Door sheet blister manufacturing technology

A manufacturing process and door panel technology, applied in the field of cabinet door processing and door panel blister manufacturing process, can solve problems such as inability to adapt to diversified needs, immature board blister technology, and inability to mass-produce, to reduce efficiency constraints and save money. Lines, the effect of increased service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

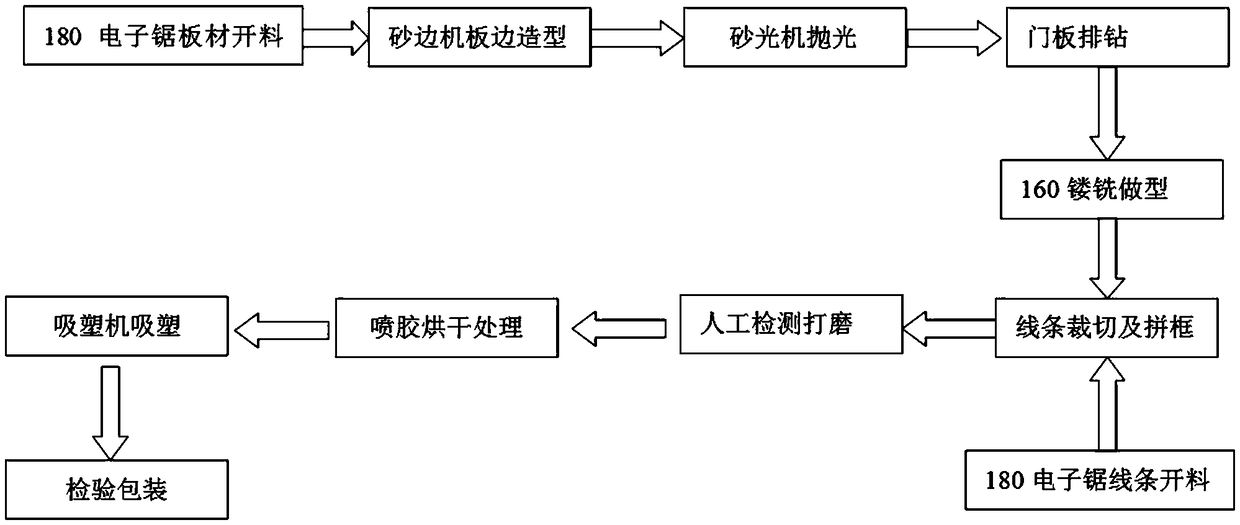

[0039] Hereinafter, the present invention will be illustrated with examples in conjunction with the drawings, such as figure 1 As shown, the present invention includes a total of eleven processes: material preparation, material cutting, edge molding by sanding machine, polishing by sanding machine, engraving and milling, drilling and drilling, line and frame molding, manual inspection and polishing, spraying Glue drying treatment, board blister, inspection and packaging.

[0040] 1. Process description:

[0041] Step 1. Material preparation: including line preparation and door panel preparation. The line is prepared with 2440*50mm plain board, and the door panel is prepared with 2440*1220*18mm plain board (medium fiber board), and melamine paper is pressed on one side. Matters needing attention: 1. Single-sided pressing of the melamine board; 2. When placing the board, the pressing surface must face up to prevent scratches on the board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com