Patents

Literature

113 results about "Test compression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

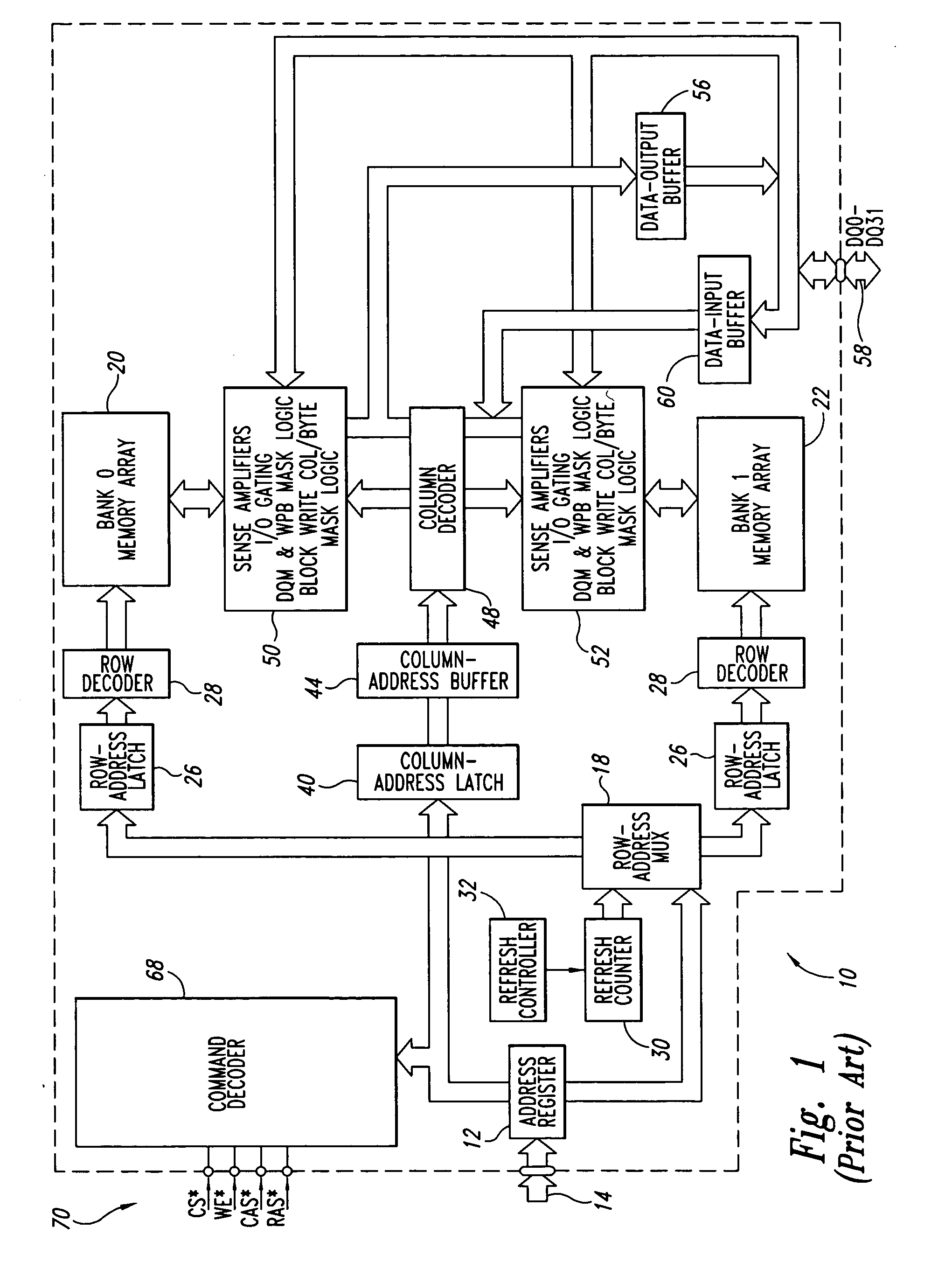

Test compression is a technique used to reduce the time and cost of testing integrated circuits. The first ICs were tested with test vectors created by hand. It proved very difficult to get good coverage of potential faults, so Design for testability (DFT) based on scan and automatic test pattern generation (ATPG) were developed to explicitly test each gate and path in a design. These techniques were very successful at creating high-quality vectors for manufacturing test, with excellent test coverage. However, as chips got bigger the ratio of logic to be tested per pin increased dramatically, and the volume of scan test data started causing a significant increase in test time, and required tester memory. This raised the cost of testing.

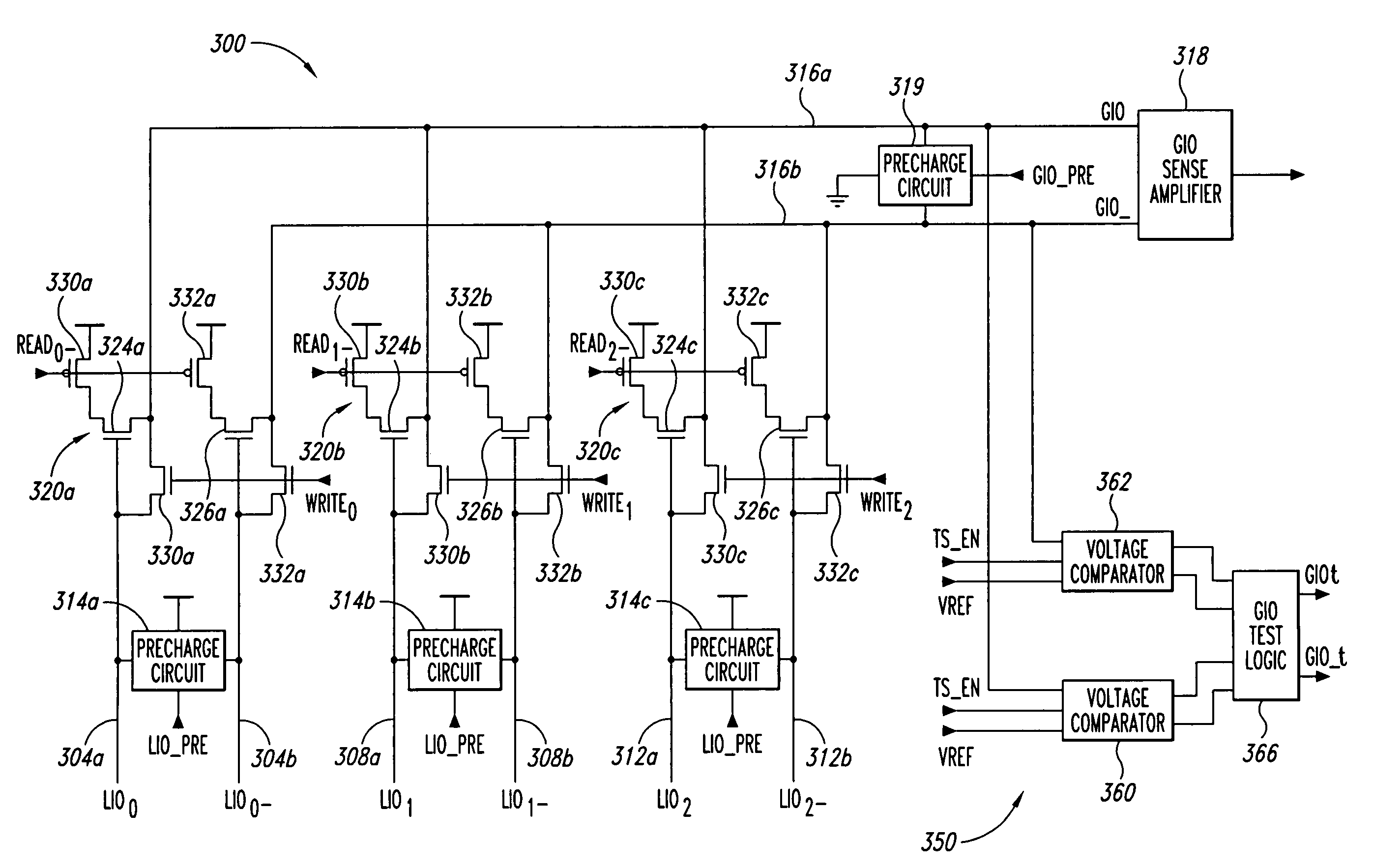

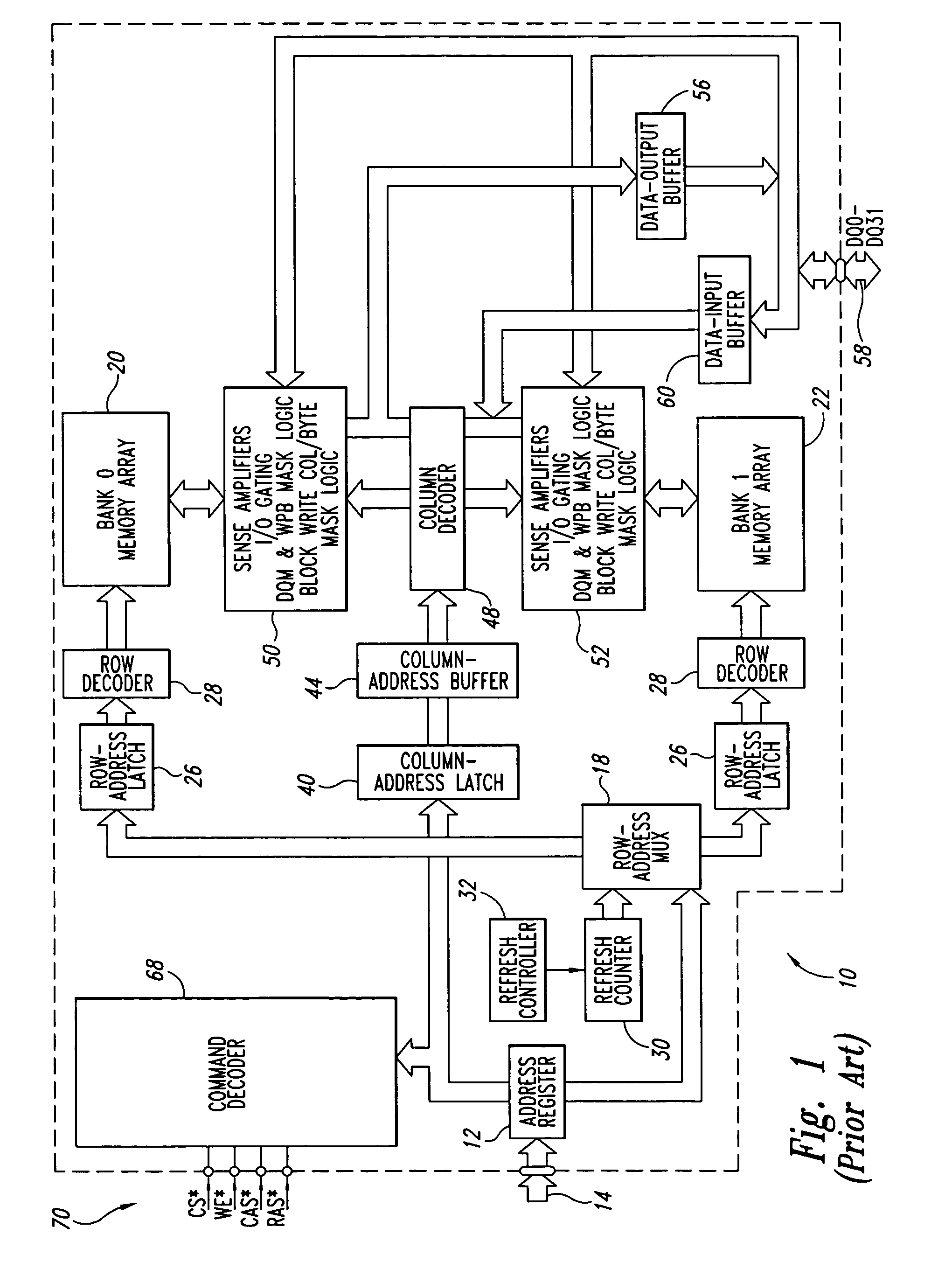

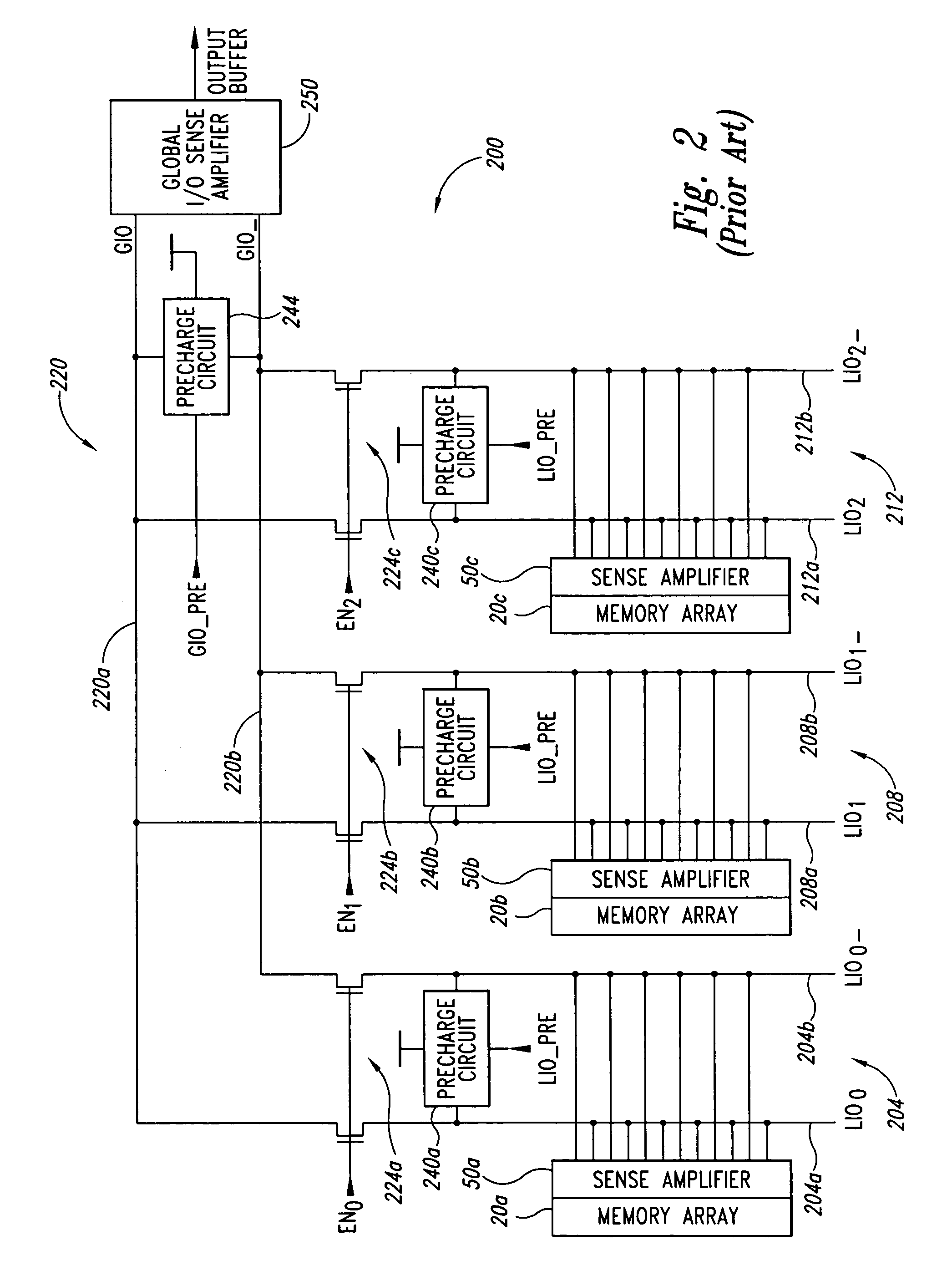

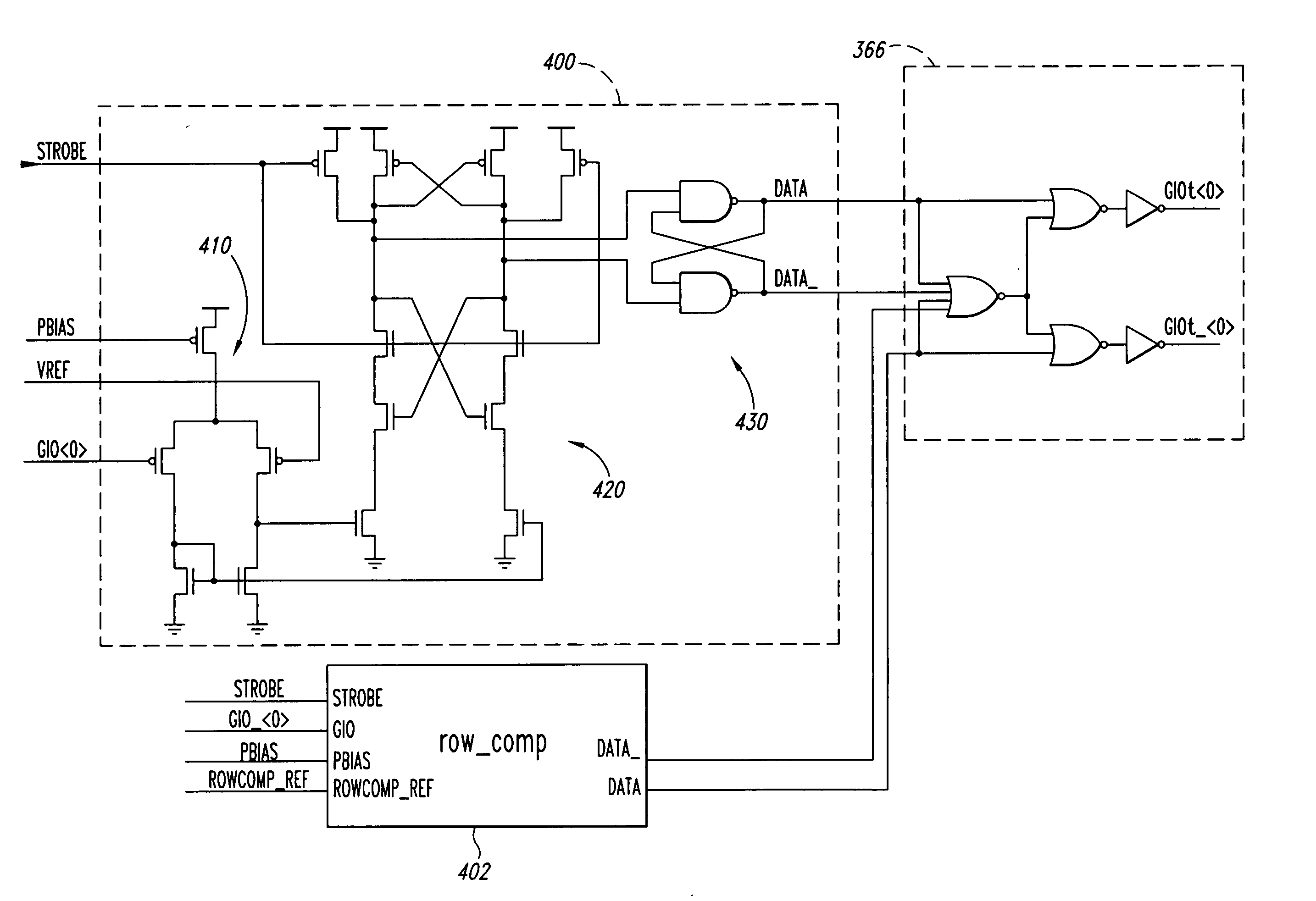

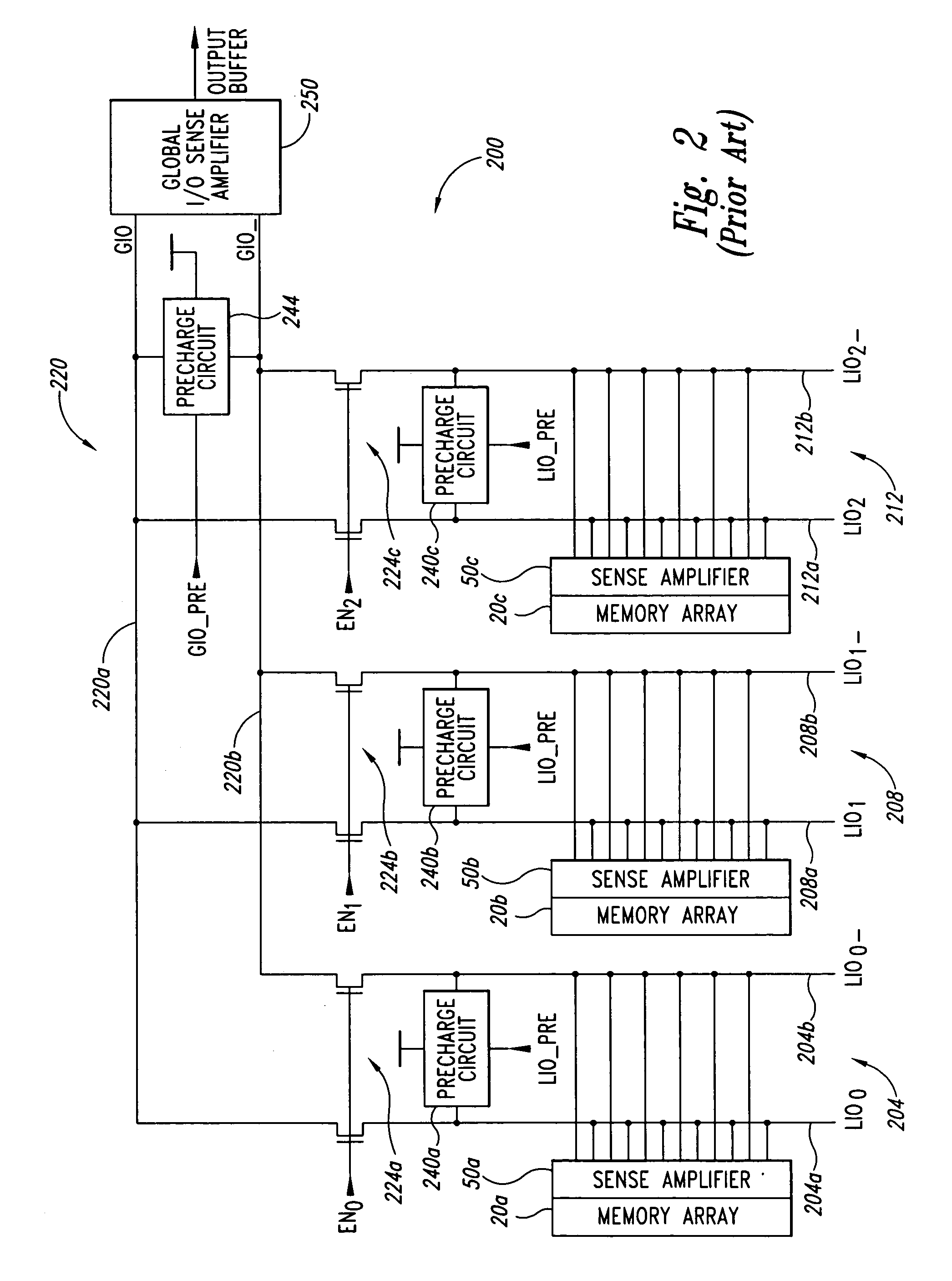

Data path having grounded precharge operation and test compression capability

A data path for coupling data between a memory cell and an input / output (IO) line sense amplifier. An IO line coupling circuit is coupled to a pair of global data lines and a pair of local data lines to couple and decouple each of the global data lines to and from a voltage supply based on the voltage levels of the local data lines for the memory read operation. For the memory write operation, the IO line coupling circuit couples and decouples each of the global data lines to and from a respective one of the local data lines. The data path also includes a first precharge circuit coupled to the global data lines to couple the global data lines to ground to precharge the signal lines prior to a memory read or write operation, and can further include a test compression circuit coupled to the global data lines.

Owner:MOSAID TECH

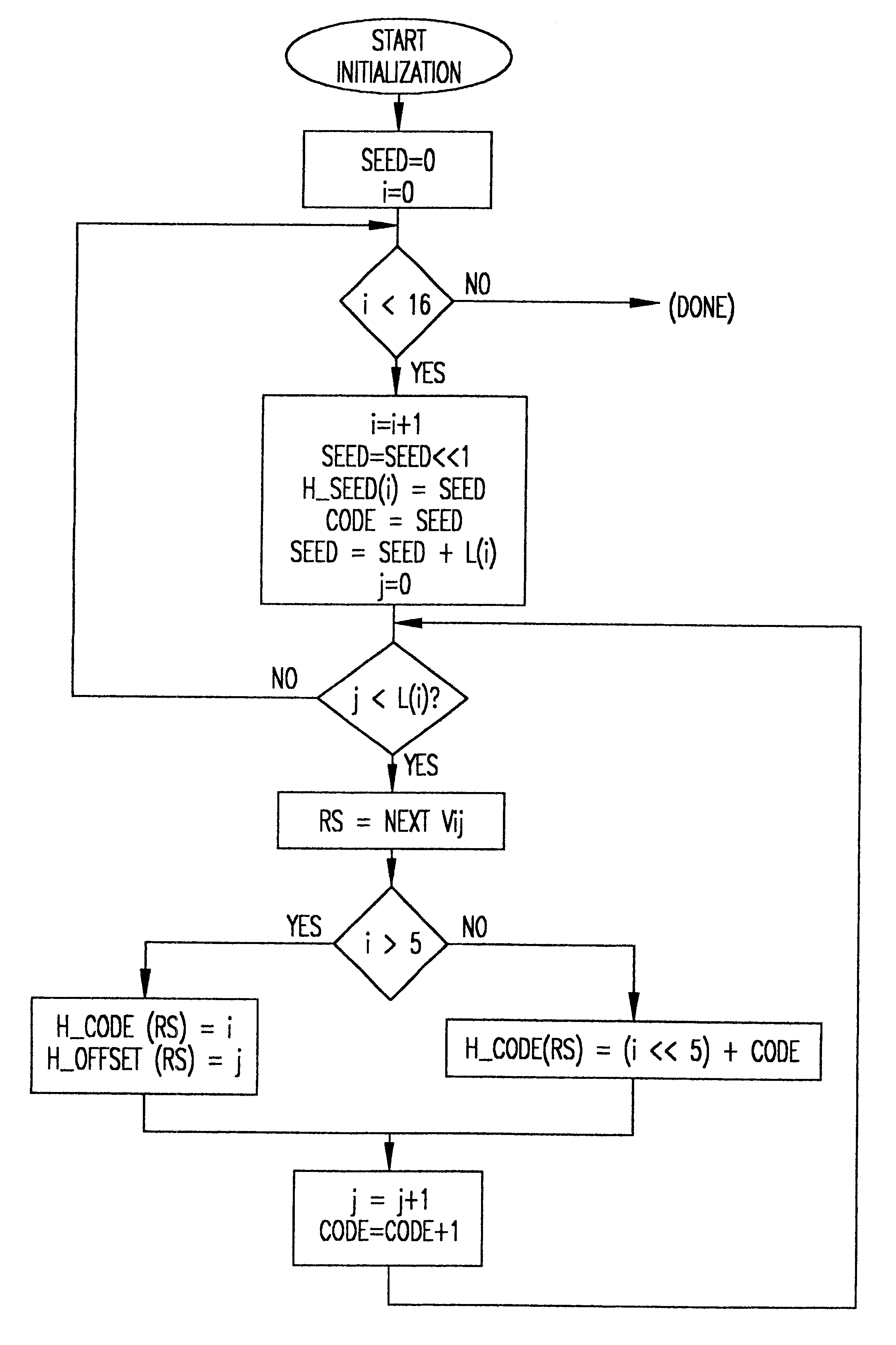

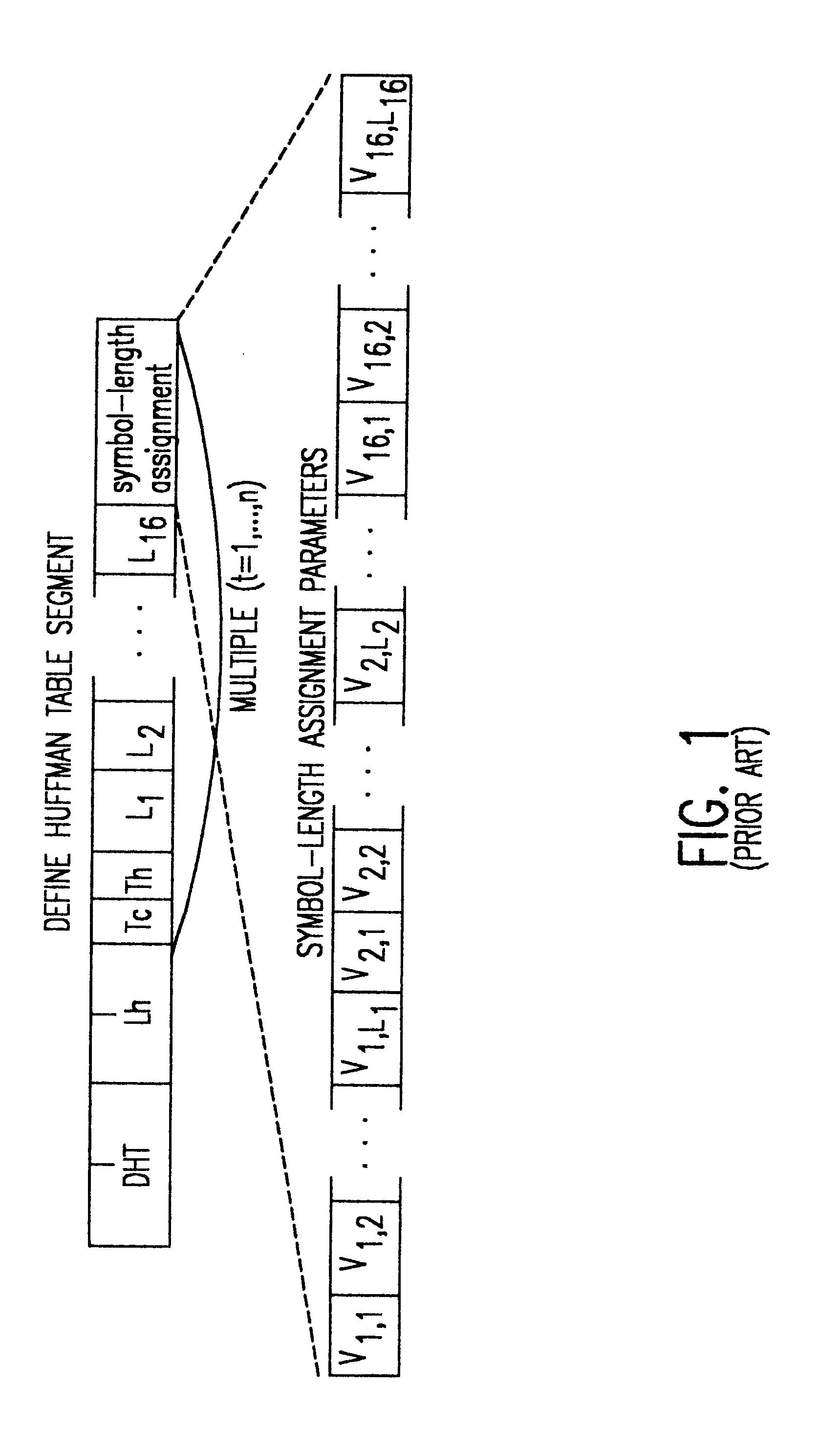

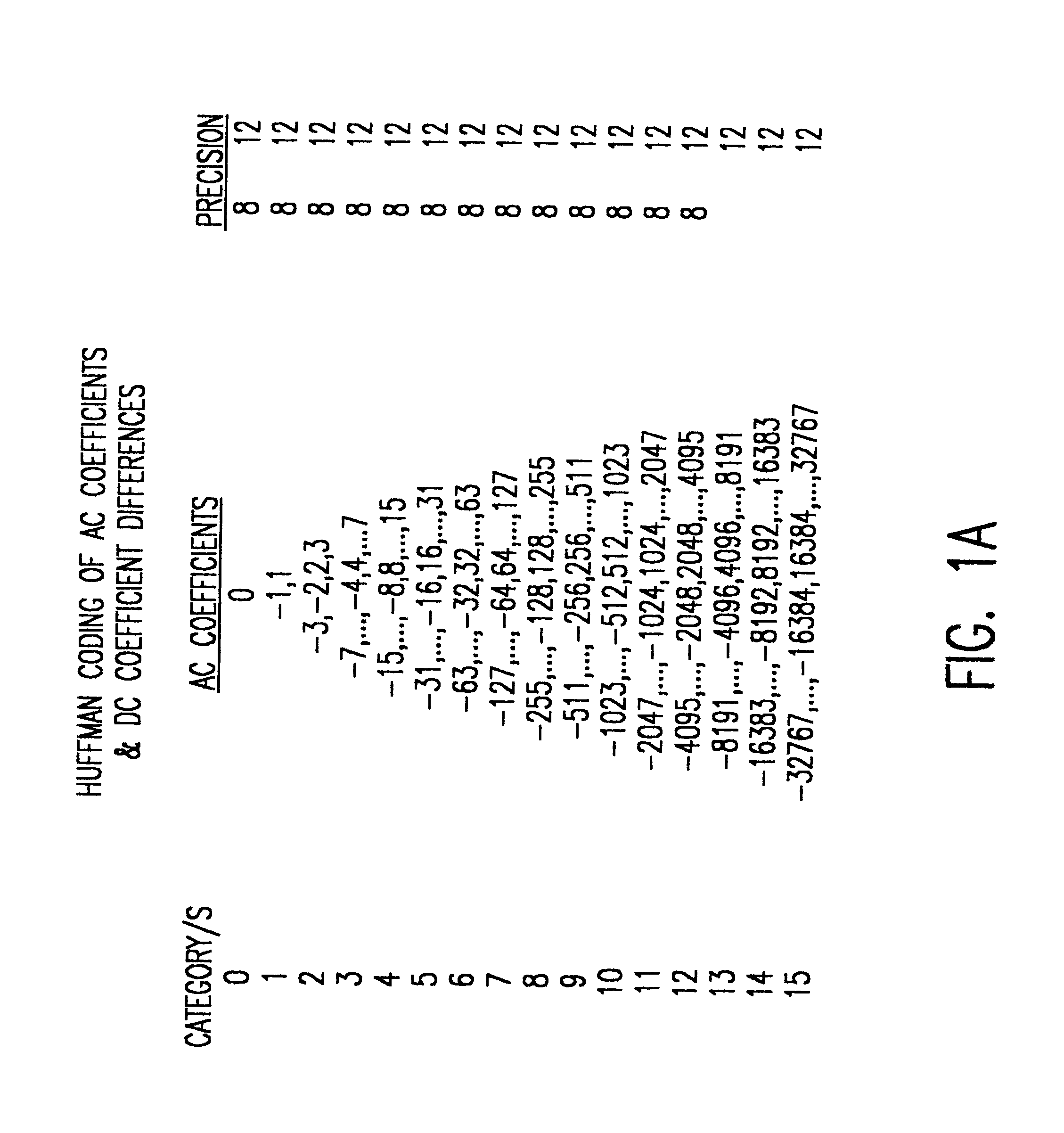

Fast JPEG huffman encoding and decoding

InactiveUS6373412B1Electric signal transmission systemsCharacter and pattern recognitionData streamJPEG

Huffman encoding, particularly from a packed data format, is simplified by using two different table formats depending on code length. Huffman tables are also reduced in size thereby. Decoding is performed in reduced time by testing for the length of valid Huffman codes in a compressed data stream and using an offset corresponding to a test criterion yielding a particular test result to provide a direct index into Huffman table symbol values while greatly reducing the size of look-up tables used for such a purpose.

