Patents

Literature

86results about How to "Simple repair process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

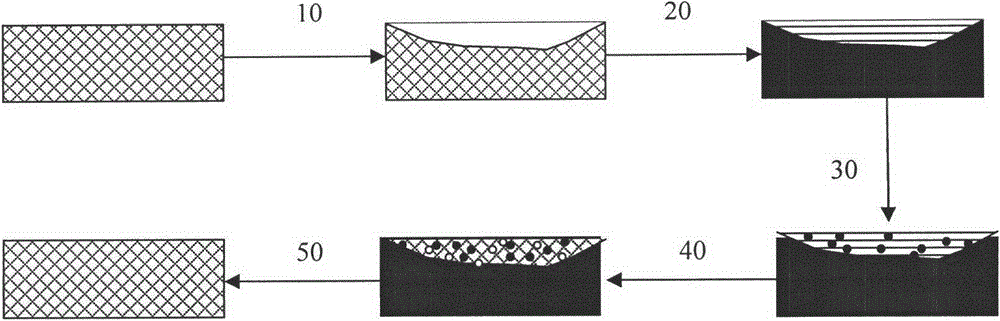

Micro LED transfer method, display panel and display device

ActiveCN109148506ASimple detection processSimple repair processSolid-state devicesSemiconductor devicesLED displayDisplay device

A Micro LED transfer method, a Micro LED display panel and a Micro LED display device are disclosed. The Micro LED display panel comprises a substrate, a pixel definition layer, and the pixel definition layer comprises an opening, a first conductive layer stacked in the opening, a photosensitive conductive bonding layer and a Micro LED structure. The photosensitive conductive bonding layer has a post-illumination curing, such that structures bonded to opposing surfaces of the photosensitive conductive bonding layer can be bonded together, due to the presence of a photosensitive conductive bonding layer, As that detection of the Micro LED can be realize during the transfer process of the Micro LED, and the subsequent detection is not performed after the bonding is complete, the step of removing the bonded abnormal display Micro LED is saved, and the detection and repair process of the Micro LED is simplified.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

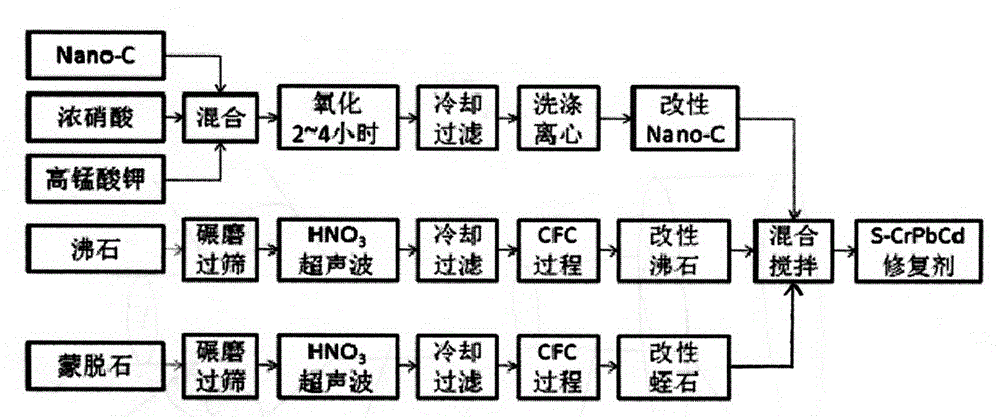

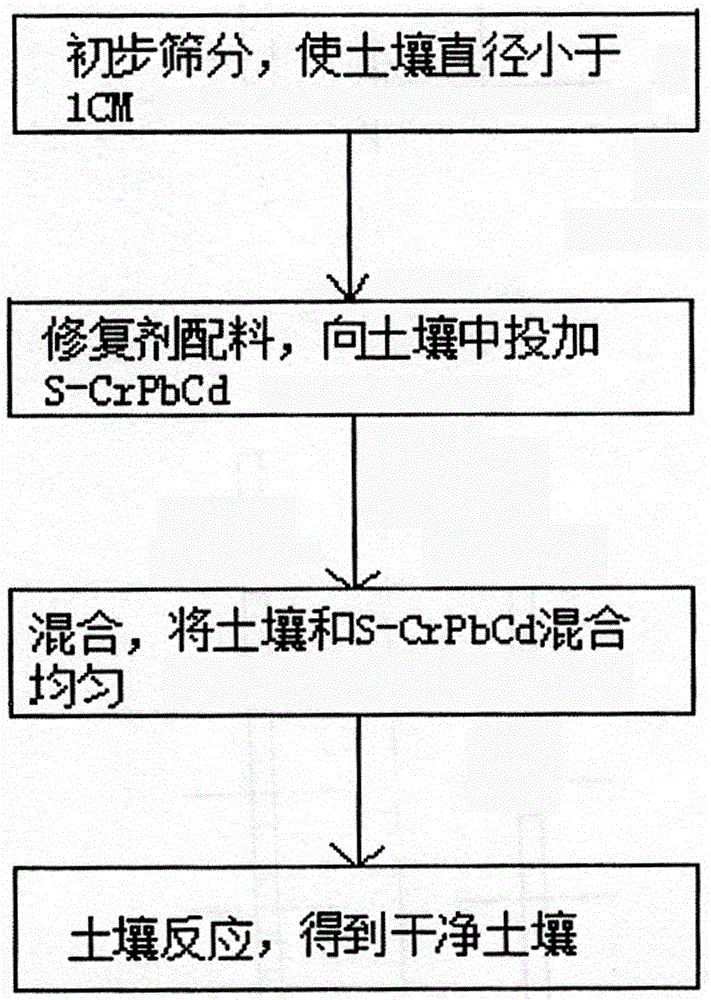

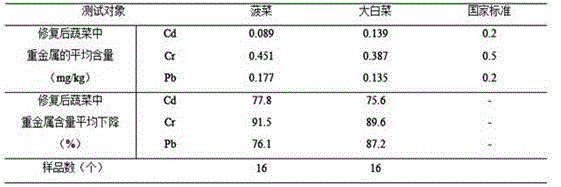

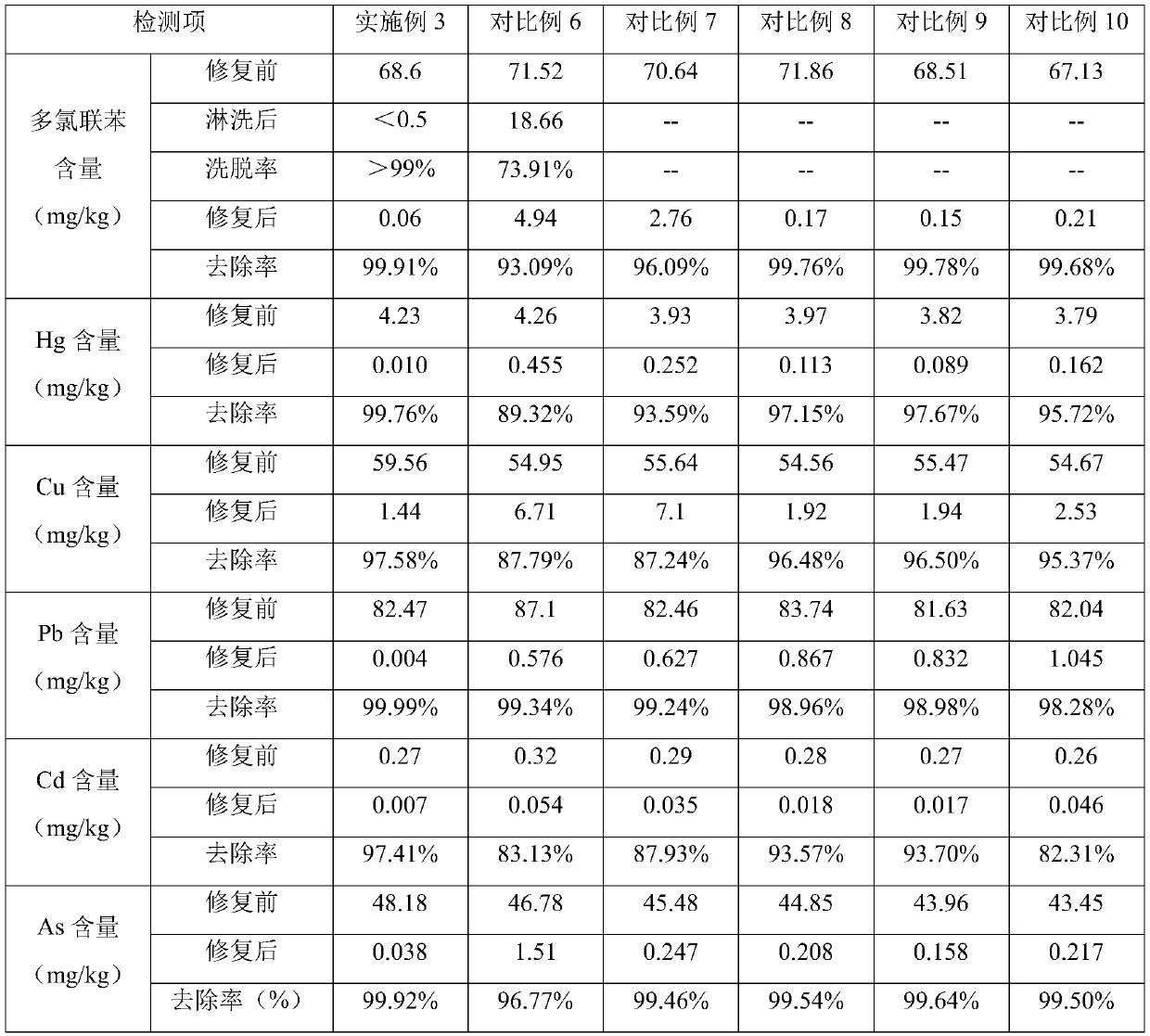

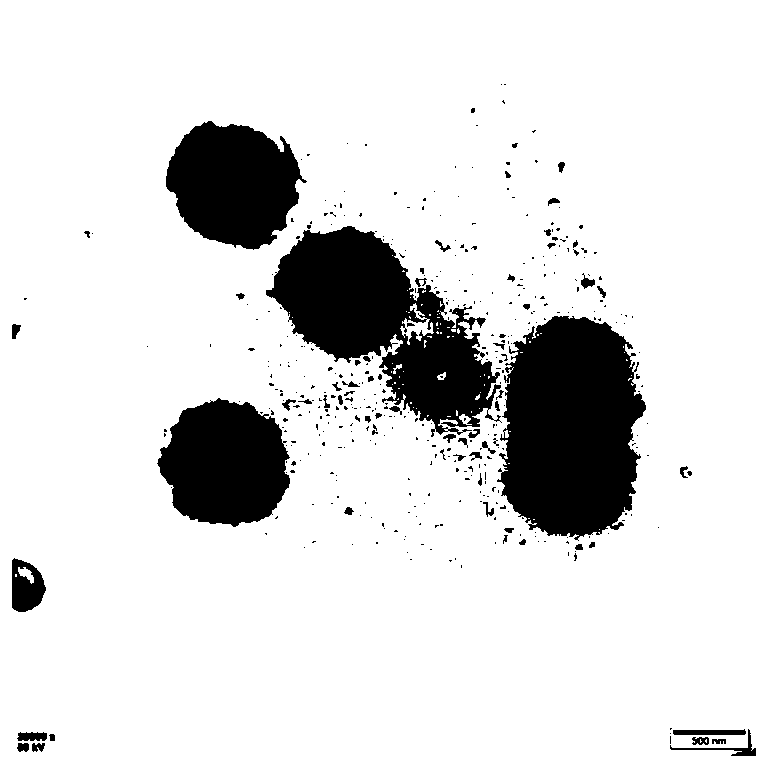

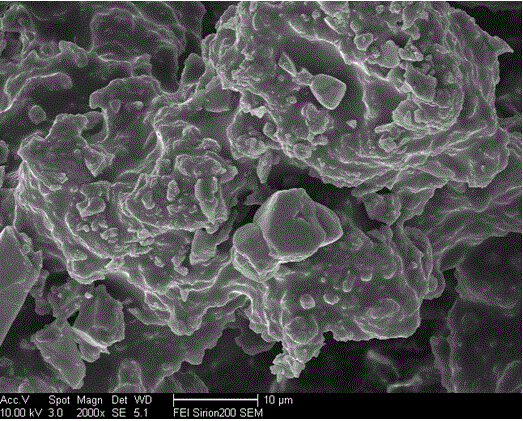

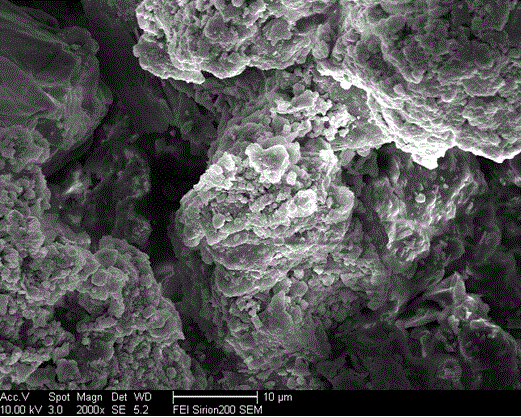

Novel material for repairing heavy metal Cr-Pb-Cd contaminated soil as well as preparation method and using method of novel material

ActiveCN104927870AGood restorativeImprove stabilityContaminated soil reclamationOrganic fertilisersSoil propertiesClay minerals

The invention discloses a novel material S-CrPbCd for repairing heavy metal Cr-Pb-Cd contaminated soil as well as a preparation method and a using method of the novel material S-CrPbCd. The material comprises 5-15 percent of modified carbon nano tube, 10-60 percent of modified clay mineral and 20-60 percent of quicklime. The S-CrPbCd can efficiently adsorb Pb, Cd and Cr in the soil, and does not obviously change the soil property and cultivability. The S-CrPbCd enables the residue amount of Pb, Cd and Cr in sensitive crops to be reduced to 75-90 percent within 1-2 months, and meanwhile, the material has the characteristics of low cost, simple preparation process, no secondary pollution, quick action and easiness in large-area popularization.

Owner:INST OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

Repair method of high temperature alloy vane by electron beam welding

InactiveCN101007366AShort residence time at high temperatureUniform temperature fieldWelding/cutting media/materialsWelding/soldering/cutting articlesRetention periodRetention time

The method of electron beam brazing repair high temperature alloy blades. The invention involves a brazing repair high temperature alloy blade method in order to solve the problems of complex repair art, long repair cycle, the need of integral heating when brazing repair, long retention period at high temperature when brazing work in original method of repair high temperature alloy blade. The method is realized by the following steps: (1) grinding off blade injury and polishing the injury part into trough, mixing the solder or alloy powder and acetone or general soldering bonding agent sold in market into cream status and putting it in groove; (2) setting process parameters and brazing; (3) when the solder or alloy powder are not melted completely, cooling it until room temperature and taking out high temperature alloy blade, the high temperature alloy blade is repaired. The electron beam brazing repair high temperature alloy blade method in the invention has simple repair process and short repair cycle, a cycle requires only 5 minutes to 10 minutes, it only heats the injury position, the retention time of blades when repaired is reduced to 0.1 ~ 10% of original method.

