Patents

Literature

227results about How to "Reduce cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

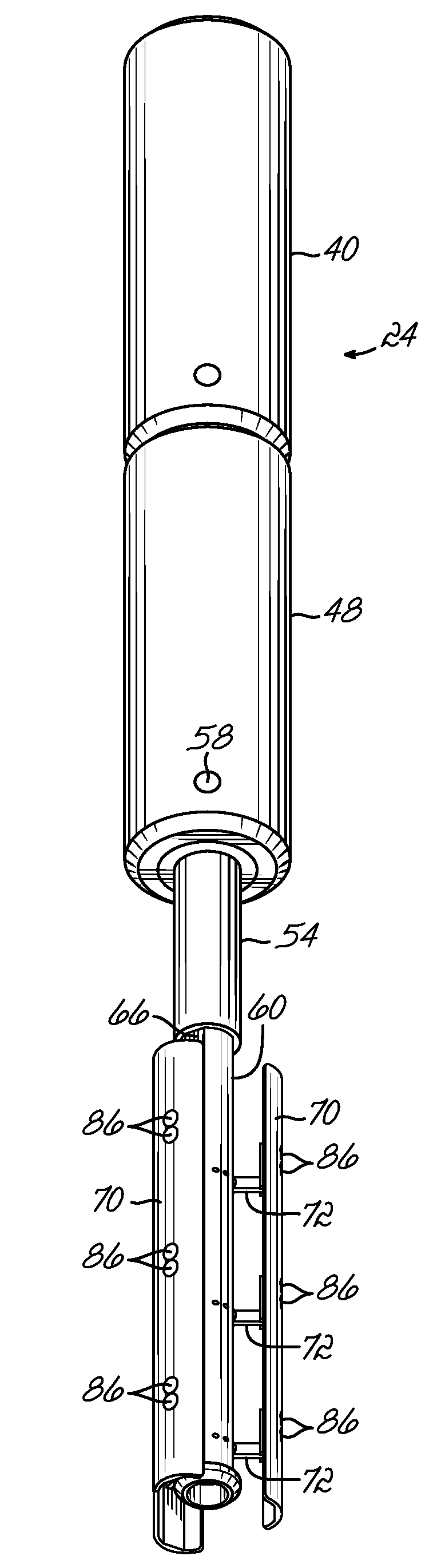

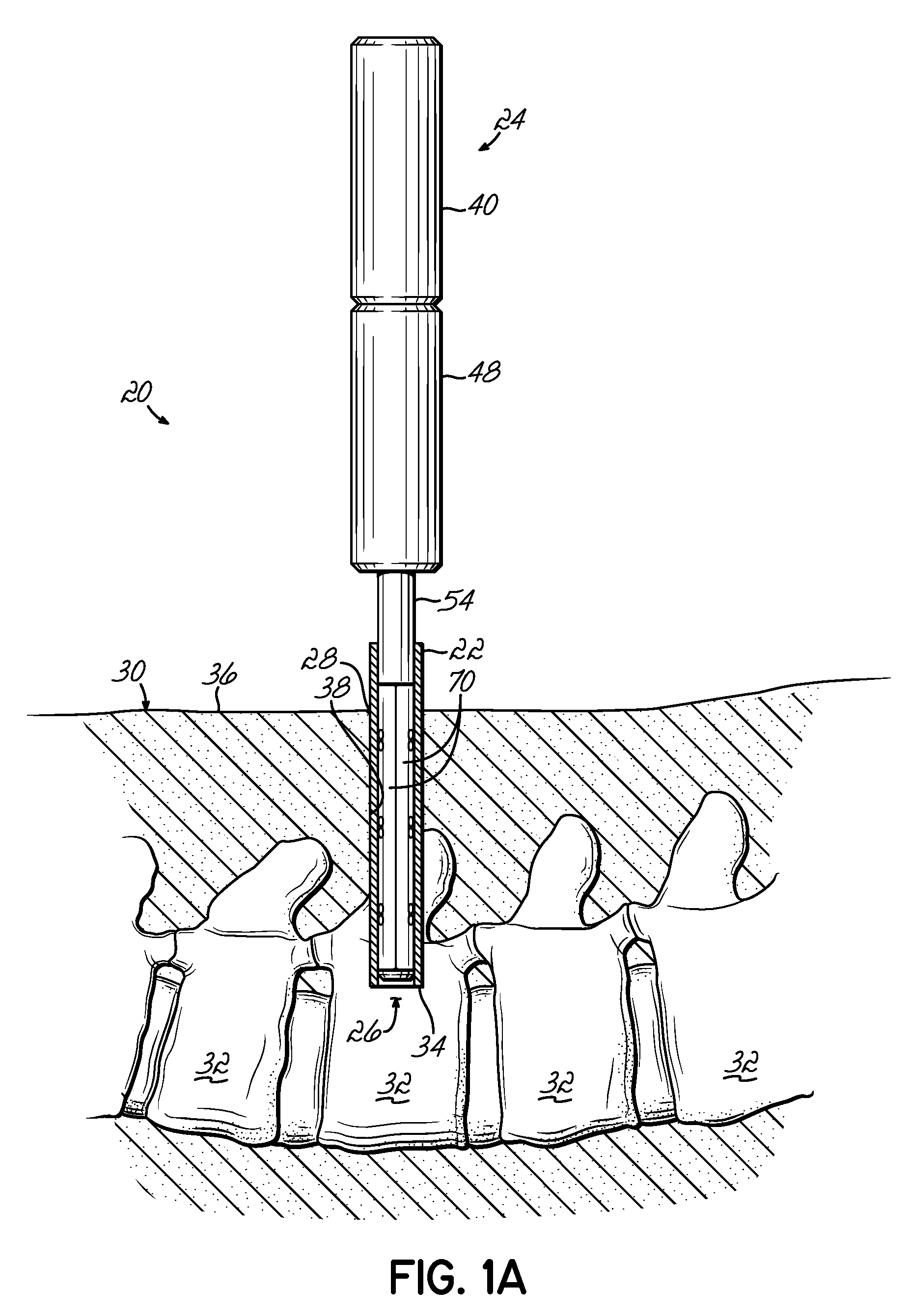

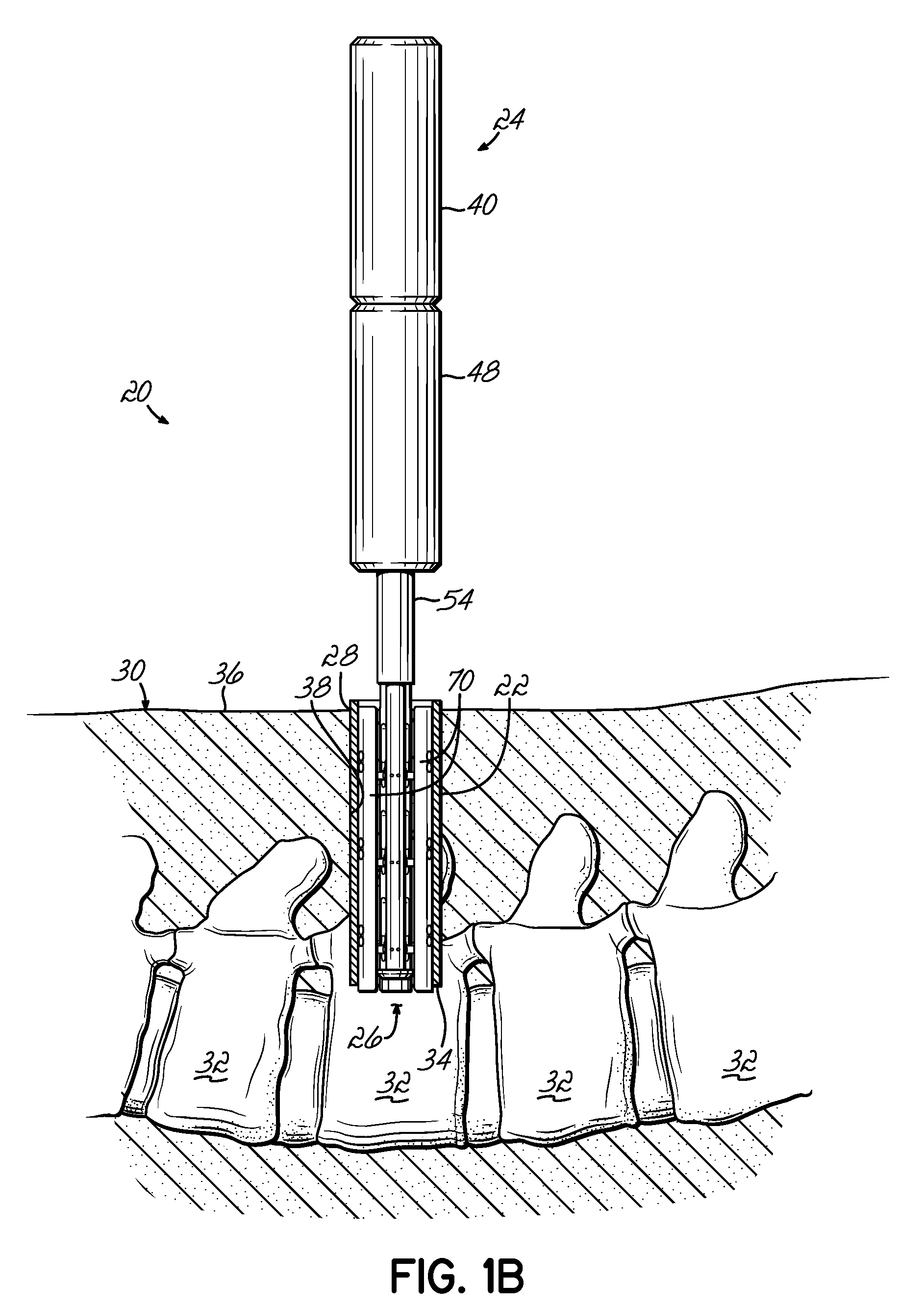

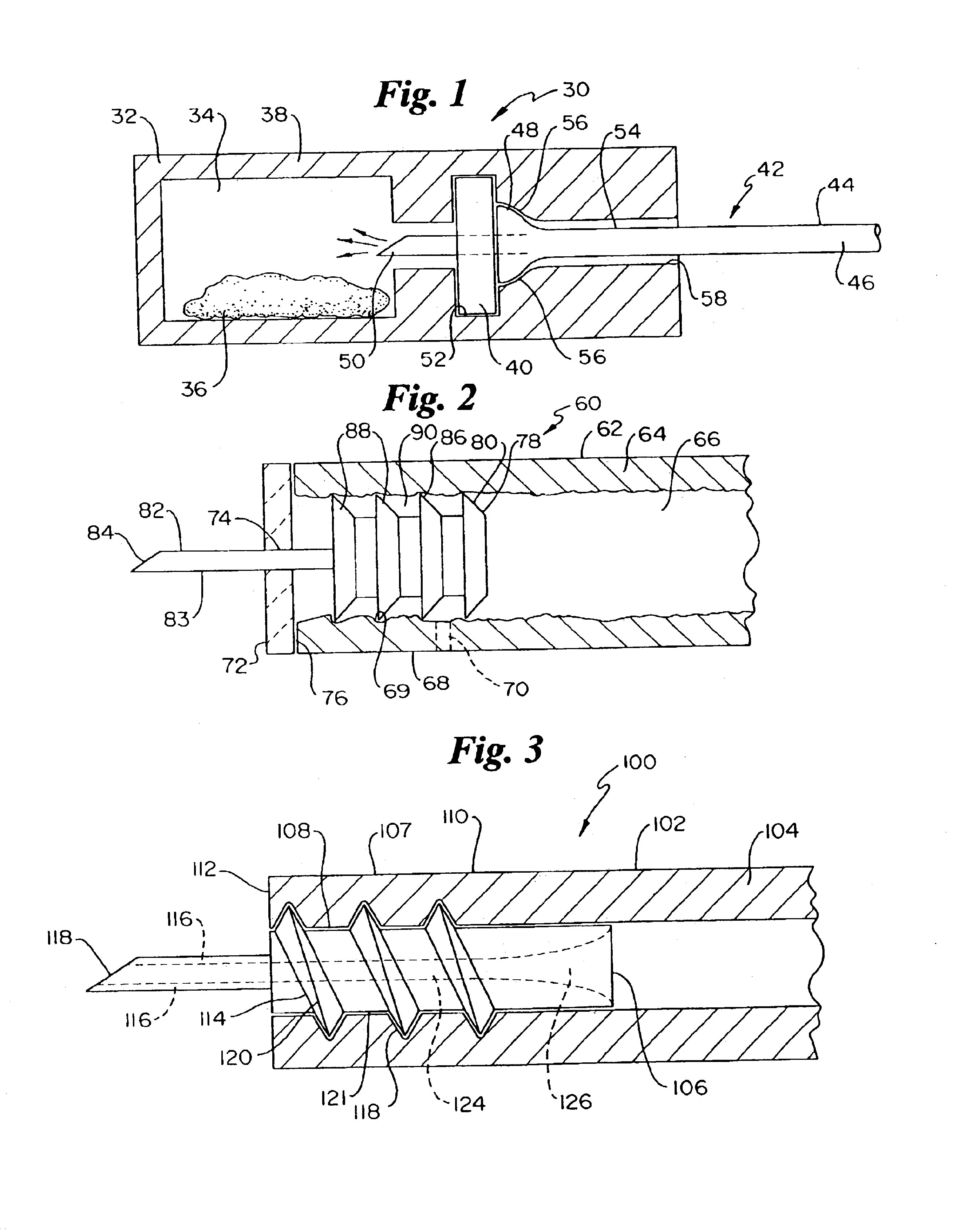

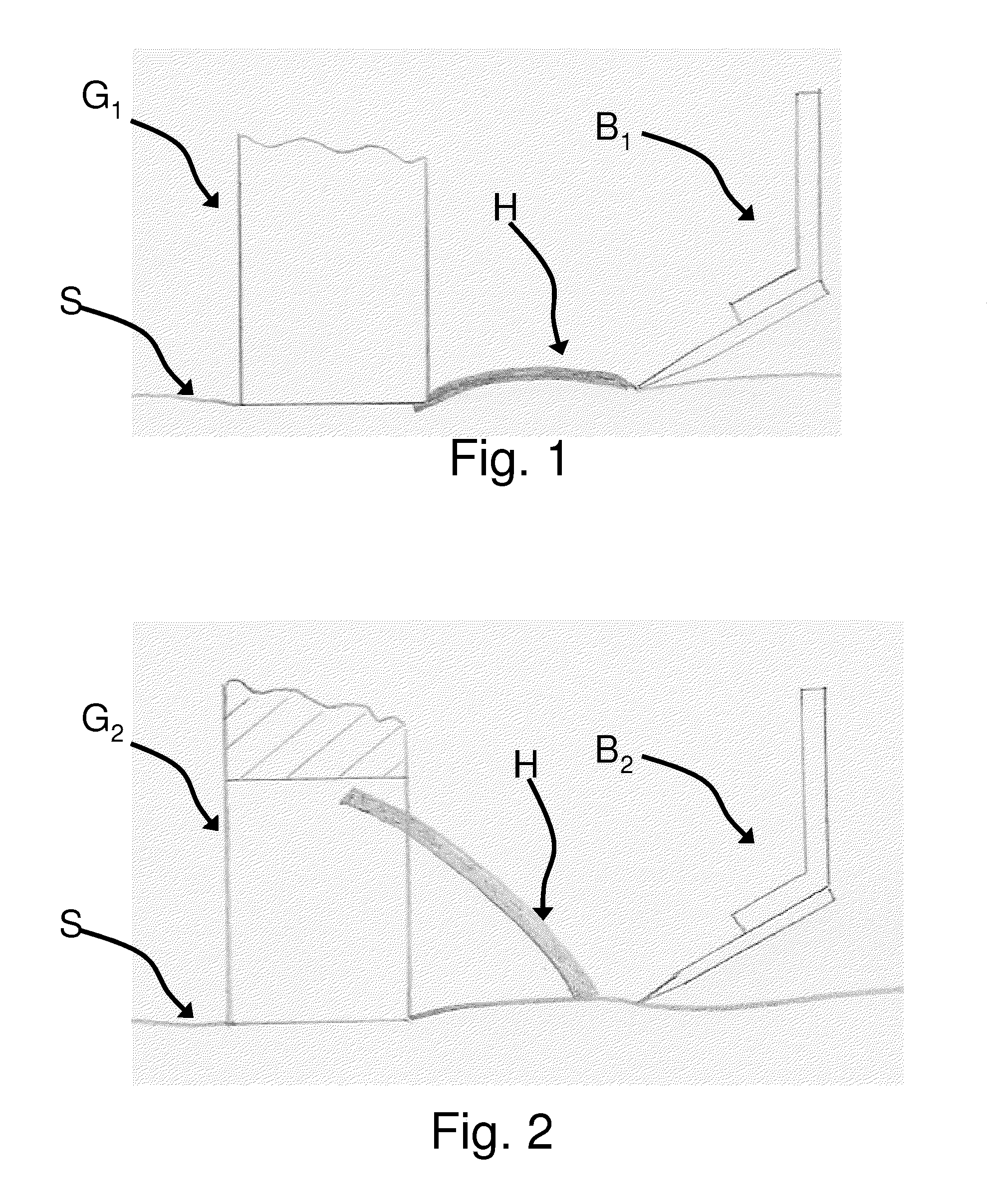

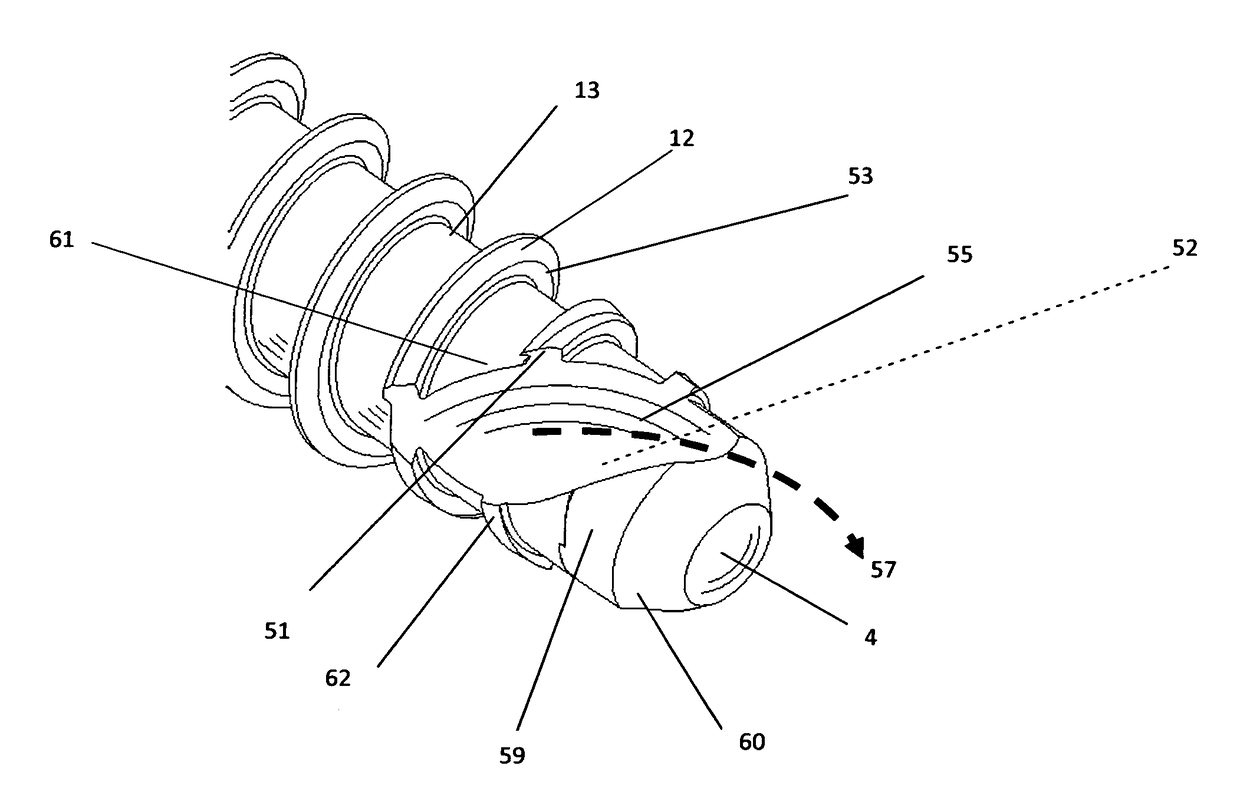

Access Port Expander And Method

InactiveUS20090024158A1Reduce cuttingMinimize and reduce wound traumaCannulasCatheterIncision SiteSurgical site

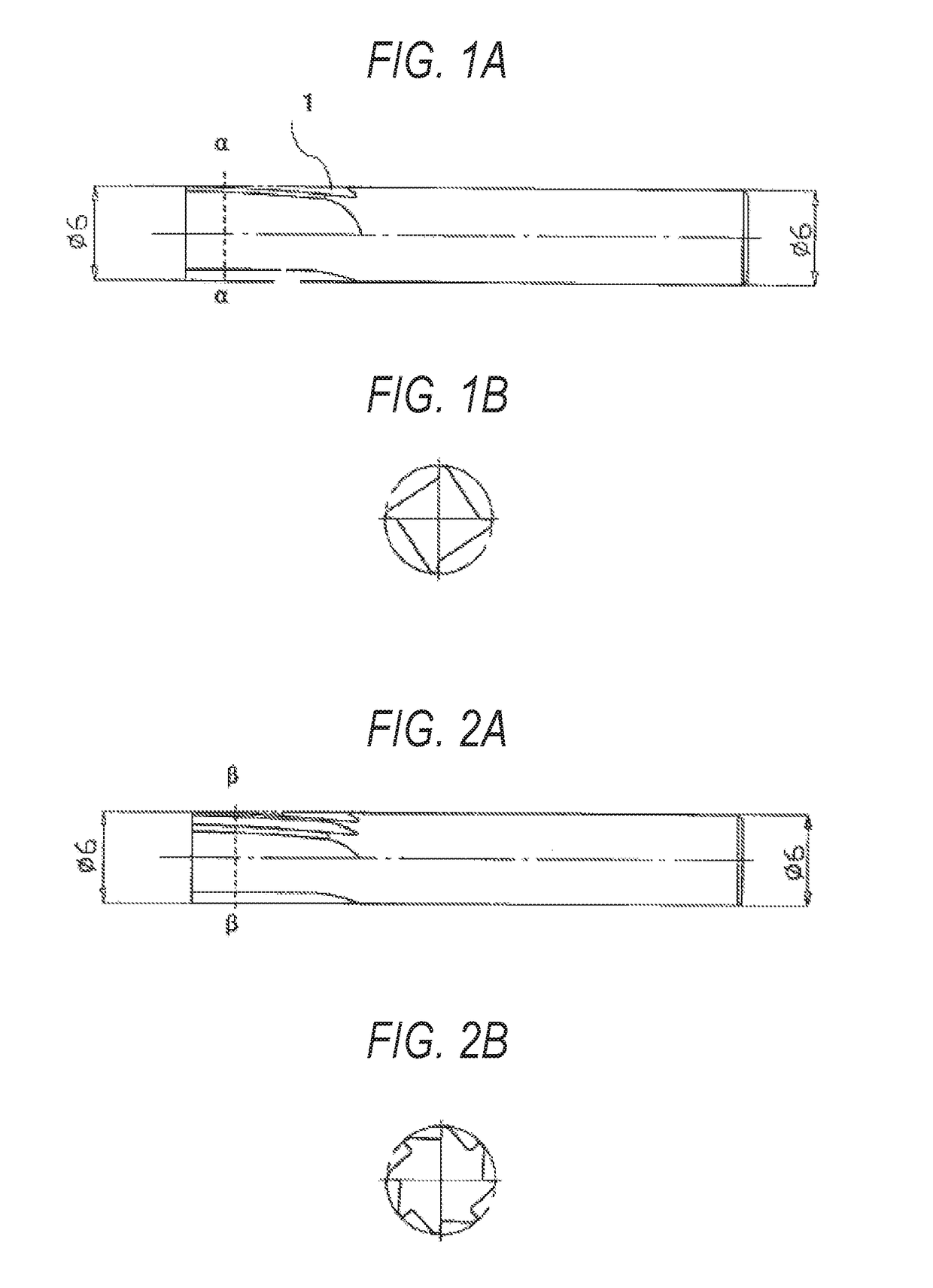

A surgical access port expander for expanding an access path between an incision site and a surgical site during a surgical procedure. The access port expander has an actuator with an actuator rod connected to a plurality of blades. The blades are movable in response to motion of the actuator rod moving in a direction substantially parallel to the blade lengths. Further, each blade is moved in a direction substantially perpendicular to its respective length from a contracted position to an expanded position.

