Patents

Literature

95results about How to "Shorten patching time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liner making technique for casting lander of blast furnace with single iron notch, and free from baking casting material for iron notch

Owner:北京联合荣大工程材料股份有限公司

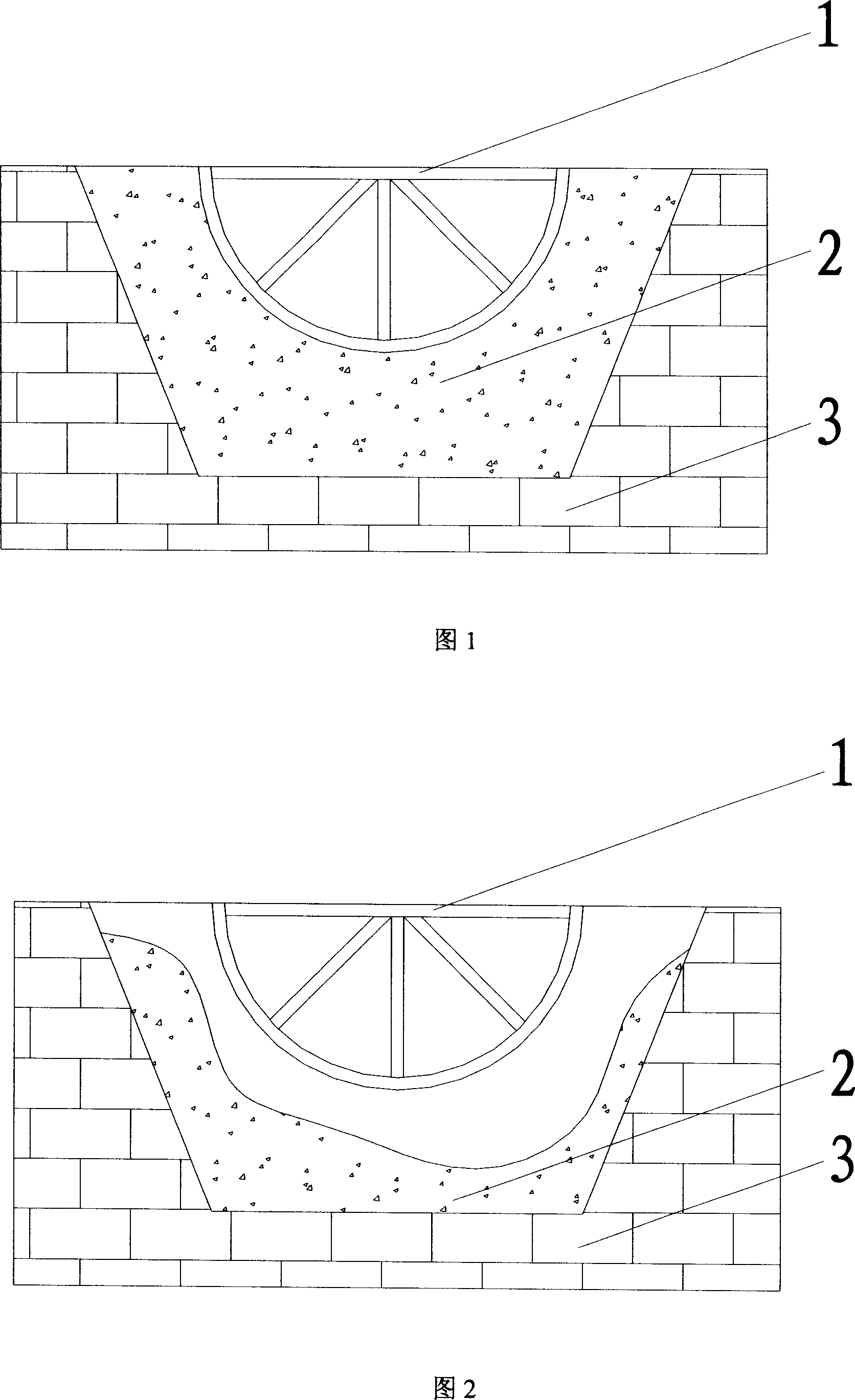

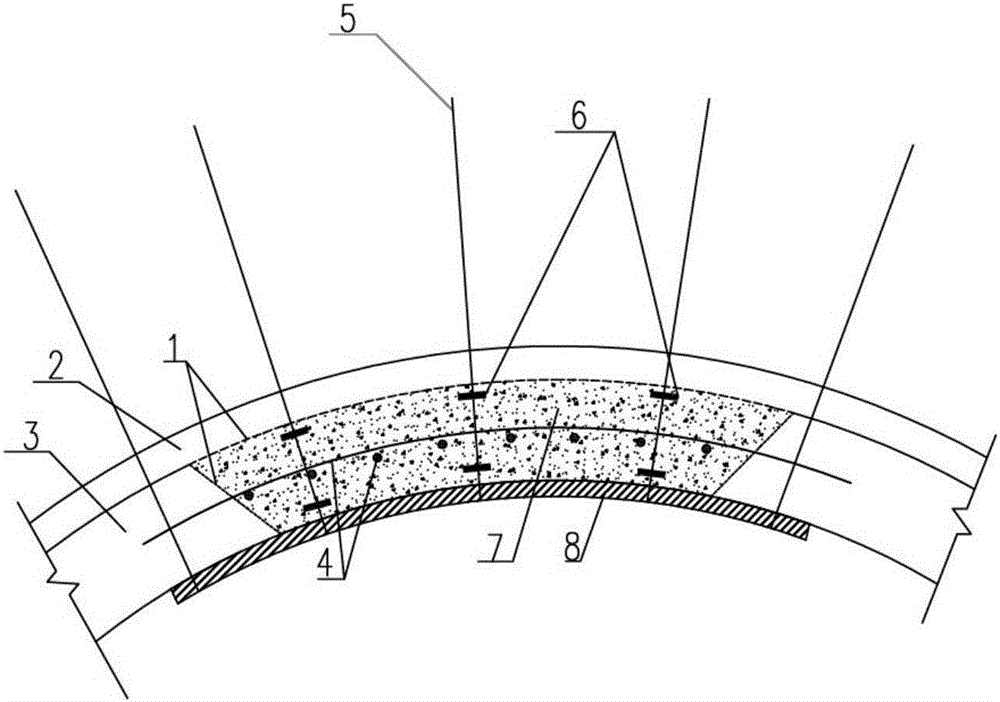

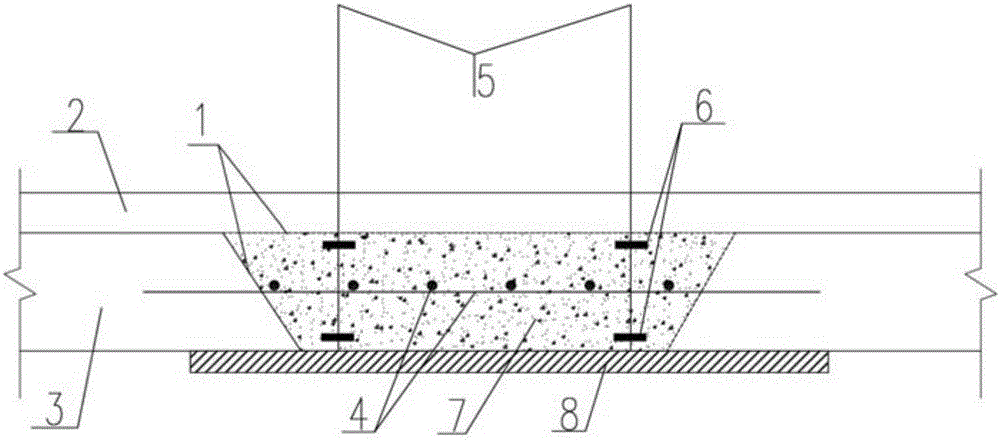

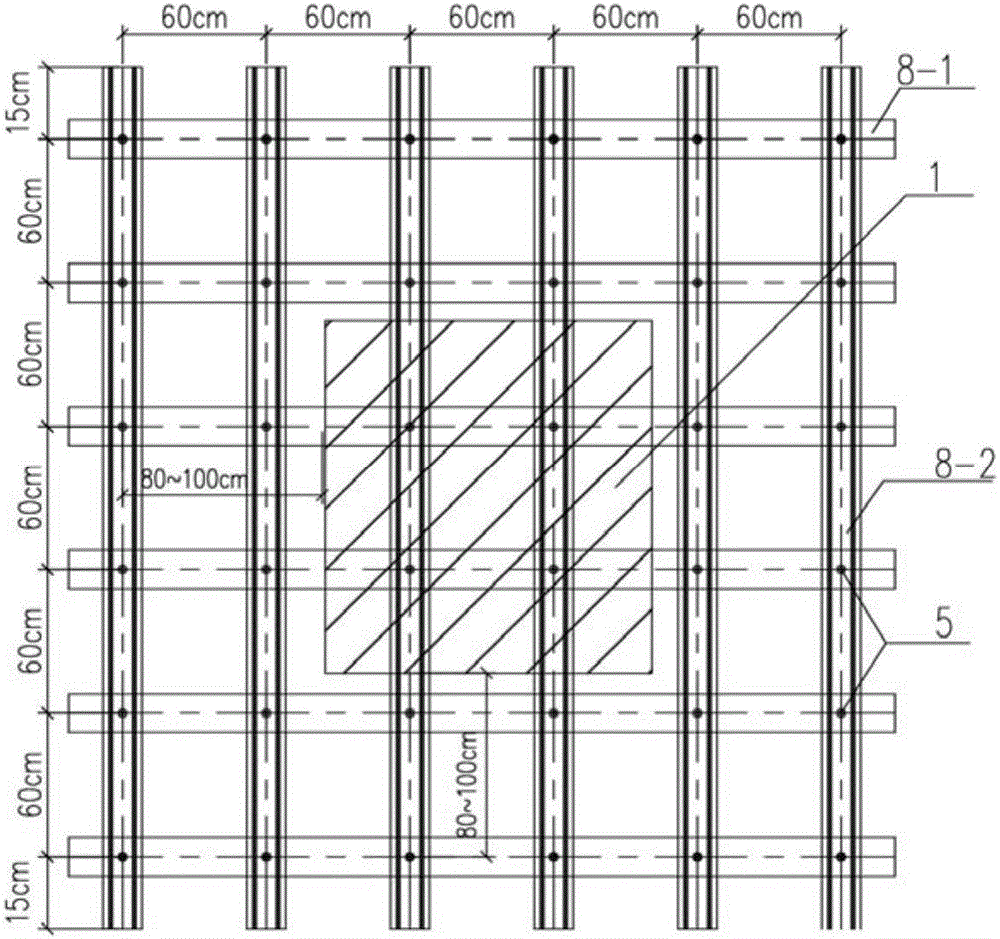

Structure and method for treating severe disengagement, cracking and other defects of tunnel lining

InactiveCN106677803AImprove stabilityAvoid wastingUnderground chambersTunnel liningEconomic benefitsOperability

The invention discloses a structure and method for treating severe disengagement, cracking and other defects of a tunnel lining. According to the method, original defective secondary lining concrete is chiseled away, and an inverted trapezoidal groove with the inside being wide and the outside being narrow is formed; steel bars are embedded in the middle of the groove in the annular direction and the longitudinal direction, and meanwhile, the steel bars and the original concrete are anchored integrally; self-propelled hollow grouting anchor rods are drilled in the groove area and surrounding the groove at the same time, and the outer side and the inner side, close to the secondary lining, of each anchor rod are wrapped with two water-swelling rubber water stop strips; and after a formwork is erected on the outer surface of the secondary lining, micro-expansion concrete is poured into the groove and is tightly connected with an original primary support and the secondary lining, so that a new lining structure is formed, the outer surface area of the micro-expansion concrete extends around till reaching the design thickness of the secondary lining and then extends again by 80-100 cm within which steel belts are hung for anchorage. The structure and method can effectively treat the defects of severe cracking and disengagement of the lining, the structure stability is good, the mechanical property is high, the problem that the defects occur again in the later period is avoided, the treatment method is high in operability, safe and reliable, and great economic benefits are achieved.

