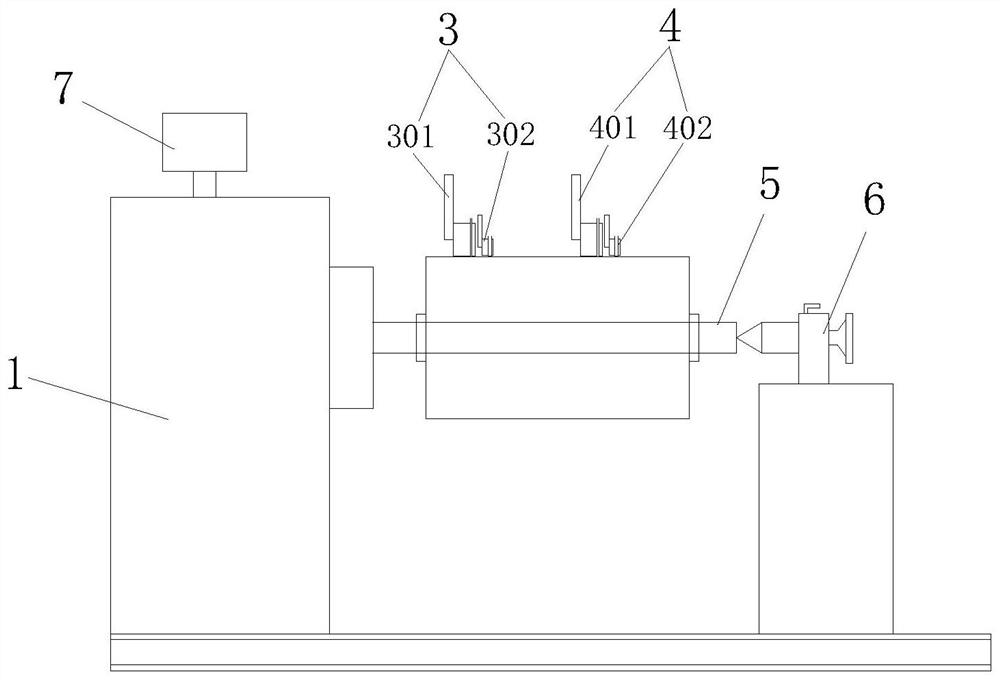

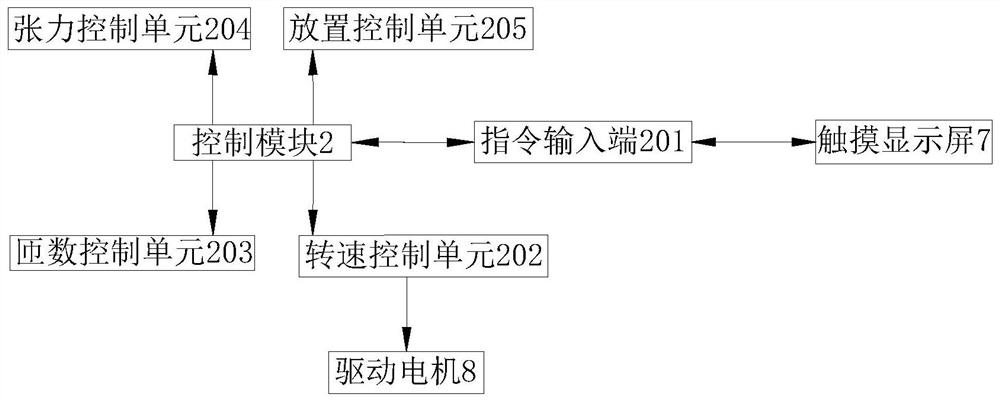

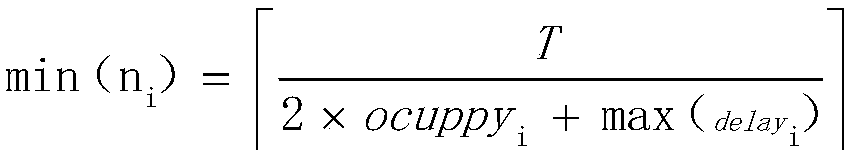

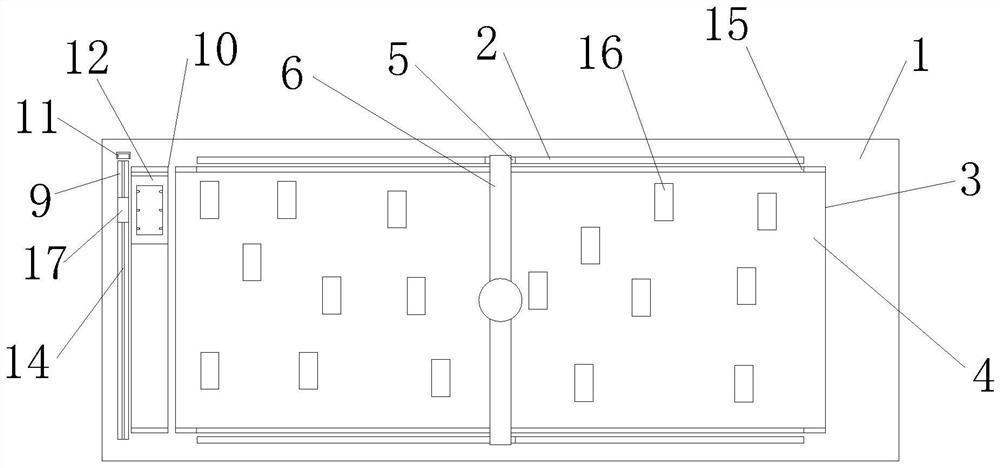

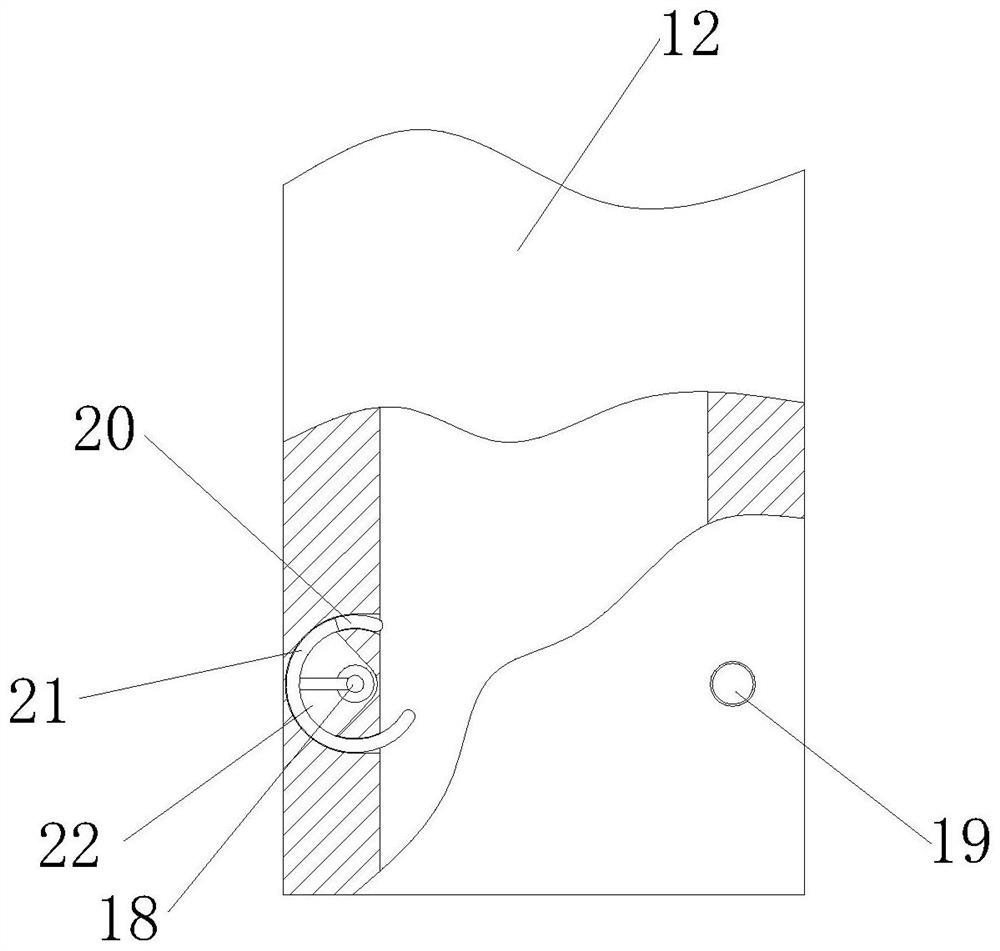

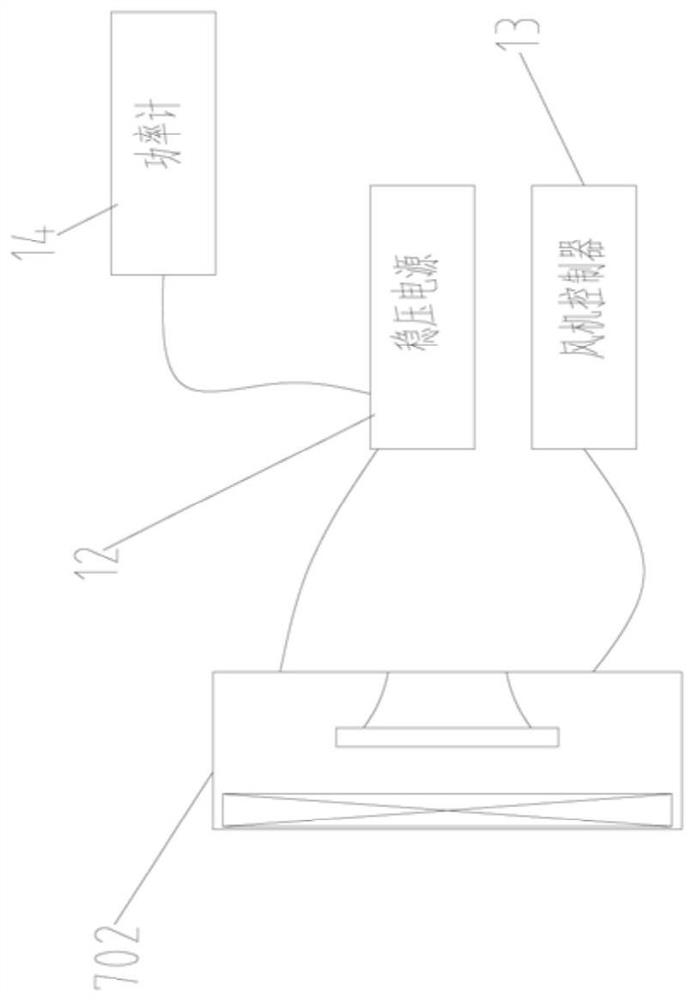

Automatic winding machine for double-end dry-type transformer

PendingCN113571331AQuality improvementRealize automatic layoutCoils manufactureWinding machineControl power

The invention discloses an automatic winding machine for a double-end dry-type transformer. The automatic winding machine comprises a shell, a control module, an instruction input end, a driving motor, a driving shaft, a first winding station and a second winding station, wherein the instruction input end, the driving motor, the driving shaft, the first winding station and the second winding station are connected with the control module. The driving motor is arranged in the shell and connected with one end of the driving shaft, and the control module can control the rotating speed of the driving shaft by adjusting the output power of the driving motor. And the driving shaft is provided with a fixing device for fixing a workpiece. The first winding station is arranged on one side of the driving shaft and comprises a first winding displacement device and a first interlayer insulation winding device. The second winding station comprises a second winding displacement device and a second interlayer insulation winding device. Compared with the prior art, the device has the following advantages that automatic arrangement and interlayer insulation automatic placement of wires can be achieved, the winding speed of a high-voltage coil is greatly increased, and the strength of an operator is reduced. The double winding stations can wind the workpiece at the same time, the overall efficiency can be improved by more than three times, and the production efficiency is further improved.