Owner:ZIMMER SPINE INC

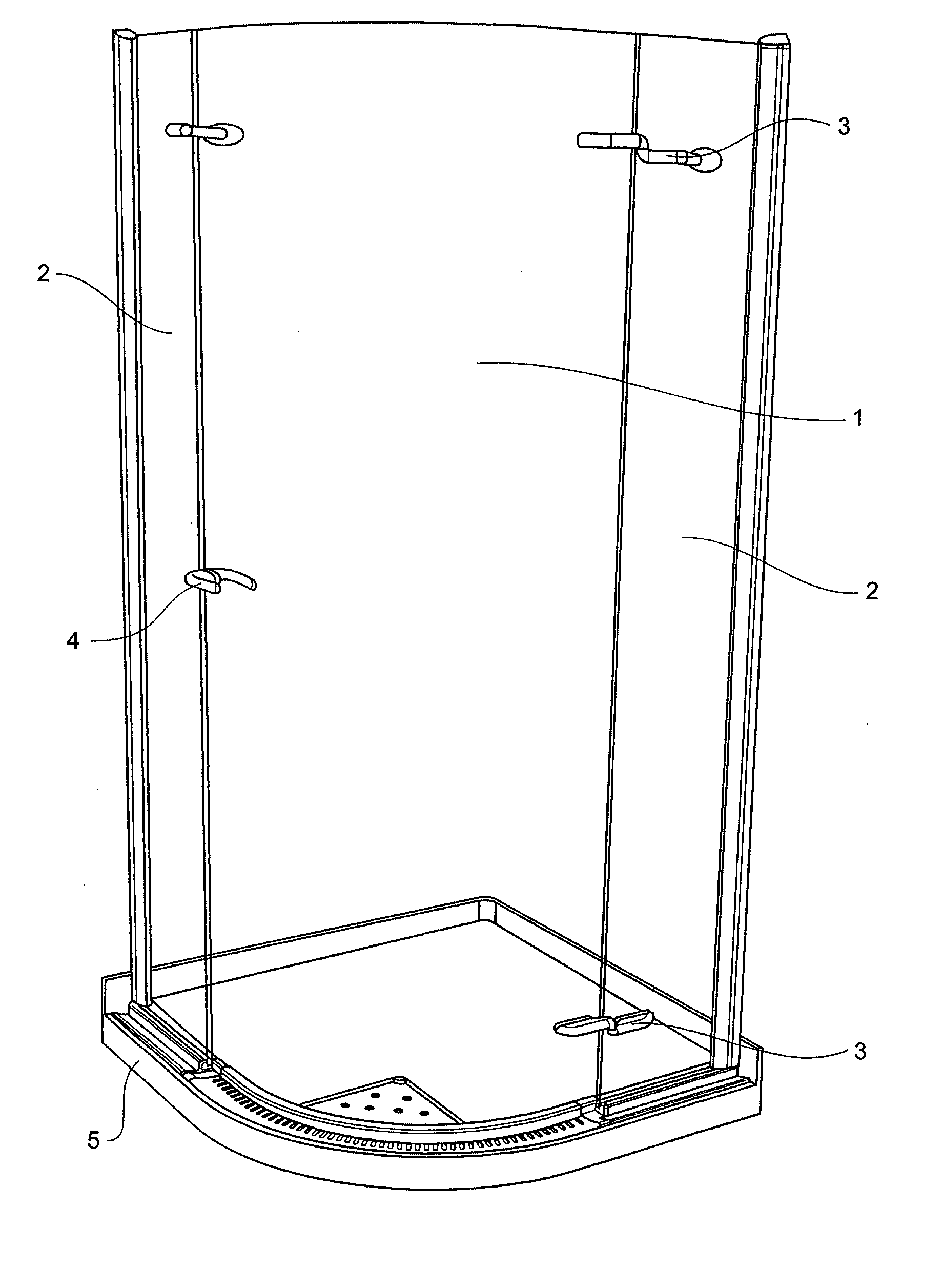

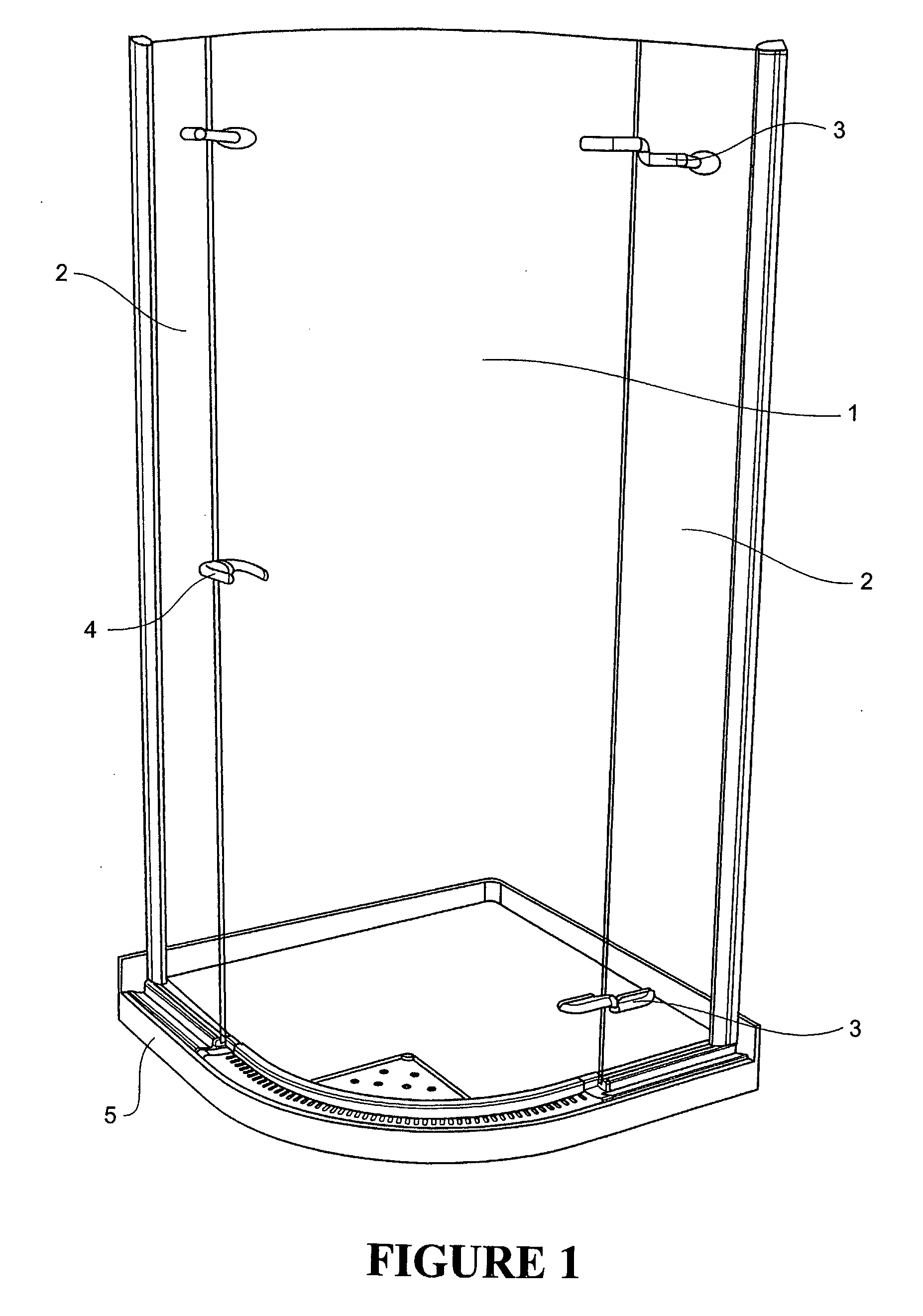

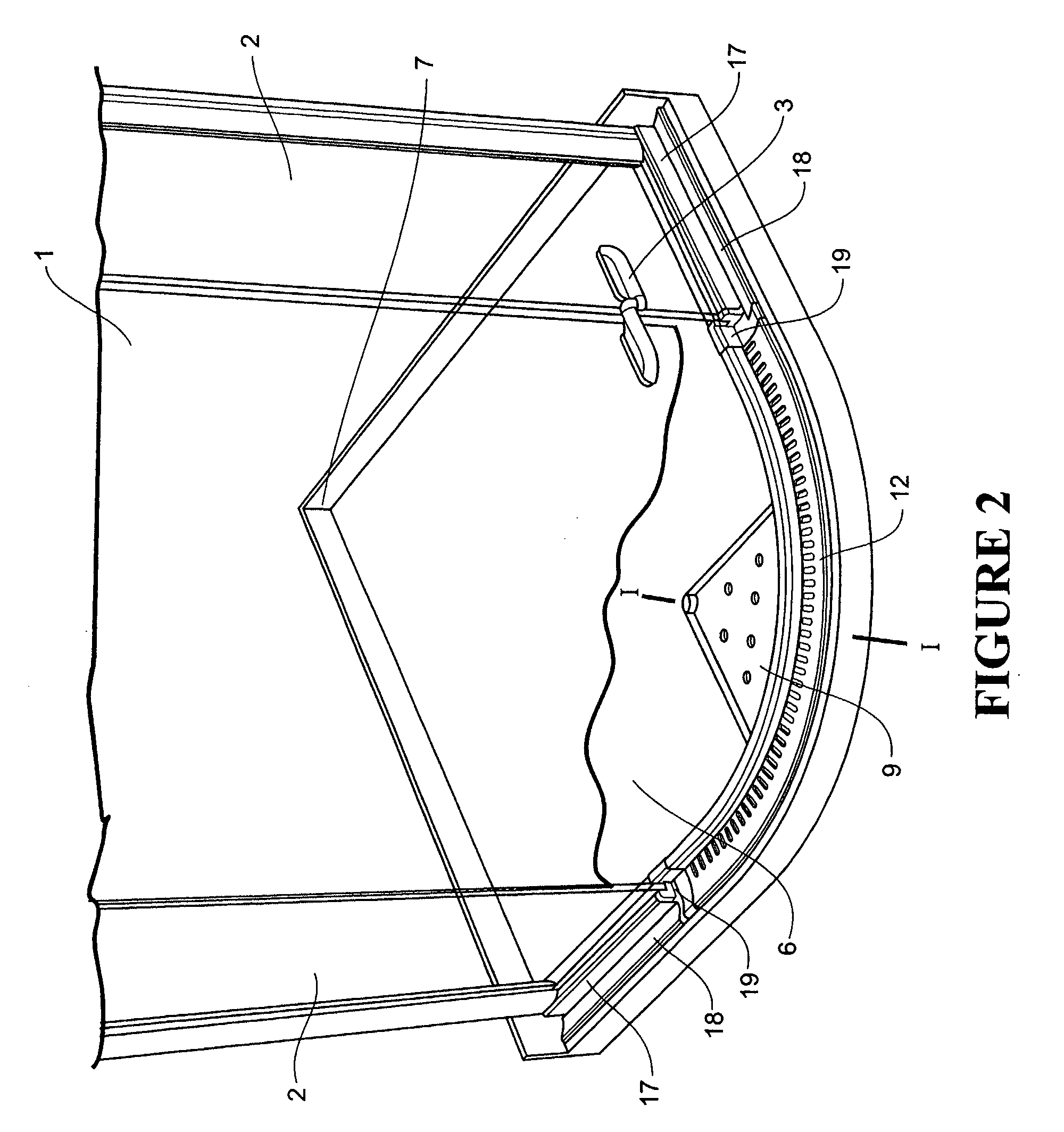

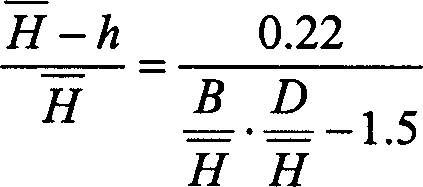

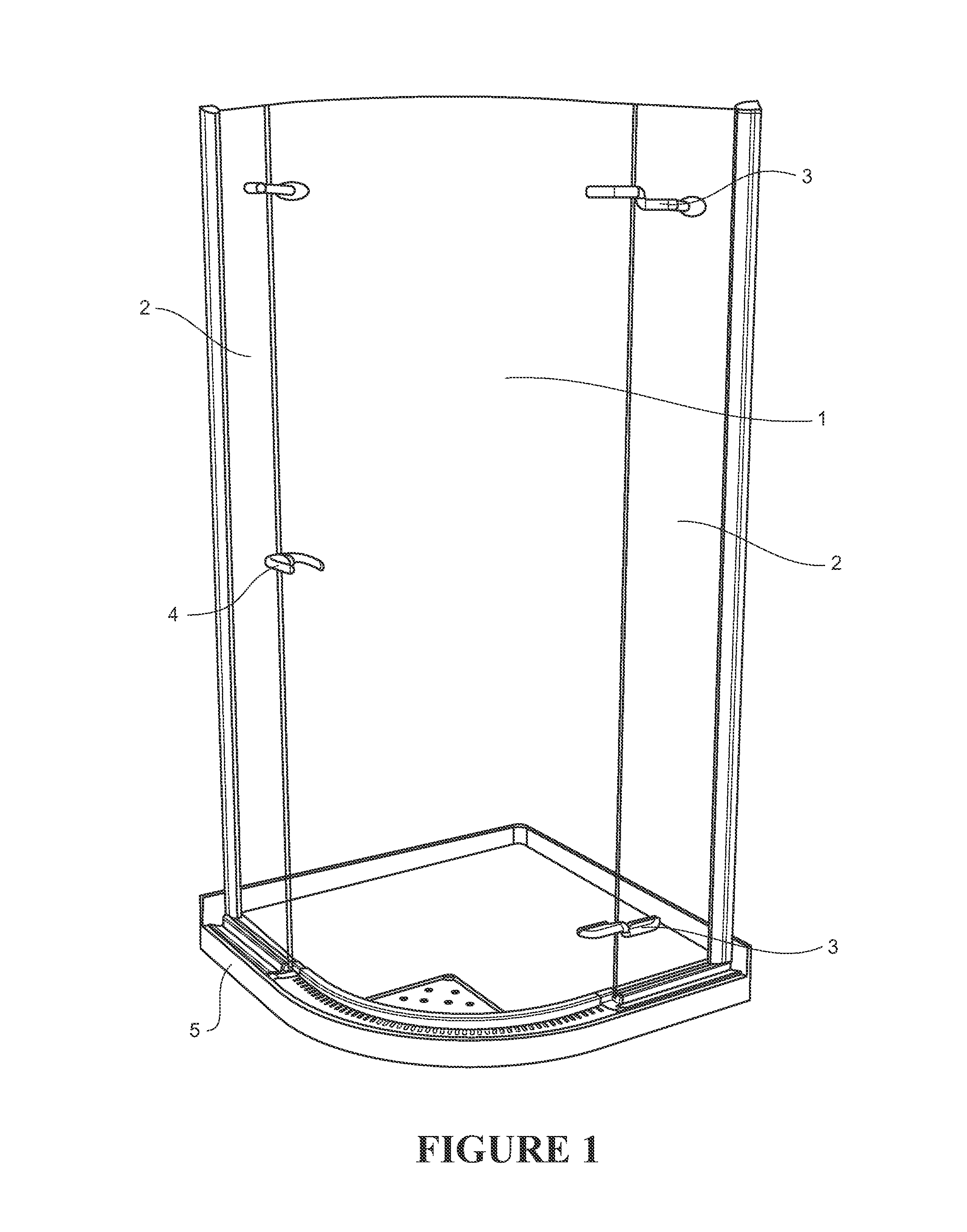

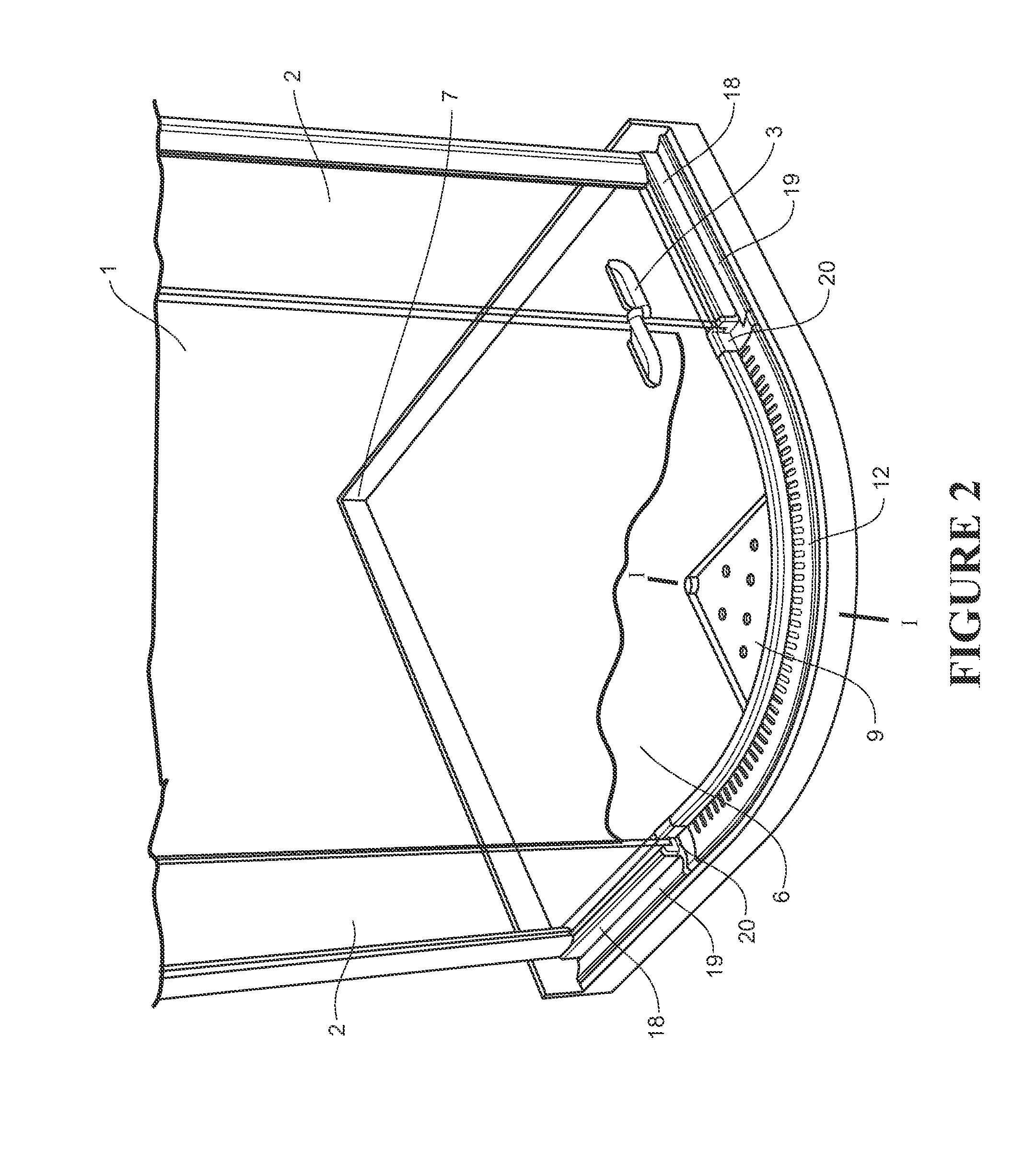

Shower enclosure and base

A shower enclosure comprises a shower base (5) having a floor (6) which falls towards a side of the shower base (5), a waste outlet at said side of the shower base, and a drain channel (11) which extends exterior to the door (1) of the enclosure, and which is arranged to drain towards the waste outlet (8). Water may flow beneath the door (1) to the drain channel (11). Preferably the drain channel (11) also extends along a foot of the return panel(s) (2). A longitudinally extending cover member (9) is preferably provided over the drain channel (11) and the waste outlet (8) may be provided at the front side of the shower base (5).

Owner:KOHLER NEW ZEALAND

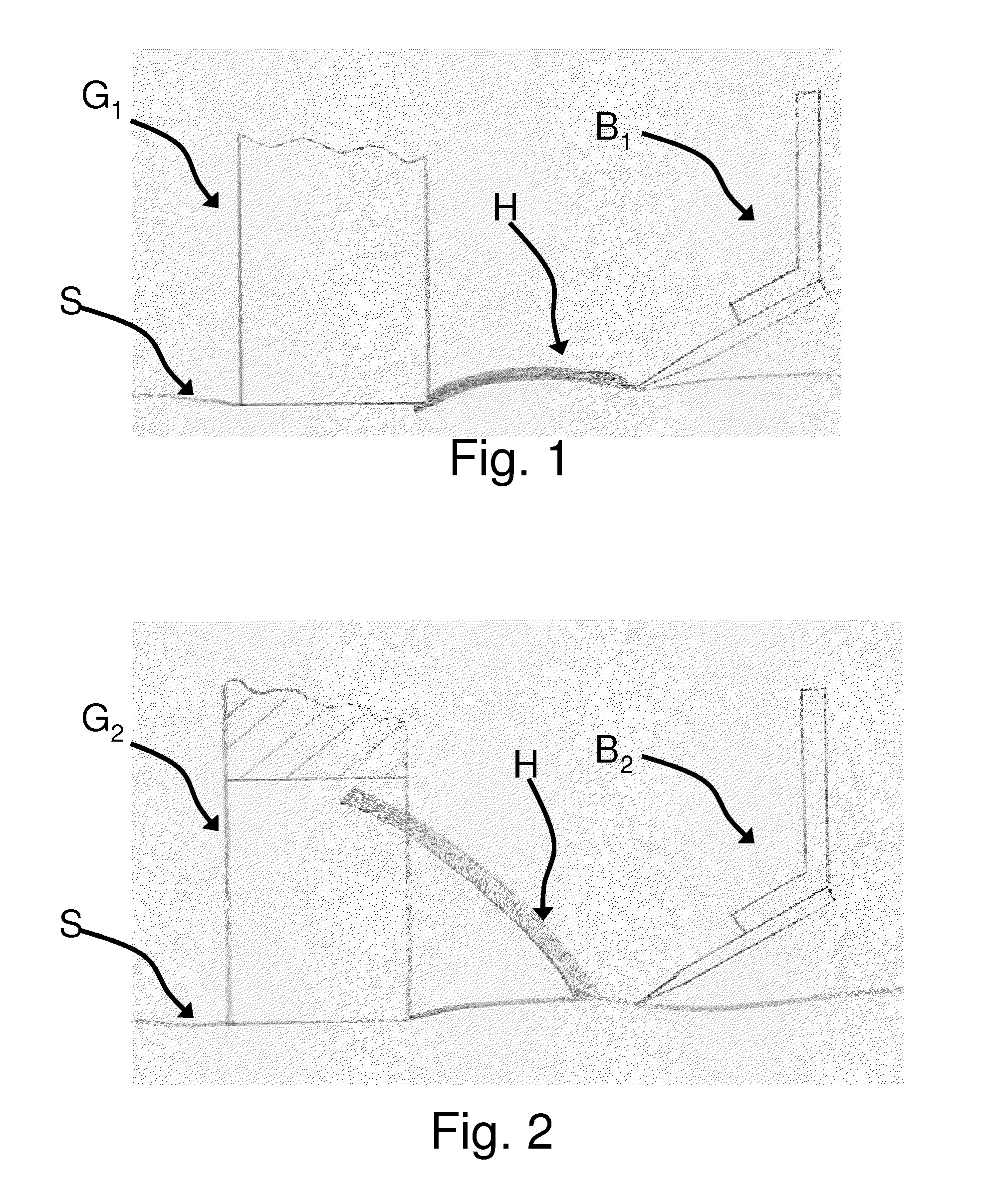

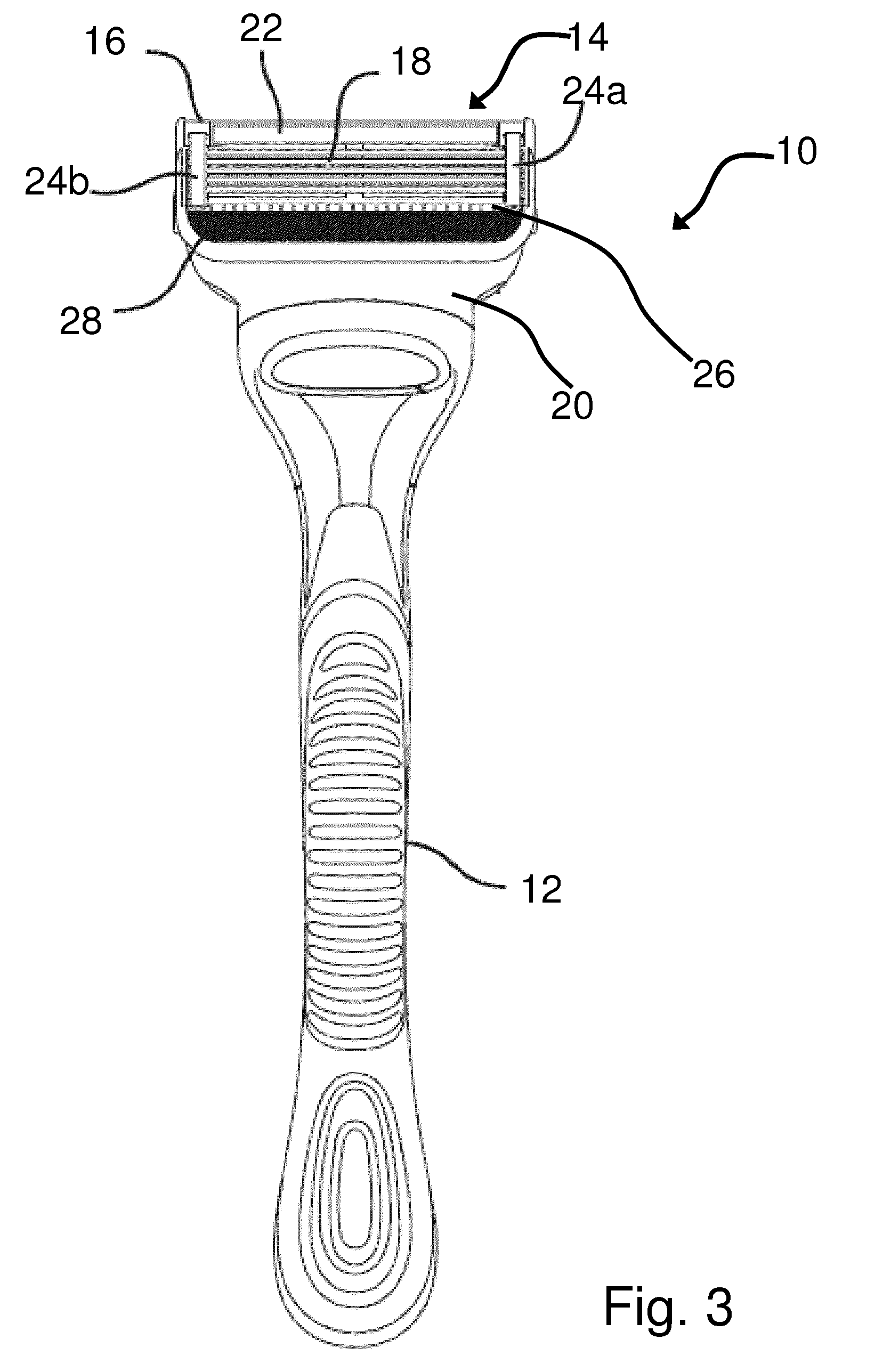

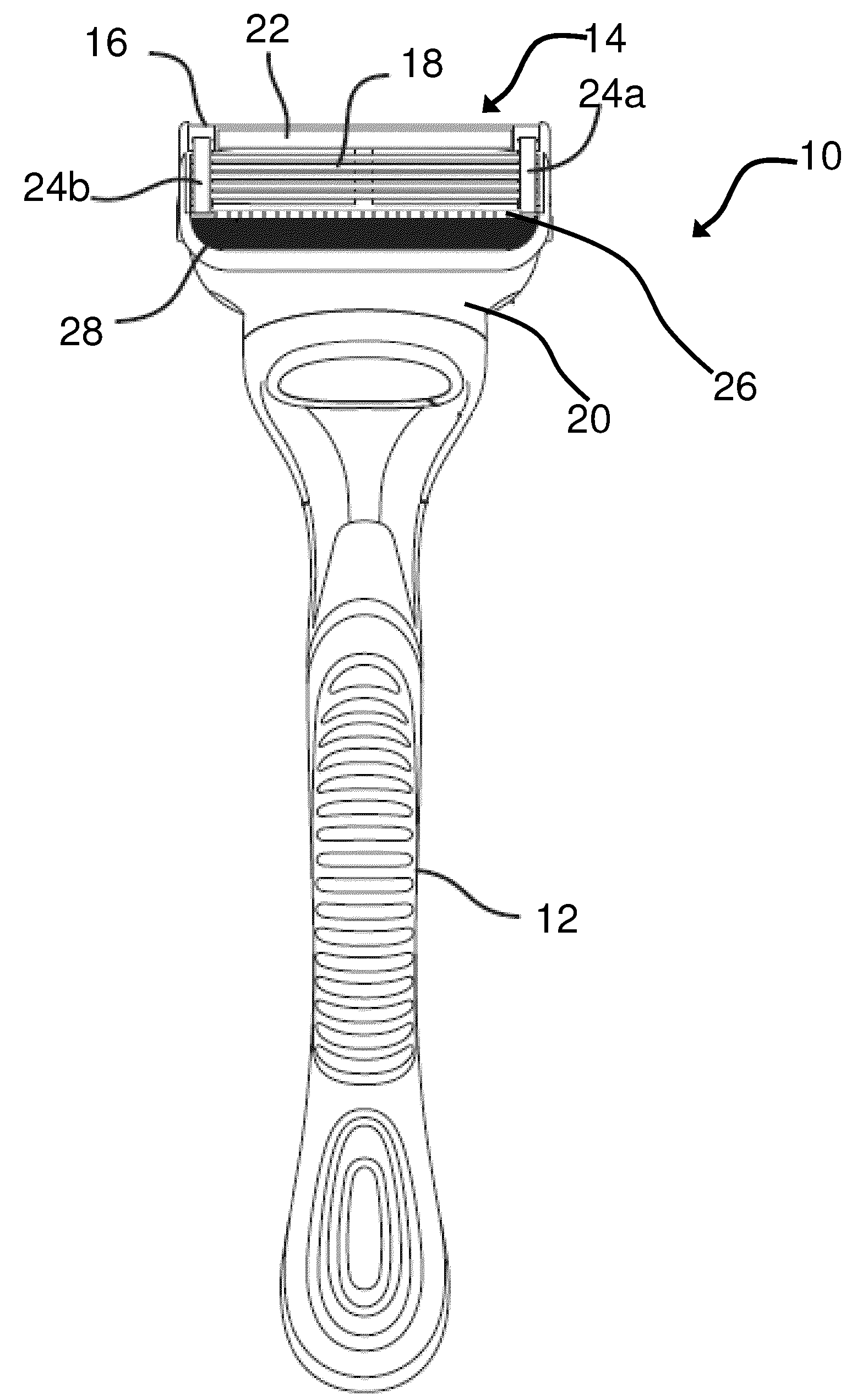

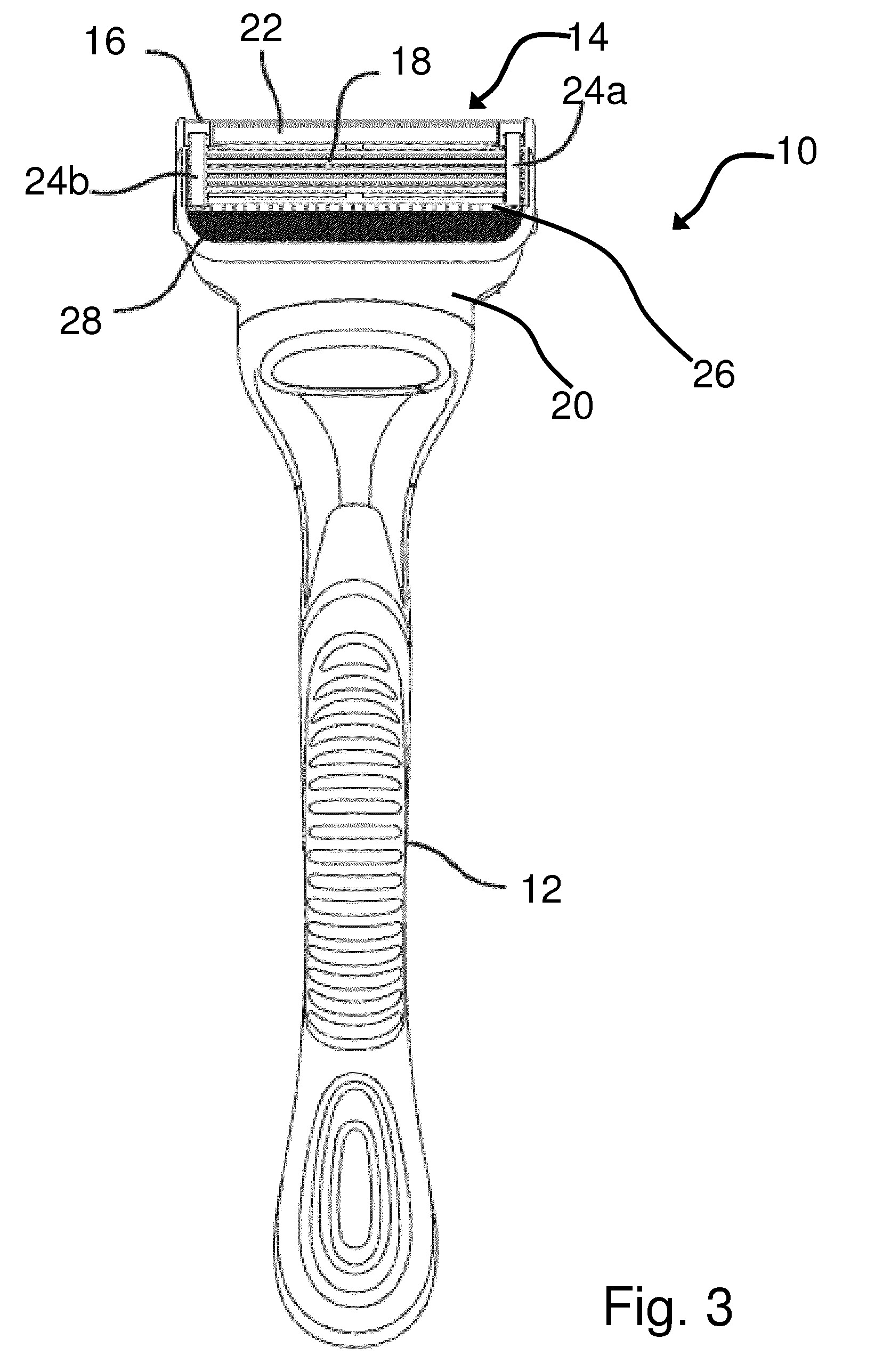

Shaving razors and cartridges

ActiveUS8209867B2Avoid discomfortImprove featuresMetal working apparatusMechanical engineeringEngineering

A shaving cartridge has a housing with at least one blade having a blade edge. The housing has a first guard in front of the blade with a plurality of projections defining a plurality of open slots extending generally transverse to the blade edge. The open slots have a width of about 0.20 mm to about 0.49 mm and a pitch of about 0.40 mm to about 0.85 mm for allowing the free passage of hair during shaving.