Owner:CHANGAN UNIV

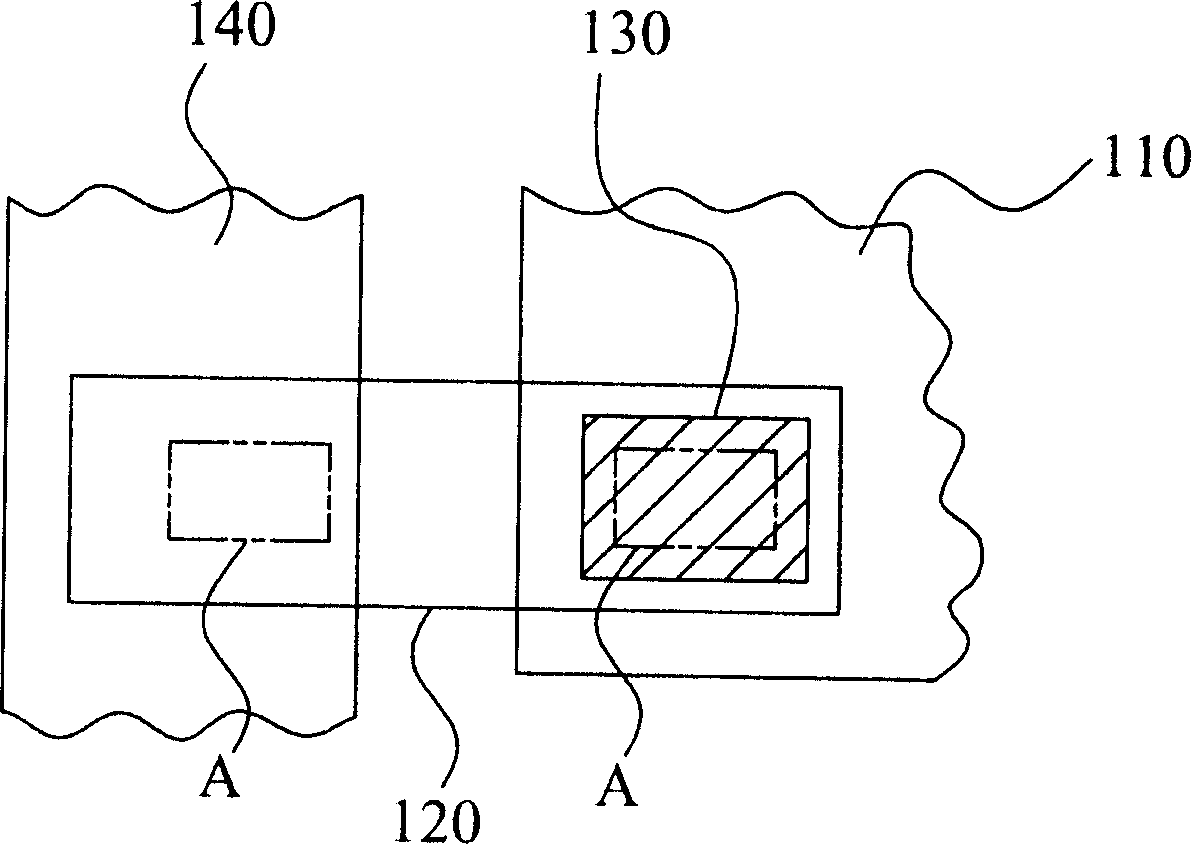

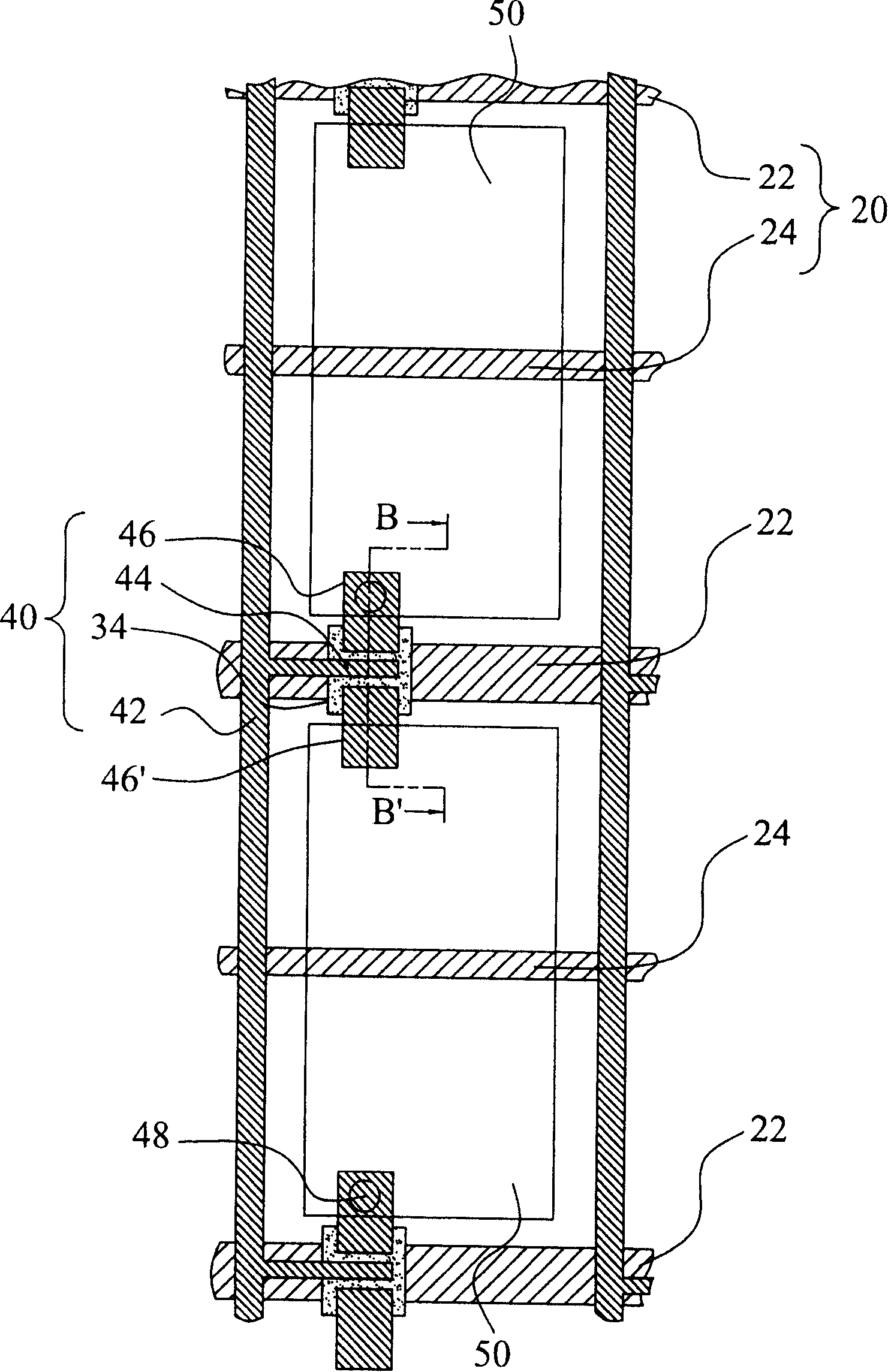

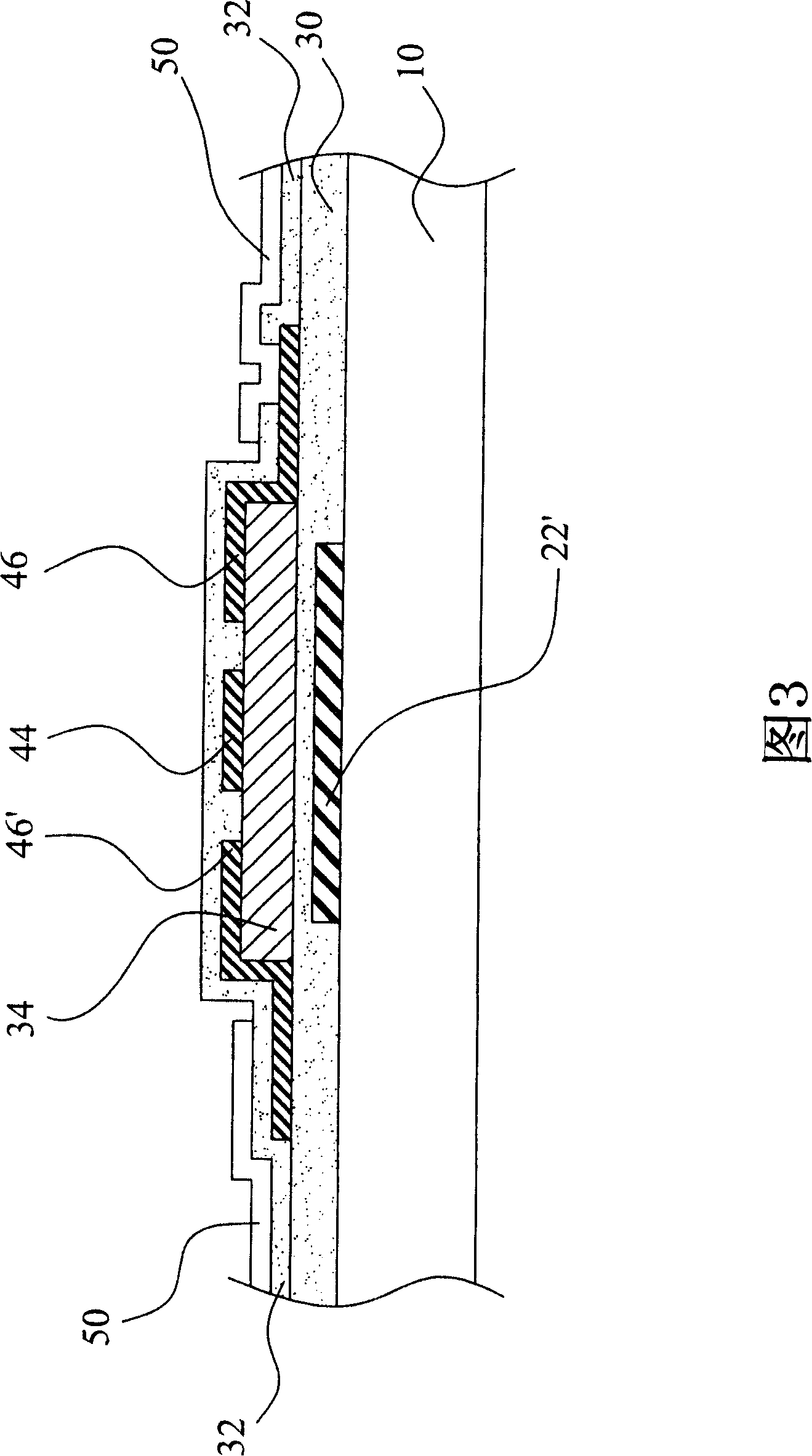

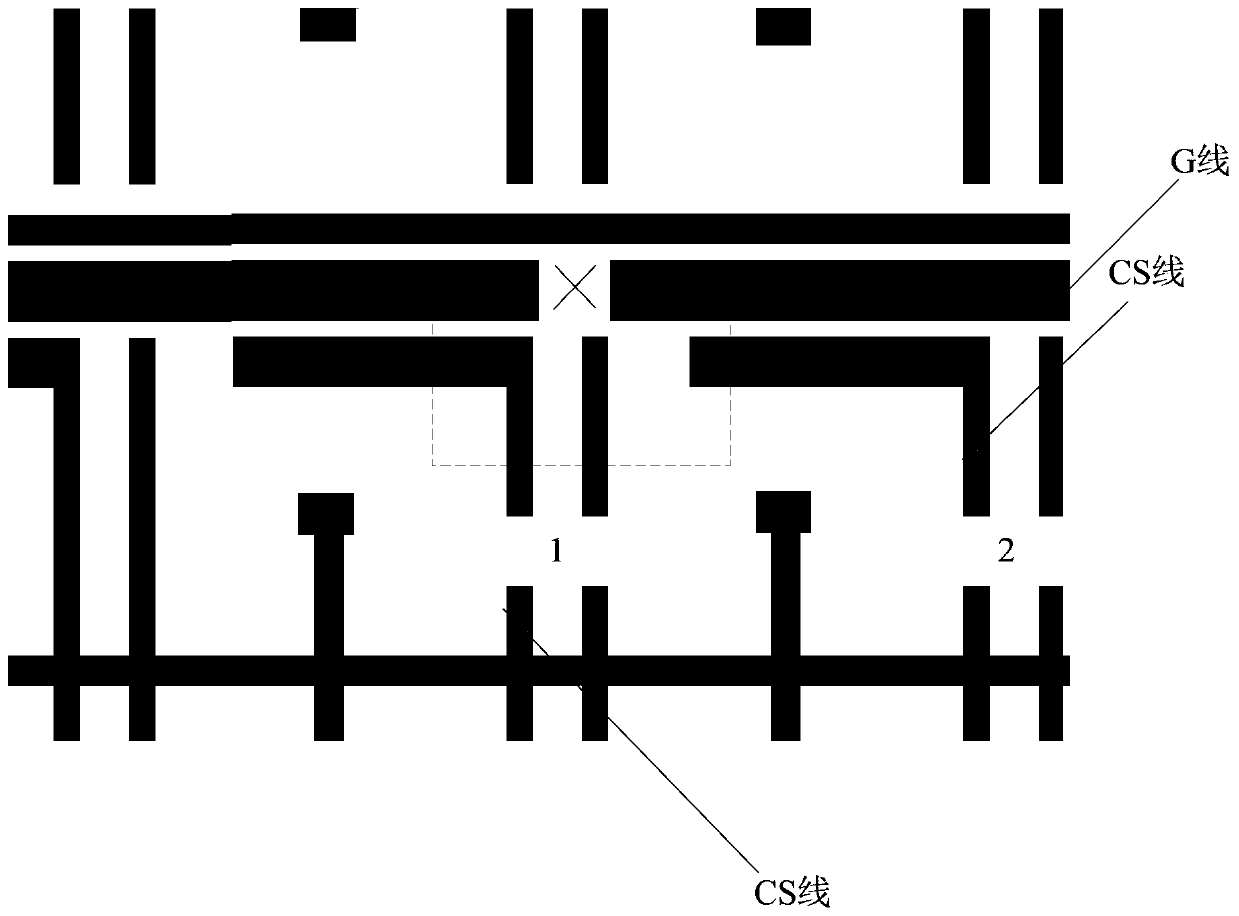

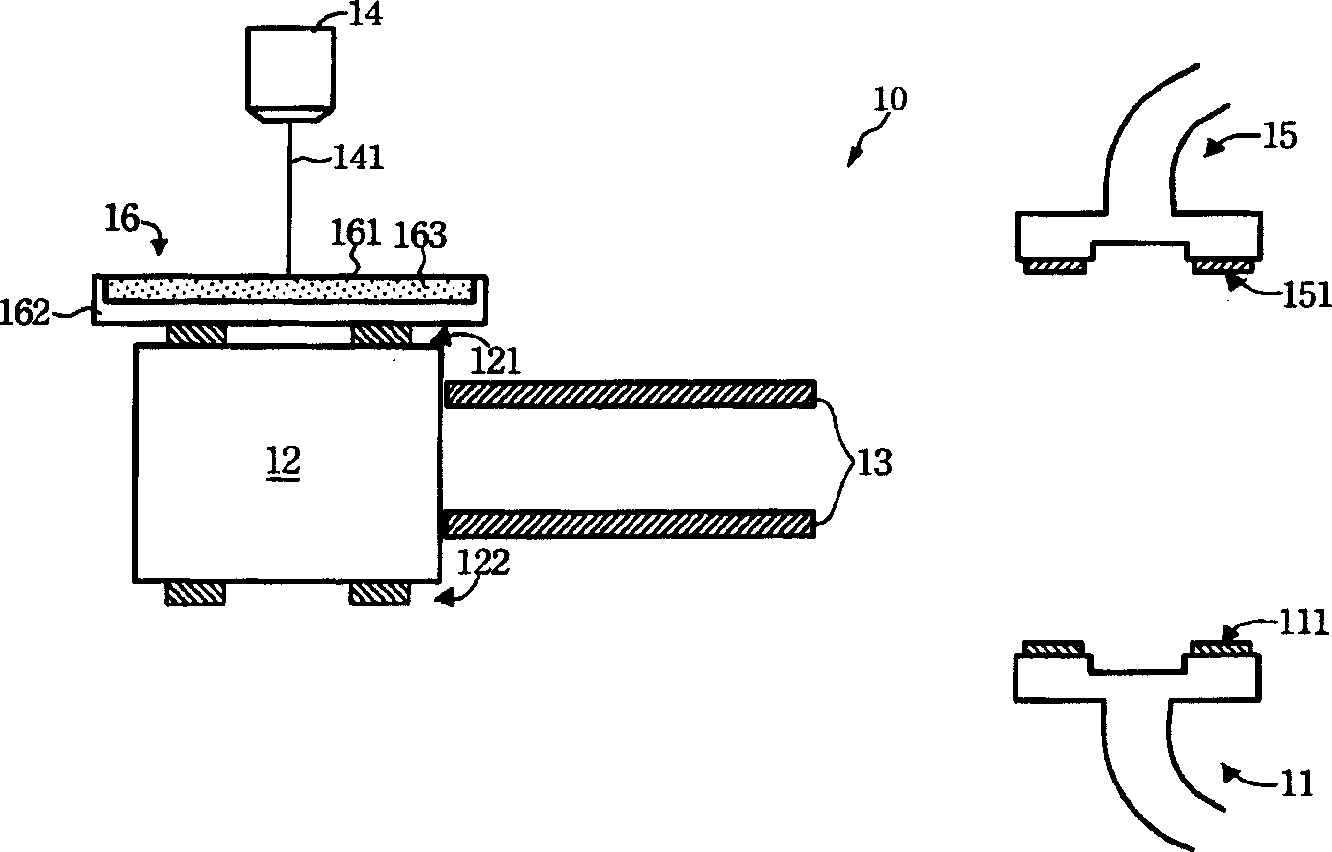

Pixel structure

InactiveCN101165904ANot easy to checkShorten patching timeTransistorSemiconductor/solid-state device detailsThin film electrodeLiquid-crystal display

The invention comprises: multi pixel regions defined by multi scan lines and multi signal lines; multi storage capacitor electrode lines; multi pixel electrodes; and multi thin film transistors. Wherein, setting up a second drain electrode for each thin film electrode; the second drain electrode and first drain electrode are set in symmetry. The first drain electrode is located at one side of the grid electrode and is connected to the pixel electrode; the second drain electrode and the first drain electrode are symmetrically located at the other side of the grid electrode, and are stacked and insulated with the pixel electrodes.

