Embedded pipeline inner support reinforcing system and reinforcing method thereof

An inner support and pipeline technology, applied in the direction of pipe elements, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the structural damage of pipes with poor flexibility in repairing resistance, the inability of new and old structures to work together in the workplace environment, and the loss of structural section size and other problems, to achieve the effect of making up for the loss of the overcurrent section, reducing the grouting work, and having a small water flow resistance coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

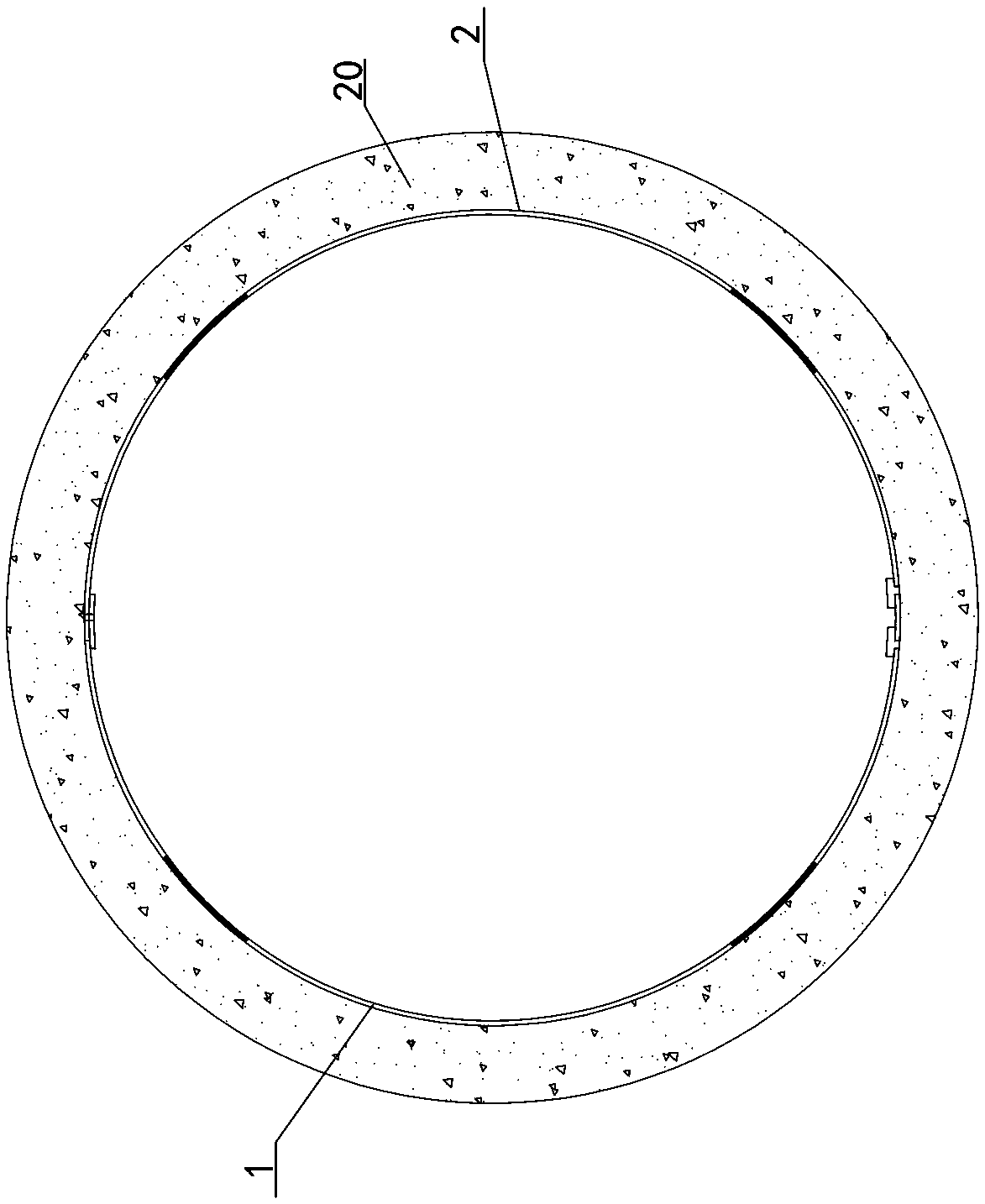

[0057] Embodiment one sees Figure 1-8 As shown, an embedded-type pipeline internal support reinforcement system includes at least two reinforcement ring supports arranged along the circumference of the pipeline 20 to be strengthened.

