Preparation method of photoresponse self-repairing fluorine-containing polyacrylate soap-free emulsion

A technology of polyacrylate and soap-free emulsion is applied in the field of preparation of light-responsive self-healing fluorine-containing polyacrylate soap-free emulsion to achieve the effects of improving stability, improving compactness and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

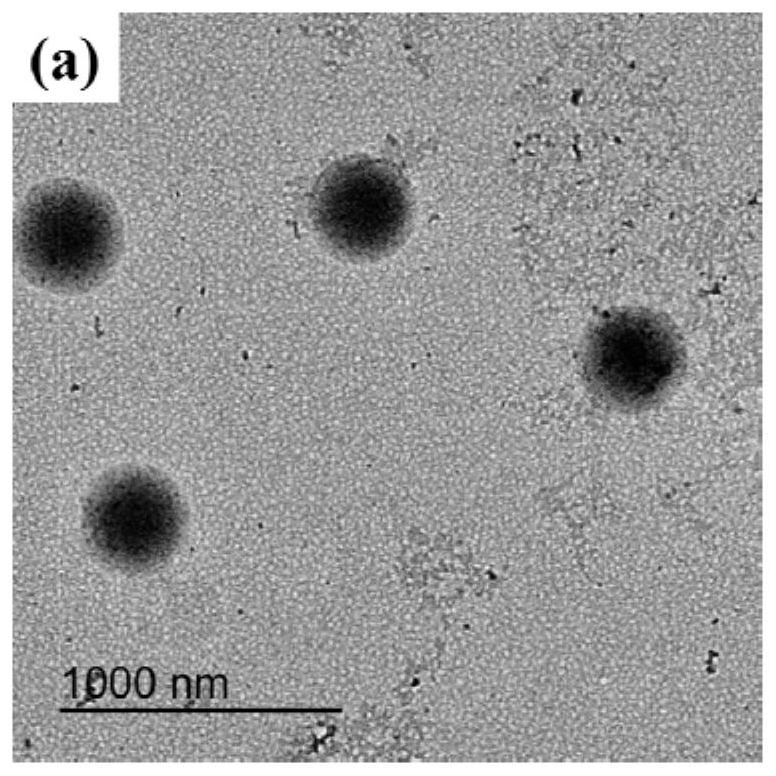

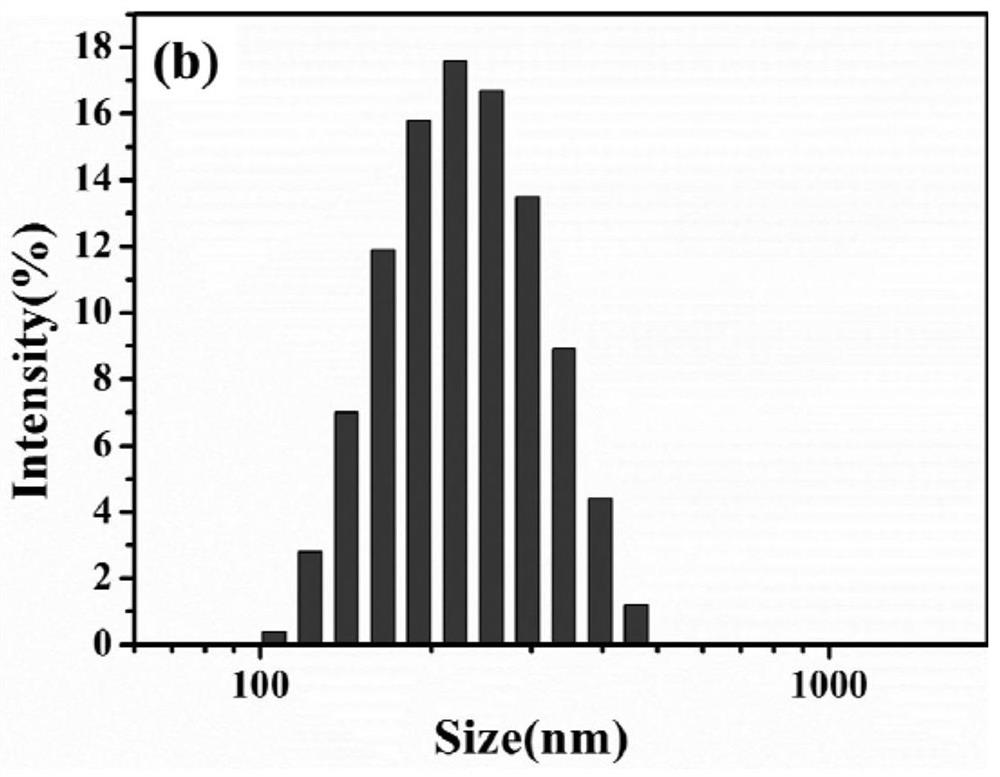

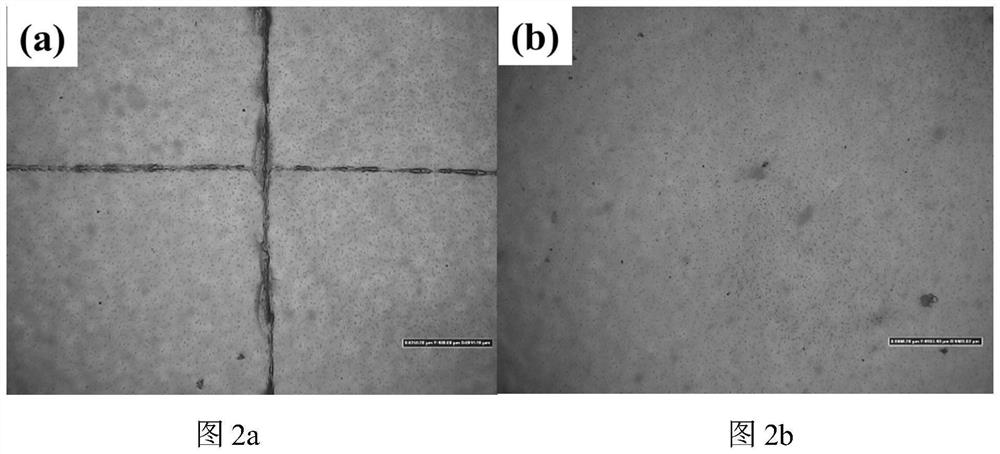

Image

Examples

Embodiment 1

[0076] Step 1. At room temperature, mix 0.30g S-1-dodecyl-S'-(α,α"-dimethyl-α"-acetic acid) trithiocarbonate, 0.04g azobisisobutyronitrile (AIBN), 10.02g of ethyl 2-(dimethylamino)acrylate, and 50g of 1,4-dioxane were sequentially added to the four-neck flask; while magnetically stirring, argon was passed for 25 minutes; the temperature was raised to 65°C, and the reaction was carried out for 10 hours. . The obtained poly-2-(dimethylamino)ethyl acrylate is purified by n-hexane, and then dried to obtain pure poly-2-(dimethylamino)ethyl acrylate;

[0077] The ratio of the amount of azobisisobutyronitrile to S-1-dodecyl-S'-(α, α"-dimethyl-α"-acetic acid) trithiocarbonate is 0.30;

[0078] The ratio of the amount of poly 2-(dimethylamino)ethyl acrylate to S-1-dodecyl-S'-(α, α"-dimethyl-α"-acetic acid) trithiocarbonate for 85.

[0079] Step 2, 3.04g of pure poly 2-(dimethylamino)ethyl acrylate, 0.012g of azobisisobutyronitrile (AIBN), 1.5g of 7-(3-acrylate propoxy)-4-methyl Cou...

Embodiment 2