Owner:CHUNGHWA PICTURE TUBES LTD

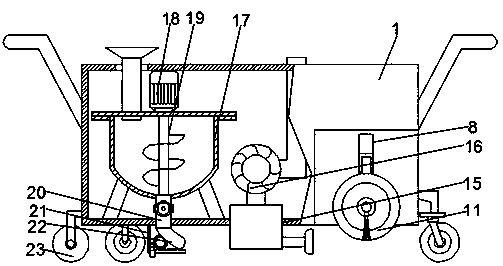

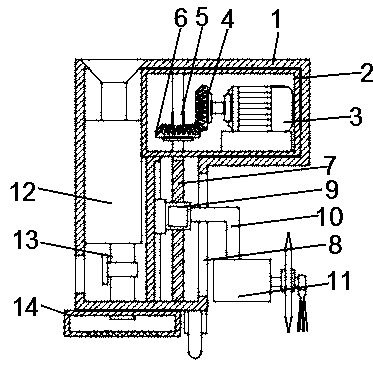

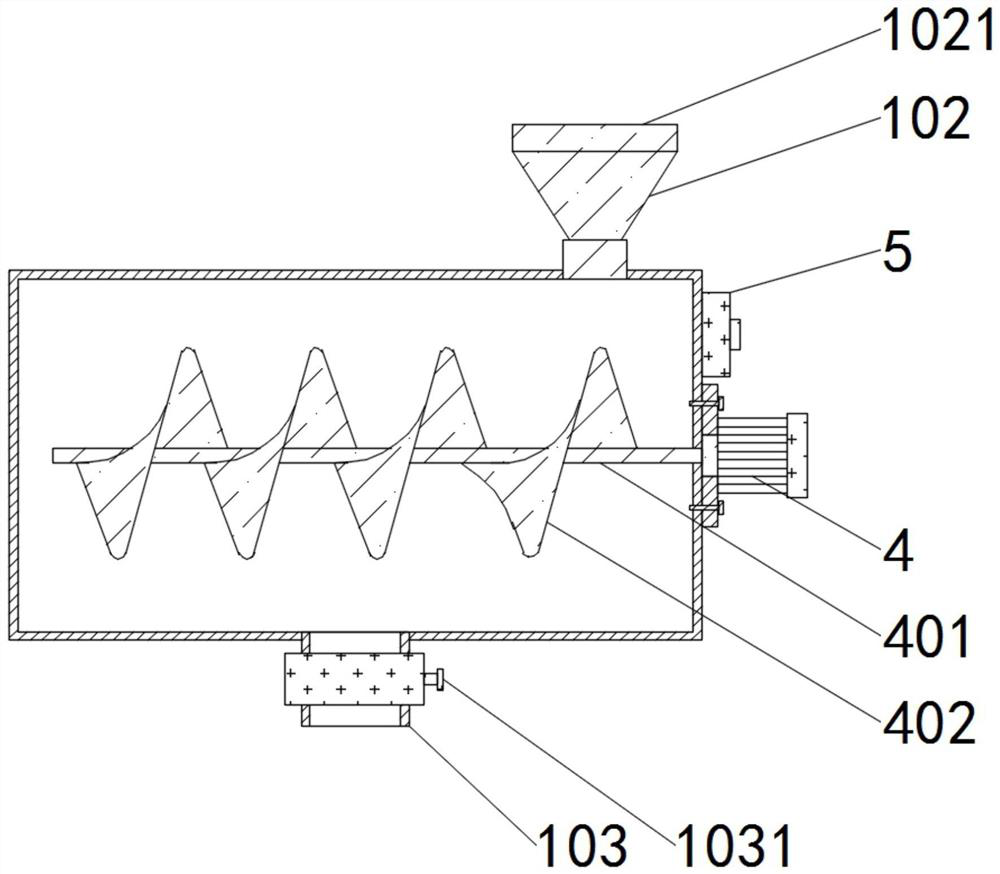

Cement road repairing machine

The invention discloses a cement road repairing machine which comprises a casing. The top of the inner wall of the casing is fixedly connected with a fixed box, the bottom of the inner wall of the fixed box is fixedly connected with an adjusting motor through a base, one side of the adjusting motor is rotatably connected with a first bevel gear through an output shaft, a rotating rod is rotatablyconnected to the top of the inner wall of the fixed box, the end, away from the fixed box, of the rotating rod extends through the fixed box and extends into the casing, the end, located in the casing, of the rotating rod is fixedly connected with a threaded rod, and the outer wall of the rotating rod is fixedly connected with a second bevel gear. The invention relates to the technical field of road machinery. The cement road repairing machine is small in size, integrates multiple functions, helps people to repair roads and complete the works including crack expansion, dust removal, material mixing, crack filling, road compression, air drying and sand dispensing of road surface repairing, greatly assists the people to complete the process of repairing roads, makes repairing tools more convenient to use, saves repairing time and improves repairing efficiency.

Owner:浙江国梁建设有限公司

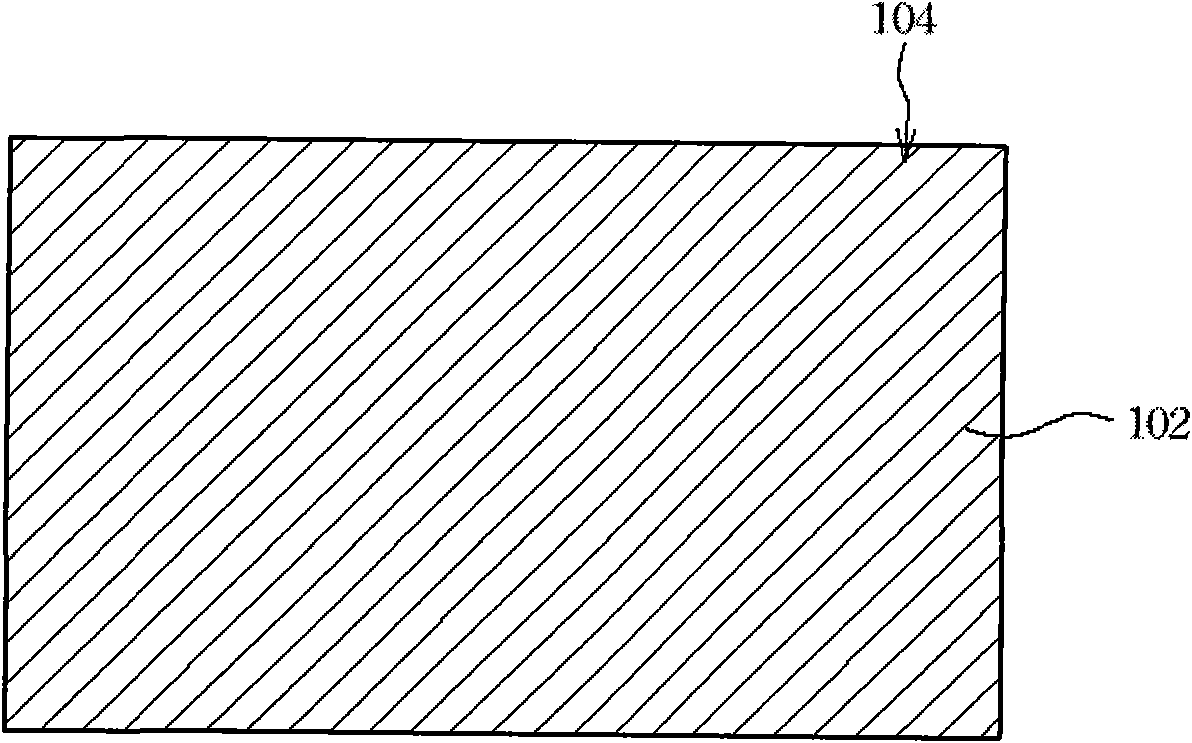

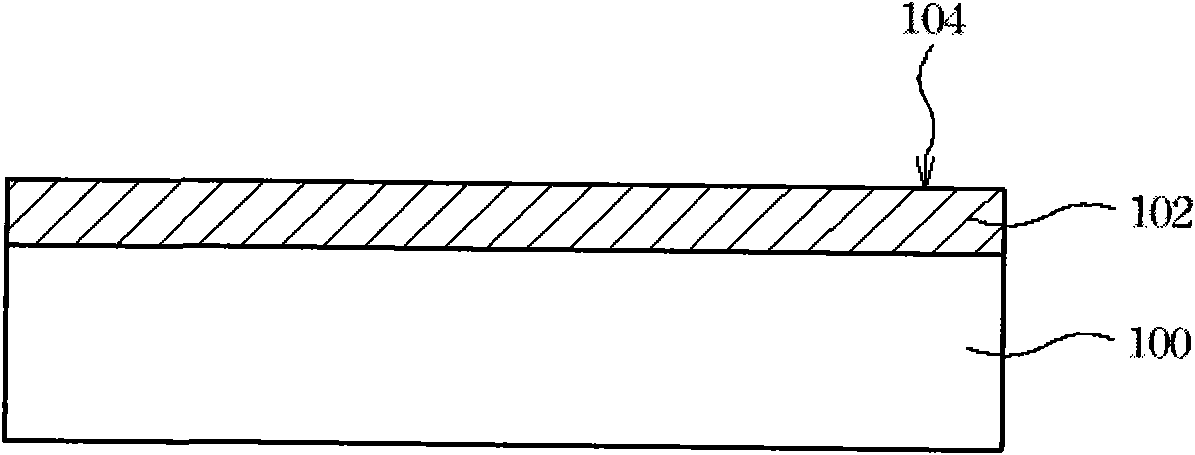

Repairing method of photoresist pattern

InactiveCN101566788AReduce usageReduce processing costsOriginals for photomechanical treatmentPhotoresistMaterials science

The invention discloses a repairing method of a photoresist pattern, which at least comprises the following steps: a material layer is formed on a substrate; a photoresist pattern is formed on the first part of the surface of the material layer, wherein the photo-etching glue pattern at least comprises a defect area exposed out of the second part of the surface of the material layer; and a repairing step is carried out to form a photo-etching glue layer which is arranged in the defect area of the photo-etching glue pattern and covers the second part of the surface of the material layer.

Owner:CONTREL TECH CO LTD

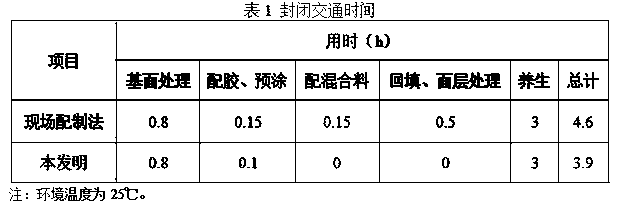

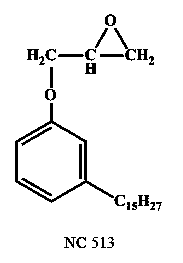

Construction method for rapidly repairing expansion joint heightening leveling layer

InactiveCN103966941AEasy to operateFast constructionBridge structural detailsRoads maintainenceEpoxyConstruction engineering

The invention discloses a construction method for rapidly repairing an expansion joint heightening leveling layer. The construction method the following steps: (1) preparing a repairing material prefabricated slab: mixing epoxy resin adhesive and aggregate to prepare a repairing material, laying the repairing material on a baseplate, and curing to obtain the repairing material prefabricated slab; (2) for a repaired area of the expansion joint heightening leveling layer, slotting according to the size of the repairing material prefabricated slab, removing a whole overlay in the slot until a concrete basal plane is exposed, removing sundries in the slot and leveling the slot, and forming a bonding plane of the repairing material prefabricated slab by the slot bottom and the slot side walls; (3) spraying the epoxy resin adhesive on the bonding plane, mounting the repairing material prefabricated slab in the slot, bonding the baseplate of the repairing material prefabricated slab with the slot bottom, and preserving for 2-4 hours to complete repairing of the expansion joint heightening leveling layer. The construction method is simple to operate, rapid in construction, carried out at a normal temperature, short in traffic closing time, and easy to control construction quality, and has high interface bonding strength of the repairing material prefabricated slab.

