Inner wall overlaying system for 90-degree elbow

A technology for elbows and components, which is applied in the field of surfacing system for the inner wall of 90° elbows, can solve the problems of inability to weld the inner wall of 90° elbows, cumbersome, welding defects at the three-section joints, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the drawings and embodiments:

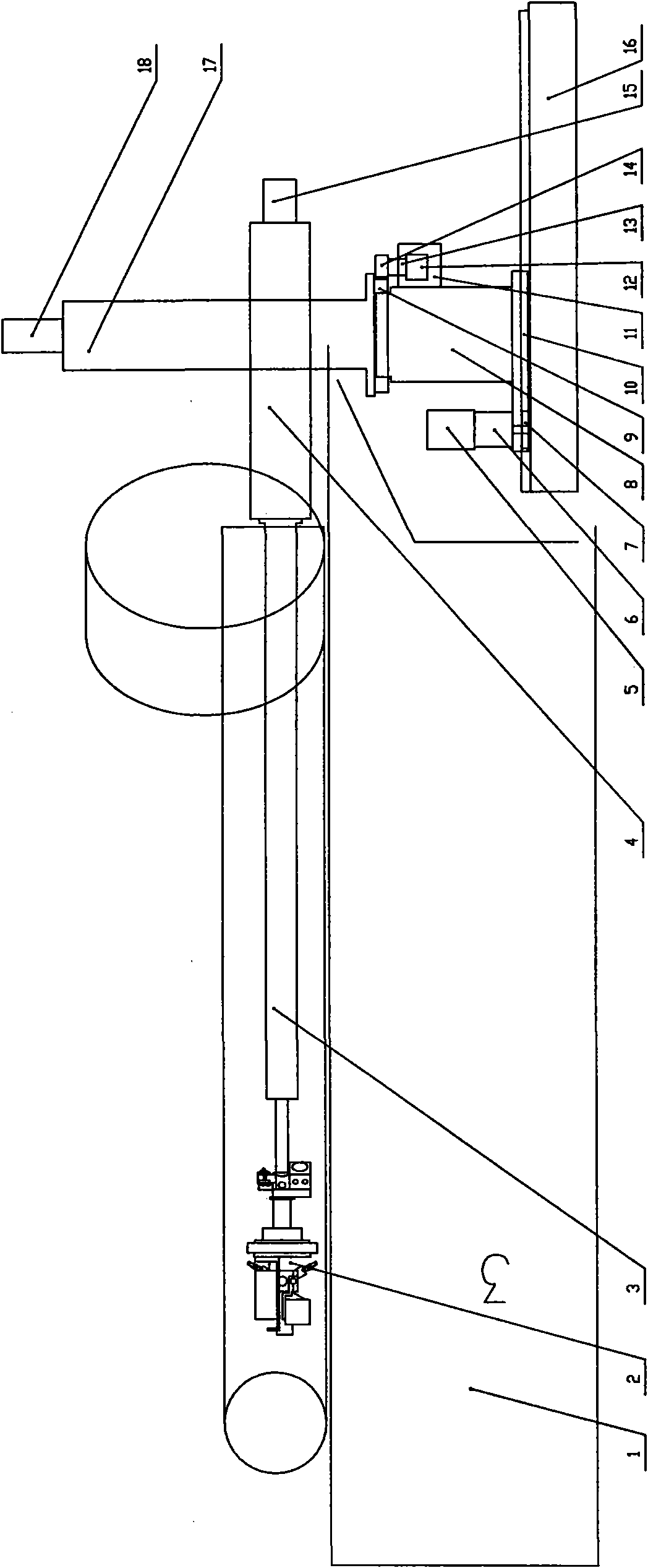

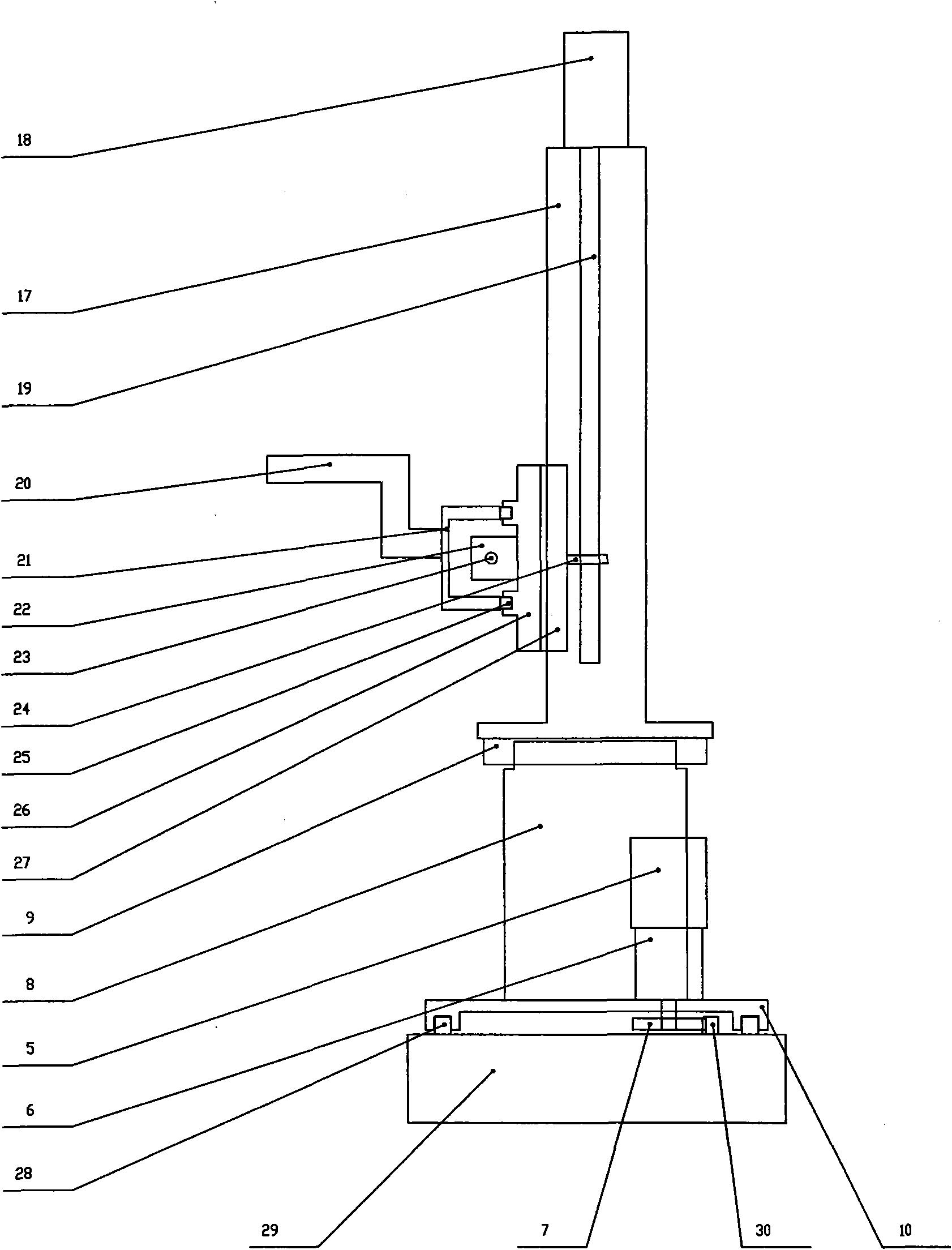

