Cable-sheath material with self-repair function, preparation method and cable sheath

A cable sheath and self-repair technology, which is applied to circuits, electrical components, organic insulators, etc., can solve the problems of complex repair process and poor repair performance of repair materials, and achieve the effect of guaranteed mechanical properties, easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

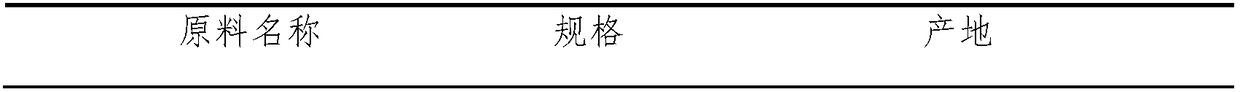

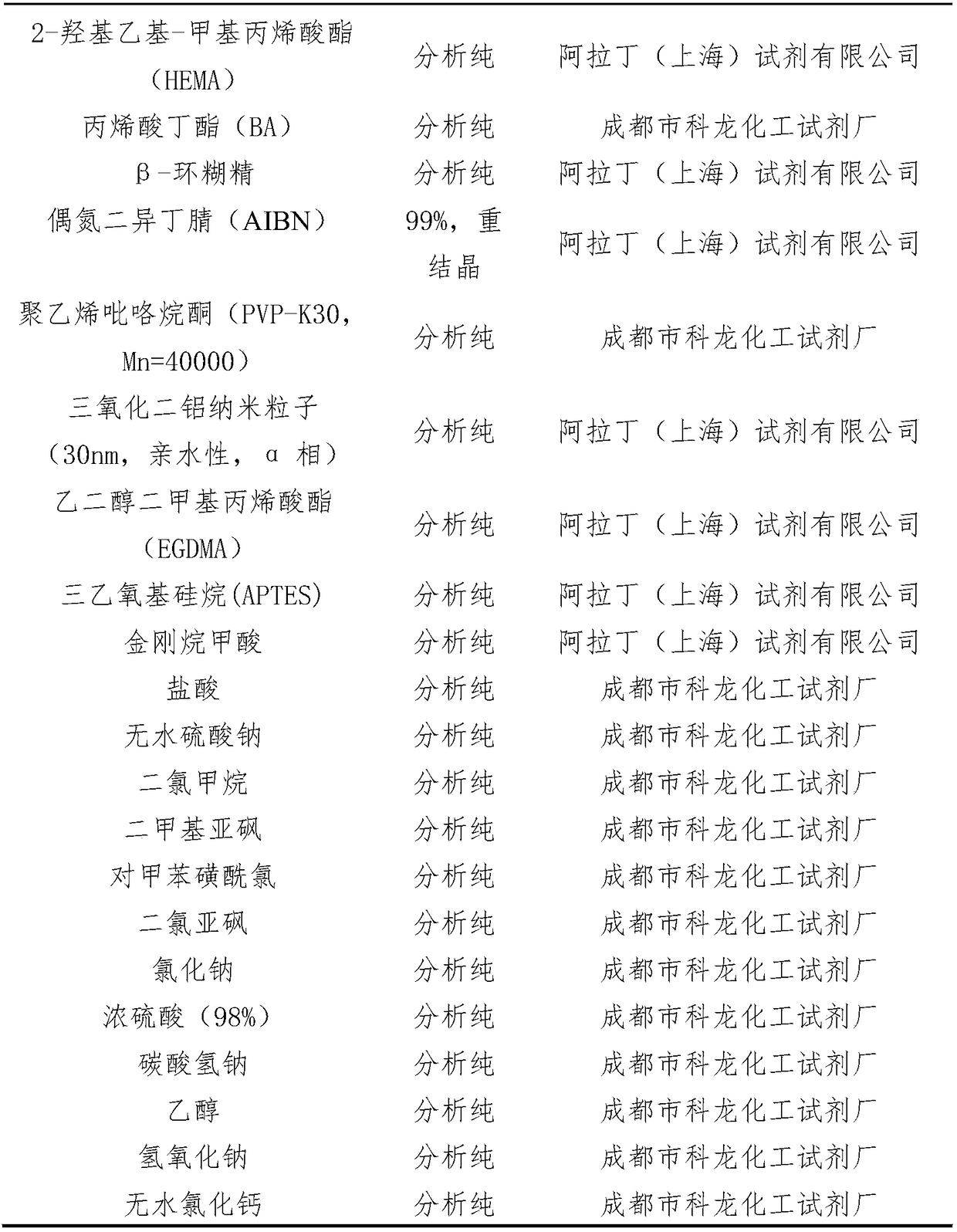

[0042] The ratio of raw materials used is as follows:

[0043]

[0044]

[0045] Add thermoplastic elastomer and self-healing polymer to the mixer and mix for a period of time, spray dioctyl phthalate into the mixer with a spray device, and stir thoroughly for 10 minutes; add antioxidant 1010 and white carbon black to the mixer Stir in the middle, fully mix evenly; put the mixed raw material into the twin-screw extruder, extrude, melt and granulate within the range of 80°C to obtain a cable sheath material with self-repairing function.

[0046] The performance test standards and results of the self-repairing cable sheath material prepared in this example are shown in Table 1.

Embodiment 2

[0048] The ratio of raw materials used is as follows:

[0049]

[0050] Add thermoplastic elastomer and self-healing polymer and mix in mixer for a period of time, spray bis(2-ethylhexyl) phthalate in mixer with spray device, fully stir for 20 minutes; light stabilizer and The white carbon black is added to the mixer and stirred, fully mixed evenly; the mixed raw materials are added to the twin-screw extruder, extruded, melted and granulated within the range of 100°C to obtain a cable sheath material with self-repairing function.

[0051] The performance test standards and results of the self-repairing cable sheath material prepared in this example are shown in Table 1.

Embodiment 3

[0053] The ratio of raw materials used is as follows:

[0054]

[0055]

[0056] Add thermoplastic elastomer and self-healing polymer to the mixer and mix for a period of time, spray diethyl phthalate into the mixer with a spray device, and stir thoroughly for 30 minutes; add ultraviolet absorber and white carbon black to the mixer Stir and fully mix evenly; put the mixed raw materials into a twin-screw extruder, extrude, melt, and granulate within the range of 120°C to obtain a cable sheath material with self-repairing function.

[0057] The performance test standards and results of the self-repairing cable sheath material prepared in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com