Owner:广州溪山环保科技有限公司

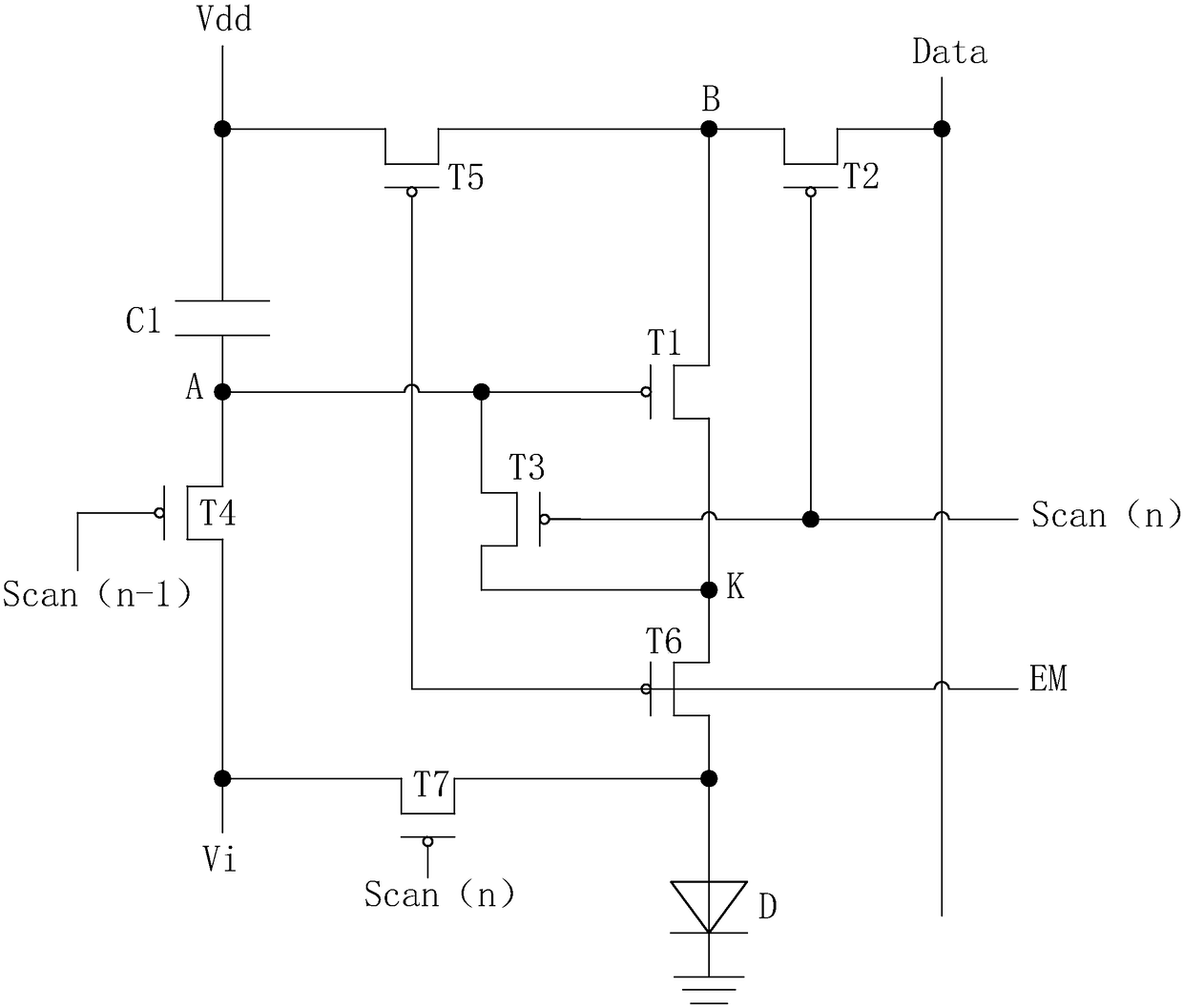

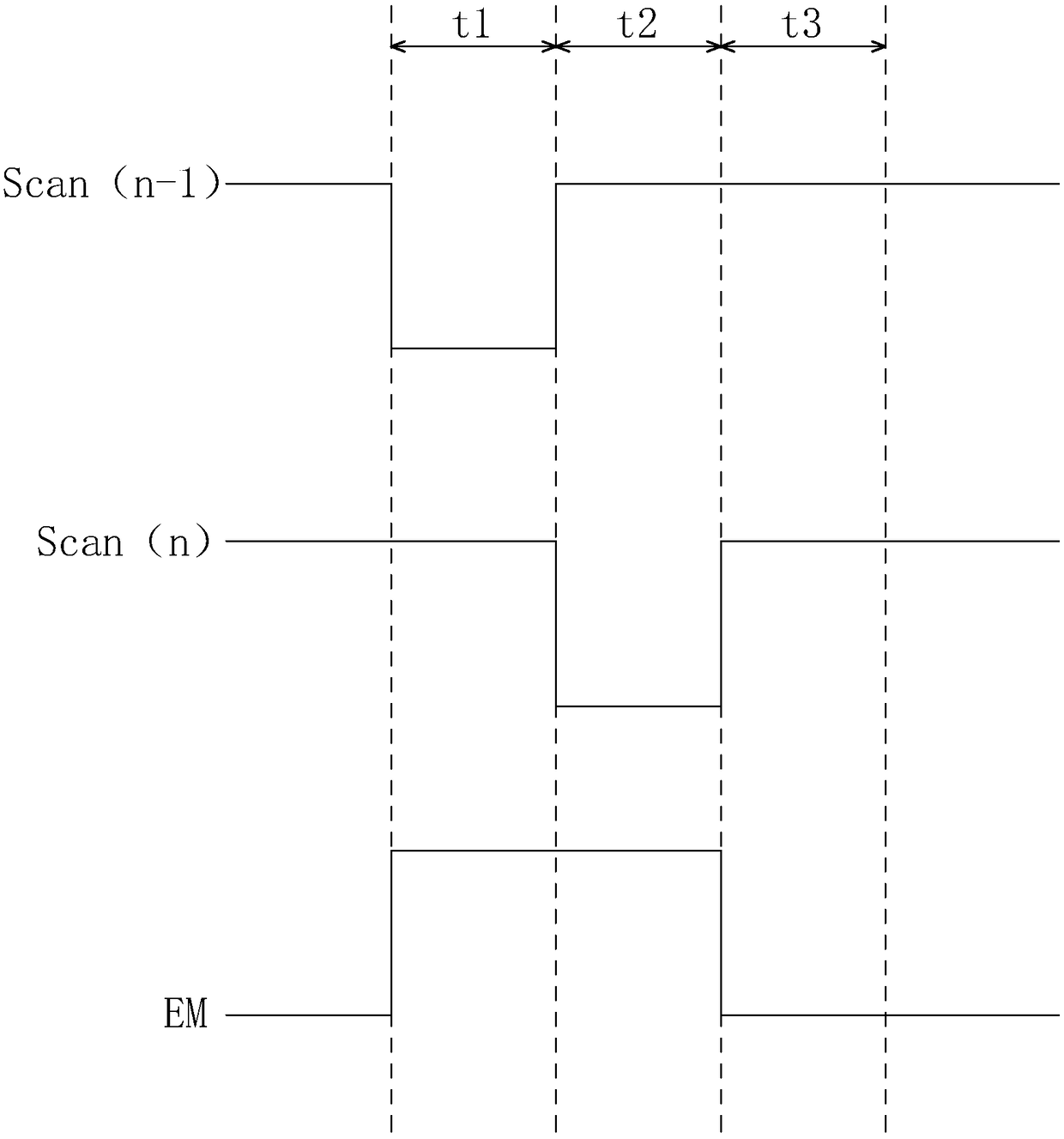

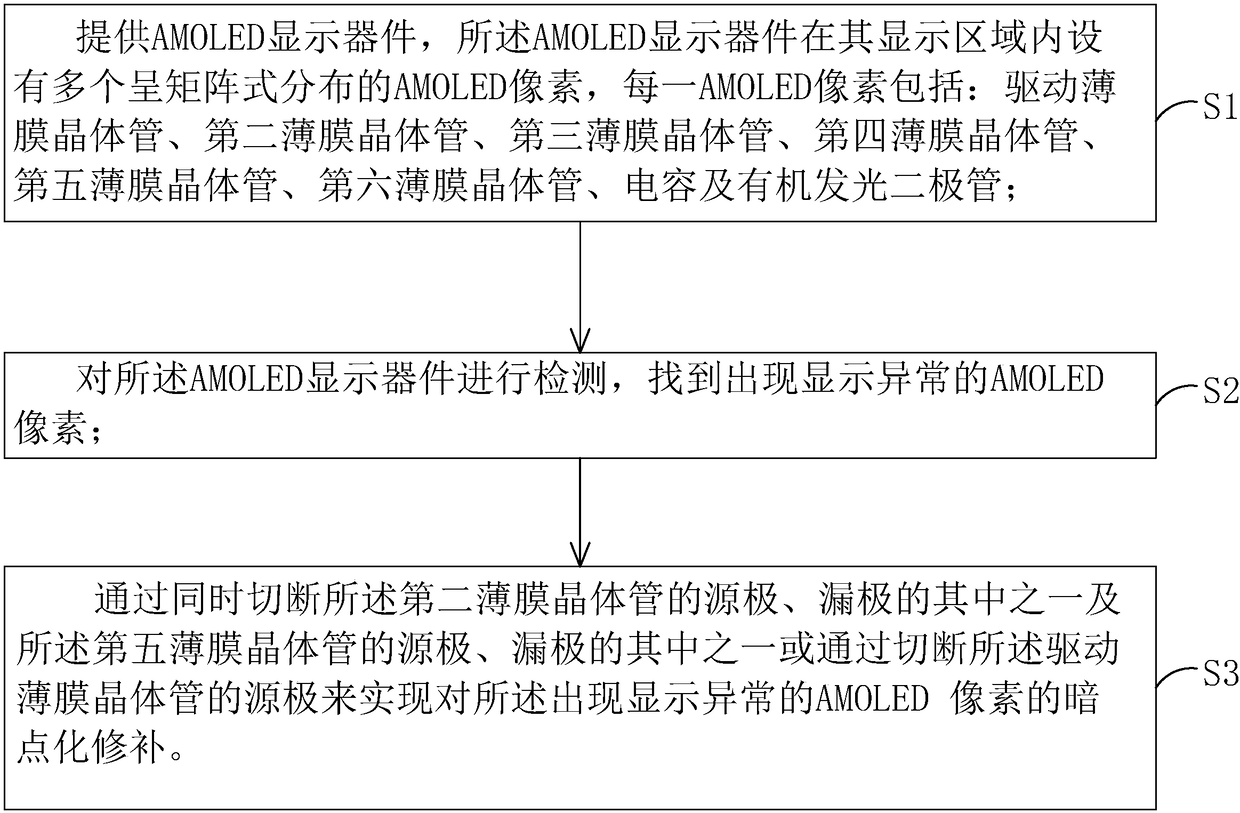

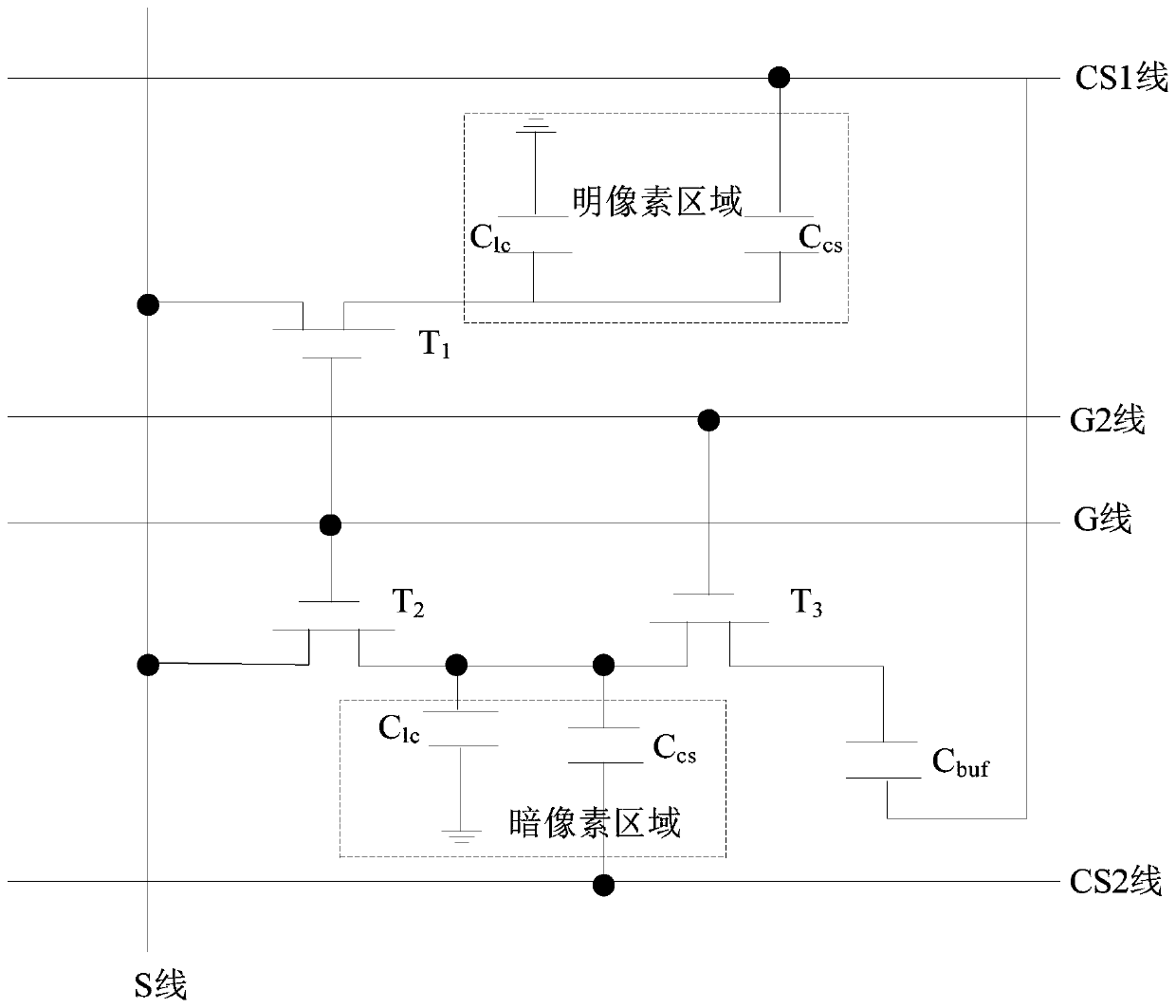

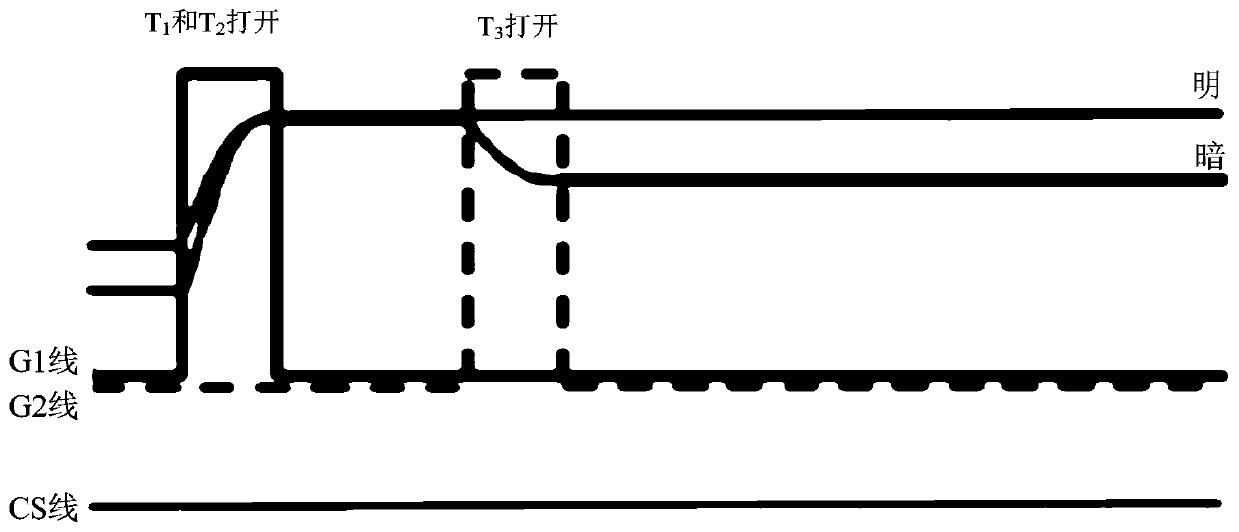

AMOLED pixel repairing method

InactiveCN108122519ARealize dark spot repairReduce laser energyStatic indicating devicesSolid-state devicesRepair timeTransmitted power

The invention provides an AMOLED pixel repairing method. According to the invention, a path for transmitting a data signal (Data) to a driving thin film transistor (T1) in an AMOLED pixel which is abnormal in display is cut off and a path for transmitting power voltage (Vdd) to the driving thin film transistor (T1) in the AMOLED pixel which is abnormal in display is cut off through simultaneouslycutting off one of a source electrode and a drain electrode of a second thin film transistor (T2) and one of a source electrode and a drain electrode of a fifth thin film transistor (T5) or through cutting off a source electrode of the driving thin film transistor (T1), thereby realizing dark spot repairing for the AMOLED pixel which is abnormal in display, being capable of reducing laser energy required by the repairing, and saving the repairing time.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

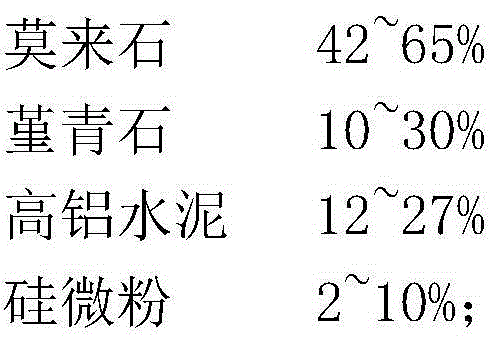

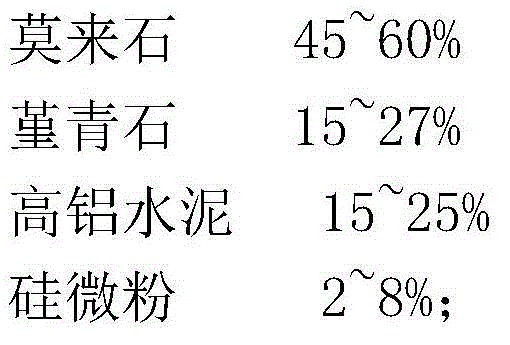

Mullite-based coating material for rocket launching pad and application of mullite-based coating material