Owner:广东中顺电气制造有限公司

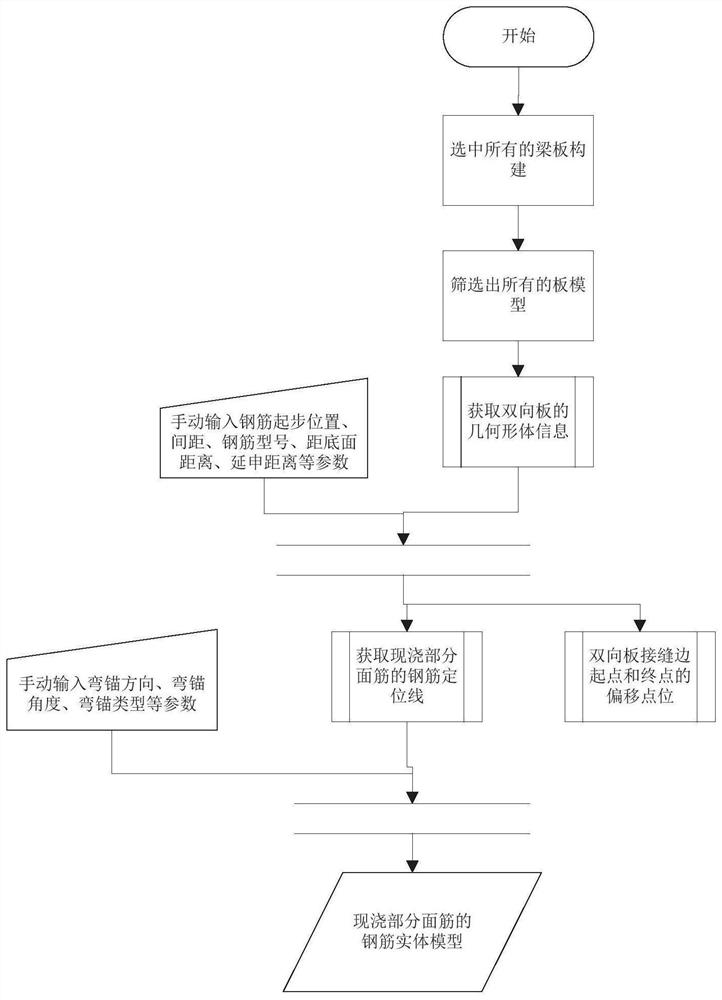

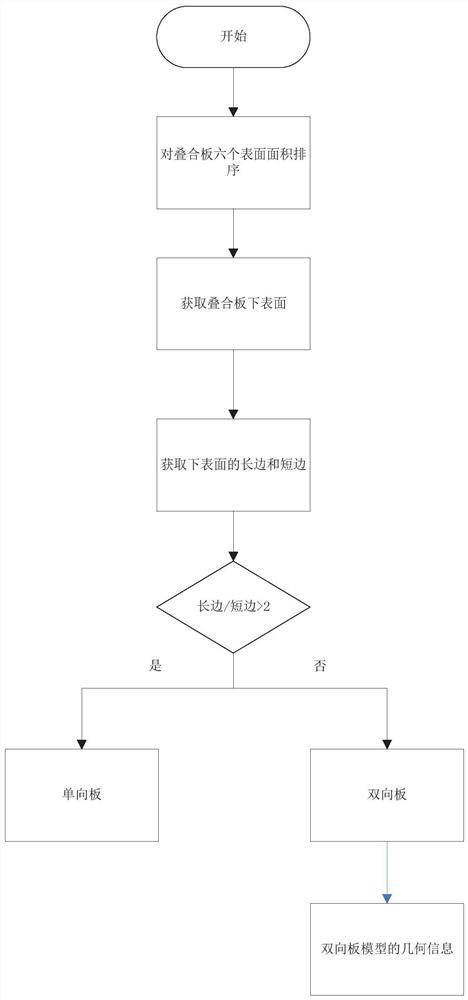

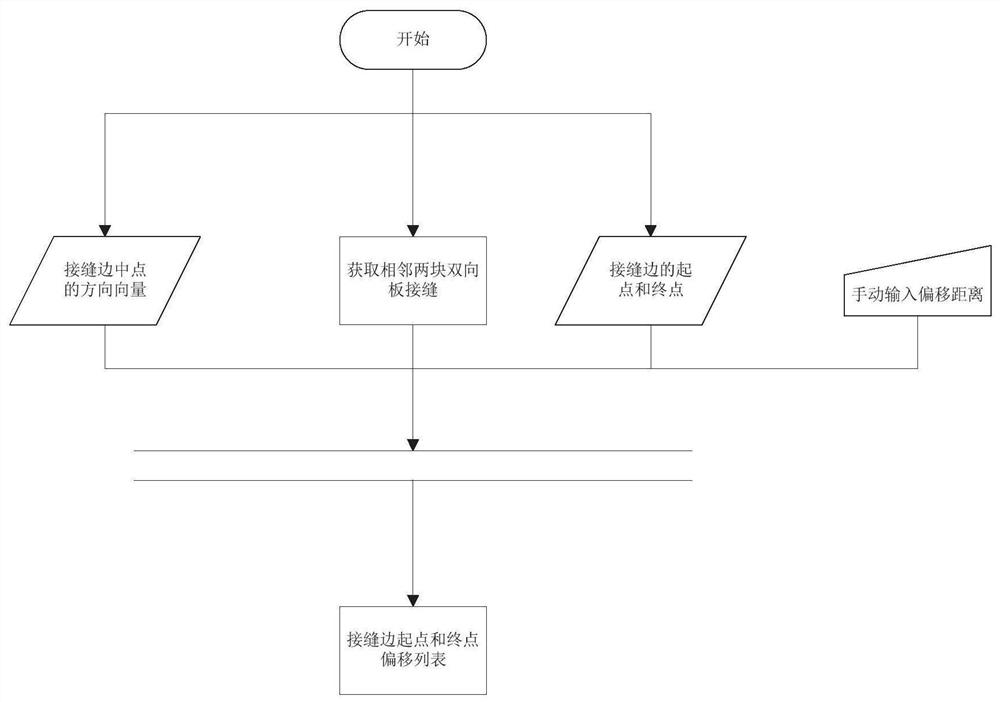

Intelligent arrangement method for two-way laminated slab surface ribs based on close splicing type joint connection technology

ActiveCN113449359ARealize automatic layoutFunction increaseGeometric CADSpecial data processing applicationsRebarMechanical engineering

The invention relates to the technical field of building construction, and discloses an intelligent arrangement method for two-way laminated slab surface ribs based on a close splicing type joint connection technology. The method mainly comprises the following steps of: extracting surface parameters of the two-way plates in a beam plate frame model, and classifying the edges of the two-way plates at different positions in a beam frame, including the edge of a beam frame end support, the edge of a beam frame middle support and the edges of three or more than three two-way plates intersected with the beam frame; and according to the arrangement rule of the cast-in-place steel bars on the surface of the laminated slab, automatically arranging the steel bars on the surface of the two-way slab corresponding to the edges, and finally obtaining a steel bar entity model of long-direction gluten and short-direction gluten of the cast-in-place part of the two-way slab. According to the method, the two-way plates at different positions in the beam frame are accurately positioned, so that reinforcing steel bars on the surfaces of the two-way plates can be adaptively arranged by setting given size, spacing and arrangement position parameters, reinforcing steel bar collision is avoided through accurate reinforcing steel bar positioning lines, and finally, reinforcing steel bar entity models are quickly generated in batches.