Owner:IBM CORP

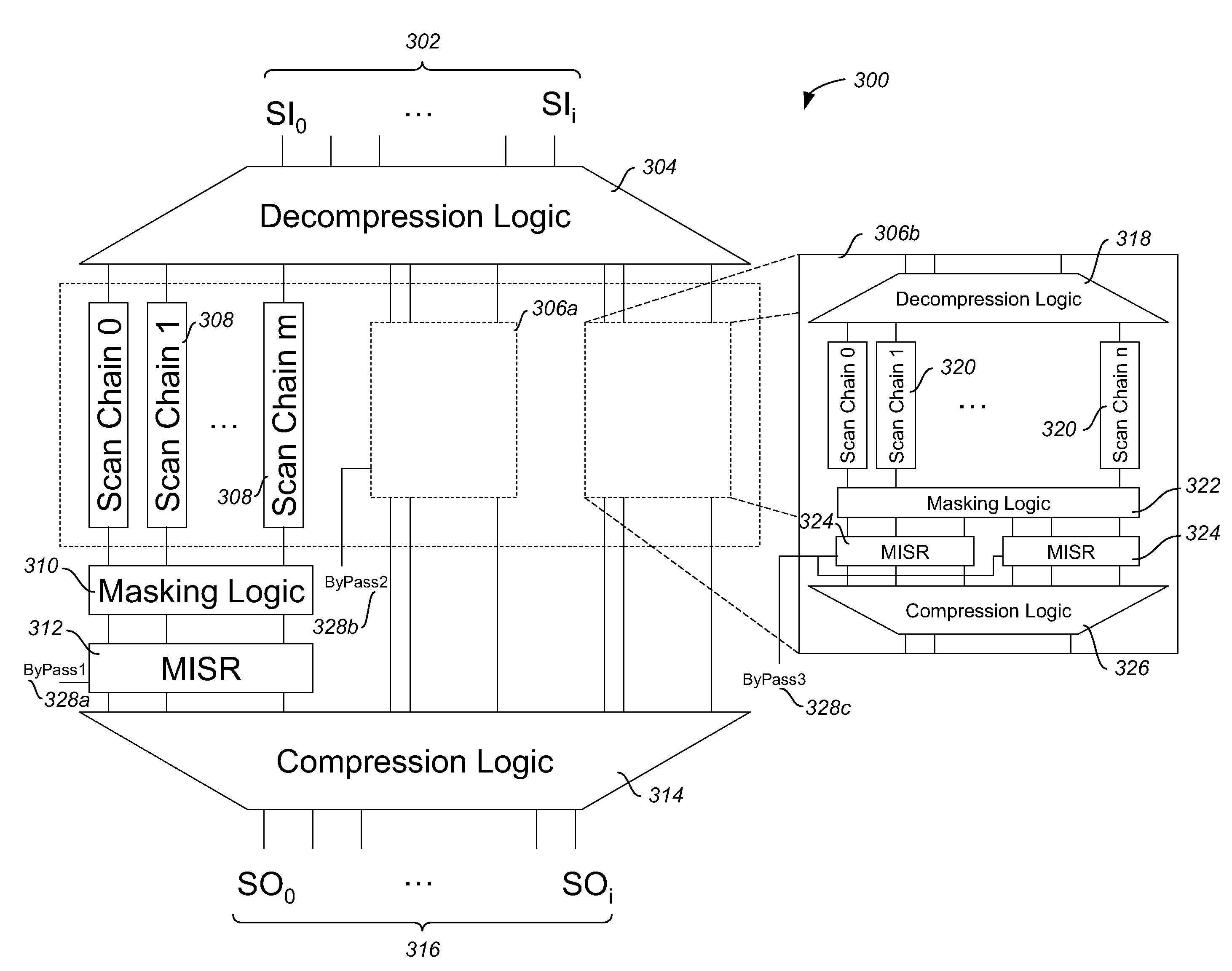

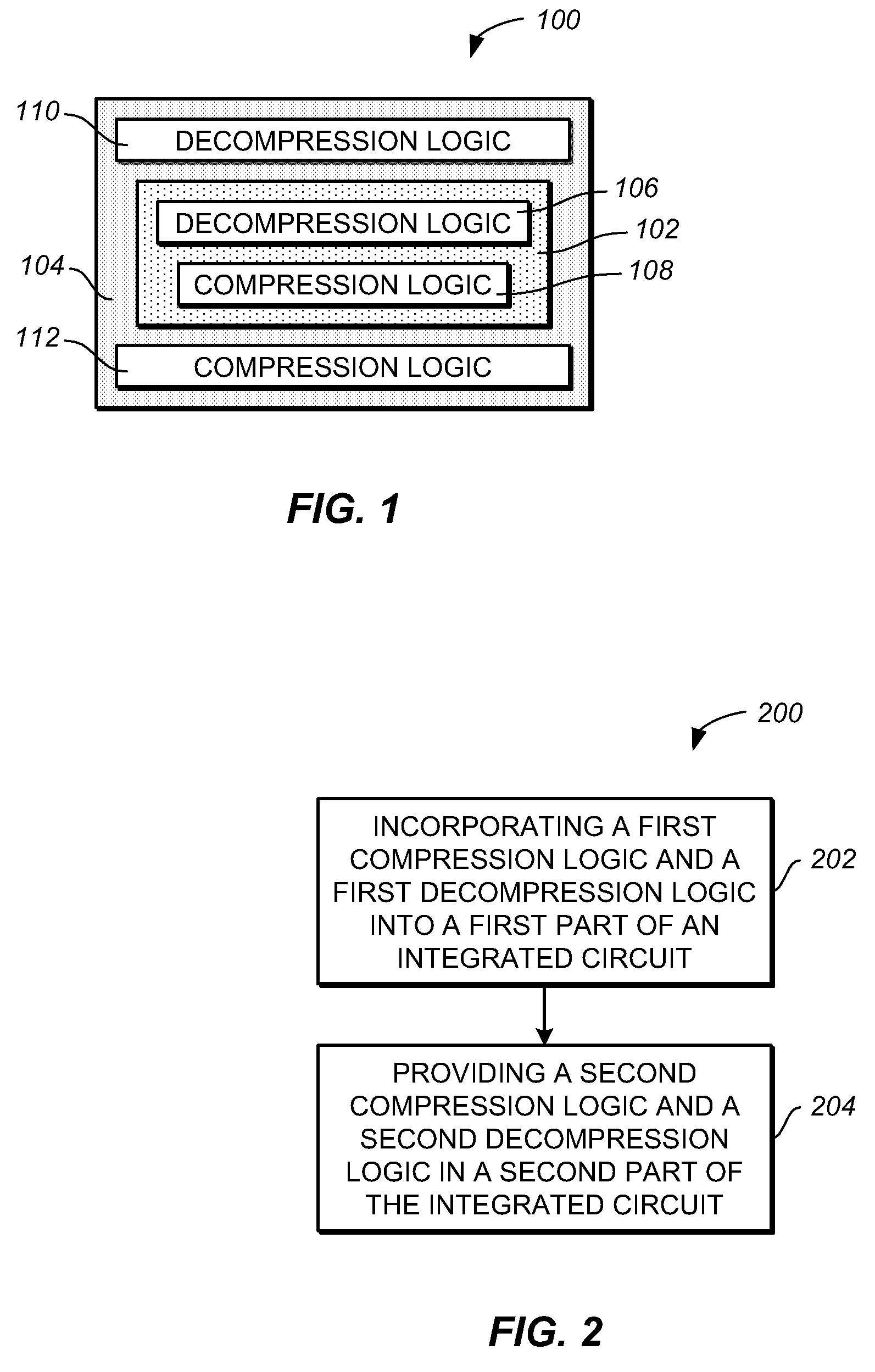

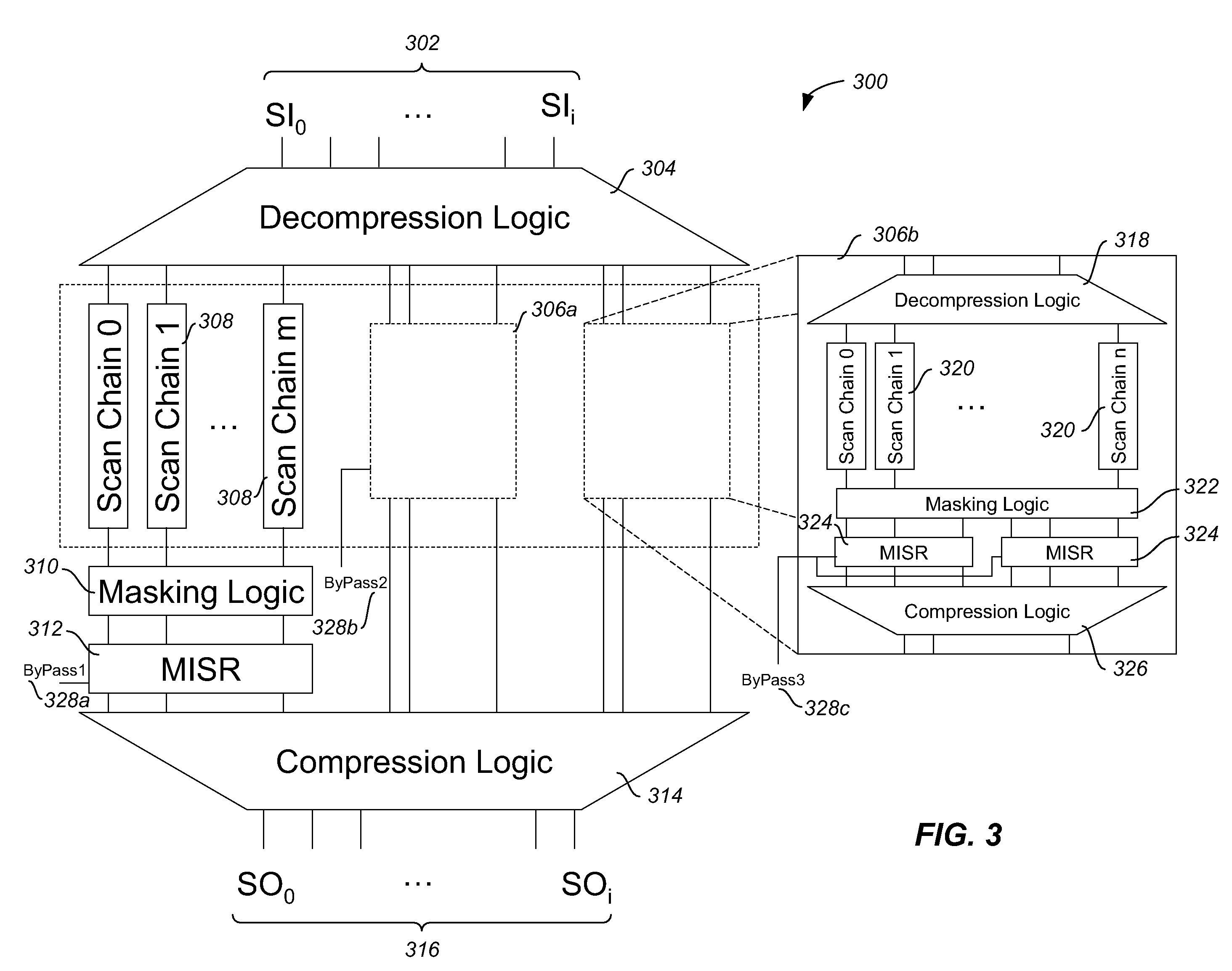

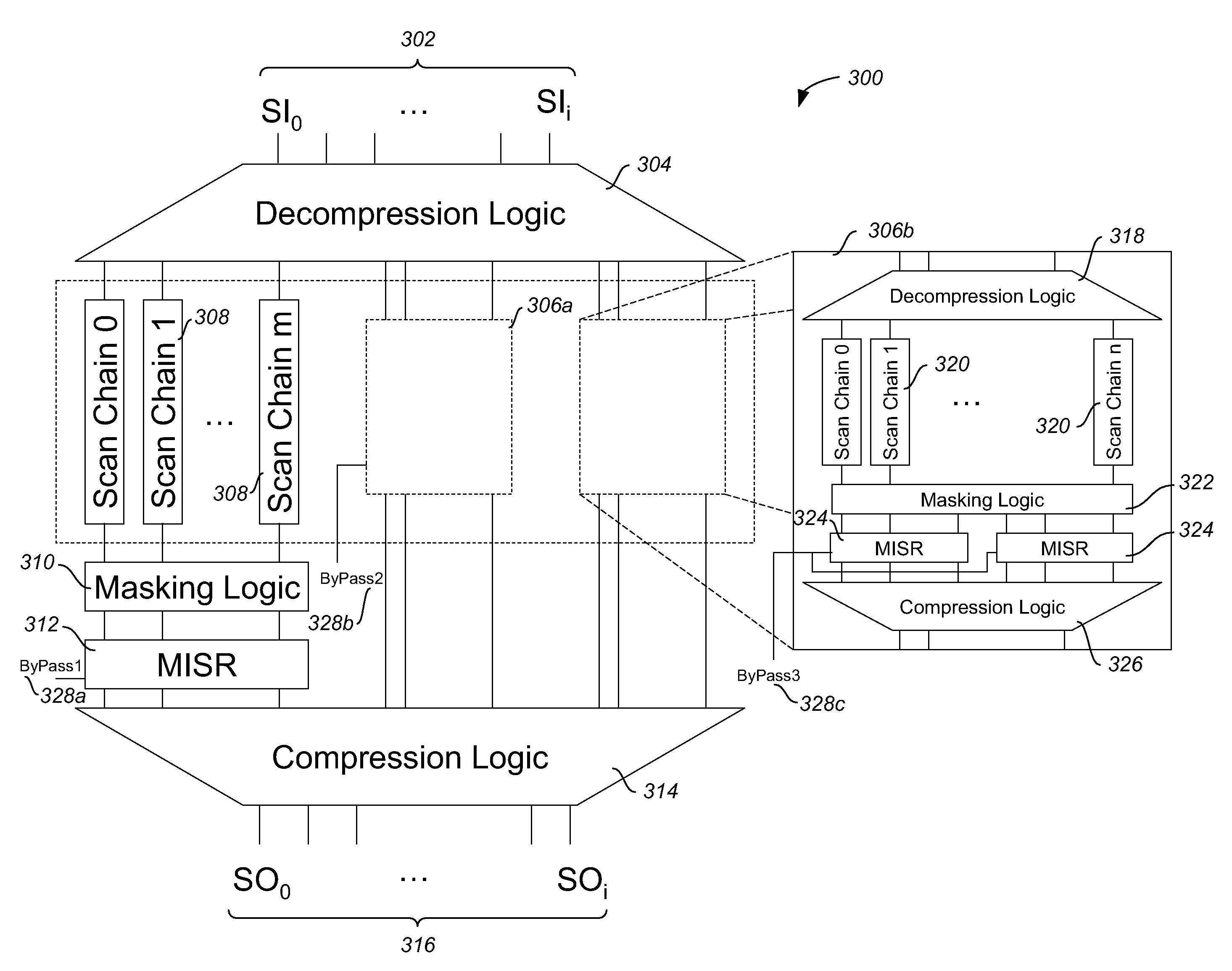

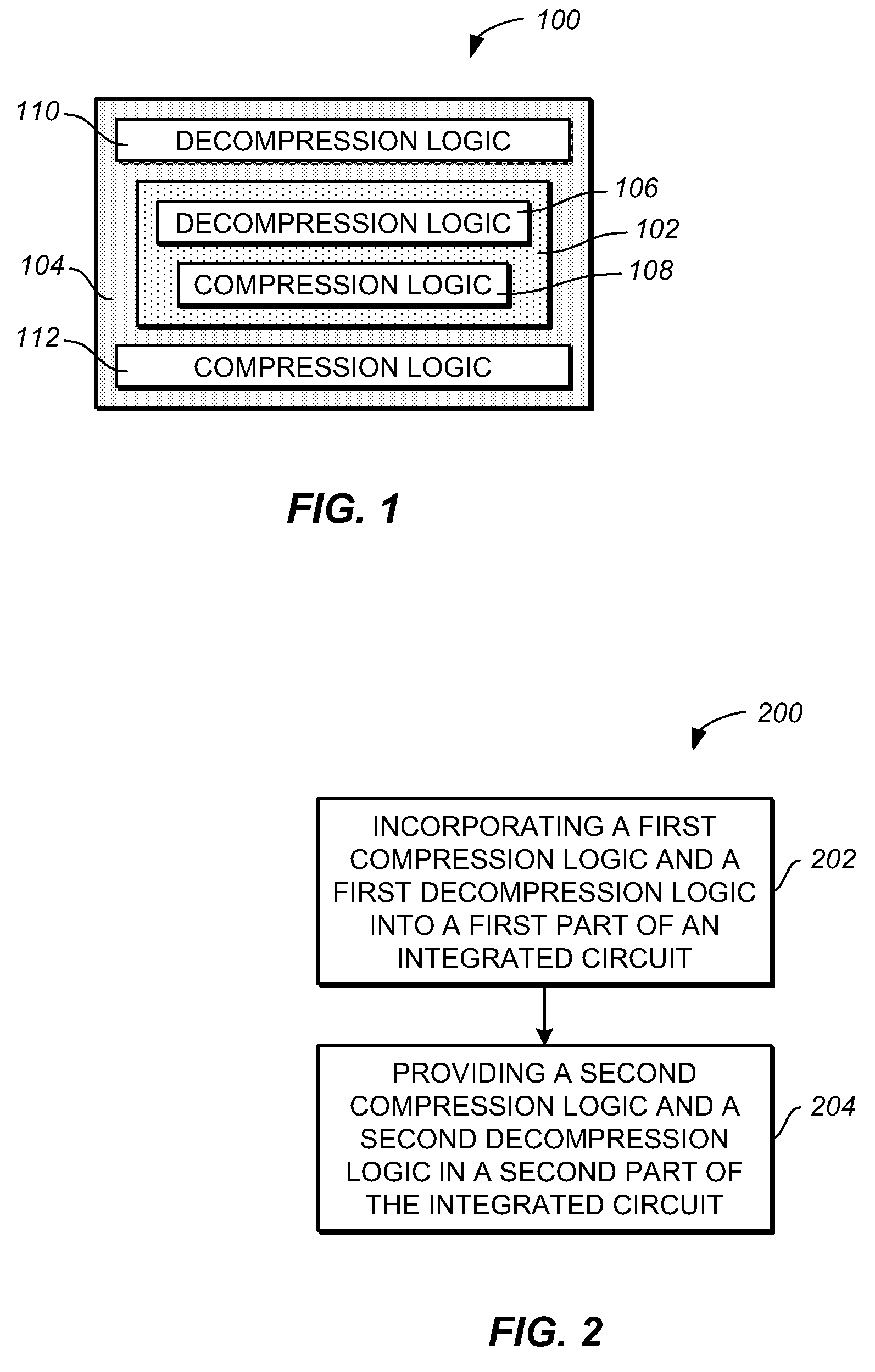

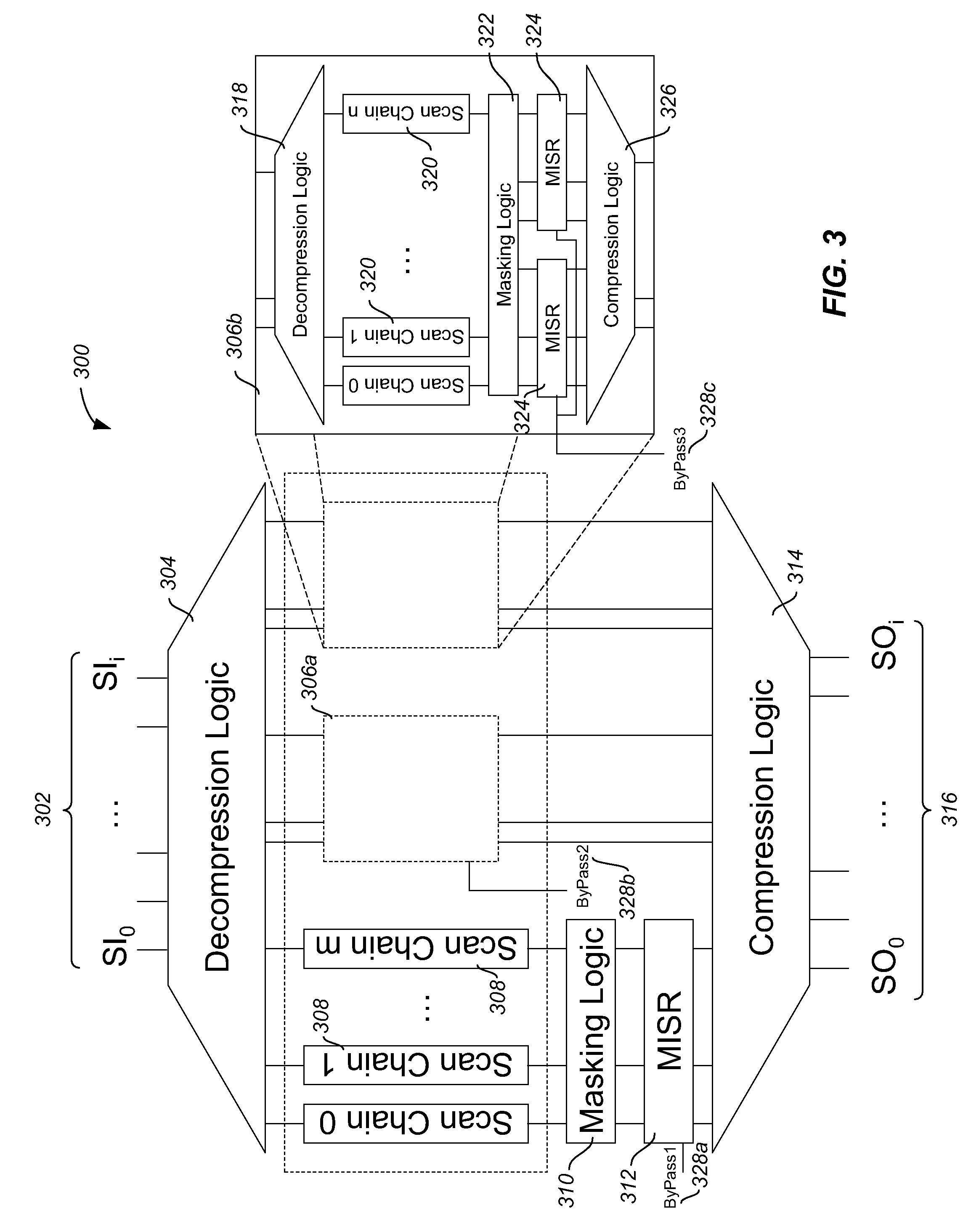

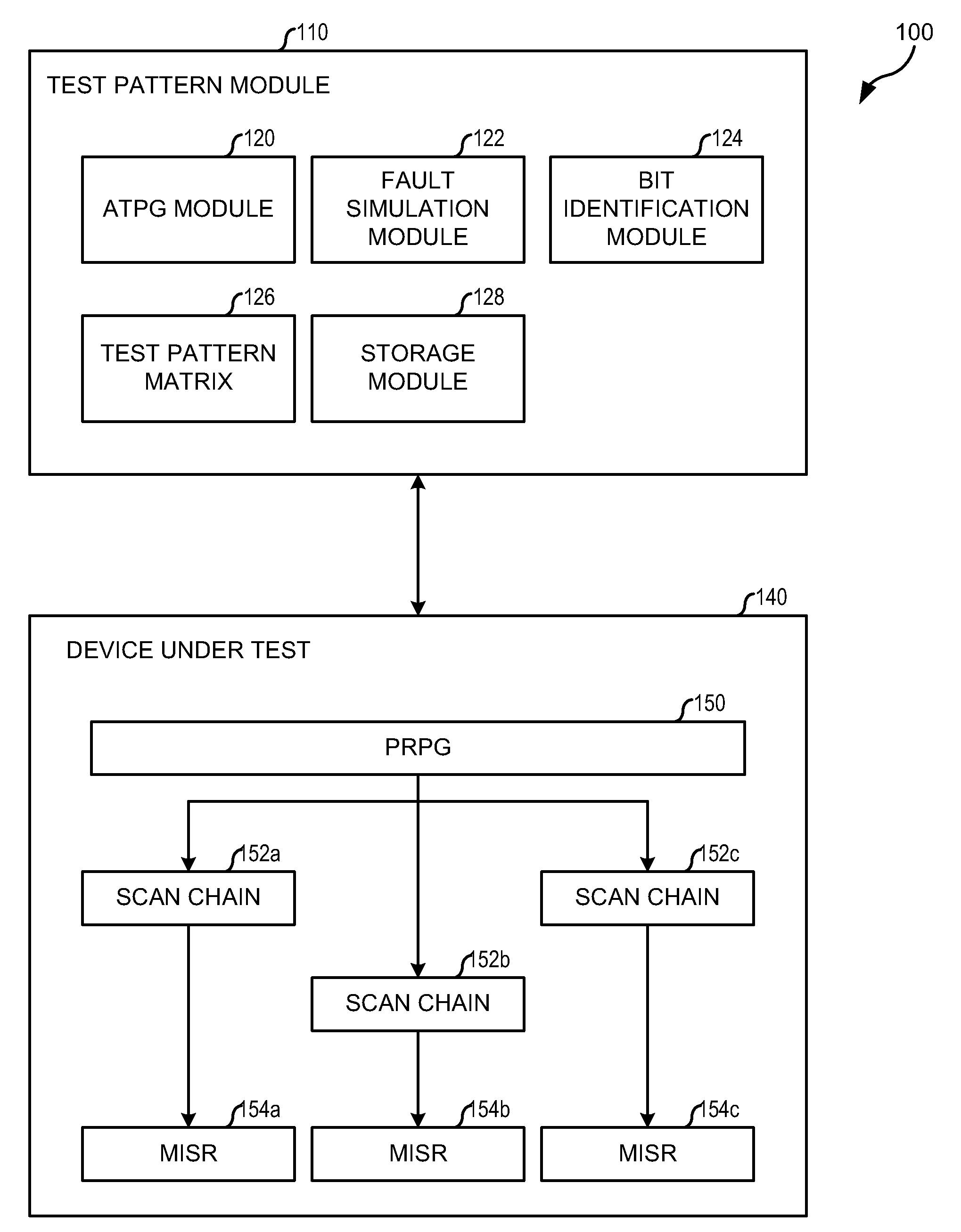

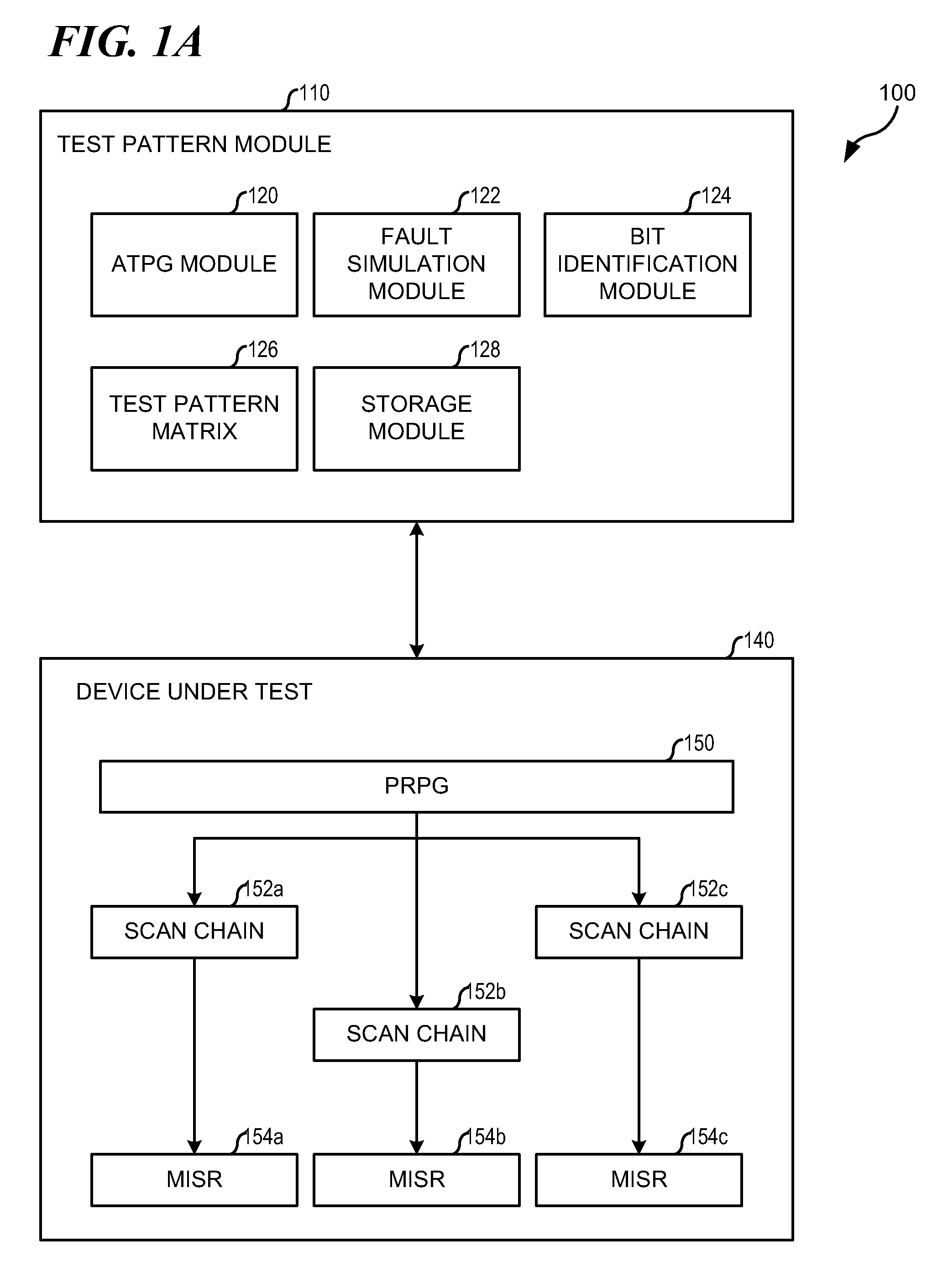

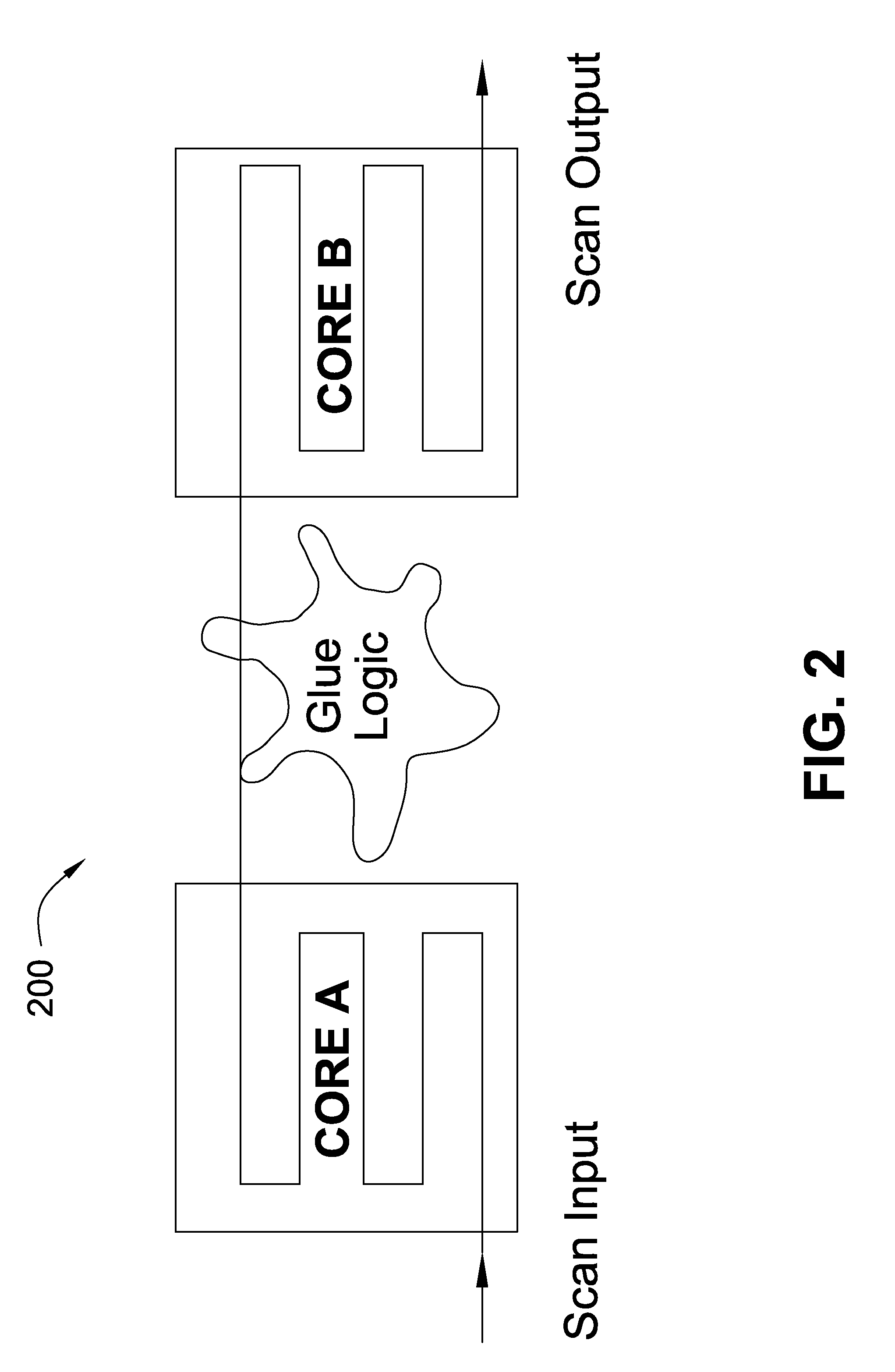

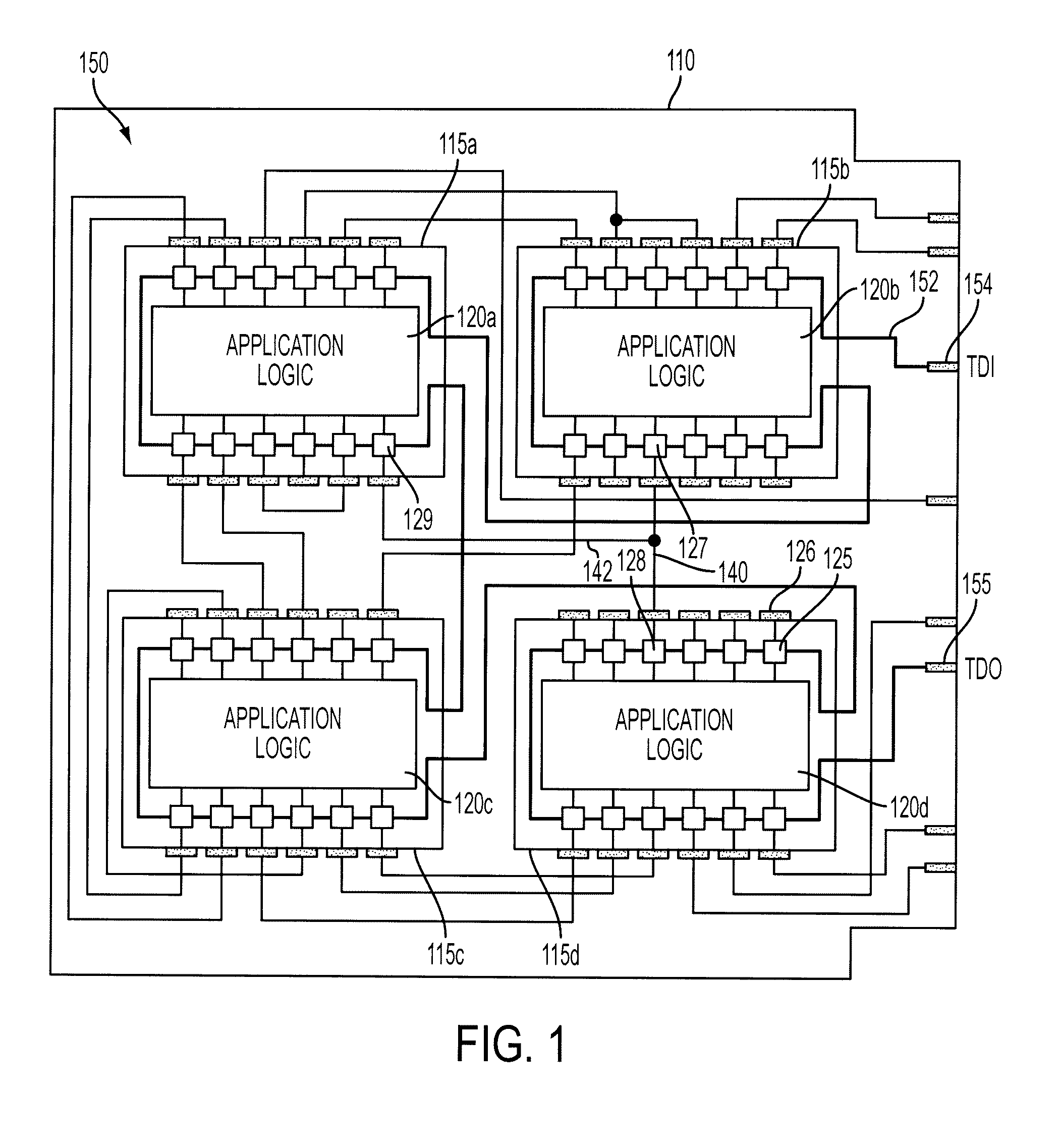

Distributed test compression for integrated circuits

ActiveUS20090119559A1Easy diagnosisElectronic circuit testingLogical operation testingEngineeringDistributed testing

A method for testing integrated circuits is provided. The method provides for incorporating compression and decompression logic into each sub-component of an integrated circuit, developing test modes that target different sub-components of the integrated circuit, selecting one of the test modes, applying a test pattern to one or more sub-components of the integrated circuit targeted by the one test mode, comparing a response from application of the test pattern to a known good response, and diagnosing the response to determine which part of the one or more sub-components targeted by the one test mode failed when the response does not match the known good response.

Owner:CADENCE DESIGN SYST INC

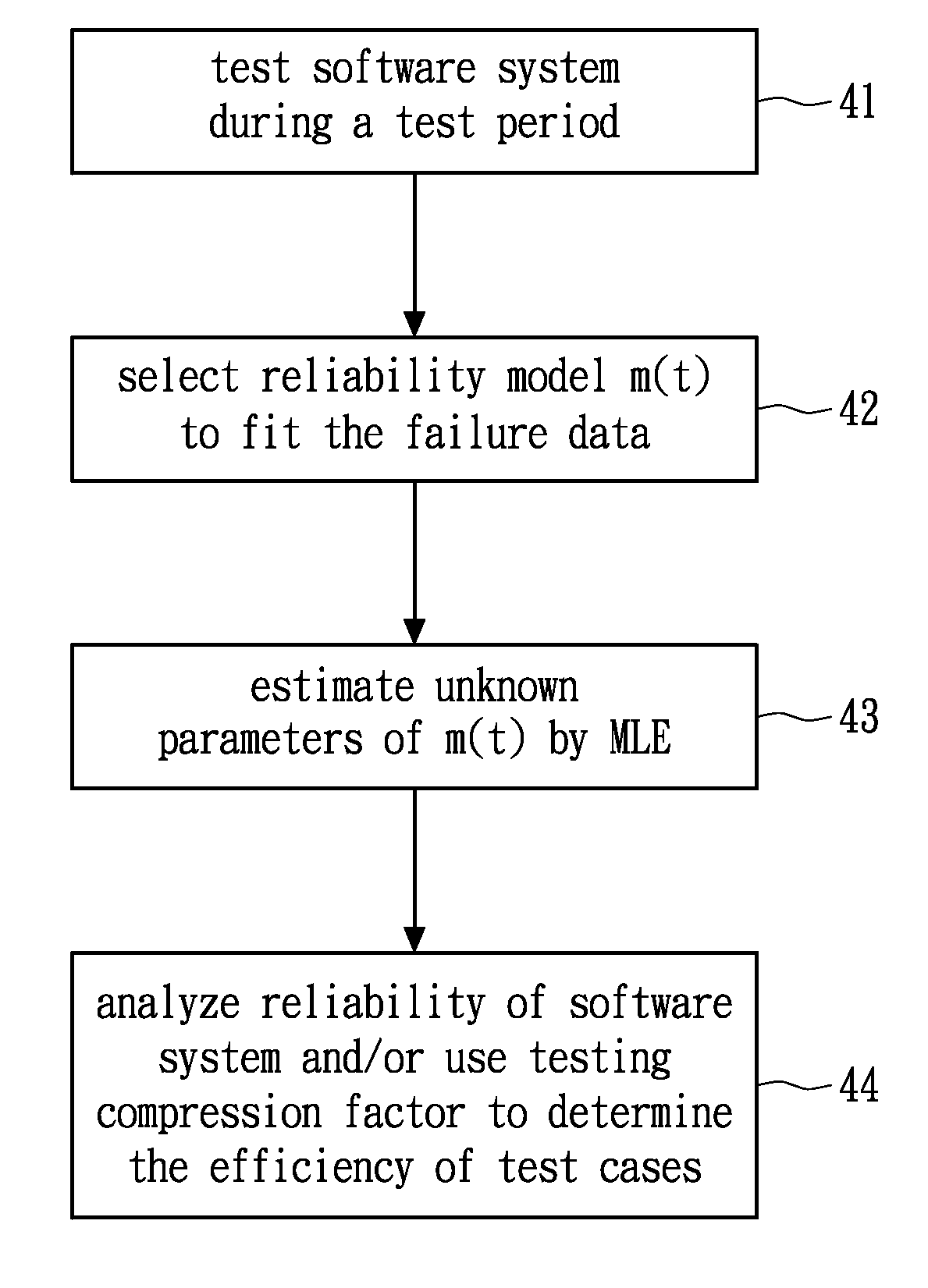

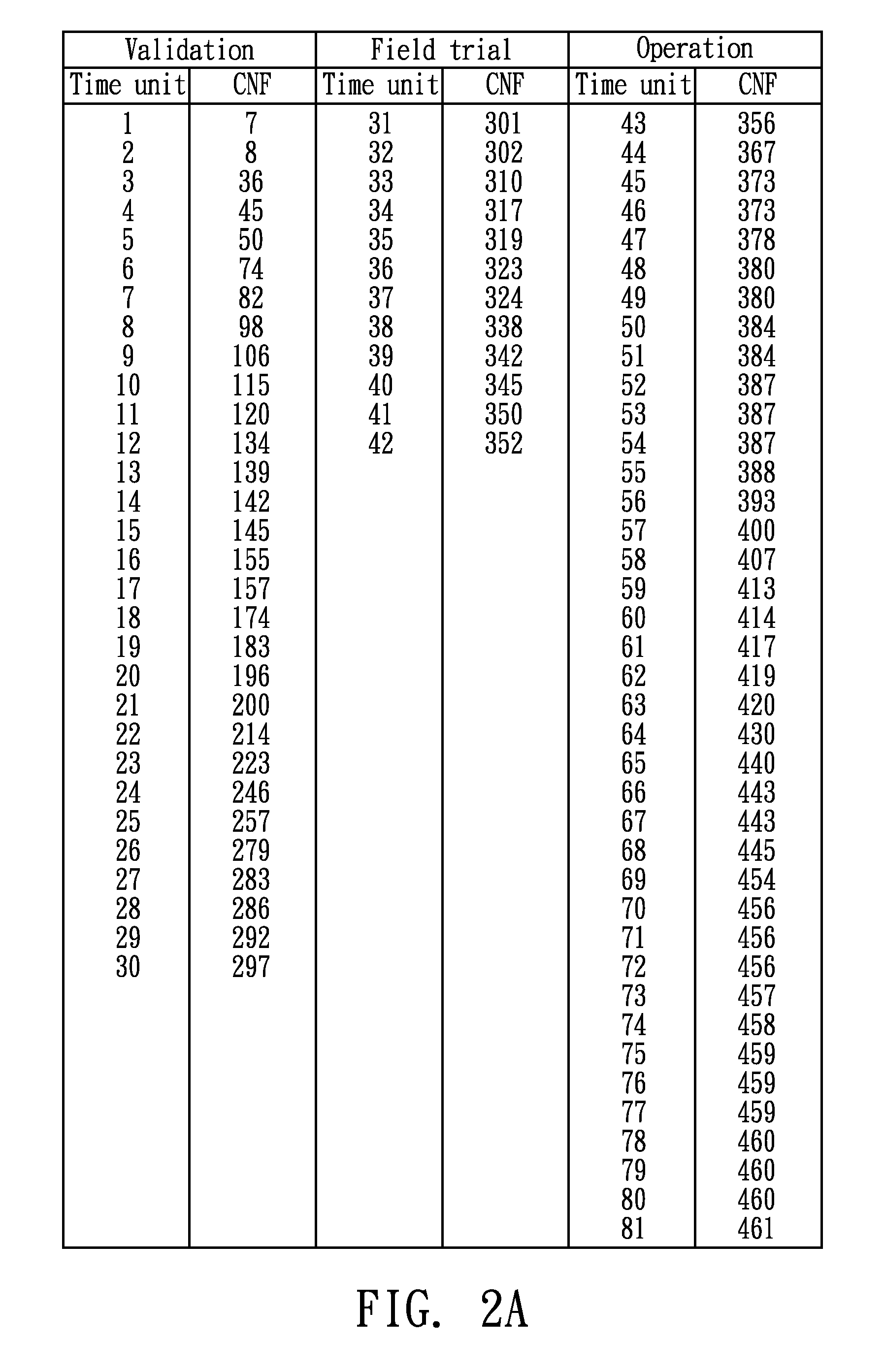

Method and system for assessing and analyzing software reliability

A method for assessing and analyzing software reliability comprises the steps of: collecting failure data from a software system during a testing period; providing a reliability model having a testing compression factor, wherein the reliability model is used to fit the failure data; providing an estimation function derived from the reliability model; obtaining the value of the testing compression factor in accordance with the estimation function; and using the testing compression factor to determine the efficiency of test cases.

Owner:NATIONAL TSING HUA UNIVERSITY

Method for computing rock II-type fracture toughness

InactiveCN1818608AImprove forecast accuracyEffective distributionPreparing sample for investigationInvestigating material hardnessType fractureHydraulic fracturing

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

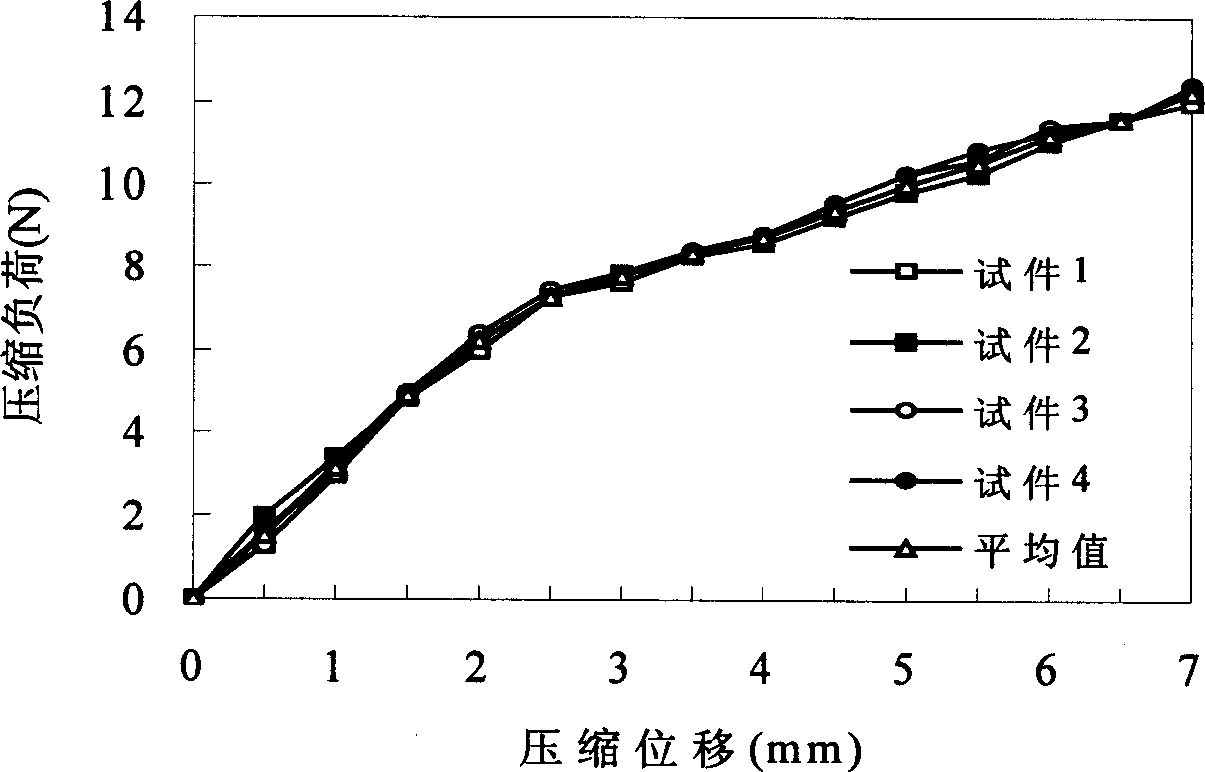

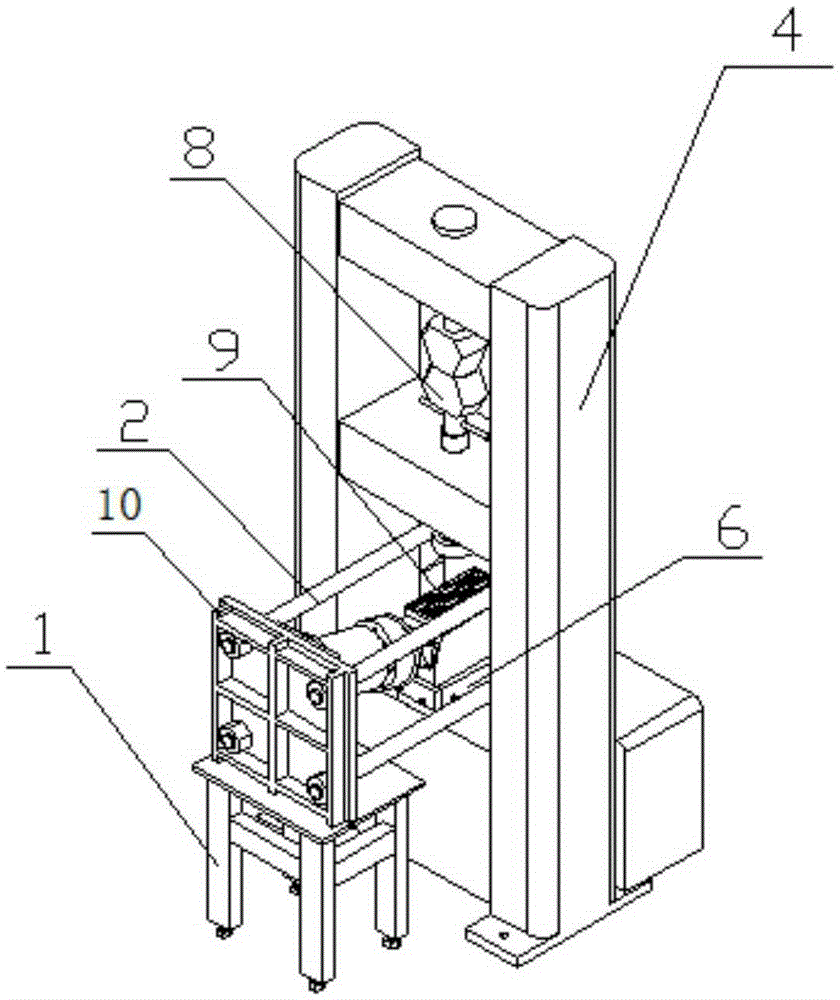

Equipment for testing compression load and displacement of scalling rope for cars

InactiveCN1687737ACorrect evaluation of closing forceProperly evaluate the effect of closing forceVehicle testingMaterial strength using tensile/compressive forcesTest fixtureStrain gauge

