Installation method and structure of indoor wood veneer of decoration engineering

An installation method and a technology for installing structures, which are applied in building construction, building material processing, covering/lining, etc., can solve problems such as low installation efficiency, high construction cost, and cumbersome construction steps, and achieve high installation efficiency and simple construction , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

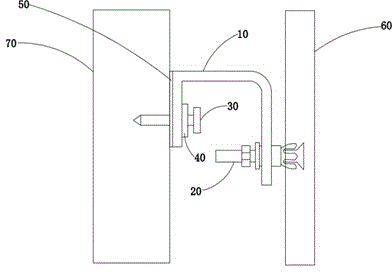

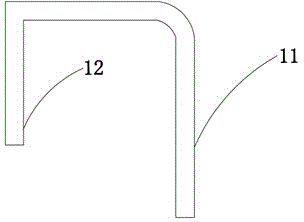

[0024] like Figure 1 to Figure 3 As shown, a method for installing indoor wood veneer panels in decoration engineering, the installation method needs to provide U-shaped connectors 10, screws 30 and back bolts 20, and the installation method includes the following steps:

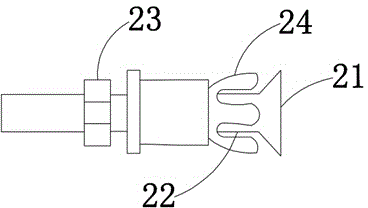

[0025] Step 1. Open an installation hole on the back of the wood veneer 60, insert the bolt head 21 of the back bolt 20 into the installation hole, and set the first connecting part 11 of the U-shaped connector 10 on the back bolt 20 On the back bolt rod 22 of the back bolt, the fastening nut 23 of the back bolt 20 is sleeved on the back bolt rod 22, and the fastening nut 23 is rotated so that the fastening nut 23 moves forward to push the back bolt expansion body 24 of the back bolt 20 to carry out The expansion is released, so that the back bolt 20 engages the wood veneer 60, and the first connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com