Owner:HARBIN INST OF TECH

Repair method for ceramic matrix composite material

The invention discloses a repair method for a ceramic matrix composite material. The repair method is characterized by comprising the following steps: performing ultrasonic washing on a worn ceramic matrix composite material sample; attaching graphite paper to an unrepaired part of the dried composite material; filling a defective part by adopting a carbon fiber prepreg; molding and curing, wherein the pressure is 10 MPa to 100 MPa, the temperature is 80 to 160 DEG C and the curing time is 3 to 6 hours; slowly rising the temperature to a high temperature for performing pyrolysis in a vacuum atmosphere; coating boron carbide and silicon nitride nano-powder slurry after the prepreg is decomposed, wherein the boron carbide and silicon nitride nano-powder slurry enter large gaps among fiber bundles; rising the temperature to a reaction temperature in the vacuum atmosphere, and introducing trichloromethyl silane gas and hydrogen serving as a carrier gas, and argon serving as a dilution gas, wherein a chemical gas phase permeates silicon carbide, and the composite material is densified. According to the repair method for the ceramic matrix composite material, the chemical gas phase permeates the silicon carbide; a repair layer and the original base material are combined tightly; the high-temperature oxidation resistance of the ceramic matrix composite material is improved; a repair process is simple; the cycle is shorter.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

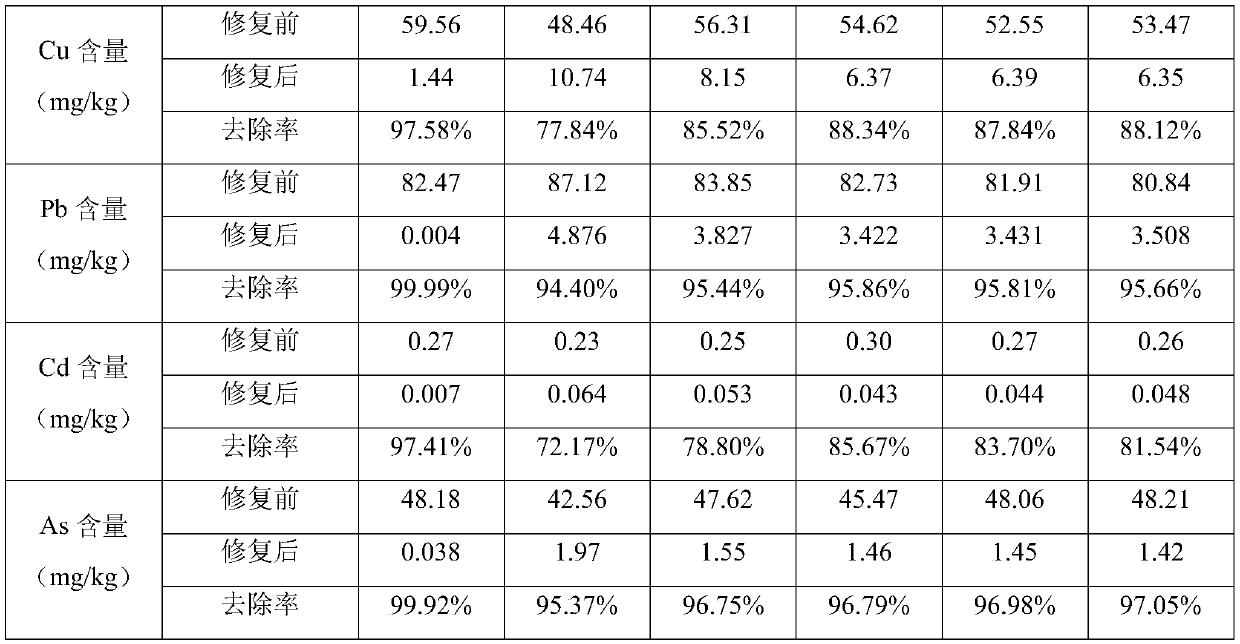

Remediation method for organic matter contaminated soil

ActiveCN110639943AReduce consumptionReduce soil remediation costsContaminated soil reclamationMembrane filtersContaminated soilsPollutant

The invention provides a remediation method for organic matter contaminated soil. The remediation method comprises the following steps that 1, soil pretreatment; 2, continuous leaching of the soil; step 3, degradation of organic pollutants and recovery of heavy metals; and step 4, soil micro-ecological restoration. According to the invention, an elution method and a biological mud method are combined; firstly, a soil dispersing agent is mixed with the soil; soil aggregation and cementation in the leaching process are avoided; the leaching speed is increased by adopting a continuous leaching mode; meanwhile, the leaching effect is improved by compounding and combining the leaching agents; through the arrangement of tan electrostatic spinning composite filter felt, the cyclic utilization ofleacheate is realized; during soil micro-ecological restoration, an immobilized mixed degradation microbial inoculum is adopted, organic pollutants which are not eluted by leacheate and surfactants adsorbed in the soil can be degraded within 2-4 days by controlling the ventilation capacity and the stirring rate, the restoration time is short, the cost is low, the restored soil does not need to besubjected to subsequent treatment and can be directly sown, and the economic benefit is good.

Owner:河南省环境保护科学研究院

In-situ spraying reparation method of horizontal aluminum busbar in electrolytic plant

InactiveCN102676970ASimple processing methodUnique process methodMolten spray coatingCoated surfaceElectrolysis

The invention relates to a reparation method of an aluminum busbar, in particular to an in-situ spraying reparation method of a horizontal aluminum busbar in an electrolytic plant. The method comprises firstly checking conditions of the busbar, performing leveling processing on the surface of the busbar, then performing preprocessing on the surface of the busbar to enable the preprocessed matrix surface to reach Sa 2.5-3.0 grade and to expose uniform metal natural color, performing rough processing on the surface of the busbar to enable roughness or riveting line depth of the surface to reach 40-80mu m, utilizing the electric arc spraying technology to spray a base layer and a working layer on the surface of the damaged busbar, finally utilizing a movable suspension milling cutter to mill the coating surface, and performing clean and smooth processing to complete the reparation of the horizontal aluminum busbar. The method can be achieved in the electrolytic plant, can effectively avoid interference of a strong magnetic field, reduces labor strength, has less consumption of labor and materials and simple and fast operation, can repair surface defects of the horizontal busbar serving as the upper structure of an aluminum cell, and can reproduce a repairing layer with excellent abrasion performance.

Owner:QINGTONGXIA ALUMINUM GRP +1

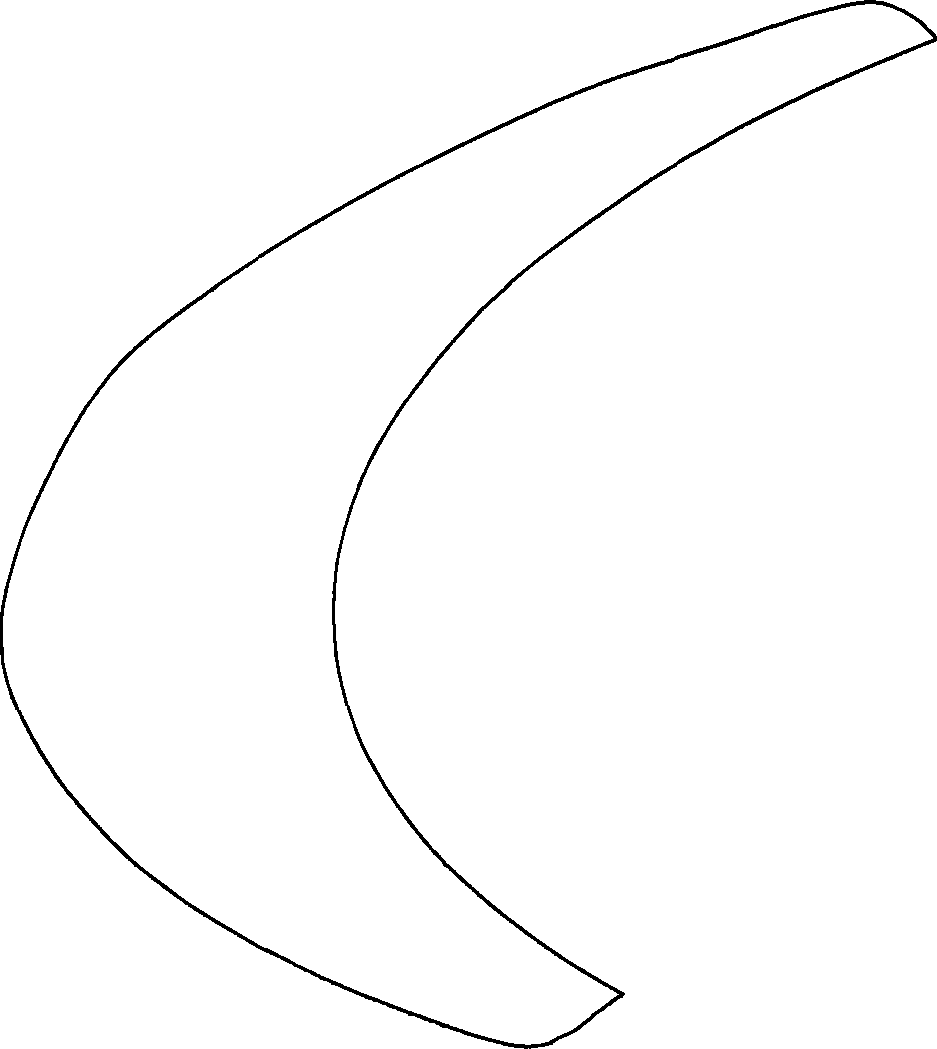

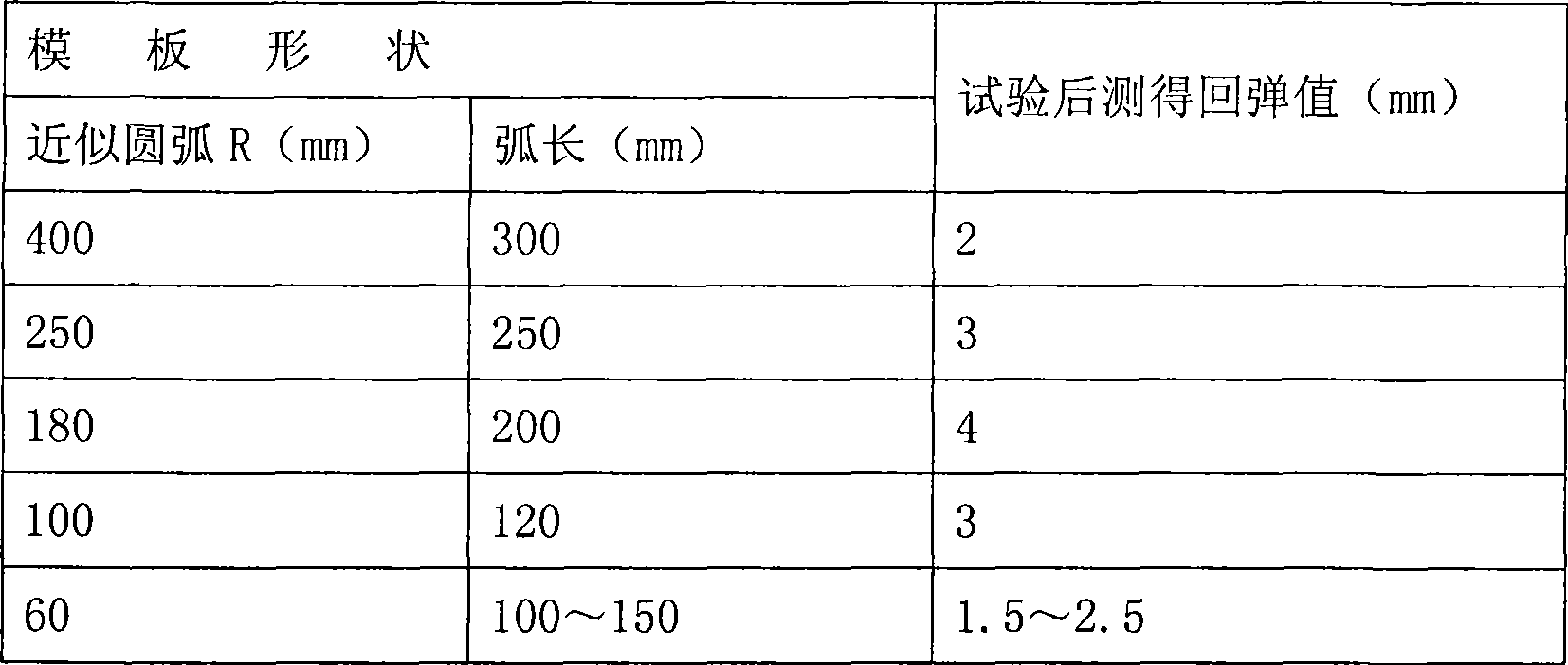

Marine water-jet propulsion passage aluminum double curved plate one-time pressure-molding technique method

ActiveCN101450365AEasy to manufactureSimple repair processForging/hammering/pressing machinesEngineeringCompression test

The invention discloses a technical method for compressing hyperbolic aluminium panels of a ship water jet flow passage to be shaped by one time. The method comprises the steps: performing linear smoothing, modeling and lay-out on the structure of a ship flow passage and manufacturing an inspection sample box and a test compression module; performing a compression test by taking an aluminium plate which is the same as a work piece plate to obtain an accurate rebound value; amending a testing compression module and manufacturing a special compression module; cutting the work piece, and drawing processing position lines on the surface of a blank; performing compression test on the special compression module to inspect the deviation values of the processing position lines of the workpiece, re-compressing to shape the workpiece after inspection and amendment and then putting the workpiece on the inspection type box to inspect the shaping accuracy; and if any error, compressing and amending again until the workpiece meets the requirements. The invention can ensure the shaping quality of workpieces, simplify the operation, improve the processing speed, and particularly can save cost, increase benefit in mass production and bring remarkable economic effect.

Owner:JIANGNAN SHIPYARD GRP CO LTD

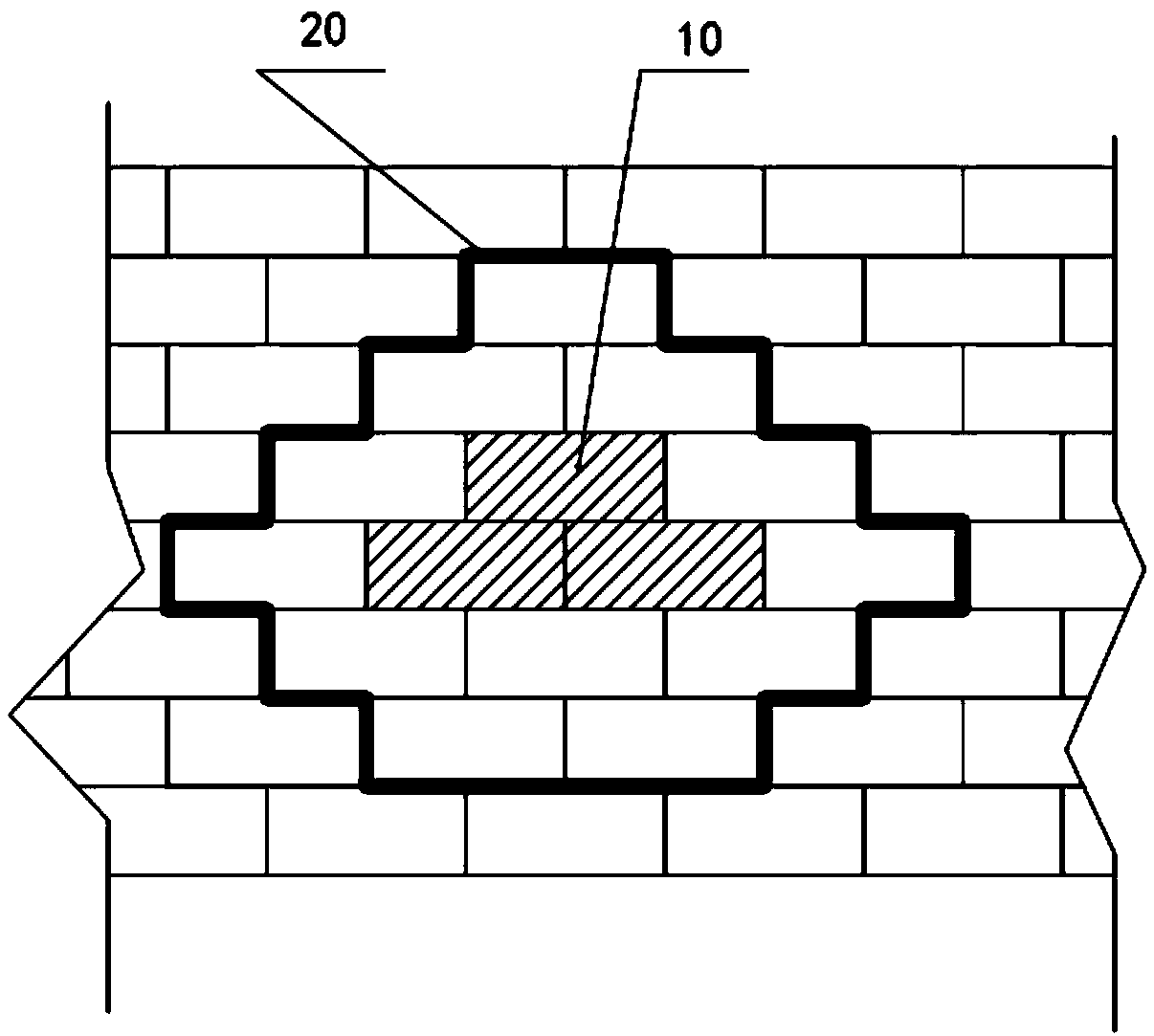

Hollow displacing repairing method of hollow exterior wall tile

The invention discloses a hollow displacing repairing method of a hollow exterior wall tile. The method comprises the following steps of (1), performing hollowness inspection, wherein a hollowness range is determined through hammering by a hollowness hammer and marking an exterior wall surface range to be cut and shoveled by means of a marking pen; (2), cutting and shoving the hollow tile, namelyfirstly cutting the exterior tile edge of the exterior wall surface range which is to be cut and shoveled and is determined in the step (1) by means of a cutting machine, and shoveling the external wall surface by means of a tool chisel until the external wall surface is totally shoveled; (3), cleaning a base layer; (4), performing interface processing, namely applying an interface agent at a shoveled part for reinforcing the base layer and improving bidirectional adhesion; (5), applying a mortar layer and leveling, namely leveling an original white layer or an inorganic mortar layer for a thickness of 3-5mm below the upper surface by means of polymer mortar or inorganic temperature-insulating mortar; (6), performing cracking-resistant reinforcing layer construction, namely hanging a net by means of decorative mortar on a leveling layer, and fixing the net by means of anchor bolts after the net is hung; and (7), mounting surface tiles.