The invention is the automobile sealing strip compressing load and displacement testing equipment. The step-by-step motor drives the driving device through the computer control; the driving device composed of the gear assistant and the thread nut assistant drives the pressing head to move straight and to press on the sealing bar; the raster ruler is equipped on the cantilever of the pressing head to get the precise displacement of the head for the reading of the digital displayer; the force sensor is equipped on the pressing head; the sealing bar produces the resistance to misshape the force sensor and is reflected by the voltage changing of the electric bridge; the computer converses the voltage value into the compressing charge of the sealing bar through the sensor; the CCD testing system is equipped at one side of the sealing bar to test the space track of the points of the section of the sealing bar. The invention can realize the complicated response test of the sealing bar and ensure the testing precision.

Owner:SHANGHAI JIAO TONG UNIV

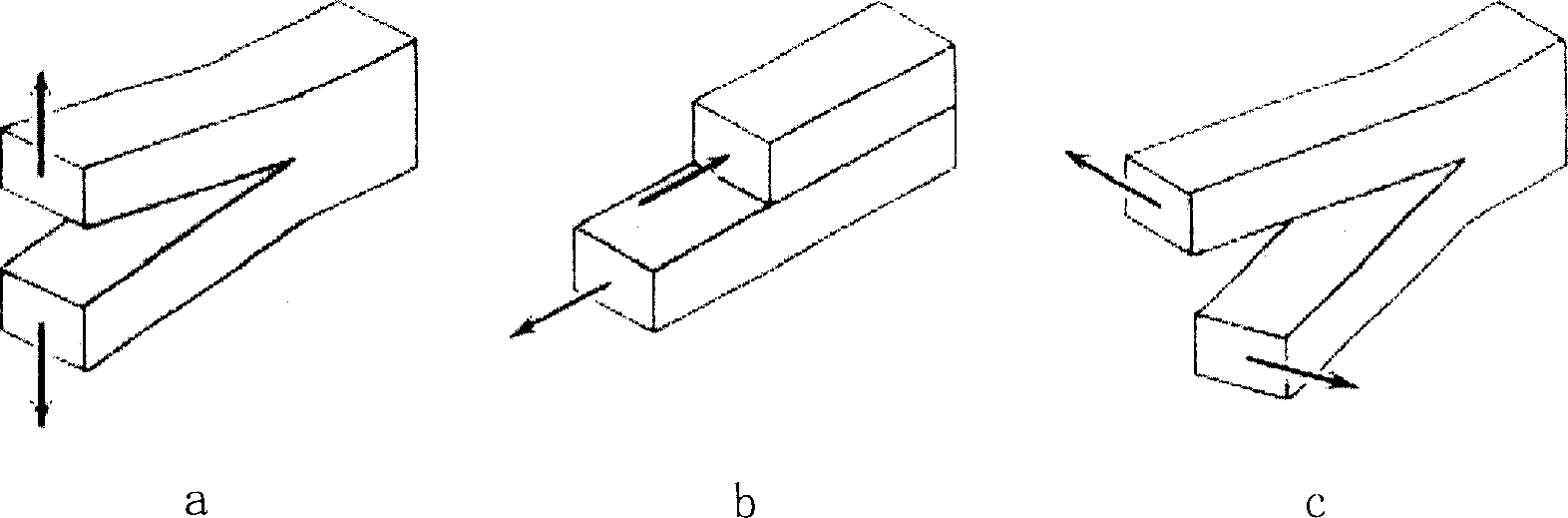

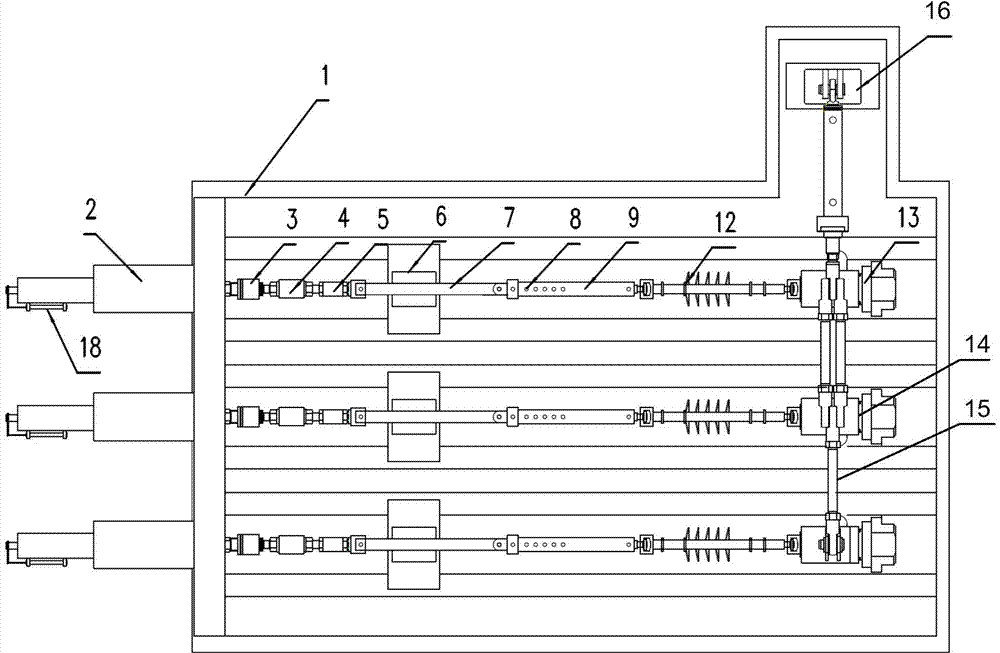

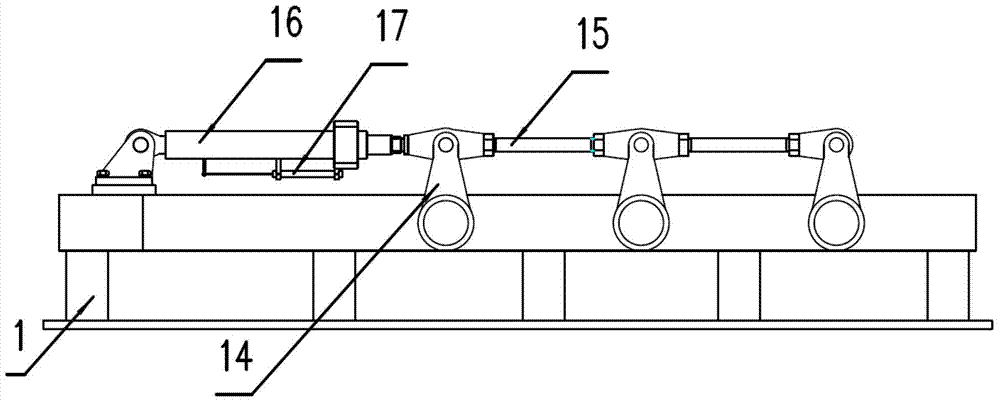

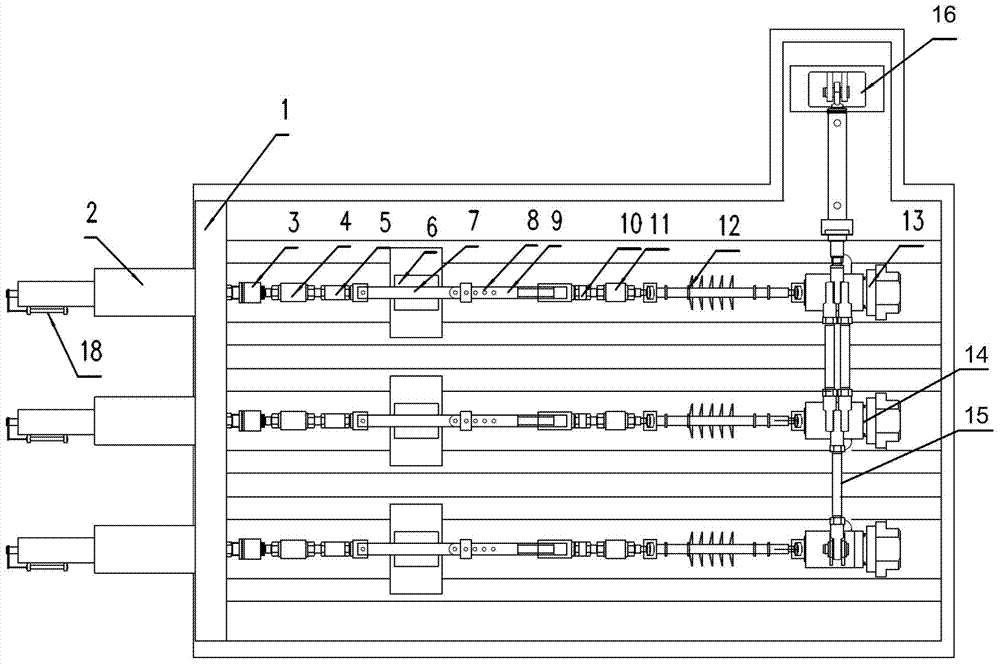

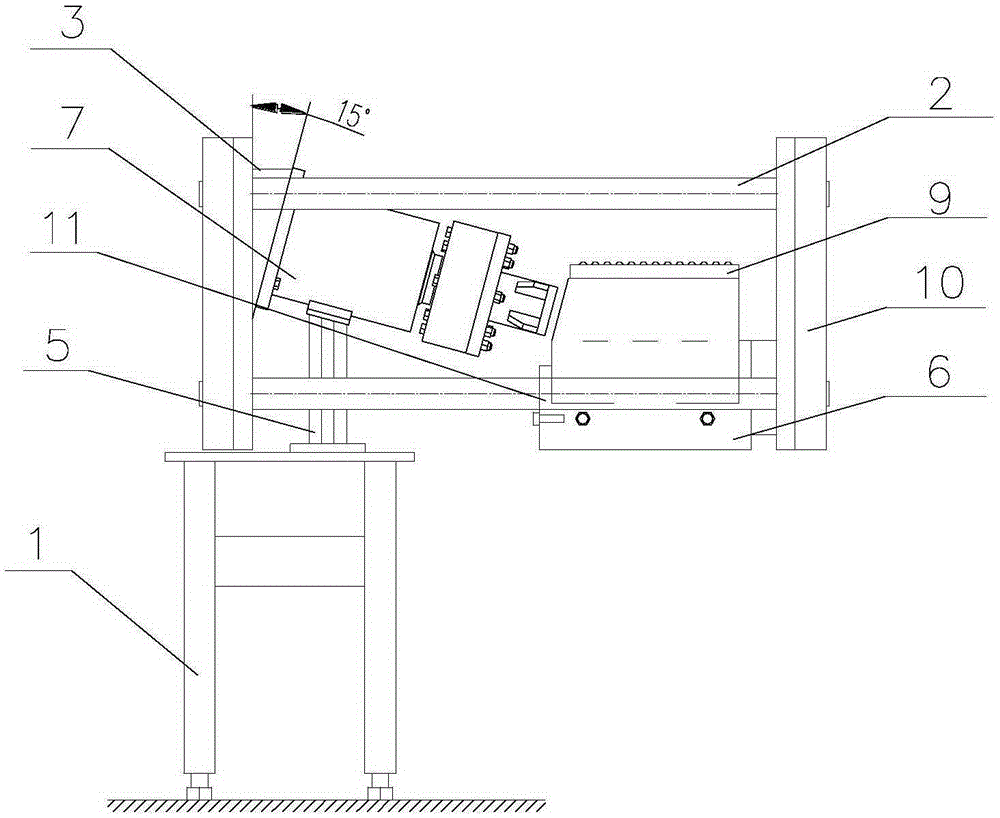

Tension-compression and torsion vibration fatigue test device

ActiveCN103616303AShorten test timeImprove test efficiencyMaterial strength using repeated/pulsating forcesTorsion fatigueTorsion test

The invention discloses a tension-compression and torsion vibration fatigue test device capable of simultaneously accomplishing tension-compression and torsion fatigue tests. The test device comprises a test device rack, a torsion test mechanism and a plurality of tension-compression test mechanisms. In each tension-compression test mechanism, a tension-compression actuating cylinder piston rod, a force sensor, a guide rod, an adjusting rod and a tested workpiece are sequentially connected end to end, wherein the adjusting rod is provided with a plurality of adjusting positions; according to the size of the tested workpiece, the guide rod is connected to the corresponding adjusting position of the adjusting rod; the guide rod does rectilinear movement under the limitation of a guide mechanism. In the torsion test mechanism, a rotating end of each bearing slewing mechanism is connected with the other end of the tested workpiece; oscillating rods of all the bearing slewing mechanisms are connected in series by a link mechanism, and the oscillating rod at one end is connected with the piston rod of a torsion actuating cylinder through a link mechanism. Tension-compression actuating cylinders, the bearing slewing mechanisms and the torsion actuating cylinder are all fixed on the test device rack.