Owner:NANCHANG UNIV +2

Ramp rod box

ActiveCN114075932BRealize root-by-root sequential entry and exitReduce labor intensityDrilling rodsDrilling casingsWell drillingOil field

Owner:山东胜油石油工程有限公司 +1

A method for distributing i/o cards used in dcs

ActiveCN104091000BRealize automatic layoutSimple designSpecial data processing applicationsCommunications systemMeasurement point

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

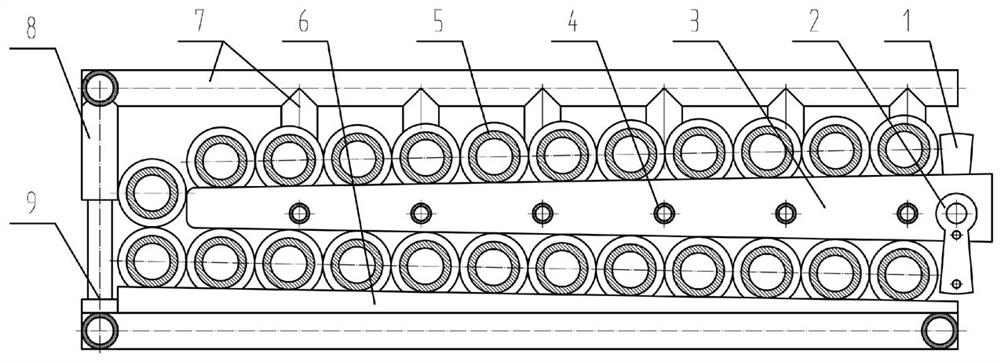

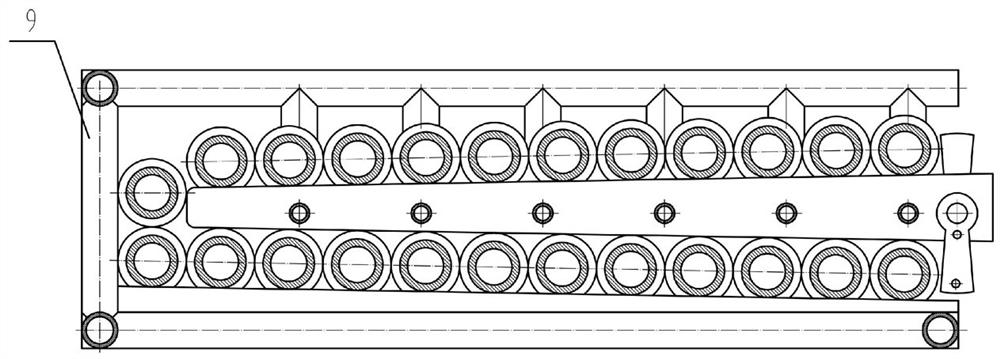

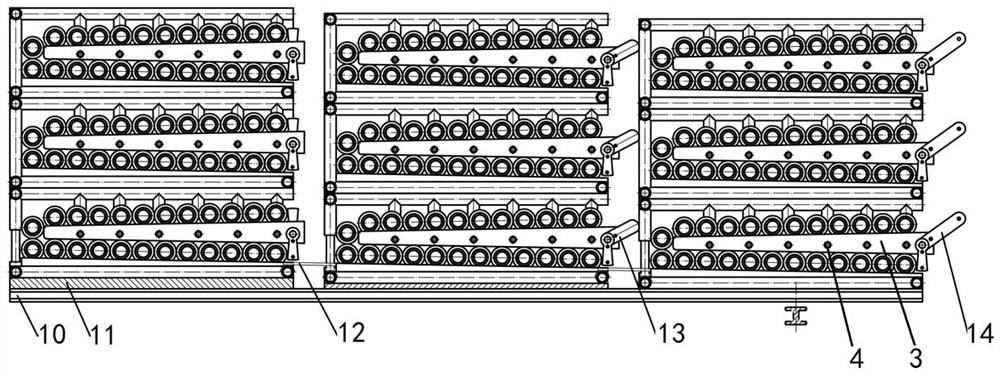

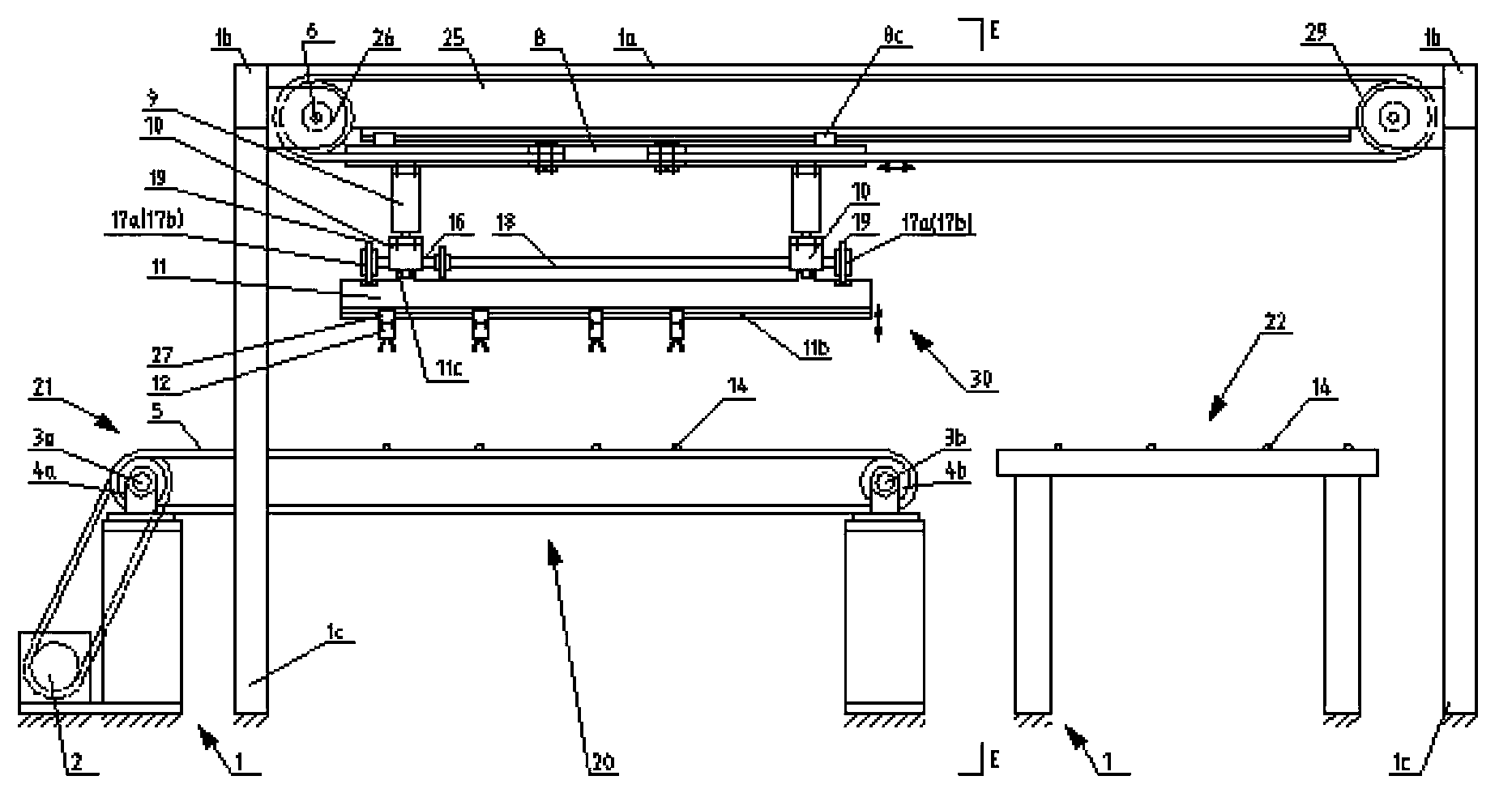

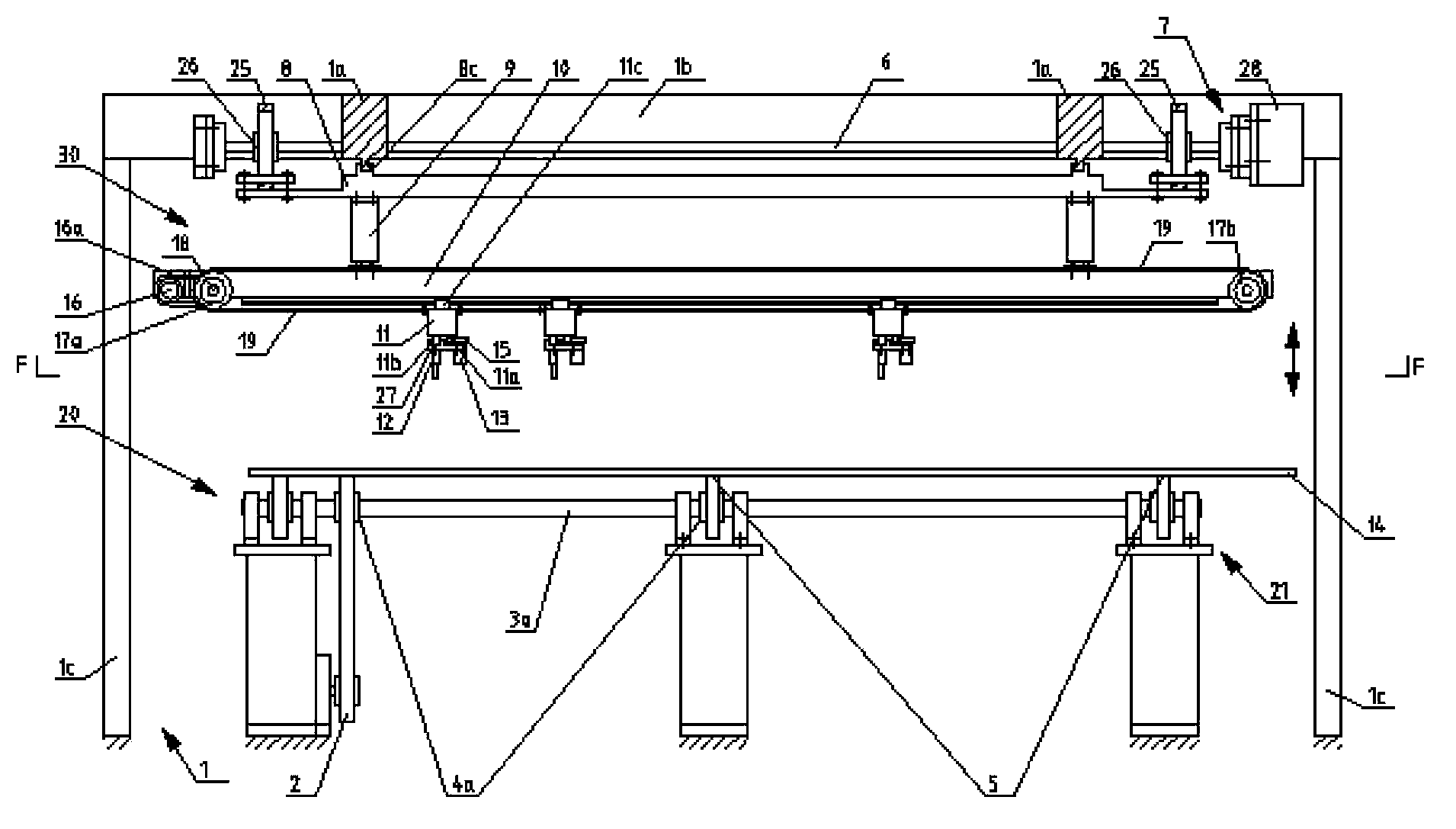

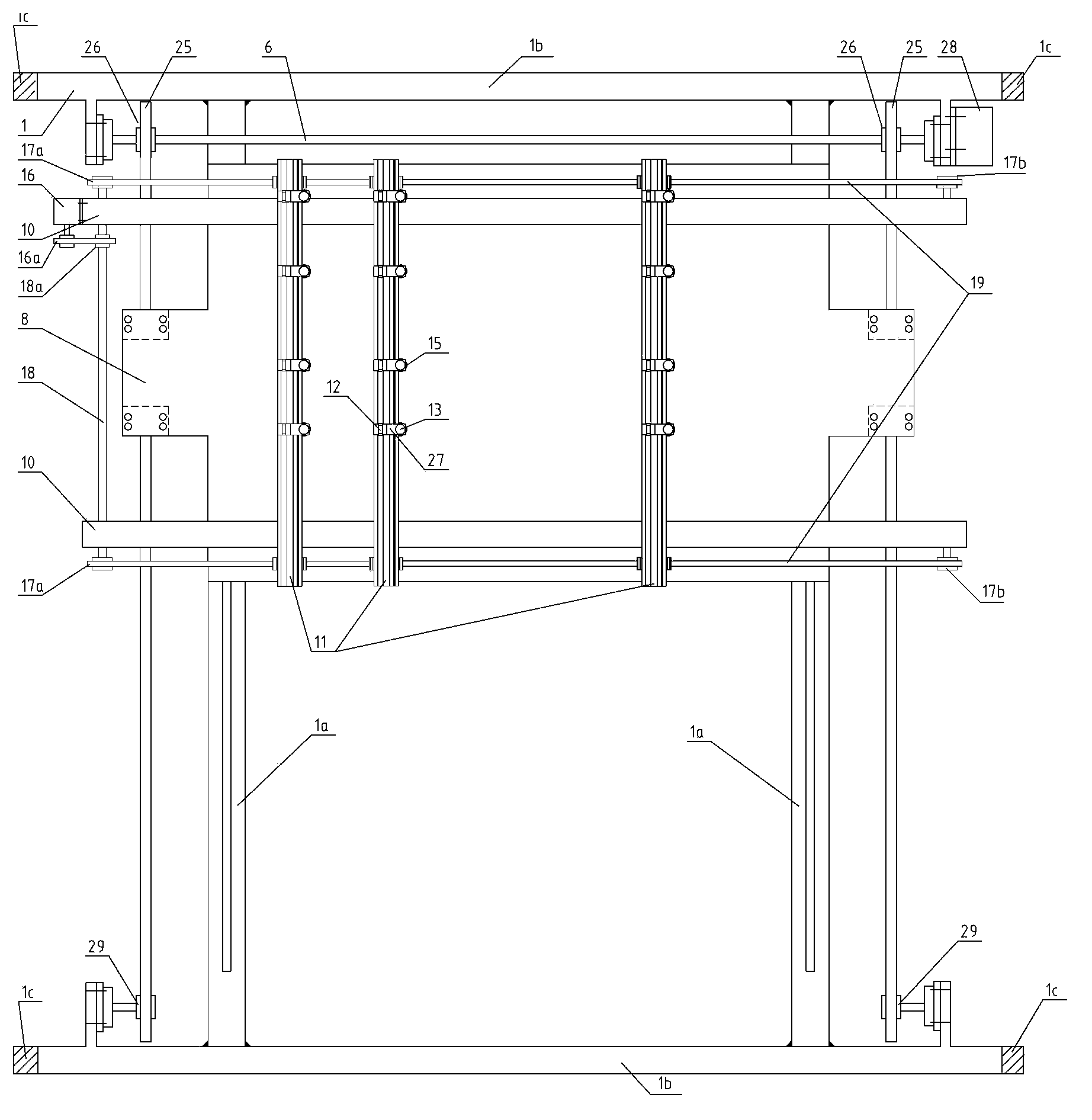

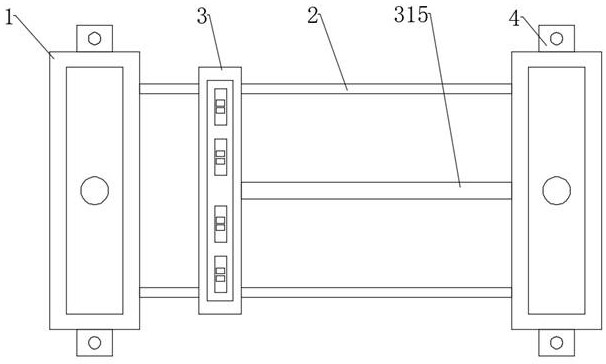

Reinforcing steel bar movement conveying mechanism of welding machine of mesh

The invention discloses a reinforcing steel bar movement conveying mechanism of a welding machine of mesh. The reinforcing steel bar conveying mechanism comprises a machine frame, a reinforcing steel bar movement input mechanism, a reinforcing steel bar movement output mechanism and a mesh welding work table. The reinforcing steel bar movement input mechanism comprises a plurality of horizontal conveying devices, and the reinforcing steel bar movement output mechanism comprises a plurality of longitudinal regulating beams, wherein a plurality of clamping mechanical arms are arranged at the bottom of each longitudinal regulating beam. The upper portion of each longitudinal regulating beam is provided with a transverse sliding block which is matched with the bottom of each transverse regulating beam in a sliding mode and is connected with the bottom of each transverse regulating beam in a hung mode, each transverse regulating beam is connected with a lifting mechanism connected with the lower portion of one conveying movement beam, and the upper portion of each conveying movement beam is hung on an upper longitudinal beam in a sliding match mode and is connected with a conveying driving mechanism which is arranged on an upper transverse beam of the machine frame. The reinforcing steel bar movement conveying mechanism has the advantages that the diameter and the length of each reinforcing steer bar on each horizontal conveying device can be regulated freely, reinforcing steer bar grids having different diameters and different intervals can be welded on the same mesh, market requirements are met, and production efficiency is high.