Owner:上海天补科技有限公司

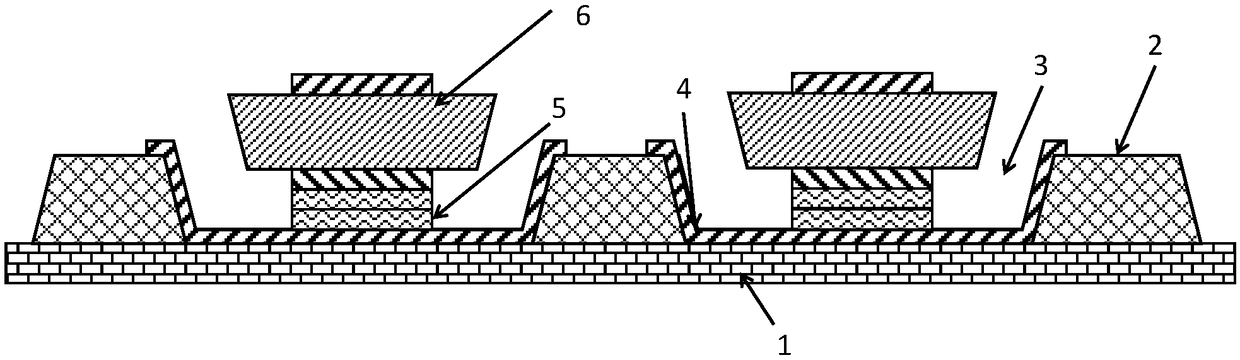

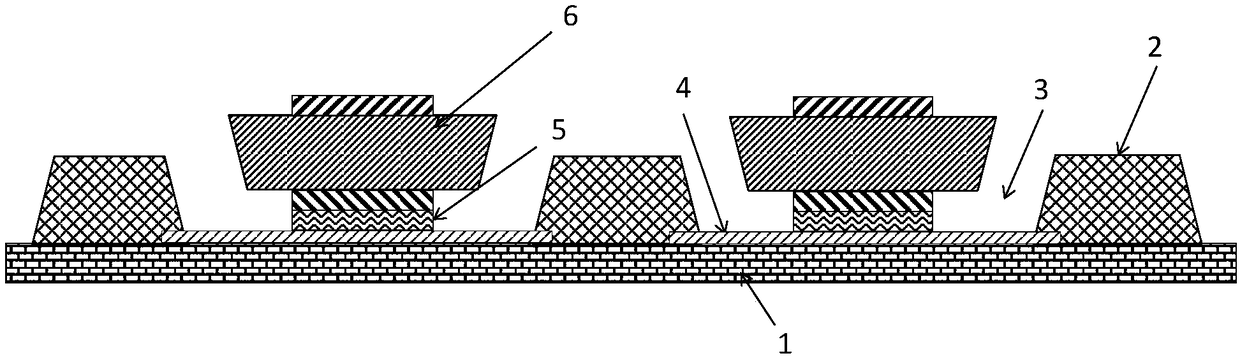

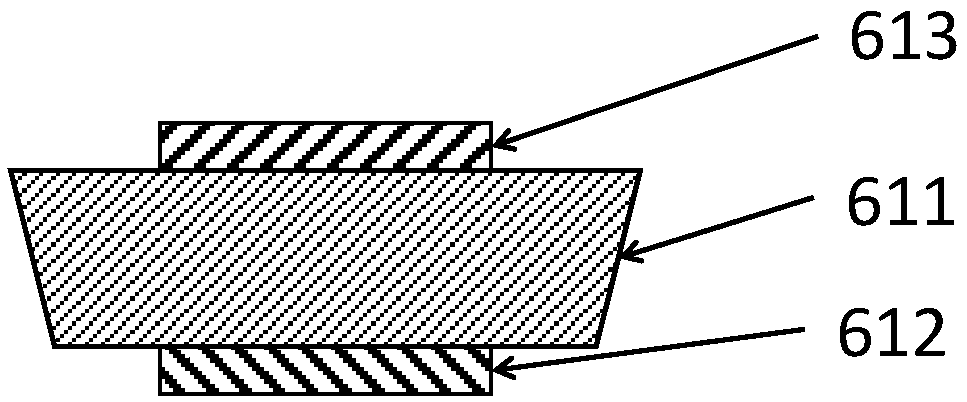

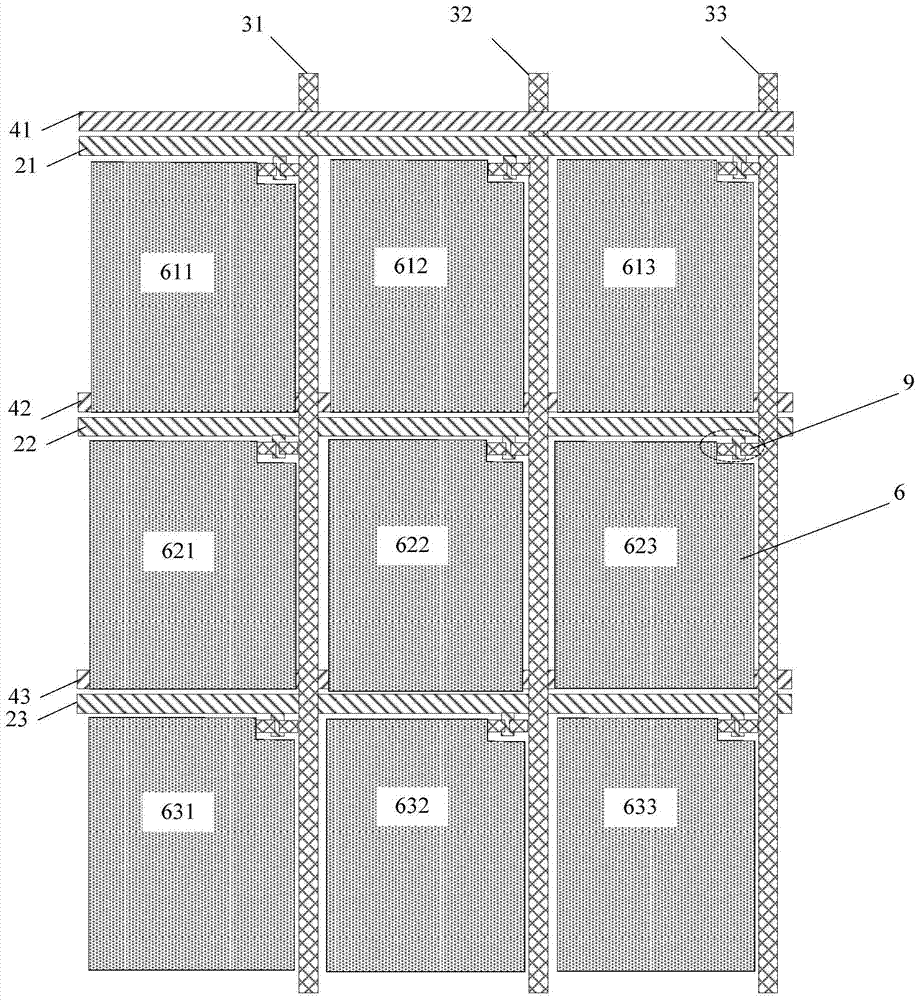

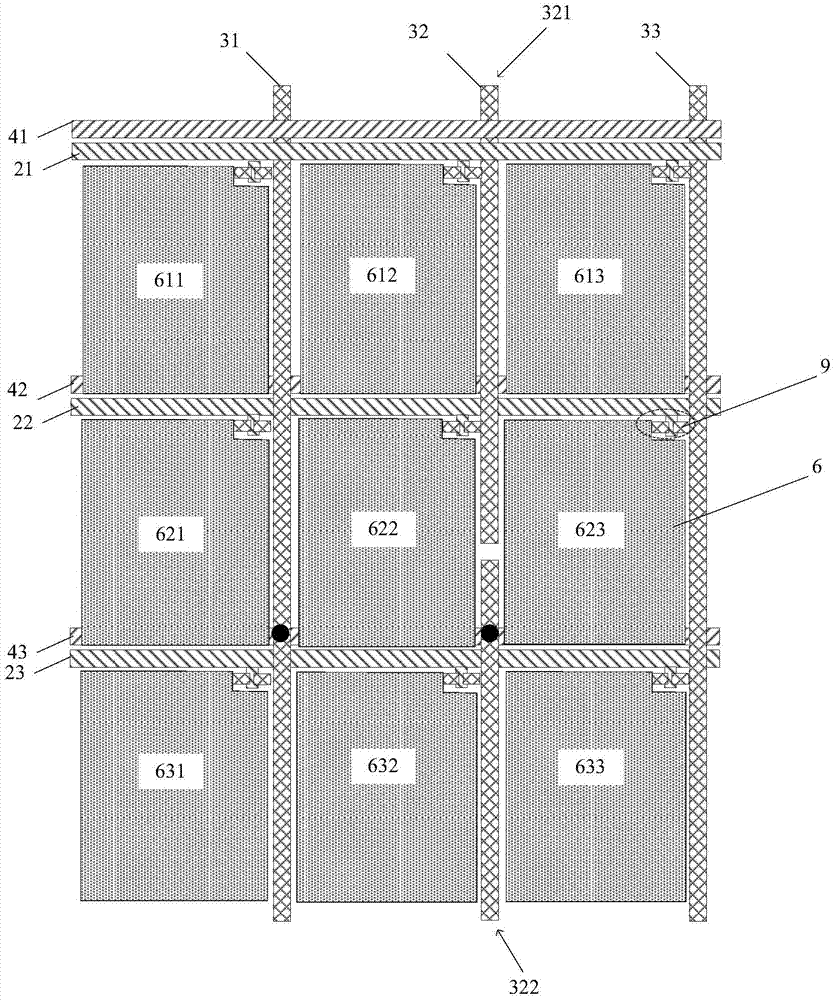

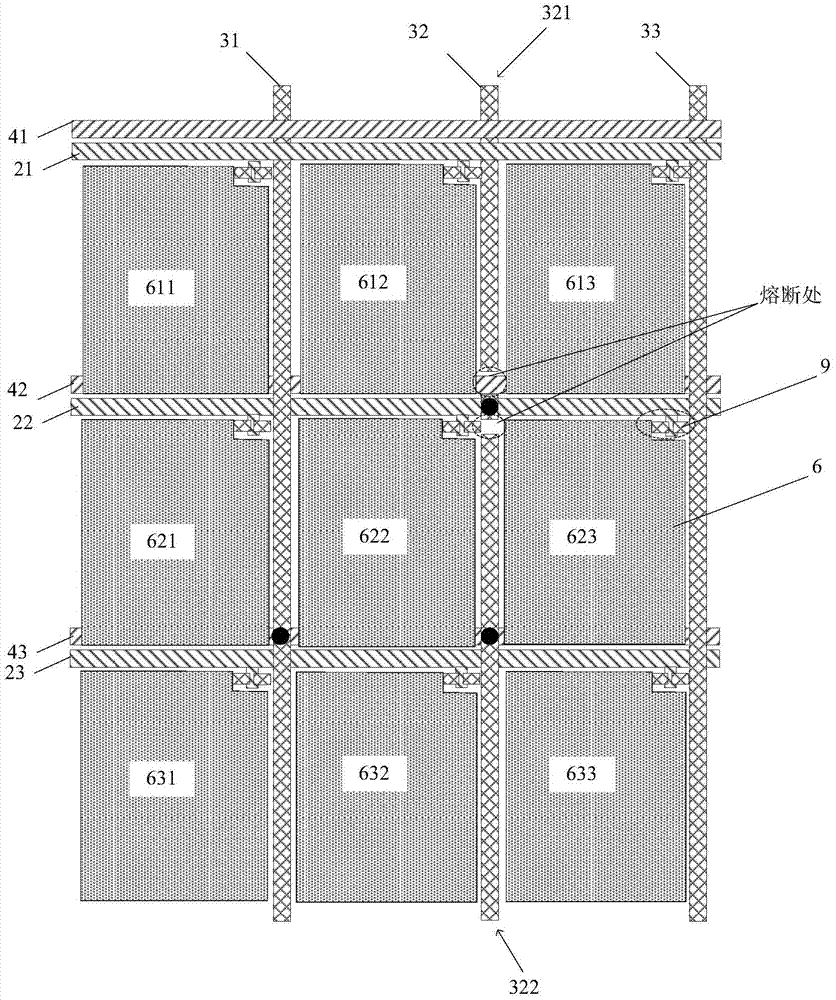

Array substrate and restoration method, test method and manufacture method thereof, and display apparatus

InactiveCN104851404ASimple repair processEasy to implementStatic indicating devicesSolid-state devicesInsulation layerRestoration method

The invention provides an array substrate and a restoration method, test method and manufacture method thereof, and a display apparatus. The array substrate comprises a substrate, a grid wire figure and a data line figure which are formed on the substrate, and a gate insulation layer formed between the grid wire figure and the data line figure, and further comprises a spare line figure formed at the same layer as the grid wire figure. The spare line figure comprises multiple spare lines parallel to grid wires in the grid wire figure, and the spare lines are distributed at positions of multiple rows of pixels which are limited by the grid wire figure and the data line figure and form vertical overlapping areas with data lines in the data line figure. The array substrate and the restoration method thereof, provided by the invention, when the array substrate generates a data line circuit break defect, can rapidly restore the defect. Besides, the restoration process is simple, and the realization is easy.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