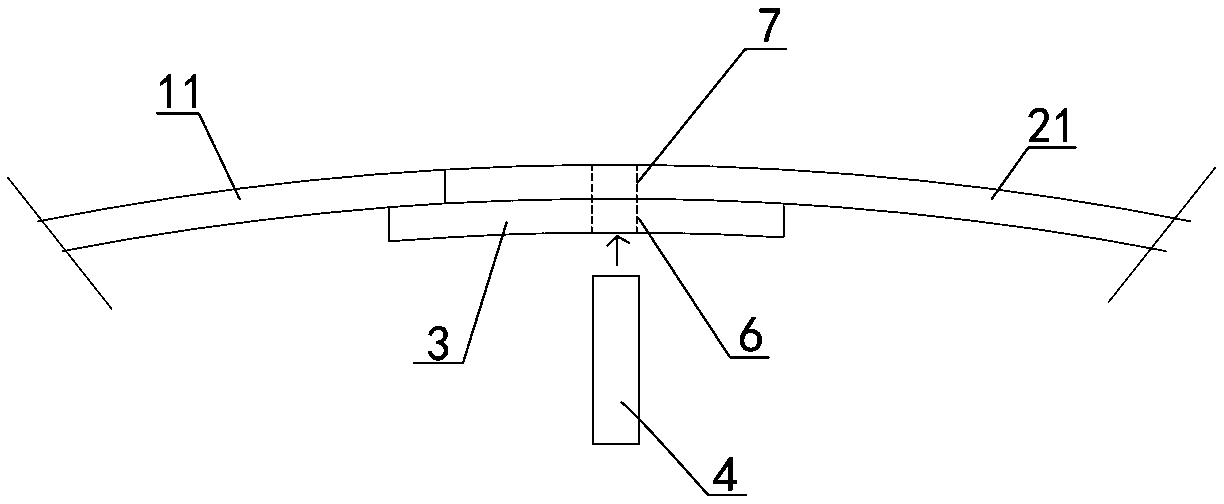

[0058] The reinforced ring bracket includes a main body made of stainless steel, and the main body includes a first component 1 , a second component 2 , a first arc-shaped connecting piece 3 , a main body connecting bolt 4 and an adapter block 5 . The first component 1 is a semi-circular arc piece adapted to the curvature along the inner wall of the pipeline to be reinforced, one end of which is the first connecting end 11 and the other end is the first fitting end 12 . The second component 2 is a semi-circular arc piece adapted to the curvature along the inner wall of the pipeline to be reinforced, one end of which is the second connecting end 21 and the other end is the second fitting end 22 .

[0059] The first arc-shaped connecting piece 3...