Owner:TJK MACHINERY TIANJIN

A communication time slot arrangement method based on time-triggered bus

ActiveCN106302062BThe time delay requirement is metRealize automatic layoutBus networksSelf adaptiveComputer science

The invention discloses a communication time slot arrangement method based on a time trigger bus. The method specifically comprises the following steps of setting the number of nodes in a system as n, wherein a time duration of a communication time slot occupied by a node i is ocuppyi, a weight value is wi and a communication period is Ti for the node I, and computing a total communication period T of a network of the system; establishing a constraint condition equation set for the node i according to the real-time requirements for functional communication of the node i, solving multiple groups of solutions related to n1-nN, selecting any group as a distribution scheme of the number of communication time slots of each node, and arranging the nodes to a queue A from big to small or from small to big according to the distributed number of the communication time slots; selecting the nodes from the queue A in sequence and uniformly arranging the communication time slots corresponding to the selected nodes on a time shaft according to the distributed number of the communication time slots; and if the time arranged by the communication time slot corresponding to the node is occupied, arranging the communication time slot after the occupied time. According to the method, the communication frame period can be periodically and adaptively adjusted according to the functions of each node of the time trigger bus.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

Automatic withstand voltage test device for insulation pad

PendingCN114152849AImplement automatic samplingRealize automatic layoutTesting dielectric strengthAutomatic controlStructural engineering

The invention discloses an insulation pad automatic withstand voltage test device which comprises a rack formed by combining or welding metal rods, the rack is divided into a lower layer and an upper layer, the lower layer is sequentially provided with a storage platform, a to-be-tested platform and a test platform from left to right, and an inlet of the test platform is provided with a test compression roller. An unwinding mechanism and a winding mechanism are arranged on the two sides of the testing platform respectively, an electrode overturning mechanism is arranged above the testing platform, and an adsorption moving mechanism is arranged on the upper layer of the testing platform. The device can be used for carrying out power frequency voltage withstanding tests on coiled rubber mats and square rubber mats, is dual-purpose, adopts automatic control, achieves the functions of automatic sampling, automatic arrangement, automatic sample collection and the like, and is high in practicability. Manual intervention is not needed, operation is simple, time and labor are saved, and testing efficiency is improved.

Owner:浙江上检电力检测有限公司

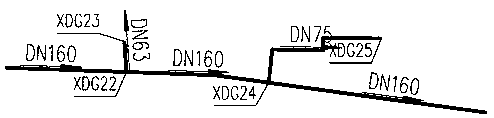

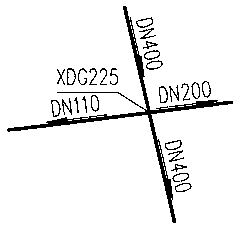

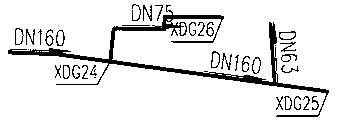

Method of automatically arranging and counting accessories in pipe network design

ActiveCN108763807ARealize automatic layoutGeometric CADSpecial data processing applicationsExhaust valveLine tubing

The invention discloses a method of automatically arranging and counting accessories in pipe network design. The method includes a joint arrangement and counting method, which includes: S11, numberingnodes of a head end and a tail end of each pipeline in the pipe network, and carrying out labeling in a graph, S12, enabling pipe diameters to correspond to node numbers of the head end and the tailend of the pipeline, S13, traversing each pipeline in the pipe network, and judging whether each node of the head end and the tail end of the pipeline is an elbow, a three-way or a four-way, and S14,judging connection pipe diameters, then defining specifications and the accessories corresponding to all the elbows, the three-ways and the four-ways; and also includes a valve well arrangement and counting method, which includes: S21, extracting elevations along the pipeline, S22, generating a profile graph according to a pipeline plane arrangement graph and the extracted elevations along the pipeline, and S23, extracting highest points and lowest points in predetermined ranges in the profile graph, and respectively arranging exhaust valve wells and emptying valve wells. The method of automatically arranging and counting the accessories can improve work efficiency of pipe piece arrangement and counting, and reduce manual job quantity.

Owner:安徽省(水利部淮河水利委员会)水利科学研究院(安徽省水利工程质量检测中心站)