The invention discloses a mullite-based coating material for a rocket launching pad. The mullite-based coating material is prepared from mullite, cordierite, high-alumina cement and silica powder. The high-temperature combustion gas stream resistant mullite-based coating material for the rocket launching pad can protect a rocket launching pad metal structure against scouring and high-temperature ablation of high-temperature combustion gas streams, ensure reliability of working of the launching pad and prolong the service life of the launching pad. The mullite-based coating material for the rocket launching pad is applicable to high-humidity, high-salt-mist and high-ultraviolet-irradiation environments, is good in anti-corrosion performance and meets requirements for protecting the base body protection material of the rocket launching pad when the rocket launching pad is developed in coastal regions where transportation and launching are more convenient. The mullite-based coating material construction is easy and convenient. Raw materials for the mullite-based coating material are free of poison and corrosion, have the advantages of saving energy and being environmentally friendly and play an important role in improvement and protection of the environment.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

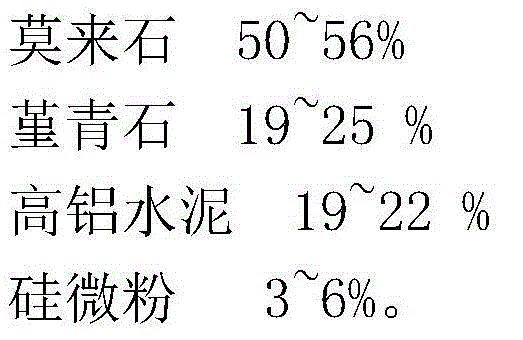

Gas pipeline repairing method and system based on Beidou differential positioning

The invention discloses a gas pipeline repairing method and system based on Beidou differential positioning. The method comprises the steps that 1, first positioning data are collected and uploaded inthe pipeline welding process; 2, the first positioning data are sent to a detector; 3, second positioning data are collected during maintenance, and a priority detection point is determined by usingthe first positioning data and the second positioning data; 4, if the priority detection point is a leaking point, the step 5 is executed, if the priority detection point is not the leaking point, detection is continued, and the step 5 is performed after the priority detection point is determined to be the leaking point; 5, the position of an excavation point is determined according to the position of the leaking point and the position of a joint point; and 6, the target position is determined according to third positioning data and position data of the excavation point, and the leaking pointof the gas pipeline is repaired after excavation. The system includes connecting equipment, the detector, repair equipment, a server and the like. By means of the gas pipeline repairing method and system, the gas pipeline repairing efficiency can be can significantly improved, the gas pipeline repairing time is shortened, the labor input cost is effectively reduced, and the dependence on the maintenance personnel experience is avoided.

Owner:BEIJING CNTEN SMART TECH CO LTD

Whole steel wire radial tyre cold-patch rubber sheet and special glue for repairing tyre using said rubber sheet

InactiveCN101134370AAvoid local secondary vulcanizationExtended service lifeNatural rubber adhesivesNon-macromolecular adhesive additivesVulcanizationDynamic balance

The present invention discloses vulcanized patch for cold repairing all steel radial tire and special glue for repairing tire with the patch. The vulcanized patch is one vulcanized and formed rubber body with adhering surface and embedded steel wire cord. When it is used in cold repairing tire, there is no need of secondary vulcanization of the local tire, and the repaired tire has greatly prolonged service life and unaffected dynamic balance and may be retreaded for the second time. The repaired tire is further vulcanized by means of the friction heat between the tire and ground and the patch has firm combination to the tire and excellent sealing performance. The cold repair has short repair period, low cost and high strength.

Owner:汪斌

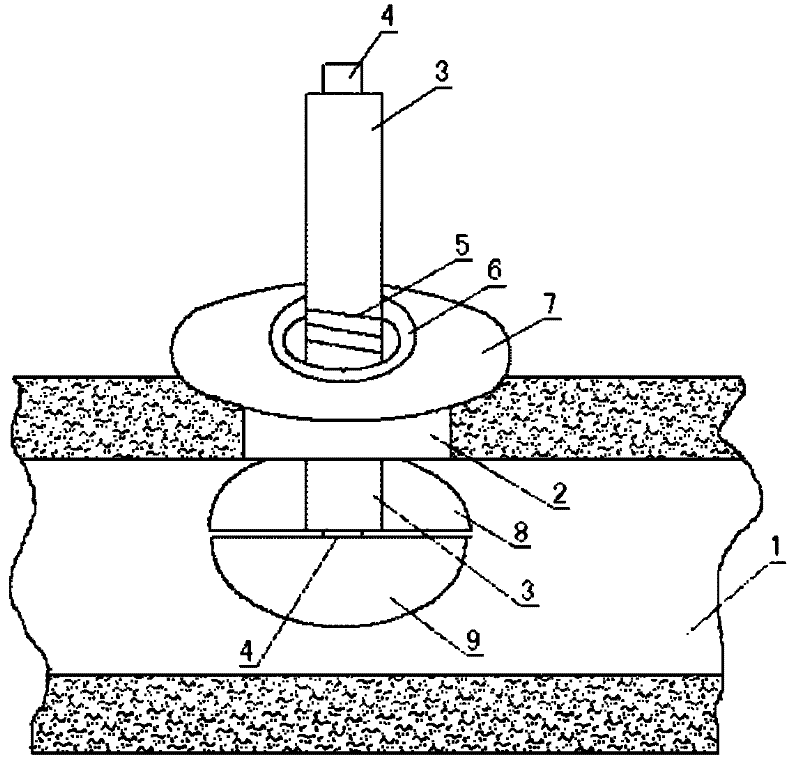

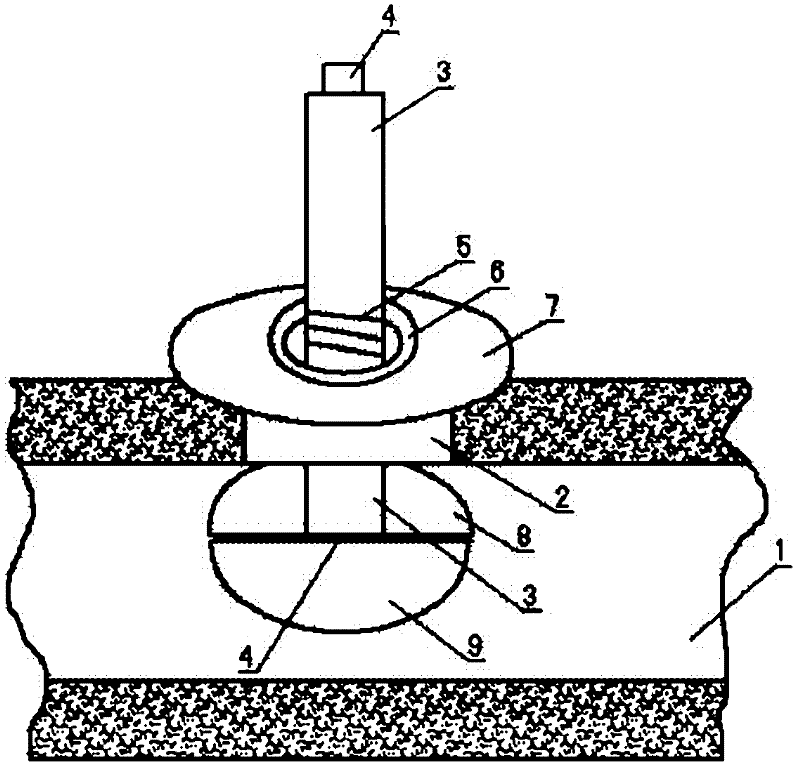

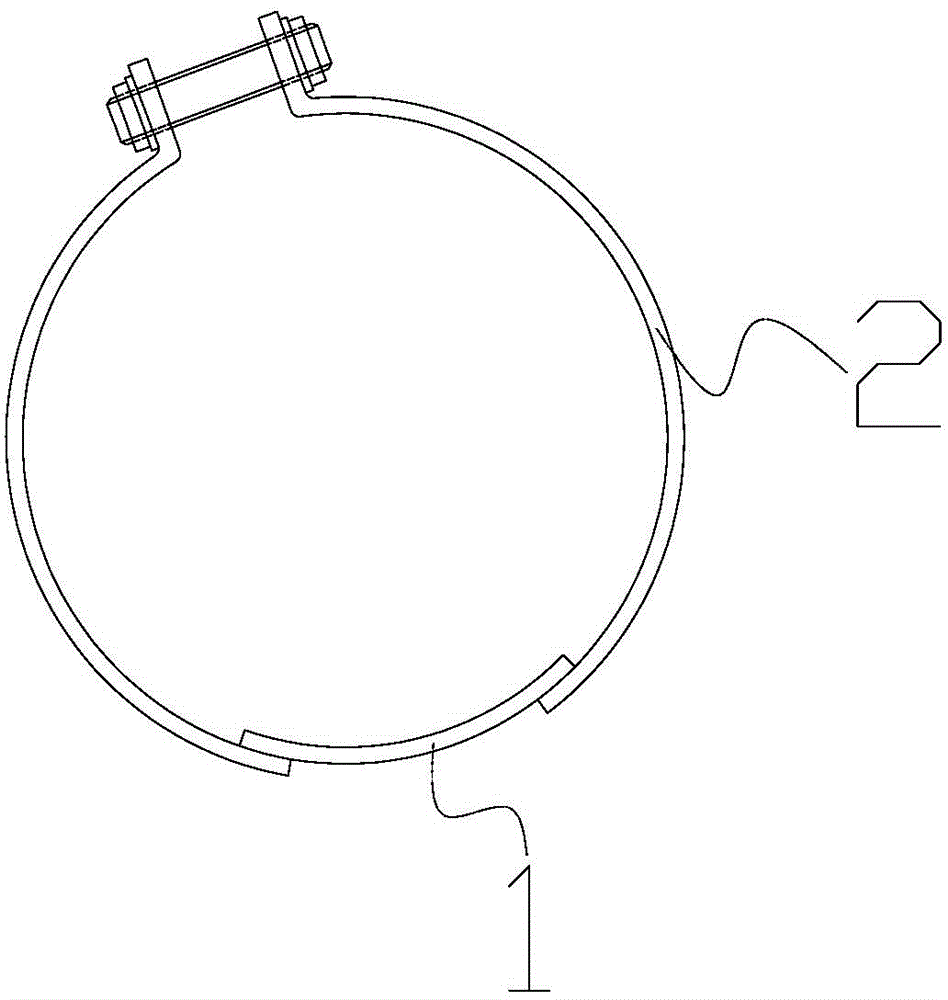

Emergency-repair tool for pipe line of prestress steel cylinder concrete pipe

The invention discloses an emergency-repair tool for a pipe line of a prestress steel cylinder concrete pipe. The tool comprises a connecting piece, a bearing part and a seal part which are respectively arranged at two ends of the connecting piece, wherein the bearing part comprises two semi-circular bearing plates which can be split and combined; the circle area formed by splitting the two semi-circular bearing plates is greater than the area of a damaged opening on a pipeline; the seal part comprises a seal plate and a fastening piece, wherein the area of the seal plate is greater than the area of the damaged opening on the pipeline; and the semi-circular bearing plate and the seal plate can be movably and respectively arranged at two sides of the damaged opening on the pipeline. In the emergency-repair tool for the pipe line of the prestress steel cylinder concrete pipe, through arranging the bearing part and the seal part, the damaged opening at the inner part and the outer part of the pipe line is respectively sealed, then further concrete is filled in the seal space, and the repair of the pipe line of the prestress steel cylinder concrete pipe can be realized, thus the emergency repair work of the pipe line can be finished without draining water in the pipe line completely.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

Broken line repairing method and device, electronic equipment and storage medium

ActiveCN111399295ASimplify the process of patching broken wiresReduce coverage areaSolid-state devicesSemiconductor/solid-state device manufacturingRepair timeStructural engineering

The invention provides a broken line repairing method and device, electronic equipment and a storage medium. The method comprises the following steps: obtaining a first metal layer according to the disconnection position of the first gate line of the first metal layer; determining the position of a first repairing point and the position of a second repairing point on two sides of the broken line position; the first repairing point and the second repairing point are respectively positioned in two adjacent pixel electrode regions; respectively forming a first repair point and a second repair point at the position of the first repair point and the position of the second repair point, and cutting off the second gate line, so that the second gate line positioned outside the first repair point and the second repair point is not conducted, and the second gate line positioned between the first repair point and the second repair point is conducted; and after the electrode layer is formed, performing broken line repair on the electrode layer according to the cut-off position of the second gate line. According to the broken line repairing method provided by the invention, the broken line repairing process of the gate line is simplified, the repairing time is shortened, and the repairing efficiency is improved.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