Owner:北京乐冶液压气动设备技术有限公司 +1

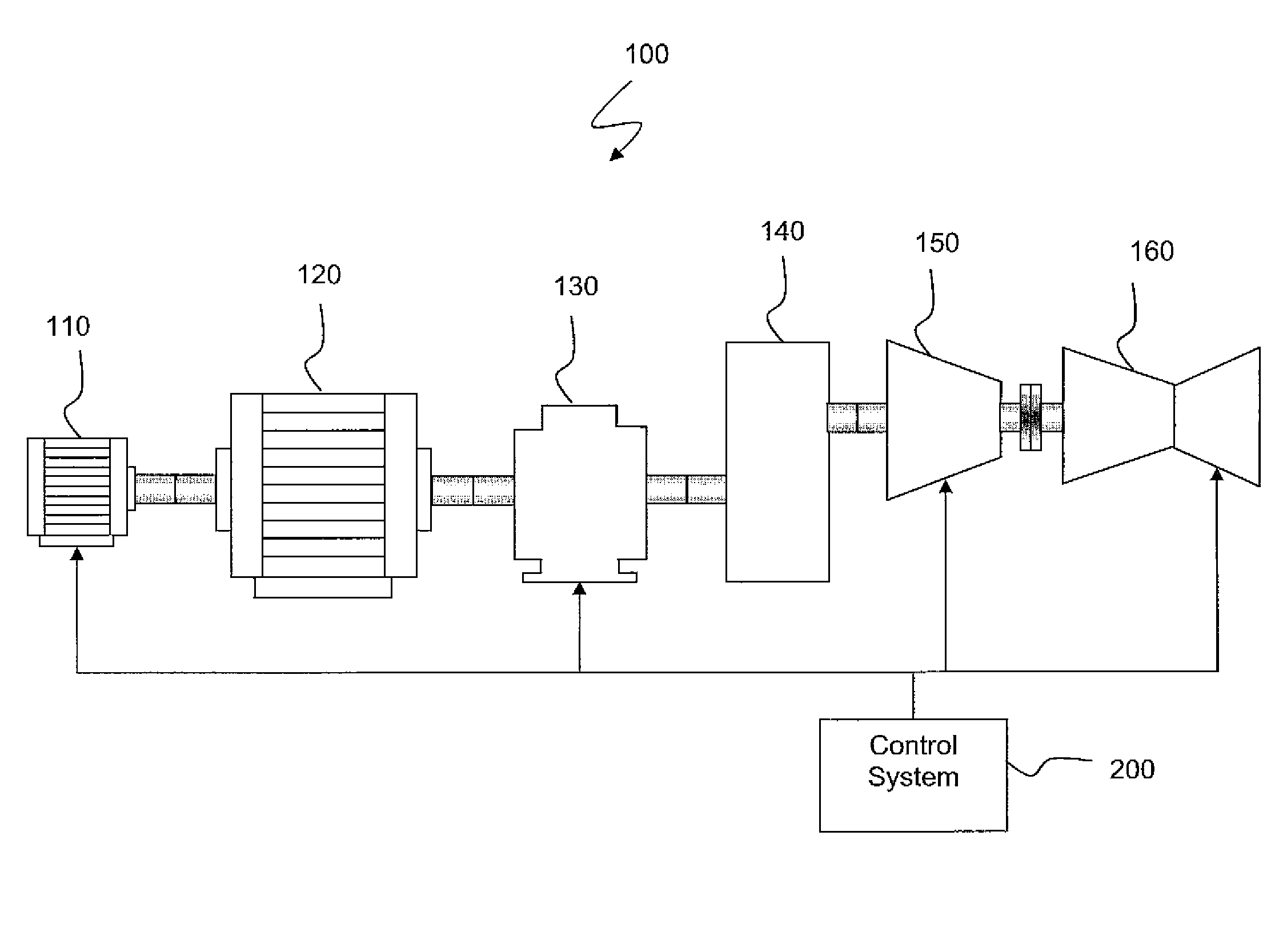

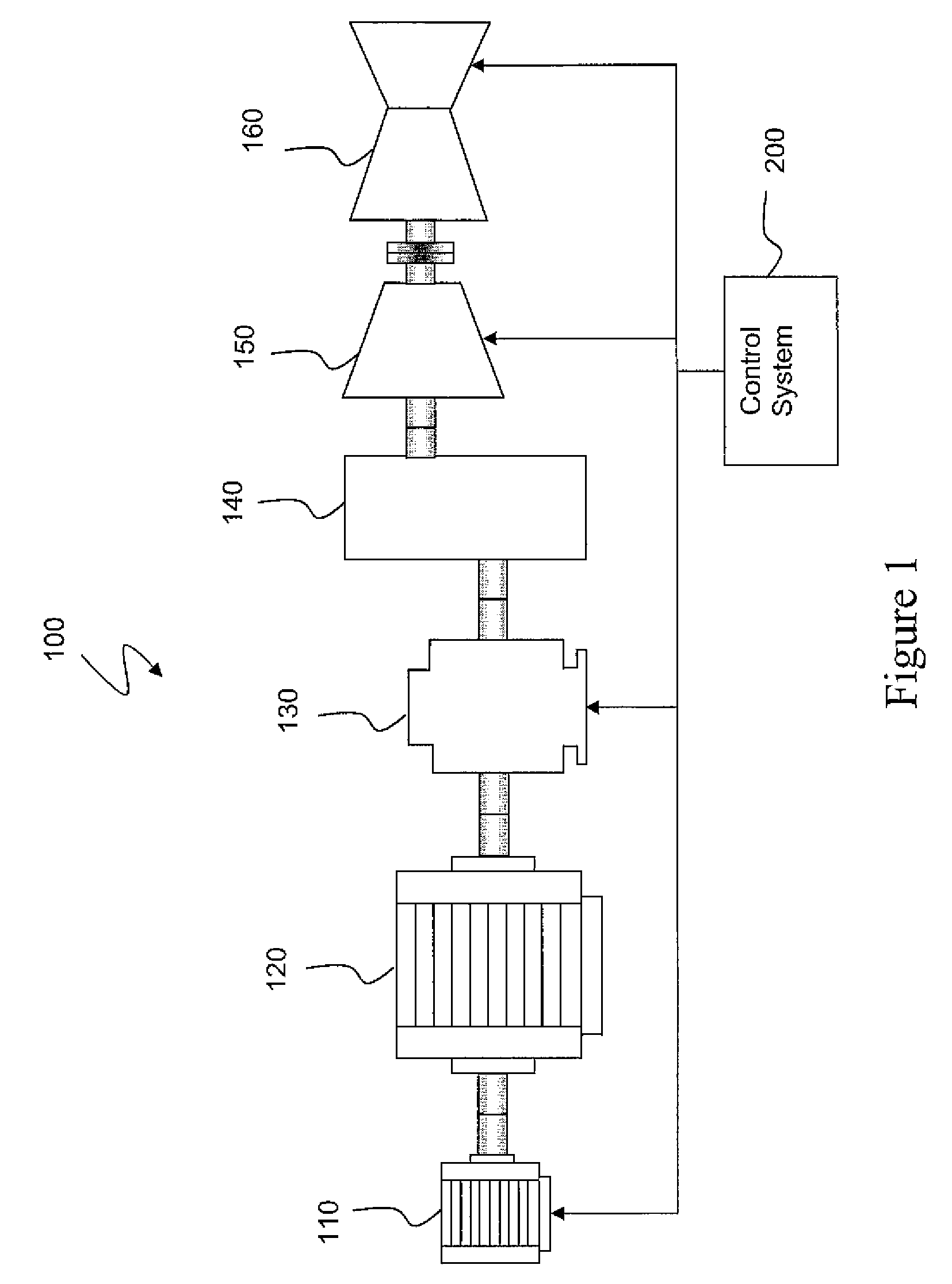

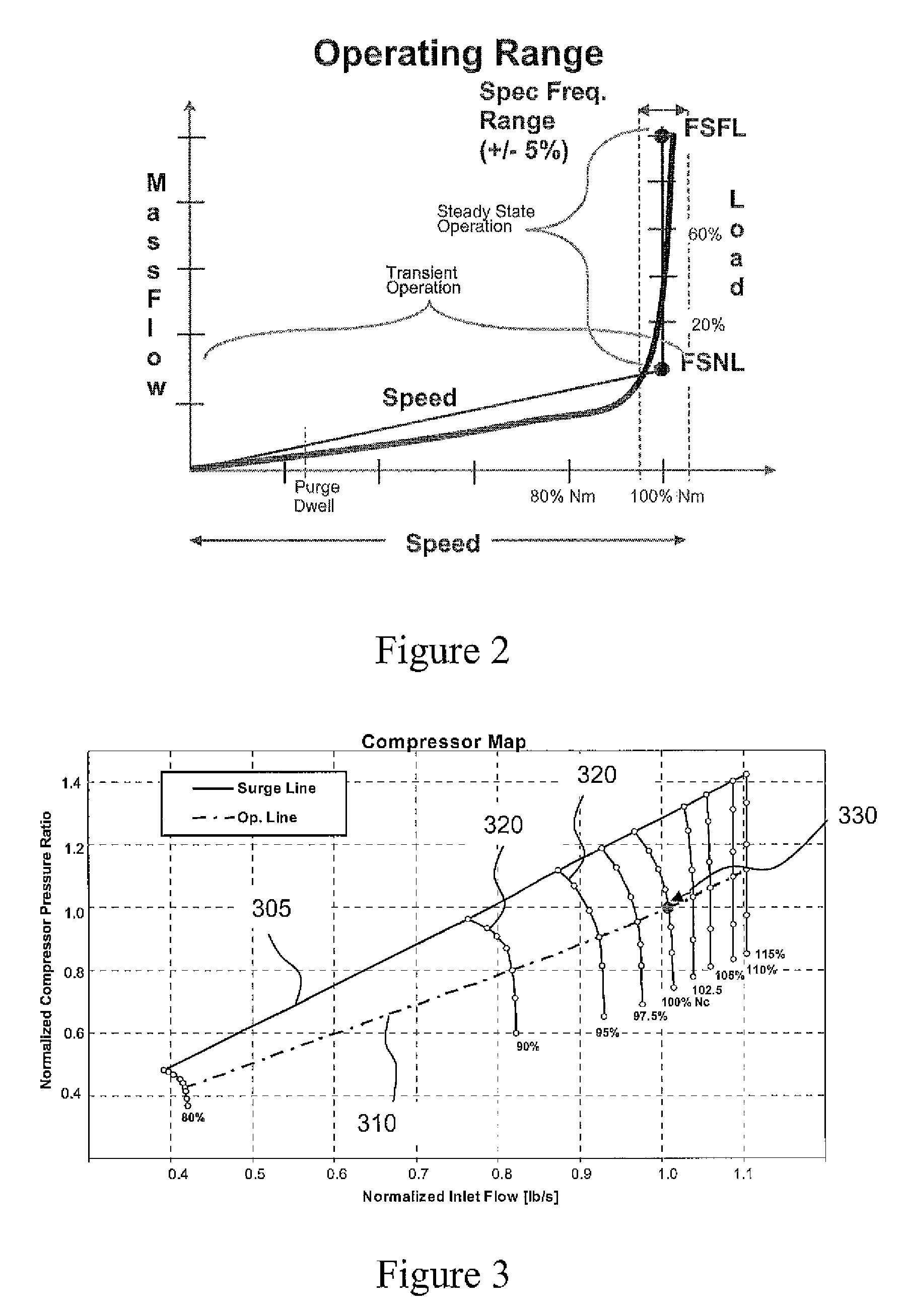

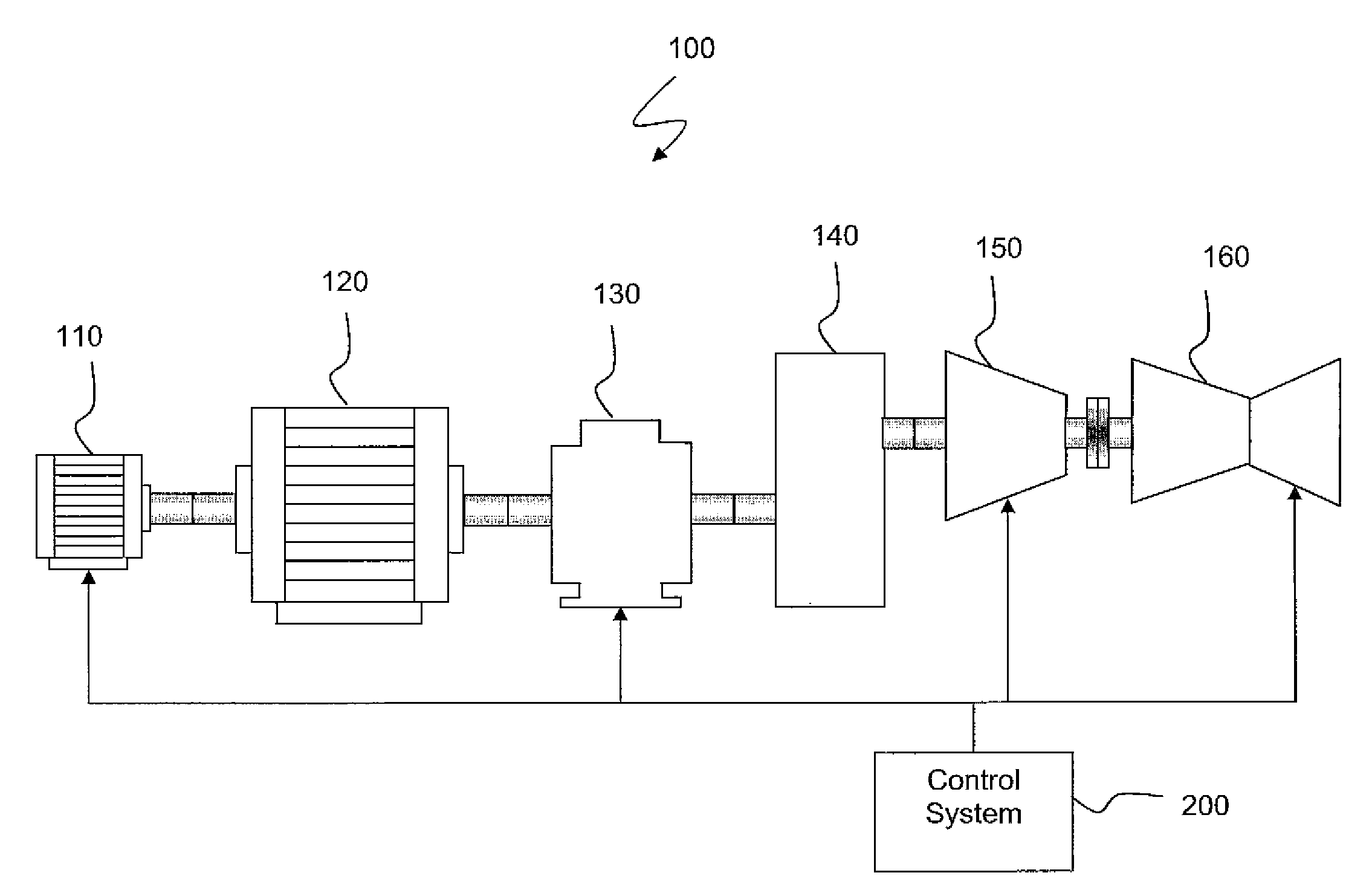

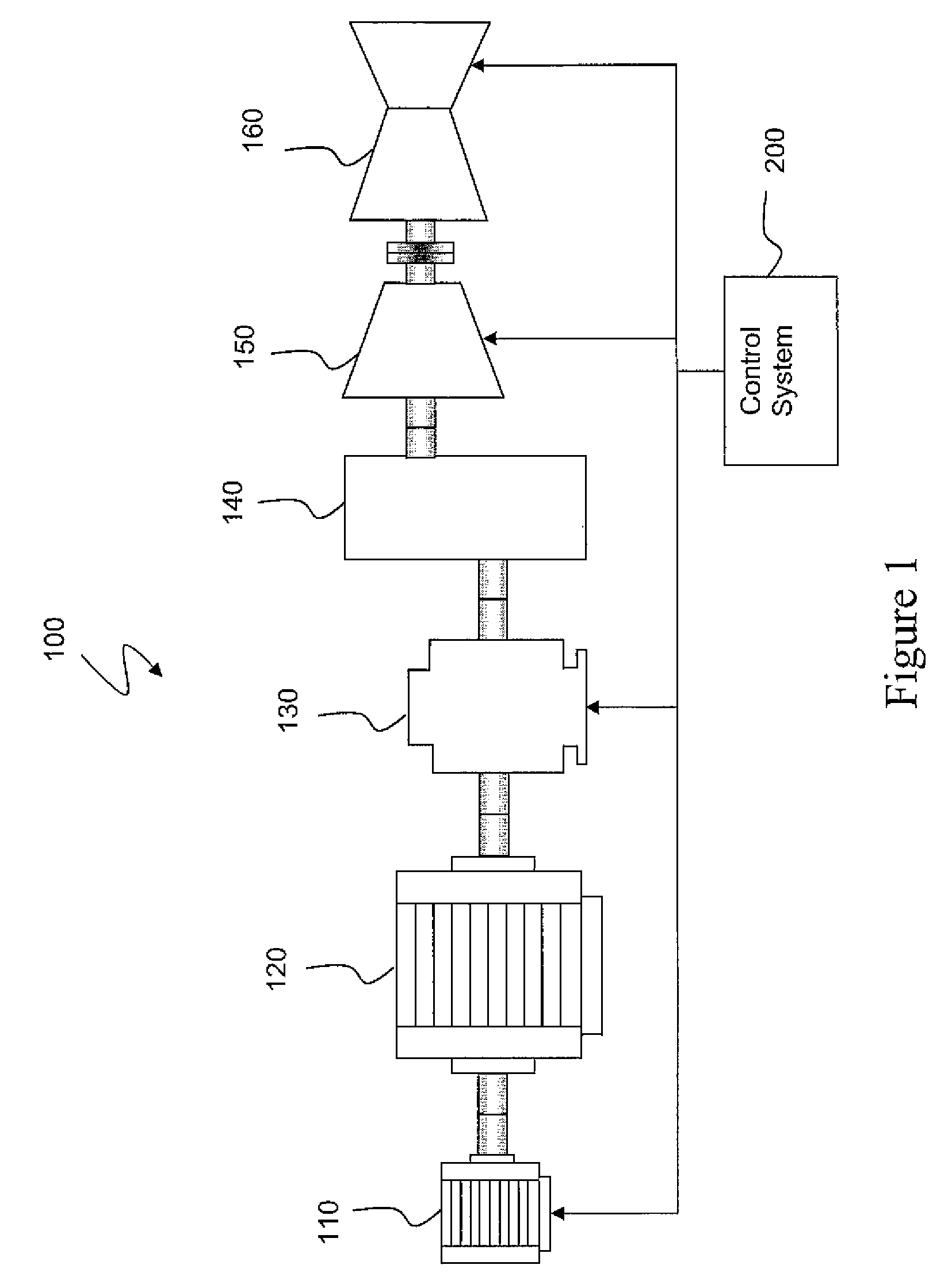

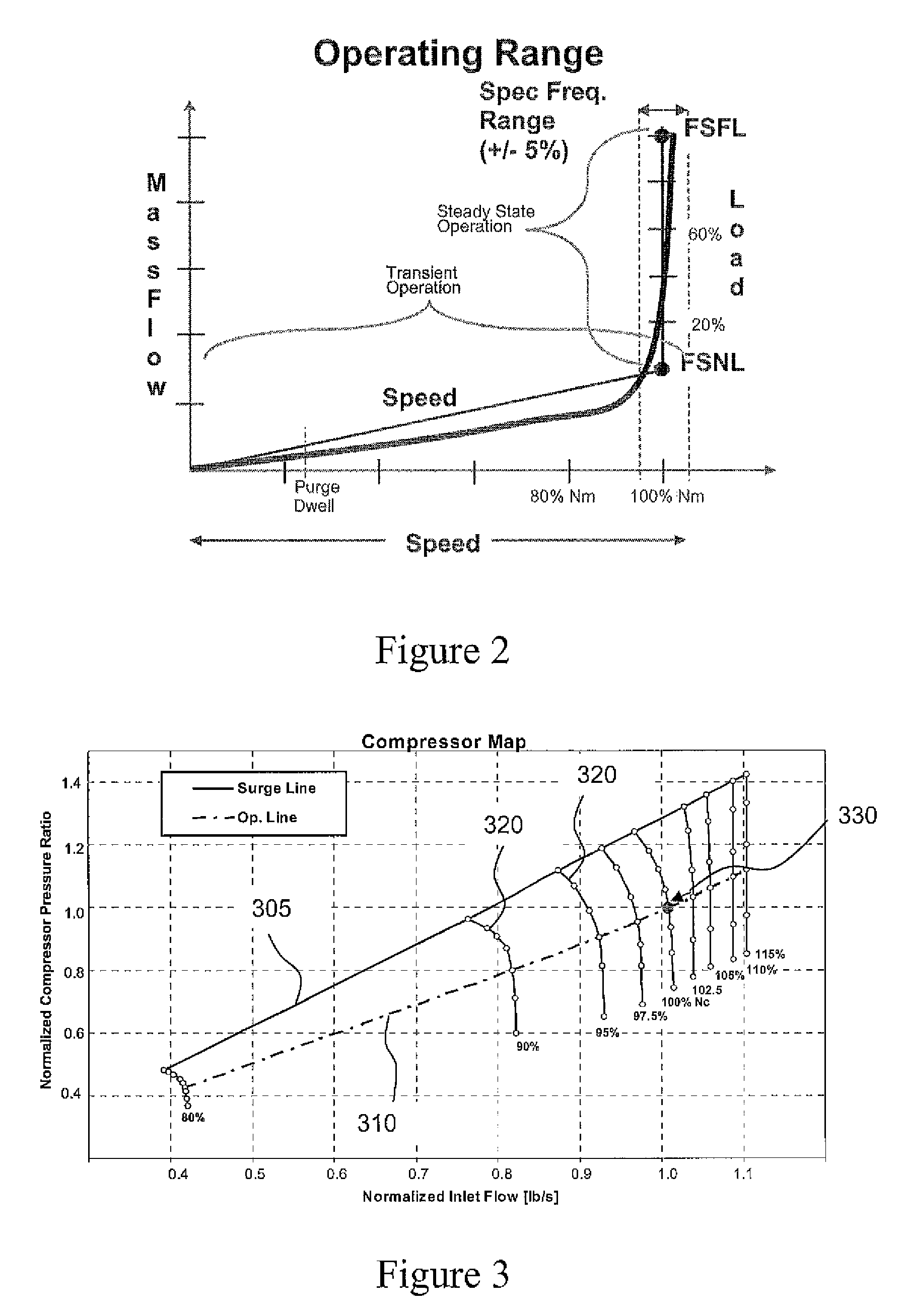

Mechanical drive train for testing full scale compressor rigs and gas turbines

A mechanical drive train for testing a full scale compressor rig is disclosed. The drive train can include an electric motor, a gear box, and a gas turbine. The compressor rig is coupled to the drive train between the gear box and gas turbine. The drive train can further include a torque converter for transferring torque from the electric motor to the compressor rig. The drive train is configured to test a full scale compressor rig over the entire speed and load operating range, allowing for full compressor mapping from choke to stall at full load, part load (power turn down) and partial speed conditions. The drive train can also be used to test a compressor rig or gas turbine over the full range of operability for the compressor rig or gas turbine without having to connect the gas turbine to the power grid at the power generation site.