[0090] Step 1. At room temperature, mix 0.12g S-(2-cyano-2-propyl)-S-dodecyltrithiocarbonyl ester, 0.014g azobisisobutyronitrile (AIBN), 8.0g 2 -(diethylamino)ethyl methacrylate and 40 g of toluene were sequentially added to the four-necked flask; while magnetic stirring was carried out, argon gas was passed for 25 min; the temperature was raised to 70° C., and the reaction was carried out for 10 h. The obtained poly 2-(diethylamino) ethyl methacrylate is purified by n-hexane, and then dried to obtain pure poly 2-(diethylamino) ethyl methacrylate;

[0091] The ratio of the amount of azobisisobutyronitrile to S-(2-cyano-2-propyl)-S-dodecyltrithiocarbonyl ester is 0.25;

[0092] The ratio of the amount of poly(2-(diethylamino)ethyl methacrylate) to S-(2-cyano-2-propyl)-S-dodecyltrithiocarbonyl ester was 124.

[0093] Step 2, 7.21g of pure poly 2-(diethylamino)ethyl methacrylate, 0.013g of azobisisobutyronitrile (AIBN), 2.5g of 7-(2-acrylate ethoxy)-4- Methyl coumarin, 1.3 g of...

Embodiment 3

[0104] Step 1. At room temperature, add 0.12g of benzyl dithiobenzoate, 0.016g of azobisisobutyronitrile (AIBN), 8.0g of N-[(3-(dimethylamino)propyl]methacrylamide, Add 40g of aniline to the four-necked flask successively; while stirring magnetically, pass argon for 25min; heat up to 75°C, and react for 9h. Use n-hexane to obtain poly-N-[(3-(dimethylamino)propyl]methacrylic acid The amide is purified, and then dried to obtain pure poly N-[(3-(dimethylamino)propyl]methacrylamide;

[0105] The ratio of the amount of azobisisobutyronitrile to benzyl dithiobenzoate is 0.20;

[0106] The amount ratio of poly-N-[(3-(dimethylamino)propyl]methacrylamide to benzyl dithiobenzoate was 95.

[0107] Step 2, 7.21g pure poly N-[(3-(dimethylamino)propyl]methacrylamide, 0.014g azobisisobutyronitrile (AIBN), 2.5g 7-(4-vinylbenzyl Oxygen)-4-methylcoumarin, 1.3g of dodecafluoroheptyl methacrylate, and 50g of aniline were sequentially added to a four-necked flask; argon was passed for 30 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com