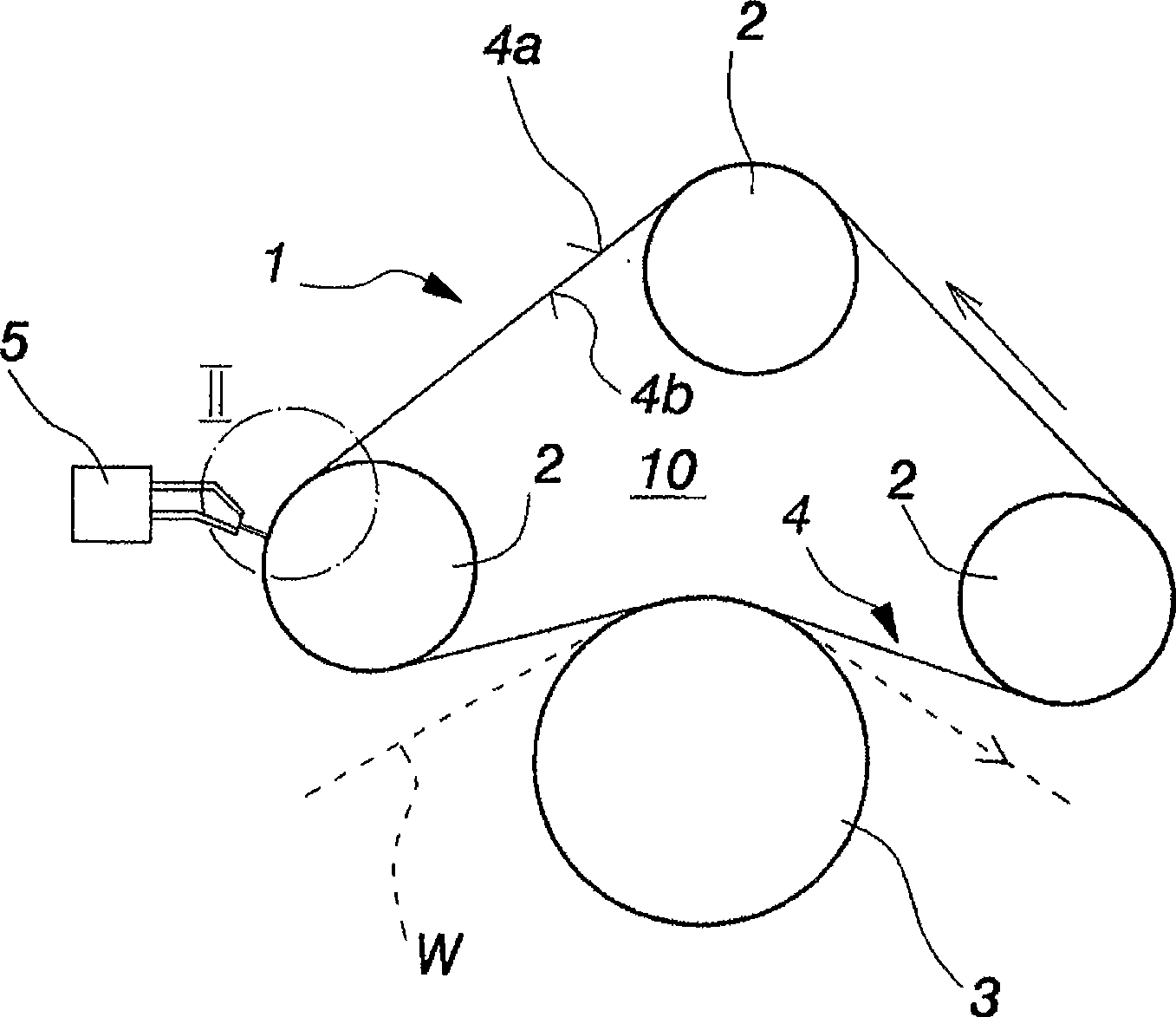

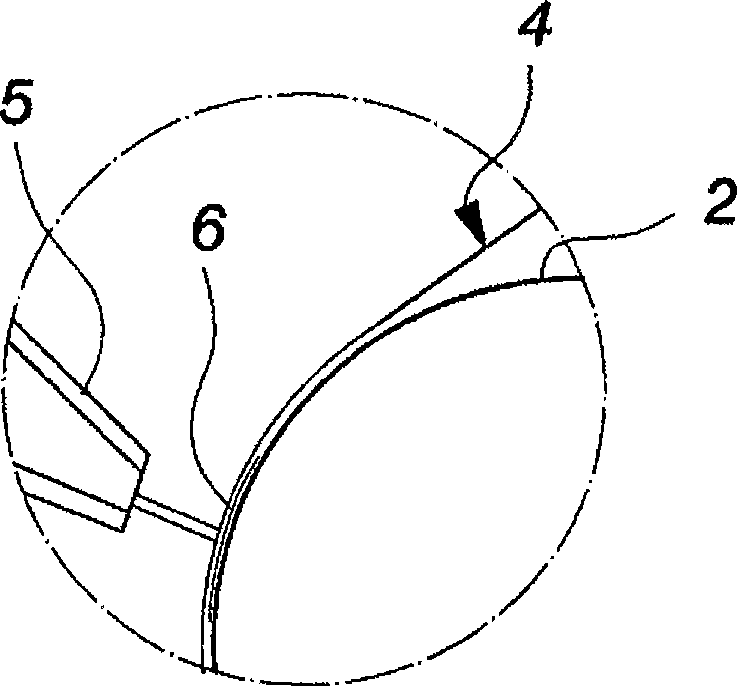

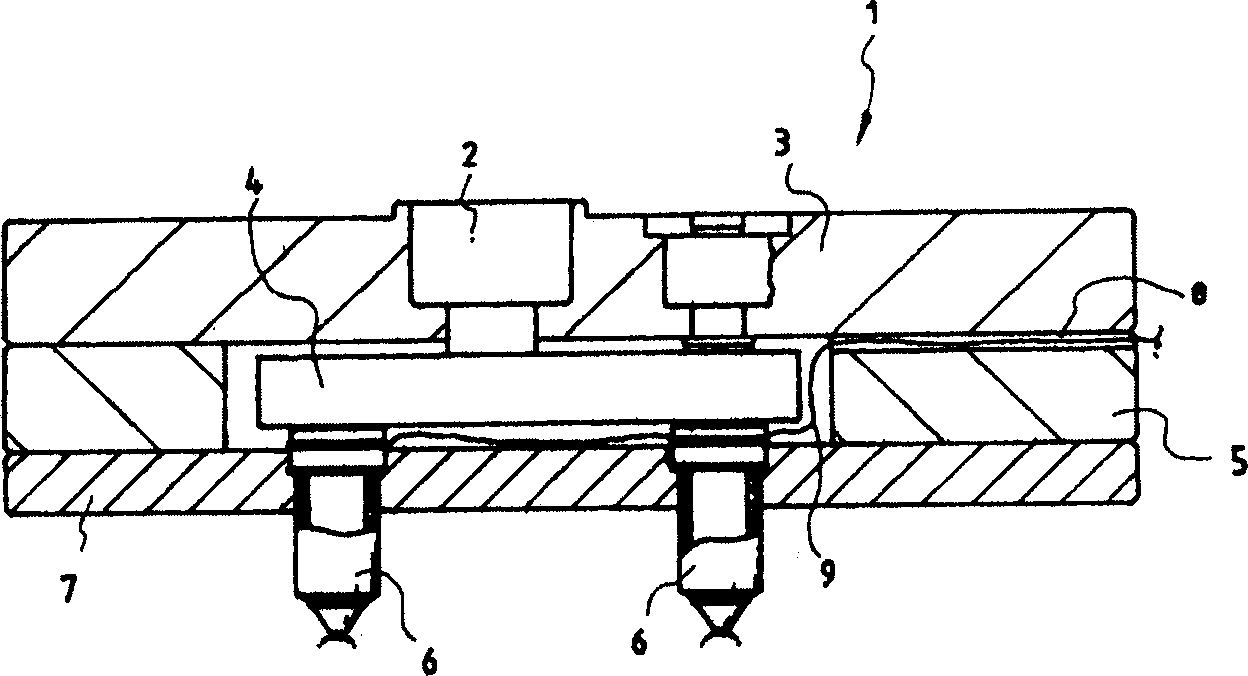

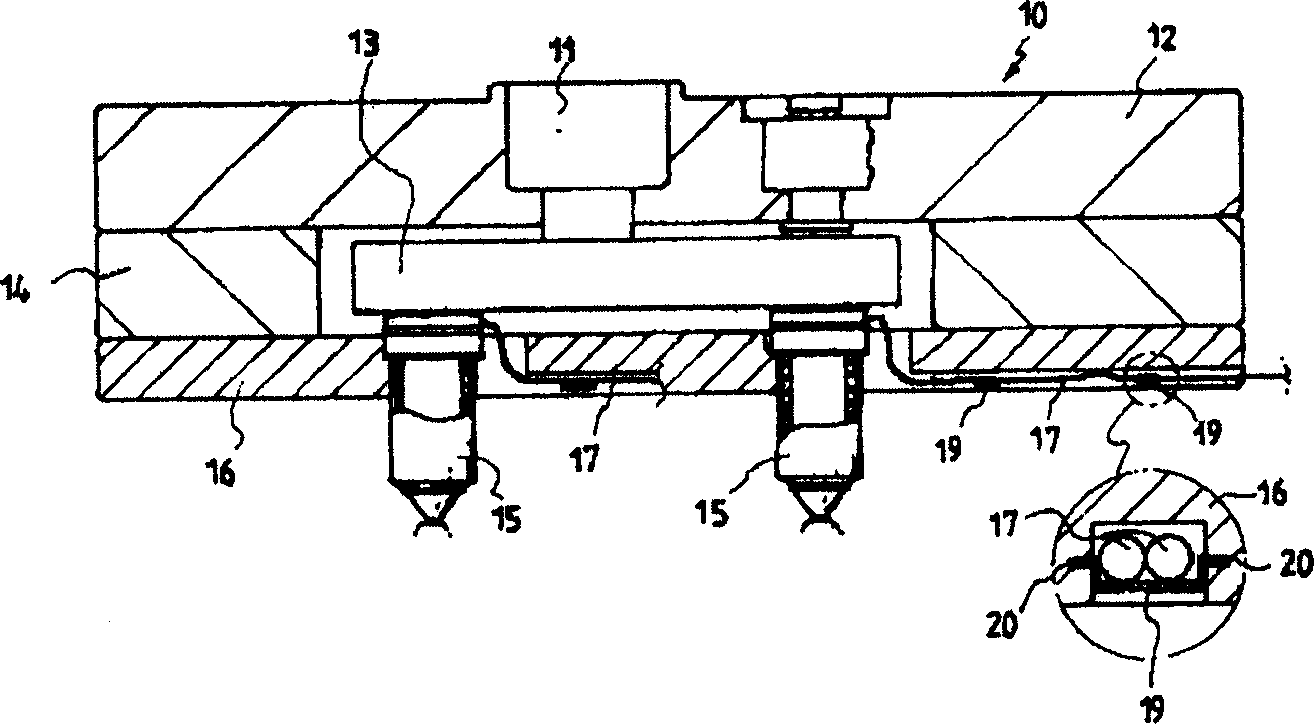

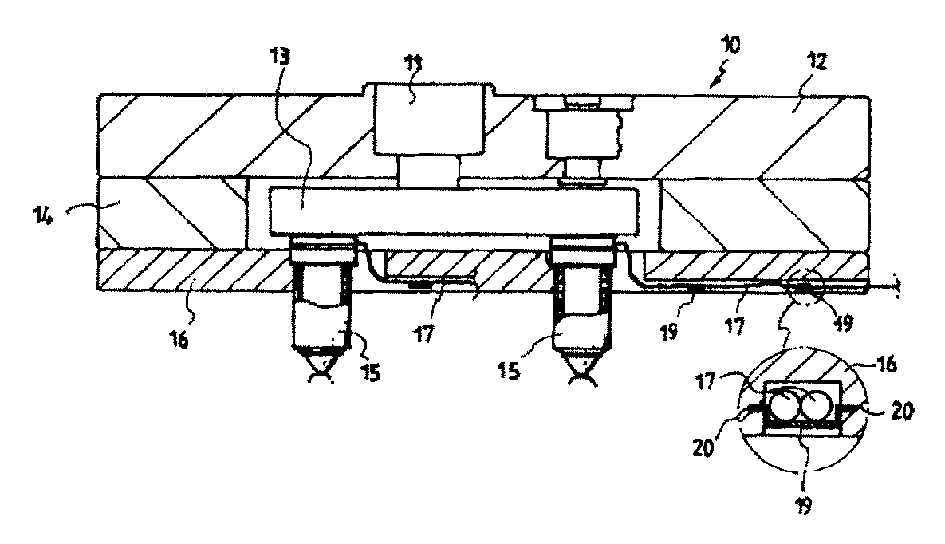

Steel strip repair welding method used in fiber breadth material machine

InactiveCN101396778AAvoid waiting timeShorten patching timeWelding/cutting auxillary devicesCalendersEngineeringSteel belt

The present invention relates to a method for mending and welding the steel strip (4) used in a fiber web machine (1). In the method, an annular metal strip (4) which is supported by a plurality of conveying roller (2) and is in an operating state is stopped from moving. The position of the metal strip (4) to be welded is stopped on a surface of the conveying roller (2) along an operating direction of the metal strip (4). The metal strip (4) is supported by the conveying roller (2) at least at the position to be welded. The metal strip (4) is executed with mending and welding from an oppositeside of the surface (4b) opposite to the conveying roller (2).

Owner:METSO PAPER INC

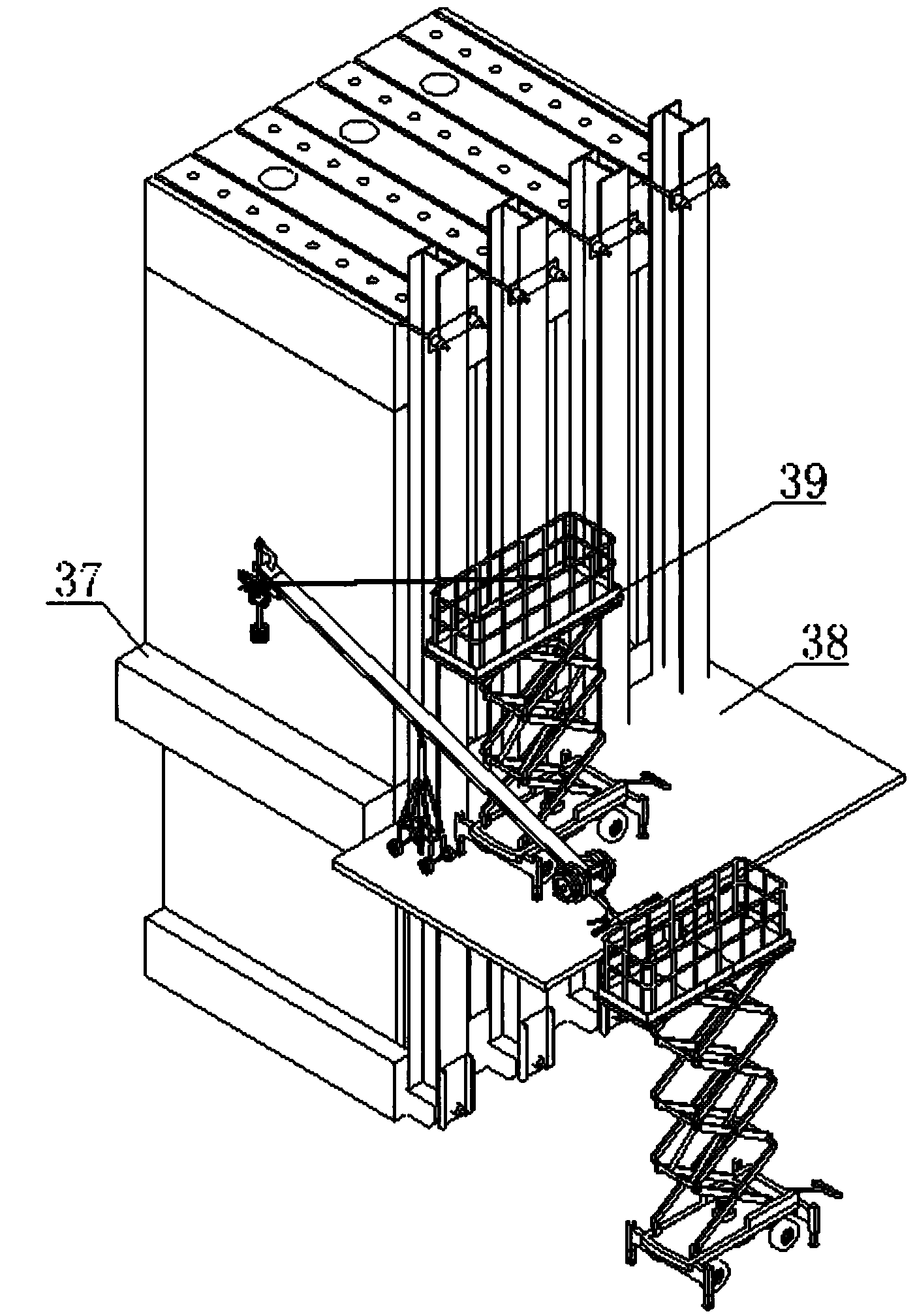

Method for hot repairing of local damage of coking chamber wall of coke oven

The invention provides a method for hot repairing of local damage of the coking chamber wall of a coke oven. The method includes the following steps: opening the gate of a coke oven, observing the coking chamber wall, and making a gun head guide rail by adopting CAD software; processing a filling repairing brick, determining the position of a rocker arm movable supporting frame, and erecting a lifting platform; operating an extension pole to carry out bonded spray repairing on a filling seam by the gun head; loosening a filling brick clamp, moving a rocker arm, aligning the spray repairing end of a surface filling spray material conveying tube with a filling brick, and carrying out leveling spray repairing; and observing the repairing effect, and archiving. The method reduces the occurrence probability of safety accidents in construction work, effectively alleviates the harms of high temperature, gas and toxic gases to human bodies, saves the repairing time and the workload for repairing secondary damage caused by cooling, greatly reduces the labor intensity, and improves the work efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP

