Sealed bag with unsealing tape

a bag and unsealed technology, applied in the field of unsealed bags, can solve the problems of messy scissors use, bag cannot be opened, and bag cannot be cut in along a straight lin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described below with reference to the related drawings.

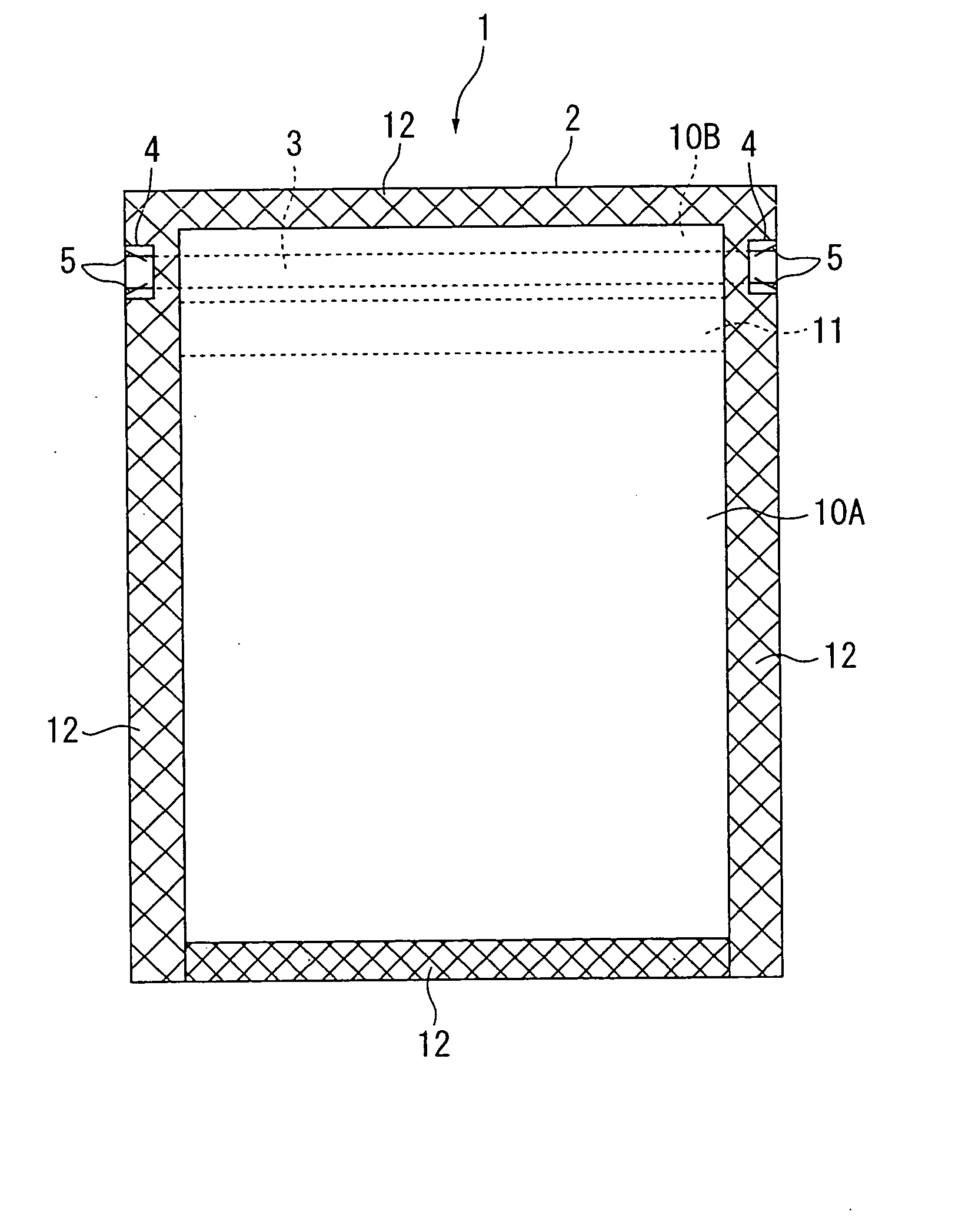

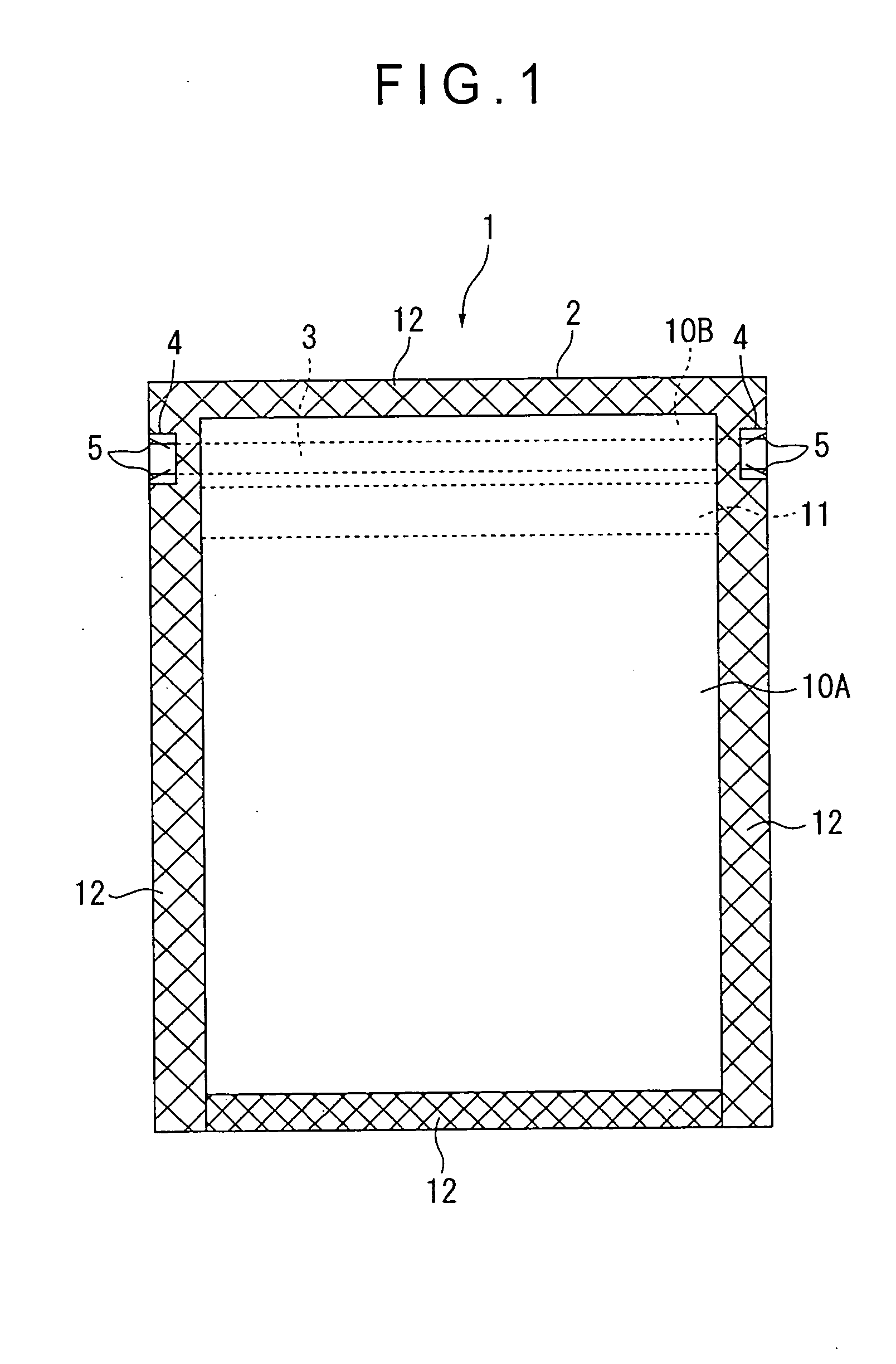

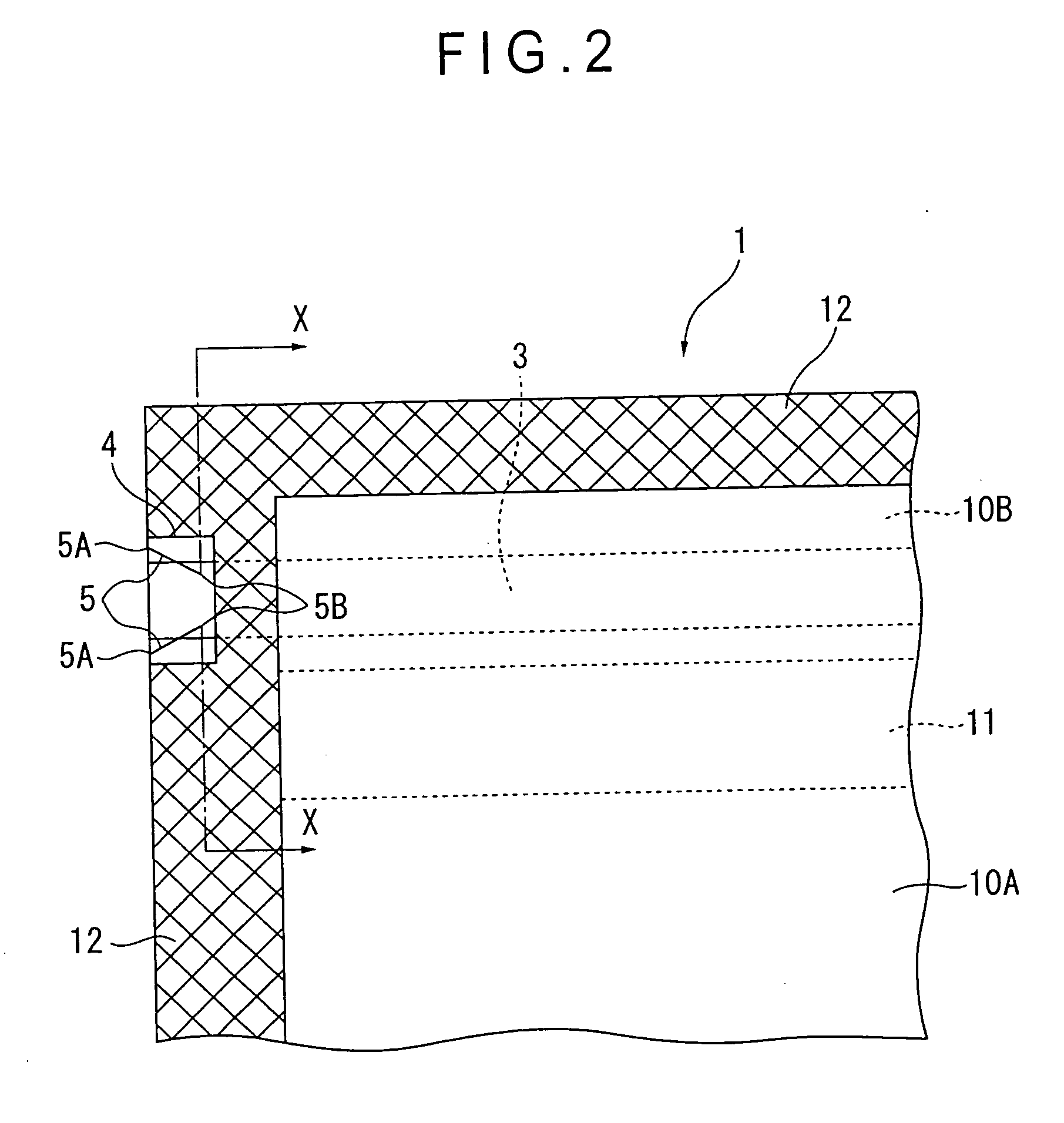

[0038]FIG. 1 shows a packaging bag 1 according to one embodiment of the present invention.

[0039] The packaging bag 1 comprises polyethylene sheets 10A (top side in the figure), 10B (rear side in the figure) sealed along the four edges thereof by means of heat sealing or the like. These sealed portions form a heat-sealed part 12. One edge of the rectangular packaging bag 1 functions as an opening part 2.

[0040] Unsealing tape 3 is wide tape made of polyolefin-based resin and is welded to the opening part 2 side on a surface of the polyethylene sheet 10B by heat sealing or the like, and is drawn uniaxially in the longitudinal direction.

[0041] A cutout part 4 is formed at an end part of the unsealing tape 3 of the packaging bag 1 on the opening part 2 side on a surface of the polyethylene sheet 1 OA and has a rectangular form.

[0042] A cut-in part 5 is formed at an end part of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com