Laser water jet processing device and application thereof

A processing device and water jet technology, which is applied in the field of laser processing and laser water jet processing devices, can solve problems such as low efficiency, small heat-affected zone, and long processing time, and achieve the effects of reducing costs, realizing industrialization, and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

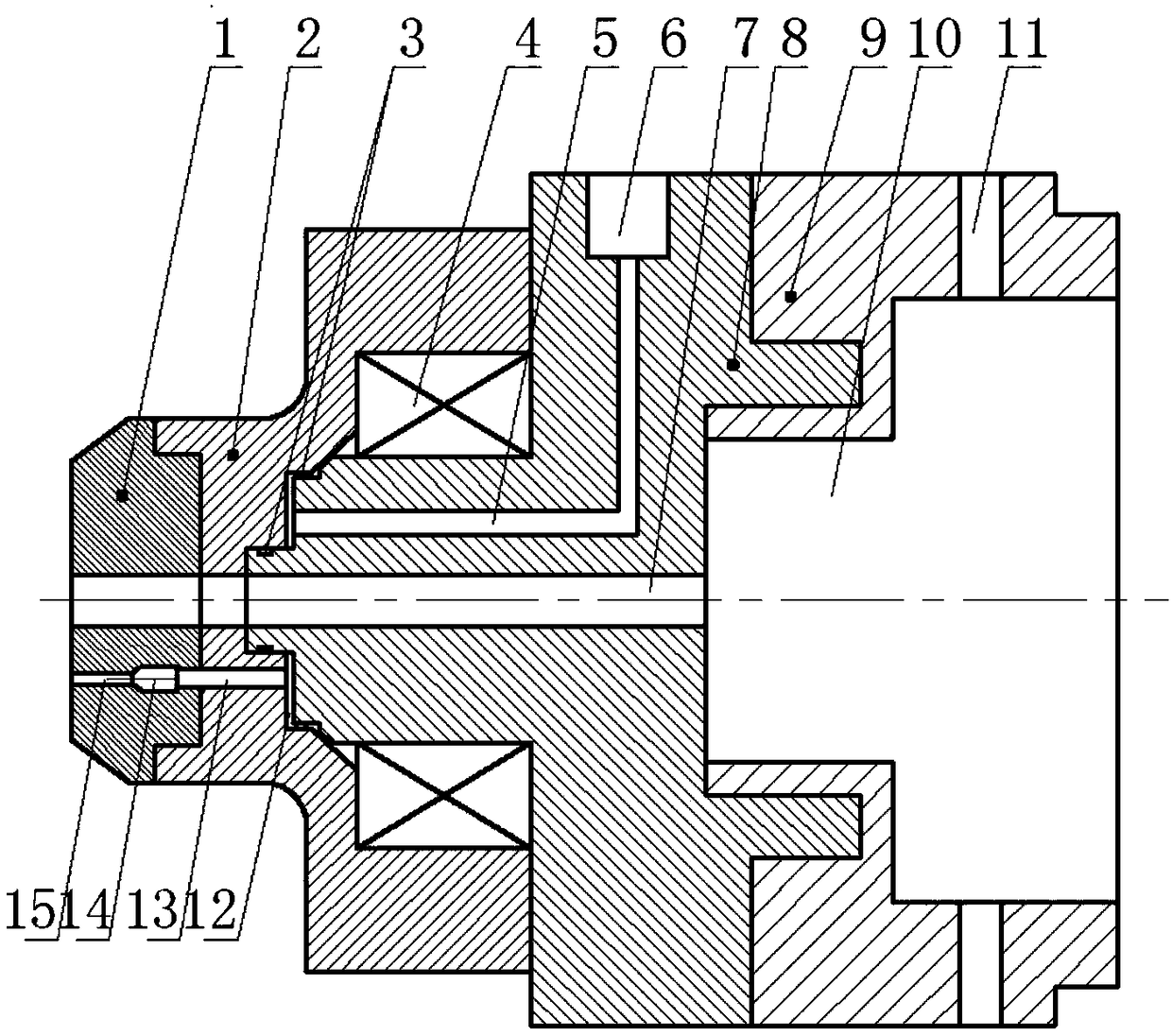

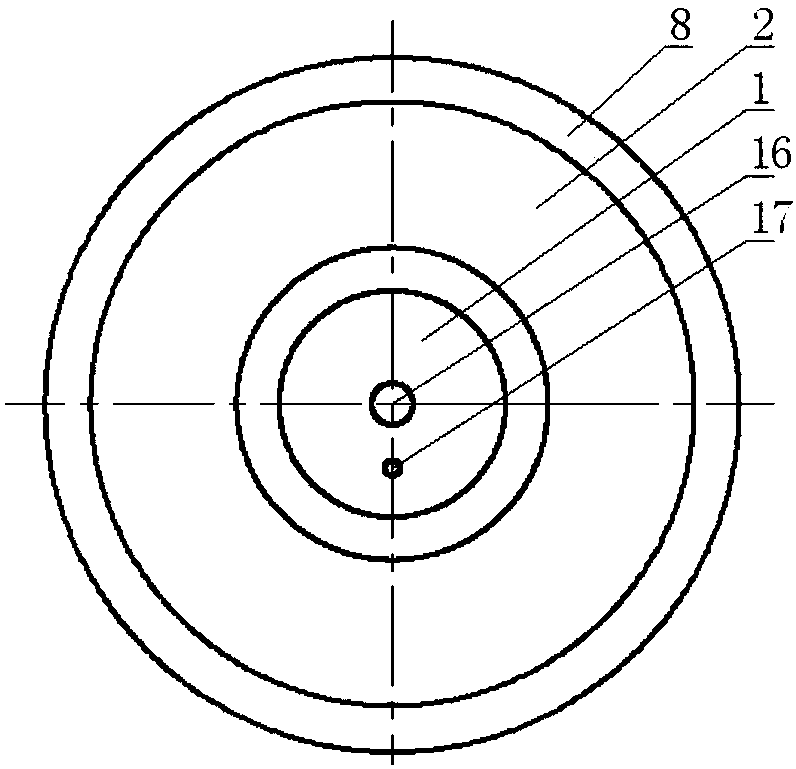

[0027] A laser water jet processing device, including a laser emitting device and a laser head connected to it, the laser head includes a nozzle 1, a rotating disk 2, a separation base 8 and a connecting seat 9 connected coaxially in sequence, and the nozzle, rotation The center of the disk and the separation base is coaxially connected with a laser through hole 7, which communicates with the laser through hole 10 of the connecting seat. Nozzle 14 is shaped on the second water flow channel 13 communicated with the first water flow channel in the rotating disk, the gap between the rotating disk and the separation base forms the third water flow channel 12, and two water flow channels are installed on b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| laser power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com