Owner:GENERAL ELECTRIC CO

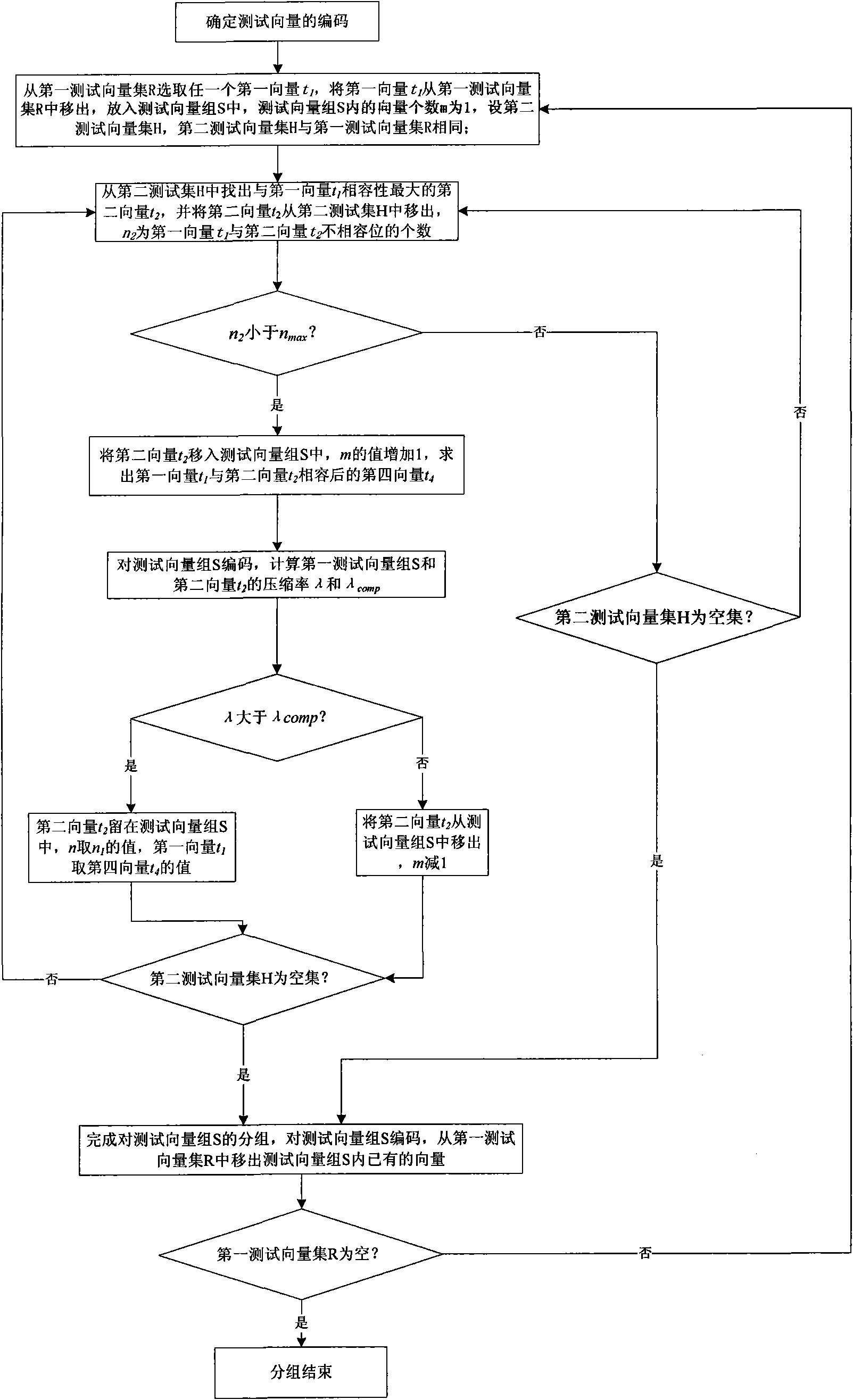

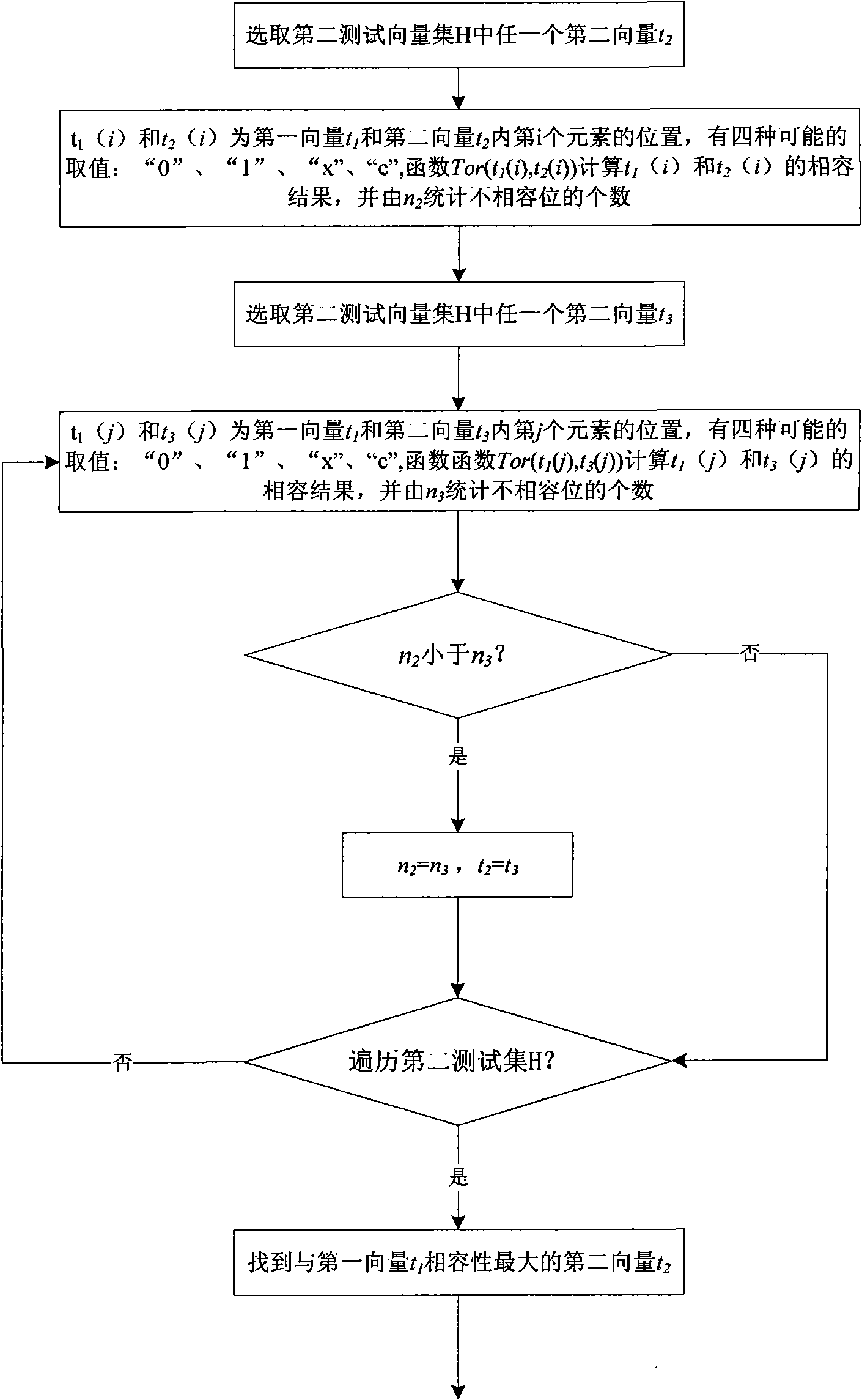

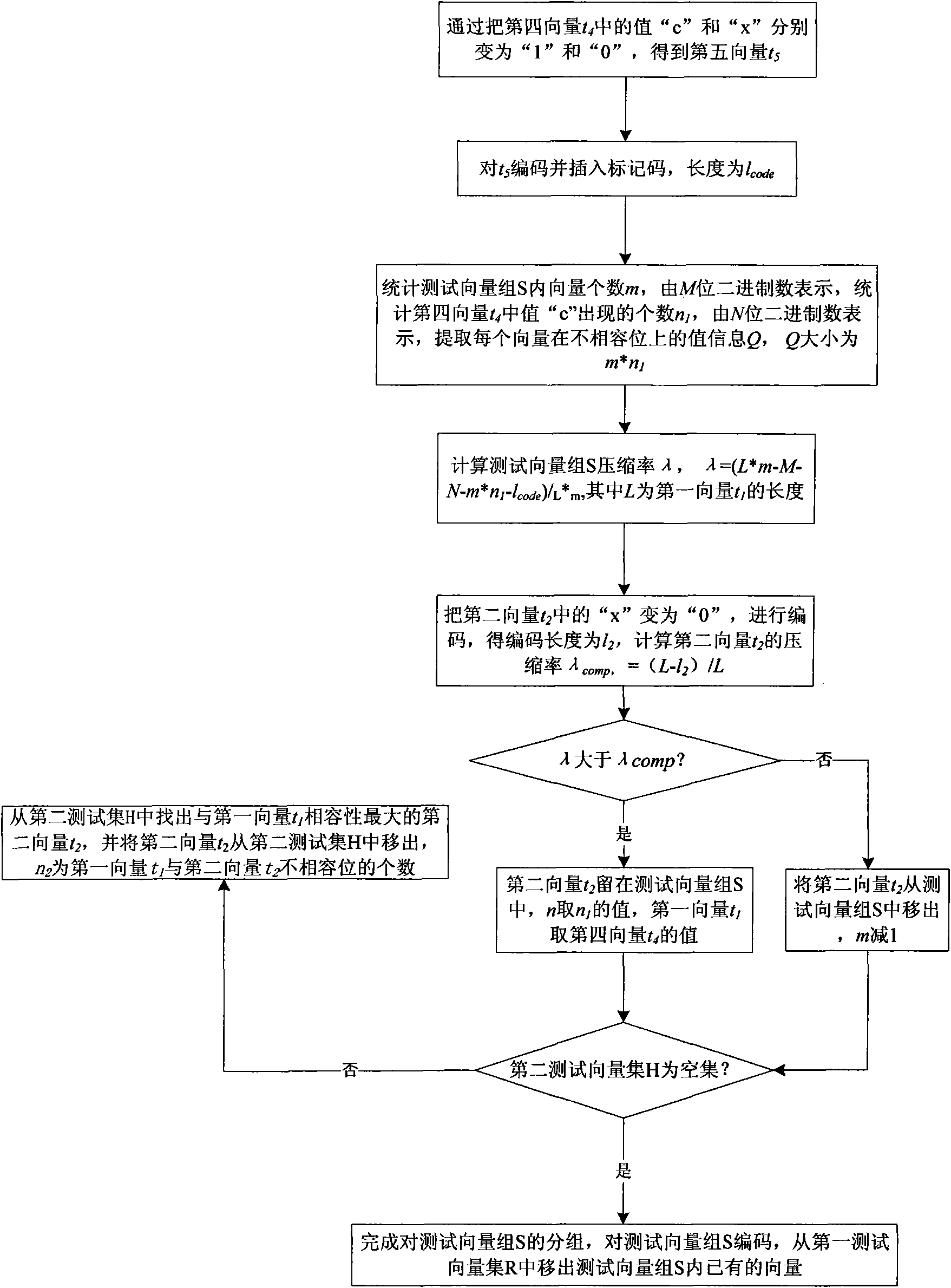

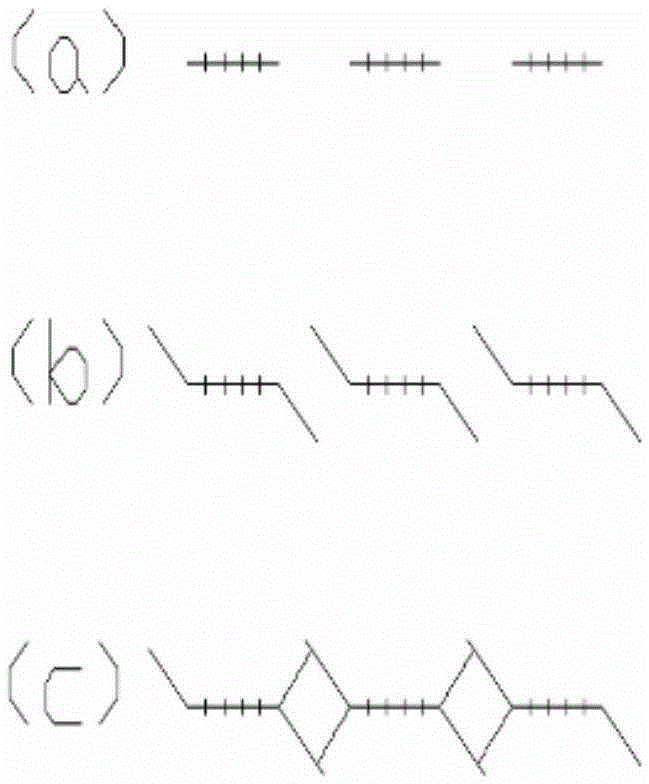

Test vector coding compression method based on test vector compatibility

The invention discloses a test vector coding compression method based on vector compatibility. The method comprises test vector compression and decompression after coding and the following steps: firstly, determining the code of a test vector, and taking vector t1 from a test vector set; completing test vector grouping and test vector group coding by combining with a vector most compatible with t1 and ensuring the increase of overall compression ratio; and during the decoding, shifting the code to a tested circuit for storage and repeating the decoding of the code till restoring the vector set before compression. The test vector coding compression method has the advantages that the method realizes grouping of the test vector set according to the relation of maximal compatibility and completes combined coding of vectors in a test vector group; the method marks an incompatible position by a mark code to substantially reduce bits required during marking by address information; moreover, both ends of the code are respectively inserted with group head information and a group division code; and during the decoding, the code of the test vector group is shifted to the tested circuit for storage so as to be reused, thereby greatly reducing the bandwidth of a testing machine and the tested circuit.

Owner:ZHEJIANG UNIV

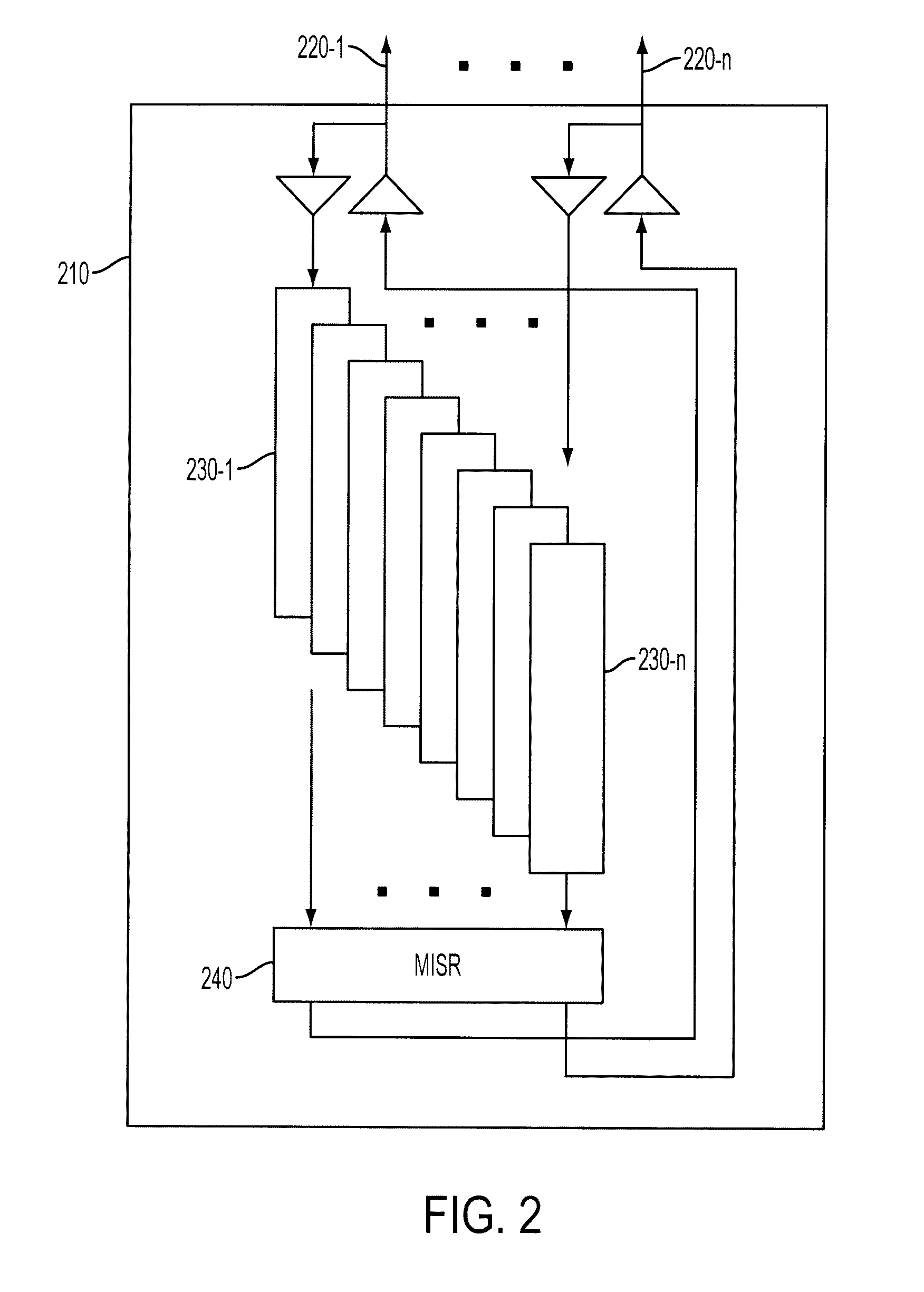

Distributed test compression for integrated circuits

ActiveUS7979764B2Easy diagnosisElectronic circuit testingError detection/correctionEngineeringDistributed testing

A method for testing integrated circuits is provided. The method provides for incorporating compression and decompression logic into each sub-component of an integrated circuit, developing test modes that target different sub-components of the integrated circuit, selecting one of the test modes, applying a test pattern to one or more sub-components of the integrated circuit targeted by the one test mode, comparing a response from application of the test pattern to a known good response, and diagnosing the response to determine which part of the one or more sub-components targeted by the one test mode failed when the response does not match the known good response.

Owner:CADENCE DESIGN SYST INC

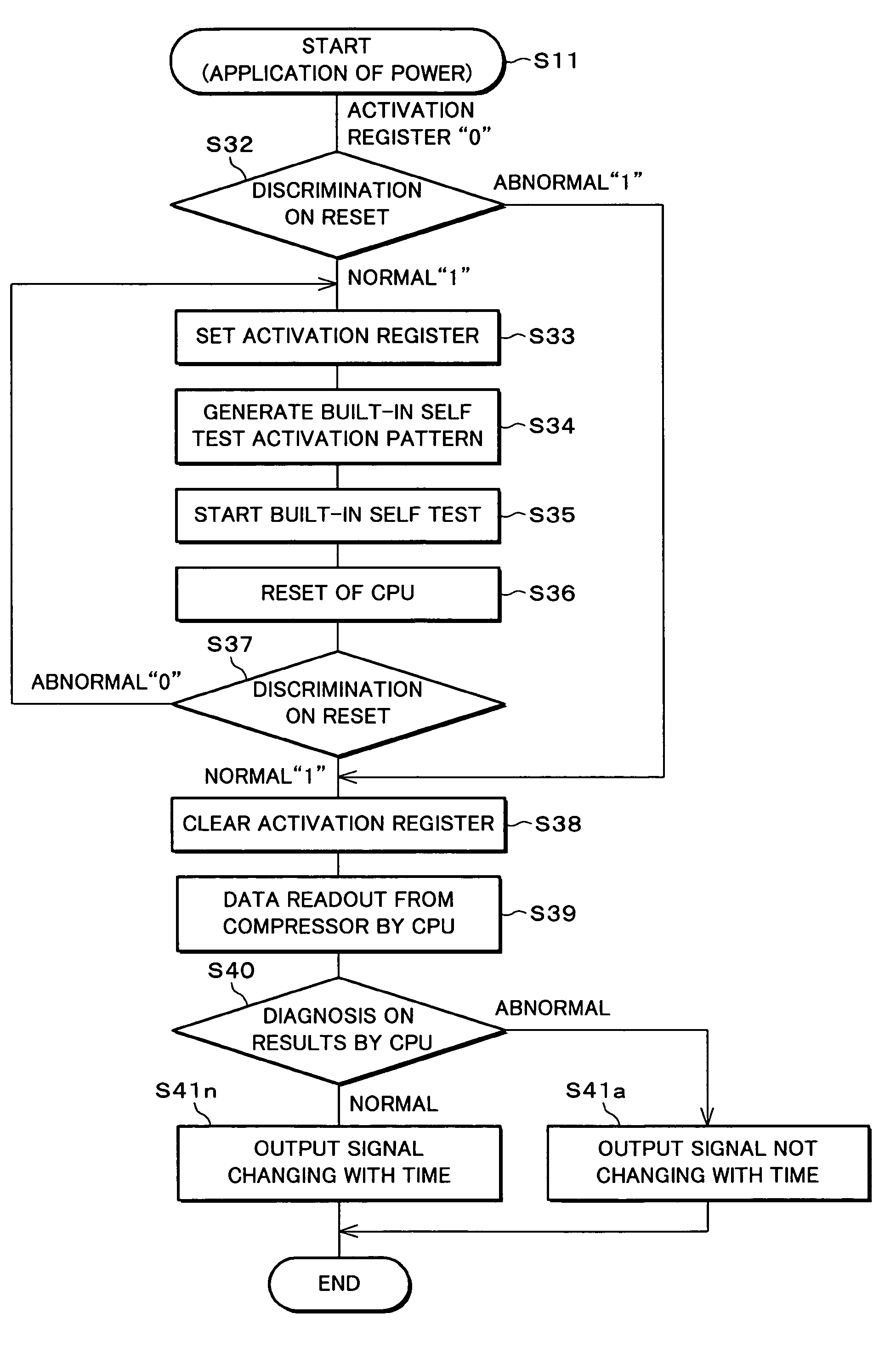

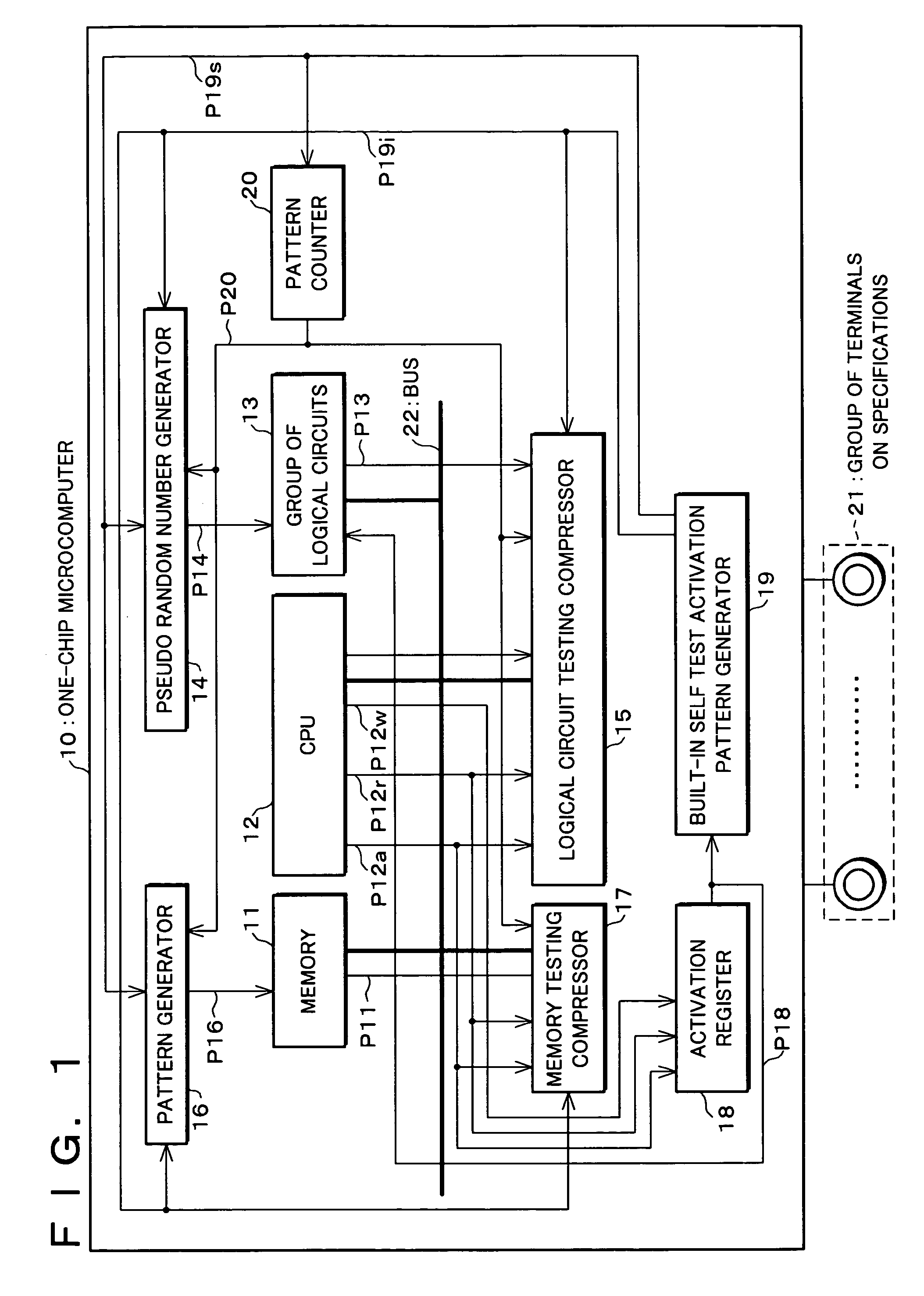

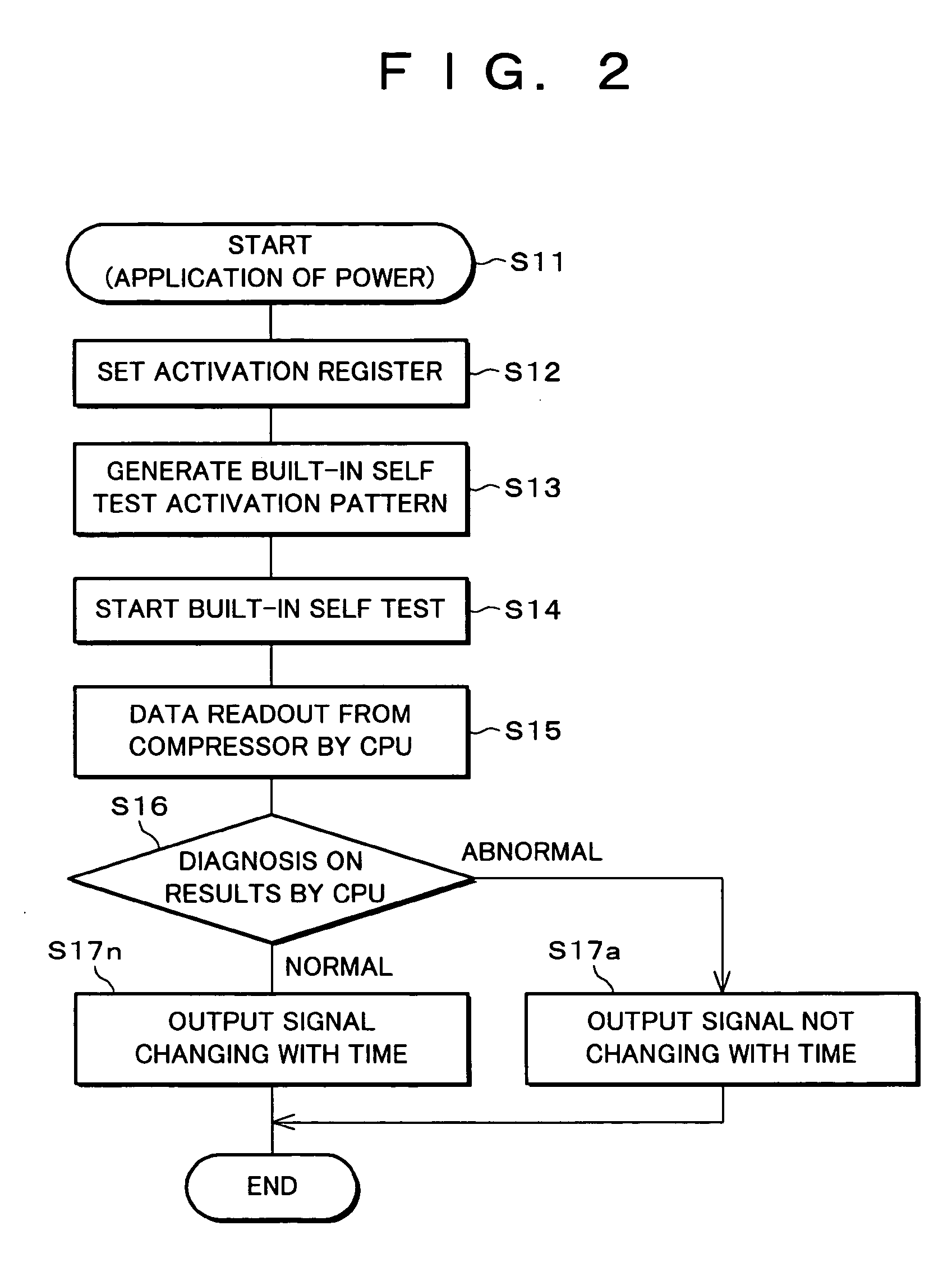

One-chip microcomputer and control method thereof as well as an IC card having such a one-chip microcomputer

InactiveUS6934884B1Increase the number ofDevelopment periodElectronic circuit testingFunctional testingMicrocontrollerBiological activation

In order to provide a built-in self testing function, a one-chip microcomputer is equipped with an activation register for activating the test operation and a built-in self test activation pattern generator for setting initial values at test control circuits (pseudo random number generator, logical circuit testing compressor, pattern generator, and memory testing compressor). In accordance with an instruction from the CPU, a built-in self test is activated so that the results of tests of the memory and the group of logical circuits are read from the memory testing compressor and the logical circuit testing compressor, and respectively compared with expected values preliminarily stored in the memory in the one-chip microcomputer; thus, the results are diagnosed. Thus, it is possible to carry out a built-in self test without using a plurality of exclusively-used test terminals.

Owner:SHARP KK +1

Mechanical drive train for testing full scale compressor rigs and gas turbines

A mechanical drive train for testing a full scale compressor rig is disclosed. The drive train can include an electric motor, a gear box, and a gas turbine. The compressor rig is coupled to the drive train between the gear box and gas turbine. The drive train can further include a torque converter for transferring torque from the electric motor to the compressor rig. The drive train is configured to test a full scale compressor rig over the entire speed and load operating range, allowing for full compressor mapping from choke to stall at full load, part load (power turn down) and partial speed conditions. The drive train can also be used to test a compressor rig or gas turbine over the full range of operability for the compressor rig or gas turbine without having to connect the gas turbine to the power grid at the power generation site.

Owner:GENERAL ELECTRIC CO

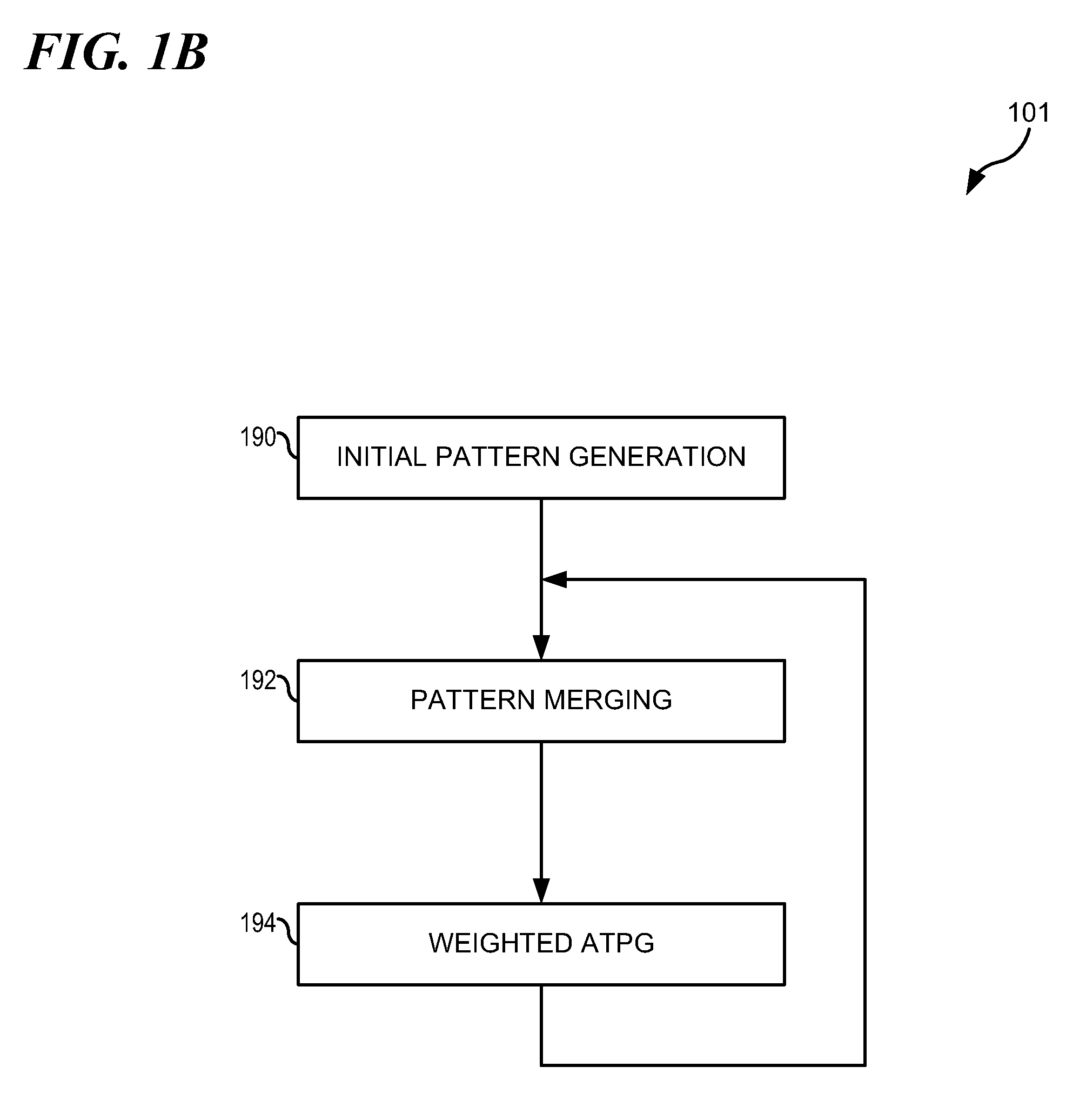

Test pattern compression

InactiveUS20100179784A1Easy to understandImprove fault coverageAmplifier modifications to reduce noise influenceResistance/reactance/impedenceFault coverageComputer science