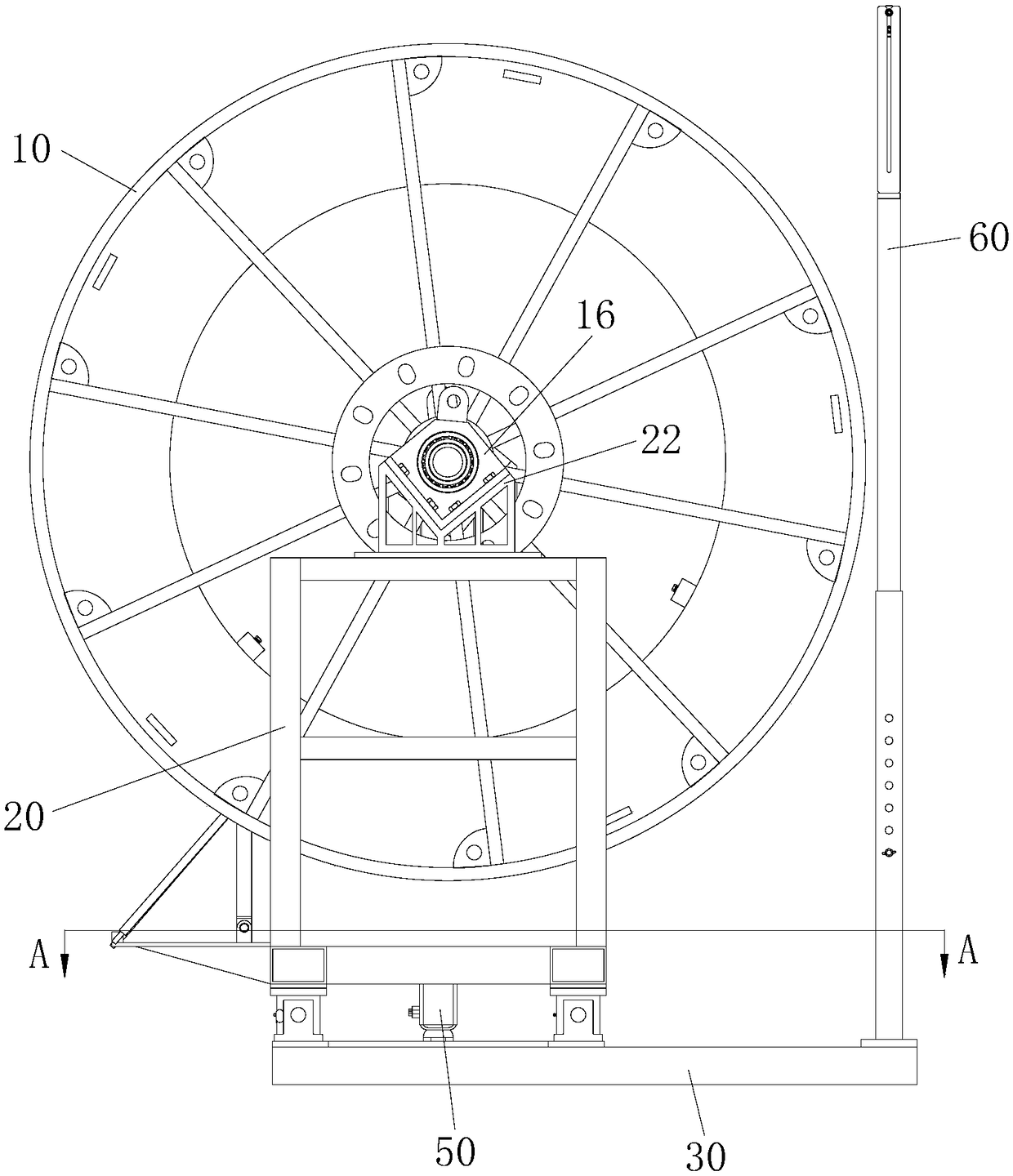

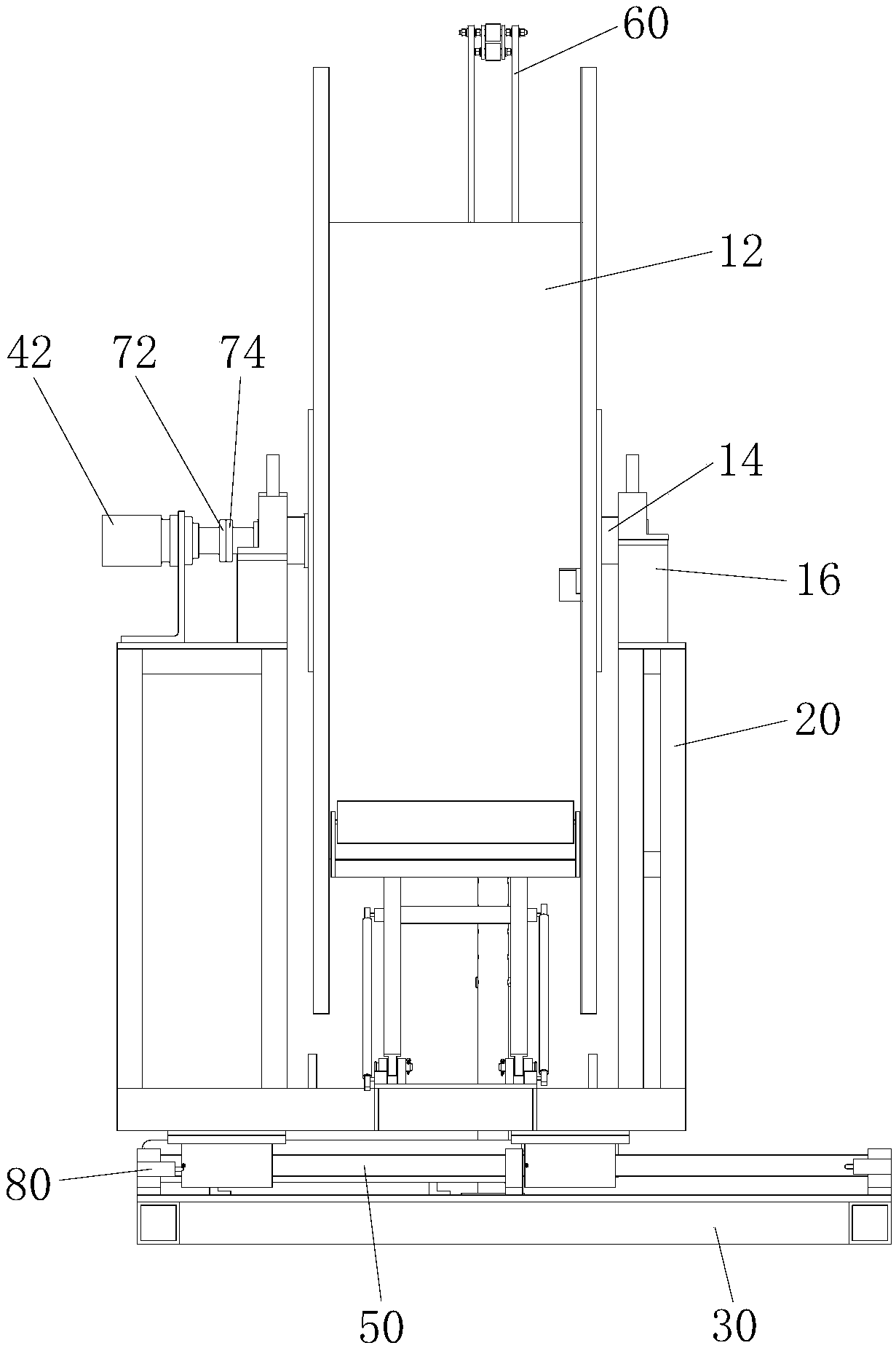

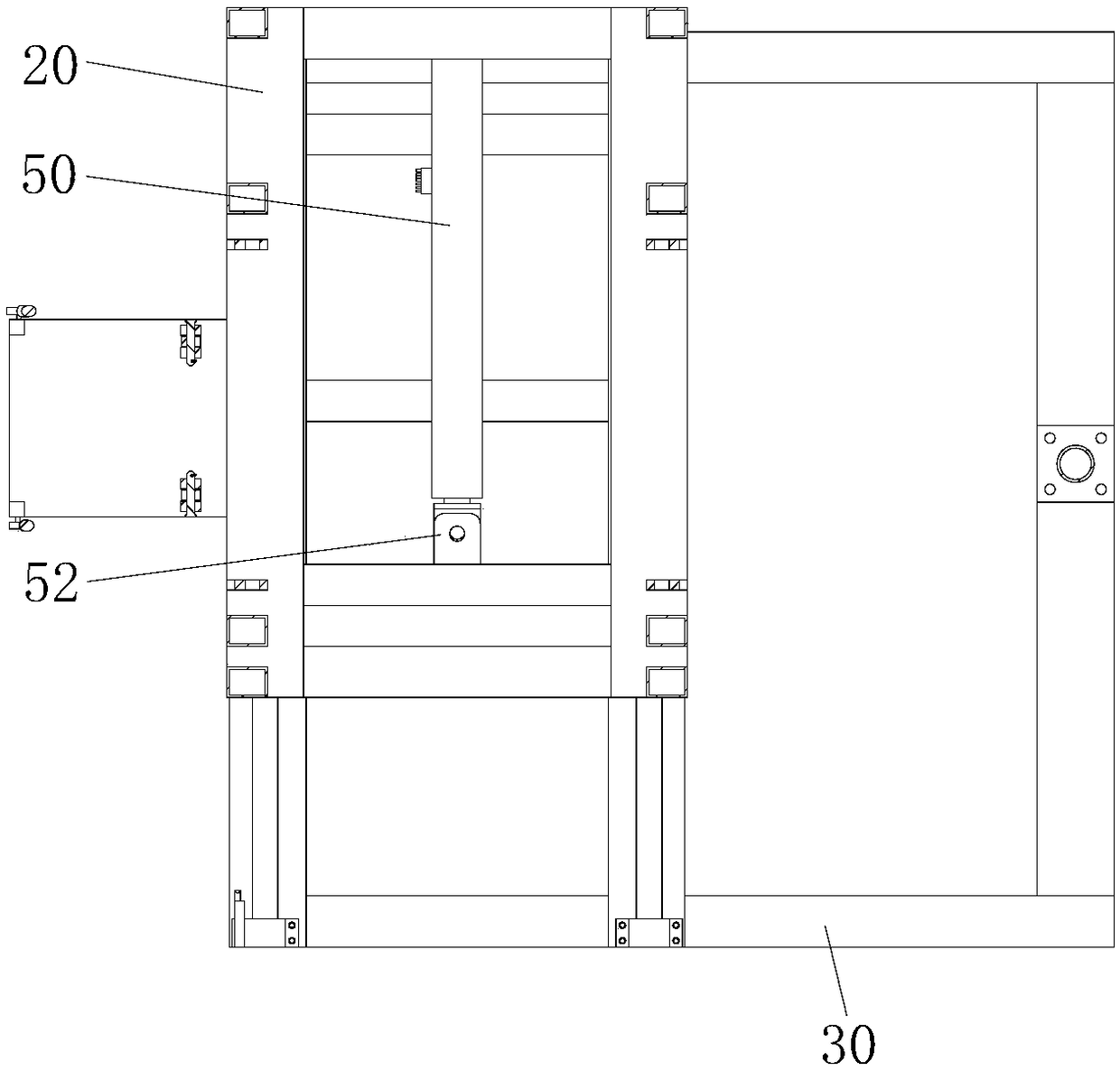

Drum winding device

Owner:BC P INC CHINA NAT PETROLEUM CORP +3

Interactive international trade sand table model

ActiveCN113870681AEasy to replaceUseful for changing placementProjectorsEducational modelsElectric machineryStructural engineering

The invention discloses an interactive international trade sand table model which comprises a rectangular plate, a guide sliding groove, a rectangular groove, a conveying belt, a guide sliding block, a U-shaped frame, a circular groove, a first motor, a strip-shaped groove, a strip-shaped hole, a second motor, a square pipe, a projector, a long screw rod, a base plate, a model distribution block, a screw hole traction block, a transmission rod, a third motor, an arc-shaped spring, an arc rod and a fan-shaped long cavity. The sand table model is reasonable in structure, the model distribution block at the bottom-most part can be loosened conveniently, the model distribution blocks making contact with the upper surface are extruded and fixed through arc springs, the function of placing the model distribution blocks one by one is achieved, the distribution positions of the model distribution blocks can be changed easily, meanwhile a first motor running in a coordinated mode drives a conveying belt to move, model distribution blocks which are placed one by one can be fully distributed on the whole conveying belt, the function of automatically arranging a sand table is achieved, related background scenes can be projected on the surface of the conveying belt, meanwhile, the bottom end of the U-shaped frame is slidably connected with the guide sliding groove through the guide sliding block, and the projection position is convenient to replace.

