Silicon-block cutting method

A cutting method and silicon block technology, which can be used in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of cutting speed, workbench moving speed, low mortar flow rate, poor cutting ability of silicon wafers, saw marks on the surface of silicon wafers, etc. problem, to achieve the effect of reducing cutting cost, reducing scrap rate and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The preparation method of the structural wire for silicon block cutting includes the following steps: 1) performing mechanical derusting treatment on the surface of the wire rod; 2) performing chemical surface rust treatment on the wire rod after the mechanical derusting treatment, and then washing and drying; 3) Heating and wire drawing to make semi-finished steel wire; 4) Heat treatment to relieve stress; 5) Heating, passing through the shaping hole mold and wire drawing machine for rotating wire drawing to make steel wire for cutting; 6) Electroplating the outer surface of steel wire for cutting Antioxidant layer, washed with water.

[0080] The material of the wire rod in step 1) is high carbon steel, the carbon content is 0.75%-0.9%, the content of sulfur and phosphorus is less than 0.02%; the anti-oxidation layer in step 6) is a brass alloy layer; the shaping hole mold in step 5) It is a ring whose inner diameter is equal to the diameter of the steel wire, and the...

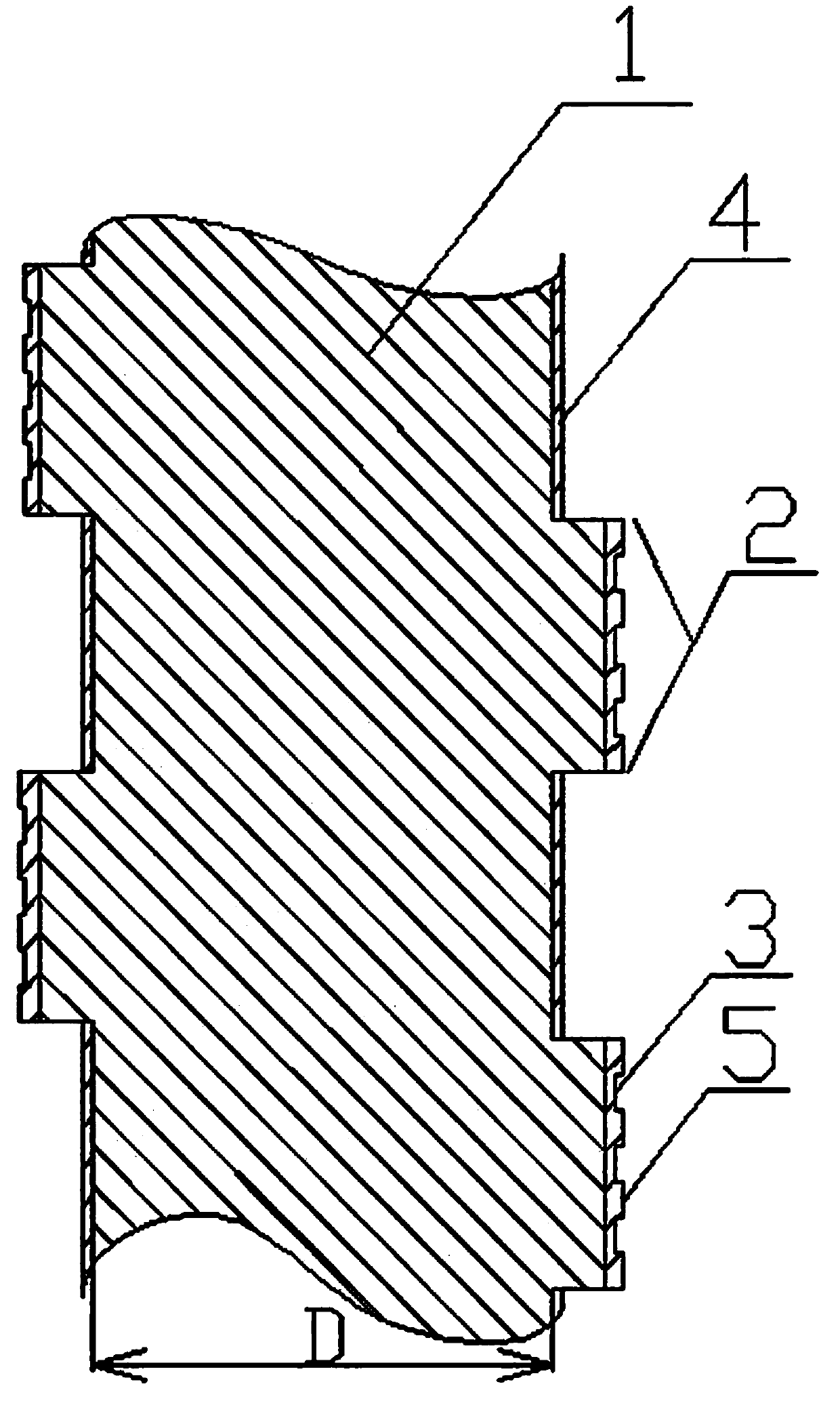

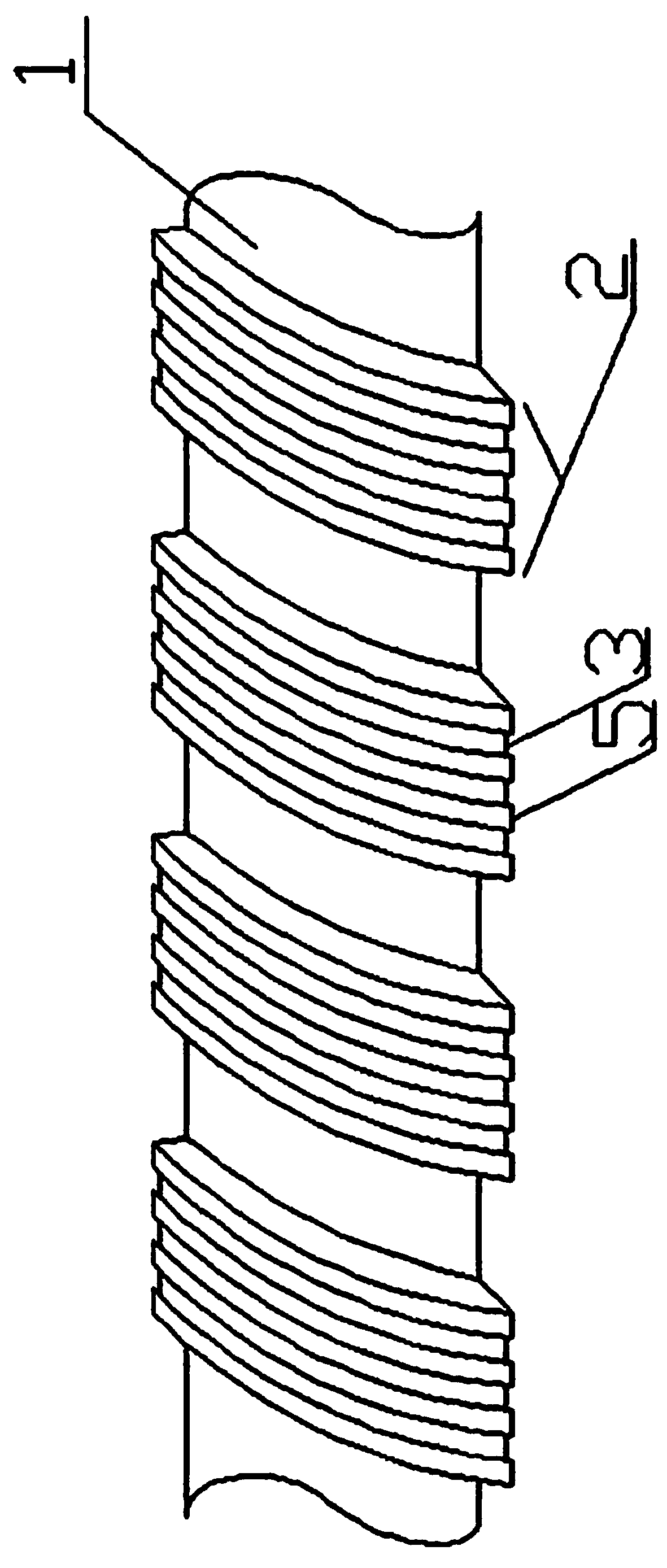

Embodiment 1