Owner:THE GILLETTE CO

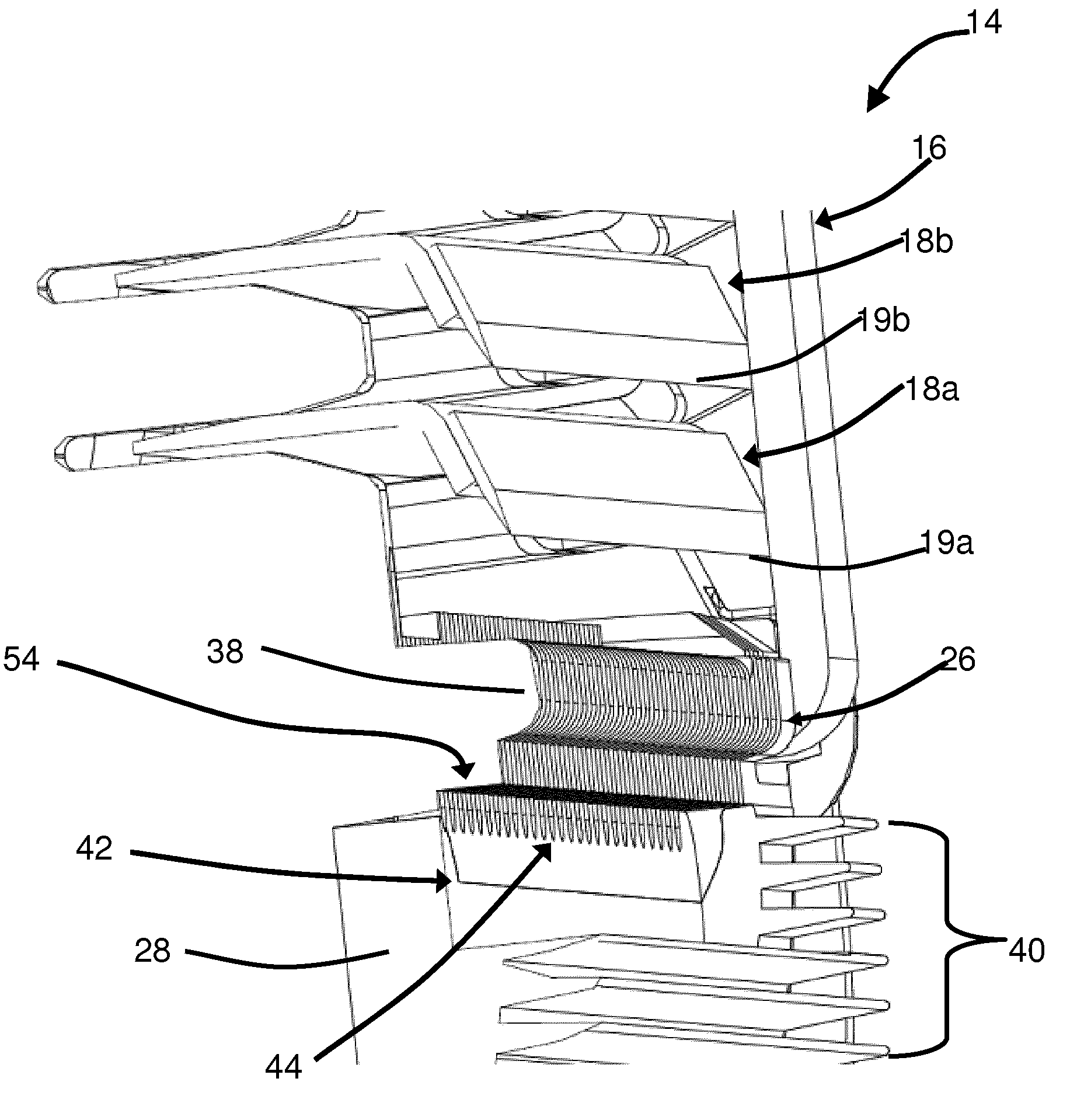

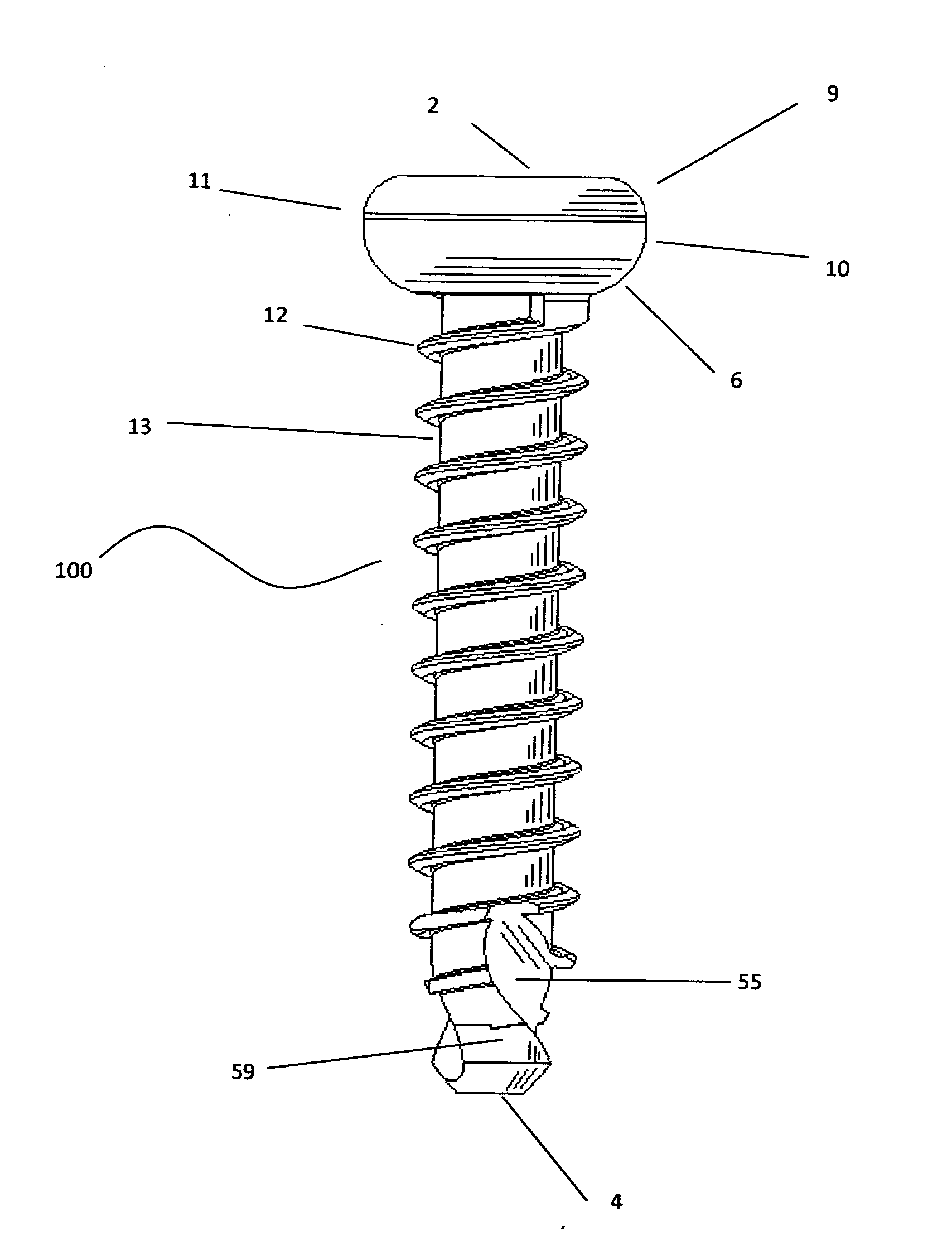

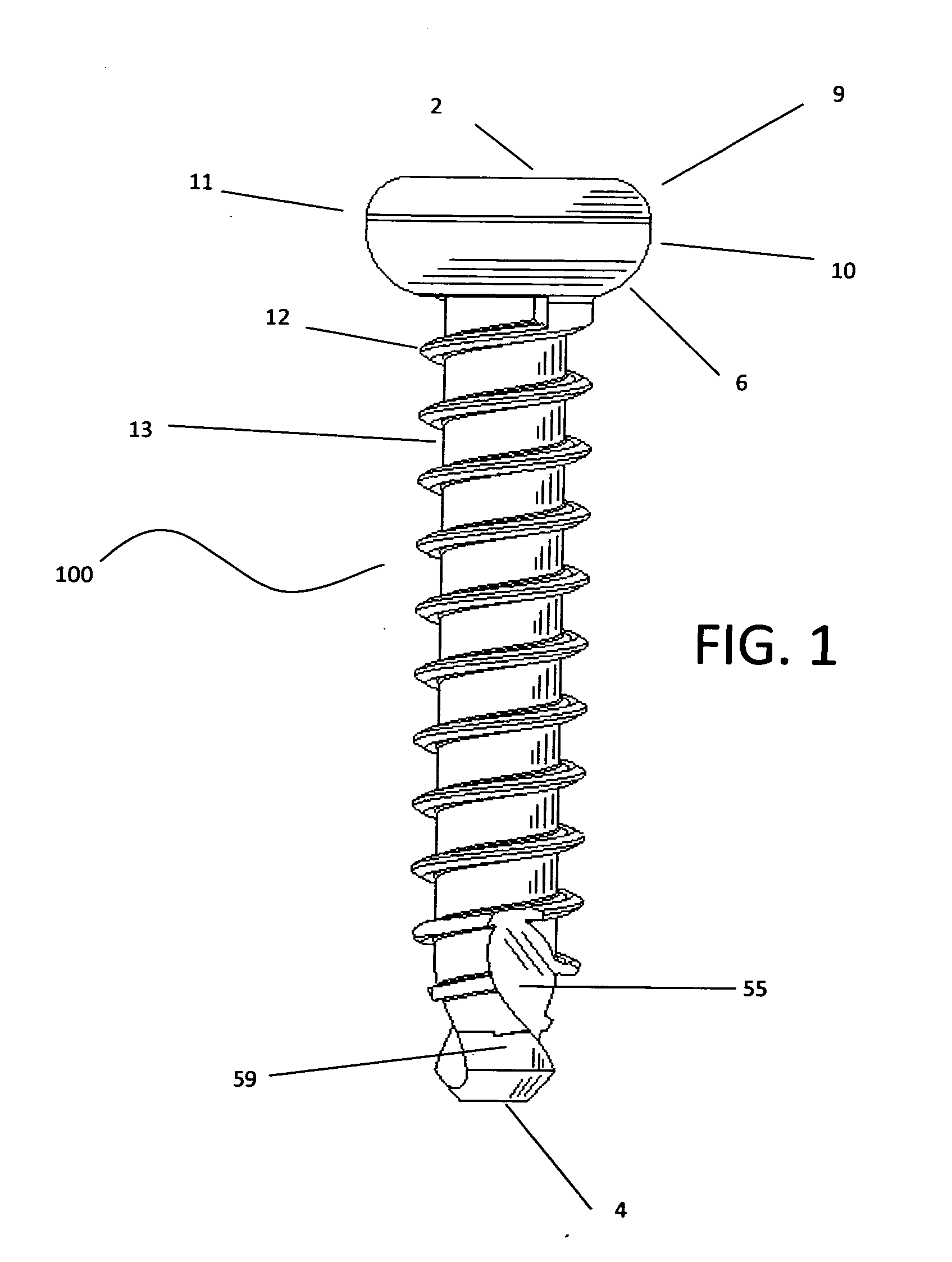

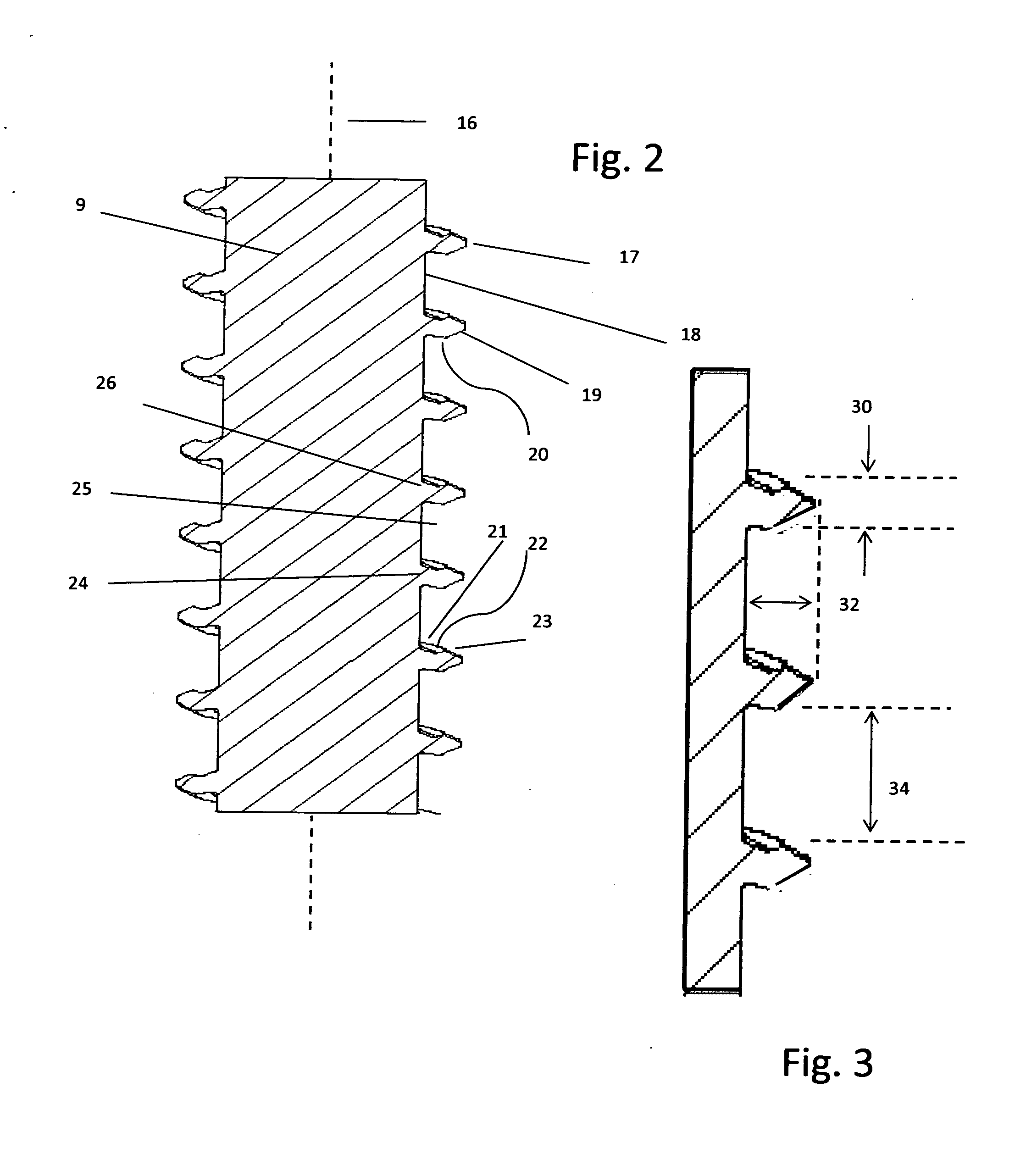

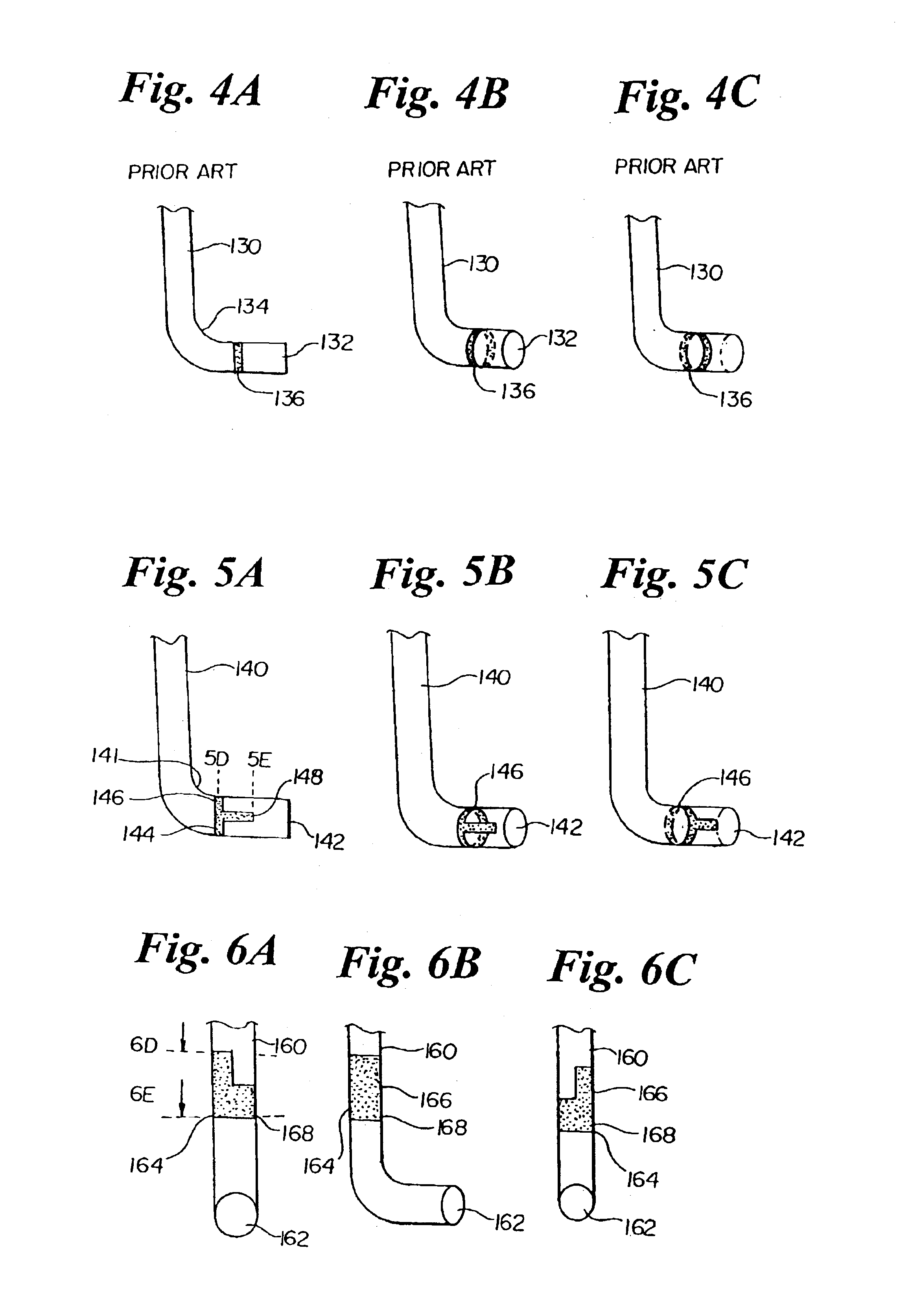

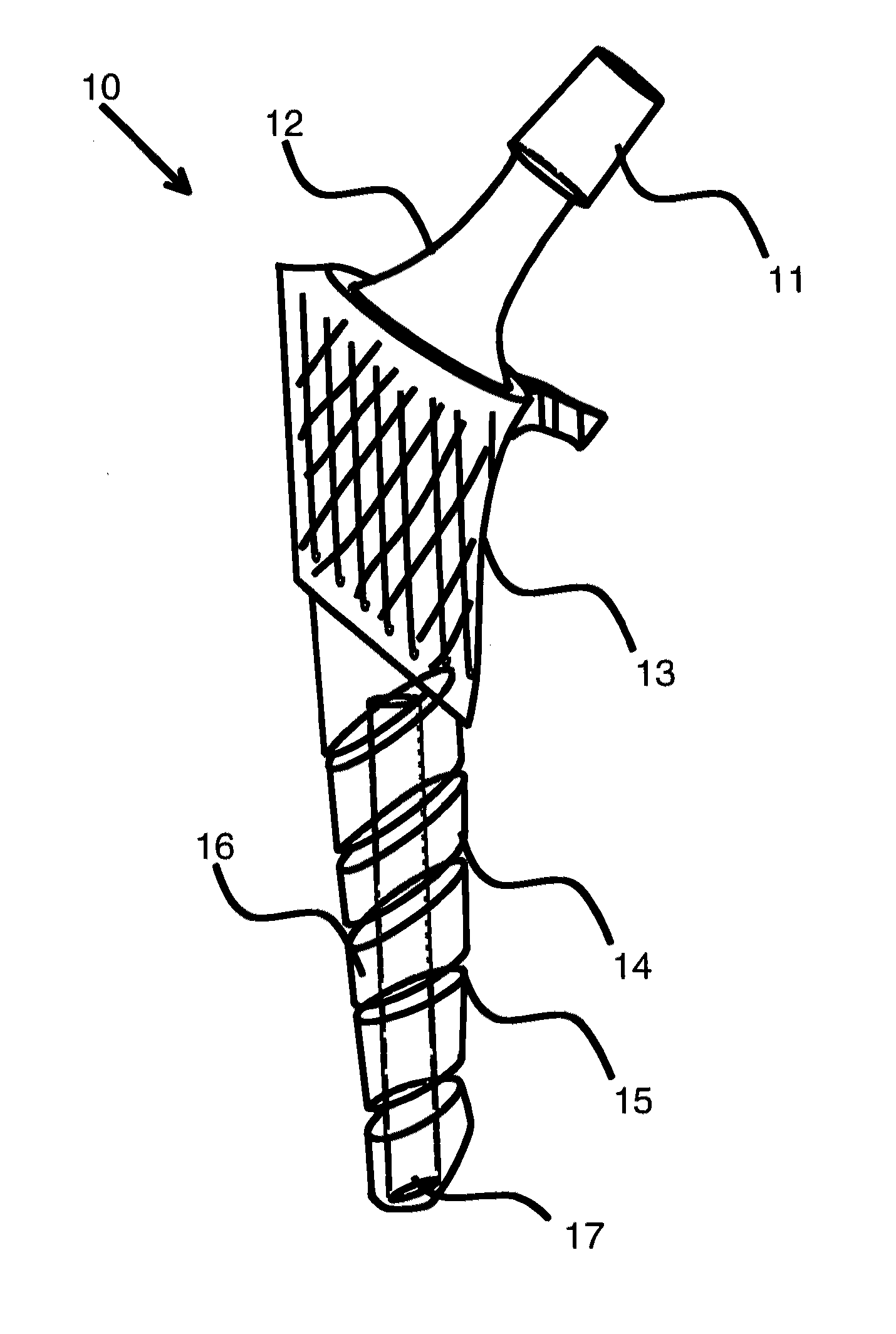

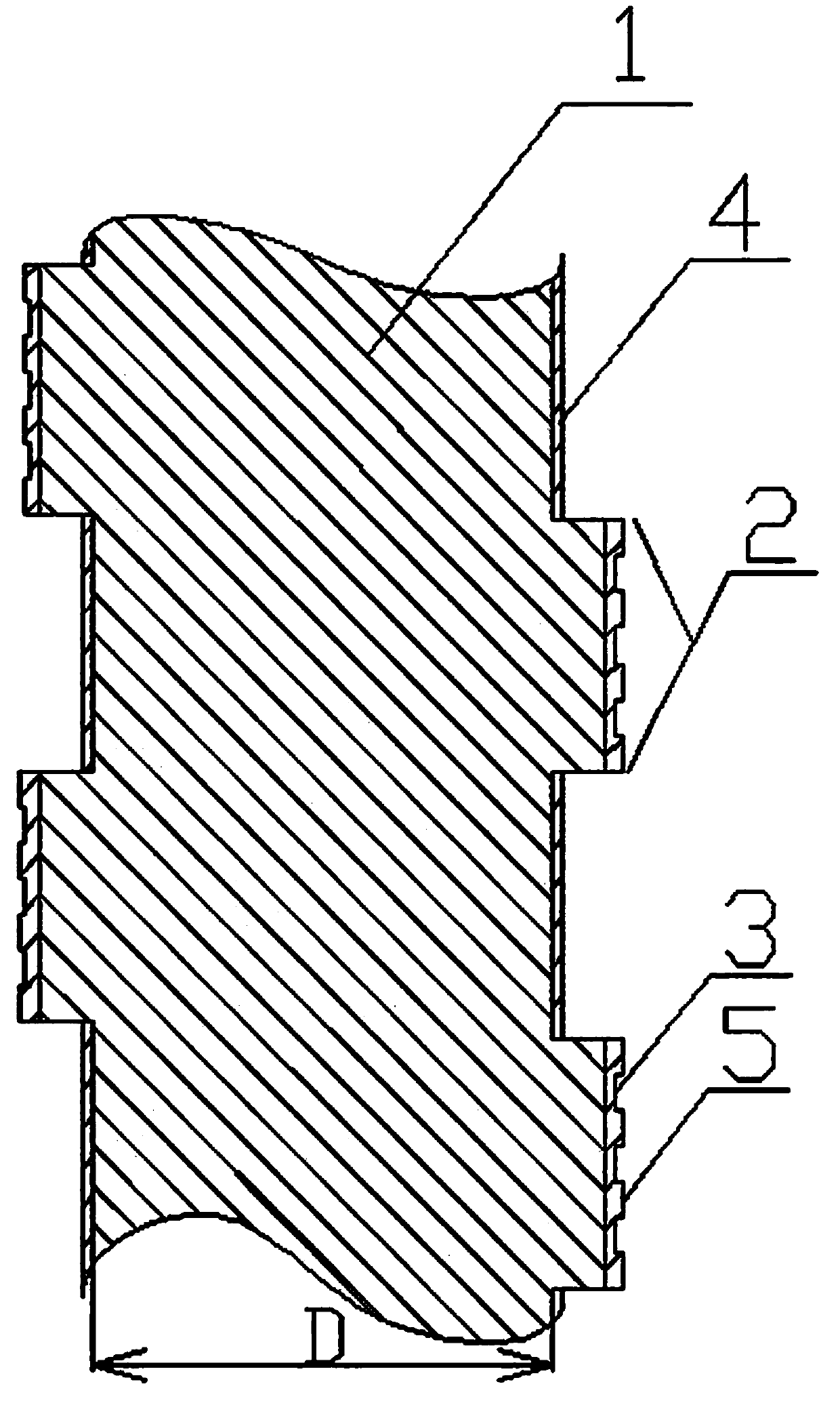

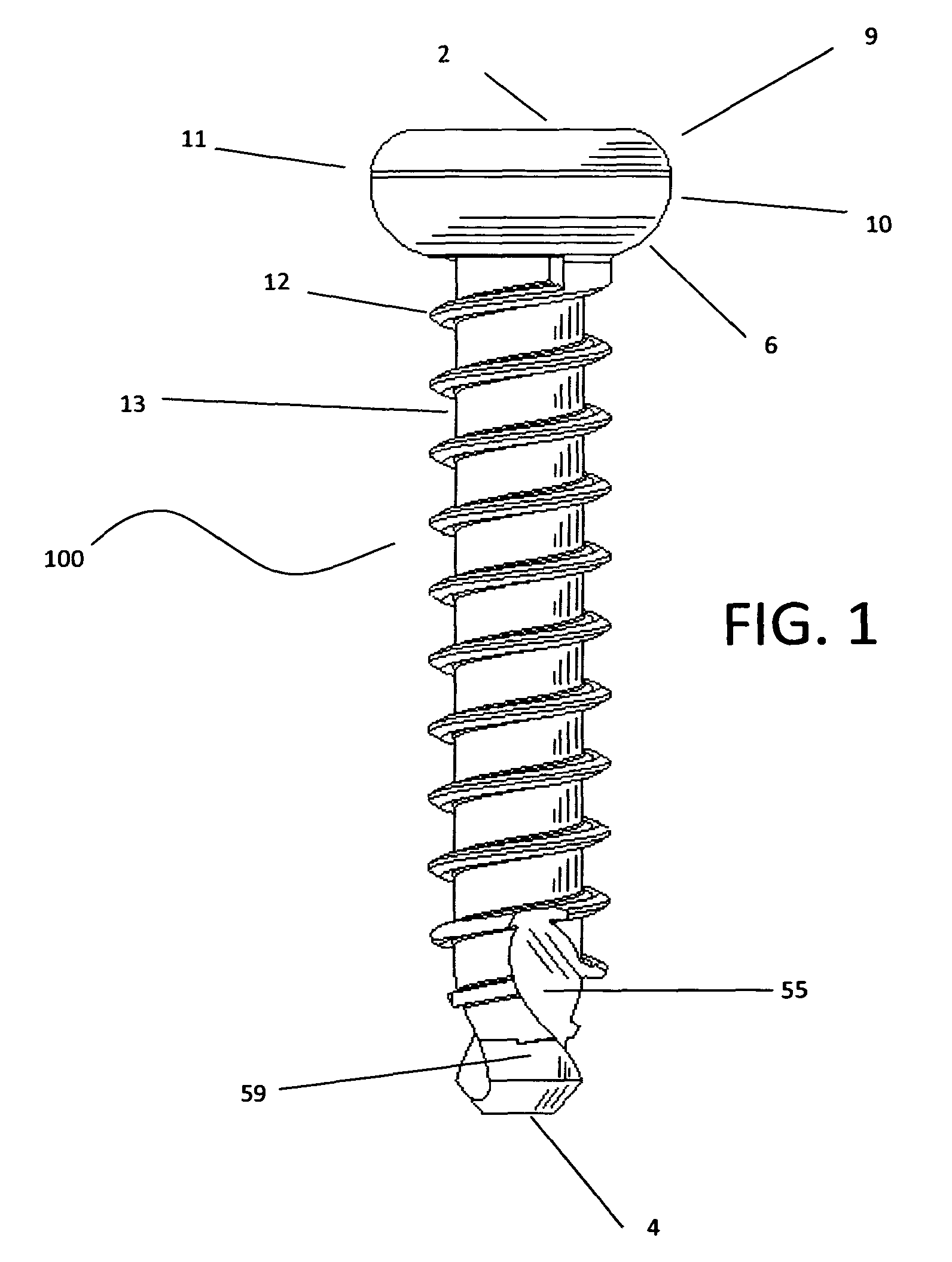

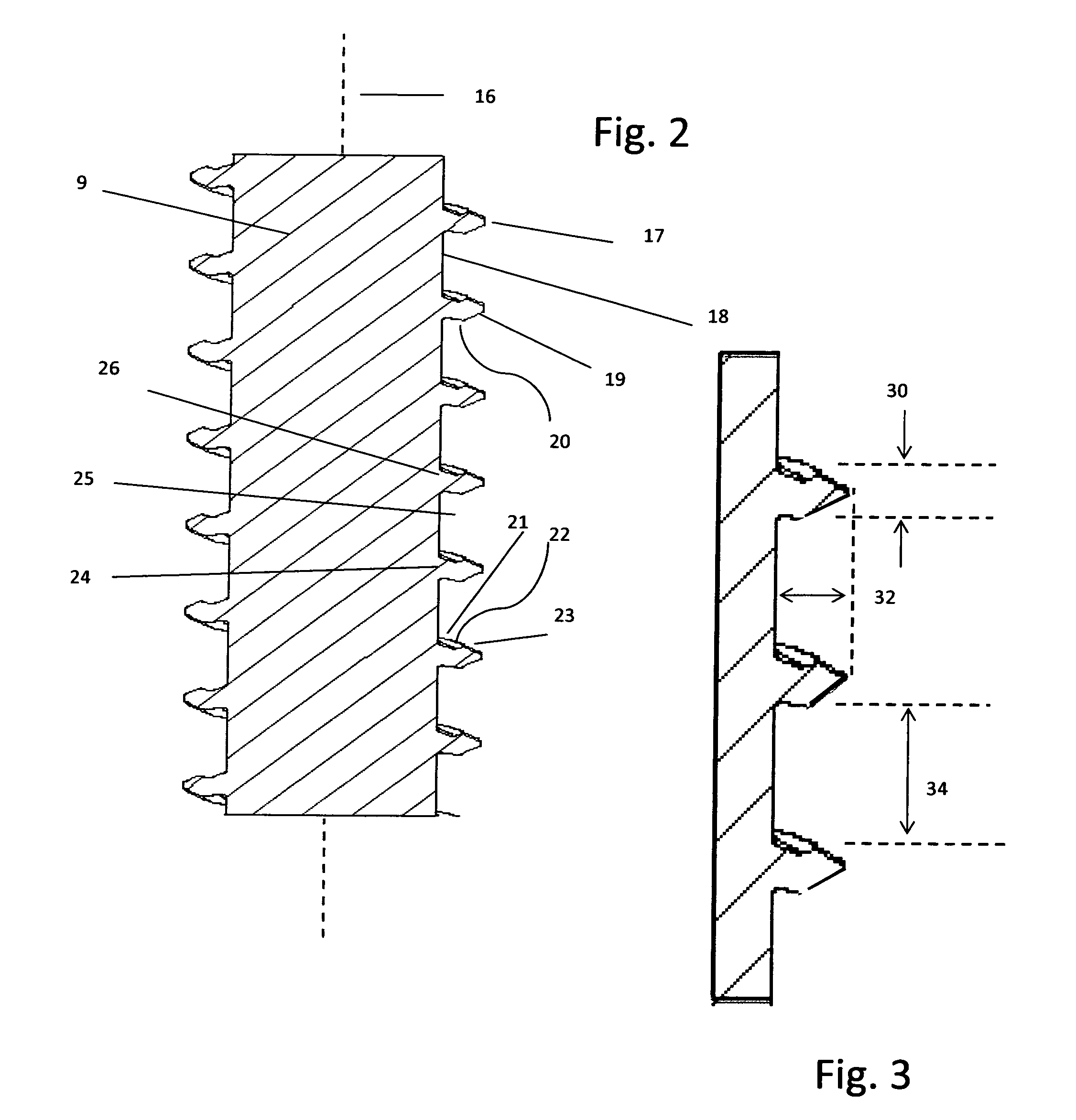

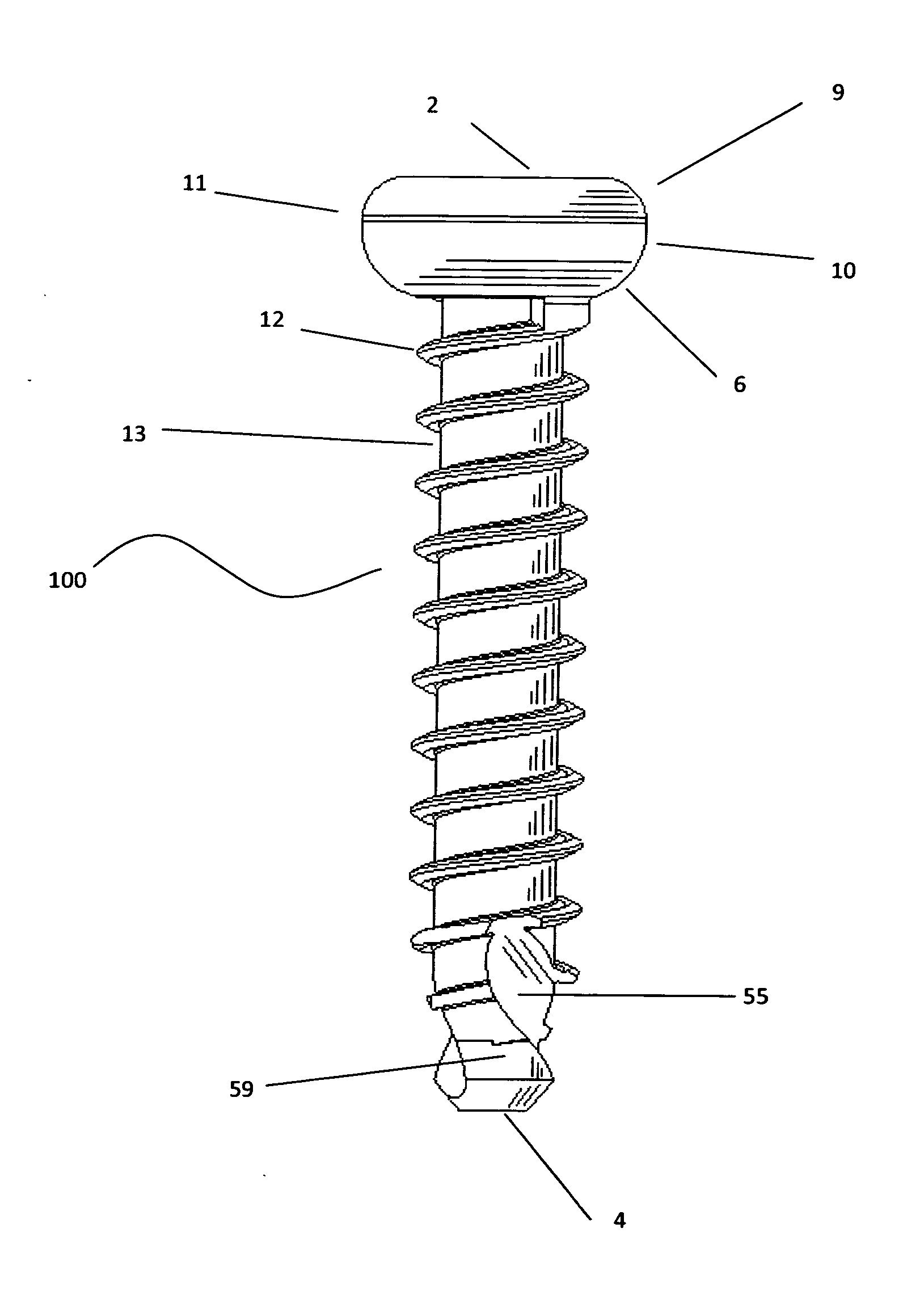

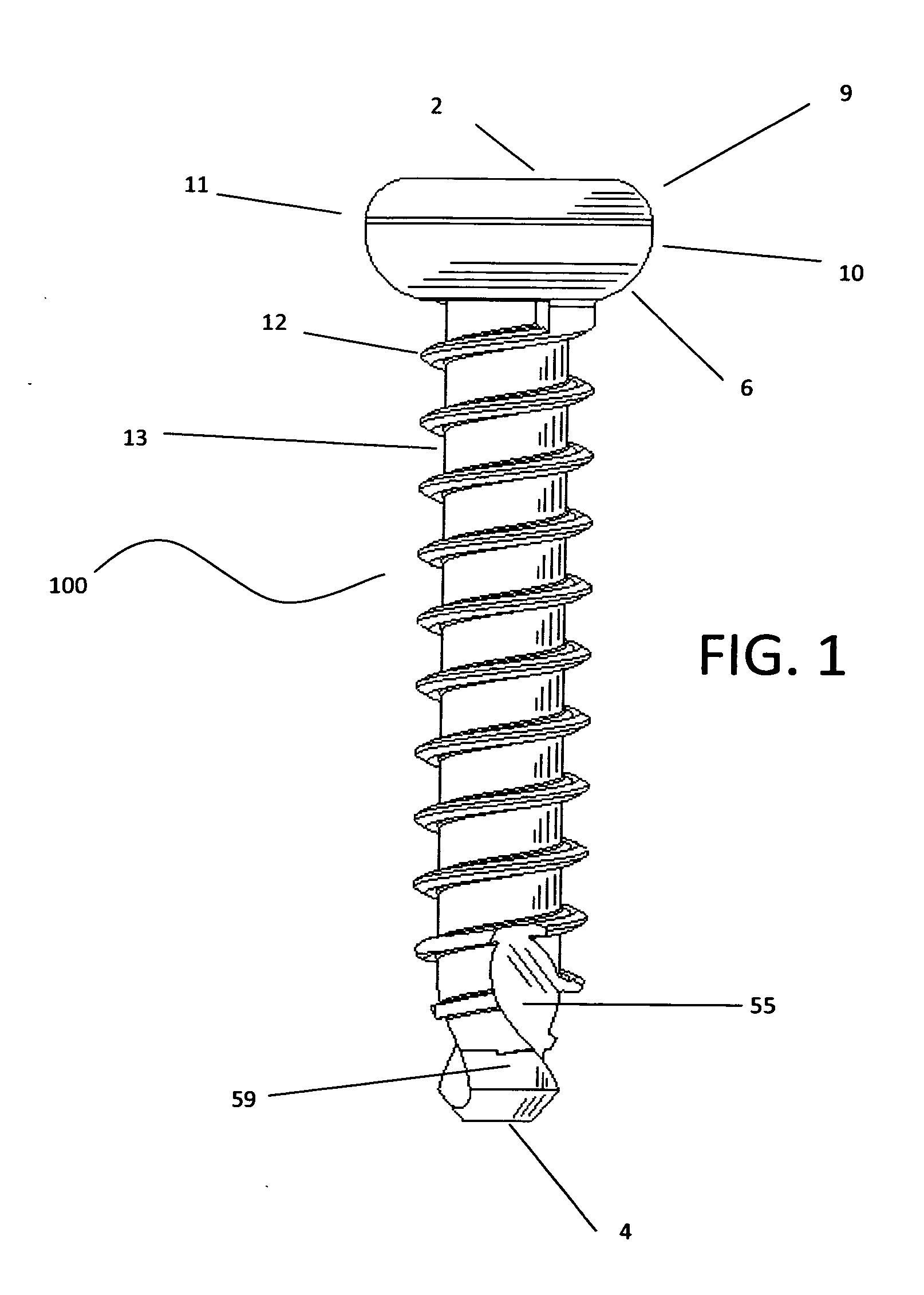

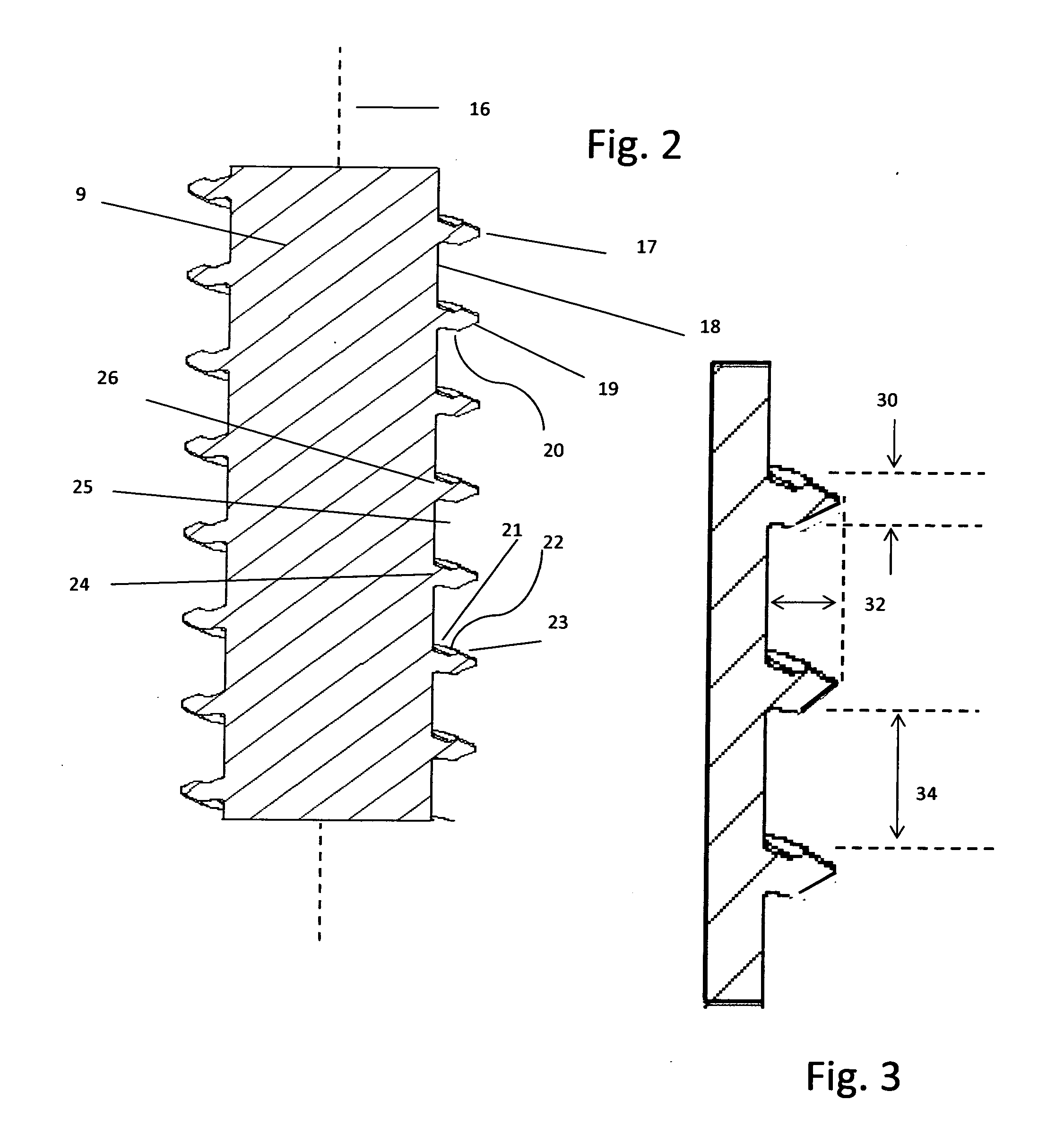

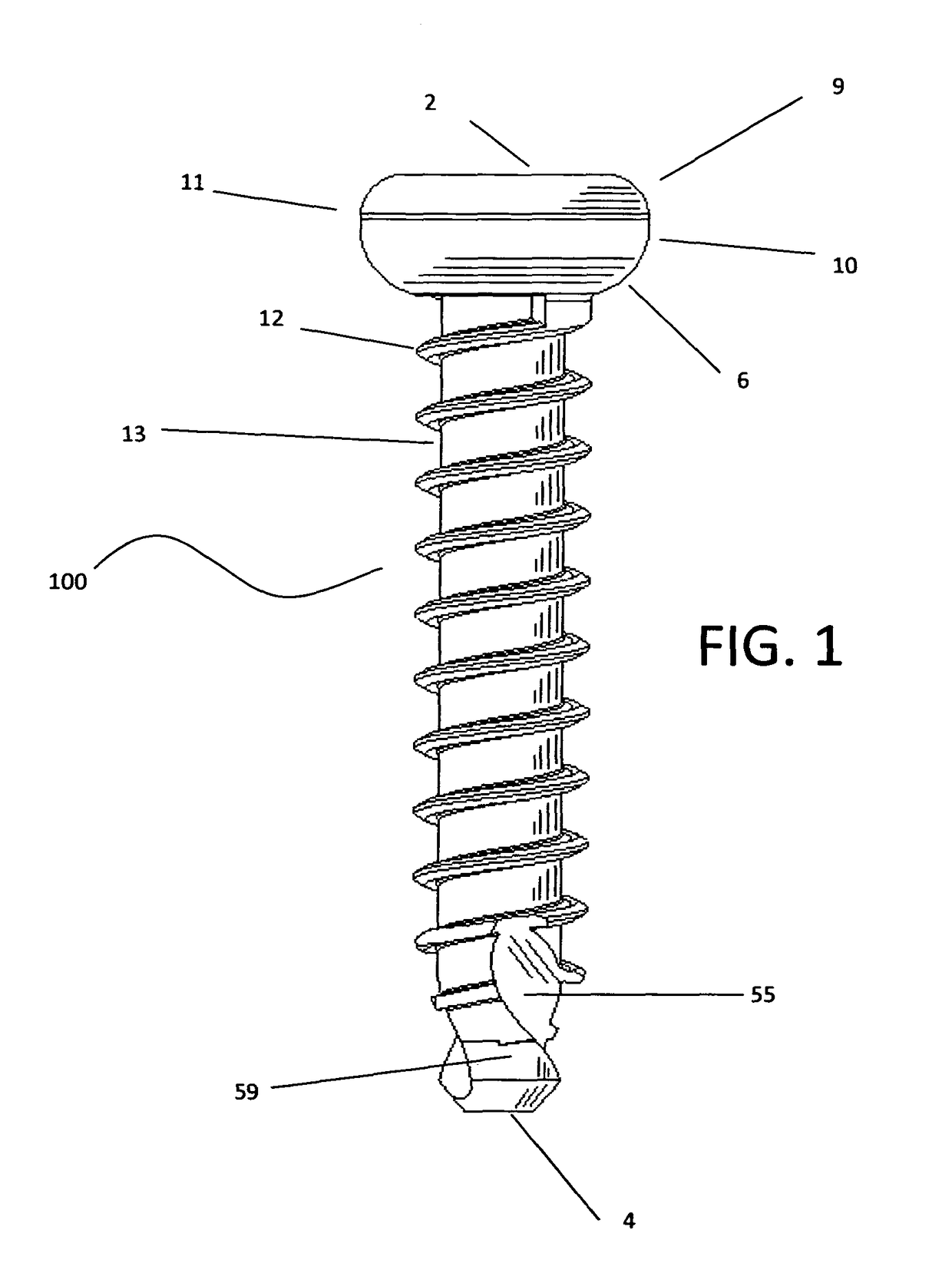

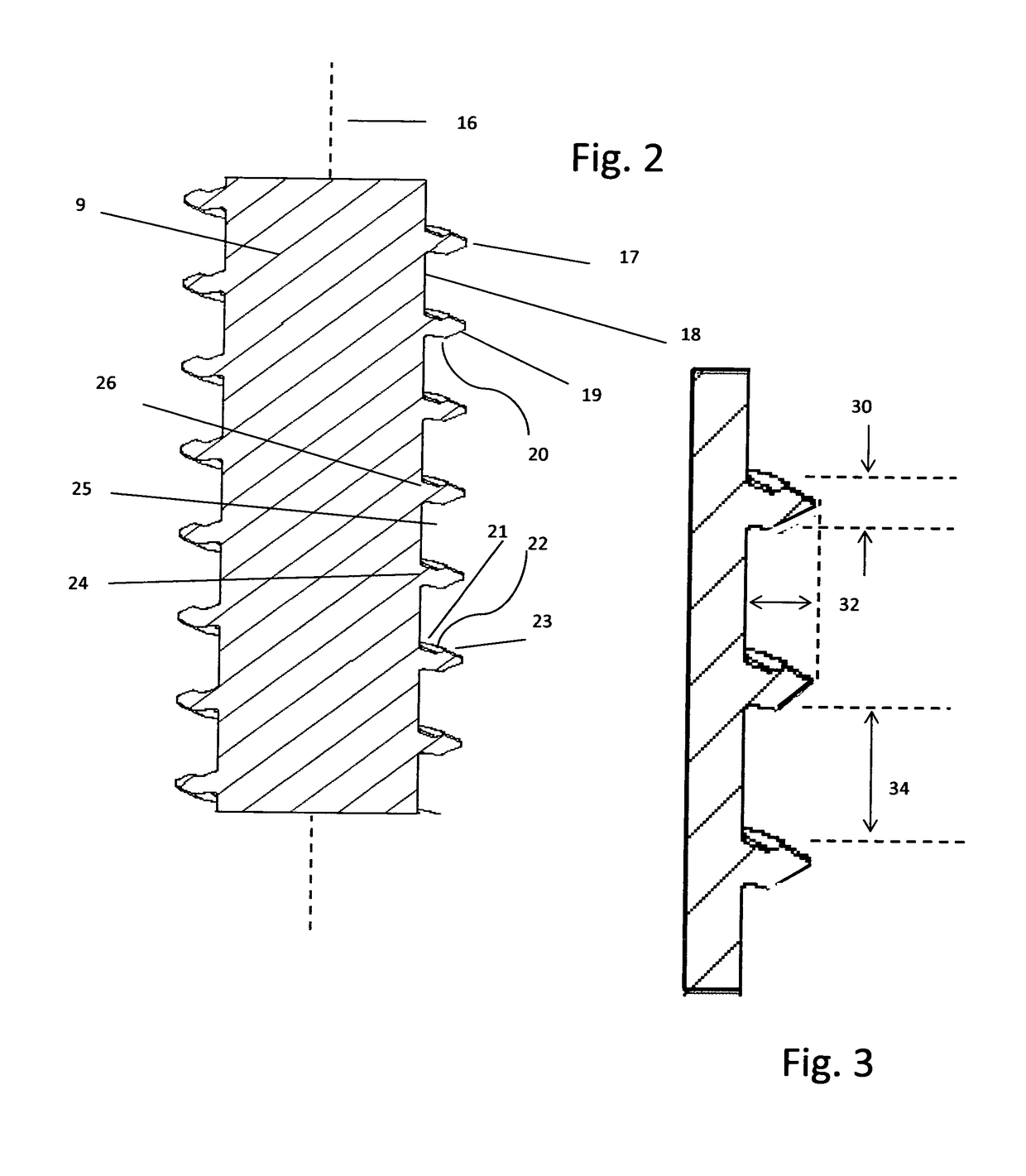

Orthopedic fastener device

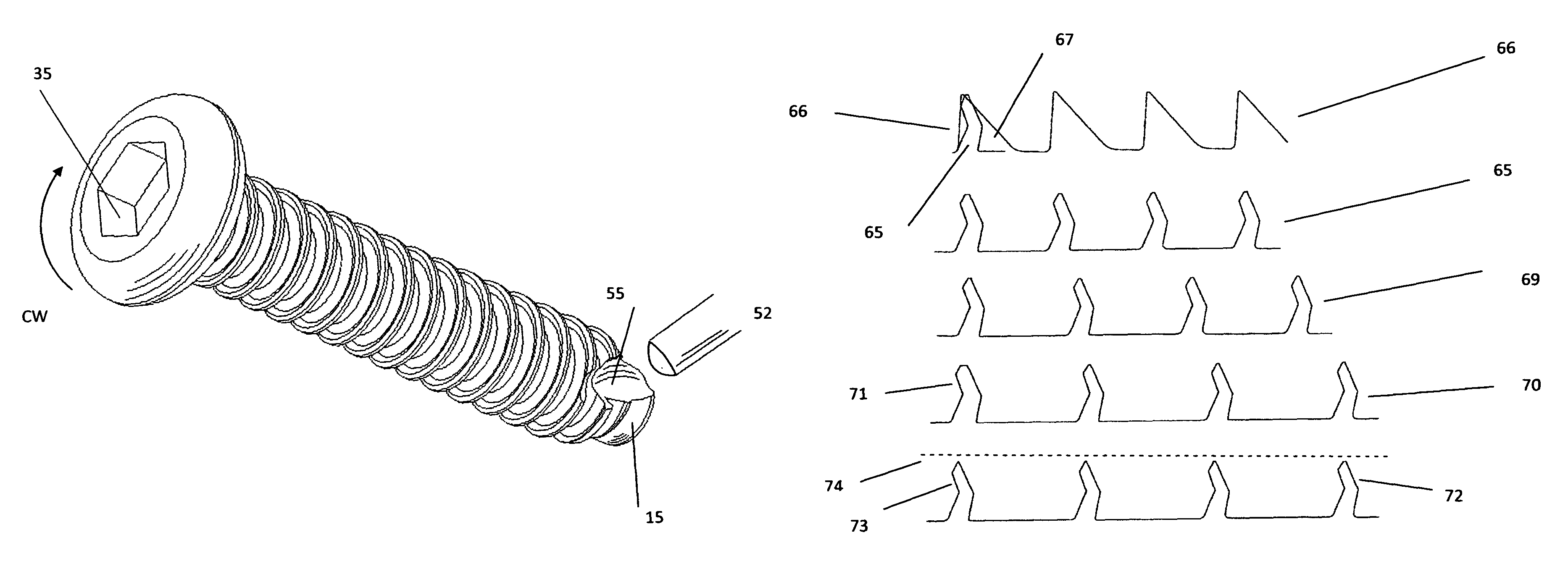

ActiveUS20140058460A1Good retentionMinimal damageSuture equipmentsLigamentsThreaded fastenerPlastic surgery

An orthopedic structure includes a method for making a threaded fastener with thread geometry and leading edge geometry which provides greater precision during installation. Specifically, thread pitch and tooth profiles are independently variable. A leading portion of the fastener advances bone shards forward of the forward of the fastener to reduce insertion torque and prevent the shards from residing in the upstream tooth profile for better retention.

Owner:RTG SCI LLC

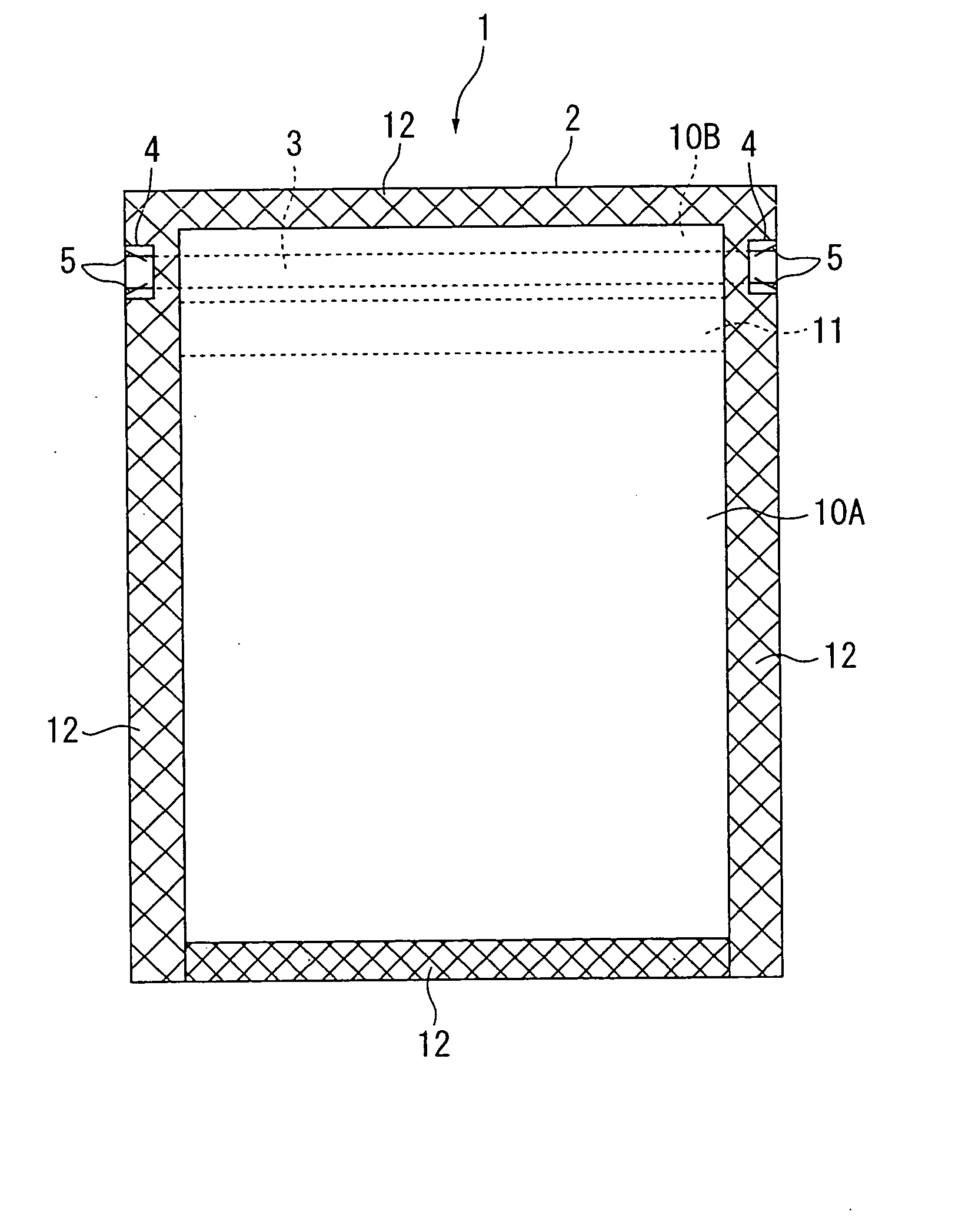

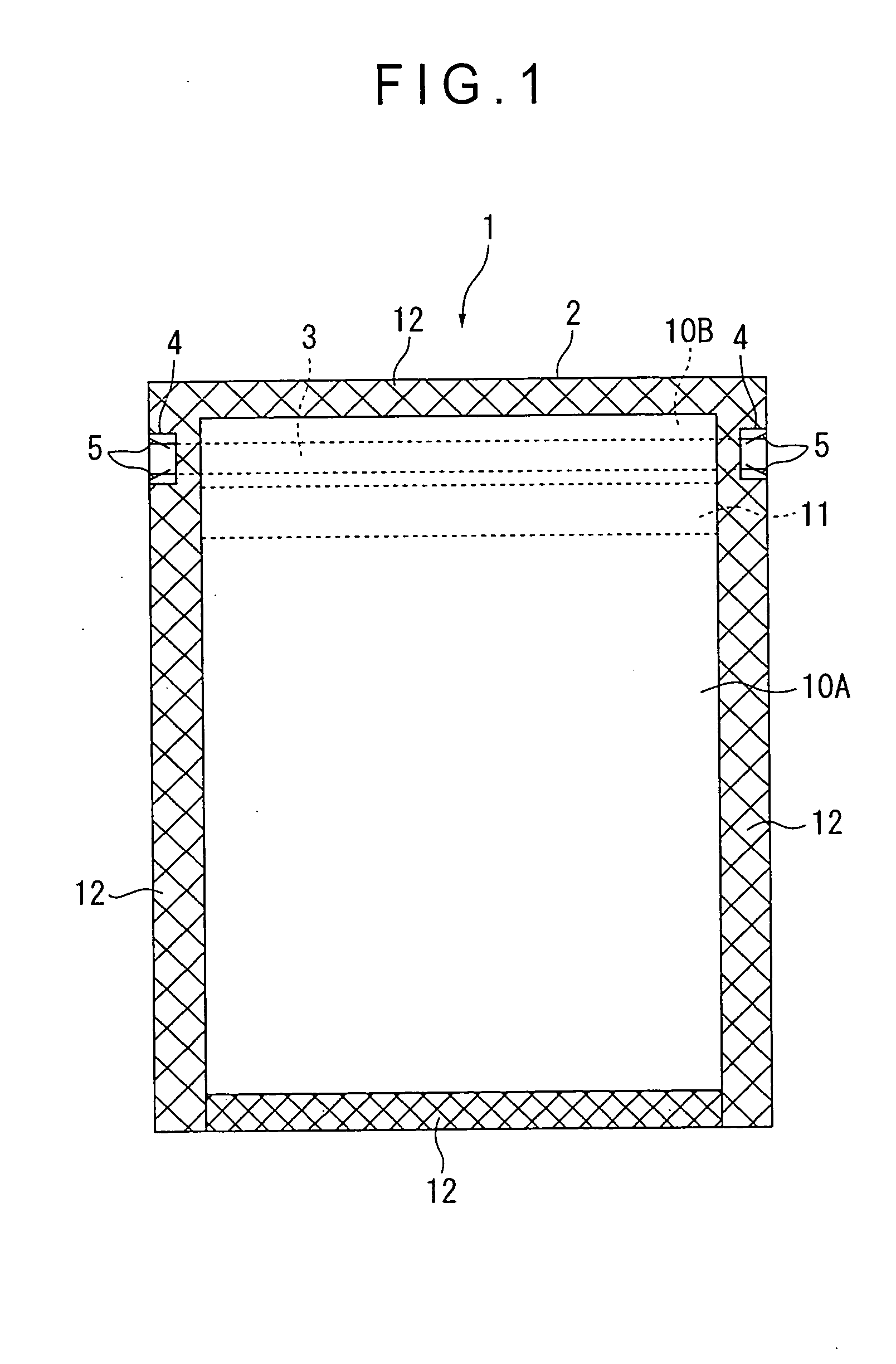

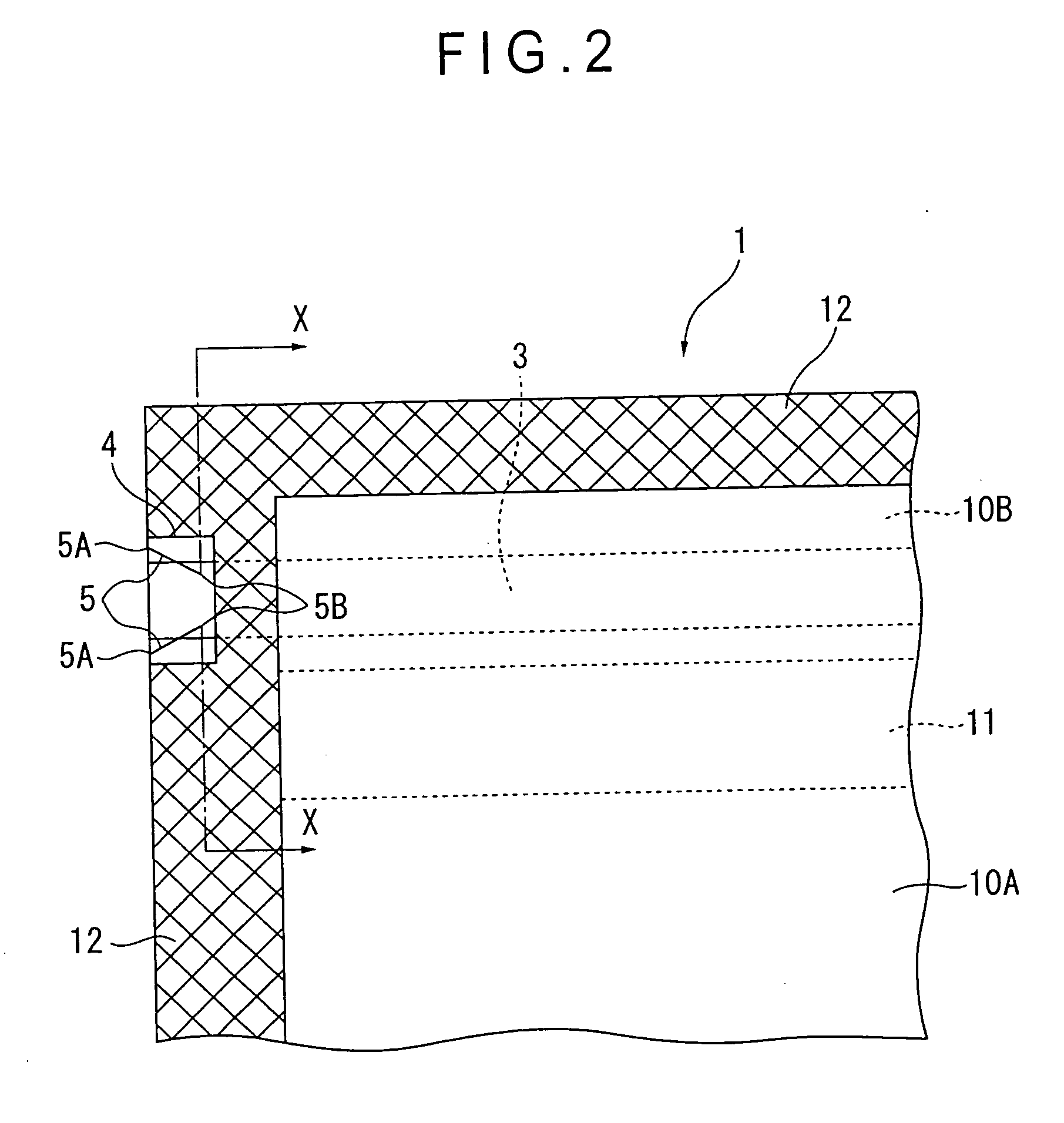

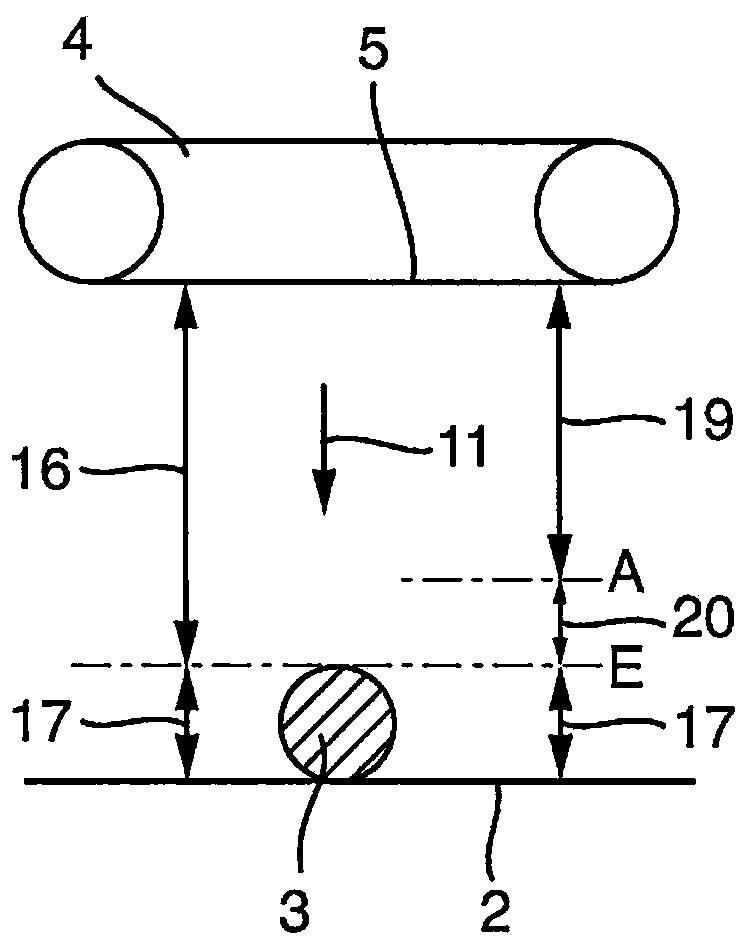

Sealed bag with unsealing tape

InactiveUS20050063624A1Improve sealingReduce cuttingEnvelopes/bags making machineryFlexible coversBand shapeEngineering

A zipper 3 (translator's comment: the zipper should be coded as 11 instead of 3) is stuck on the opening part 2 side of a packaging bag 1 and a heat-sealed part 12 is formed in the outer side from the zipper 3 (translator's comment: the zipper should be coded as 11 instead of 3) to seal the packaging bag 1. A band-shaped unsealing tape 3 is stuck, in parallel to the opening part 2, on one inner surface of the packaging bag 1 in an area between