Owner:QINGDAO HUANGHAI UNIV

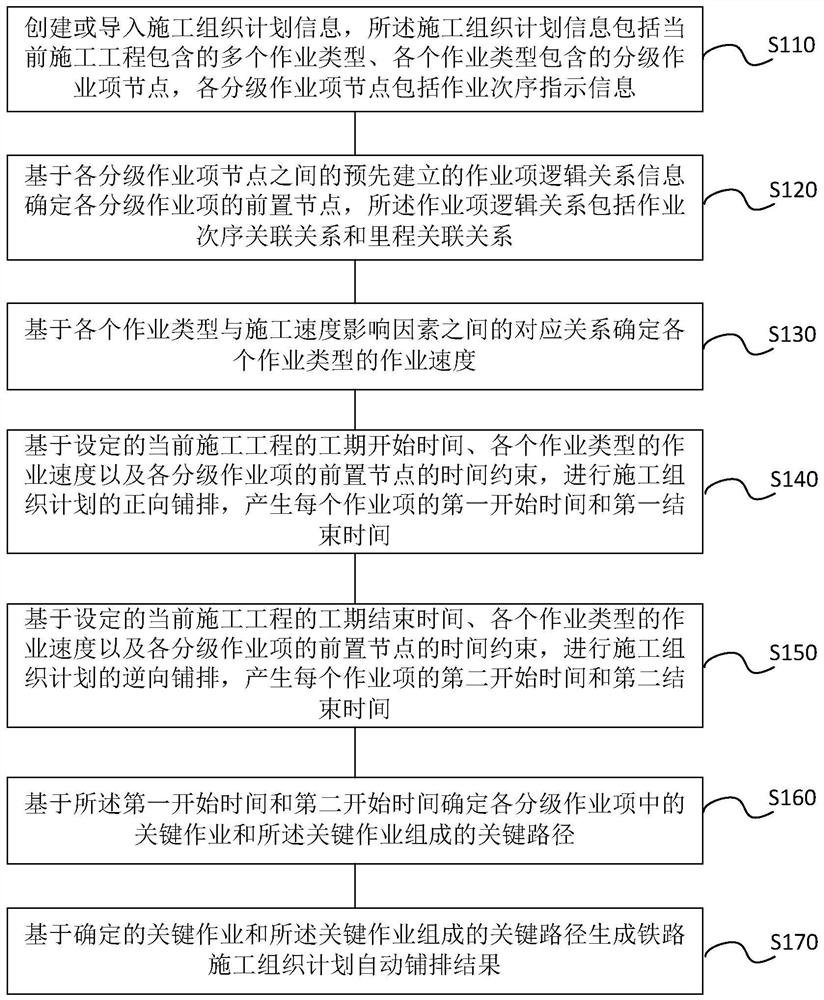

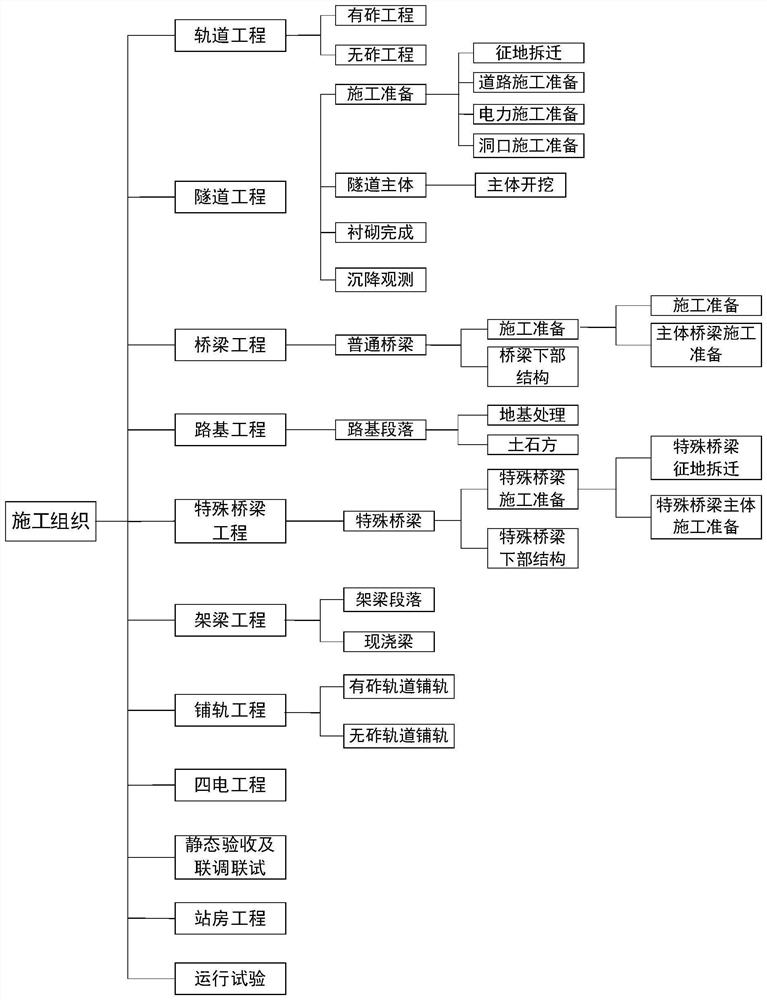

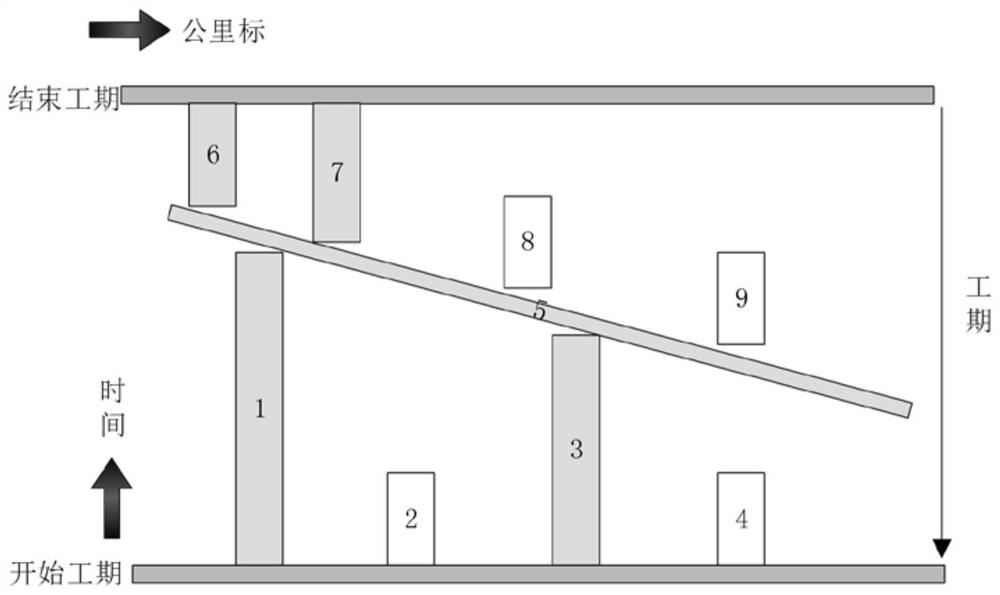

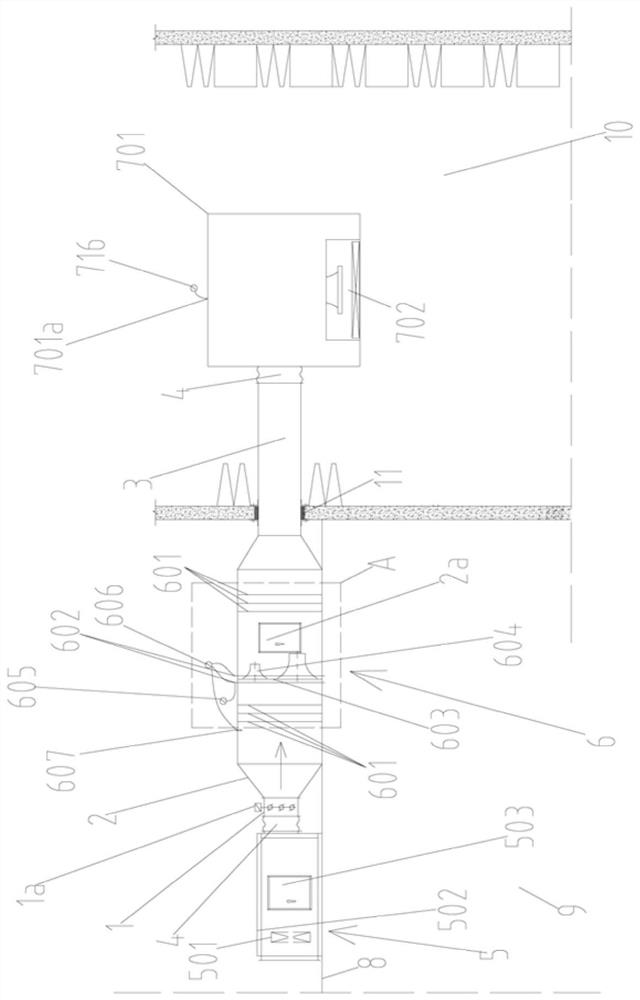

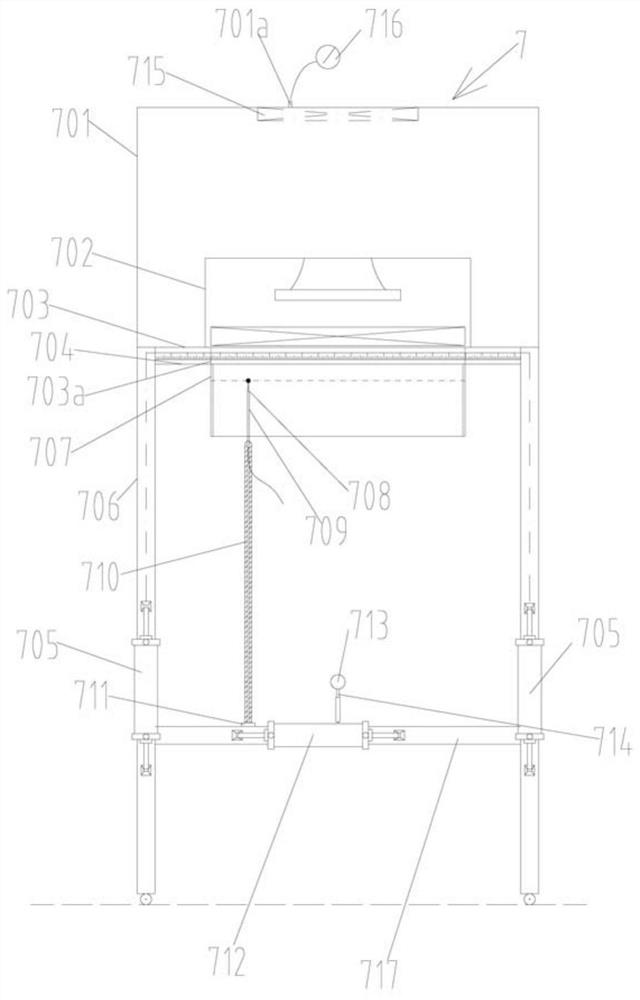

Railway construction organization plan automatic laying method and system and storage medium