Owner:IBM CORP

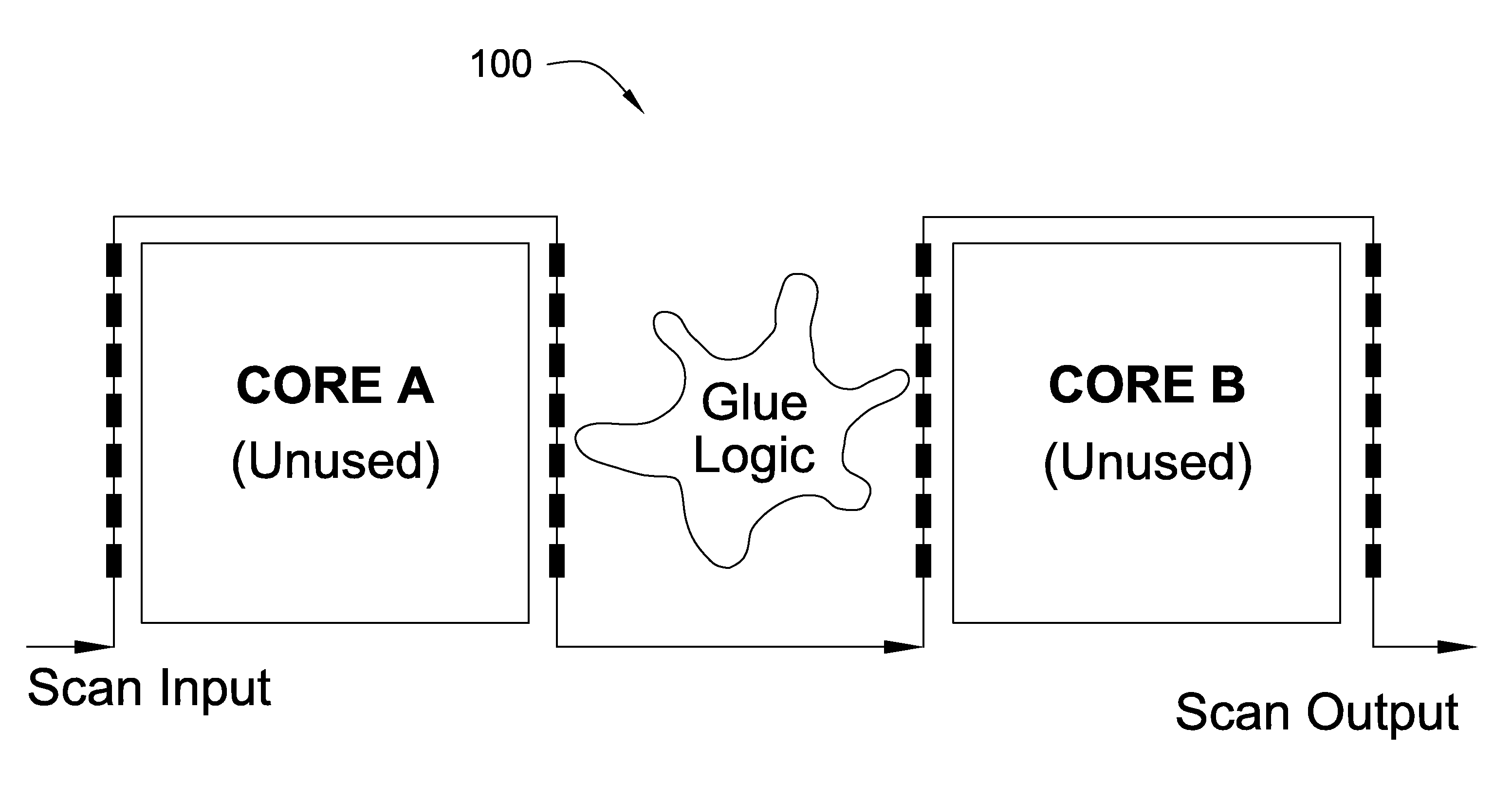

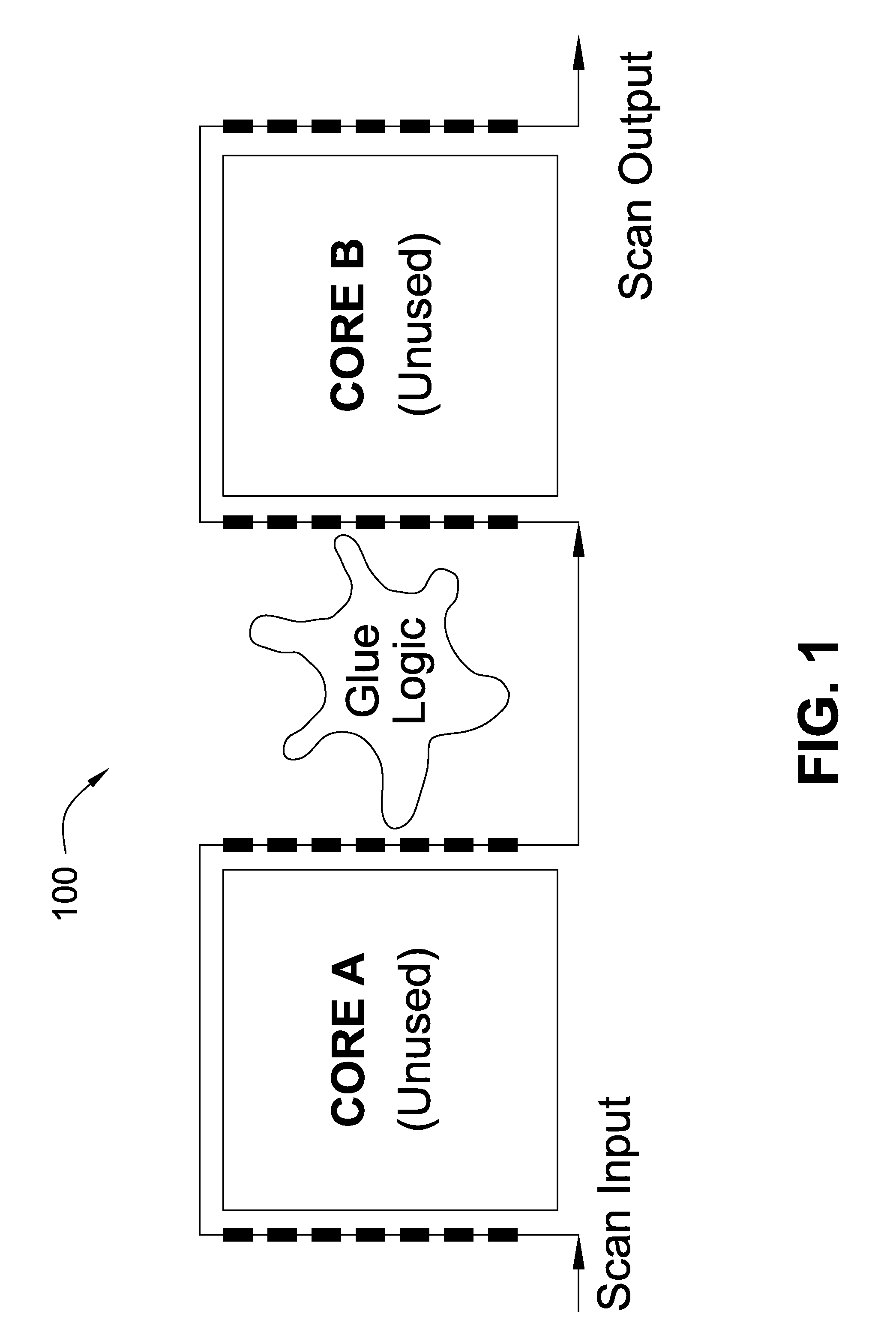

DFT TECHNIQUES TO REDUCE TEST TIME AND POWER FOR SoCs

A technique for reducing the overhead of daisy chain test mode in divide-and-conquer testing using intermediate test modes that do not span all cores or all flip-flops in the core. The partial residual test mode spans across a subset of the cores and allows to bound the number of cores that a full residual test mode may span across. The interaction of the cores among one another at the top-level is analyzed and the minimum number of flip-flops in a core that must participate in a intermediate test mode is selected. Algorithms are devised to analyze the interactions among the cores and build data structures which are used for identifying intermediate test modes. Using a reconfigurable scan segment architecture, intermediate test modes are implemented that are designed to work with all known test compression solutions. Since the length of the longest scan chain in an intermediate residual test mode is much smaller than the length of the longest scan chain in the full residual test mode, there is a substantial improvement in test application time as well as test peak power.

Owner:TEXAS INSTR INC

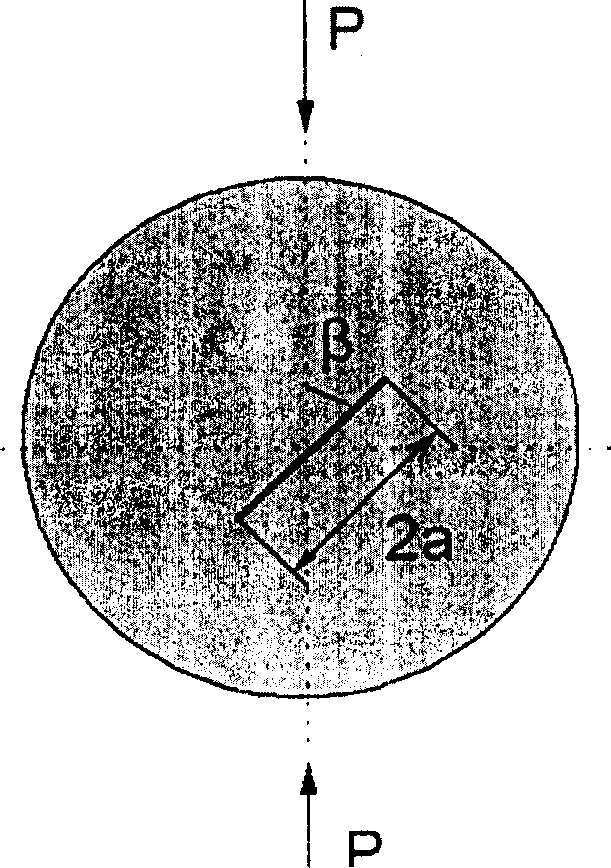

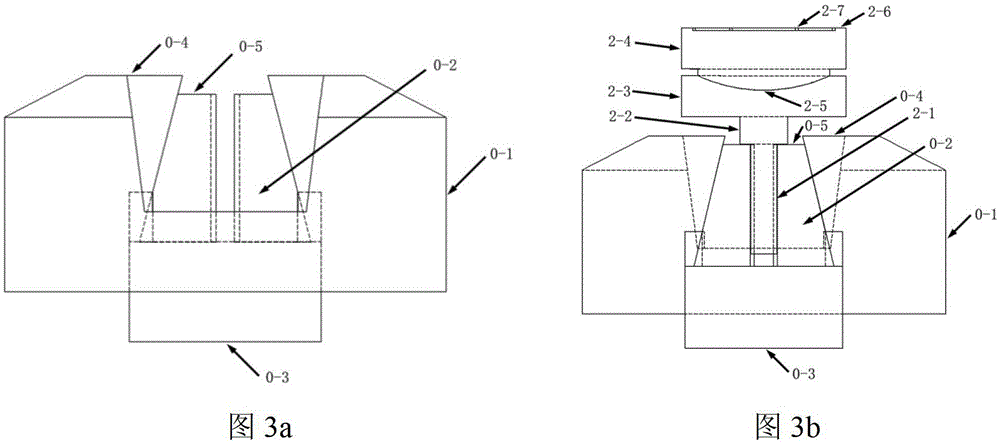

Testing method for testing compression-shear performance of jointed rock

InactiveCN105319130AEven by forceAccuracy is easy to guaranteeMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesNormal loadEngineering

The invention discloses a testing method for testing the compression-shear performance of jointed rock. The method includes the following steps of preparing a tested test piece with a slope, putting the tested test piece on a test piece fixing base, exerting normal loads on the tested test piece, exerting inclined loads perpendicular to the slope on the tested test piece after the normal stress reaches a preset value, gradually increasing the inclined loads, reducing the load value of the normal loads, keeping the normal stress in the loading process unchanged, making the shear force increased continuously till the tested test piece is broken, and making the inclined loads and the normal loads intersect in the preset shear face of the tested test piece so that bending moment can be prevented from being generated in the loading process. The whole method is easy and convenient to implement; compared with the prior art, the method has the advantages that the bending moment can be prevented in the loading process, test errors are reduced, the accuracy of test results can be easily ensured, and the method is suitable for various civil engineering construction occasions and has the outstanding substantive advantages and remarkable progresses of being simple in structure, easy to manufacture, convenient to operate and the like.

Owner:SHANDONG UNIV +3

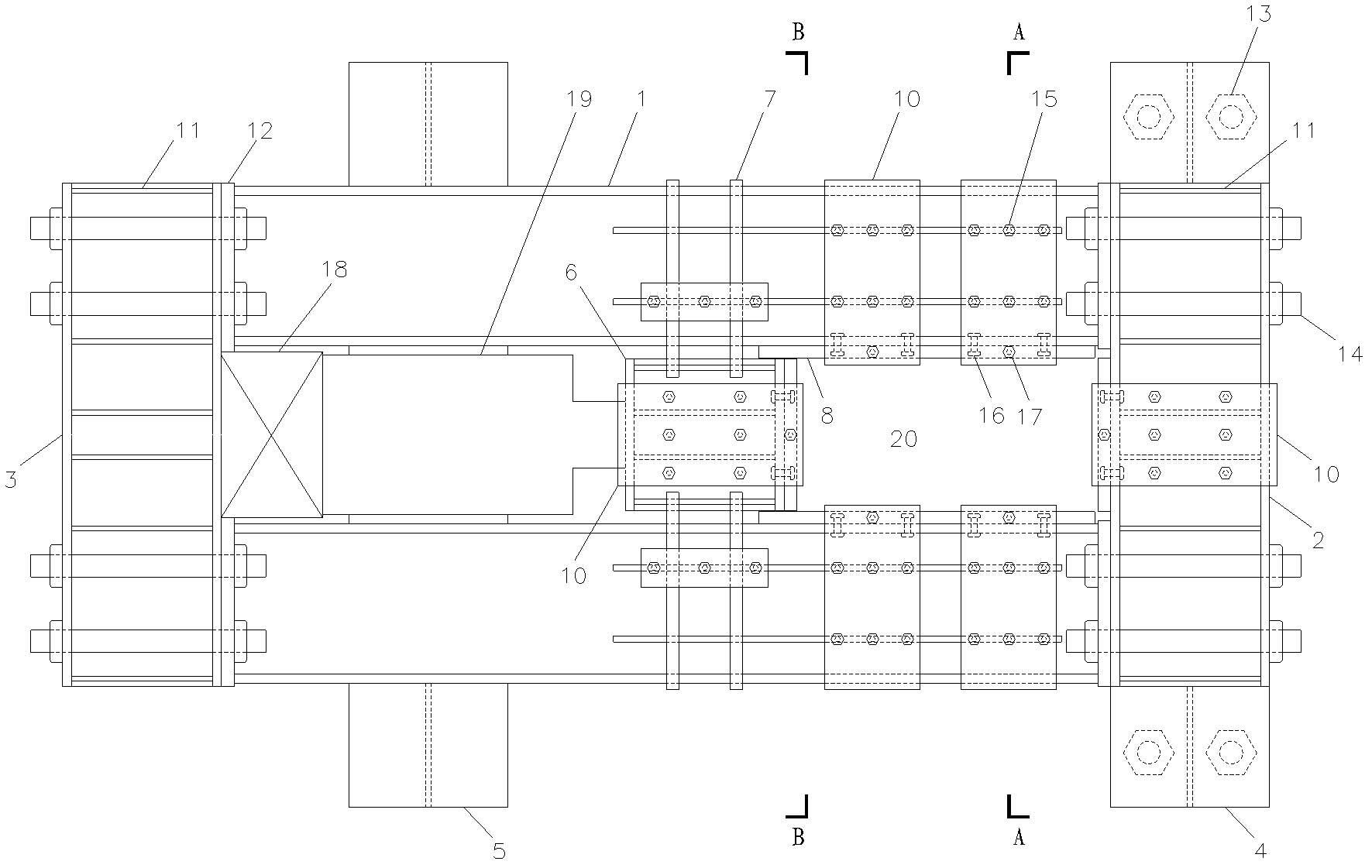

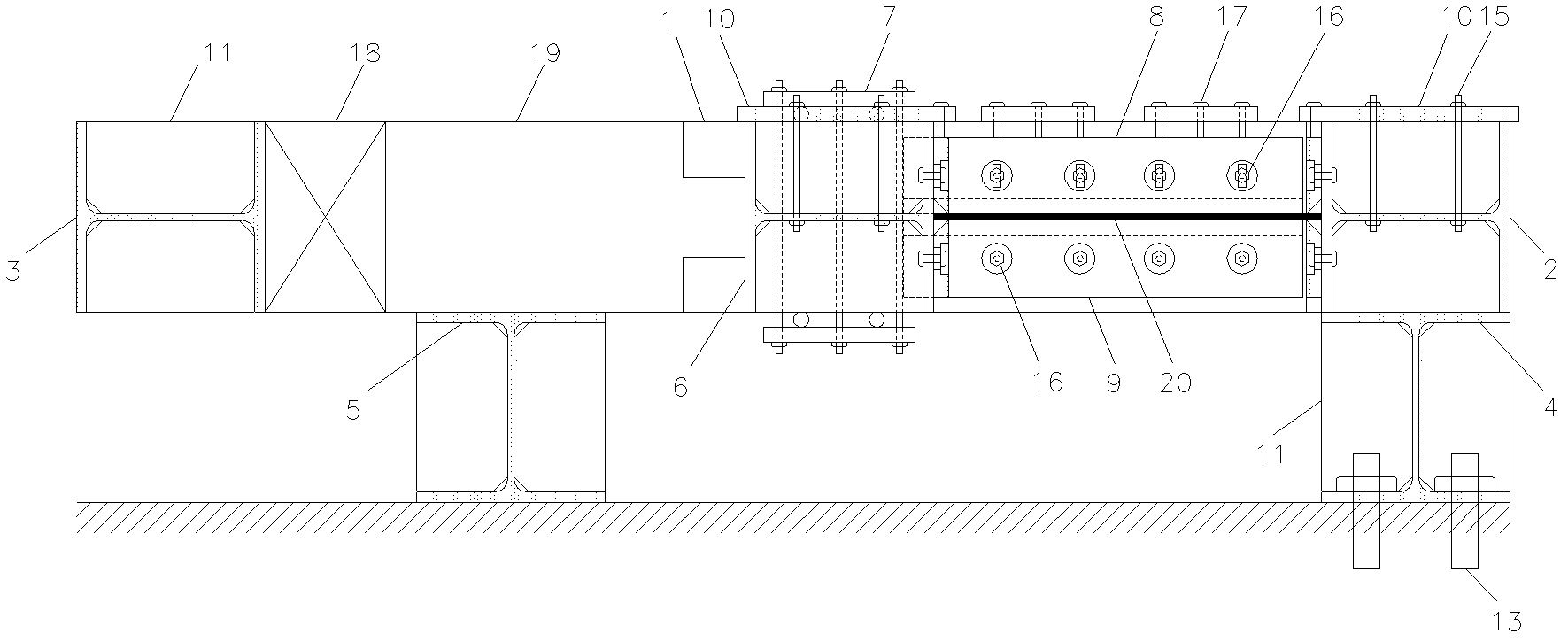

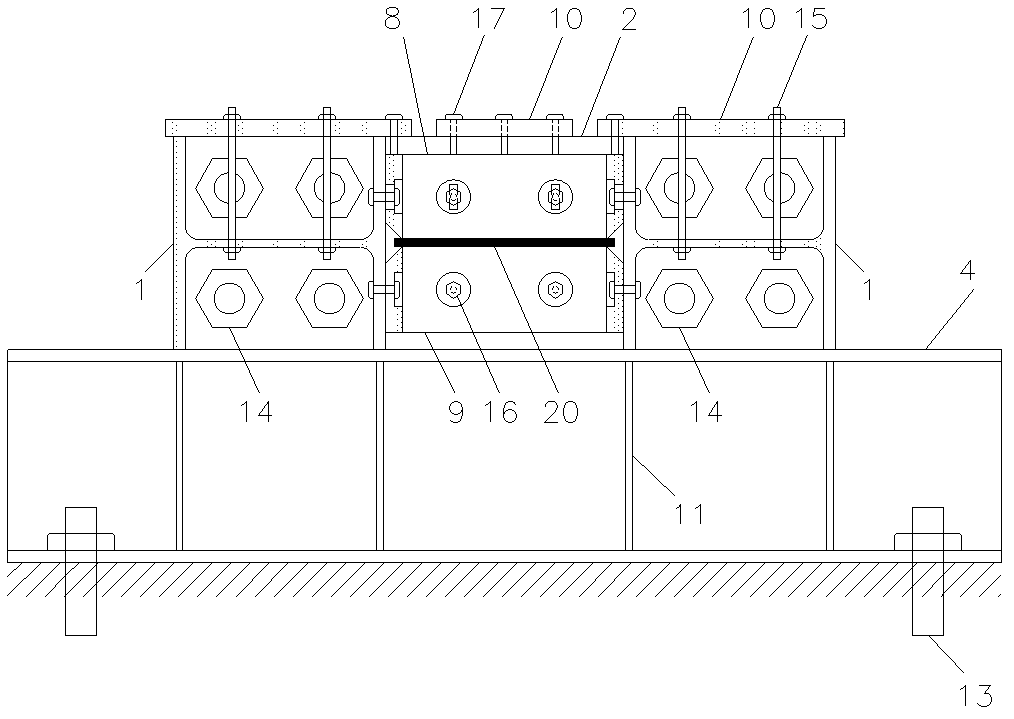

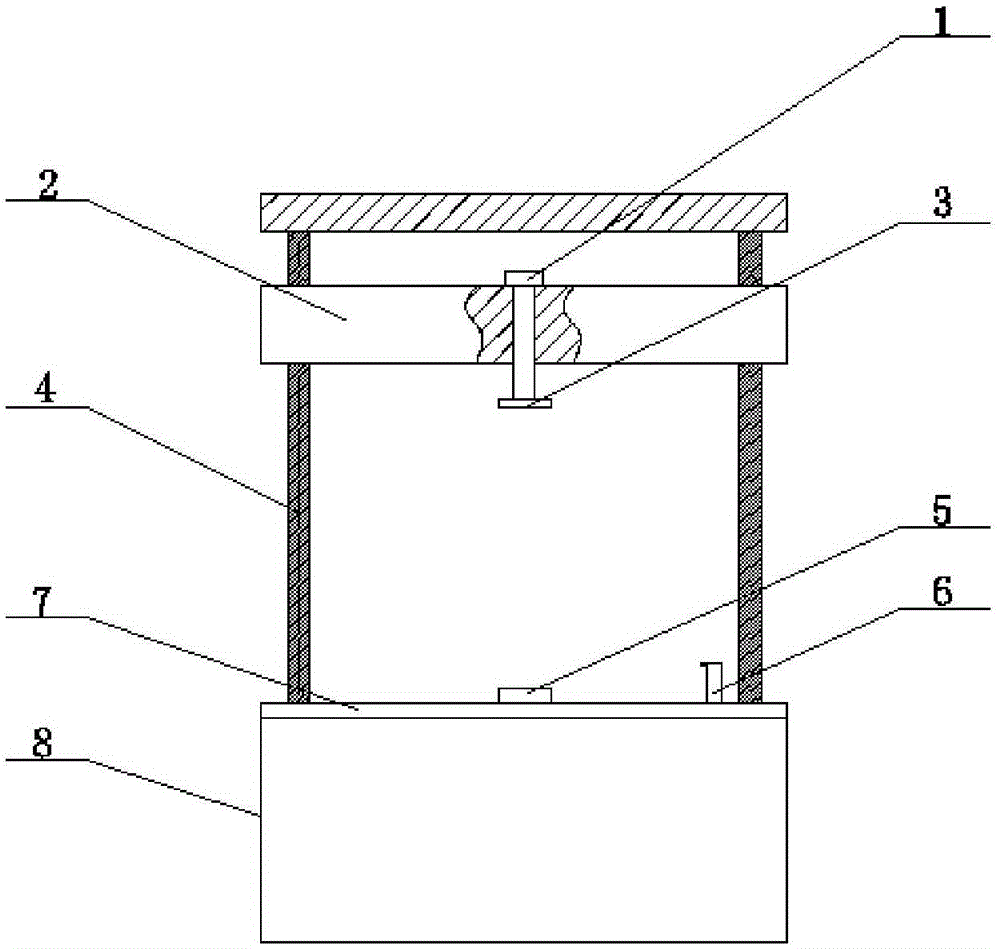

Device for testing compression in rectangular steel plate surface

InactiveCN102539243AMeet the requirements of scientific experimentsRealize the loadMaterial strength using tensile/compressive forcesSheet steelRigid block

The invention discloses a device for testing compression in a rectangular steel plate surface, belonging to the field of civil engineering professional testing devices. The device is formed by connecting a square main frame with H-shaped steel through a bolt, and can be used for self-balance in a test load. In the device, a load guide rigid block is arranged between a hydraulic jack and a steel plate loading edge, so that uniform compression loading is realized, and off-plate simple support constraint conditions are provided for four sides of a test steel plate through a wedge-shaped support plate. In the entire testing device, the size of a component can be adjusted flexibly according to the size of a test piece, so that the loading requirements of steel plates of different sizes are met. Due to the adoption of the device, uniform compression testing in the rectangular steel plate surface is more convenient, and the batch testing requirements of test pieces are met simultaneously; and the device can be applied to civil engineering teaching and scientific research testing.

Owner:SHANGHAI JIAO TONG UNIV

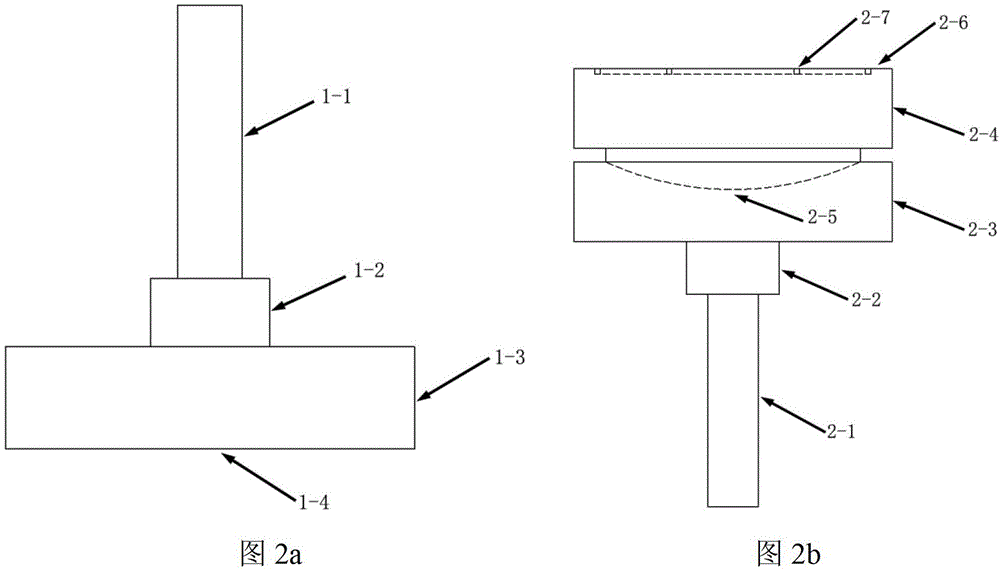

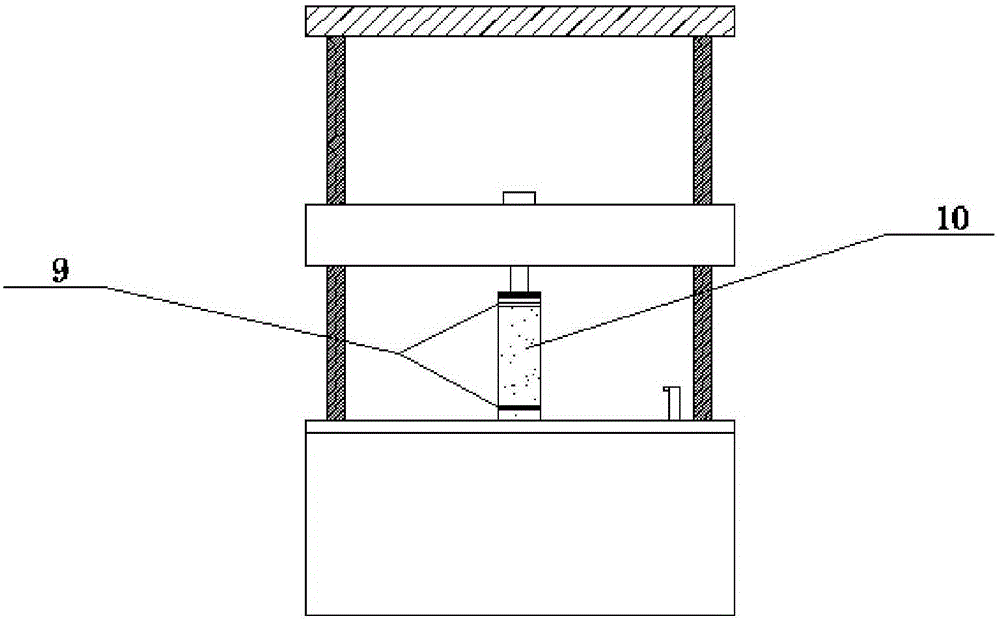

Compression-resisting clamping tool for testing compression resistance of non-metallic materials

InactiveCN102914468AHigh pressure bearing surface hardnessPrecise positioningStrength propertiesLower limitMetallic materials

The invention discloses a compression-resisting clamping tool for testing the compression resistance of non-metallic materials, belonging to the technical field of material performance testing. The compression-resisting clamping tool comprises an upper part and a lower part; the upper part has the structure that: an upper held rod is arranged on the upper part of an upper limiting block and fixedly connected with the upper limiting block, and the upper limiting block is fixedly connected with an upper compression-bearing part, wherein the diameter of the upper limiting block is larger than that of the upper held rod; the lower part has the structure that: a lower held part is arranged on the lower part of a lower limiting block and fixedly connected with the lower limiting block, wherein the diameter of the lower limiting block is larger than that of the lower held rod; the lower limiting block is fixedly connected with a first lower compression-bearing plate; the first lower compression-bearing plate is connected with a second lower compression-bearing plate in a ball-joint way; and a lower compression-bearing surface is one of the surfaces of the second lower compression-bearing plate and provided with scales for positioning the sample. The compression-resisting clamping tool disclosed by the invention has high testing precision, the compression-bearing surfaces have high hardness, the sample can be placed and positioned accurately, and the compression process and testing of the non-metallic materials with large cross sections can be realized.

Owner:TSINGHUA UNIV

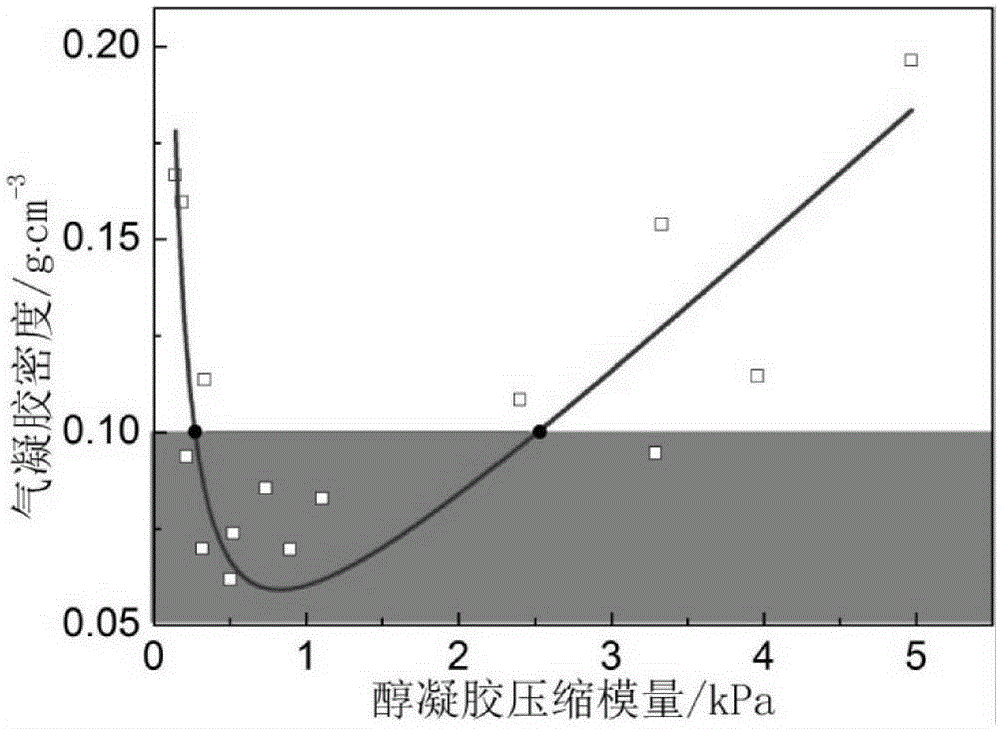

Ambient preparation and control method of low-density SiO2 aerogel

InactiveCN105174274ASolve the problem of many parameters affecting the preparation processSolve the difficulty of controlSilicaAmbient pressureSolvent

The invention provides an ambient preparation and control method of low-density SiO2 aerogel. The method comprises the following steps of mixing silica sol prepared through acid catalysis and alkaline catalysis methods to prepare the SiO2 aerogel; aging the prepared SiO2 aerogel, testing compression modulus of the aged SiO2 aerogel, and stopping aging when the compression modulus of the aerogel achieves 0.25 to 2.5kPa; then carrying out one-step method surface modification and solvent replacement on the aged SiO2 aerogel to obtain modified SiO2 aerogel; using normal hexane to clean the modified SiO2 aerogel for many times, and ambient pressure drying at the temperature of 60 to 90 DEG C to respectively prepare the low-density SiO2 aerogel. The compression strength monitoring method is simple, so that the low-density SiO2 aerogel preparation process control is more feasible. The adopted ambient preparation method is low in cost and simple in process, and can be used for mass production.

