Method for repairing mechanical damage of radial tire

A radial tire and tire technology, applied in tires, other household appliances, household appliances, etc., can solve problems such as long time, easy patch fall off, and repair steps for wound damage, achieving high repair efficiency, ensuring reinforcement and sealing effect, Repair effect improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

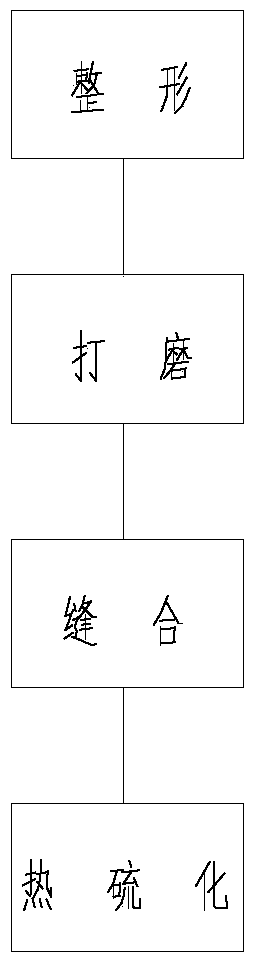

Method used

Image

Examples

Embodiment 1

[0040] A hard injury wound with a length of 10cm on the outside of the radial tire, when the present invention is used to repair:

[0041] 1) Wound plastic treatment, using a rubber digging knife to cut in a rectangle to form a rectangular opening with a length of 10cm and a width of 10mm;

[0042] 2) Grinding the wound, grinding the inner side and the outer side of the wound respectively. The inner side of the wound is based on the selected patch, and its circumference is 5mm wider than the patch. Grind until the inner side of the tire wall completely exposes the new rubber, and at the same time, the tire cannot be exposed The outer side of the wound is ground around the rectangular opening, the upper and lower parts of the rectangular opening have a grinding width of 15 mm, and the left and right parts have a grinding width of 10 mm. The grinding depth of the outer side is greater than that of the inner side and is ground to the sidewall line of the tire. There is 1mm rubber...

Embodiment 2

[0049] There are two near-distance hard wounds on the outside of the radial tire, wherein the two wounds exist in parallel, the distance is 5mm, and the left and right lengths are 8cm. When the present invention is used for repairing:

[0050] 1) Wound plastic treatment, use a rubber digging knife to dig through the two wounds, and dig out a rectangular opening with a length of 8cm and a width of 15mm;

[0051] 2) Wound grinding treatment, the inner side of the wound and the outer side of the wound are polished separately. The inner side of the wound is based on the selected patch, and its surrounding area is 6mm wider than the patch. It is polished until the inner side of the tire wall completely exposes the new rubber, and at the same time, it cannot be exposed. The inner line layer of the tire; when grinding the outside of the wound, the grinding width of the upper and lower parts of the rectangular opening is 12mm, and the grinding width of the left and right parts is 12mm....

Embodiment 3

[0060] There is an internal wound on the side of the radial tire that is not leaking but bulging. The maximum broken wire length at the bulge is 10mm. When the invention is used for repairing:

[0061] 1) Wound plastic treatment, use a rubber digging knife to dig out a square opening with a length and width of 10mm from the wound inside the bulge, and its length is equal to the maximum side length of the bulge;

[0062] 2) Grinding the wound, using a low-speed pneumatic grinder with a semi-circular grinding wheel to grind the inner wound of the tire. The grinding range is based on the selected patch, and its circumference is 4mm wider than the patch. Grind to The inner side of the tire wall completely exposes the new rubber, and at the same time, the inner layer of the tire cannot be exposed; the outer side of the wound is ground with a low-speed pneumatic grinder equipped with an oblate grinding wheel. 15mm, the grinding depth on the outer side is greater than that on the inn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com