ActiveCN114331067ARealize automatic layoutRealize automatic deductionResourcesStart timeIndustrial engineering

Owner:INST OF COMPUTING TECH CHINA ACAD OF RAILWAY SCI +2

A system for comprehensive performance testing of fan filter unit

ActiveCN110043500BAccuracy requirements metExquisite settingPump controlNon-positive displacement fluid enginesAir volumeAir velocity

The invention relates to a system for comprehensive performance testing of a fan filter unit in the technical field of mechanical and electrical equipment performance testing, comprising: a computer; a surface wind speed measurement component with a plenum box capable of accommodating a tested FFU; an anechoic laboratory for Accommodate the static pressure box body and face velocity measurement components; fan components controlled by computer; air volume measurement components controlled by computer; Among them, the fan parts and the air volume measurement parts are arranged in the position outside the anechoic laboratory of the induced air pipeline in sequence according to the direction of the air flow, and the air inlet end of the fan part is connected to the outside atmosphere; the surface wind speed measurement parts include thermal anemometer, The detection ends of the acoustic measuring instrument, the thermal anemometer, and the acoustic measuring instrument are all facing the air outlet of the tested FFU. It solves the problem that the acoustic test and aerodynamic performance test in the anechoic laboratory cannot be combined; completes the test of all performance parameters of the tested FFU with a high degree of automation.

Owner:予哲机电工程咨询(上海)有限公司 +1

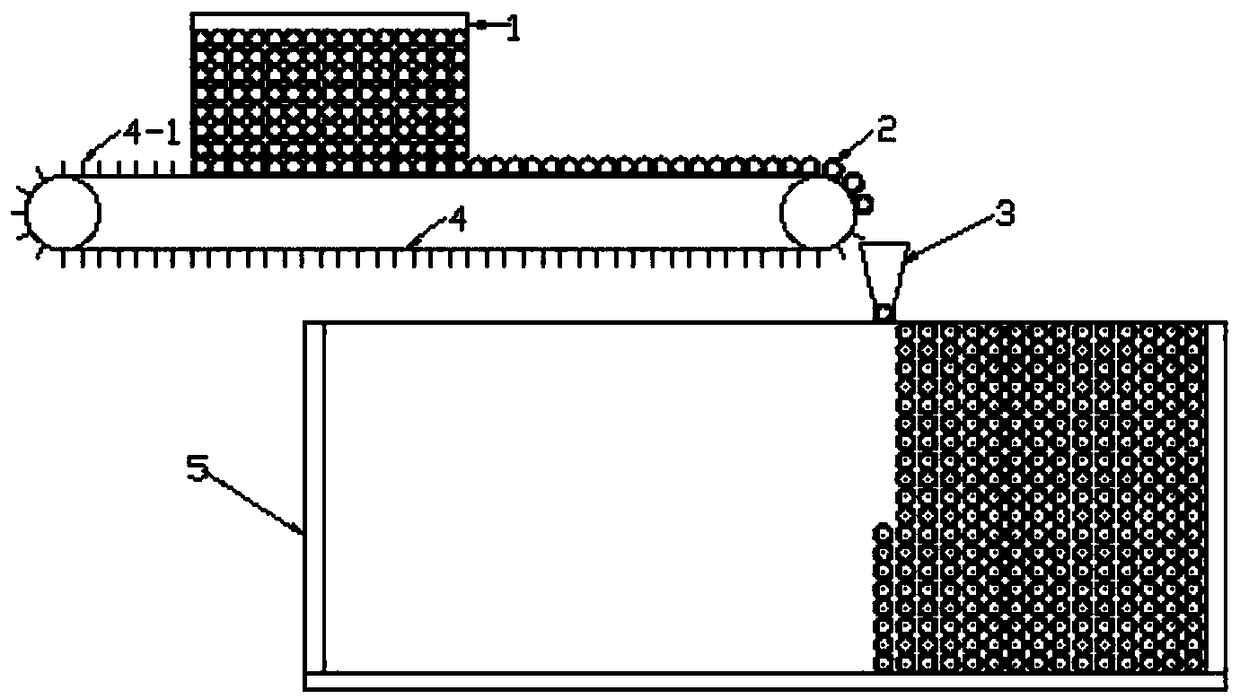

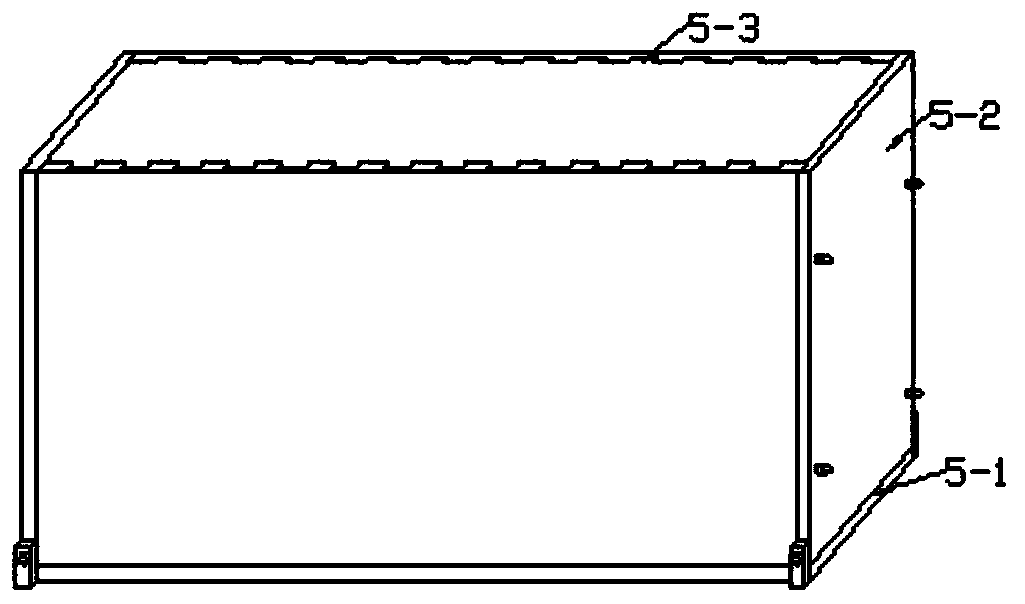

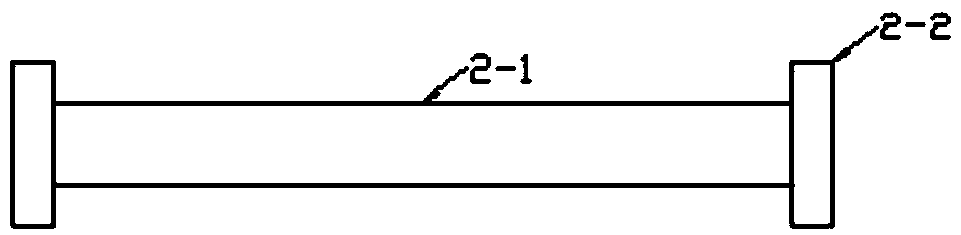

A light-transmitting concrete preparation device and preparation method

ActiveCN106493852BRealize automatic layoutAvoid affecting the appearanceFeeding arrangmentsStructural engineeringEngineering

Owner:中建西部建设西南有限公司 +1

Apparatus for automated assembly and routing of electrical apparatuses

ActiveCN114696270AEasy to operateEasy to checkElectrical apparatusStructural engineeringElectric equipment

The invention provides equipment for automatic assembly and wiring of electrical equipment, and relates to the field of household kitchens. The automatic assembling and wiring equipment for the electrical equipment comprises two wire pressing devices, a sliding rod is fixedly connected between the two wire pressing devices, the outer surface of the sliding rod is slidably connected with a wire pulling device, the front surface and the rear surface of each wire pressing device are fixedly connected with mounting blocks, and the mounting blocks are fixedly connected with the wire pressing devices. The wire pressing device comprises a base, and a first extrusion groove is formed in the base. The pressing plate is controlled by the screwing block to drive the ejector rod and the ejector plate to move downwards, the ejector plate extrudes the clamping rod and presses the clamping rod into the first extrusion groove for fixing the power lines, operation is simple, the multiple line pressing mechanisms are arranged on the line pressing device, the power lines are separated from one another, convenience is provided for subsequent inspection or maintenance, and meanwhile the appearance is more attractive.

Owner:海安明宇智能控制技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com