Automatic winding machine for double-end dry-type transformer

A dry-type transformer and automatic winding machine technology, which is applied in coil manufacturing and other directions, can solve the problems of poor product resistance consistency, error-prone number of turns, stacking and other problems, and achieve the effect of reducing operator strength and improving winding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

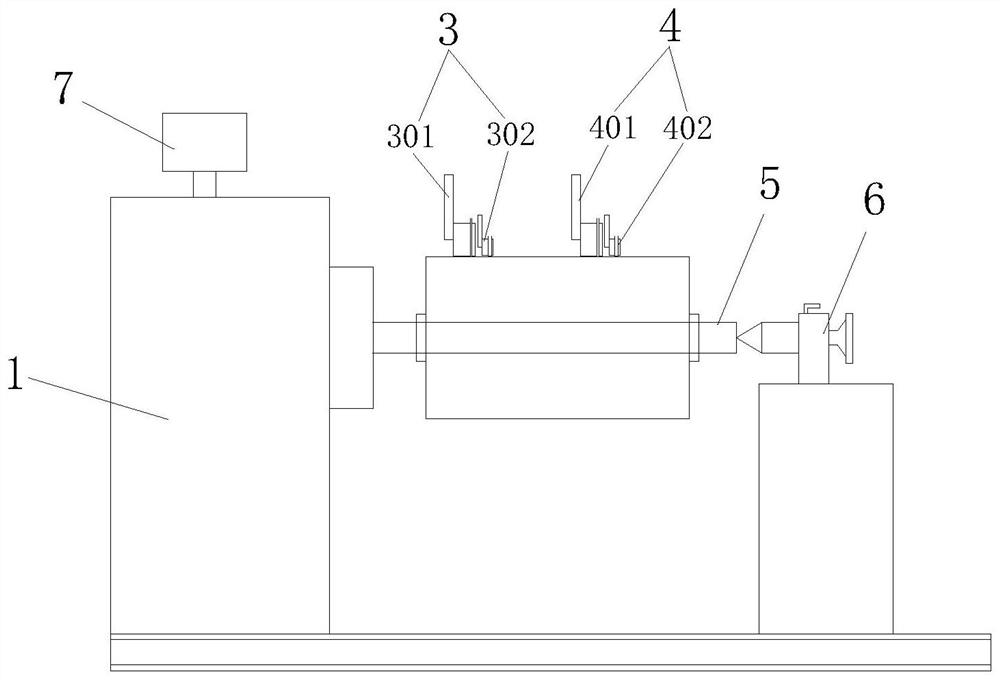

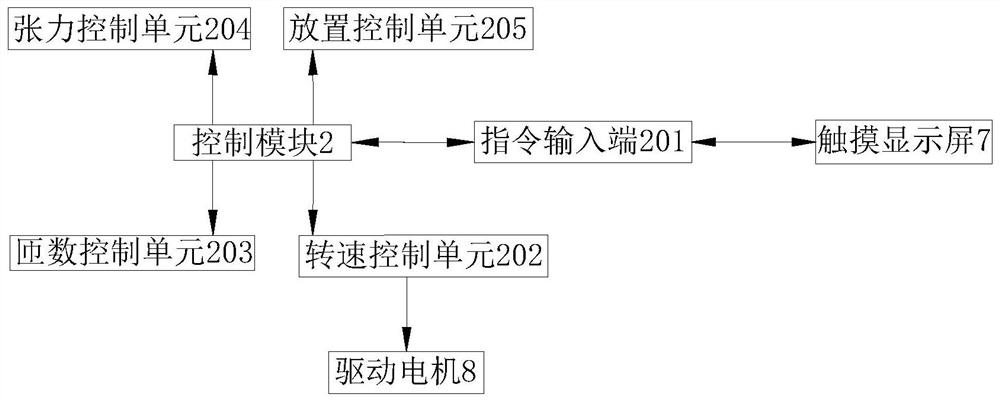

[0025] Such as figure 1 As shown, a double-headed dry-type transformer automatic winding machine includes a housing 1, a control module 2, an instruction input terminal 201 connected to the control module 2, a driving motor 8, a driving shaft 5, and a first winding station 3 And the second winding station 4. The double winding station can wind the workpiece at the same time, and the overall efficiency can be increased by more than 3 times, which greatly improves the production efficiency.

[0026] The driving motor 8 is arranged in the housing 1 and connected to one end of the driving shaft 5 . The control module 2 can control the speed of the driving shaft 5 by adjustin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com