Embodiment 2

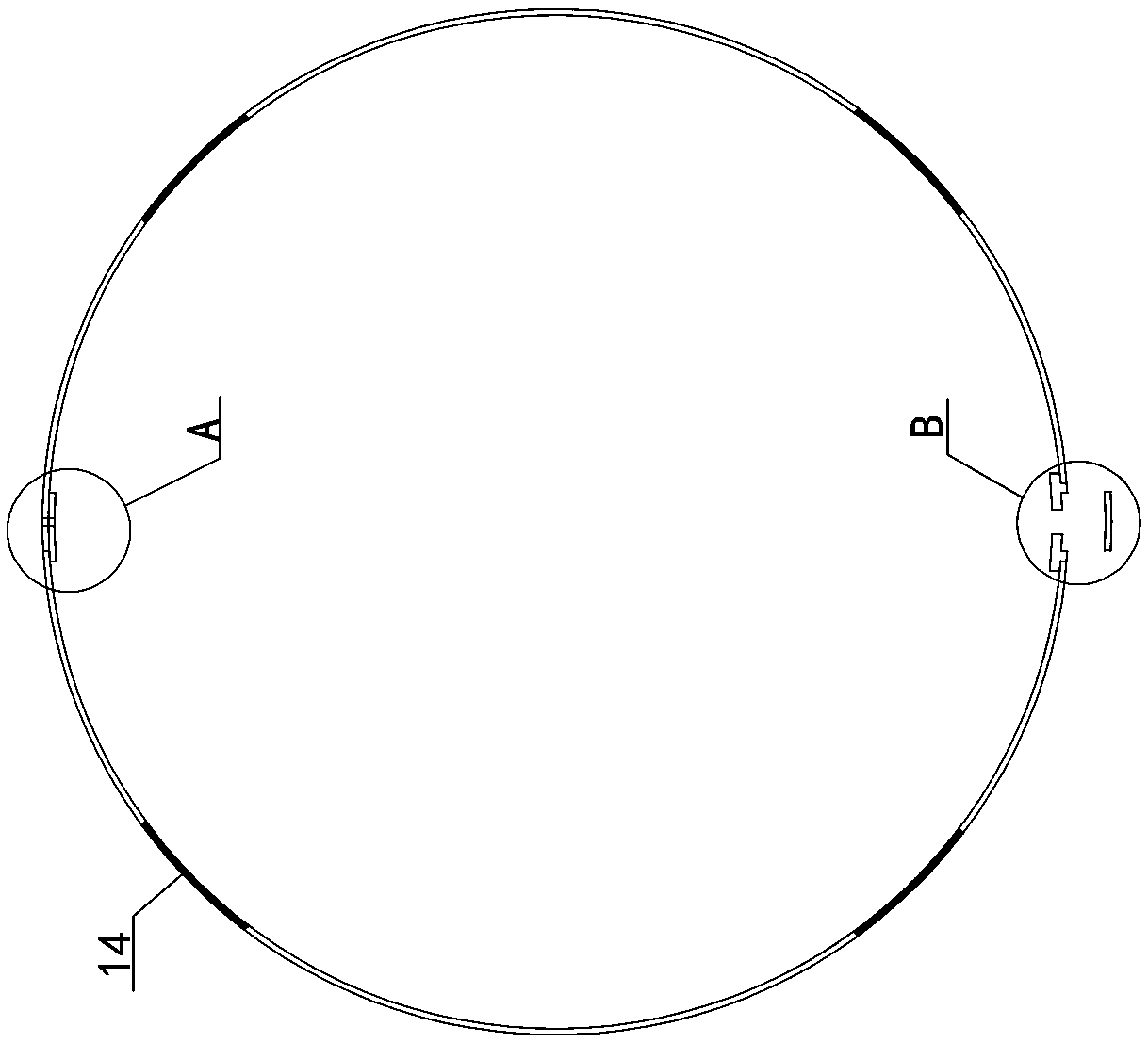

[0077] Embodiment two see Figure 11-12 As shown, the difference from Embodiment 1 is that this embodiment is a full-length stent. The main body and the wing plate form plug boards 14a and slots 14b that are arranged alternately along the circumferential interval of the reinforced ring bracket and are adapted in size. The plug plate 14a of the reinforcement ring support is inserted in the slot 14b of the front reinforcement ring support, the plug plate 14a of the front reinforcement ring support is inserted in the slot 14b of the rear reinforcement ring support, and the front reinforcement ring support The steel cylinder is integrally connected with the rear truss reinforcement ring bracket socket and closed, and the deformation of the steel cylinder along the pipeline direction and radially outward is restrained, and the radially inward direction is free.

[0078] In this embodiment, five wings are arranged on the main body, two and a half lines are arranged on the upper win...

Embodiment 3

[0080] Embodiment three see Figure 11 and Figure 13 As shown, different from the second embodiment, the wing plate 14 is provided with a wing plate hole 8, and the front reinforcement ring bracket and the rear reinforcement ring bracket are fixedly connected by a second arc-shaped connecting piece 19, The arc of the second arc-shaped connecting piece 19 is adapted to the arc of the inner wall of the main body, and the second arc-shaped connecting piece is arranged circumferentially.

[0081] Therefore, in the reinforcement method of this embodiment, the position corresponding to the flange hole 8 on the second arc-shaped connecting piece 19 is all provided with a second bolt hole 17, and the front reinforcement ring bracket and the rear reinforcement ring bracket correspond to each other. The inner wall of the wing plate 14 is bolted through the wing plate connecting bolts 18 passing through the second bolt hole 17 and the wing plate hole 8 in sequence. The steel cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com