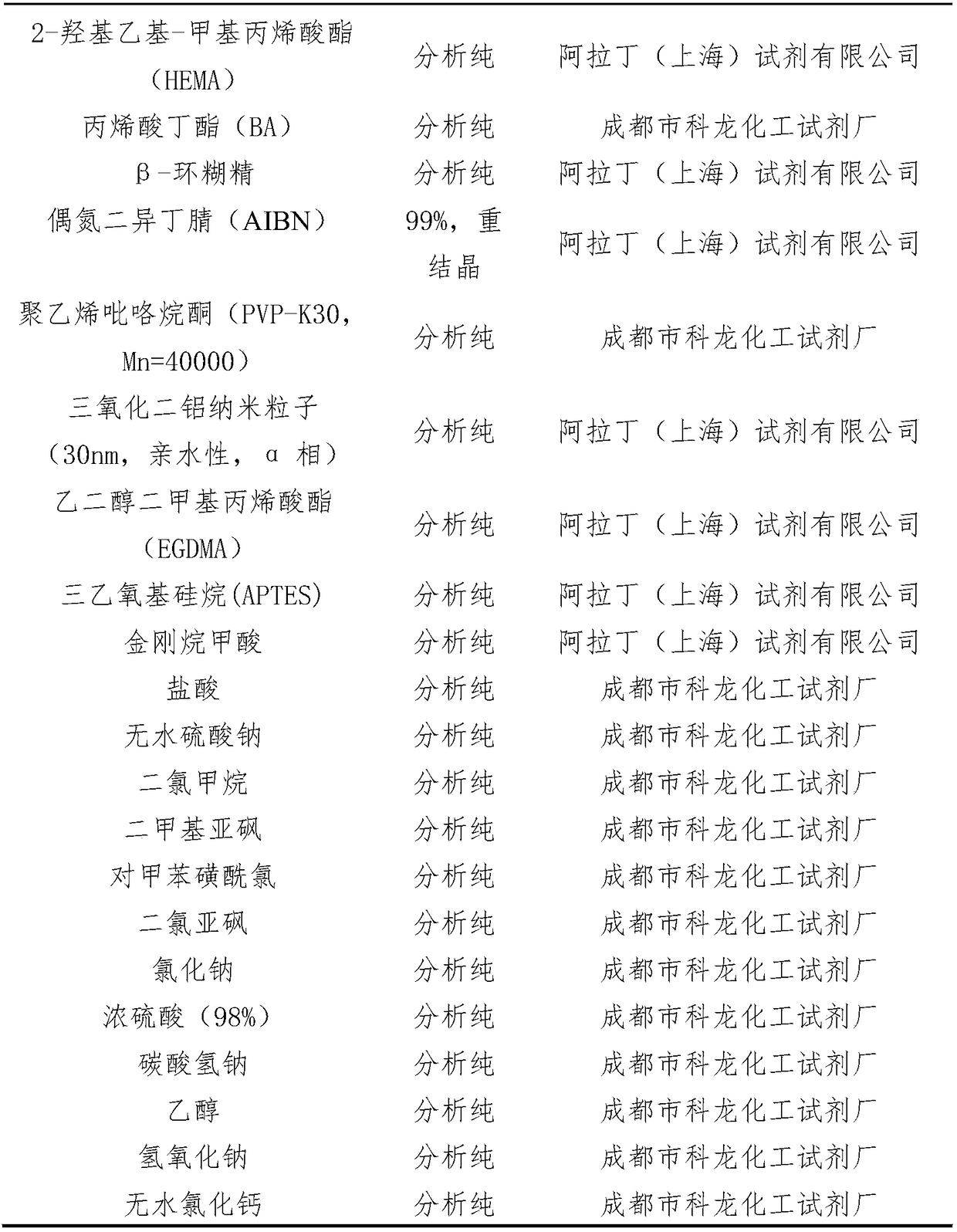

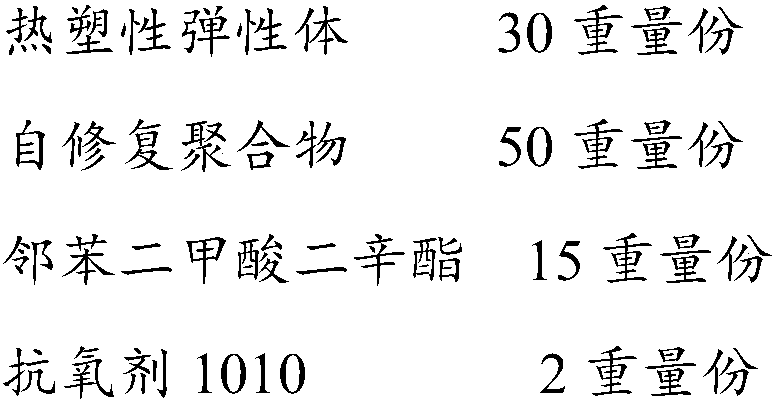

Cable-sheath material with self-repair function, preparation method and cable sheath

ActiveCN108342048AGuaranteed mechanical propertiesGuaranteed electrical performancePlastic/resin/waxes insulatorsElastomerPlasticizer

The invention provides a cable-sheath material with a self-repair function. The cable-sheath material is prepared from the following raw materials in parts by weight: 30 to 100 parts of thermoplasticelastomer, 30 to 70 parts of self-repair polymer, 15 to 35 parts of plasticizer, 1 to 8 parts of stabilizer and 2 to 4 parts of reinforcing agent. The self-repair polymer forms a structure similar toa cross-linking point through adopting a polyacrylate copolymer elastomer as a base material and introducing a host group cyclodextrin and a guest group adamantane into a copolymer system, wherein thecyclodextrin group and the adamantane group can be bound together through such supramolecular acting force of host-guest recognition; such a physical cross-linking point can tend to recombination ina normal-temperature environment; the cross-linking point is regenerated; the damaged position of the material is self-repaired by the regeneration of the cross-linking point, and then, through addingadditives of the plasticizer, the reinforcing agent, the stabilizer, and the like, the mechanical performance and electrical performance of the material are ensured.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

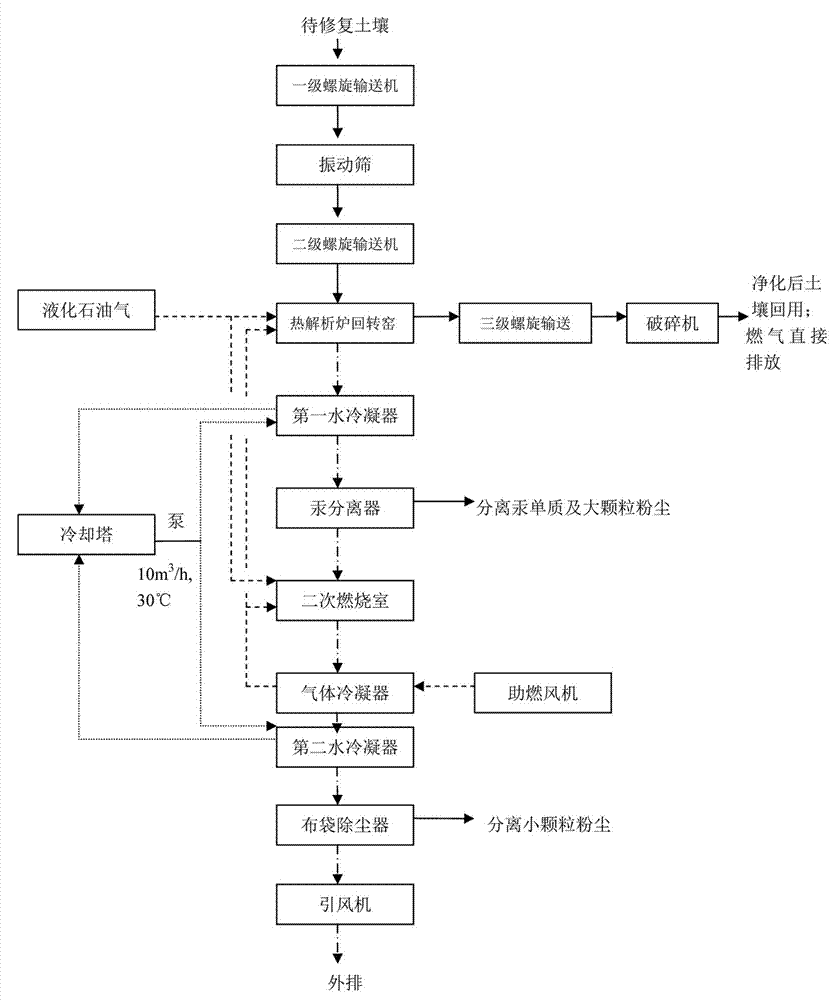

Soil remediation method

ActiveCN102527705BSolve pollutionSimple repair processContaminated soil reclamationSoil remediationExhaust fumes

The invention discloses a soil remediation method, comprising the following steps: (1) conveying to-be-remedied soil to a vibrating screen via a first-level spiral conveyer, conveying the screened soil to a rotary kiln of a thermal desorption furnace via a second-level spiral conveyer to heat and desorb the soil; (2) conveying the roasted soil to a crusher via a third-level spiral conveyer to crush; (3) decreasing the temperature of waste gas from the rotary kiln of the thermal desorption furnace to 280-320 DEG C through a first water condenser; (4) separating dust particles and liquid mercury from the waste gas passing through the first water condenser in a mercury separator; and (5) burning the waste gas from the mercury separator in a secondary combustor, decreasing the temperature of the waste gas to 150-200 DEG C via a gas condenser and a second water condenser, dedusting the gas via a bag-type dust remover and discharging the dedusted gas through a draught fan. The soil remediation method disclosed by the invention has the advantages that: the soil pollution problem can be well solved; the remedied soil can be directly used; in addition, the remediation process is simple andpracticable, and the cost is low.

Owner:广州市金龙峰环保设备工程股份有限公司 +1

Flywheel crack repair method

ActiveCN104162761AStrength Improvement and EnhancementImproved and increased shear strengthMolten stateAlloy

The invention discloses a flywheel crack repair method. The flywheel crack repair method includes the following steps of firstly, conducting grinding in the direction of a crack with the crack as the center to form a groove, and conducting milling at certain intervals in the direction perpendicular to the groove to form a plurality of ditch grooves, wherein the depth of the ditch grooves is larger than or equal to one third of the depth of the groove; secondly, drilling through holes with the starting point and the ending point of the crack as the circle centers; thirdly, conducing bead welding in the ditch grooves through stainless steel electrodes, wherein the height of bead welding ranges from one half to two thirds of the depth of the ditch grooves; fourthly, preheating a flywheel to the temperature of 600 DEG C to 800 DEG C, pouring molten-state nickel-cobalt- molybdenum-manganese-base alloy into the rest of the space of the through hole and the rest of the space of the groove, and conducting cooling at the room temperature; fifthly, machining and removing the redundant dead welding material and the redundant pouring material till the size is qualified. The flywheel crack repair method is simple in repair process and good in repair effect; the repaired flywheel is long in service life, and the flywheel crack repair method is suitable for repairing the crack of the flywheel in batches.

Owner:青岛海之冠汽车配件制造有限公司

A method for repairing shrinkage cavities in car topcoat

ActiveCN102284409ADoes not affect appearanceLower level requirementsPretreated surfacesSpecial surfacesVarnishRepair method

The invention relates to a method for repairing the finish paint defects of a car, in particular to a method for repairing a finish paint shrinkage cavity of the car, which comprises the steps that: a. the shrinkage cavity is cleaned; b. varnish is injected into and fully fills a concave hole of the shrinkage cavity; c. the shrinkage cavity is dried and cured; d. after a paint film is cured, the shrinkage cavity is ground by sandpaper; and e. the shrinkage cavity is polished. Because the scheme is adopted, pits of the shrinkage cavity are fully eliminated, the repaired shrinkage cavity appears the color of the original paint which is consistent with that of the paint of other parts due to the transparency of the varnish, so that color difference is avoided, the appearance effect of the finish paint is not affected, the repairing procedures are simpler, the requirement on the level of an operator is not high, manpower and material cost is saved, and the working efficiency is improved.

Owner:CHERY AUTOMOBILE CO LTD

Stainless steel surface repairing technology and repairing paint

InactiveCN106622904AIncrease usageImprove appearance qualityAnti-corrosive paintsSpecial surfacesSilver pasteProcess specification

The invention discloses a stainless steel surface repairing technology and repairing paint and relates to the field of coatings and metal surface repairing. According to the technical scheme, the stainless steel surface repairing technology includes the following steps that firstly, a to-be-repaired part is ground till the surface is flat according to a conventional process specification, and conventional cleaning is conducted; secondly, paint is prepared, and the raw materials of the paint include, by mass, 31.0-42.0 parts of plated silver resin, 2.0-4.0 parts of aluminum silver paste, 0.28-0.5 part of a silver powder arranging agent, 1.0-3.0 parts of an adhesive force accelerator, 1.2-2.5 parts of an anti-scratching agent, 0.1-0.8 part of a leveling agent and 53.0-59.0 parts of a solvent; and thirdly, the paint obtained in the second step is evenly sprayed to the to-be-repaired part treated in the first step. The stainless steel surface repairing technology and the repairing paint has the beneficial effects that the technology is simple, operation is flexible, the hardness of a paint film is high, the scratching resisting performance is high, the adhesion force is good, the color of the paint is highly similar to that of a stainless steel machine shell, and environment-friendly safety is high.

Owner:石家庄国祥运输设备有限公司 +1

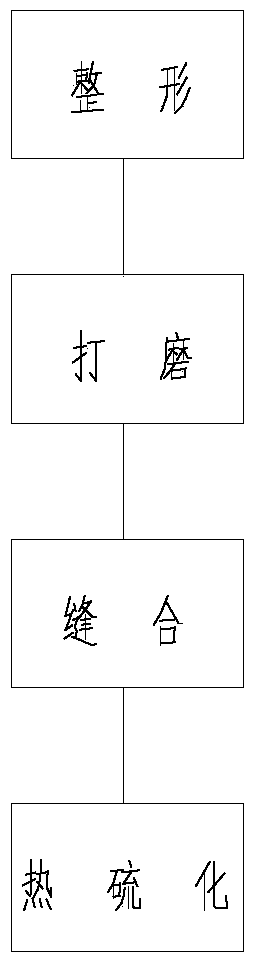

Method for repairing mechanical damage of radial tire

The invention provides a method for repairing mechanical damage of a radial tire, relates to the technical field of tire repair, and aims to solve the problems that a patch is easy to flake off, which causes second damage to the broken part, multiple repair steps and long repair time in the conventional repair technology. The method comprises the following steps: 1) shaping treatment is performed on the broken part so as to from a rectangular digging opening; 2) polishing treatment is performed on the broken part so as to enable the new rubber of a tire to be exposed completely, meanwhile, the line layer structure of the tire is not exposed; 3) stitching treatment is performed on the broken part, stitching is started from one corner of the digging opening, and threads are arranged in a cross manner up and down within a polishing range, and vertically arranged in the direction from the inner side of the tire to the outer side of the tire; 4) rubber hot vulcanization treatment is performed, a vulcanizing agent and raw rubber repaired newly are adopted for performing extrusion heat vulcanization treatment in a vulcanizing machine. According to the invention, the reinforcement of the interior of the broken part and rubber hot vulcanization treatment are combined, and reinforcement and vulcanization treatment are completed at one step, so that a patch inside the repaired tire is solid and firm, and is less susceptible to flaking, the repair process is simplified greatly, the repair efficiency is high, and the using effect is excellent.