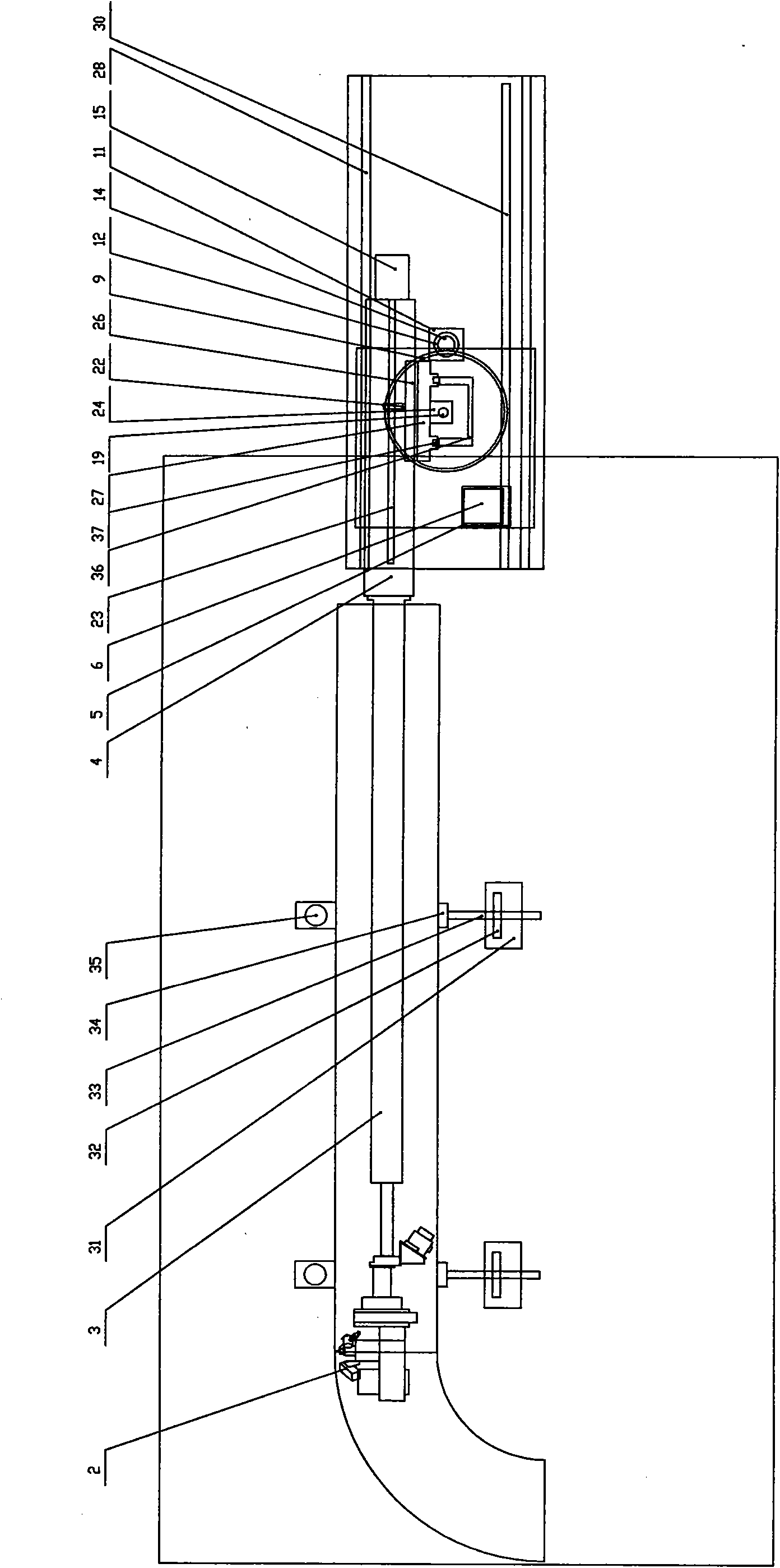

[0016] The 90° elbow surfacing system of the present invention is mainly composed of a platform and a fixture assembly 1, a translational guide assembly 16, a rotation assembly 8, a column assembly 17, a cross arm assembly 4, a straight arm 3, a small sliding arm 39, and a welding head 2 grade structure, this welding system can weld both straight pipe and 90° elbow.

[0017] See image 3 , Figure 4 , The platform and clamp assembly 1 are equipped with a positioning rod 35 adjustable in position in the direction of the vertical pipe and a tightening assembly 31 corresponding to the positioning rod 35. The tightening assembly 31 is supported by a support 32. , The tightening screw 33 and the tightening block 34, the support 32 is fixed on the platform table with screws, on which is mounted a tightening screw 33 that is fastened by a nut and can move up and down. The fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com