the zipper 3 (translator's comment: the zipper should be coded as 11 instead of 3) and the heat-sealed part 12. A cutout part 4 is formed on a surface opposite to the surface with the unsealing tape 3 stuck thereon at the end part of the unsealing tape 3. A pair of cut-in parts 5 are formed on the packaging bag 1 at the end part of the unsealing tape 3.

Owner:IDEMITSU UNITECH CO LTD

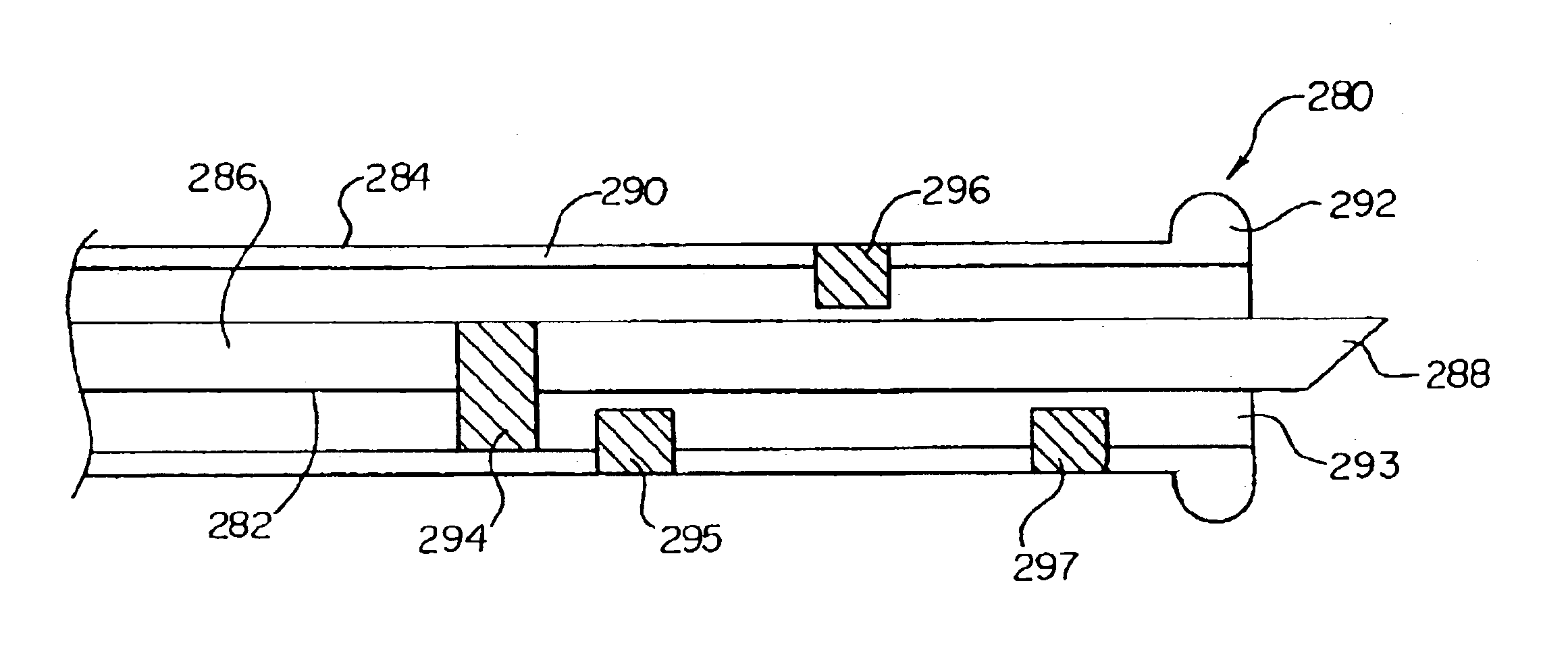

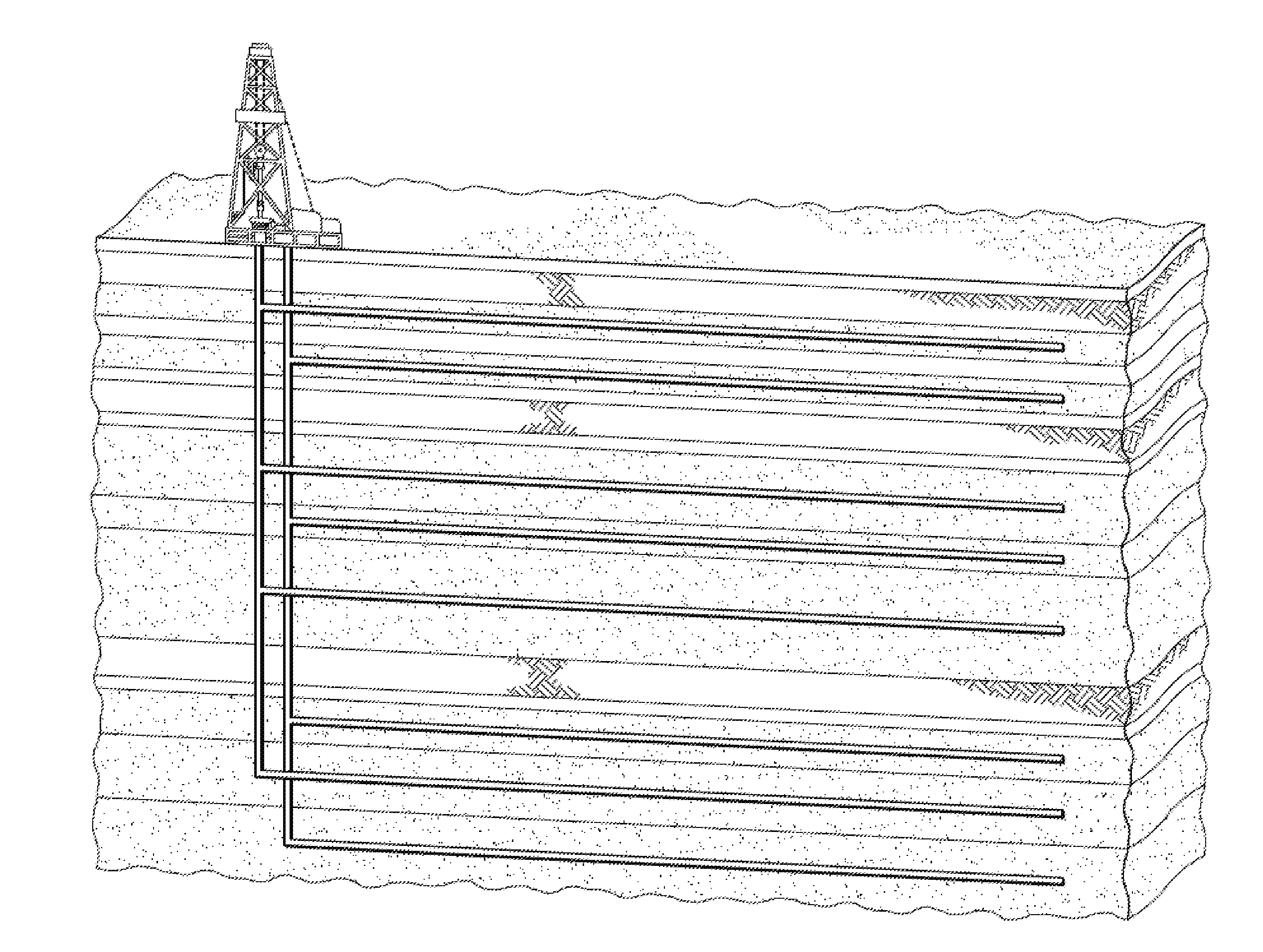

Infusion devices and method

InactiveUS6939322B2Less sharpReduce cuttingUltrasonic/sonic/infrasonic diagnosticsGuide needlesCardiac muscleInjection point

Myocardial revascularization catheters and methods are provided herein. Catheters in accord with the present invention may include an outer shaft and an inner shaft where the inner shaft may be slidably and rotatably disposed in the outer shaft and the distal movement of the inner shaft may be arrested by the engagement of stops and catches located within the inner and outer shaft Methods in accord with the current invention may include providing a therapeutic, providing a radiopaque contrast media, injecting the therapeutic through a lumen into the myocardium of the heart, and injecting the radiopaque contrast media through a lumen into myocardium of the heart. In this example, the location of the injection the radiopaque material may be chosen to indicate the injection point of the injection of the therapeutic.

Owner:BOSTON SCI SCIMED INC

Shaving Razors and Cartridges

ActiveUS20100083510A1Avoid discomfortImprove rinsing characteristicMetal working apparatusEngineeringKnife blades

A shaving cartridge has a housing with at least one blade having a blade edge. The housing has a first guard in front of the blade with a plurality of projections defining a plurality of open slots extending generally transverse to the blade edge. The open slots have a width of about 0.20 mm to about 0.49 mm and a pitch of about 0.40 mm to about 0.85 mm for allowing the free passage of hair during shaving.