Owner:SHIJIAZHUANG DENAIFU TECH

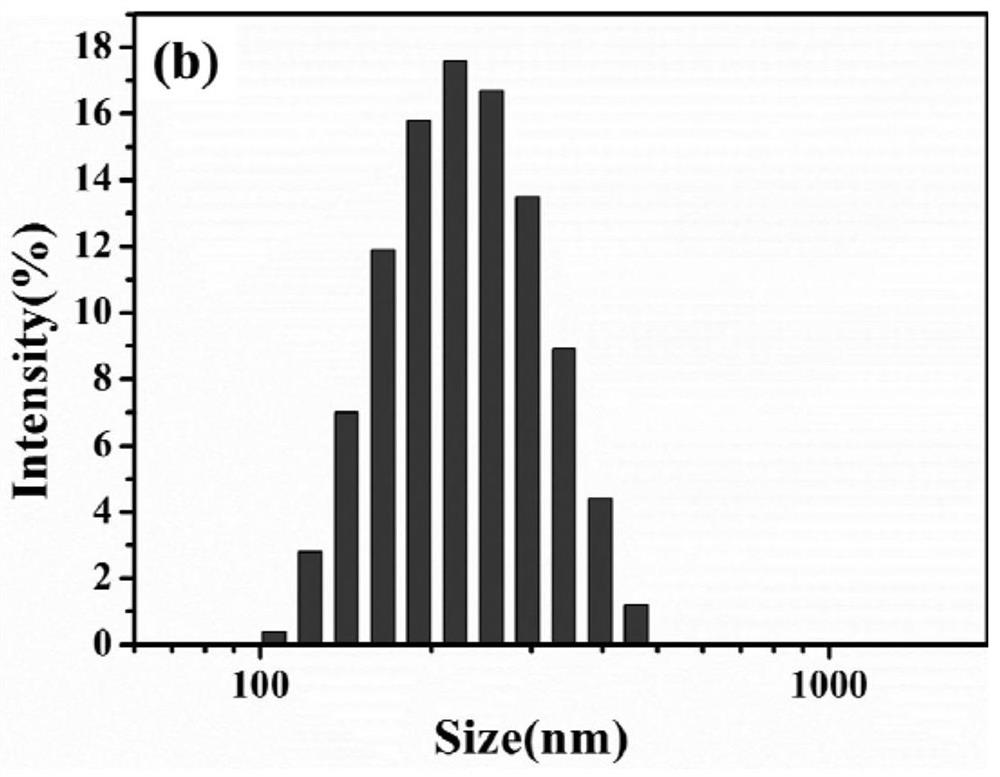

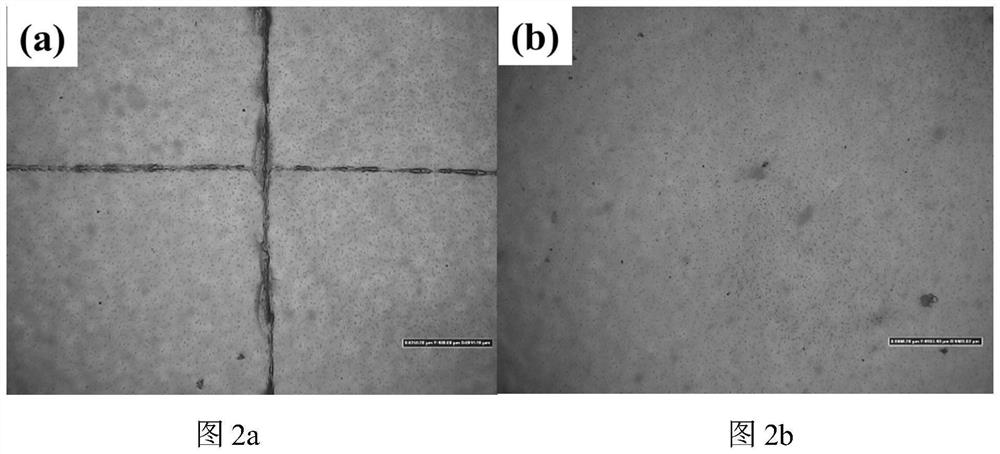

Preparation method of photoresponseive cellulose nanocrystalline/fluorine-containing polyacrylate self-repairing material

The invention discloses a p photoresponseive cellulose nanocrystalline / fluorine-containing polyacrylate self-repairing material. A preparation method specifically comprises the following steps: step 1, preparing a Pickering emulsion; wherein uniformly mixing photoresponsive amphiphilic block copolymer graft-modified cellulose nanocrystalline, water and a mixed monomer according to a mass ratio of(0.01-0.03): (2-60): (1-3) to obtain the Pickering emulsion; and 2, preparing the photoresponsive cellulose nanocrystalline / fluorine-containing polyacrylate composite emulsion. The photoresponsive cellulose nanocrystalline / fluorine-containing polyacrylate self-repairing material disclosed by the invention has the characteristic of self-repairing.

Owner:SHAANXI UNIV OF SCI & TECH

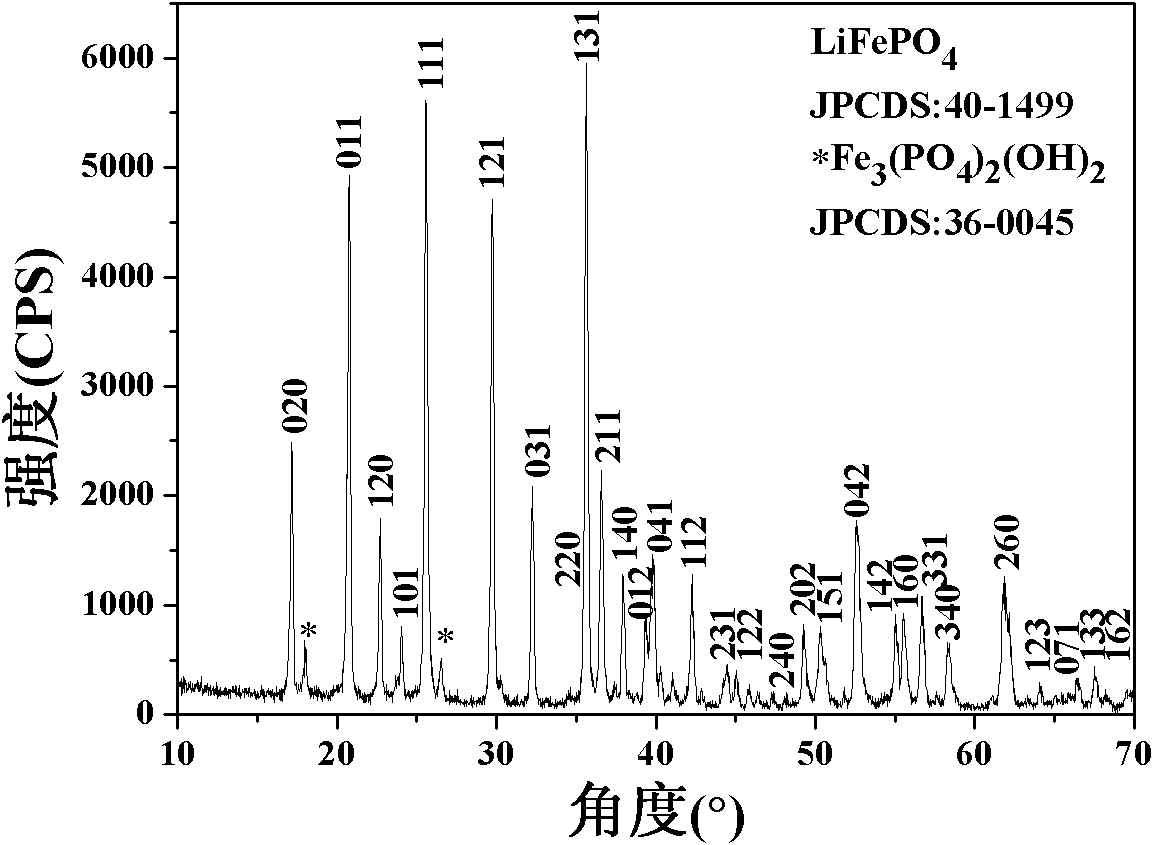

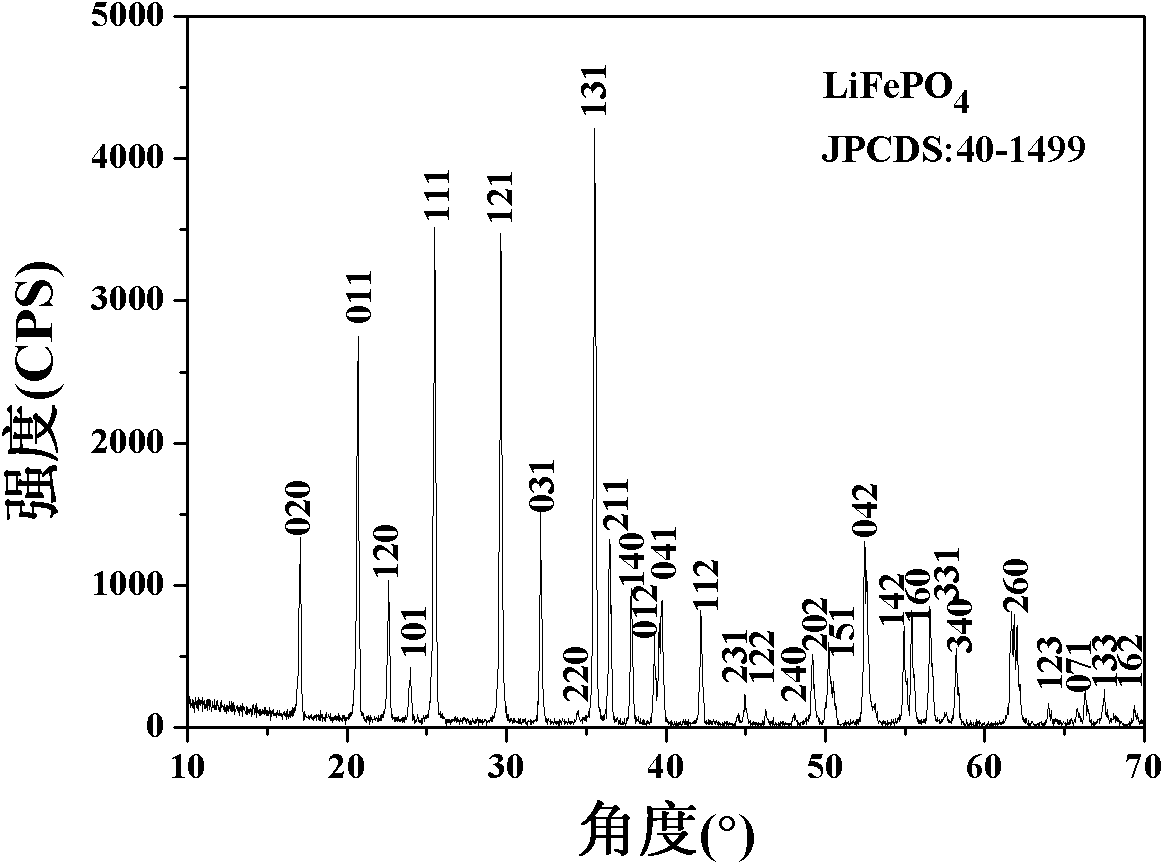

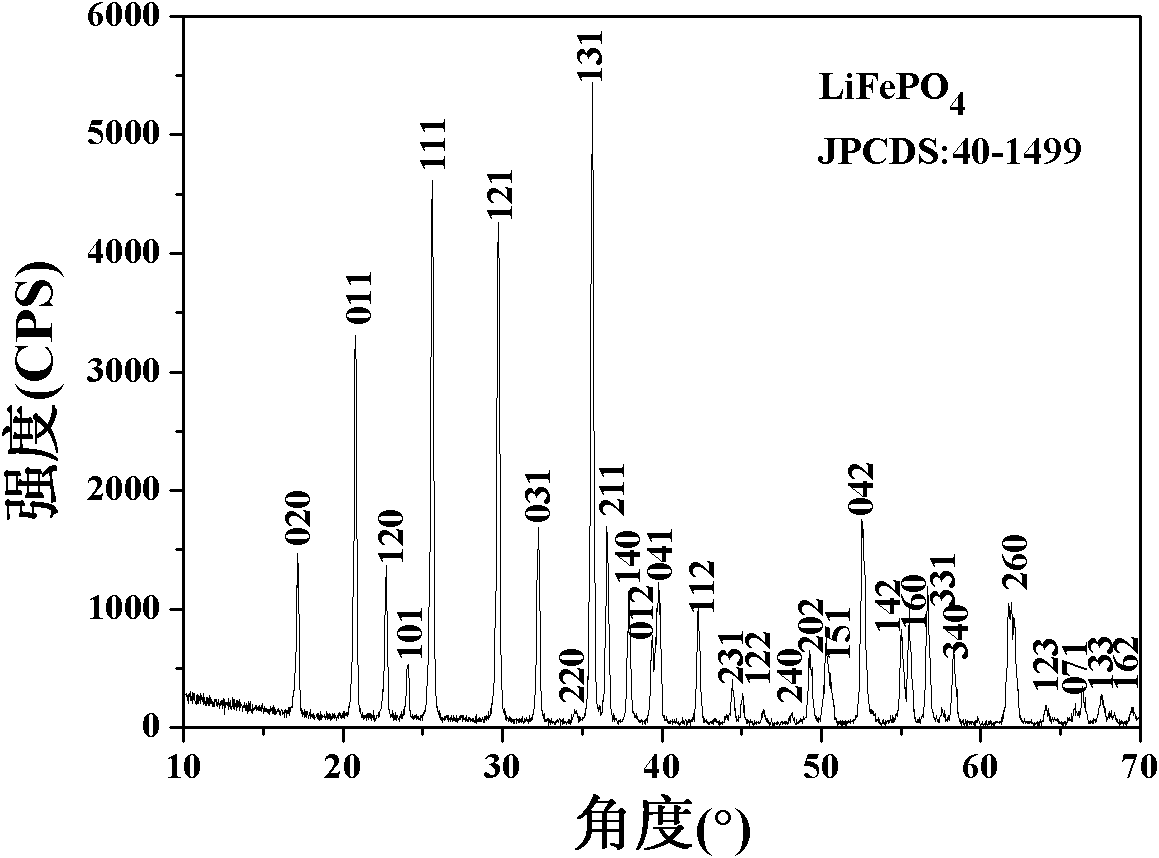

Method for repair and regeneration of waste lithium iron phosphate battery cathode material

ActiveCN102208707BComparative Electrochemical PerformanceReduce pollutionSolid waste disposalWaste accumulators reclaimingLithium iron phosphateEngineering

The invention discloses a method for repair and regeneration of waste lithium iron phosphate battery cathode materials, which allows a lithium-source solution or a suspension to react with a recovered waste lithium iron phosphate battery material by a hydrothermal reaction or a solvent-thermal reaction, or allows the recovered waste lithium iron phosphate battery material to be processed by solid-phase ball-milling and calcination with the lithium source, performs liquid-phase or solid-phase direct lithium-supplementing repair of delithiated waste lithium iron phosphate, and then performs pertinent repair and regeneration by coating conductive agents or coating conductive agents and doping metal ions. The invention adopts a direct repair and regeneration method; the repaired waste lithium iron phosphate battery cathode material has excellent performance, and the specific capacity can reach above 90% of the specific capacity before discard; the method not only can effectively reduce environmental pollution of waste batteries, but also can make full use of waste resources and changes waste into valuables.

Owner:HEFEI UNIV OF TECH

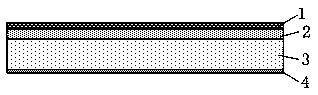

Conveyor belt wear repair treatment structure and repair treatment method

PendingCN109849381ALess material investmentSmall footprintBeltsEthylene-propylene-diene-monomerRepair material

The invention discloses a conveyor belt wear repair treatment structure and a repair treatment method. The repair treatment structure is a layered structure, and comprises an outer protective film layer, an ultra-high molecular weight polyethylene outer layer and an ethylene-propylene-diene monomer bottom layer from outside to inside in sequence. The repair treatment method adopts a local cold repairing mode, and comprises the following steps: a, cleaning and drying the position and the periphery to be repaired of a conveyor belt; b, cutting off surface rubber at a damaged position along the edge of the damaged position of the conveyor belt; c, roughening the cut edge, and cleaning; d, accurately cutting a repairing material according to the cutting size and thickness, roughening, and cleaning; and e, coating the surface required to be repaired of the conveyor belt and the bottom surface of the ethylene-propylene-diene monomer bottom layer of the repairing material with a cold repairing adhesive, and fitting and compacting the surface required to be repaired of the conveyor belt and the bottom surface of the ethylene-propylene-diene monomer bottom layer of the repairing material. According to the conveyor belt wear repair treatment structure and the repair treatment method, the problems, such as wear, scratches, breakage, overlapped part cracking and the like, of the conveyor belt can be effectively solved; and the conveyor belt wear repair treatment structure and the repair treatment method has the characteristic of quick repair on site.