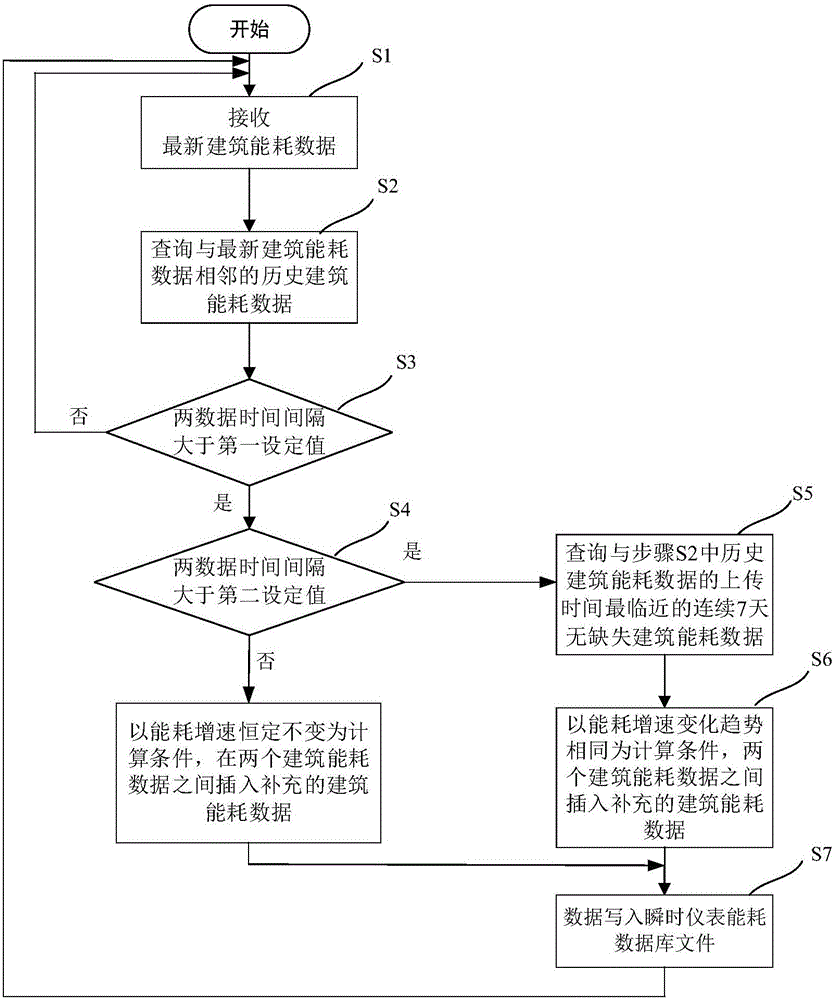

Regional building energy consumption platform data mending method

ActiveCN105930349AReduce manual data maintenanceShorten patching timeData processing applicationsEnergy efficient computingMissing dataBuilding energy

The invention relates to a regional building energy consumption platform data mending method. The method includes the following steps: receiving building energy consumption data from a data source in real time, mending missing data according to a meter number and the uploading time, and inserting complemented building energy consumption data to an energy consumption database to reduce manual data maintenance of maintenance workers; determining uploading time intervals, performing rapid treatment on building energy consumption data with short missing time intervals so as to reduce the data mending time; and performing special treatment on building energy consumption data with long missing time intervals, allowing the complemented energy consumption data to be close to actual energy consumption data and meet the energy consumption trend of a building per week to the greatest extend in the condition that the energy growth trends in adjacent 7 days are identical. Compared with the prior art, the method can mend the building energy consumption data in real time, allow the complemented energy consumption data to be close to the actual data to the greatest extent, and has a high execution efficiency.

Owner:SHANGHAI SIIC LONGCHUANG SMARTER ENERGY TECH CO LTD

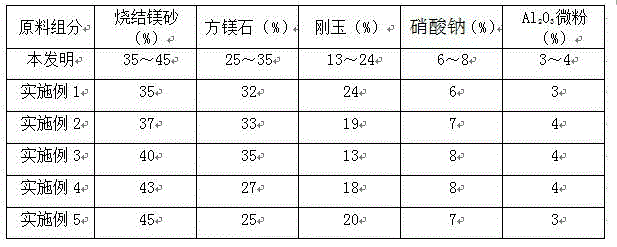

Thermal gunning material for RH furnace lower portion groove working lining magnesium-aluminum spinel brick

The invention relates to a thermal gunning material for a RH furnace lower portion groove working lining magnesium-aluminum spinel brick. A purpose of the present invention is to solve the technical problems of high bounce rate, long repair work time and difficult low-silicon smelting during the hot-state repair of the RH furnace lower portion groove working lining magnesium-aluminum spinel brick in the prior art. The thermal gunning material comprises the following raw materials by weight: 35-45% of sintered magnesia, 25-35% of periclase, 13-24% of corundum, 6-8% of sodium nitrate, and 3-4% of Al203 micro-powder. According to the present invention, the thermal gunning material is mainly used for the hot-state repair of the RH furnace lower portion groove working lining magnesium-aluminum spinel brick, wherein the service life of the RH furnace lower portion groove working lining achieves more than 4 times the original service life after the repair, and compared with the bounce rate of the existing gunning material of 20%, the bounce rate of the gunning material of the present invention is reduced to less than or equal to 5% during the thermal repair.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

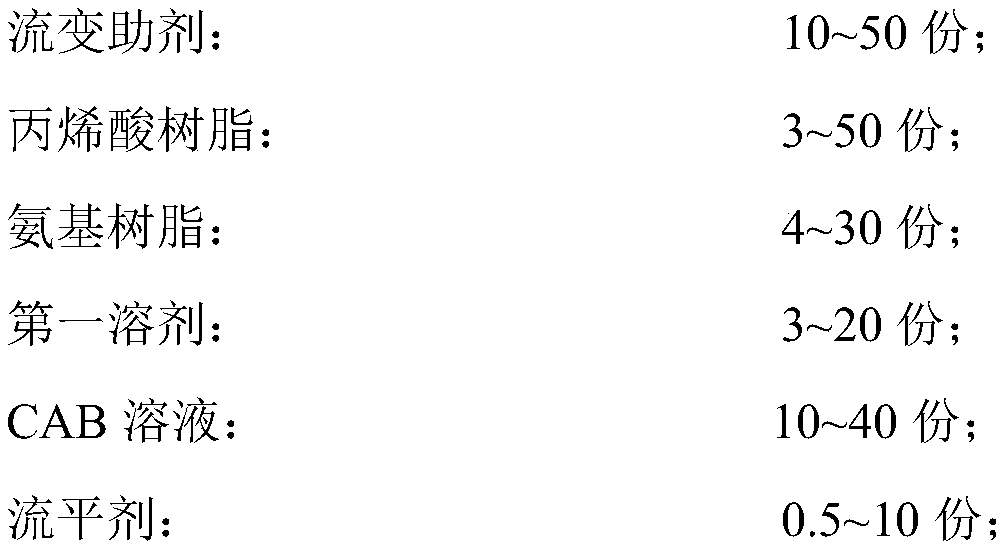

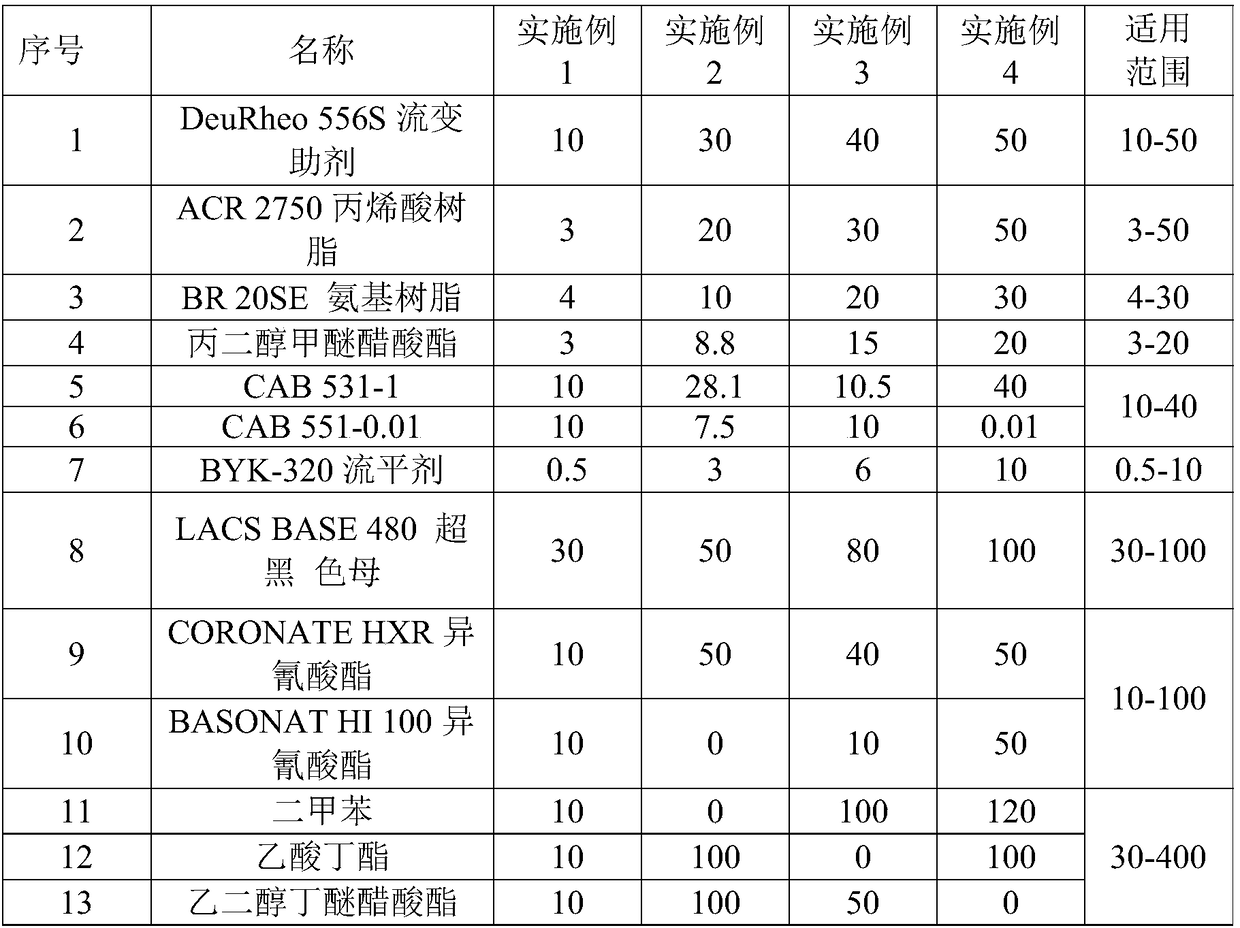

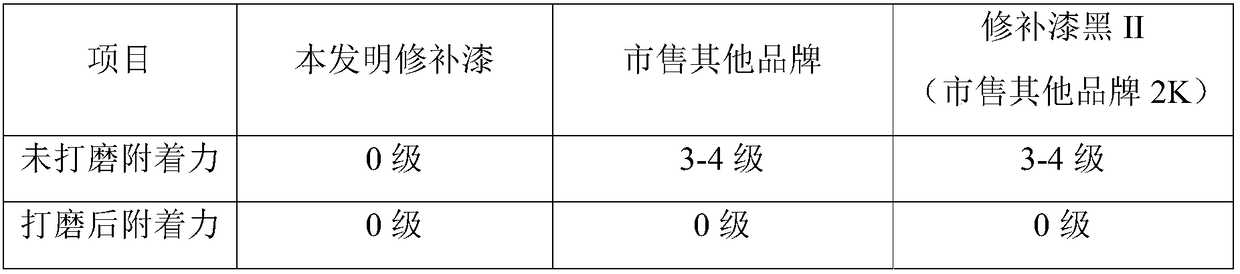

High-adhesive-force and low-temperature refinishing paint composition and preparation method thereof

The invention discloses a high-adhesive-force and low-temperature refinishing paint composition and a preparation method thereof. The refinishing paint composition is prepared from a curing componentand a diluting component, wherein the curing component is prepared from the following components: a rheological auxiliary agent, acrylic resin, amino resin, a first solvent, a CAB (Cellulose Acetate Butyrate) solution and a leveling agent; the diluting component is prepared from the following components: a second solvent, a third solvent, a fourth solvent, a leveling agent, first isocyanate and second isocyanate. The preparation method of the refinishing paint composition comprises preparation of the curing component and preparation of the diluting component. After refinishing paint provided by the invention is subjected to color mixing, requirements on various refinishing paint in the market can be met. In a construction process, the surface of a coated part does not need to be subjectedto polishing treatment in a refinishing or coating process and the refinishing paint is directly sprayed, so that a refinishing procedure is accelerated and the time of a refinishing process is shortened; meanwhile, manual polishing is reduced and the refinishing cost is saved.