[0085] The outer surface of the steel wire is coated with an anti-oxidation layer 4 , and the outer surface of the steel wire 1 is provided with spiral protrusions 2 . The diameter D of the steel wire 1 is 0.10 mm, and the spiral protrusion 2 is a rectangular thread. On the shaft section, the width of the rectangular thread is 0.10 mm, the distance between the roots of the thread grooves is 0.08 mm, and the thread depth is 0.06 mm. The steel wire 1 is made of high carbon steel, with a carbon content of 0.75%-0.9%, and a sulfur and phosphorus content of less than 0.02%. An anti-oxidation layer 4 is electroplated so that a relatively dense structure is attached to the surface of the steel wire, which protects the steel wire, prevents the steel wire from being oxidized, and effectively prevents the main body of the steel wire from directly contacting the silicon chip. The anti-oxidation layer 4 is preferably a brass alloy layer to prevent the steel wire from being worn. The desi...

Embodiment 2

[0096] A steel wire for cutting silicon wafers, comprising a steel wire 1, the outer surface of the steel wire 1 is coated with an anti-oxidation layer 4, and the outer surface of the steel wire 1 is provided with spiral protrusions 2. The diameter D of the steel wire 1 is 0.15 mm, and the spiral protrusion 2 is a rectangular thread. On the shaft section, the width of the rectangular thread is 0.20 mm, the distance between the roots of the thread grooves is 0.07 mm, and the thread depth is 0.08 mm.

[0097] The spiral protrusion 2 is provided with a small groove 3, and the small groove 3 is wound along the direction of the spiral protrusion 2. There are three small grooves 3 with a rectangular cross-section; the width of the small grooves 3 is 0.02 mm, the depth is 0.017 mm, and the width of the small protrusions 5 between adjacent small grooves 3 is 0.035 mm. The design of the small groove 3 is convenient for the steel wire to hold some ground silicon powder in the process of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com