Owner:蓝色海洋(天津)工程技术有限公司

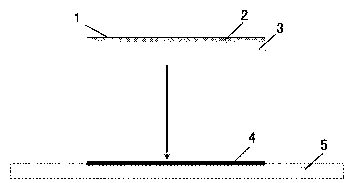

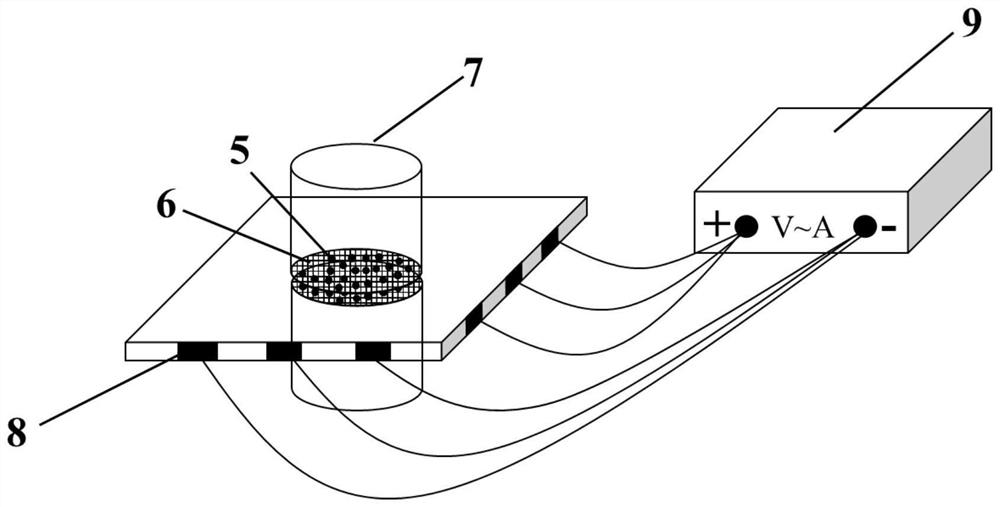

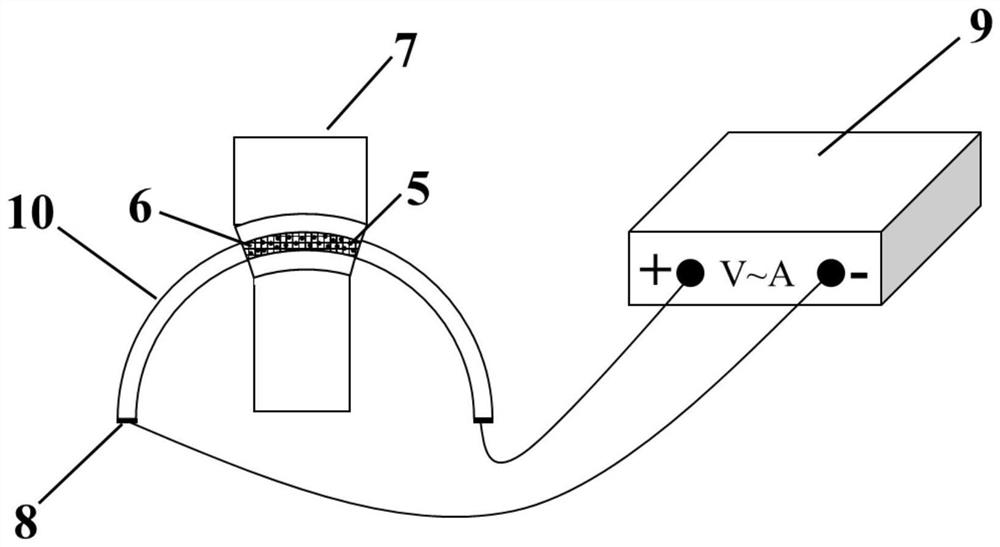

Device and method for repairing layering damage of carbon fiber reinforced thermosetting resin-based composite material

The invention discloses a device and method for repairing layering damage of a carbon fiber reinforced thermosetting resin-based composite material. The repairing device comprises an electrode, a pressure head assembly and an external power source, wherein the pressure head assembly clamps to-be-repaired carbon fiber reinforced thermosetting resin matrix composite components up and down in the pressure head assembly, the pressure head assembly can adjust the pressure according to different working conditions under the synergistic effect of a built-in power source and a pressure sensor, and the external power supply can adjust current parameters according to carbon fiber reinforced thermosetting resin matrix composite components with different sizes and material components under the synergistic effect of the built-in power supply and a transformer. According to the device and method, the layering damage of the repaired composite material components is not expanded, the performance can be recovered to 80%-90% of that before the damage, the actual maintenance requirement is met, the repairing period is greatly shortened, component replacement type maintenance is changed into repairing type maintenance, and the maintenance cost is greatly saved.

Owner:TONGJI UNIV

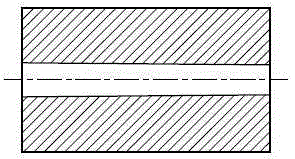

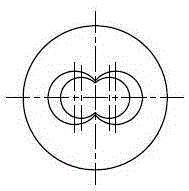

Preparation method for high-wear-resistance and repairable conical double cylinders

The invention discloses a preparation method for high-wear-resistance and repairable conical double cylinders. The preparation method comprises the following steps: carrying out boring machining on a round steel forged piece to form conical double cylinder blanks with inner holes which are two intersected circles and with cross sections which are splayed rings respectively; machining common steel into mandrels having the same conicity as the conicity of the inner holes of the cylinders, spraying and welding a low-melting-point alloy wear-resistant layer on the surfaces of the two mandrels respectively, sleeving the conical double cylinder mandrels in the holes of the cylinder blanks, and compacting to form cylinder assemblies; placing the cylinder assemblies in a vacuum furnace and carrying out heating treatment; and removing redundant mandrel materials on a large head and a small head of each assembly through turning machining, carrying out boring machining on the cylinders, and removing the mandrel materials inlaid in the holes of the cylinders. The preparation method disclosed by the invention solves the problem that the conical double cylinders are difficult to realize centrifugal compound casting, the alloy wear-resistant layers and the inner holes of the conical holes realize metallurgical bonding in a vacuum sintering state, the bonding strength of the metallurgical bonding is higher than that of inlaying hard alloy materials, and the wear-resistant layers cannot fall off during a use process; and moreover, the production efficiency of an extruder is increased, the replacement cost is saved, and the economic benefits are improved.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

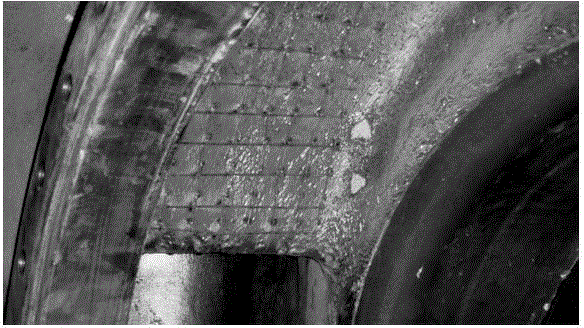

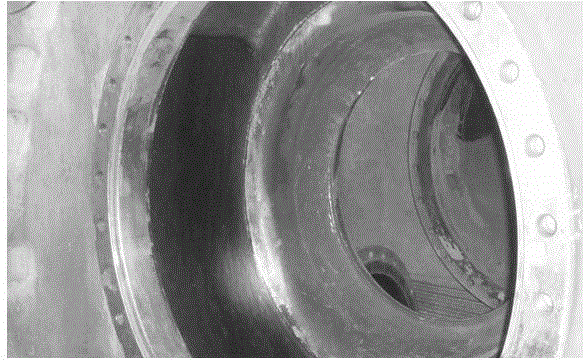

Full-repairing technology for housing of desulphurization circulating pump

The invention discloses a full-repairing technology for a housing of a desulphurization circulating pump. The full-repairing technology comprises the following steps: performing welding framework processing on a worn and corroded pump housing; performing sand-blast machining on a pump body flow-passing surface and a welding framework; performing chemical cleaning under the conditions of wind prevention, dust prevention, and room temperature or normal temperature; polishing the circulating pump, and then coating the circulating pump with an abrasion-resistant and anti-corrosive material and the like. According to the full-repairing technology provided by the invention, after being repaired by adopting the full-repairing technology, the circulating pump can be continuously operated for 4000 hours or more, the housing of the circulating pump repaired by adopting the technology is intact integrally and an abrasion-resistant and anti-corrosive layer is prevented from peeling, cracking and the like, parts, easy to abrade, at an impeller ring, an impeller outlet and the like are free of obvious abrasion traces, the effect superior than expected effect is achieved, the service life of the pump housing is preliminarily estimated to be more than two years. The repairing technology is simple, and excellent in controllability.

Owner:XIANGTAN JIEXI ENVIRONMENT TECH CO LTD

Preparation method of anti-wear easy-to-repair super-hydrophobic coating

ActiveCN104672995AWear-resistantImprove wear resistanceConjugated diene hydrocarbon coatingsPretreated surfacesEpoxyDiethylenetriamine

The invention discloses a preparation method of an anti-wear easy-to-repair super-hydrophobic coating. The preparation method comprises the following steps: 1, mixing butadiene styrene rubber powder, epoxy resin E-44, ethyl acetate and diethylenetriamine in a certain proportion, spraying on a substrate and curing at 20 DEG C; and 2, uniformly mixing epoxy resin E-44, ethyl acetate, diethylenetriamine and amino silicon oil and spraying on a coating obtained in the step 1 and curing at 20 DEG C to obtain the super-hydrophobic coating. According to the technical scheme, the preparation method has the advantages as follows: 1) the prepared coating has a wide application range and can be applied to glass, metal, wooden and ceramic substrates; 2) the prepared coating has an anti-wear property; 3) the prepared coating is easy to repair and the original super-hydrophobic property can be recovered through a simple spraying process after the coating is worn; 4) the production process can be implemented in a 20 DEG C temperature environment rather than a high temperature environment and therefore the production process has low requirement on the environment; and 5) the process is simple, the production cost is low, curing can be carried out at room temperature, and the production process can be used for processing the surface of a large-area and special-shaped test piece and can be applicable to outdoor construction.

Owner:山东天汇防水股份有限公司

Ceramic product material

The invention discloses a ceramic product material which comprises the following components by weight: 1-2.1 parts of carbon nanotubes, 12-18 parts of aluminium powder with a particle size of 5-8 um, 90-100 parts of kaolin powder with a particle size of 3-4 um, 10-15 parts of limestone, 2.5-5 parts of nanometer ZrO2, 30-40 parts of nanometer TiC, 0.5-4 parts of nanometer BN, and 1-4 parts of nanometer B4C.

Owner:广东非凡实业有限公司

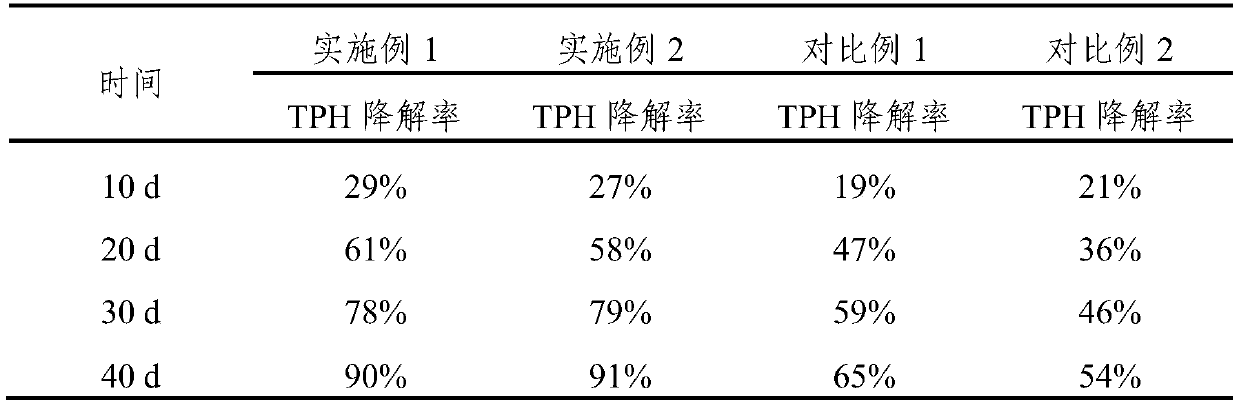

Complex microbial inoculant for petroleum hydrocarbon and benzene series treatment as well as preparation method and application thereof

The invention relates to the field of biotechnology and environmental protection, in particular to a microbial inoculant, and particularly relates to a complex microbial inoculant for petroleum hydrocarbon and benzene series treatment as well as a preparation method and application thereof. The active ingredients of the complex microbial inoculant comprise aspergillus oryzae, streptomyces, pseudomonas putida, pseudomonas alcaligenes, brevibacterium epidermidis and Erwinia; and the complex microbial inoculant is especially suitable for treating soil polluted by petroleum hydrocarbon and benzeneseries. After the complex microbial inoculant disclosed by the invention is added into the soil polluted by the petroleum hydrocarbon and benzene series, indigenous degrading flora can be rapidly propagated, and the remediation process can be rapidly started; in the repairing process, the indigenous degrading bacteria are always in the dominant flora status, and high degradation efficiency is kept for a long time through the synergistic cooperation of the flora in the complex microbial inoculant; and finally, the polluted soil is completely repaired, the degradation rate of petroleum hydrocarbon and benzene series is high, and the removal rate of BTEX and TPH can reach 98% or above.

Owner:BEIJING GUOHUAN TSINGHUA ENVIRONMENT ENG DESIGN & RES INST CO LTD BEIJING CHINA

Method for repairing secondary fiber or recycled fiber keratinization

The invention discloses a method for repairing secondary fiber or recycled fiber keratinization.The secondary fiber or the recycled fiber is added into an alkali urine solution which has been pre-cooled to a low temperature, then a regeneration liquid is added to reconstitute the fiber hydrogen bond network and repair keratinization, filtered, repeatedly washed to be neutral, so that a fiber pulpis obtained.The repairing method breaks through atraditional partial repairing method, such as pulping, chemical additives, physical grading and mixing, and the like, and has advantages of simplein repair process, mild in condition and thorough in repair. Water retention value after secondary / recycled fiber repair with different reuse times can reach 131.01%-145.57%,which is equivalent to or slightly higher than that of primary fiber, corresponding to having carrying outreversal repair of the keratinization of the secondary fiber or the recycled fiber, so that the process can prolong life cycle of the secondary fiber or the recycled fiber, providing a brand-new technique for pulpand papermaking technology to improve the water retention value of the secondary fiber or the recycled fiber.