Owner:THE GILLETTE CO

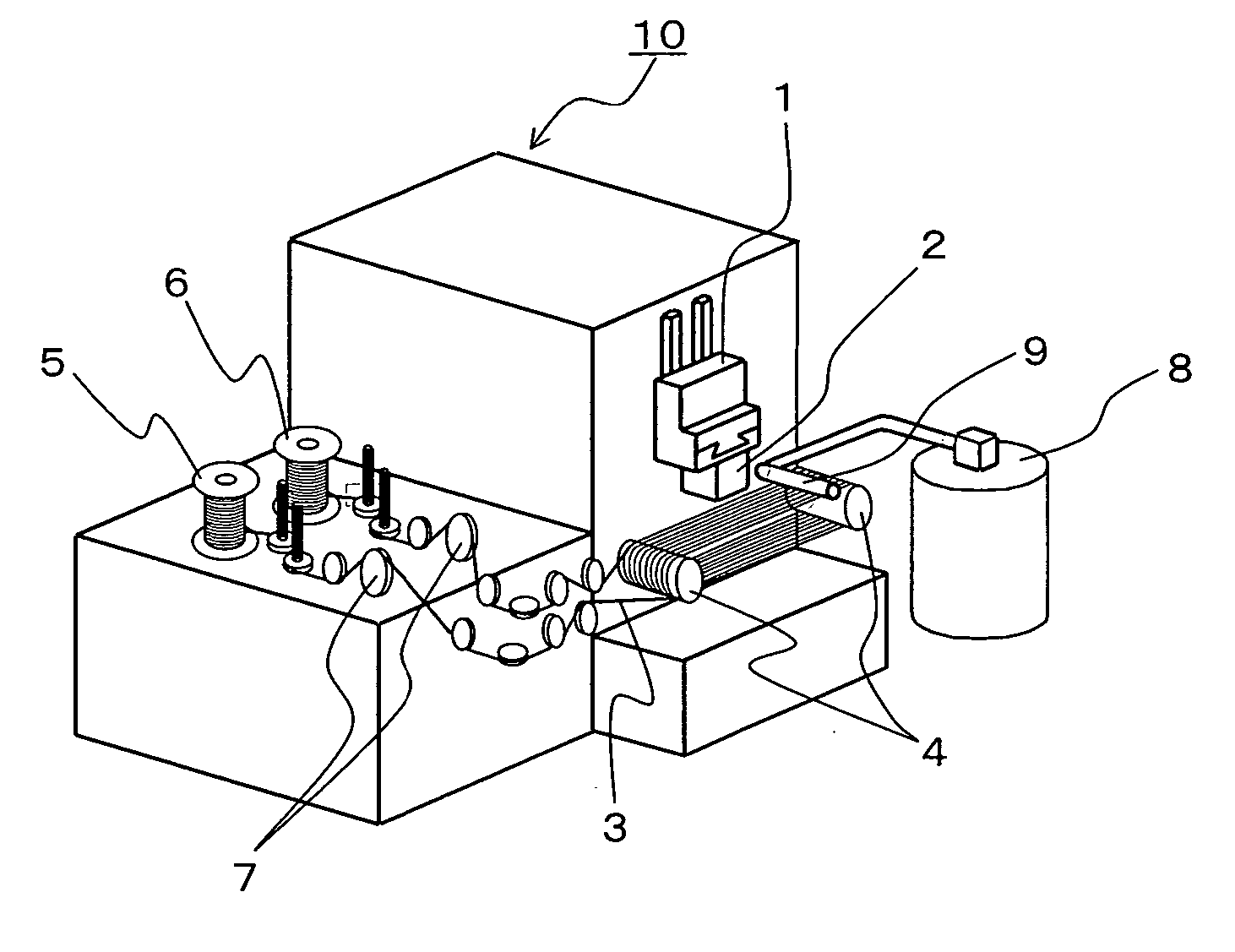

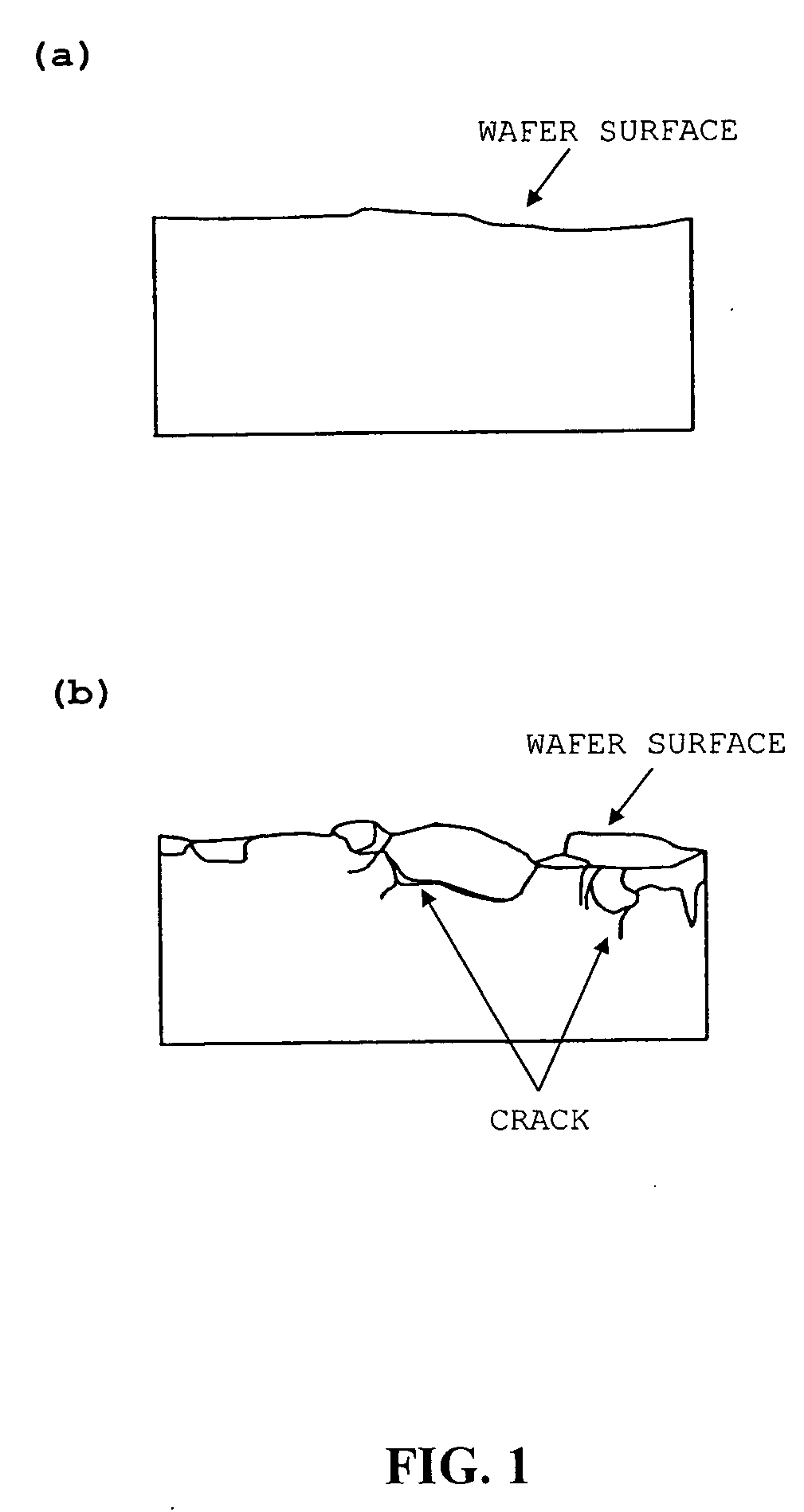

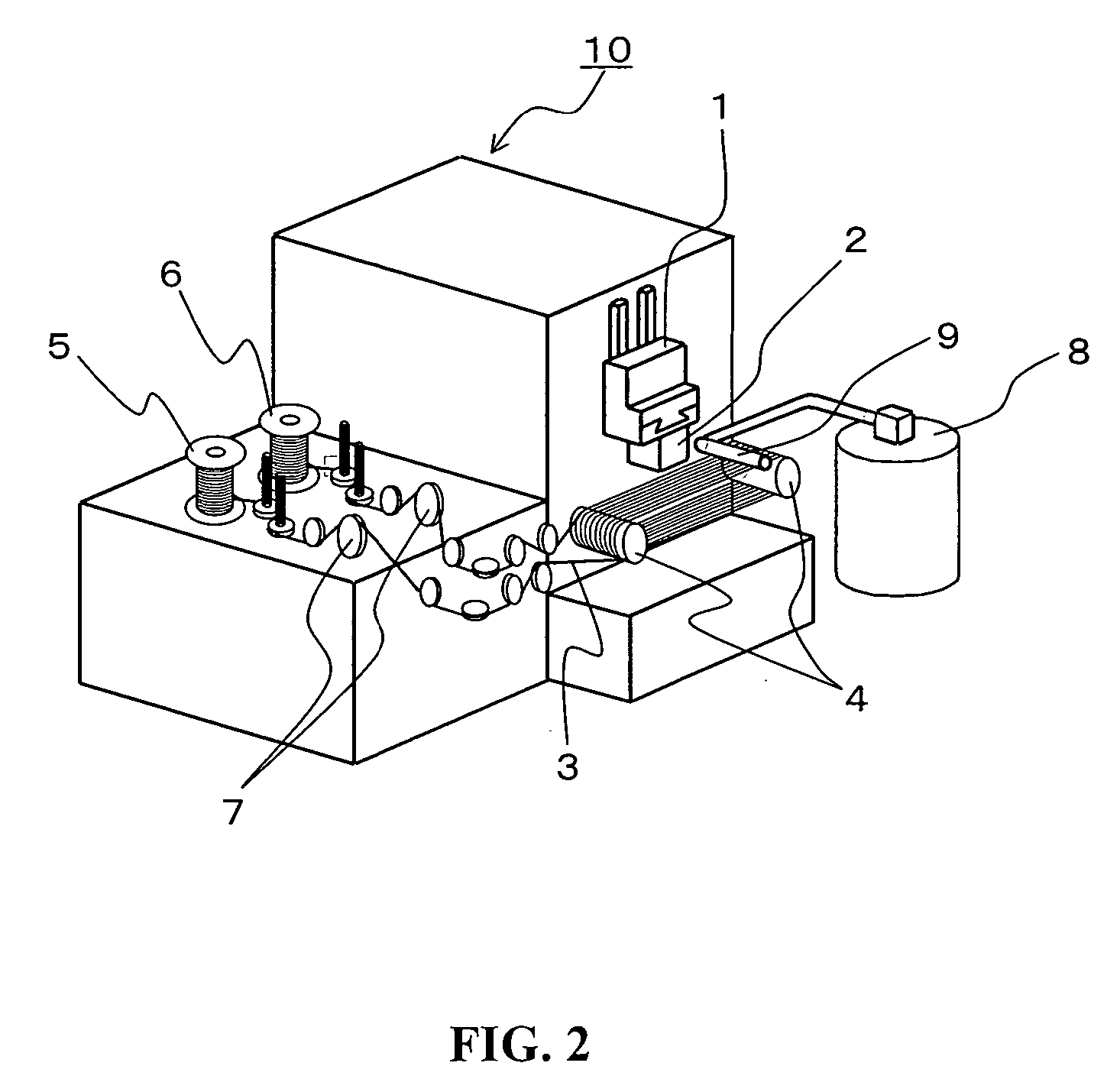

Slurry for slicing silicon ingot and method for slicing silicon ingot using same

InactiveUS20060075687A1Reduce cuttingReduce resistancePigmenting treatmentOther chemical processesSlurryIngot

In a slurry for cutting a silicon ingot according to the present invention, a content of a basic material is at least 3.5% by mass with respect to the total mass of a liquid component of a slurry, organic amine is contained in a mass ratio of 0.5 to 5.0 with respect to water in a liquid component of the slurry, and pH of the slurry is 12 or more. Furthermore, according to a method of cutting a silicon ingot according to the present invention, the above-mentioned slurry for cutting a silicon ingot is used at 65° C. to 95° C. Consequently, the cutting resistance during cutting processing of a silicon ingot is reduced, and a wafer of high quality can be obtained efficiently.

Owner:MITSUBISHI ELECTRIC CORP

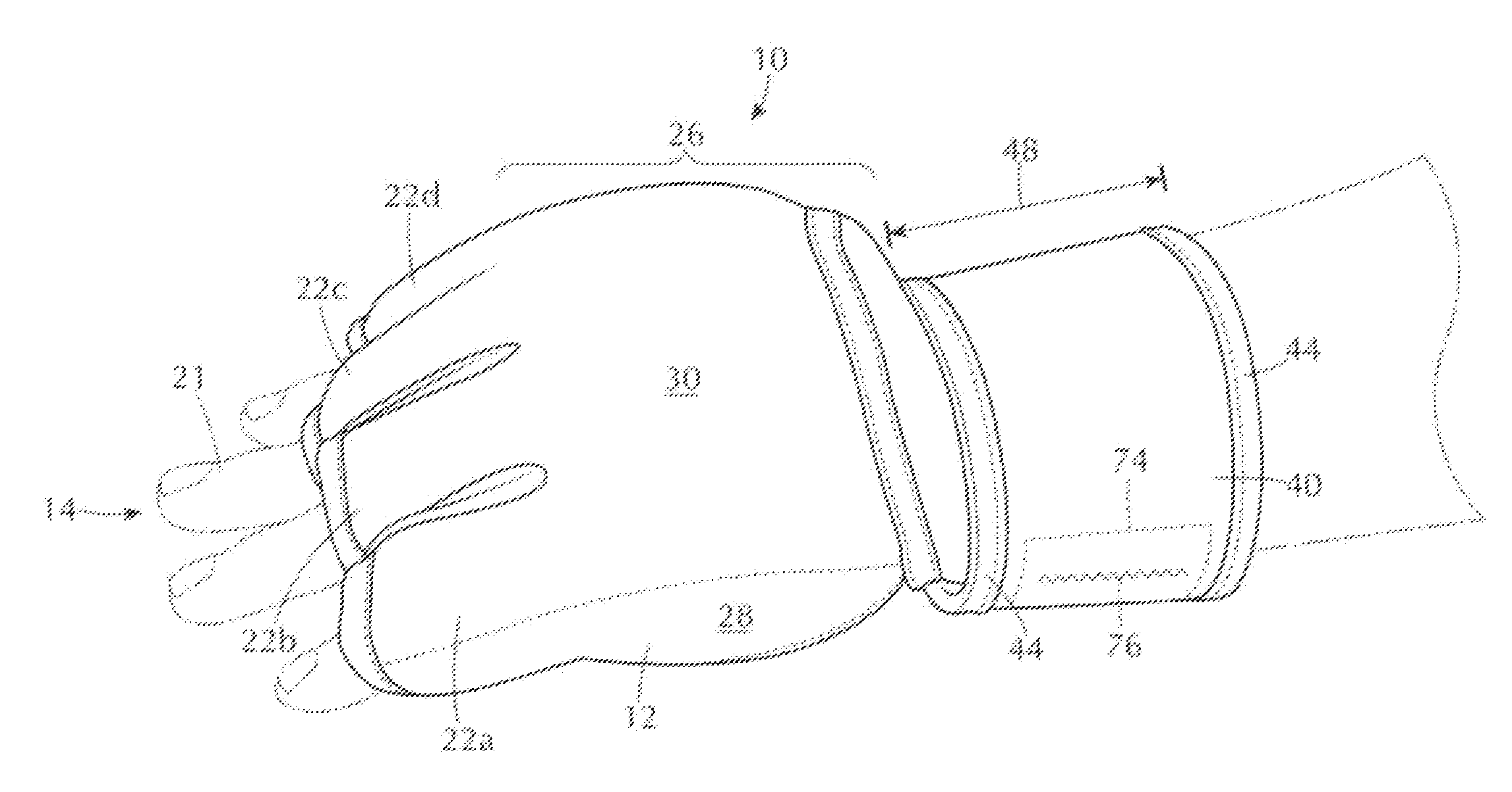

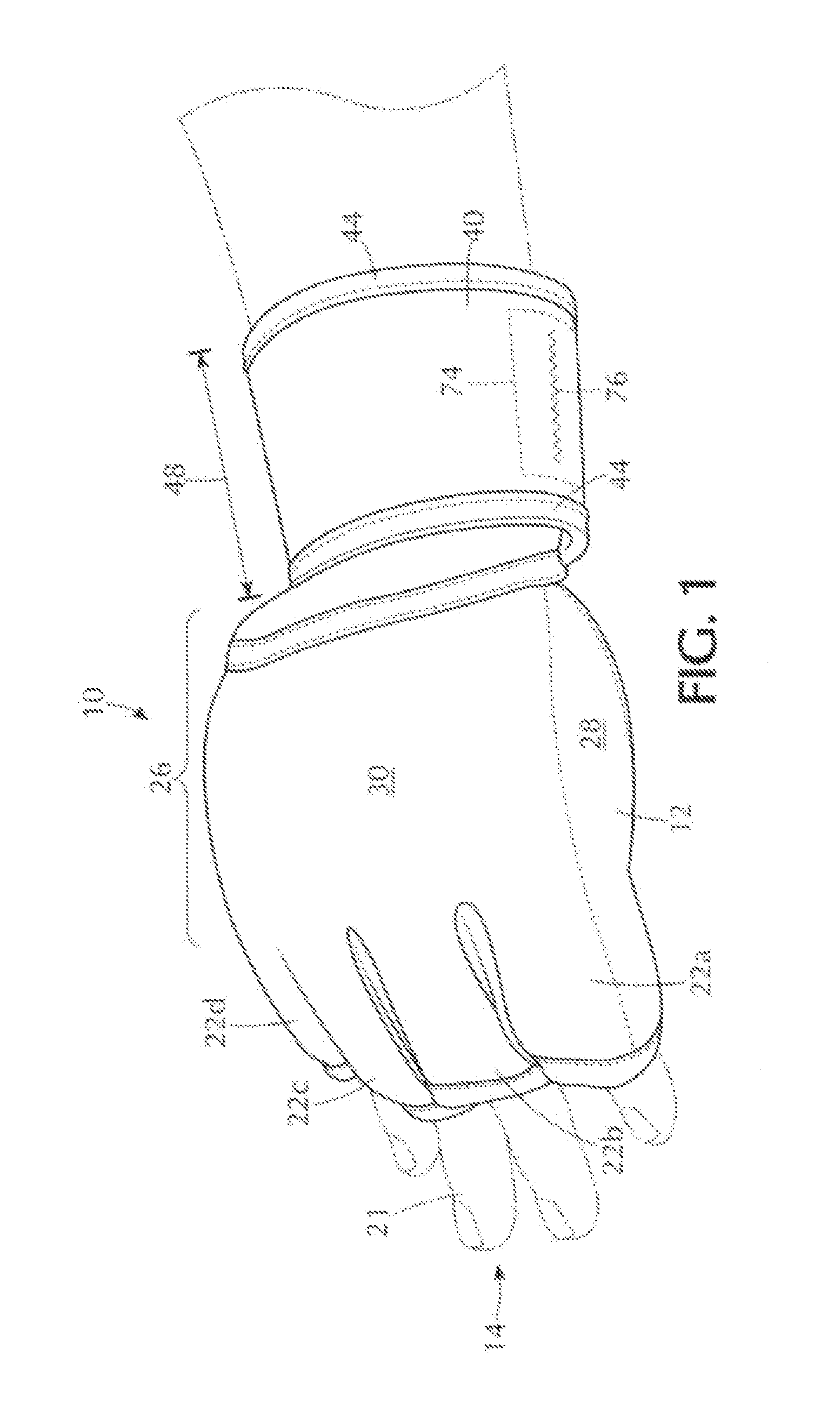

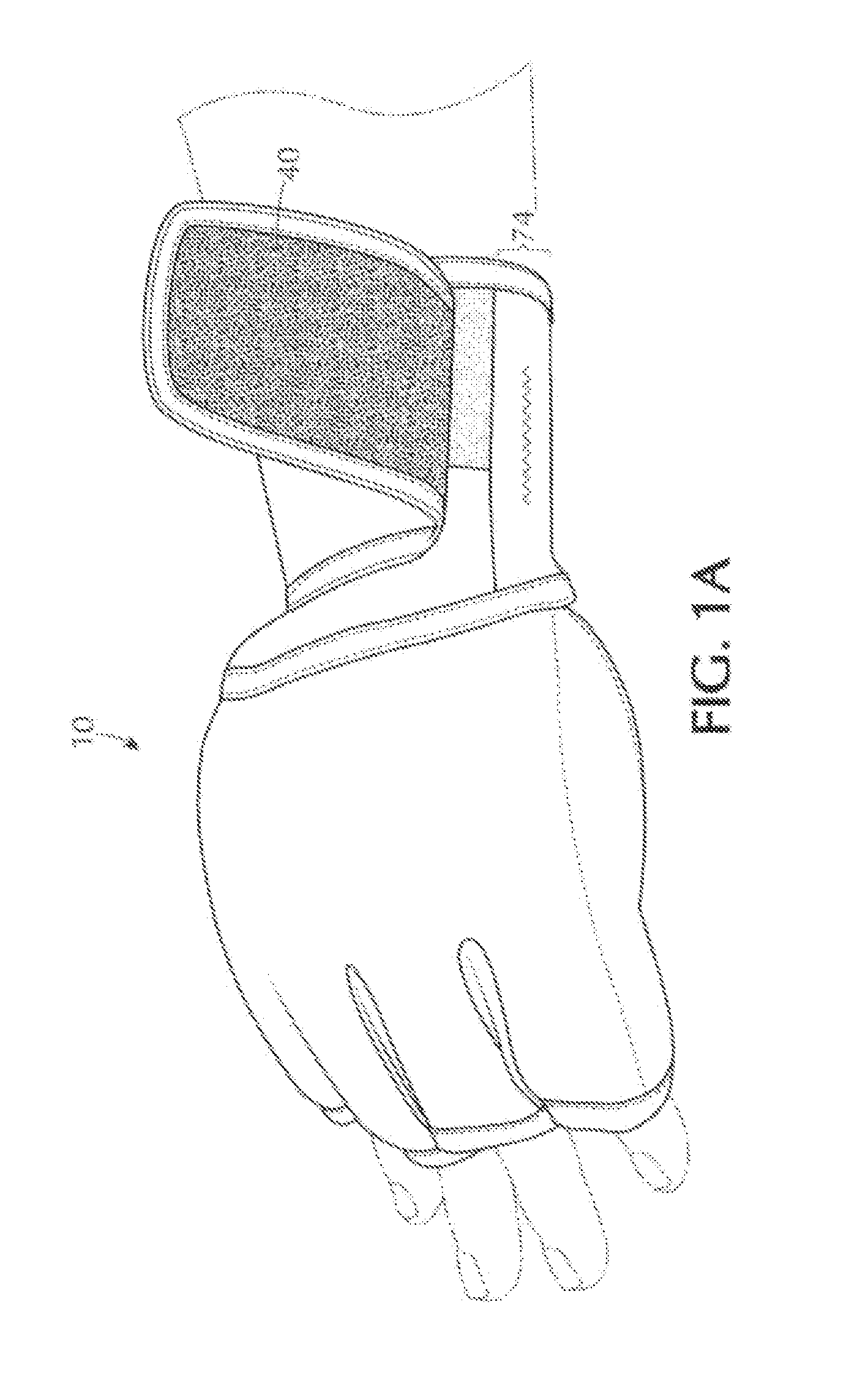

Mixed martial arts equipment

An MMA fighting glove is disclosed herein which has a smooth front profile especially at the top and lateral side of the glove when the glove is clenched. In this manner, the glove is less likely to cut an opponent's skin or training partner's skin when the lateral side grazes the opponent or training partner. Moreover, a sleeve may cover a strap mechanism of the MMA glove described herein or a prior art MMA glove to cover any protrusions or aberrations of the strap mechanism to further mitigate cutting of the opponent or training partner.

Owner:BISAILLON ALBERT

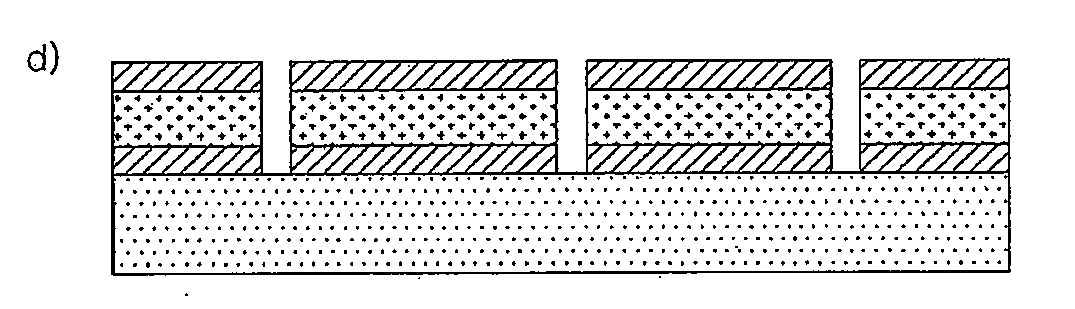

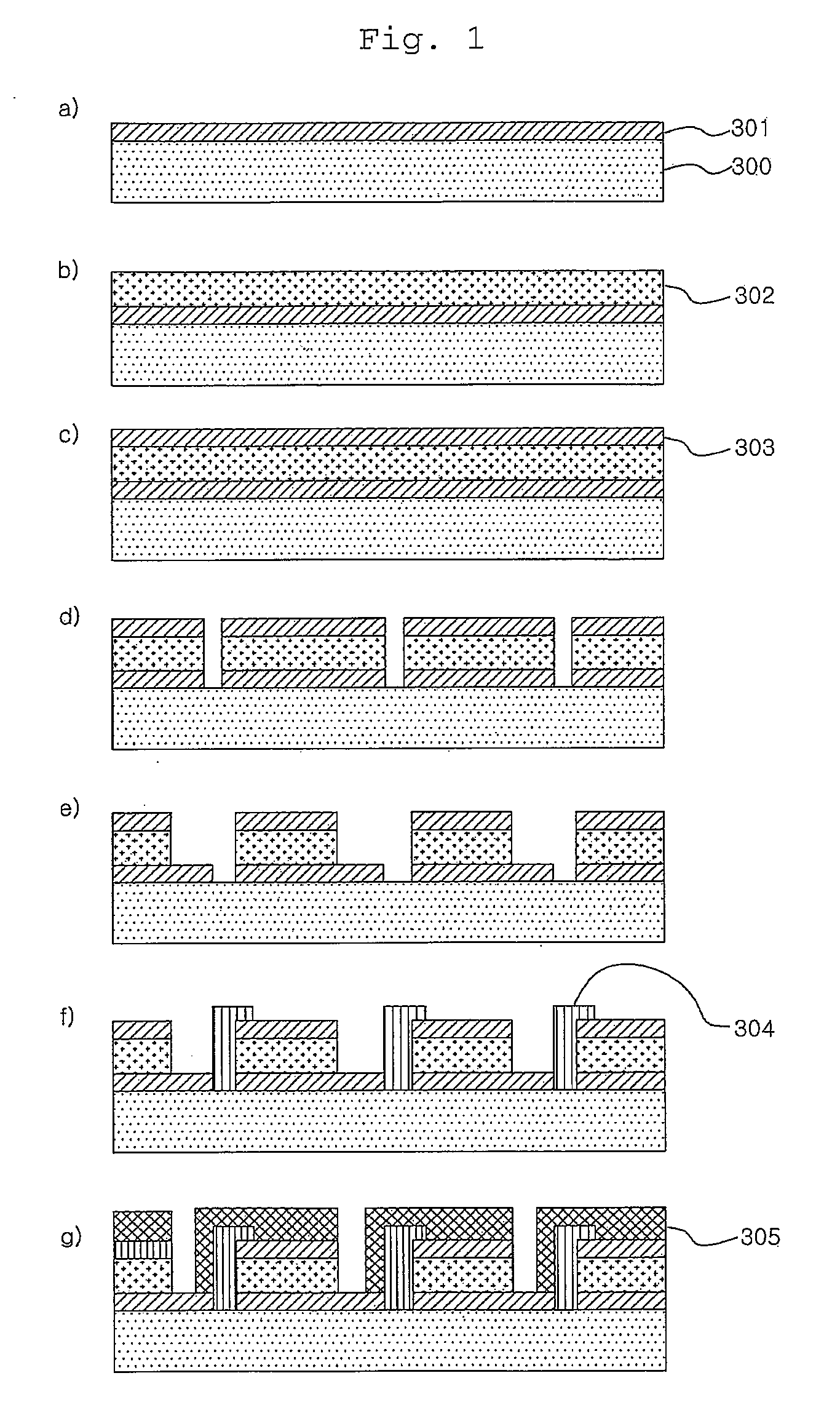

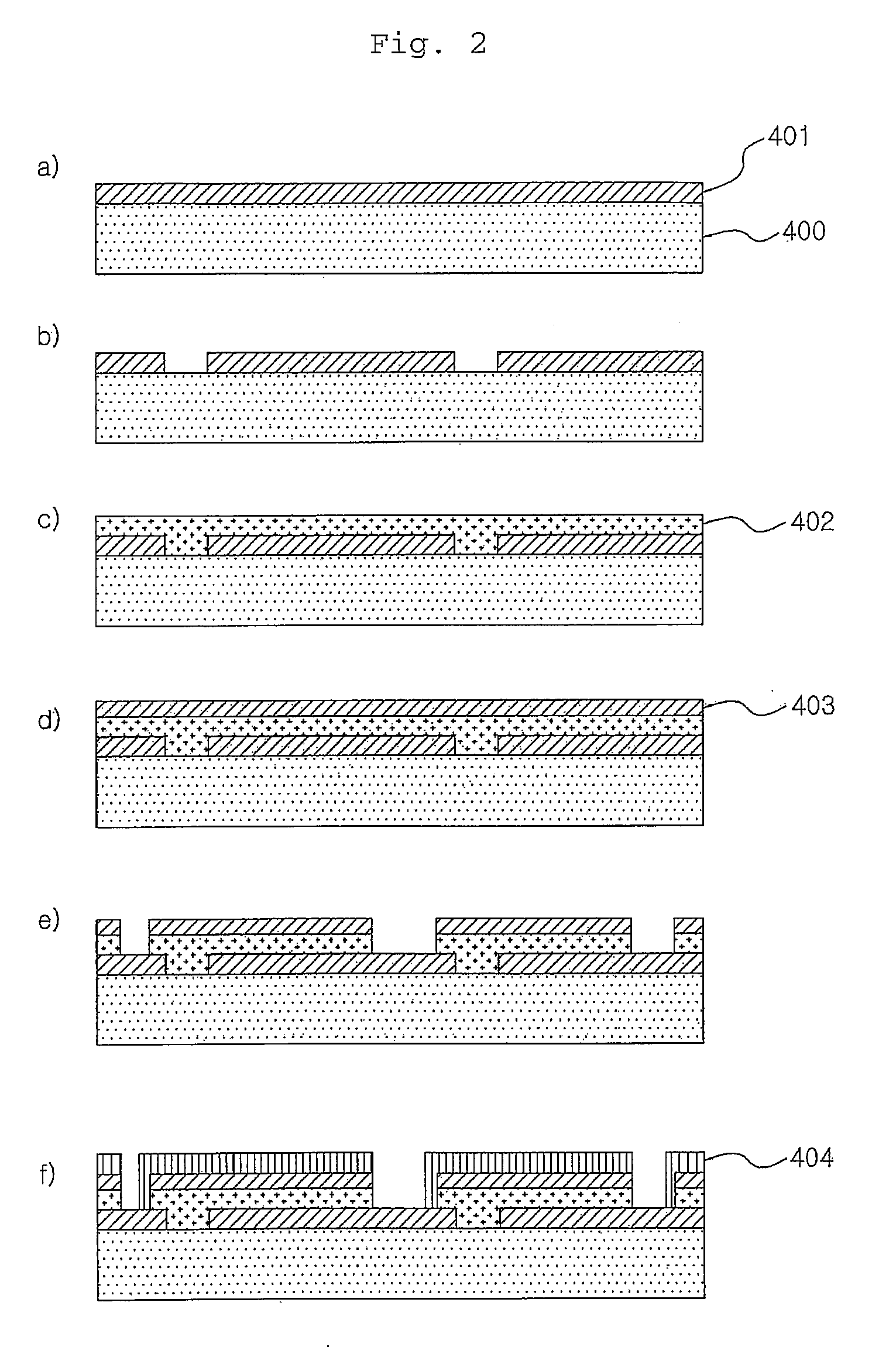

Thin-film type solar cell and method for manufacturing the same

InactiveUS20100059100A1Reduce frequencyIncrease cost reducing effectPV power plantsSemiconductor/solid-state device manufacturingEngineeringSolar cell

Disclosed are a method for manufacturing a thin-film type solar cell and a thin-film type solar cell obtained thereby that uses a direct printing method and reduces the frequency of a cutting process.