Owner:GUANGZHOU UNIVERSITY

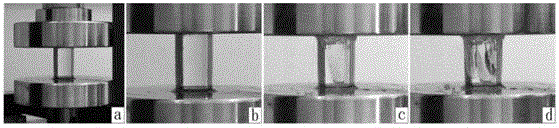

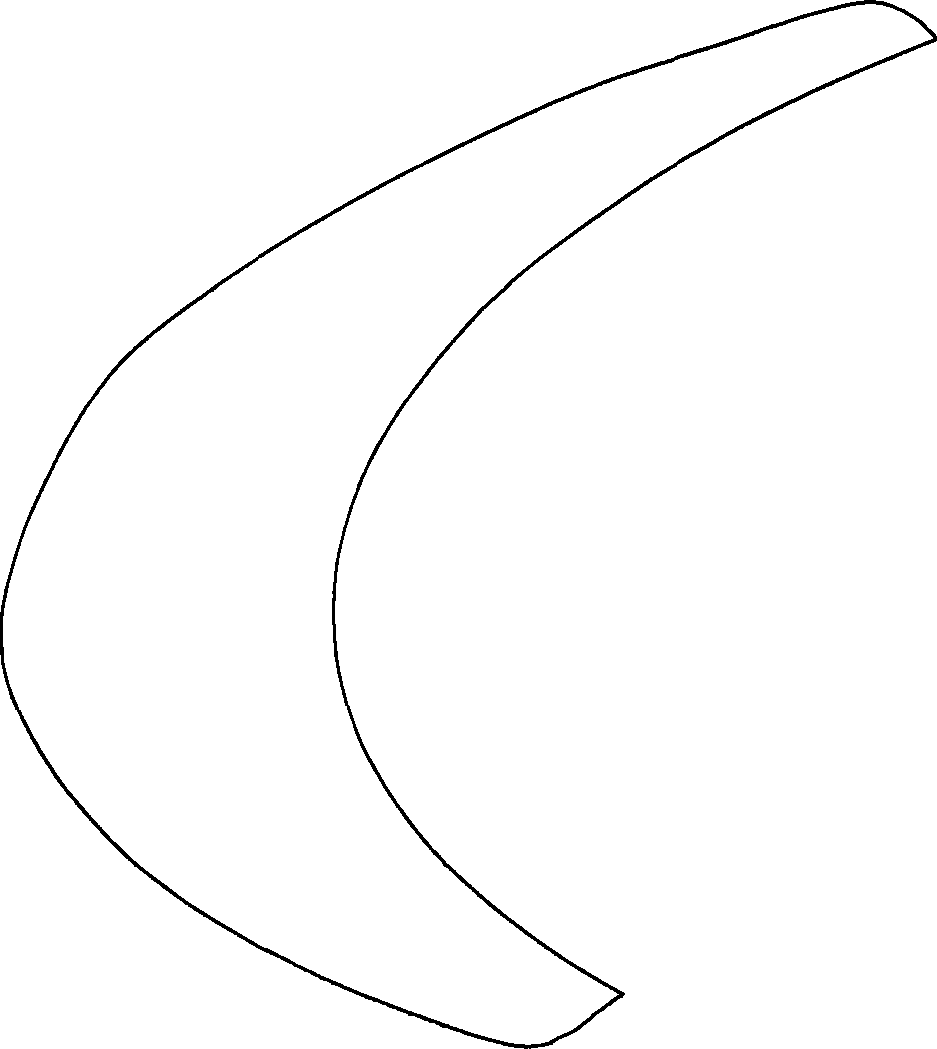

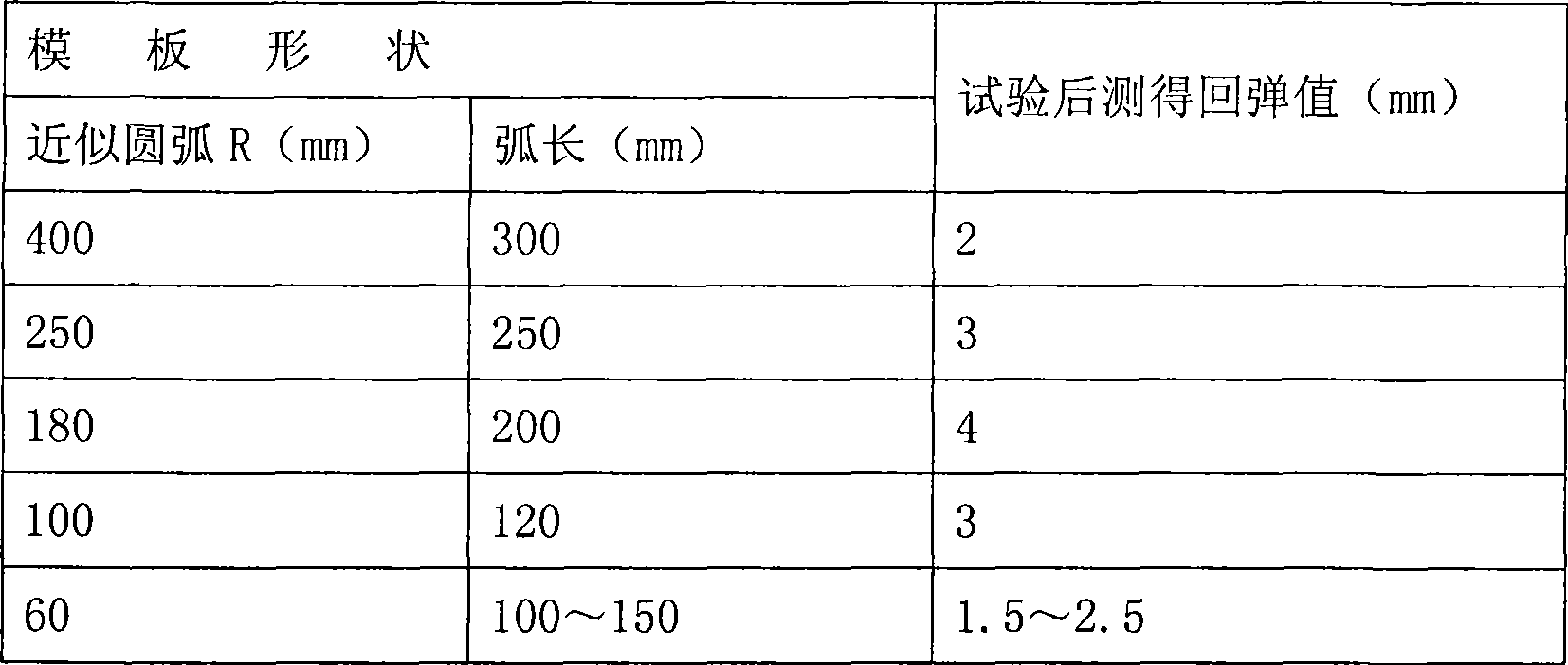

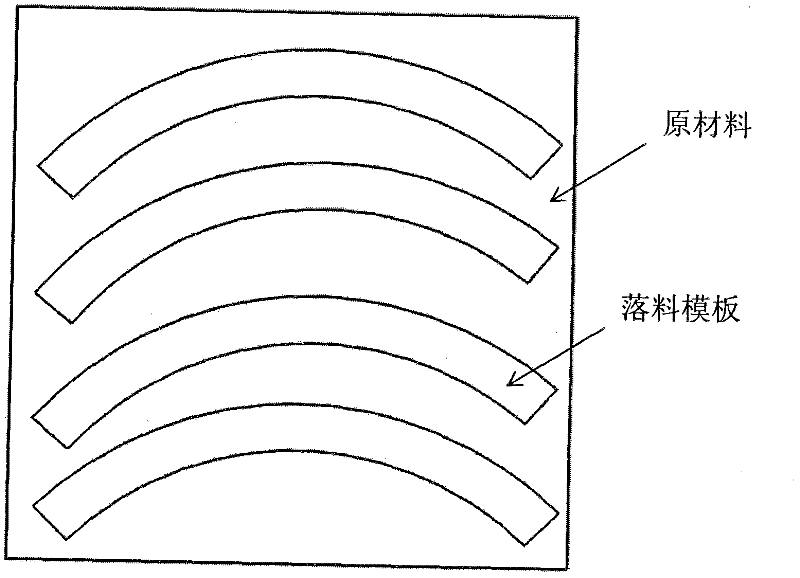

Marine water-jet propulsion passage aluminum double curved plate one-time pressure-molding technique method

ActiveCN101450365AEasy to manufactureSimple repair processForging/hammering/pressing machinesEngineeringCompression test

The invention discloses a technical method for compressing hyperbolic aluminium panels of a ship water jet flow passage to be shaped by one time. The method comprises the steps: performing linear smoothing, modeling and lay-out on the structure of a ship flow passage and manufacturing an inspection sample box and a test compression module; performing a compression test by taking an aluminium plate which is the same as a work piece plate to obtain an accurate rebound value; amending a testing compression module and manufacturing a special compression module; cutting the work piece, and drawing processing position lines on the surface of a blank; performing compression test on the special compression module to inspect the deviation values of the processing position lines of the workpiece, re-compressing to shape the workpiece after inspection and amendment and then putting the workpiece on the inspection type box to inspect the shaping accuracy; and if any error, compressing and amending again until the workpiece meets the requirements. The invention can ensure the shaping quality of workpieces, simplify the operation, improve the processing speed, and particularly can save cost, increase benefit in mass production and bring remarkable economic effect.

Owner:JIANGNAN SHIPYARD GRP CO LTD

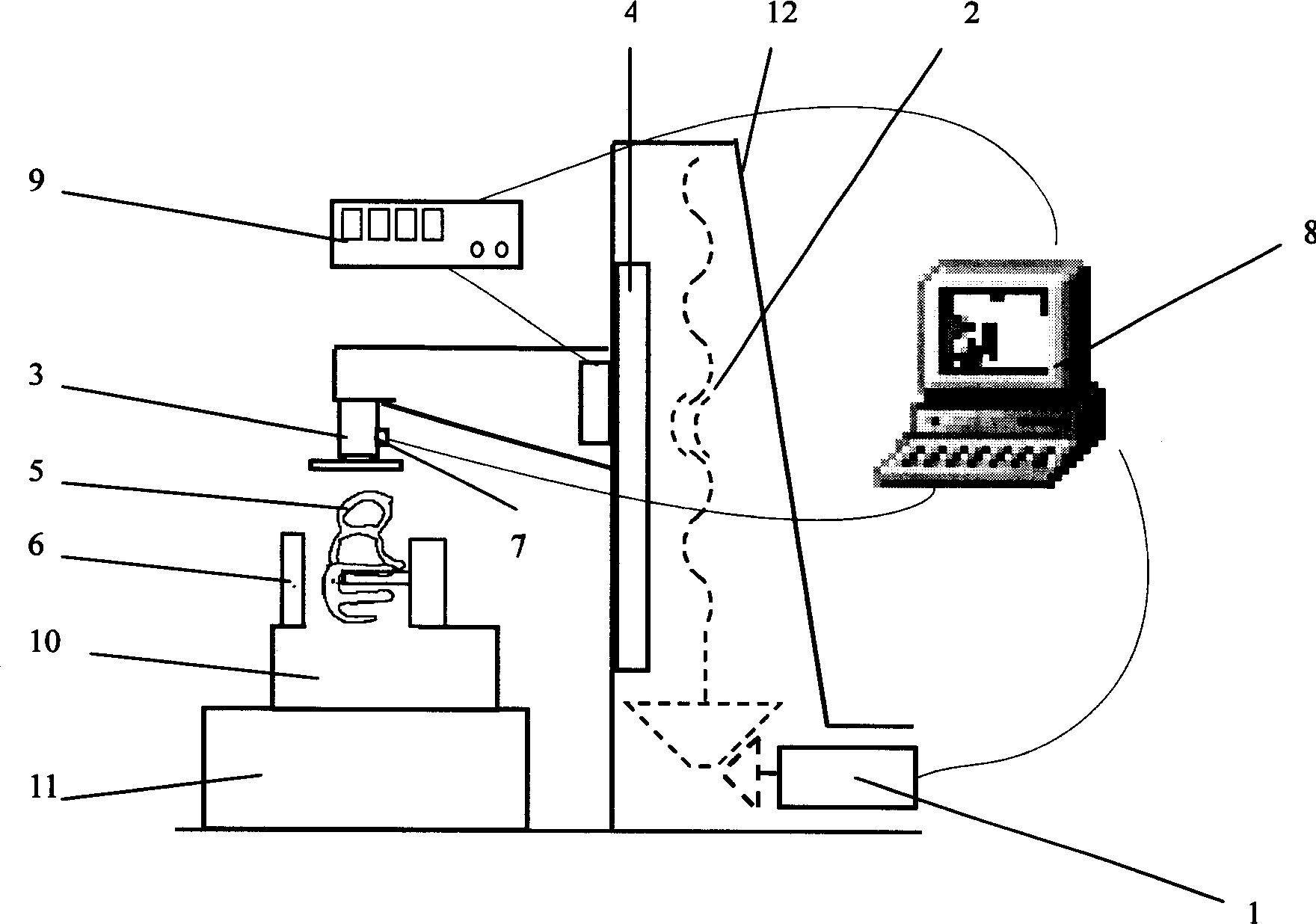

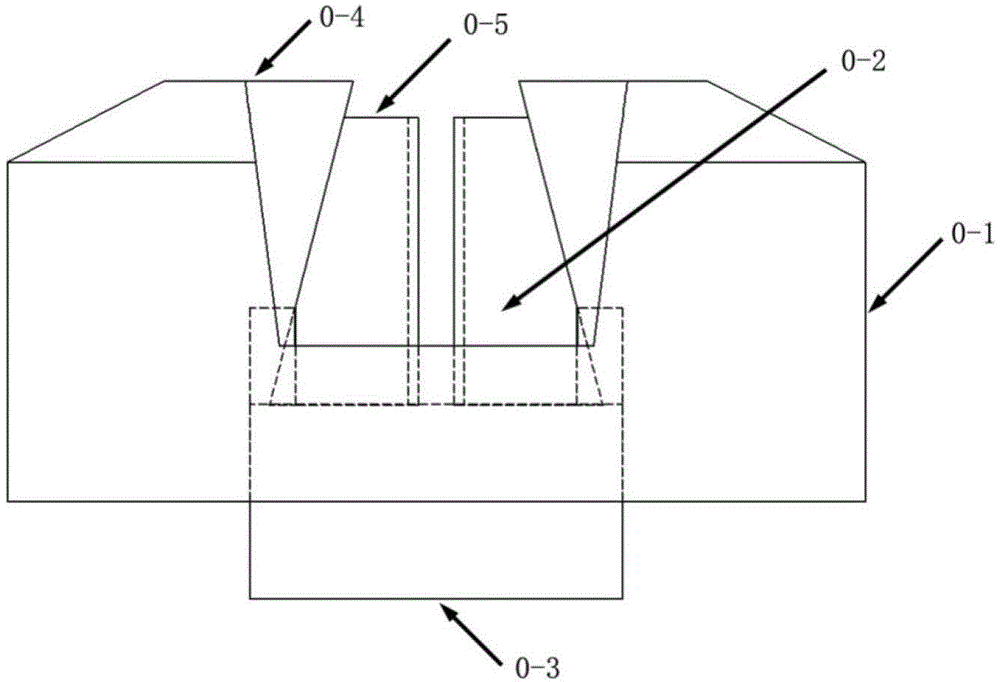

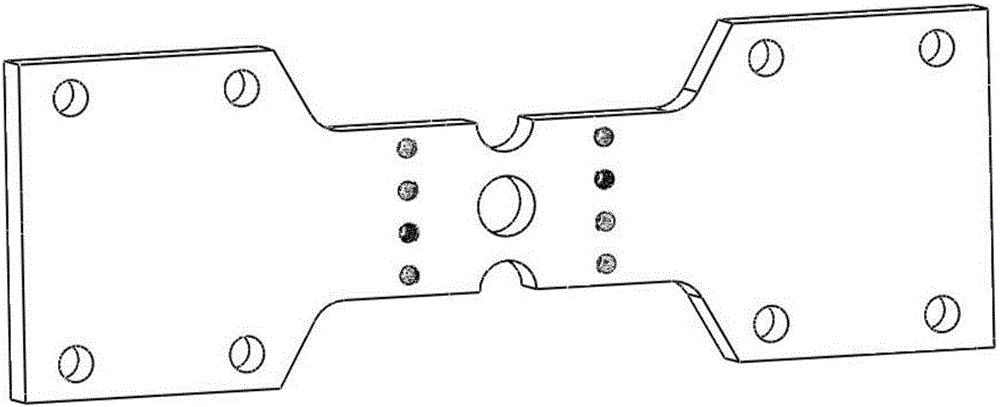

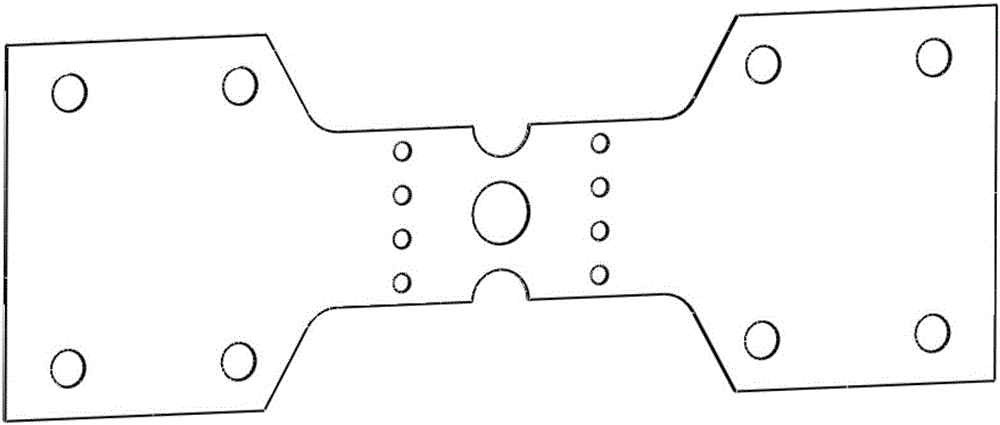

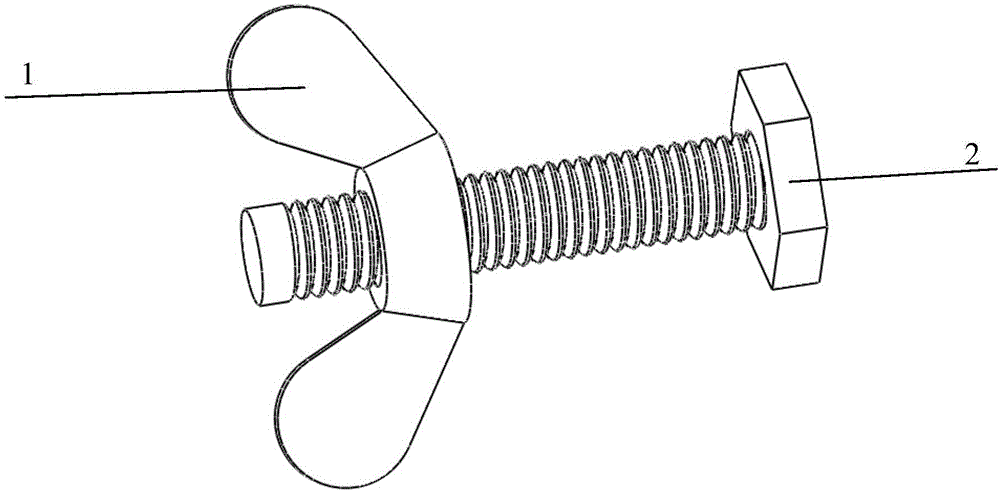

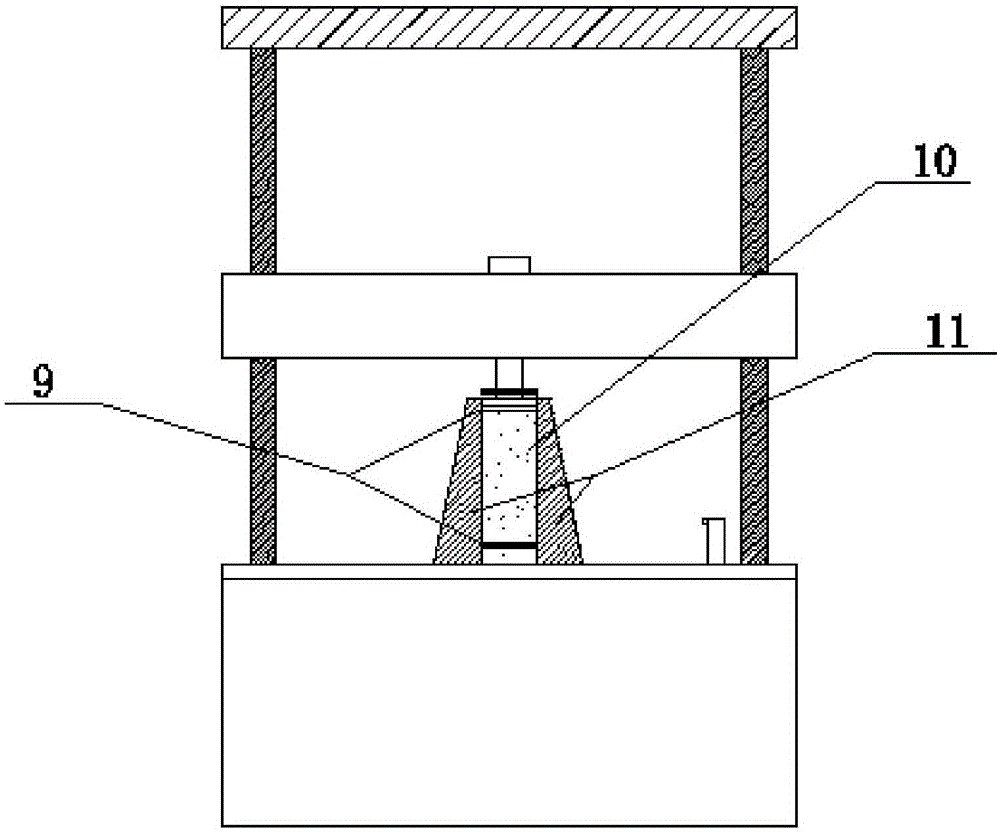

Anti-destabilization universal clamp used for compression performance test of edge/central notch composite material laminated plate

The invention discloses an anti-destabilization universal clamp used for compression performance test of an edge / central notch composite material laminated plate. The anti-destabilization universal clamp consists of a dog bone shaped metal clamping plate, PA6 nylon sandwiches, butterfly nuts and bolts, an opening reinforcing accessory and the like, wherein the dog bone shaped metal clamping plate comprises an edge opening and a central opening, wherein a connecting relationship is as follows: the PA6 nylon sandwiches are arranged on the upper and lower surfaces of the laminated plate, the dog bone shaped clamping plate is arranged on the surface of the upper nylon sandwich and the surface of the lower nylon sandwich; 8 pairs of butterfly nuts and bolts are used for fastening the dog bone shaped clamping plate; the nylon sandwiches and the laminated plate are clamped; and a semi-cylindrical convex table of the opening reinforcing accessory is inserted into an opening of the clamping plate, and is fixedly arranged on the metal clamping plate through a butterfly bolt and a threaded hole. According to the anti-destabilization universal clamp disclosed by the invention, sub parts are exquisitely matched and connected, so that the anti-destabilization universal clamp is simple, convenient, practical and delicate, effectively prevents an edge / central notch composite material from generating bending and destabilization as well as friction between the clamp and a test sample, can test crack initiation and expansion at an edge / central notch in real time, and provides technical means for testing compression performance of the laminated plate.

Owner:BEIHANG UNIV

Data path having grounded precharge operation and test compression capability

A data path for coupling data between a memory cell and an input / output (IO) line sense amplifier. An IO line coupling circuit is coupled to a pair of global data lines and a pair of local data lines to couple and decouple each of the global data lines to and from a voltage supply based on the voltage levels of the local data lines for the memory read operation. For the memory write operation, the IO line coupling circuit couples and decouples each of the global data lines to and from a respective one of the local data lines. The data path also includes a first precharge circuit coupled to the global data lines to couple the global data lines to ground to precharge the signal lines prior to a memory read or write operation, and can further include a test compression circuit coupled to the global data lines.

Owner:MOSAID TECH

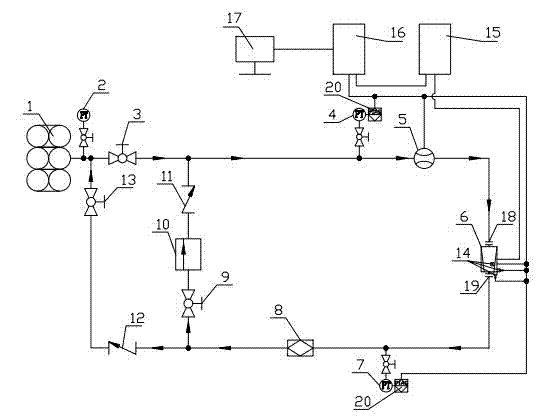

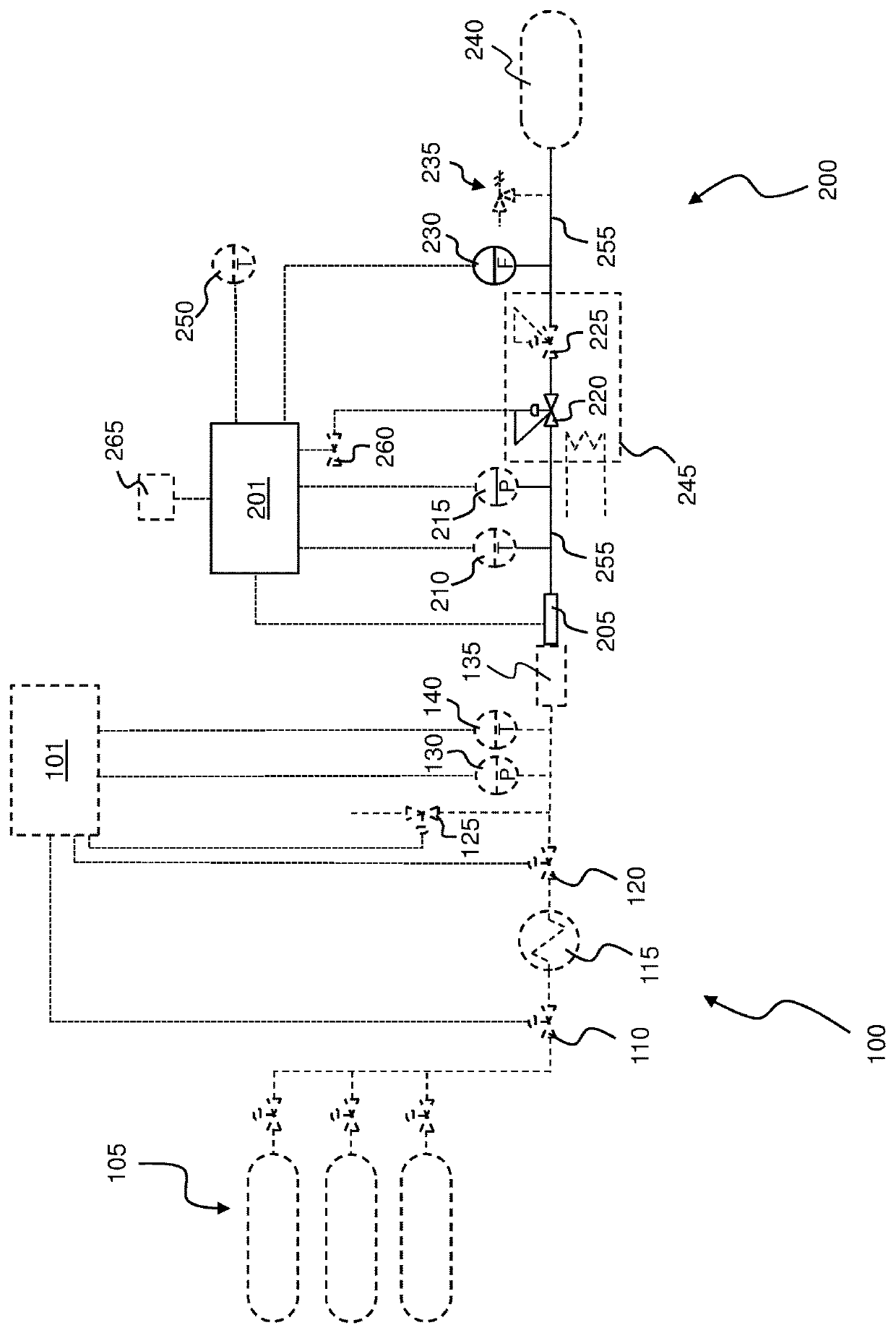

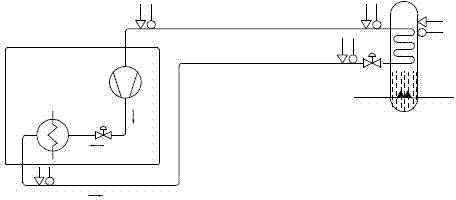

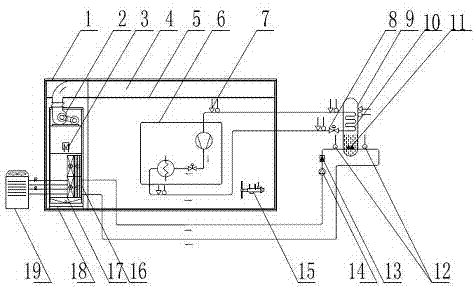

Compressor performance testing system

The invention discloses a compressor performance testing system which comprises a gas storage cylinder group 1, a vibrating detector 14 and a microprocessor 16. A compressor inlet and a compressor outlet are arranged on a compressor 6 under test; a ball valve 3 and a turbine flowmeter 5 are sequentially arranged on an input pipeline between the gas storage cylinder group 1 and the compressor inlet; a filter 8, a one-way valve 12 and a ball valve 13 arranged on an output pipeline between the compressor outlet and the gas storage cylinder group 1; and the filter 8, a ball valve 9, a pressure regulating valve 10, a one-way valve 11 and the turbine flowmeter 5 are sequentially arranged on a circulating connecting pipeline arranged between the compressor outlet and the compressor inlet. The testing system adopts nitrogen to simulate the rated condition of the compressor 6 under test, performs test detection to the reliable performance of the compressor 6 under test in the condition of rated condition, and judges the conformance between the compressor 6 under test and design, so as to ensure that the manufactured compressors are all reliable and safe.

Owner:ZHEJIANG QIANGSHENG COMPRESSOR MFG

Ceramic liner for electric pressure cooking saucepan

The invention relates to a ceramic liner for an electric pressure cooking saucepan, which is characterized by comprising the following components: 15 to 25 wt% of bright yellow stone, 12 to 20 wt% of mullite, 4 to 7 wt% of cordierite, 5 to 10 wt% of talc, 13 to 22 wt% of red mud and / or white mud, 15 to 30 wt% of argil, and 2 to 8 wt% of suzhou clay. The content of SiO2 of the cooking saucepan is less than or equal to 52 wt%, and the content of Al2O3 of the cooking saucepan ranges from 32 to 37 wt%. The invention not only retains the advantages of the liner of a ceramic pot but also overcomes the defects that the liner of the ceramic pot cannot bear high pressure, and the heat stability cannot meet the use requirement, can reach the test compression strength of 80 to 100 MPa, and is used stably for more than or equal to 1 year under the conventional cold-hot alternation.