Owner:KUNMING UNIV OF SCI & TECH

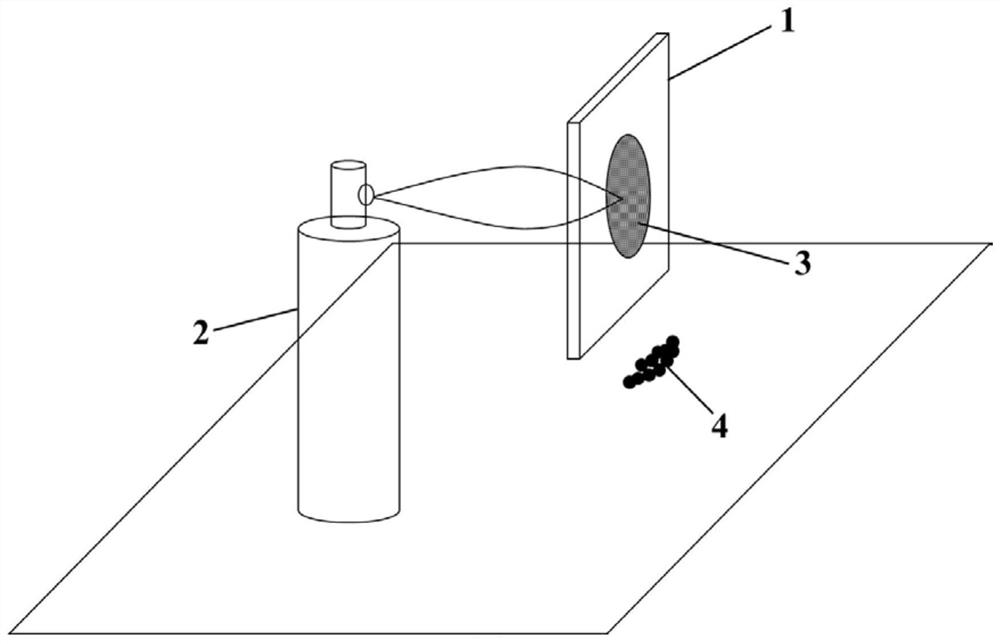

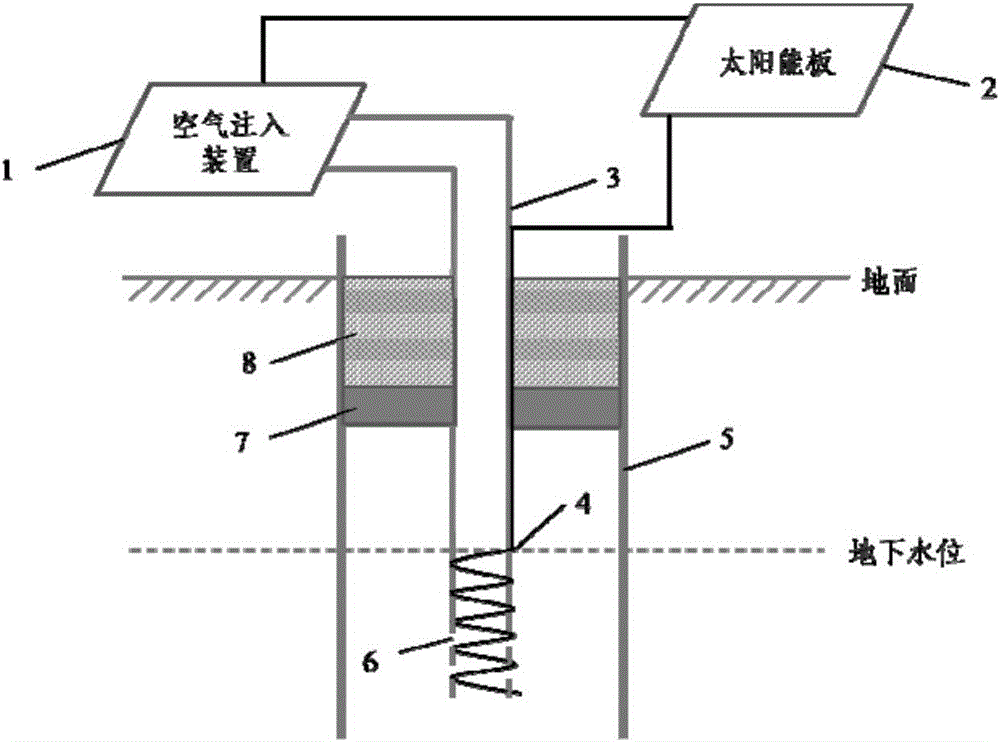

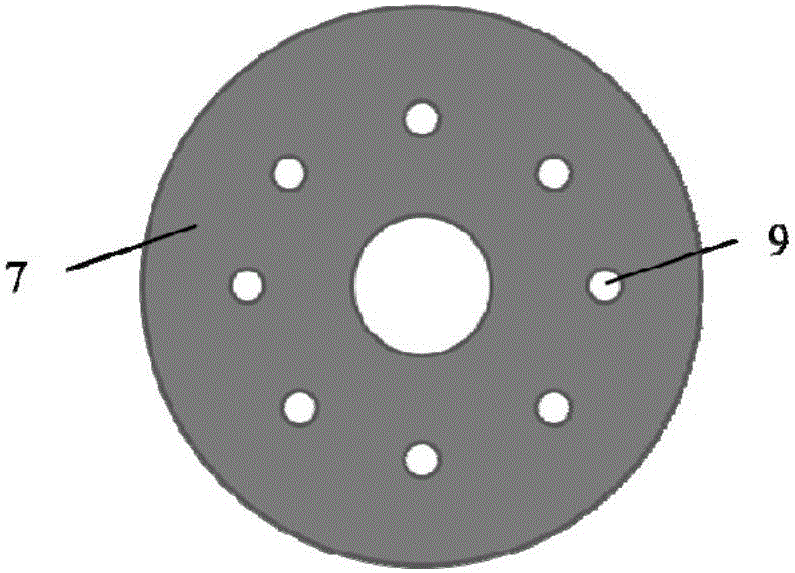

Repairing device and method for pollution of underground water volatile organic matters

InactiveCN106277113AAvoid consumptionSolve pollutionWater contaminantsDispersed particle separationElectrical resistance and conductanceEngineering

The invention provides a passive repairing device for pollution of underground water volatile organic matters. A solar panel is arranged on the ground and is used for converting solar energy into electric energy which is used as power of an air injection device and a power supply for heating a resistance wire; the air injection device is arranged on the ground, is connected with an air injection pipe and is used for injecting air into underground water; the air injection pipe is located at a central position of an underground water well; a sieve hole is formed in a pipe wall of the tail end of the air injection pipe; the resistance wire is wound at the outer part of the tail end of the air injection pipe located below an underground water level; one end of the resistance wire is connected with a solar panel output power supply and the other end of the resistance wire is connected with the air injection pipe; an adsorption material filling separation plate is arranged under the ground and in the underground water well; a through hole is formed in the adsorption material filling separation plate; an adsorption material is charged above the adsorption material filling separation plate. The invention further discloses a repairing method for the pollution of the underground water volatile organic matters by utilizing the repairing device. According to the passive repairing device and the repairing method, a whole repairing process is simple and the adsorption material is easy to replace; the operation is flexible and the cost is low.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

A kind of heavy metal polluted soil remediation method

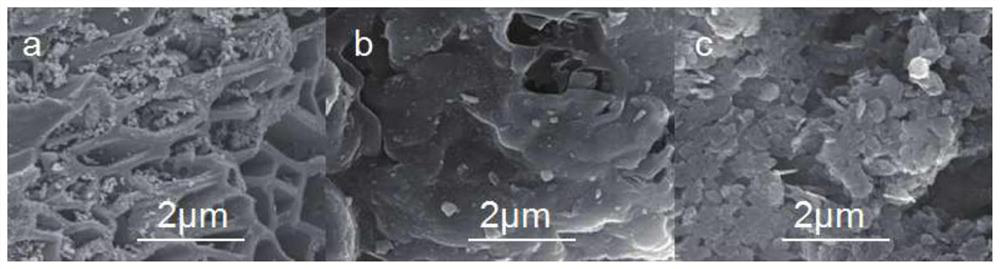

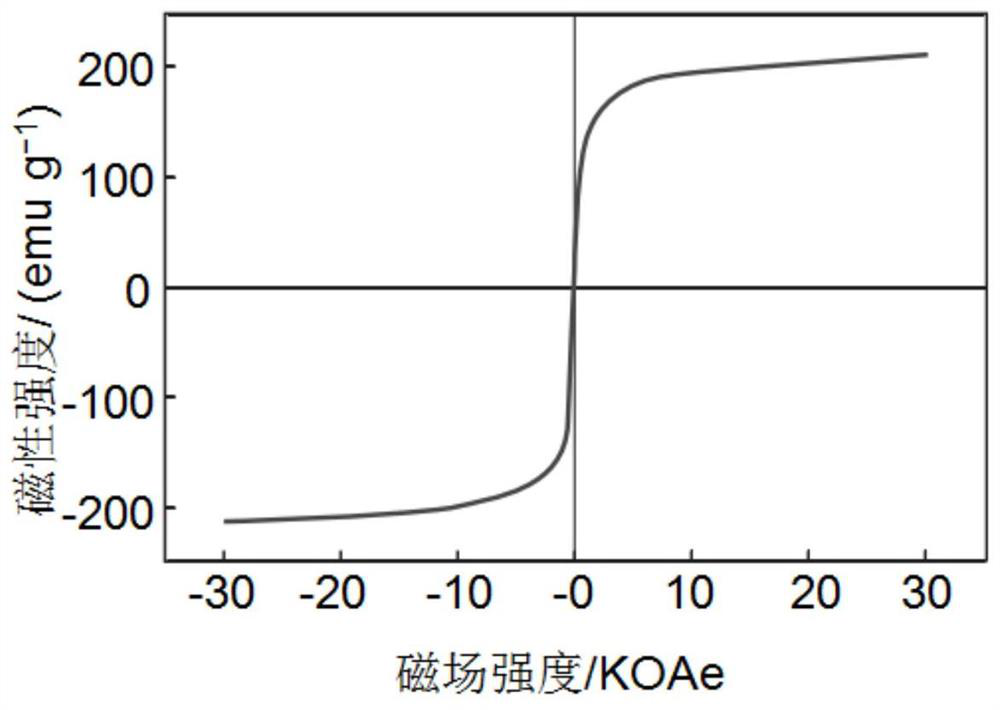

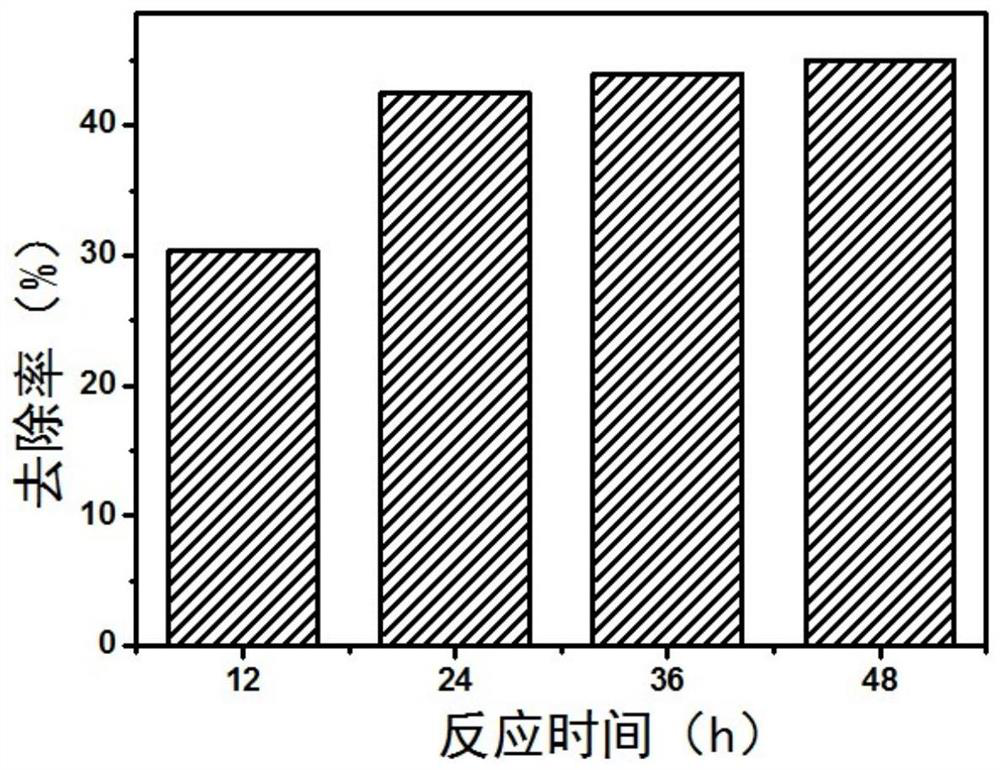

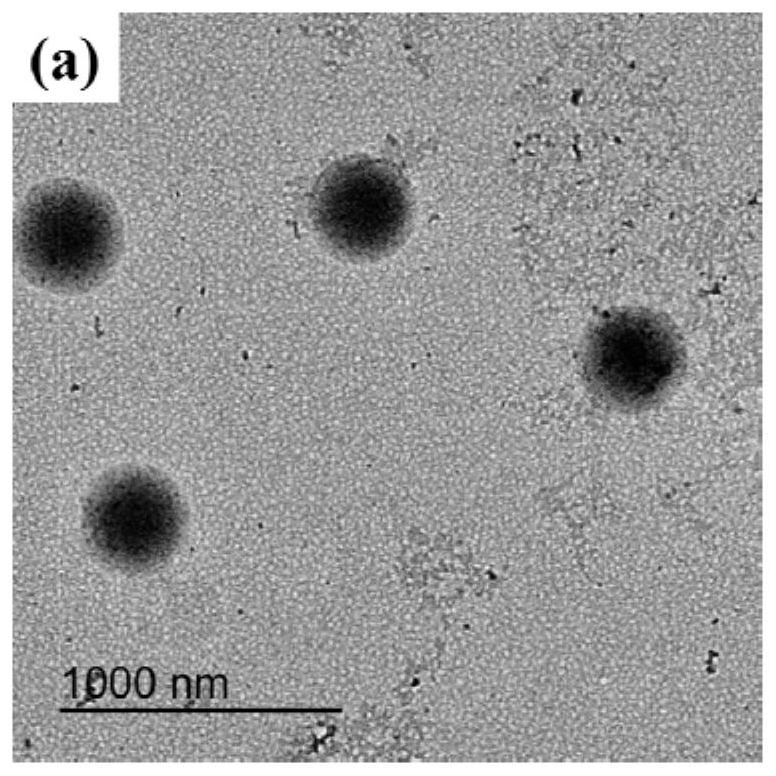

InactiveCN111570494BLoose structureLarge specific surface areaContaminated soil reclamationSoil scienceEnvironmental engineering

The invention discloses a method for remediating heavy metal polluted soil, which comprises the following steps: water is poured into the soil, and then 0.5-2% of modified magnetic biochar is put into the soil according to the mass of the soil, and the modified magnetic biochar is fully stirred evenly to make the modified magnetic biochar and soil It is in a mixed state of mud and water. After standing still, add water and stir to make the modified magnetic biochar float out of the water, and then recover the magnetic biochar enriched in free Cd and soil clay particles, so as to achieve the purpose of reducing the total Cd in the soil. With the help of the magnetic and floating properties of the modified magnetic biochar, the invention enriches free Cd and soil particles with high Cd concentration, reduces the amount of Cd in the soil, and at the same time, the application of the modified magnetic biochar can also improve the soil . The modified magnetic biochar prepared by the invention has the ability to float, can be recovered by magnetic force, has simple restoration process, strong operability, and is green and environment-friendly, and is an environment-friendly restoration technology.

Owner:山东省鲁南地质工程勘察院(山东省地质矿产勘查开发局第二地质大队)

Preparation method of photoresponse self-repairing fluorine-containing polyacrylate soap-free emulsion

The invention discloses a preparation method of a photoresponse self-repairing fluorine-containing polyacrylate soap-free emulsion. The preparation method comprises the following steps: step 1, synthesizing a photoresponse fluorine-containing amphiphilic block polymer with an active end group; and step 2, preparing the photoresponse self-repairing fluorine-containing polyacrylate soap-free emulsion through RAFT (reversible addition fragmentation chain transfer) soap-free emulsion polymerization. The photoresponse amphiphilic block copolymer used in the invention not only can play a role in emulsification, but also can participate in polymerization reaction, so that the photoresponse amphiphilic block copolymer is bonded to emulsion particles in the form of covalent bonds, the adverse effect of a conventional micromolecule emulsifier on the properties of emulsion and film is eliminated, and the self-repairing of the film can be realized under the action of light stimulation.