Owner:LG ELECTRONICS INC

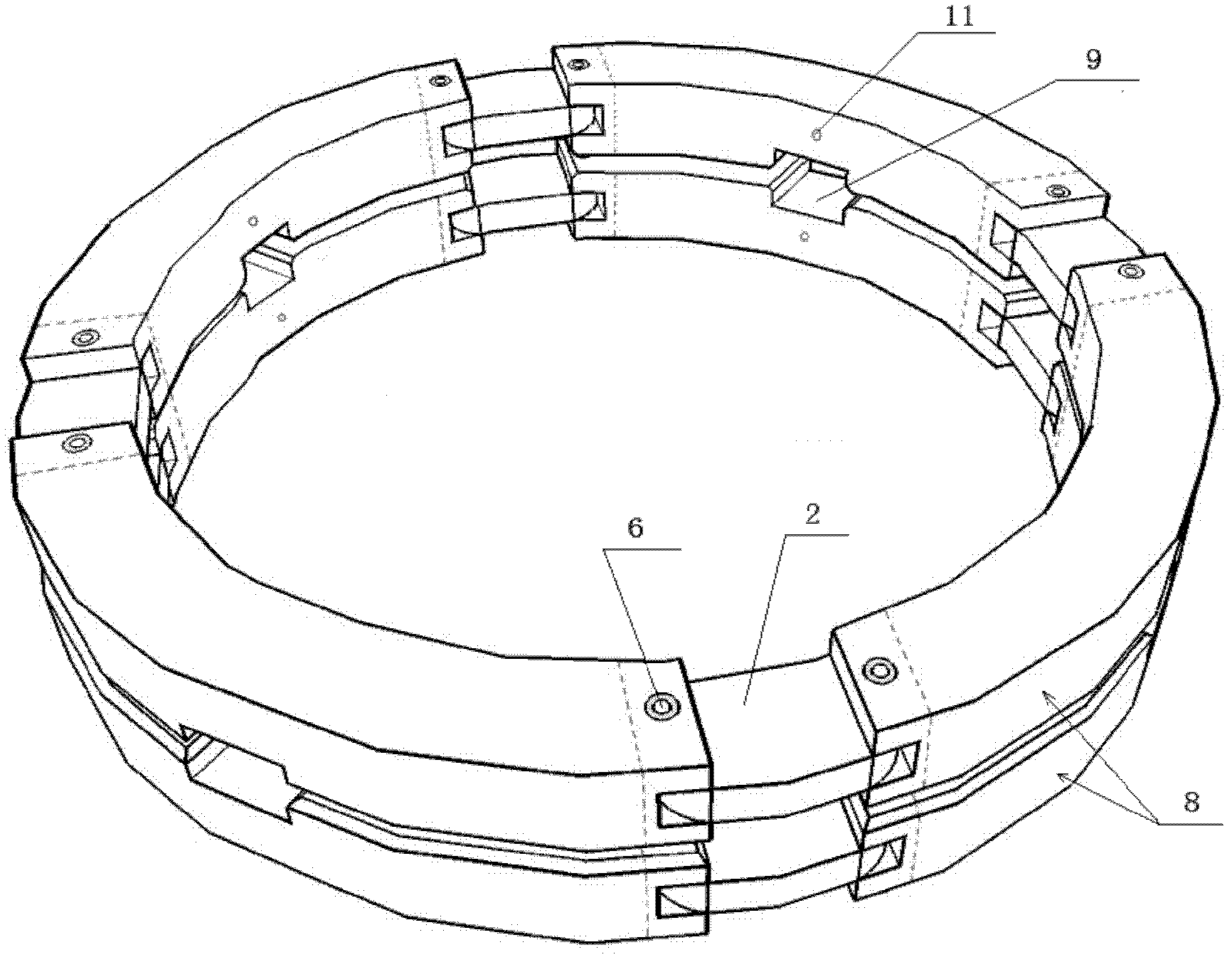

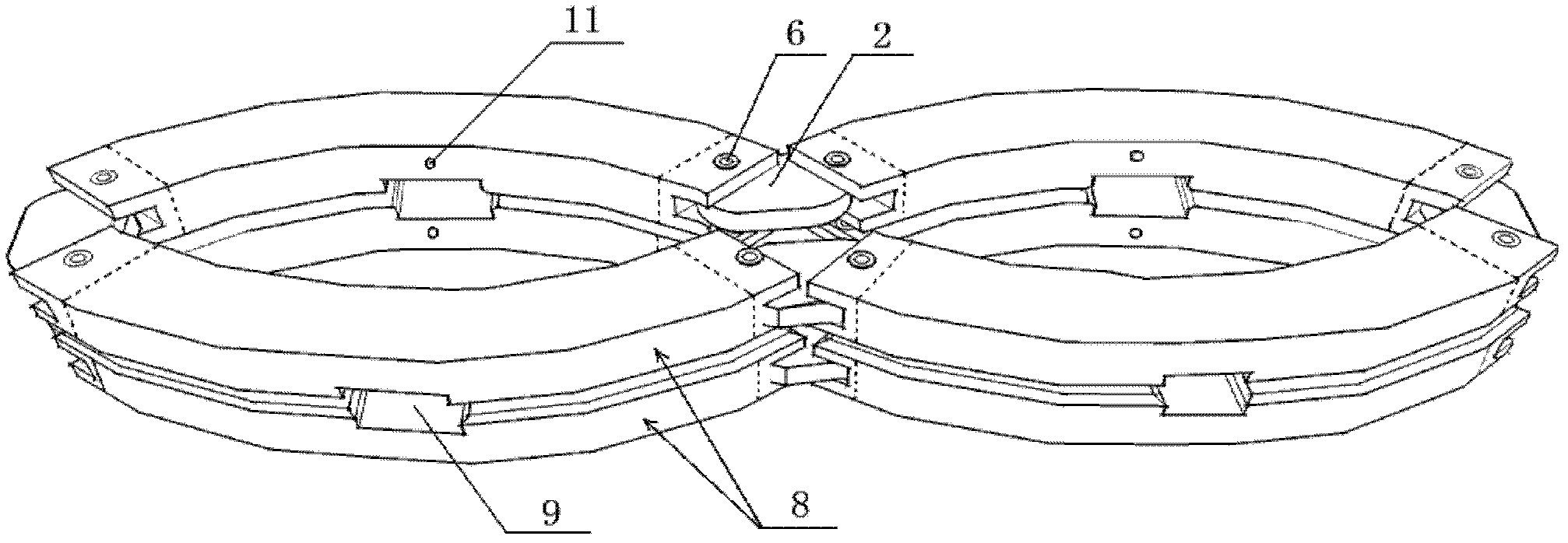

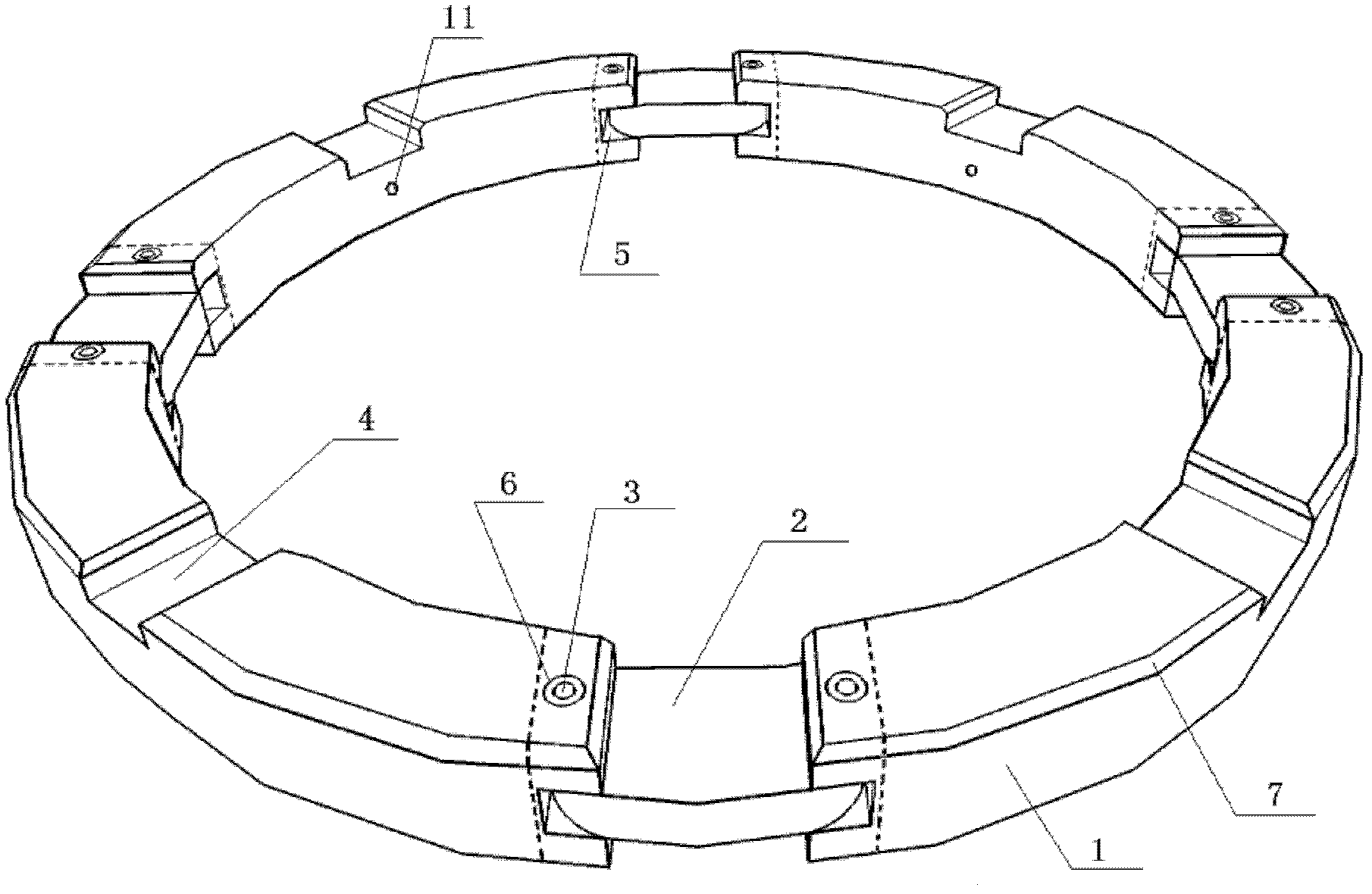

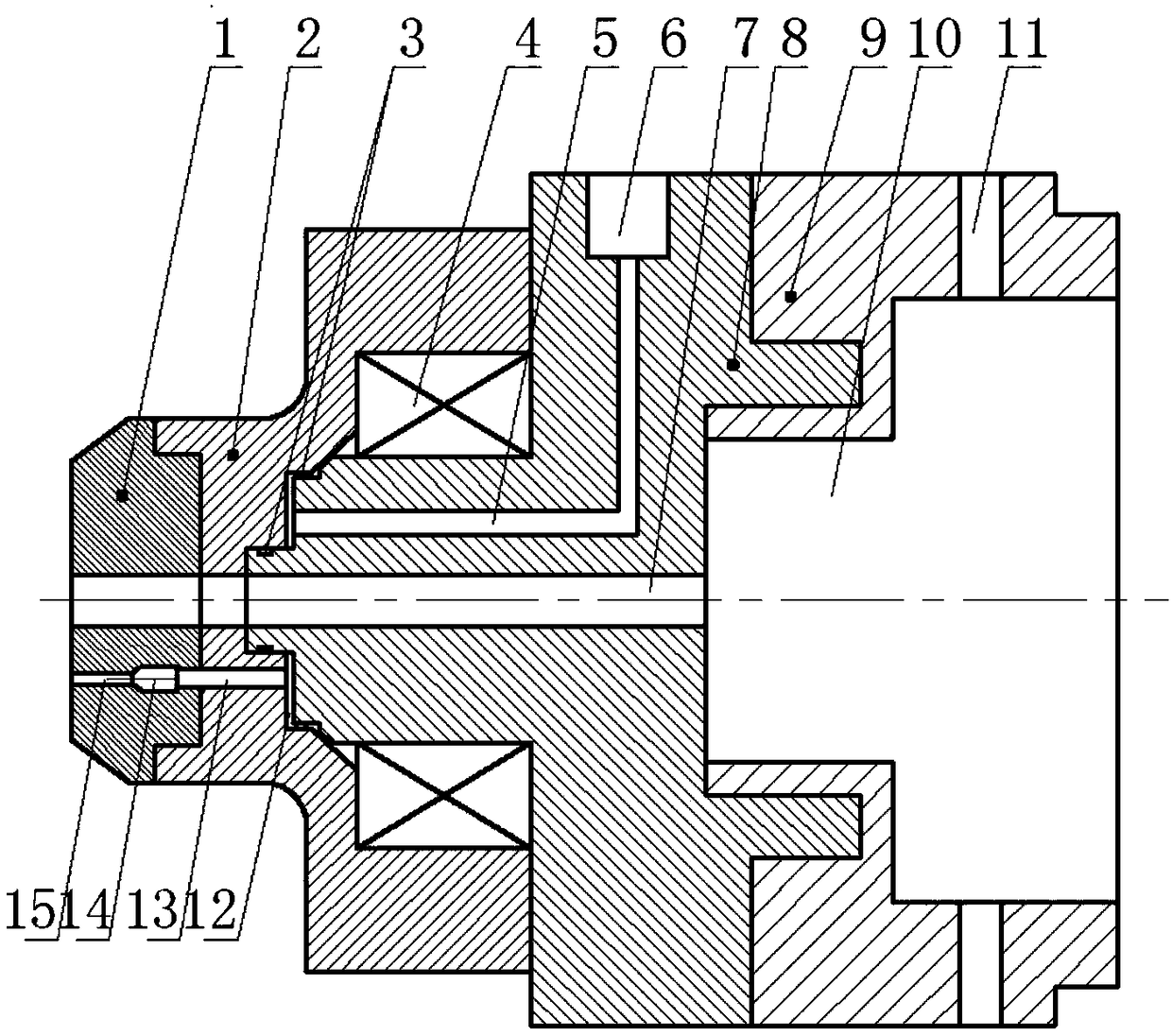

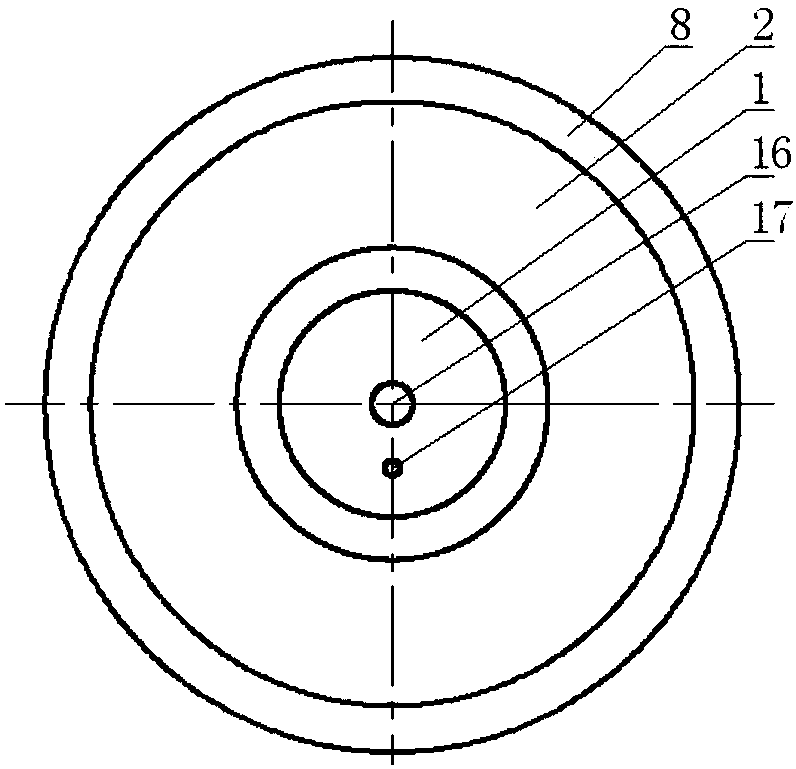

Discontinuous deformable surgical anastomosing magnetic ring

ActiveCN102525587ASimple structureFlexible and stable structureSurgical staplesRing blockMagnetic poles

The invention relates to a discontinuous deformable surgical anastomosing magnetic ring. The discontinuous deformable surgical anastomosing magnetic ring is provided with two magnetic ring bodies, wherein the magnetic ring bodies are the same in structure and opposite in magnetic poles and are arranged in a piling up manner; each magnetic ring body comprises a plurality of arc-shaped magnetic ring blocks and a plurality of connecting pieces; the arc-shaped magnetic ring blocks are movably connected in an end-to-end manner by the connecting pieces respectively through rivets so as to form the magnetic ring bodies; a plurality of discontinuous anastomosing gaps are formed in the upper surfaces of the arc-shaped magnetic ring blocks of one magnetic ring body; a plurality of discontinuous anastomosing gaps are formed in the lower surfaces of the arc-shaped magnetic ring blocks of the other magnetic ring body; the connecting pieces of the two magnetic ring bodies arranged in a piling up manner are oppositely arranged; and the discontinuous anastomosing gaps of the two magnetic ring bodies are arranged in an abutting manner so as to form a discontinuous anastomosing port. The discontinuous deformable surgical anastomosing magnetic ring is light in weight and large in magnetic force, is deformable, and can be easily discharged from a human body, the stability and the involutory accuracy of the magnetic ring are enhanced, and the magnetic losses are reduced; and the discontinuous deformable surgical anastomosing magnetic ring has the characteristics of surgical discontinuous anastomosis, and pressure gradients can be locally formed at the anastomosing port further, so that the tissue healing is better, and the discontinuous deformable surgical anastomosing magnetic ring can be applied to the fields, such as PPH (Procedure for Prolapse and Hemorrhoids), rectal low-order anus-preserving operation, circumcision, colostomy, minimally invasive endoscopic resection and anastomosis, and the like.

Owner:广东省虚拟医学科技有限公司

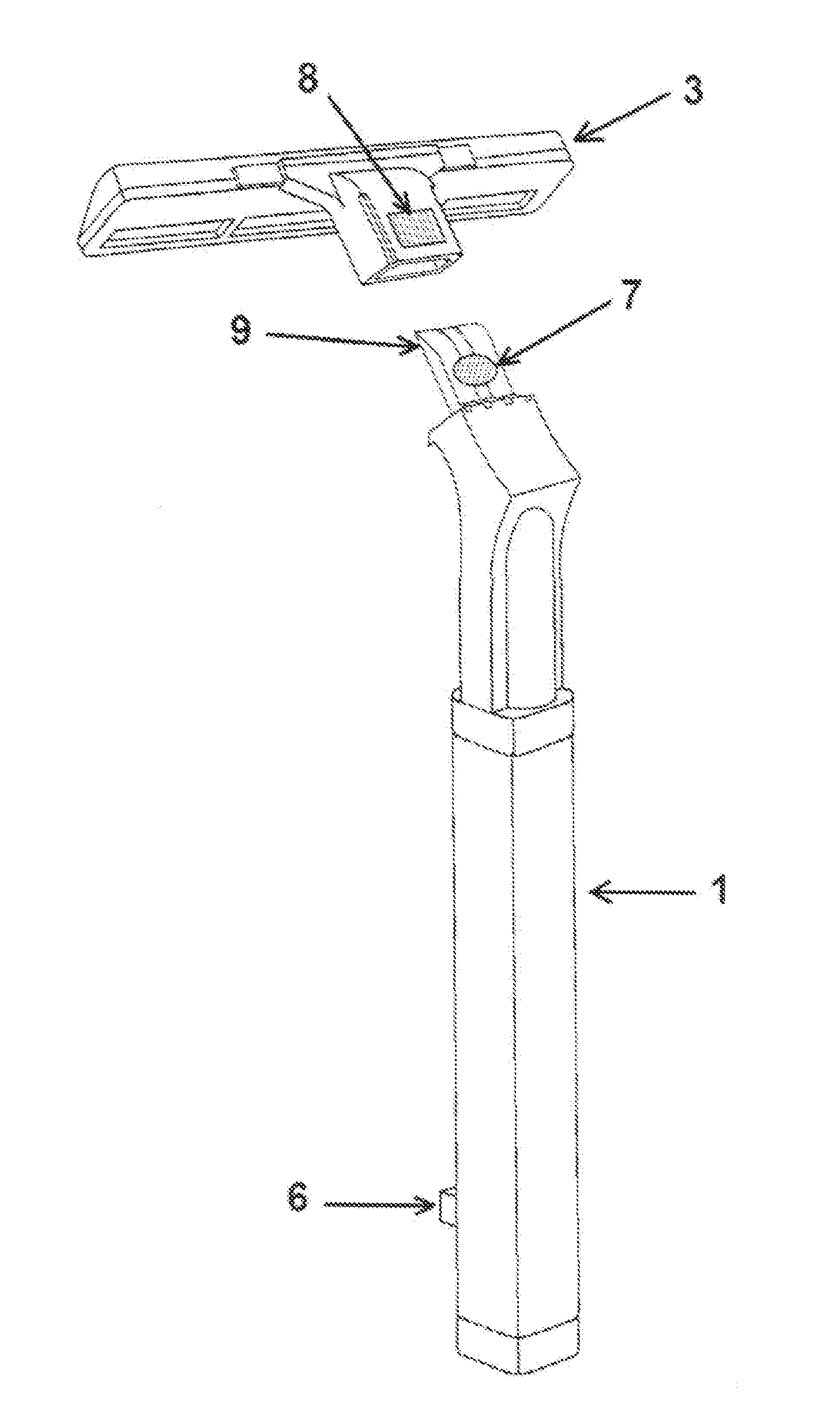

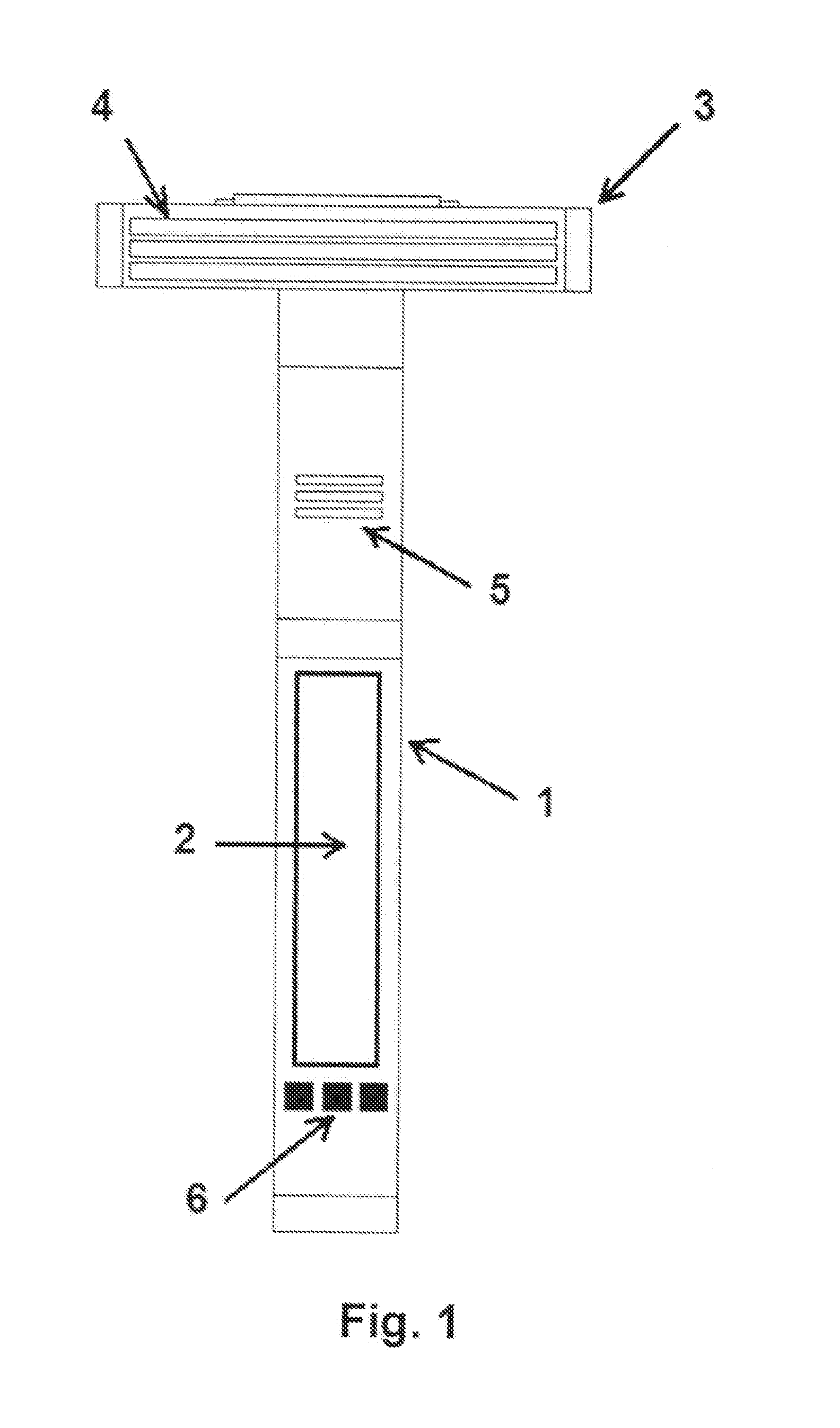

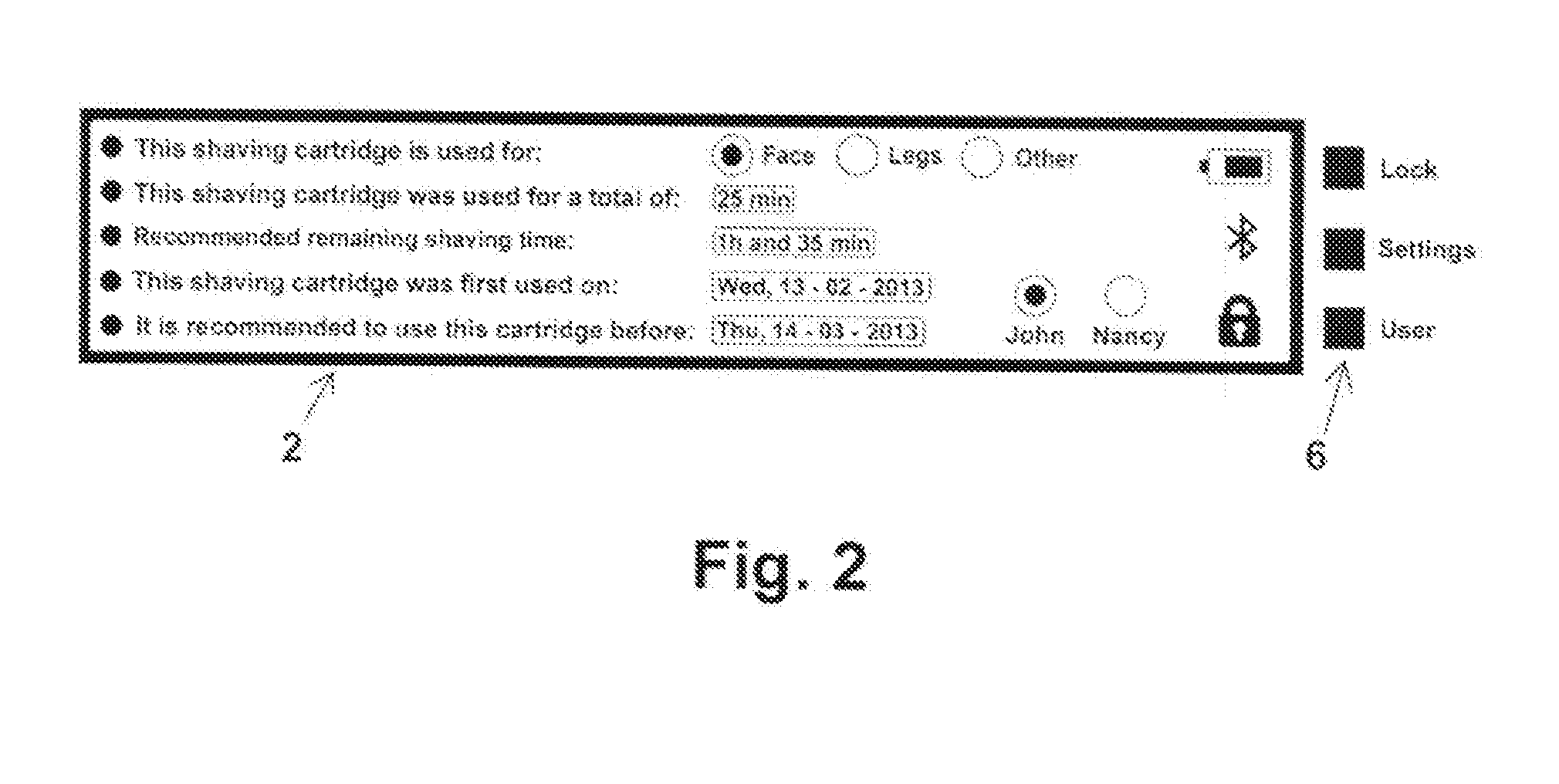

Smart razor handle

InactiveUS20150051845A1Process economyImprove performancePlug gaugesMetal working apparatusEngineeringLoudspeaker

Smart razor handle with scanner, pressure sensor, processing unit, memory, programming keys, and integrated screen is aimed to enhance performance, ease of use, and provide additional comfort to the user while using shaving cartridge. The smart handle provides the user with important information regarding the shaving cartridges through the integrated screen, and speaker.

Owner:KALED AL HASAN

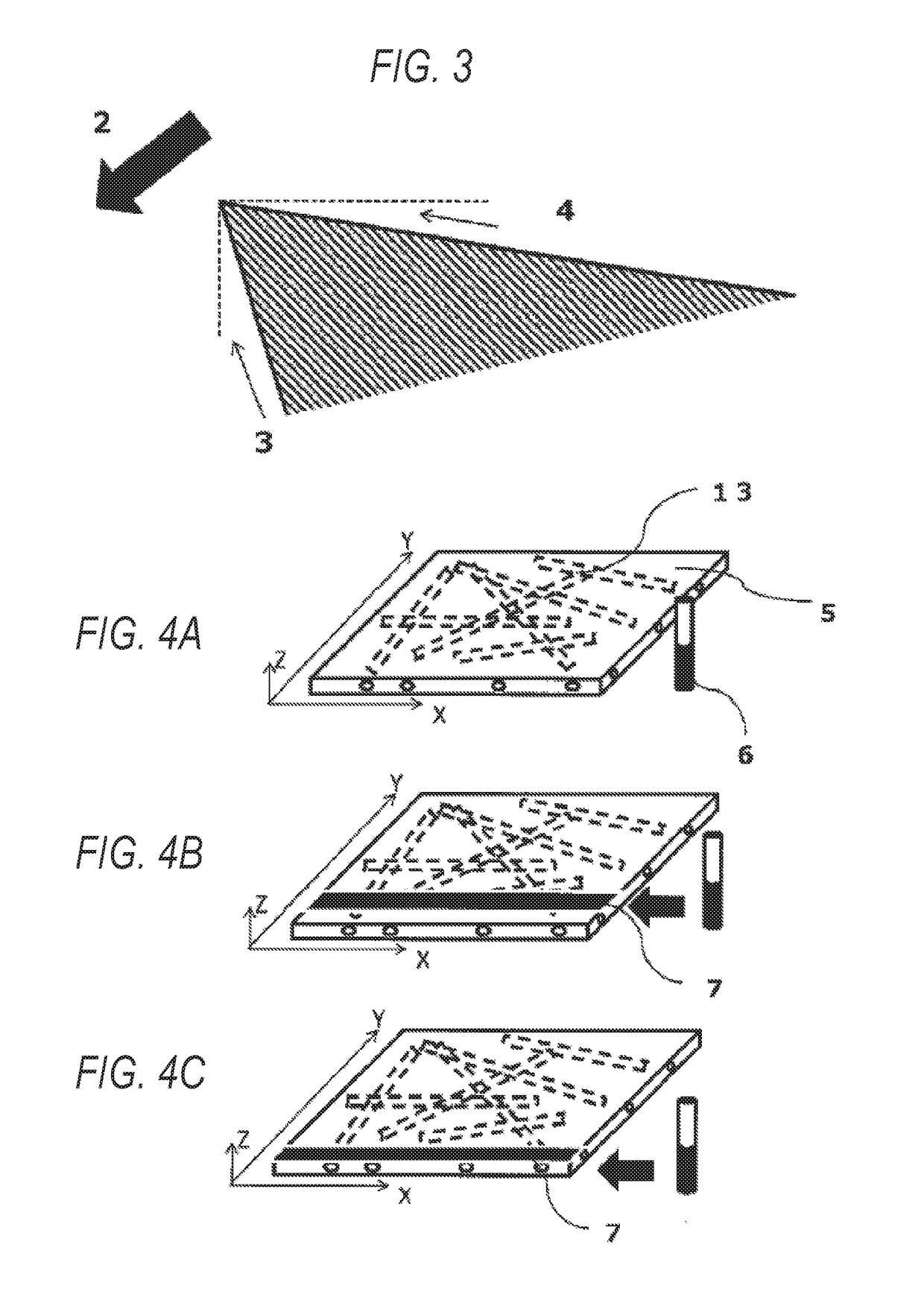

Method for production of molded article of plant- derived composite material, molded article of plant-derived composite material, method for production of plant-derived composite material, and plant-derived composite material

ActiveUS20100004358A1High mechanical strengthEfficient preparationIon-exchange process apparatusCosmetic preparationsPolymer sciencePresent method

The present invention provides a method for production of a molded article comprising a plant-derived composite material in which a plant-derived material is evenly dispersed and a plant-derived composite material molded article prepared therewith, and a method for production of a plant-derived composite material in which a plant-derived material is evenly dispersed and a plant-derived composite material prepared therewith. The present method for production of a molded article is a method for producing a molded article composed of a plant-derived composite material comprising a plant-derived material (e.g., a kenaf core) and a thermoplastic resin (e.g., polypropylene, polylactic acid), and comprises a process in which the plant-derived material is pressed to obtain raw-material pellets, a process in which the raw-material pellets and the thermoplastic resin are kneaded to obtain a plant-derived composite material, and a process in which the plant-derived composite material is molded into a molded article composed of the plant-derived composite material. The present molded article is obtained by the method.