Owner:宜兴市大成陶瓷有限公司

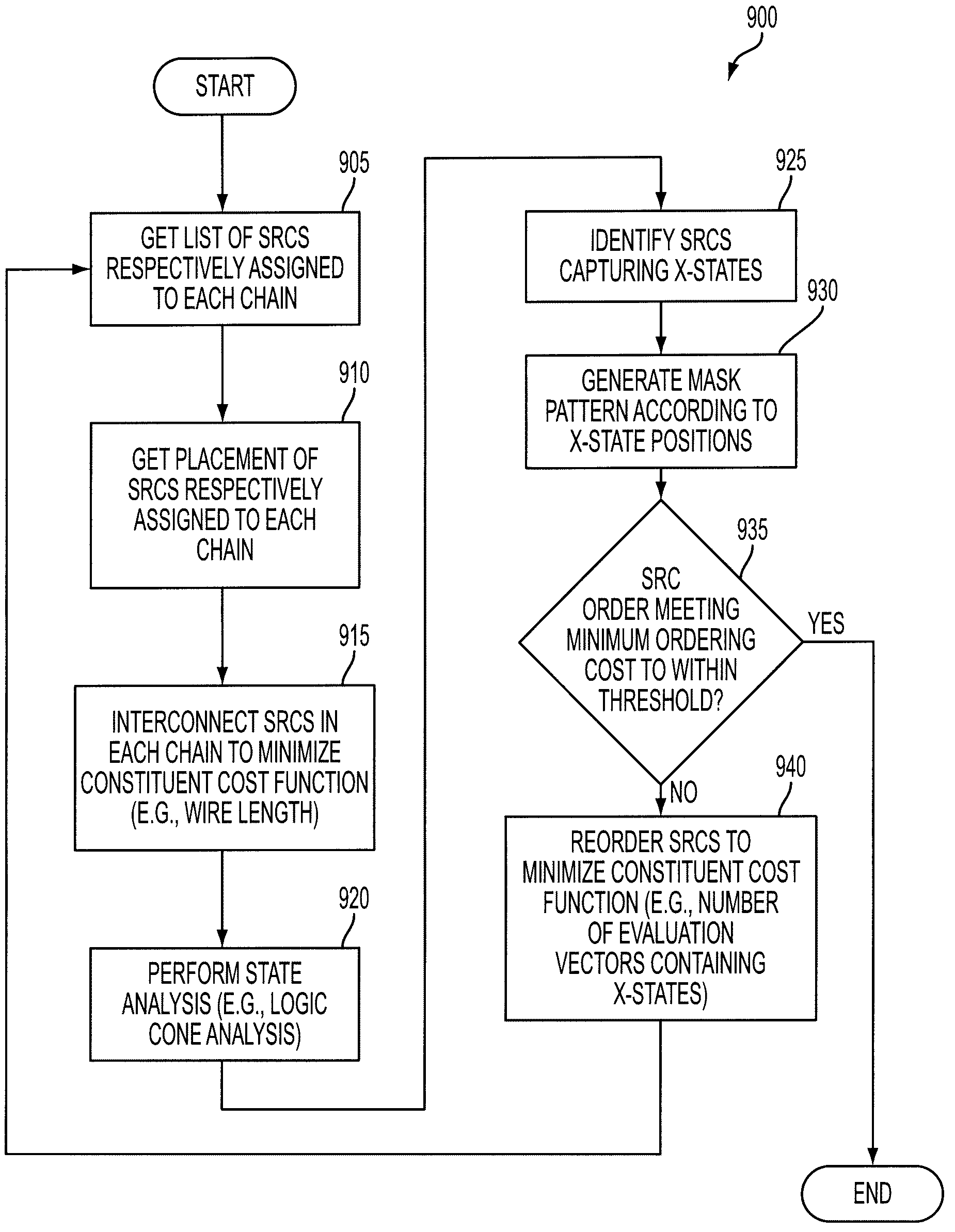

Testing to prescribe state capture by, and state retrieval from scan registers

InactiveUS7886263B1Detecting faulty computer hardwareElectrical testingComputer hardwareProcessor register

State retention cells of a test circuit embedded in an electrical circuit are interconnected to form one or more scan chains. The scan chains are interconnected so that unknown states, or X-states, are shifted through the scan chains in an order other than the order in which the states were captured by the state retention cells of the scan chain. Such reordering of response states in individual scan chains may be used to align the X-states across multiple scan chains to achieve higher test compression scan register circuit testing.

Owner:CADENCE DESIGN SYST INC

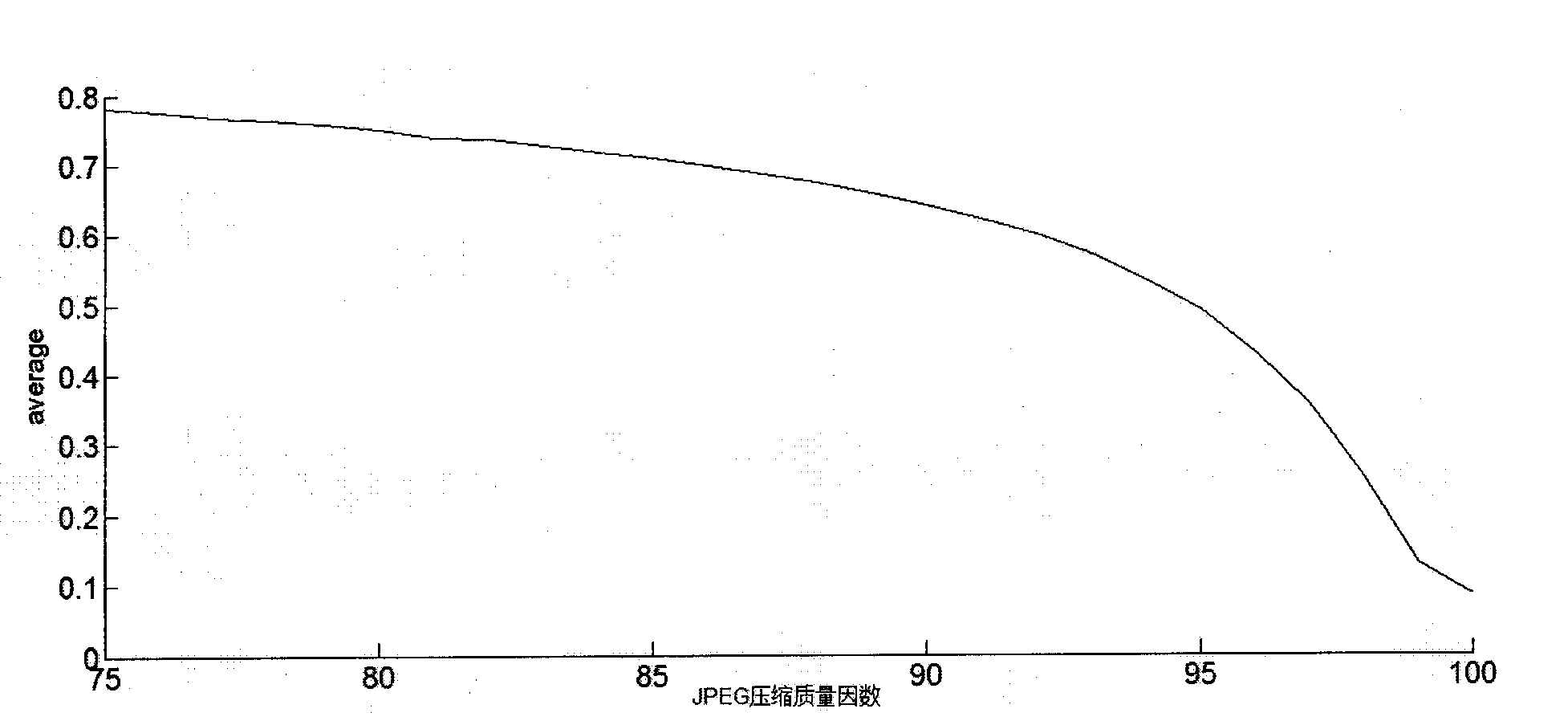

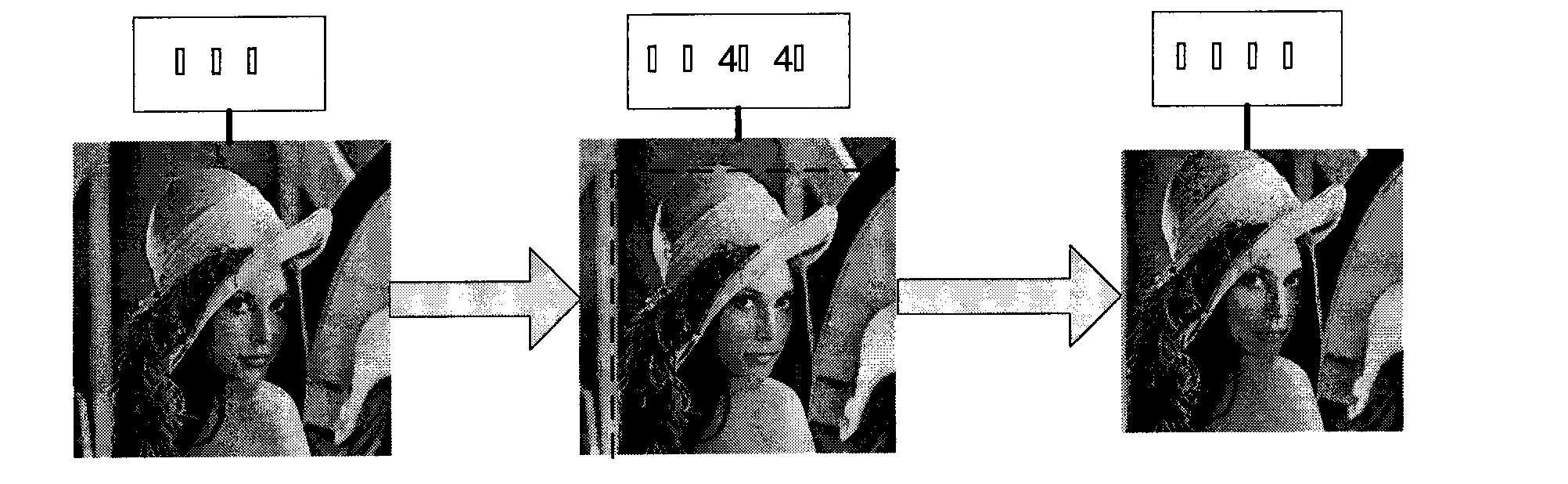

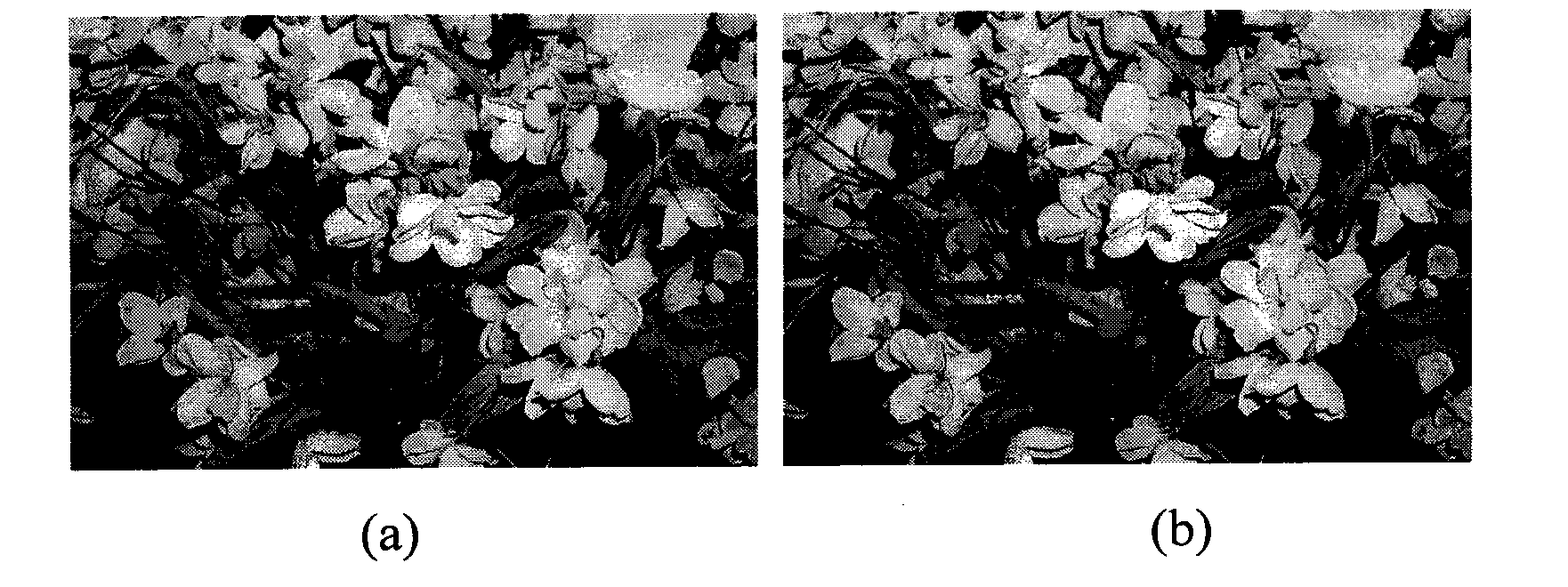

Method for testing compression history of BMP image based on loss amount of image information

The invention relates to a method for testing the compression history of a BMP image based on the loss amount of image information, belonging to the technical field of signal and information processing. The method is characterized by comprising the steps of: under the condition of only obtaining a digital image, cutting the BMP image to be tested into 4 rows and 4 lines; evaluating an original image; compressing the image to be tested and the evaluated original image into two JPEG images, the quality factor of which is 100; extracting the characteristic by comparing the loss amount of the image information of the two JPEG images; and testing the compression history of the large quantities of the images with a Fisher linear classifier in a classifying way, or judging the compression historyof the single BMP image with original compression quality factor by means of threshold value segmentation. The method can exactly identify and prove the compression history of the many or single BMPimage(s). The method is applicable to the field of information security.

Owner:DALIAN UNIV OF TECH

Apparatus and method for testing compressed gas dispensing stations

Testing apparatus and method for testing compressed gas dispensing stations where a back pressure regulator is used to imitate filling of receiving vessels without the need for receiving vessels. A mass flow sensor measures the mass of compressed gas dispensed to the testing apparatus, and a controller calculates the pressure for the back pressure regulator to imitate filling of a receiving vessel.

Owner:AIR PROD & CHEM INC

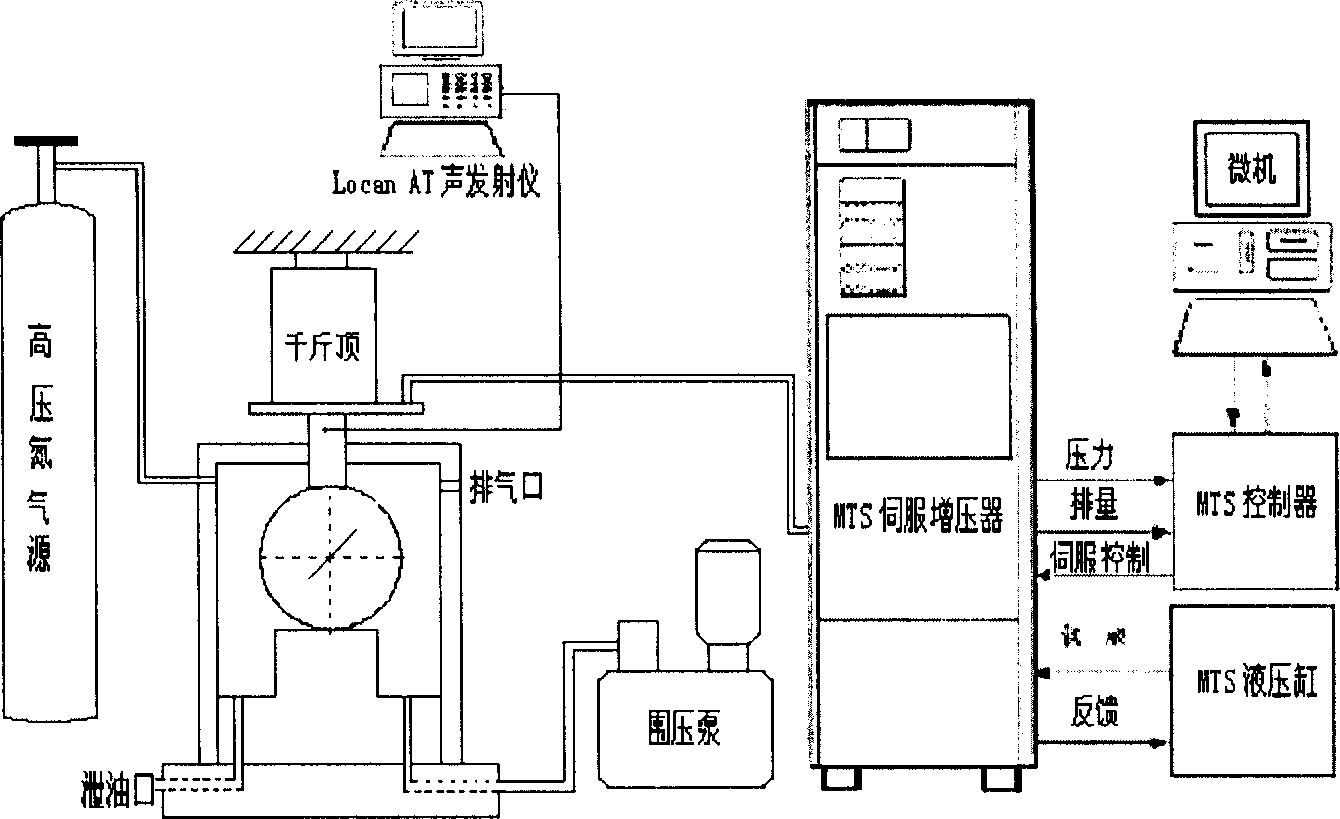

Apparatus for testing compression strength of sea ice

InactiveCN105115820AClosely connectedOvercome the disadvantage of instabilityMaterial strength using tensile/compressive forcesUniaxial compressionRemote control

An apparatus for testing the compression strength of sea ice comprises a sea ice pressure testing machine, a loading system and a data acquisition system. Pressure test comprises sea ice sample uniaxial compression test and sea ice sample confined compression test. Compared with apparatuses in the prior art, the apparatus created in the invention has the advantages of simple system structure, wireless remote control of loading, compact connection of all system mechanisms, avoiding of unstable factors of split type equipment in the loading and collecting process, and improvement of the test result accuracy; and the apparatus allows the temperature of the above sea ice sample to be obtained when the compression strength of the sea ice is tested, is helpful for further knowing interaction mechanisms and influence factors of the sea ice and an offshore structure, and facilities construction of the offshore structure with strong ice resistance.

Owner:DALIAN UNIV OF TECH

Program automatic upgrading control method and device, computer equipment and storage medium

PendingCN110059001AAutomated package testingReduce duplication of packaging workVersion controlSoftware testing/debuggingNetwork packetProgram testing

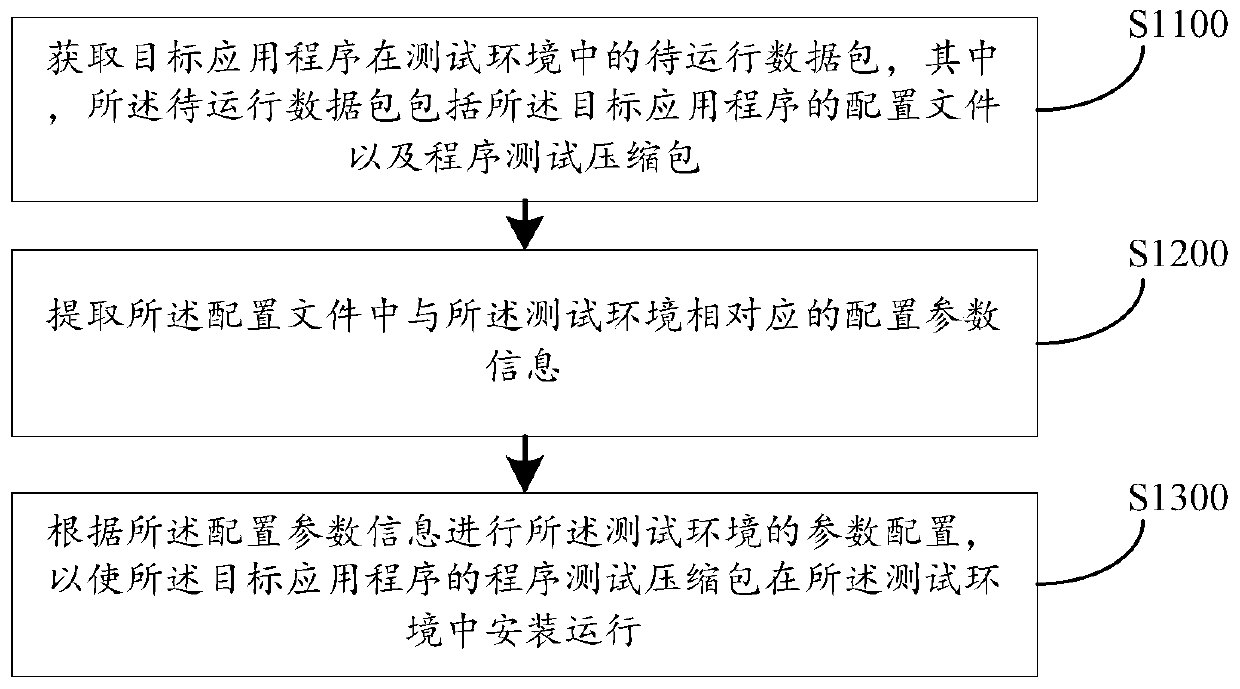

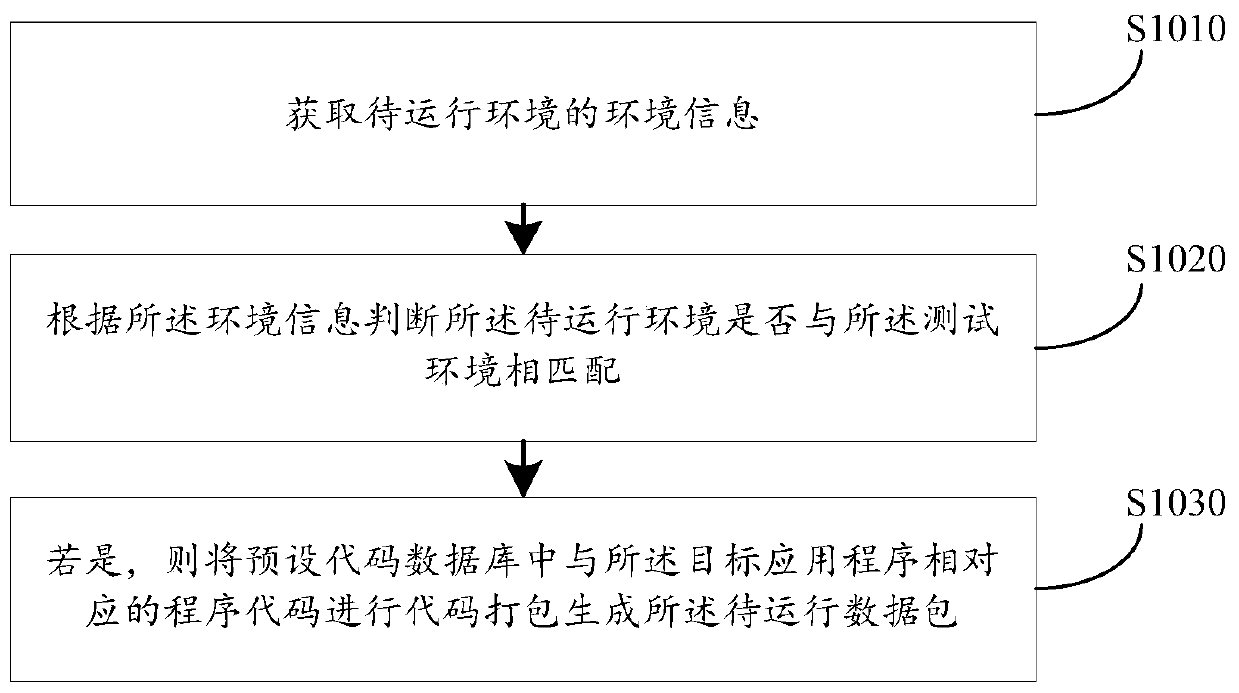

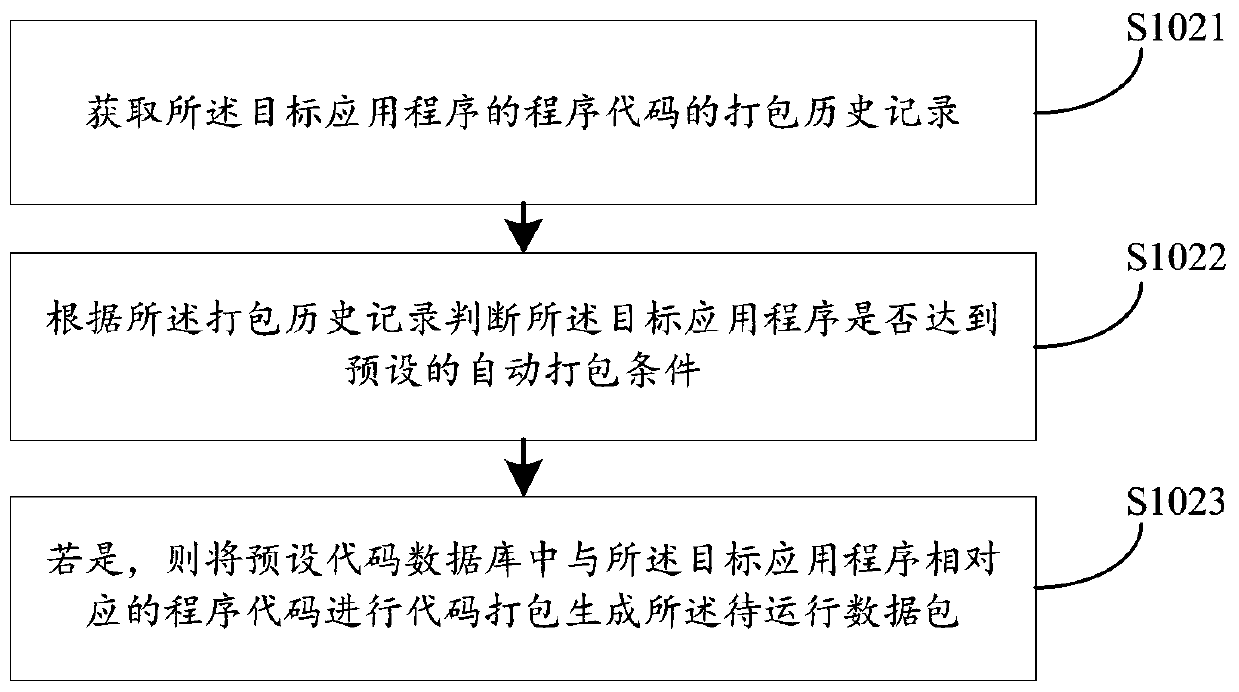

The embodiment of the invention discloses a program automatic upgrading control method and device, computer equipment and a storage medium, and the method comprises the following steps: obtaining a to-be-operated data packet of a target application program in a test environment, the to-be-operated data packet comprising a configuration file of the target application program and a program test compression packet; extracting configuration parameter information corresponding to the test environment in the configuration file; and carrying out parameter configuration of the test environment according to the configuration parameter information, so that the program test compression package of the target application program is installed and operated in the test environment. The to-be-operated datapacket of the target application program in the test environment is obtained, and then parameter configuration is carried out on the test environment according to the configuration file in the to-be-operated data packet, so that the target application program can be installed and operated in the test environment, the code packaging test of the application program is automatically realized, the repeated packaging work of testers is reduced, the functions of the application program can be tested in time, and the development efficiency is improved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

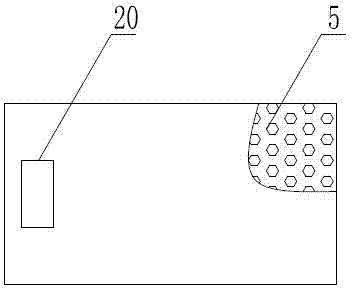

An air-cooled compression condensing unit performance test system

ActiveCN102269661AReduce operating energy consumptionAccurate measurementStructural/machines measurementCalorimeterTest performanceAir cycle

The invention discloses a testing system for performance of an air-cooled compression condensing unit, and belongs to the technical field of building environment and equipment engineering. The testing system comprises an air circulation processing system, a refrigerant circulating system and an energy balancing and metering system, wherein the air circulation processing system comprises a testing environment room, a fan, an air processing unit and a compression condensing unit matched therewith, and an air sampling device; high-temperature high-pressure refrigerant liquid from the compression condensing unit to be tested is throttled into a gas-liquid diphasic fluid by a throttle valve, enters an evaporation coil in a calorimeter instrument, and is heated by a second refrigerant into overheat steam to return to the compression condensing unit to be tested, so that the whole refrigeration circulation is completed; and secondary refrigerants in a surface cooling coil in the air processing unit in a centrifugal pump and a heating coil in the calorimeter instrument forms a secondary refrigerant circulation by a centrifugal pump. The system can realize energy self-balance, reduce running energy consumption and accurately test performance parameters, such as refrigerating capacity, of the air-cooled compression condensing unit.

Owner:NANJING NORMAL UNIVERSITY

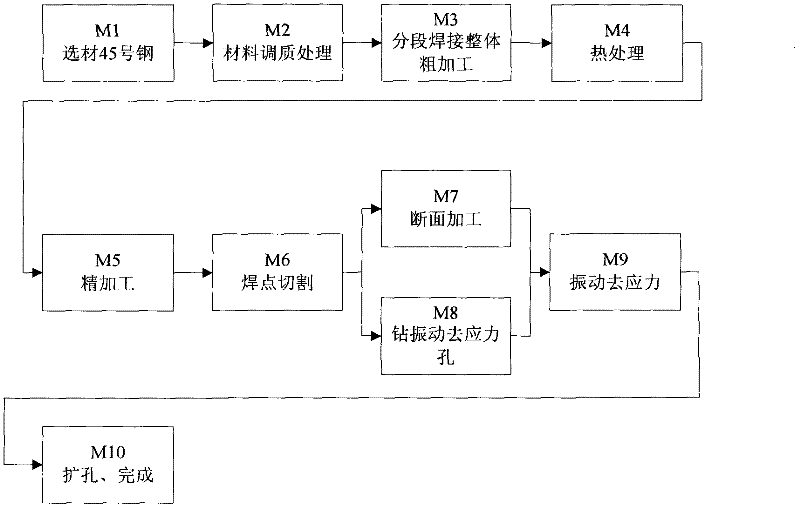

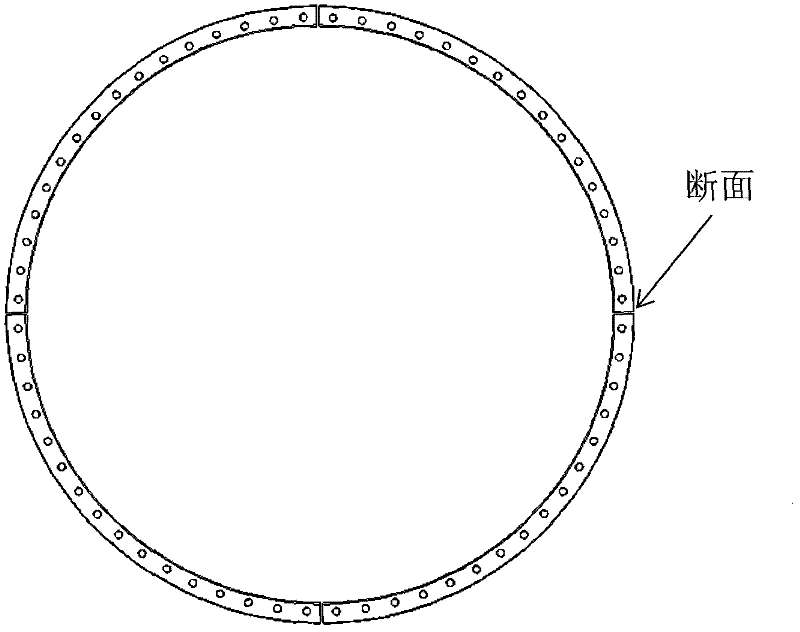

Anti-deformation manufacturing method for mechanical test compression ring for aircraft

The invention discloses an anti-deformation manufacturing method for a mechanical test compression ring for an aircraft. The method includes the steps: tempering compression ring materials; cutting the compression ring materials to obtain subsections of the compression ring, and connecting the subsections of the compression ring into a whole; performing annealing or artificial aging heat treatment for the whole compression ring; finishing the whole compression ring according to the design size; cutting a welding point of the whole compression ring to obtain a plurality of subsections of the compression ring again; machining cross sections of the subsections of the compression ring according to design requirements; drilling vibrational stress removing holes on the subsections of the compression ring; vibrating the subsections of the compression ring to remove stress; and broaching the subsections of the compression ring after vibrational stress removal to complete the whole manufacturing process. The method is used for reducing residual stress in the process of machining the compression ring and effectively preventing the compression ring from deforming in use, and has the advantages of low machining cost, convenient and visual machining steps, high adaptability and universality and the like.

Owner:SHANGHAI INST OF SATELLITE EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com