Owner:SHAANXI UNIV OF SCI & TECH

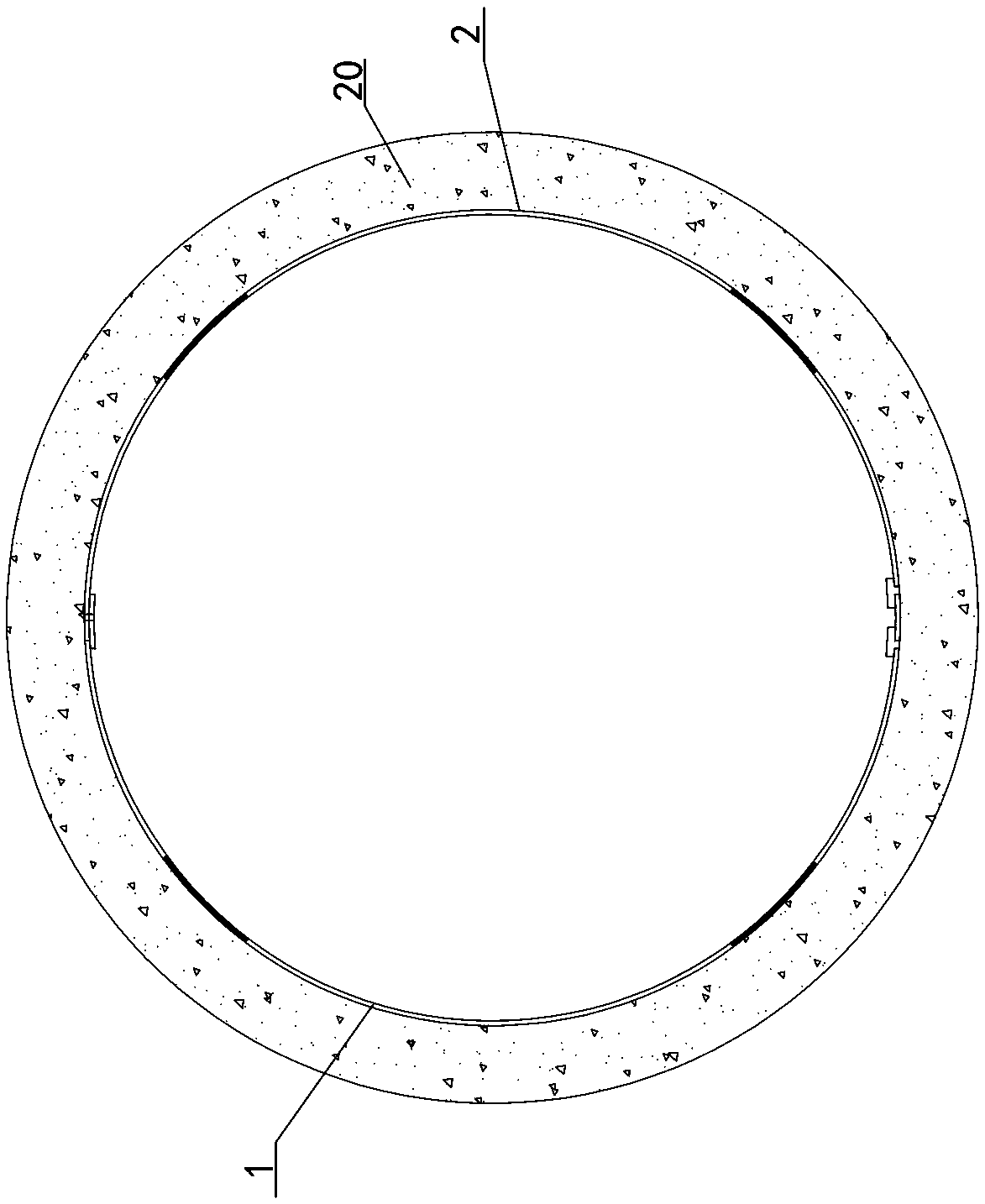

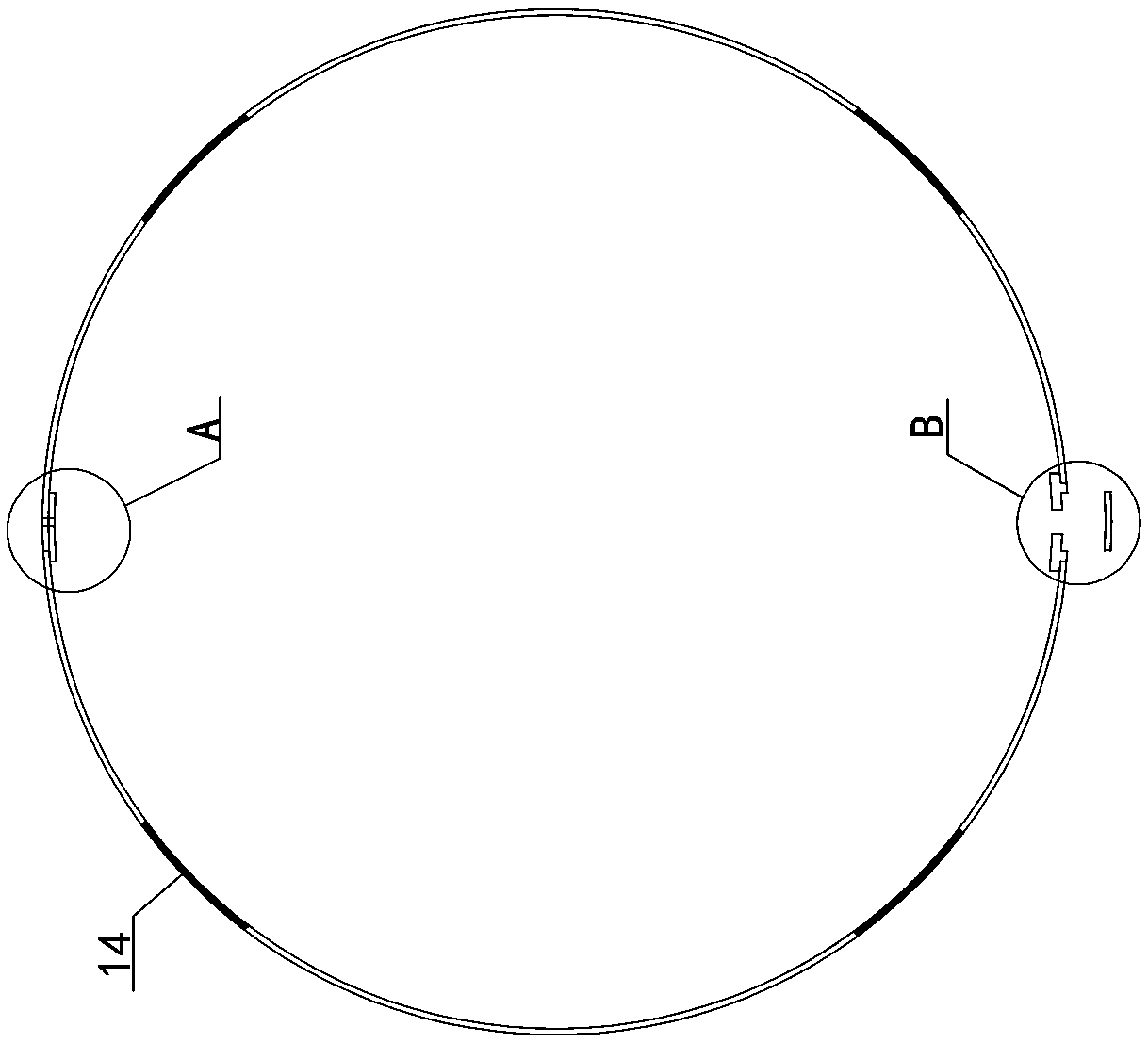

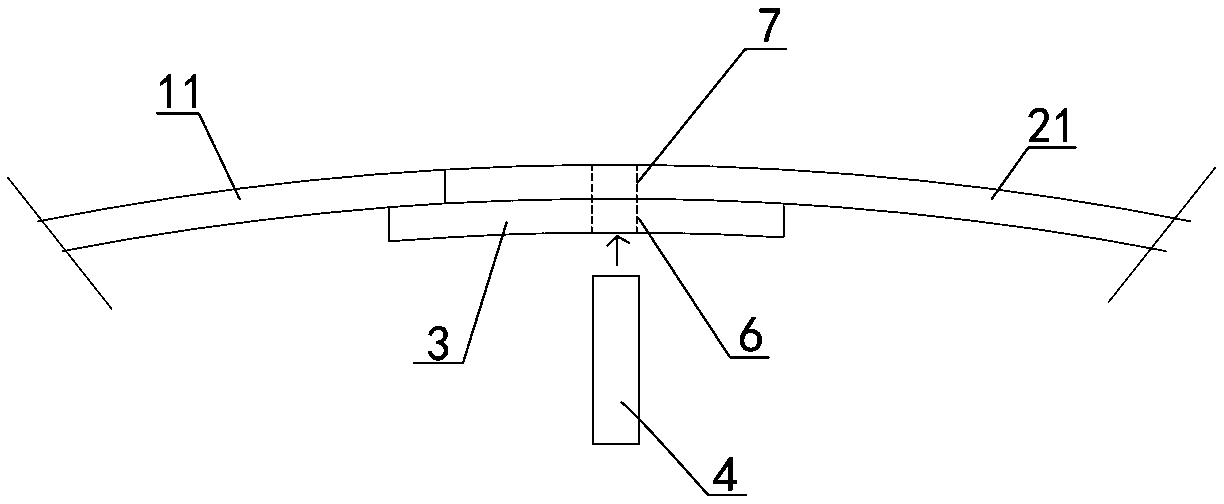

Embedded pipeline inner support reinforcing system and reinforcing method thereof

PendingCN107859806AReduce grouting workGuaranteed reinforcement effectPipe elementsEngineeringRepair processes

The invention discloses an embedded pipeline inner support reinforcing system and a reinforcing method thereof. The reinforcing system comprises a reinforced circular ring support, wherein the reinforced circular ring support comprises a main body, and the main body comprises a first assembly, a second assembly, a first arc-shaped connecting piece, a main body connecting bolt and an adaptive block; and one end of the first assembly is fixedly connected with one end of the second assembly, and the other end of the first assembly is connected with the other end of the second assembly to form a complete closed circular ring through coordination of a first limiting clamping block, a second limiting clamping block and the adaptive block. The reinforcing method thereof comprises the following steps of strand pipeline current situation verification, design and manufacture of the reinforced circular ring support, first assembly installation, second assembly installation, limiting clamping groove expansion of an expansion device and adaptive block embeddedness and the like. According to the embedded pipeline inner support reinforcing system and the reinforcing method thereof, a damaged pipeline is subjected to structural non-excavation repair, radial tension enables the support to be tightly attached to a to-be-reinforced structure, the new and old structures cooperatively work to makeup irregular change of the section size of the damaged pipeline, so that reinforcing quality is guaranteed, the repairing process is simplified, and the service life of the pipeline is prolonged.

Owner:BEIJING MUNICIPAL ENG RES INST +1

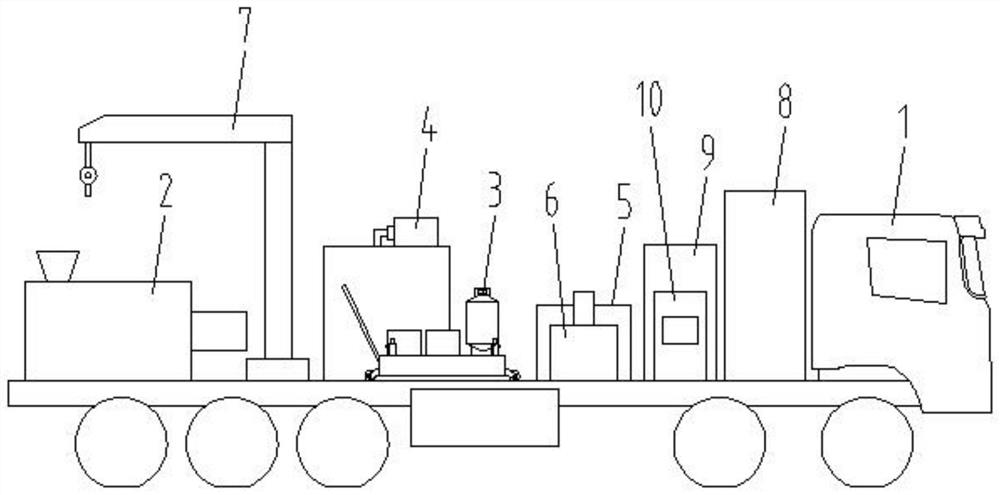

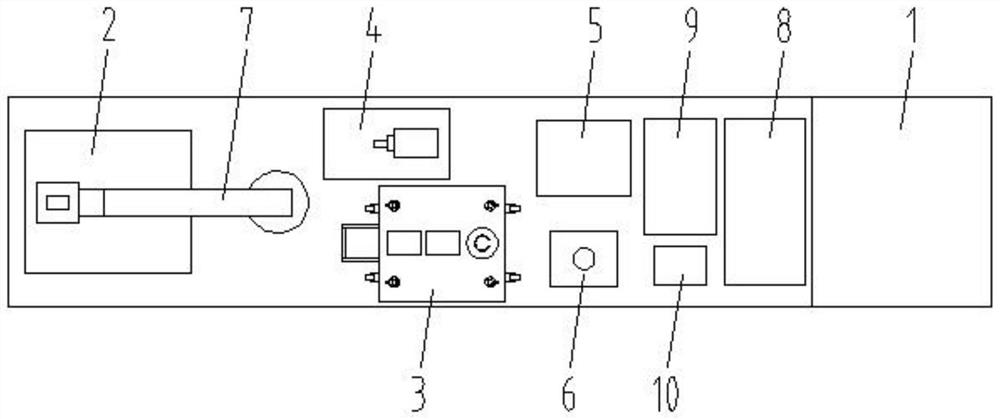

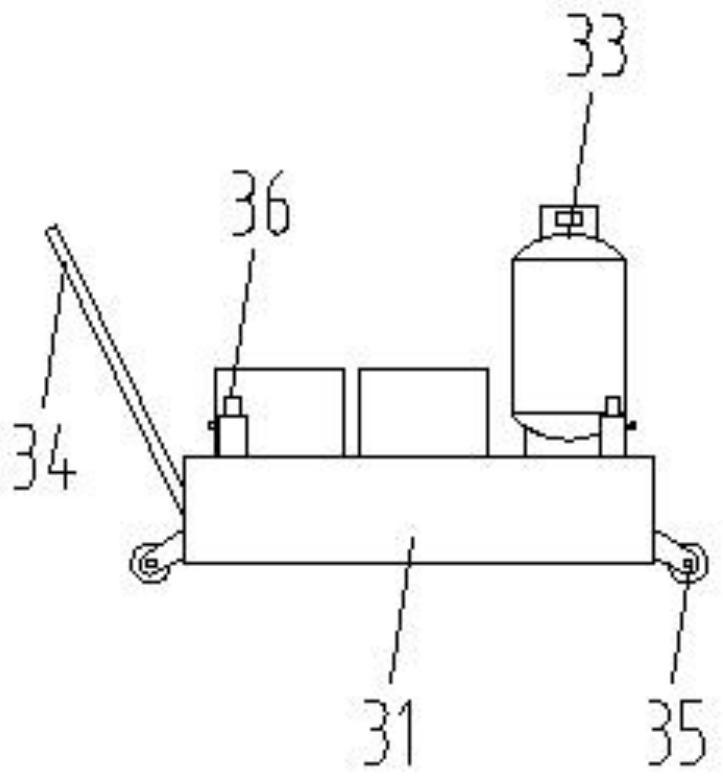

Asphalt pavement thermal regeneration comprehensive repairing vehicle and pavement repairing method

PendingCN114319047AAvoid heatingReduce manual labor intensityRoads maintainencePower stationBitumen emulsion

The invention discloses an asphalt pavement thermal regeneration comprehensive repairing vehicle which comprises a loading chassis and a loading assembly, and the loading assembly comprises an asphalt concrete heating device, an intelligent partition pavement heating device, an emulsified asphalt spraying device, a power generator, a movable hydraulic power station and a hoisting crane. The asphalt concrete heating device is used for storing asphalt concrete and heating and stirring the asphalt concrete, the intelligent zoning pavement heating device can perform selective zoning heating on an asphalt pavement according to disease distribution positions, and the emulsified asphalt spraying device is used for spraying emulsified asphalt to a repairing area in the repairing process. The power generator is used for providing electric energy required during pavement repairing, the movable hydraulic power station is used for providing required hydraulic pressure for equipment, and the hoisting crane is used for providing hoisting operation during repairing. Various mechanical devices are integrated on the repairing vehicle, and a hot repairing process is adopted, so that the labor intensity of workers is reduced, and the repairing construction efficiency is improved.

Owner:LUZHOU VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com