Owner:TOYOTA BOSHOKU KK

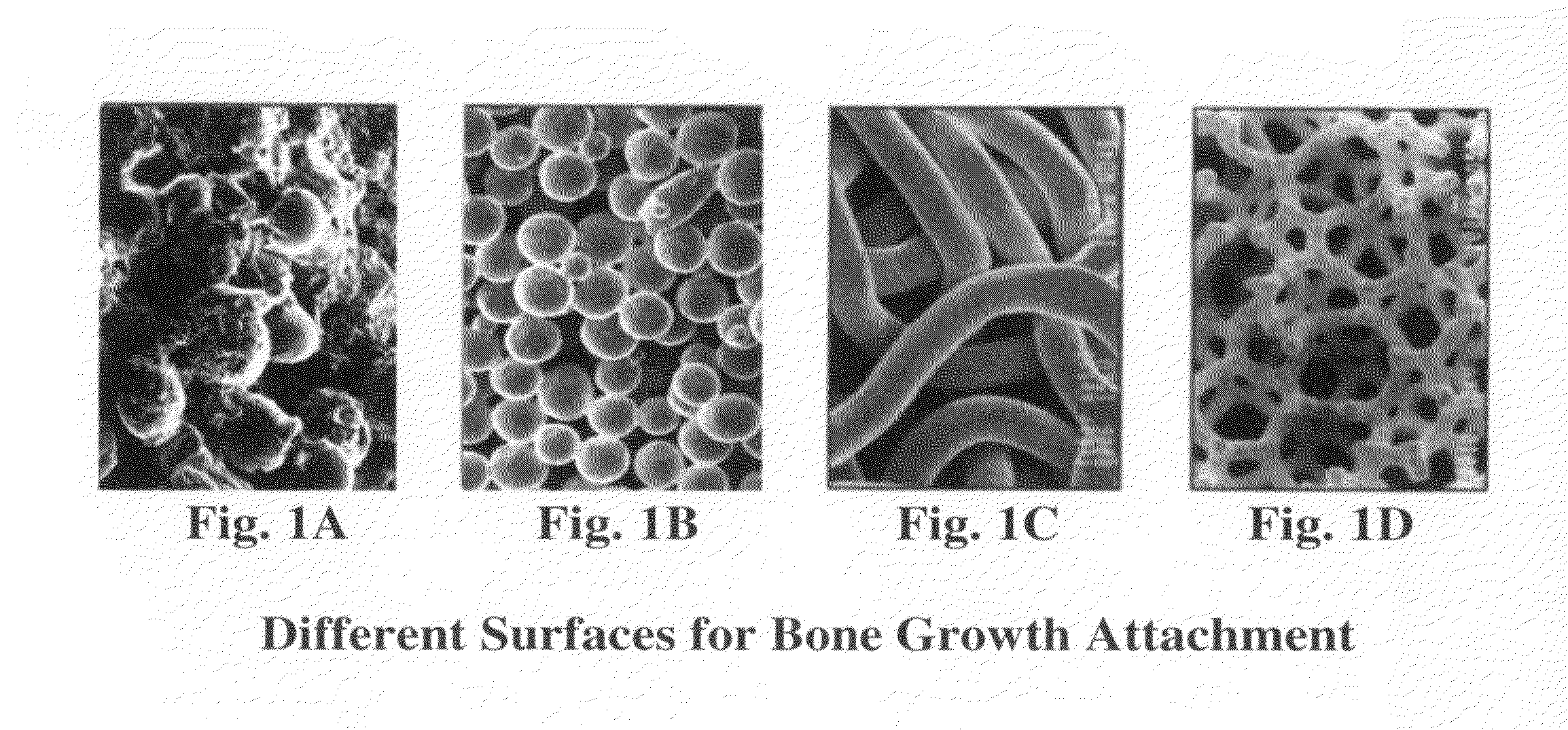

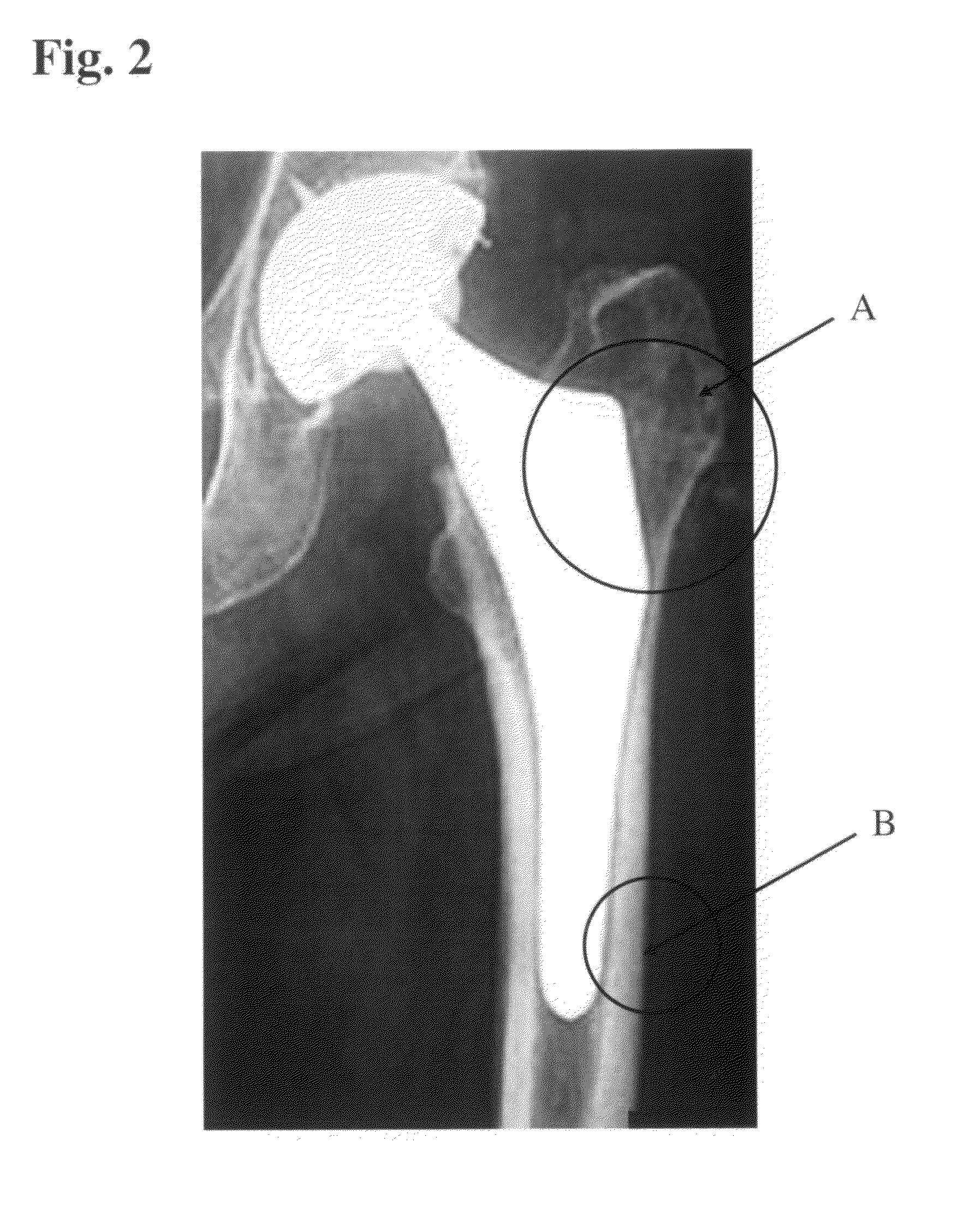

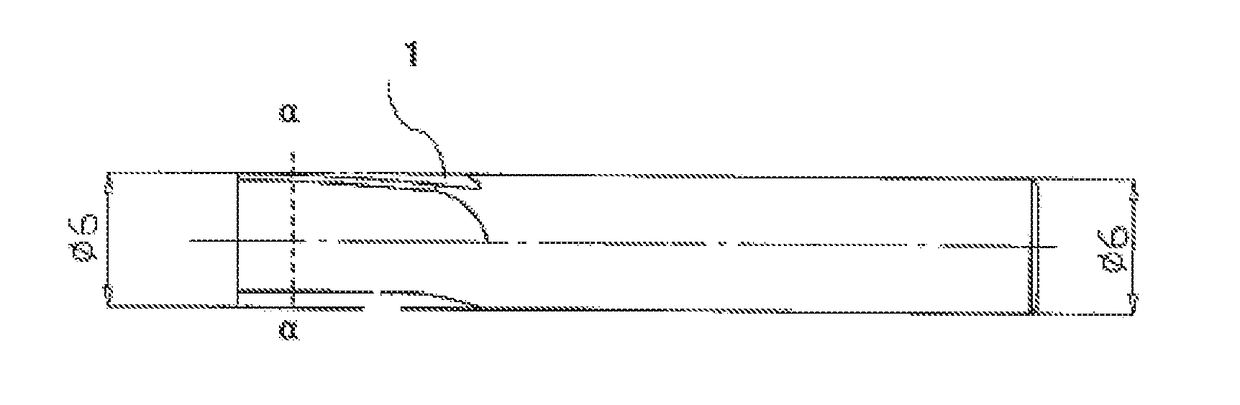

Load bearing implants

ActiveUS20120245700A1Minimizing excessive loadingPreventing of wear debrisInternal osteosythesisJoint implantsThighNatural bone

A bio-compatible femoral stem is made from a bio-compatible titanium alloy or cobalt-chromium alloy, each of which have an elastic modulus far greater than that of natural bone. When the implant heals within a bone cavity, the implant essentially carries substantially the entire load. Transfer of load to the surrounding bone tissue is lost or resorbed due to lack of use after implant healing. Flexing a stiff implant applies a very large load at the implant distal end. The bone cortex is thereby allowed to thicken due to excessive load, causing thigh pain long after implant healing. The femoral implant has a bone ingrowth coating on the proximal end, allowing firm attachment of the implant in the bone cavity. The distal end has a central aperture and a helical machined groove that permits flexing of the distal portion of the femoral implant stem. This flexing is occurs in a manner similar to surrounding bone tissue, preventing thigh pain.

Owner:SIDEBOTHAM CHRISTOPHER G

Carbon Fiber Reinforced Resin Processed Product having End Surface and Method of Manufacturing the Same

The present invention is aimed to provide a carbon fiber reinforced resin processed product which is almost free from the problems described above on a processed surface subjected to cutting or the like and has an end surface where generation of a burr is suppressed, has favorable surface properties, and surface nature, and particularly smoothness is excellent; and provides a carbon fiber reinforced resin processed product having an end surface which has fibers and a resin, wherein the end surface has a surface roughness (Rz) within a range from 5 μm to 50 μm.

Owner:TEIJIN LTD

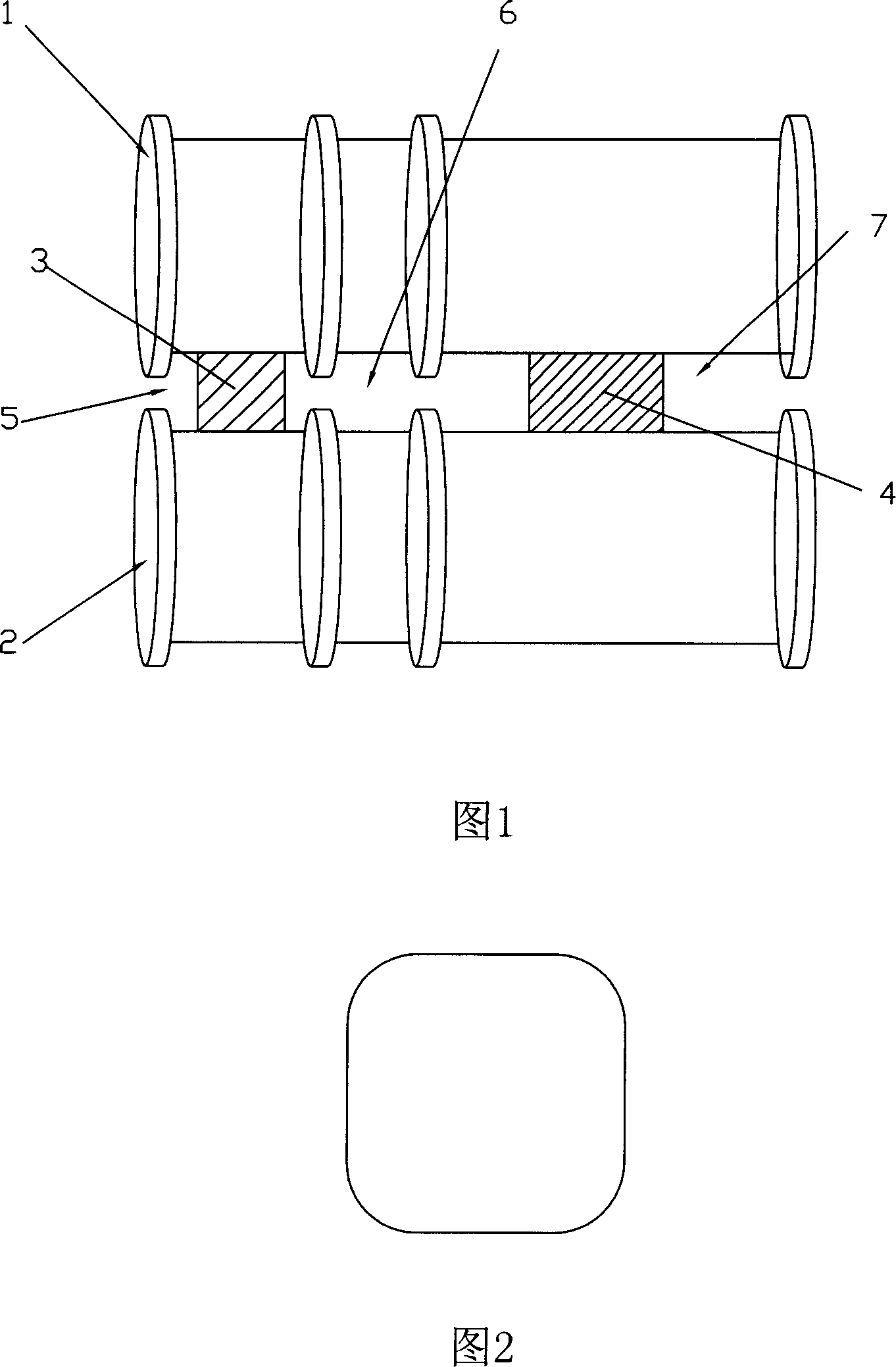

Laser water jet processing device and application thereof

The invention relates to a laser water jet processing device and application thereof. The processing device comprises a laser emitting device and a laser head connected to the laser emitting device. The laser head comprises a spray-head, a rotating disc, a separation pedestal and a connecting seat which are successively and coaxially connected. A laser through hole is formed in the center of the spray-head, the center of the rotating disc and the center of the separation pedestal in a coaxial communication mode. The laser through hole communicates with a laser penetrating hole of the connecting seat. A first water flow passage is formed in the spray-head. A water spray head is installed in the first water flow passage. A second water flow passage is formed in the rotating disc. A third water flow passage is formed in a gap between the rotating disc and the separation pedestal. A fourth water flow passage is formed in the separation pedestal. A water inlet is formed in the outer wall ofthe separation pedestal. Multiple auxiliary gas inlets are formed in the connecting seat. More efficient cutting can be realized, materials can be quickly cooled down by a water jet in the cutting process, and a high-precision device is not necessary for the water jet. Cost of the device is greatly reduced, and industrialization is favorable for realizing.

Owner:TIANJIN UNIV OF SCI & TECH

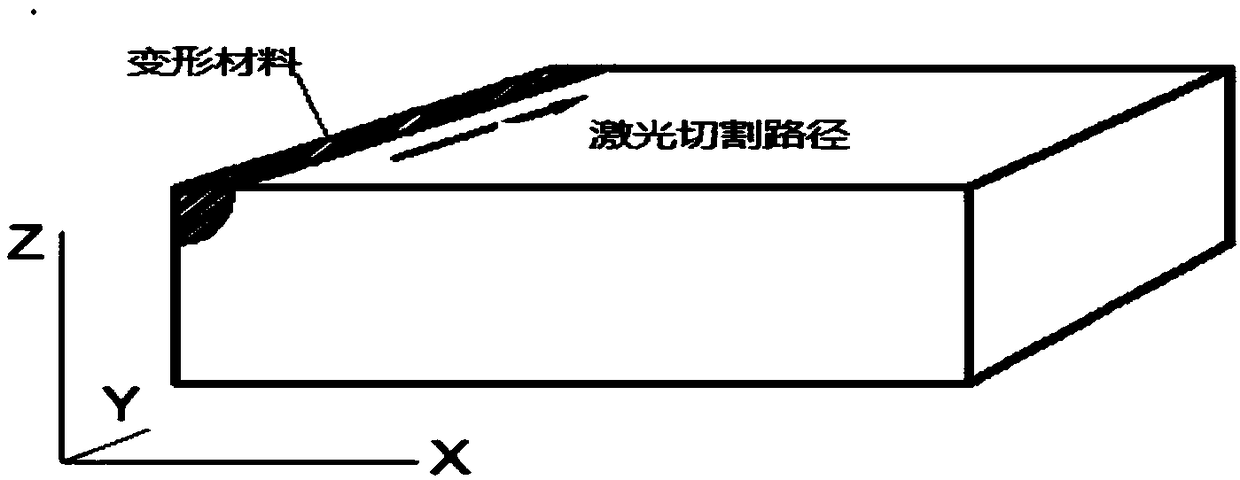

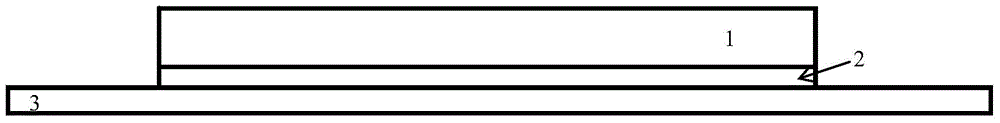

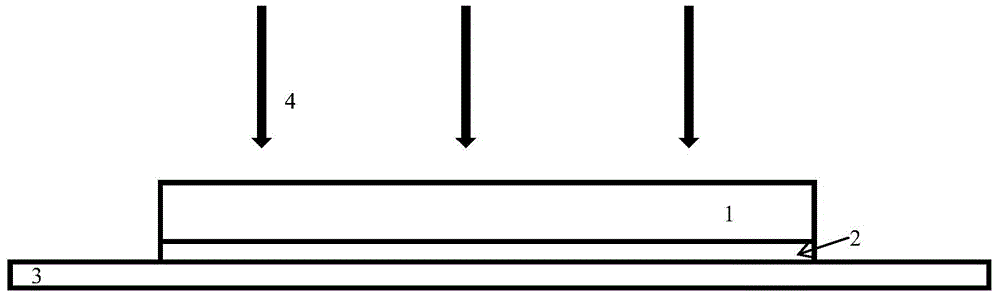

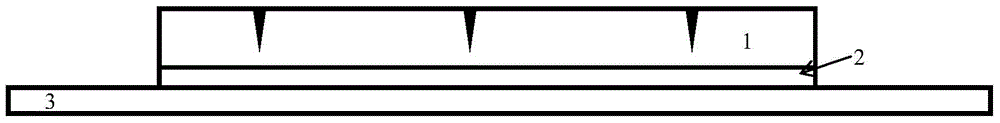

Laser cutting method for high-power power electronic device wafer

ActiveCN104599960AReduce cuttingAvoid damageSemiconductor/solid-state device manufacturingLaser beam welding apparatusLaser scribingLaser cutting

The invention discloses a cutting method for a high-power power electronic device chip. The cutting method for the high-power power electronic device chip includes that carrying out laser scribing on the back of a substrate of a device made of wide band-gap semiconductor material, and using a breaker to break the front according to the back scratch. The depth of the back scratch is about 1 / 10 to 1 / 4 of the chip thickness. The cutting method for the high-power power electronic device chip uses a laser beam focusing cutting method, the laser beam cuts the high-power device through back scribing, an active region at the front of the chip is greatly guaranteed, the front region is not damaged, the edges of the device are regular, and the reliability and yield of the large-area chip are greatly improved.

Owner:STATE GRID CORP OF CHINA +1

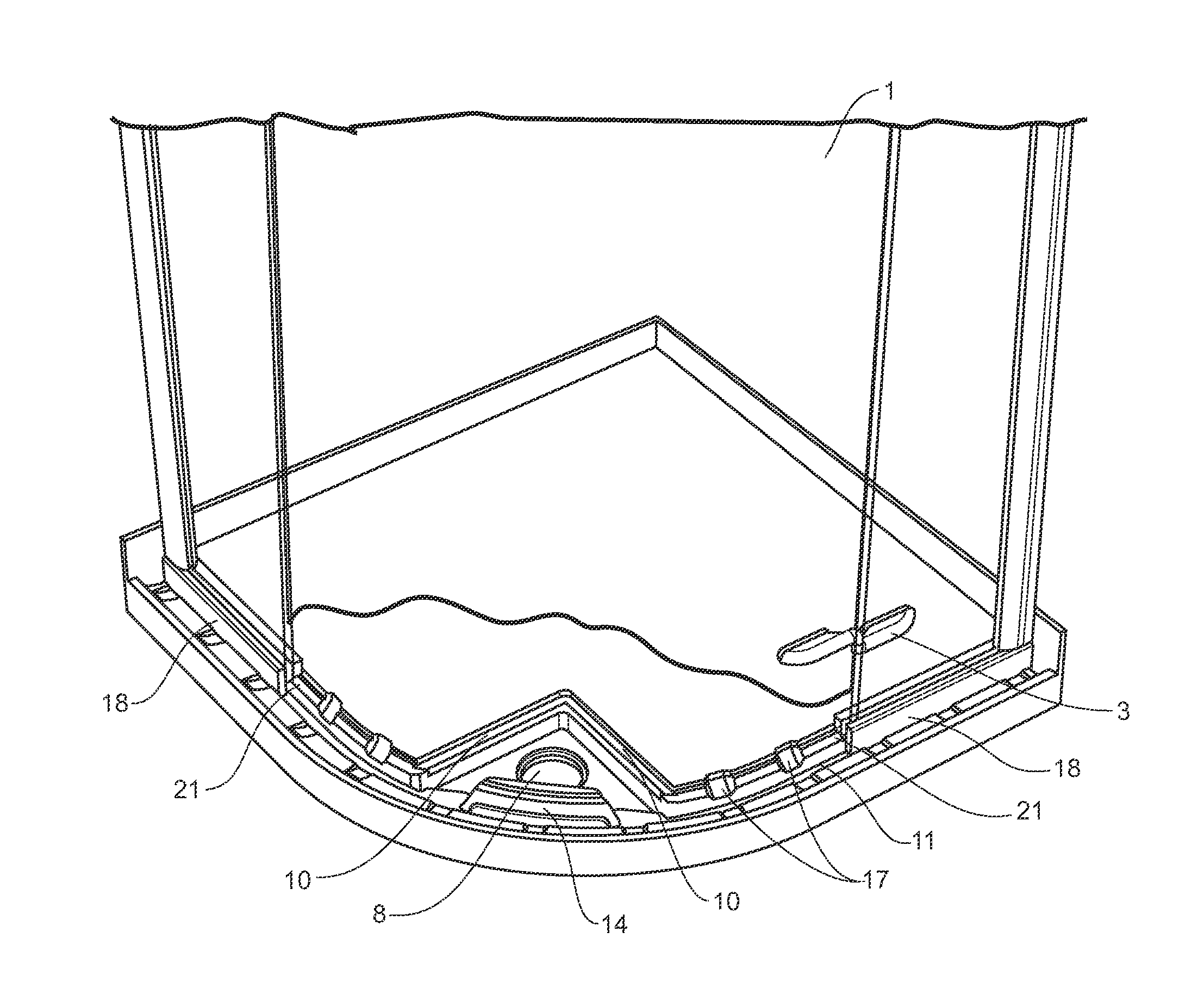

Method for rolling large-size square steel by single machine frame without groove

ActiveCN101024227AIncrease profitReduce manufacturing costMetal rolling arrangementsEngineeringLarge size

The invention discloses single frame non slot rolling large size square steel method. It adopts big delivery head two-high reversing blooming mill system. Each of blank side is repeatedly made into roller pressing underside and free spread side, processed reciprocating many passes non slot rolling by the horizontal mill to form finished product. It uses critical percent of reduction control method to control the size of the single and double drum ratio in the approved range, control width to height ratio to remove rolling off square. Thus the invention can reduce pass positioning, produce the large square steel product with high quality and flexible size by using non slot rolling technique.

Owner:BAOSHAN IRON & STEEL CO LTD

Shower enclosure and base

Owner:KOHLER NEW ZEALAND

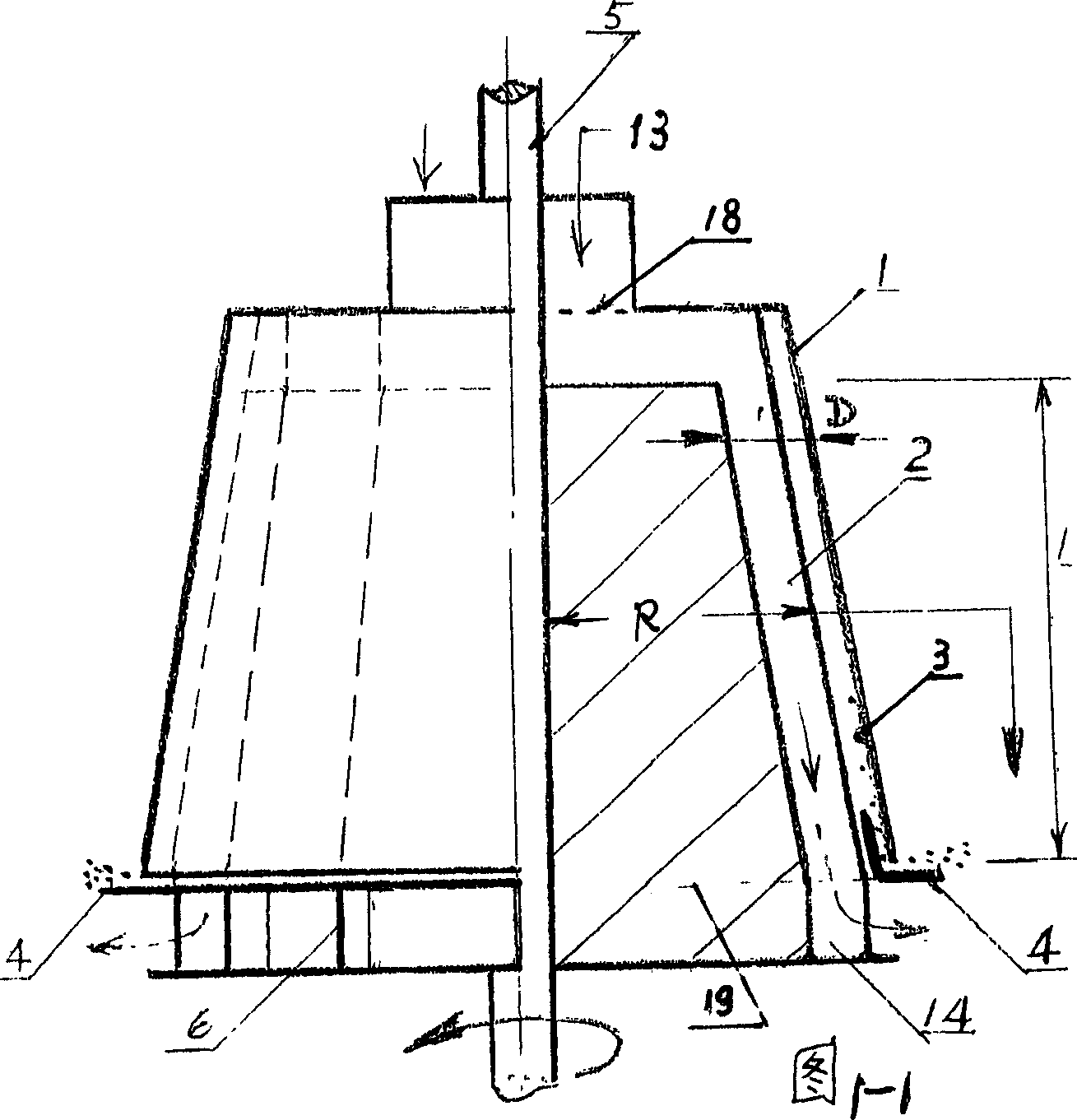

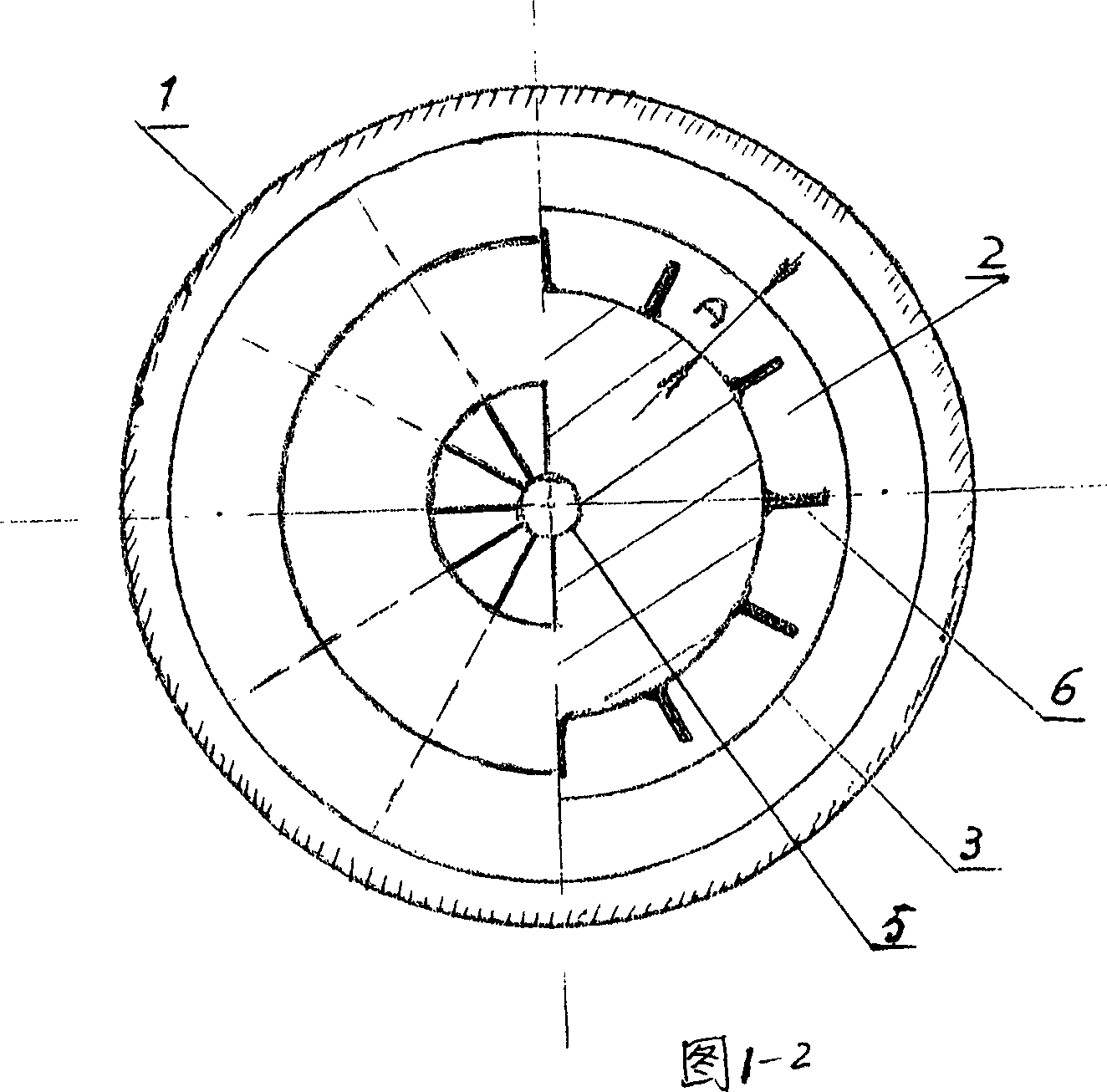

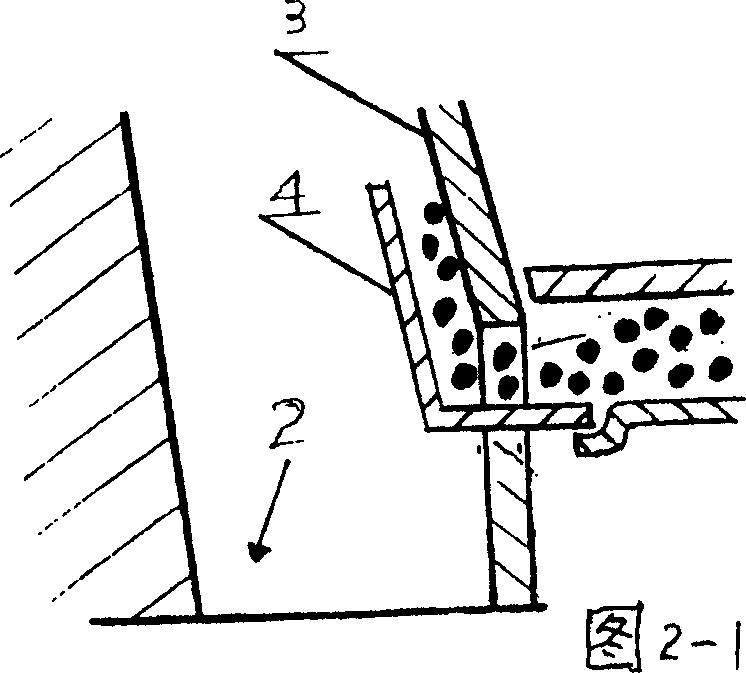

Centrifugal separator

InactiveCN1727071AAvoid dragging and liftingPlay a self-cleaning roleRotary centrifugesRotational axisEngineering

A centrifugal separator for treating polluted gas is composed of a central rotary shaft, an external casing, and several settling tubes, which are arranged in axial symmertrical mode relative to central rotary shaft to form a circular table shape and along the mother lines to become inclinded, and are revolving around said central rotary shaft. Said settling tube has a smooth settling inner surface at its far end. Its advantages are high separation efficiency and gas flow, and self-cleaning.

Owner:潘雨力

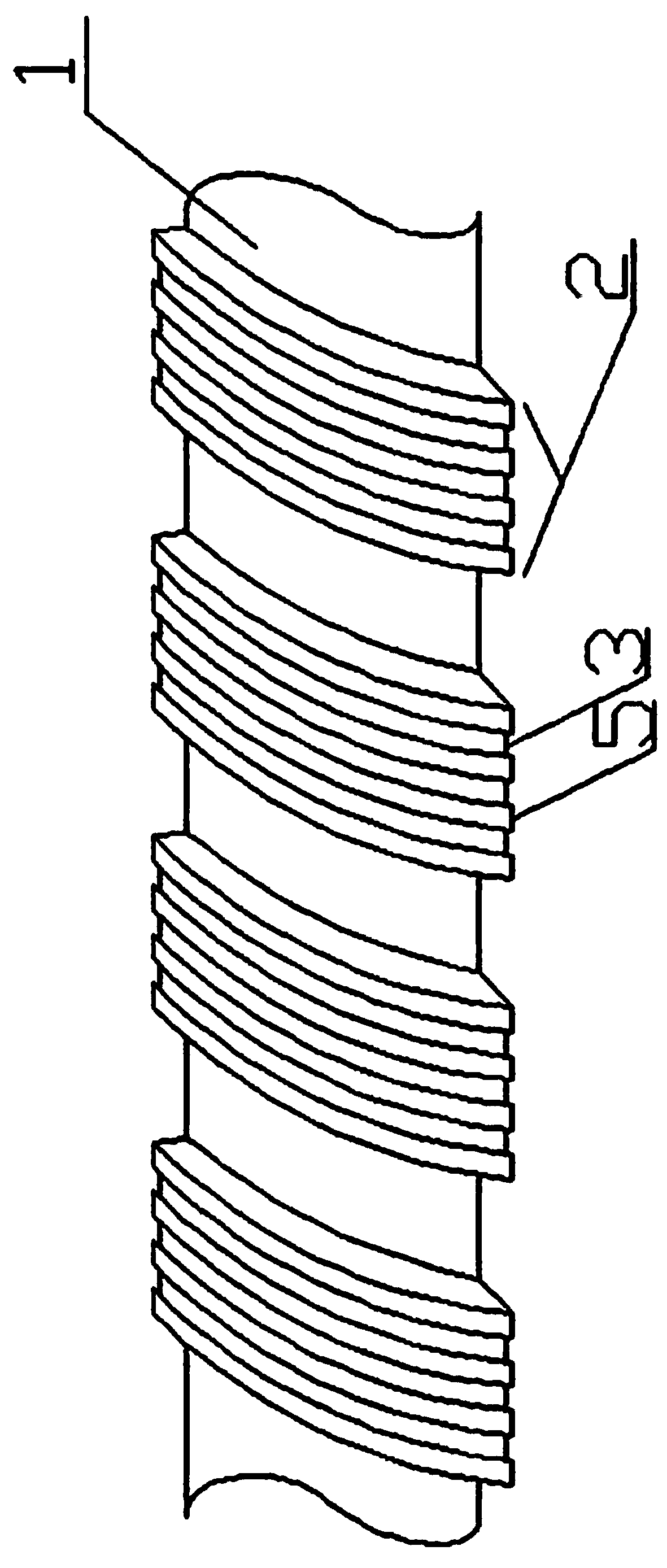

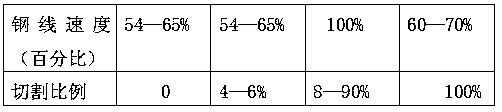

Silicon-block cutting method

InactiveCN103448154AImprove work efficiencyShorten the timeFine working devicesVolumetric Mass DensityOxidation resistant

The invention discloses a silicon-block cutting method, which relates to the technical field of crystalline-silicon manufacture. The method comprises the following steps of respectively preparing the usage amounts of recycled silicon carbide and a recycled suspending liquid used in mortar as 40 to 100 percent, modulating the density of the mortar as 1.625 to 1.635kg / L, and adding the mortar according to the effective cutting length of a silicon block in the cutting process, wherein the adding proportion of the added mortar is 0.235 to 0.3L / mm, and the adding amount of the mortar is equal to the effective cutting length of the silicon block multiplied by the adding proportion of the mortar; selecting a guiding wheel to enable the notch of the guiding wheel to be matched with a steel wire; setting the cutting speed of the steel wire as 12 to 14m / s, the moving speed of a worktable as 250 to 330mu m / min and the flow quantity of the mortar as 130 to 160kg / min, cutting the silicon block, and cooling; cutting a structural wire, the outer surface of which is provided with spiral bulges and is coated with an anti-oxidation layer by the steel wire. According to the invention, through the technical matching property of the cutting speed of the steel wire, the moving speed of the worktable and the flow quantity of the mortar, the updating of the mortar is reduced, the production cost can be lowered, the rate of fragments generated in silicon-block cutting is reduced, the rate of finished products is increased, and the quality of the products is improved.

Owner:HENGSHUI YINGLI NEW ENERGY

Orthopedic fastener method

ActiveUS9079263B2Easy to keepMinimal damageTurning machine accessoriesThread cutting machinesLeading edgeEngineering

An orthopedic structure includes a method for making a threaded fastener with thread geometry and leading edge geometry which provides greater precision during installation. Specifically, thread pitch and tooth profiles are independently variable. A leading portion of the fastener advances bone shards forward of the forward of the fastener to reduce insertion torque and prevent the shards from residing in the upstream tooth profile for better retention.

Owner:RTG SCI LLC

Orthopedic fastener method

ActiveUS20140053696A1Great retentionMinimal damageTurning machine accessoriesThread cutting machinesThreaded fastenerPlastic surgery

An orthopedic structure includes a method for making a threaded fastener with thread geometry and leading edge geometry which provides greater precision during installation. Specifically, thread pitch and tooth profiles are independently variable. A leading portion of the fastener advances bone shards forward of the forward of the fastener to reduce insertion torque and prevent the shards from residing in the upstream tooth profile for better retention.

Owner:RTG SCI LLC

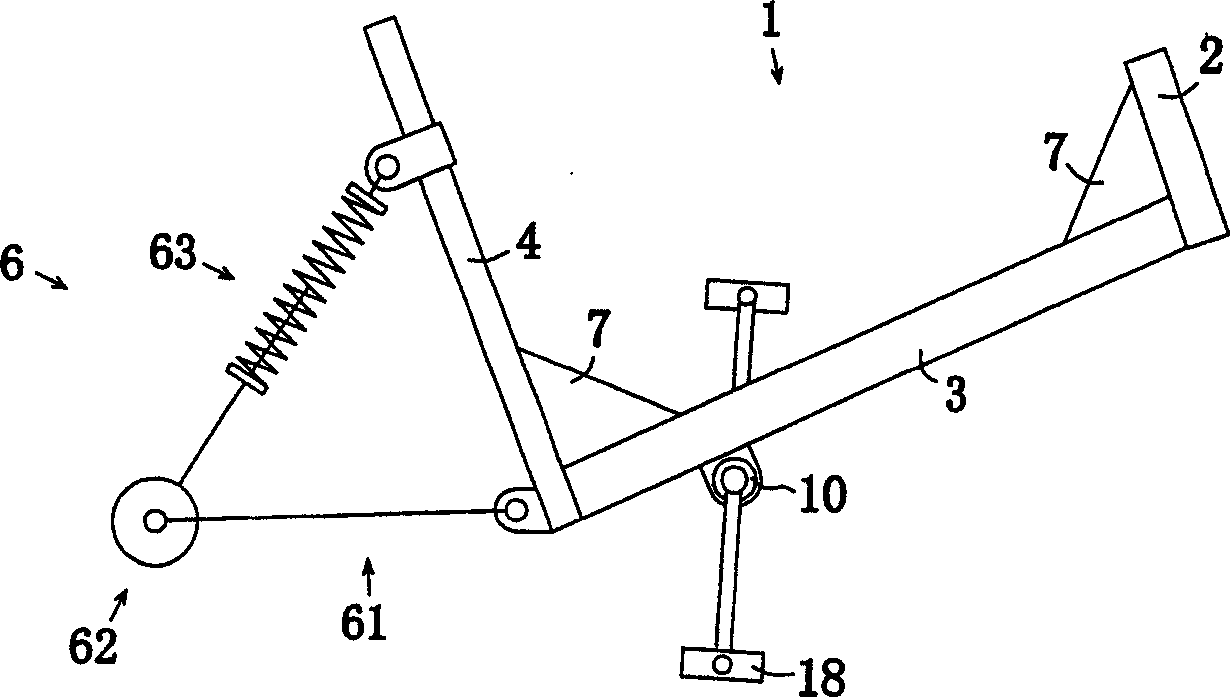

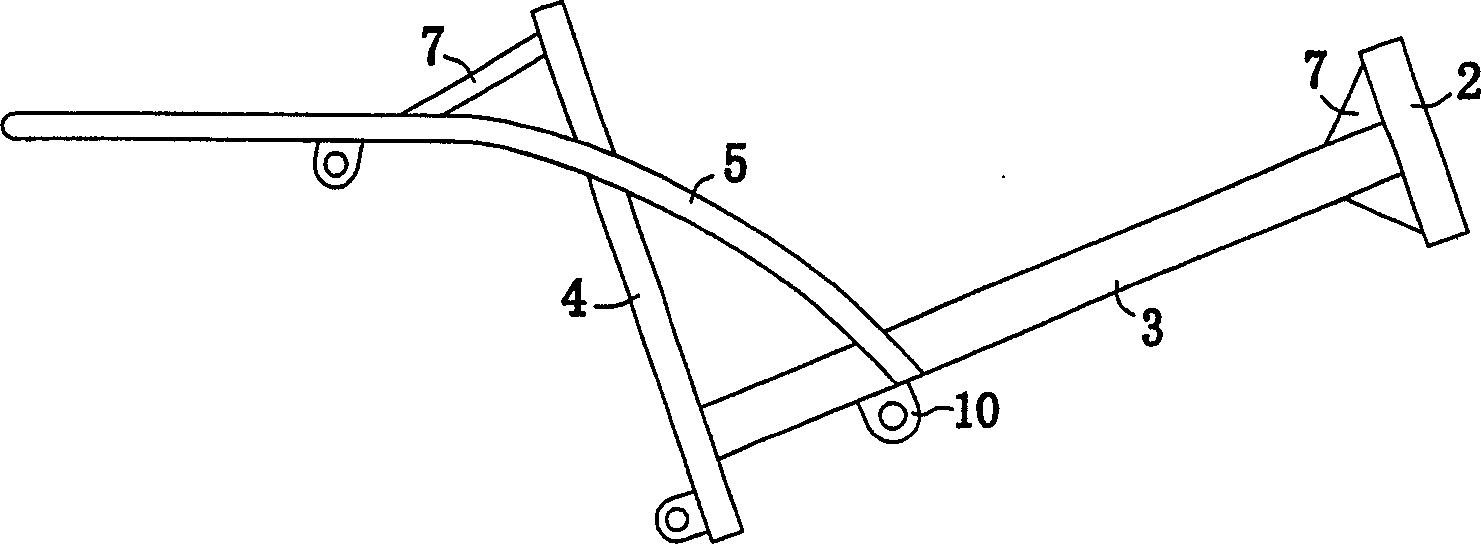

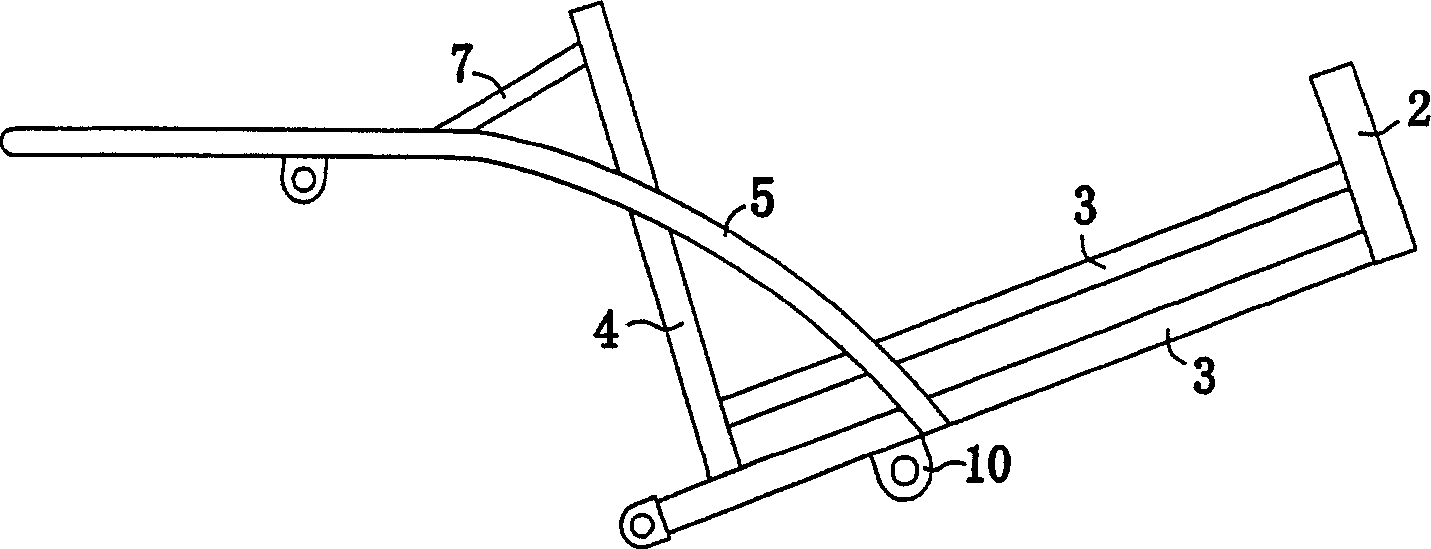

Mini type tricycle and its car frame

A miniature tricycle has a frame consisting of a main frame, a sleeve pipe for central axle and installed in main frame, and connecting mechanism of back axle, which is composed of guide part, connecting plate assemblage and vibration damper. Said main frame is composed of front pipe, lower pipes and vertical back pipe (or L-shaped or U-shaped frame), which are connected to become V-shaped, H-shaped, or U-shaped frame. Its advantages are simple structure and high stability.

Owner:FOSHAN NANHAI SANEAGLE BICYCLE CO LTD

Orthopedic fastener device

An orthopedic structure includes a method for making a threaded fastener with thread geometry and leading edge geometry which provides greater precision during installation. Specifically, thread pitch and tooth profiles are independently variable. A leading portion of the fastener advances bone shards forward of the forward of the fastener to reduce insertion torque and prevent the shards from residing in the upstream tooth profile for better retention.

Owner:RTG SCI LLC

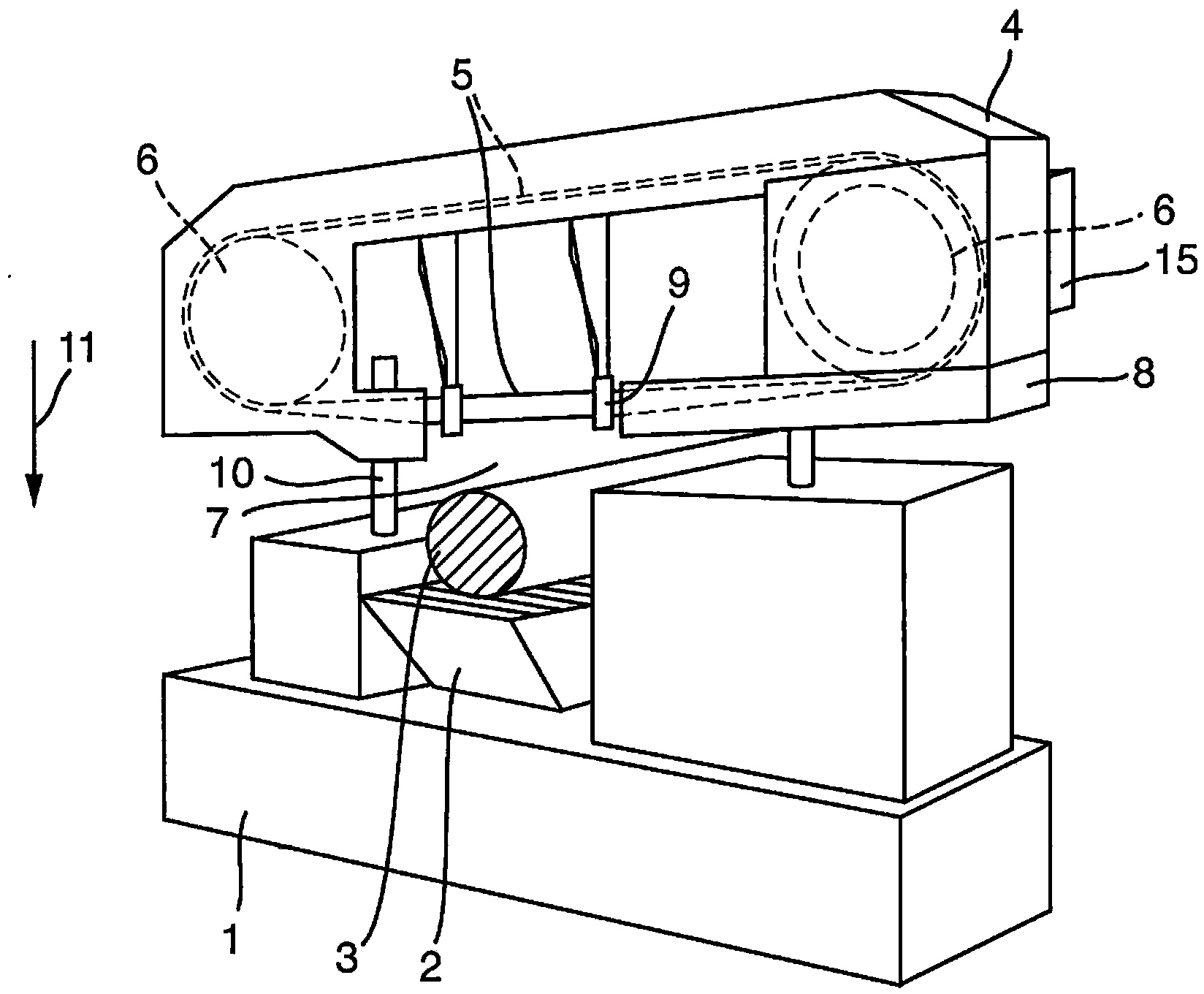

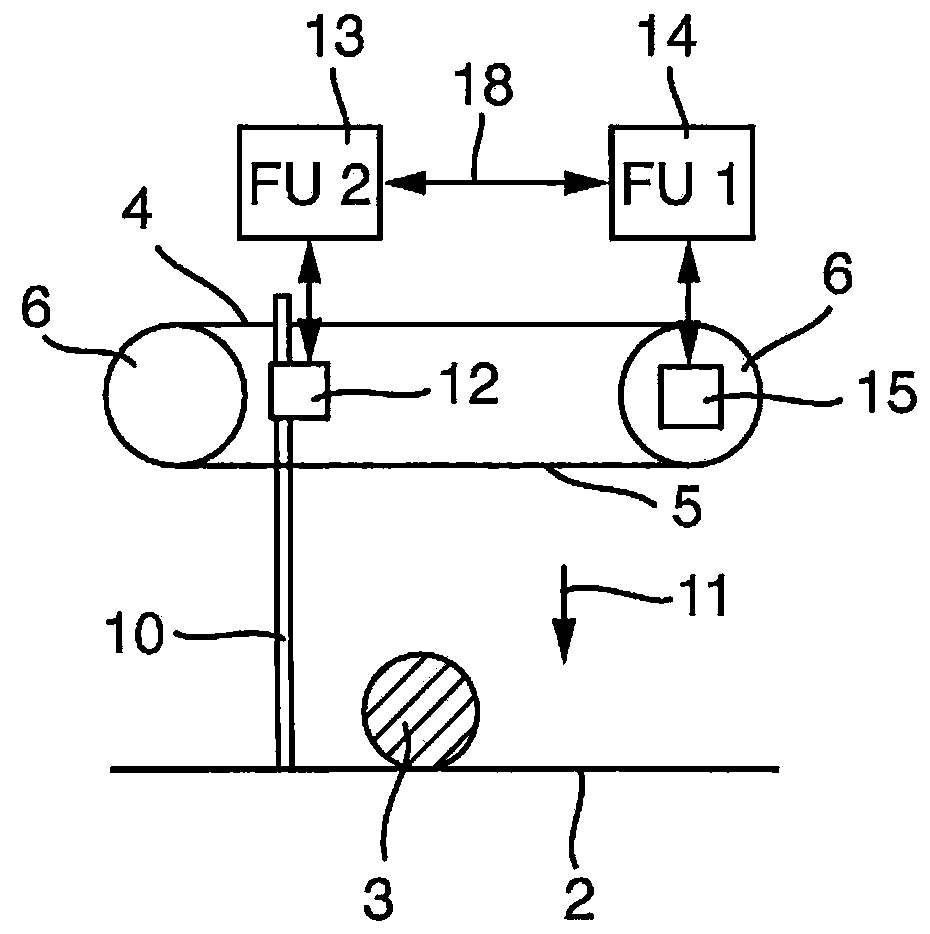

Sawing machine and method for controlling a sawing machine

ActiveCN104227500AAvoid damageExtend your lifeMetal sawing devicesAutomatic control devicesFrequency changerControl engineering

A method for controlling a sawing machine with a sawing tool, which is driven by an electrical sawing tool drive with a first frequency converter, and with a sawing feed device for moving the driven sawing tool at a feed rate in relation to a workpiece to be sawn, and also to such a sawing machine. The feed rate is changed over from an idling feed rate to a working feed rate when the sawing tool engages in the workpiece. A value of a physical variable which corresponds to the torque transferred from the sawing tool drive to the sawing tool or from which a change in this torque can be calculated is determined here at the first frequency converter. The changeover from the idling feed rate to the working feed rate takes place in dependence on the value of this physical variable.

Owner:KEURO BESITZ & EDV DIENSTLEISTUNGS

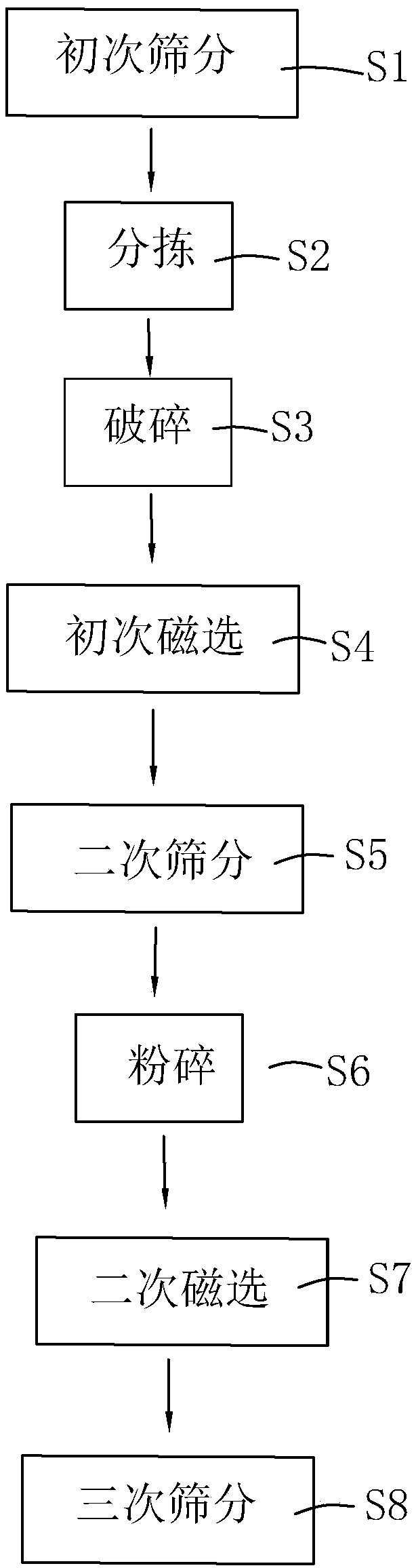

Comprehensive treatment method for building waste

The invention relates to a comprehensive treatment method for building waste and belongs to the technical field of waste treatment. Building waste begins to be treated after being sieved, in this way,in the sieving process, waste soil and metal materials, wood materials, plastic materials and paper material with small sizes in the building waste can be sieved and removed, workers can sort the building waste more conveniently, and the possibility that the workers are cut or stabbed due to the fact that the waste soil influences the visibility or the metal materials or the wood materials are small in size and not prone to be found can be lowered. After the building waste is treated by the comprehensive treatment method for the building waste, soil resources can be saved, the comprehensive treatment method is more environmentally friendly, and environmental pollution is lowered.

Owner:四川元丰建设项目管理有限公司

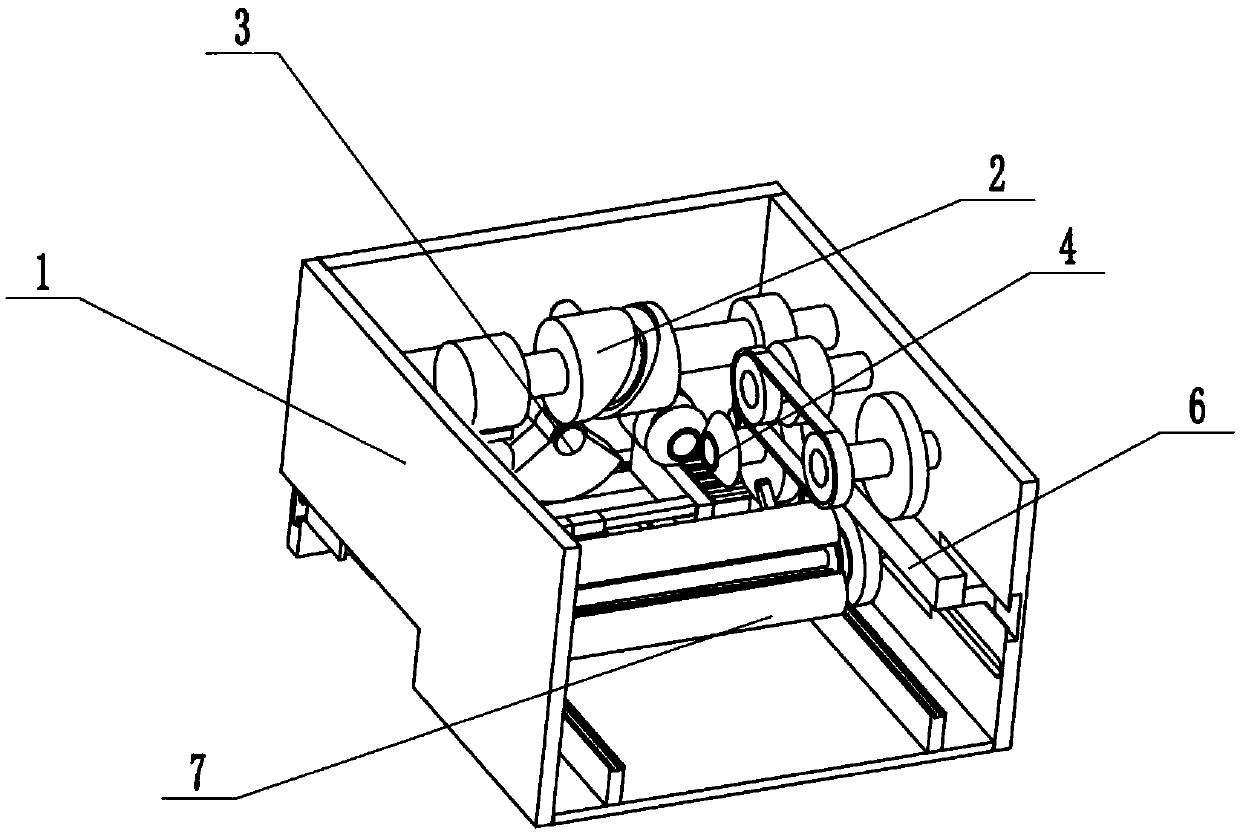

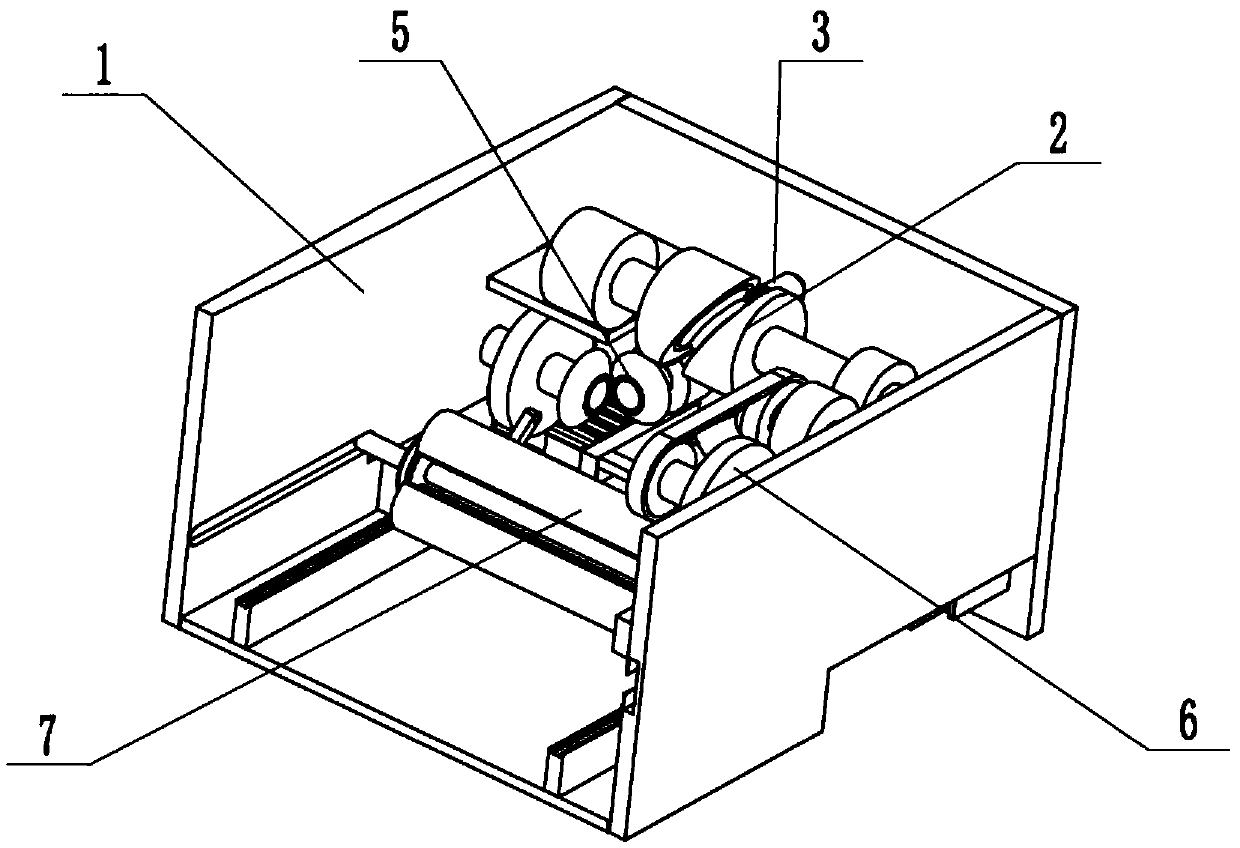

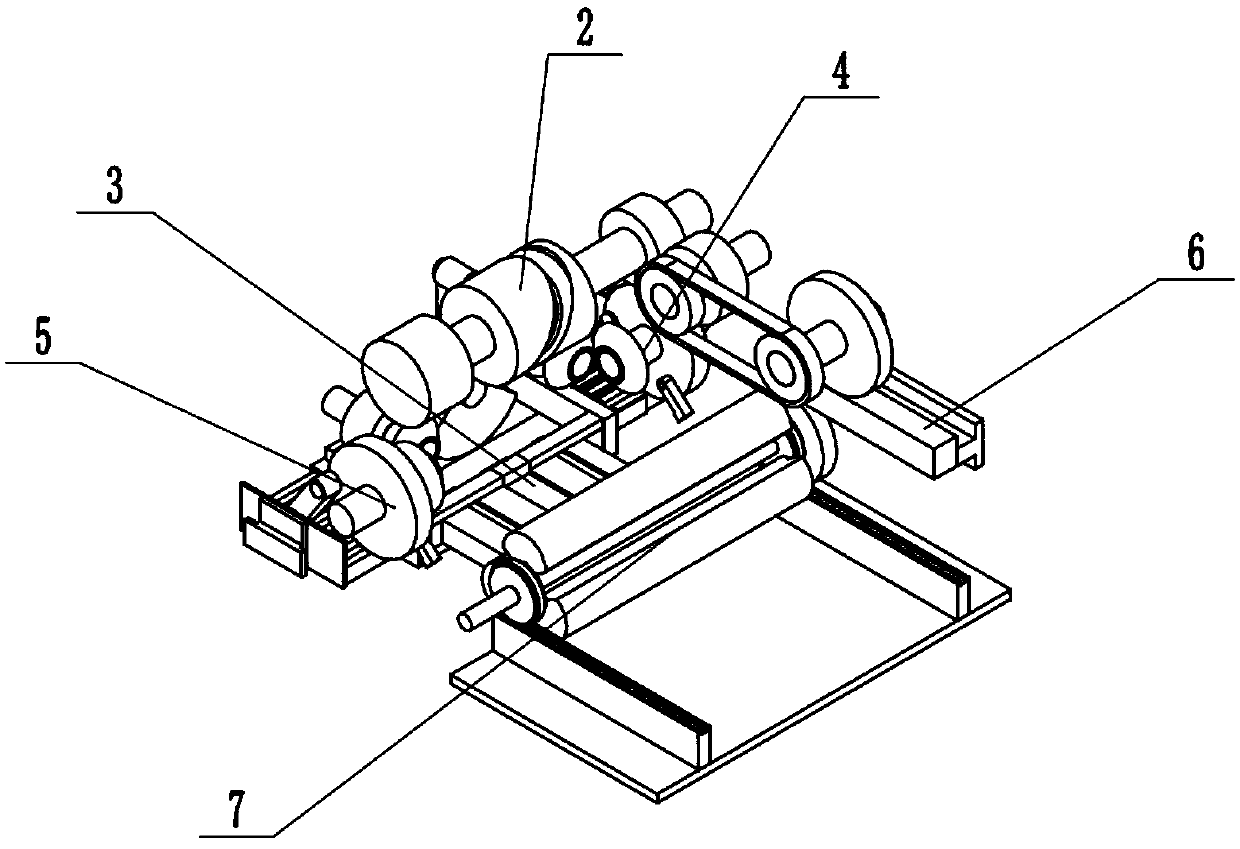

Industrial automatic slitting device for batch potato powder

The invention relates to the field of potato powder cutting, in particular to an industrial automatic slitting device for batch potato powder. The device comprises a bracket support, a driver, an intermittent propulsion cutter, a right pushing tightening device, a left pushing tightening device, a clamping propeller and a clamp, wherein the driver is fixedly connected to the bracket support, the upper end of the intermittent propulsion cutter is connected to the interior of the driver in a sliding manner, and the lower end of the intermittent propulsion cutter is connected to the rear end of the inner wall of the bracket support in a sliding manner; the right pushing tightening device and the left pushing tightening device are respectively connected to the left end and the right end of theinner wall of the bracket support in a sliding manner; and the clamping propeller is meshed with the driver in a transmission manner. The device has the beneficial effects that the tiled potato powder produced by a traditional production process can be automatically and rapidly cut into specified strips, manpower is saved through the safe, hygienic and rapid cutting, and application is convenient.

Owner:CHANGSHA CHUANGHONG AGRI TECH DEV

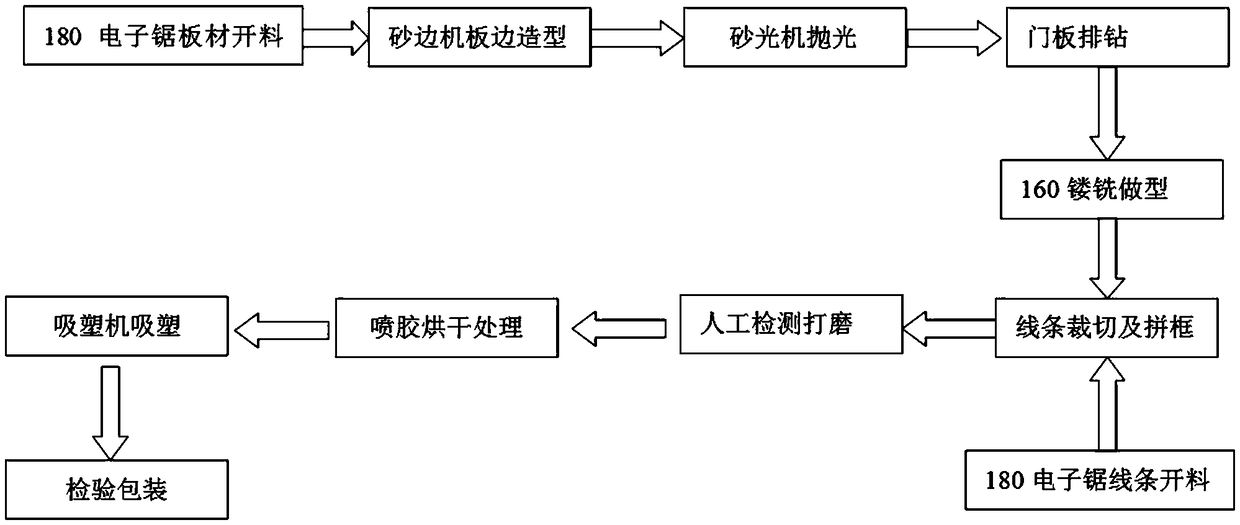

Door sheet blister manufacturing technology

InactiveCN108868490AVarious shapesAdapt to aesthetic requirementsDoor leavesSanderMaterials preparation

The invention discloses a door sheet blister manufacturing technology. The door sheet blister manufacturing technology comprises the eleven steps of material preparation, sheet sawing, sheet edge shaping by using edge belt sander, polishing through a sander, routing moulding, drilling through a dowelling jig, line cutting and framing, manual inspection and polishing, glue spraying and drying, sheet blister packaging and inspection and packaging. According to a blister door manufactured by using the technology, the product quality is greatly improved, the attractive degree of the product is improved, the production efficiency is improved, no waste gas and no waste water are discharged, and no pollution to the environment is caused; an automatic waste recycling device is arranged on equipment, after being recycled, and the wastes are uniformly disposed by the governmental environmental sanitation department. Equipment noise generated during production meets the industrial enterprise noise standards of GB12348; by means of the manufacturing technology, collision and damage of the produced sheets in the carrying process are effectively reduced, and the yield is improved.

Owner:索菲亚家居湖北有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com