Owner:LANGFANG NIPPON PAINT

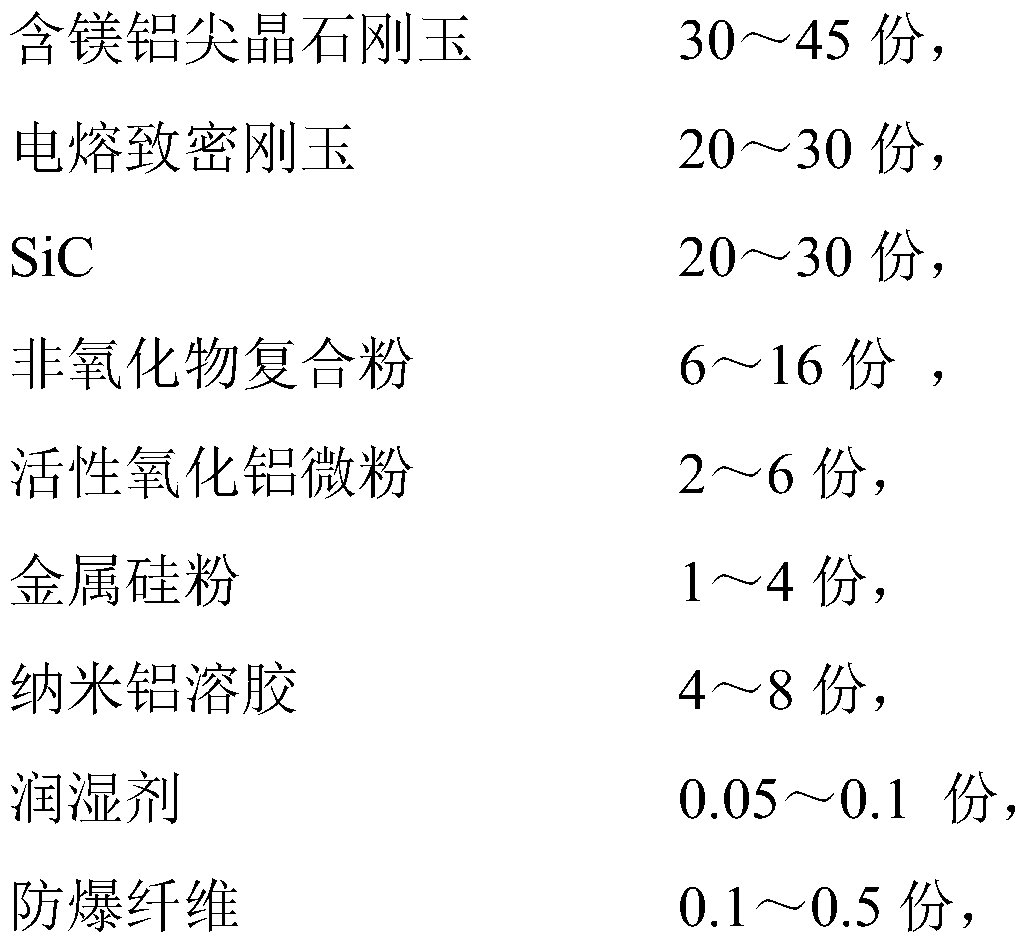

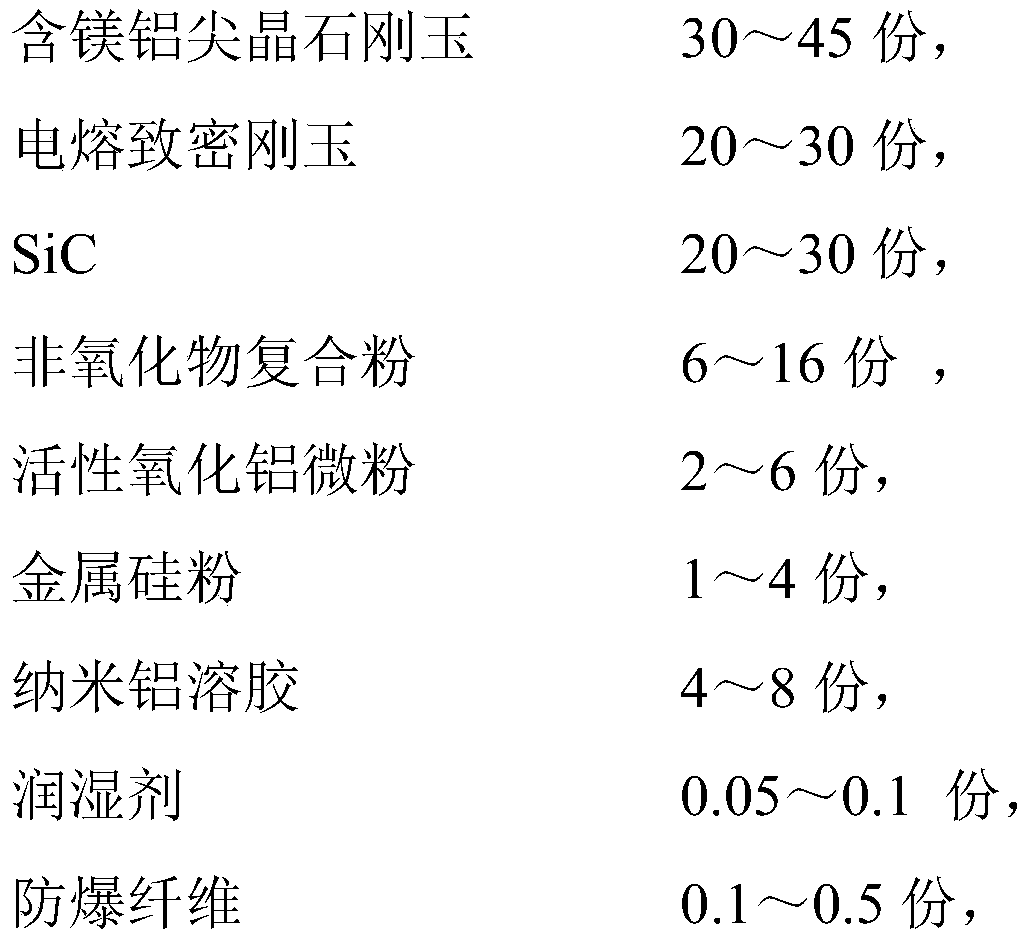

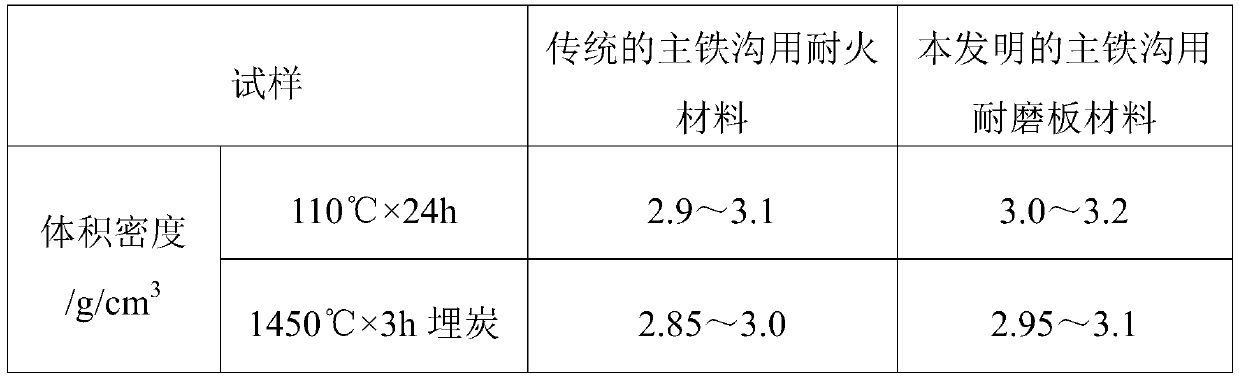

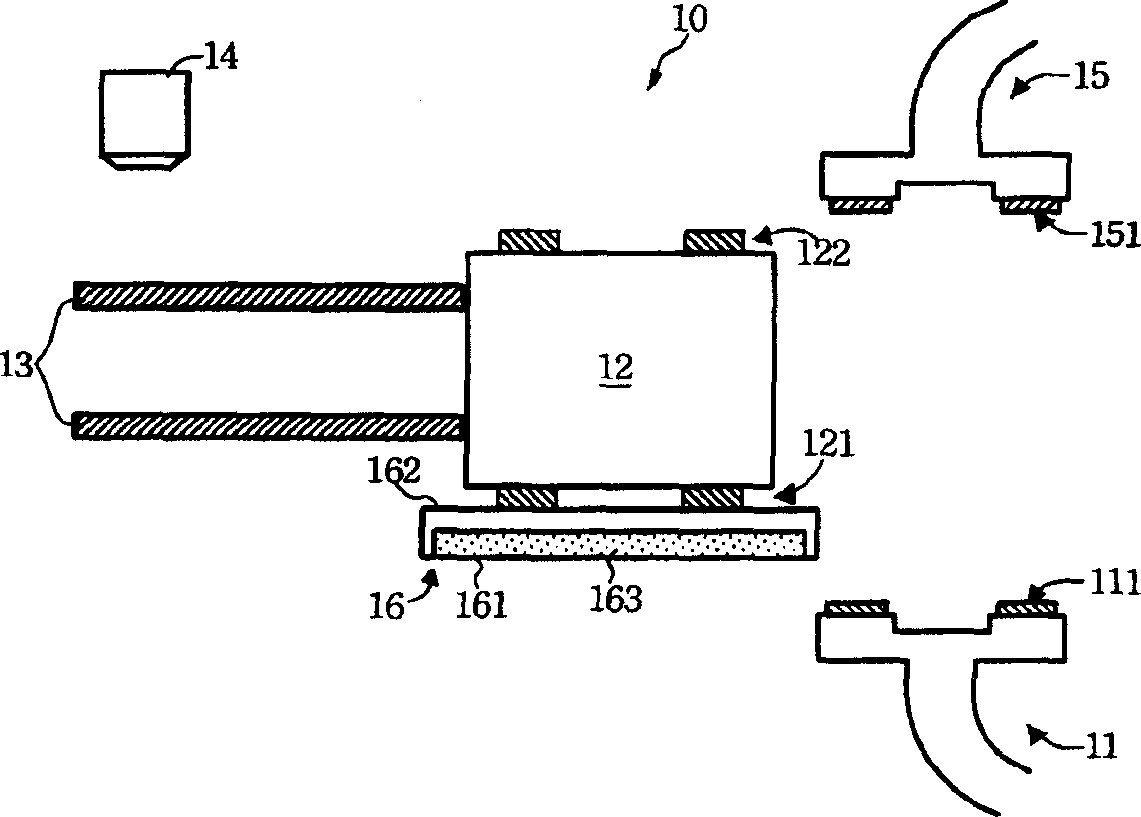

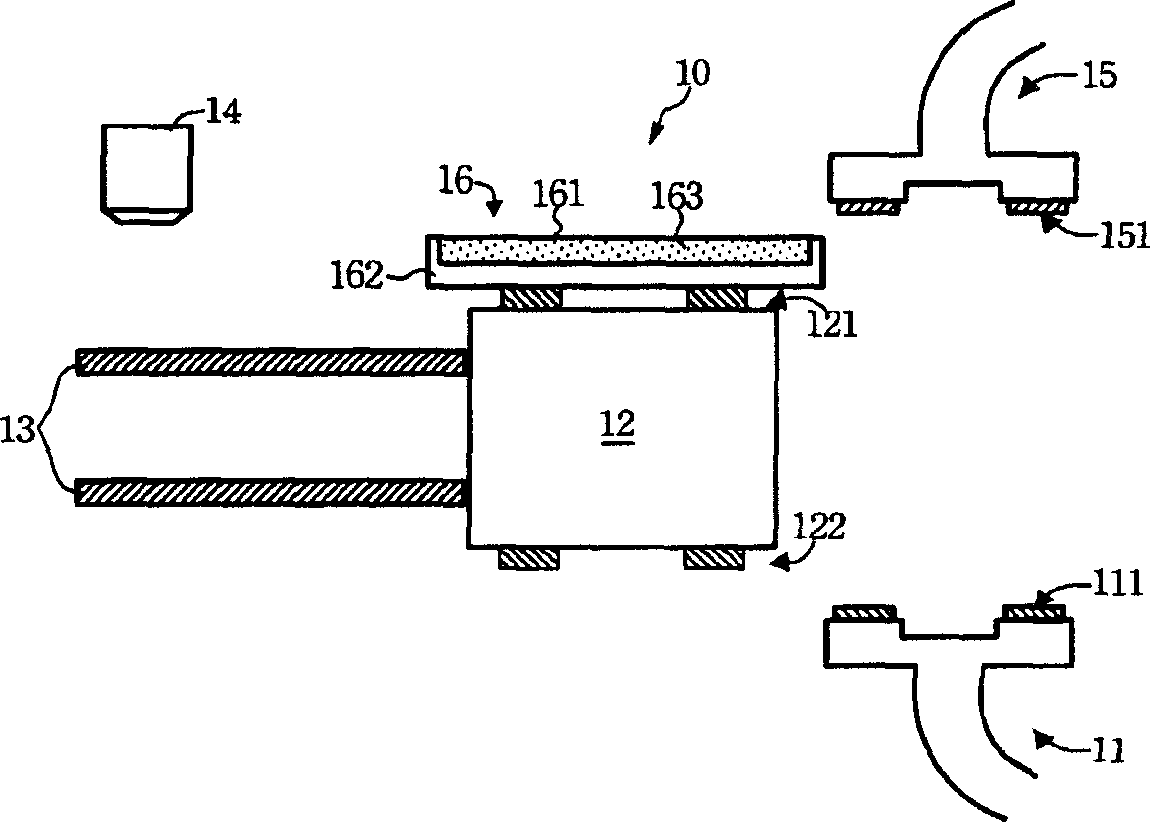

Nano-sol combined wear-resistant board used for main iron channel of blast furnace and production method and application thereof

ActiveCN109851333AImprove erosion and wear resistanceImprove thermal shock resistanceFiberWear resistant

The invention discloses a nano-sol combined wear-resistant board used for a main iron channel of a blast furnace. Raw materials of the wear-resistant board comprise, in parts by weight, 30-45 parts ofmagnesium-containing aluminium-containing spinel alumina, 20-30 parts of electro-fused dense alumina, 20-30 parts of SiC, 6-16 parts of nonoxide compound powder, 2-6 parts of activated aluminium oxide micro powder, 1-4 parts of silicon metal powder, 4-8 parts of nano-aluminum sol, 0.05-0.1 part of wetting agent and 0.1-0.5 part of explosion-proof fibers, wherein the nonoxide compound powder is composed of, in parts by weight, 1-3 parts of carbon black, 2-4 parts of silicon nitride, 1-5 parts of titanium carbonitride and 2-4 parts of aluminium titanate. The invention further discloses a production method and application of the wear-resistant board. By means of the nano-sol combined wear-resistant board used for the main iron channel of the blast furnace and the production method and the application thereof, the erosion resistance, the wear resistance and the corrosion resistance of a lining material of the main iron channel can be improved, a work environment of workers can be improved, remedial work time of the main iron channel can be shortened, and the service life of the main iron channel can be prolonged.

Owner:CHINA JINGYE ENG TECH CO LTD +2

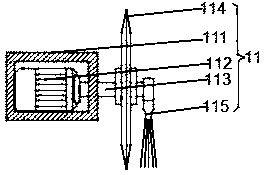

Method and its machine for repairing display panel bright spot

The machine includes working platform and laser creation device. The working platform possesses at least one adsorbing mechanism. Being setup below the working platform, the adsorbing mechanism is in use for adsorbing up surface of display faceplate. Being setup below the working platform, laser creation device can generate laser to display faceplate in order to repair bright spot on display faceplate.

Owner:AU OPTRONICS CORP

Method for clearing off brick residues at broken holes in wall of coke oven hot repair carbonization chamber

The invention provides a method for clearing off brick residues at broken holes in wall of a coke oven hot repair carbonization chamber. The method comprises the following steps: the construction workers observe an elevation position at the broken holes, determining the height and depth of the broken holes in the carbonization chamber, a rocker arm is manipulated, a sight hole is aligned to the broken holes in wall of the carbonization chamber, the broken holes image information can be obtained through a high temperature camera; damaged bricks which are characterized in that the outer bricks are small and inner bricks are large at the broken holes in wall of the carbonization chamber are cleaned by observating; the sight hole is aligned to the broken holes in wall of the carbonization chamber for checking the broken holes, the broken holes image information can be obtained, a hot repair plan is made, and then a brick filling and spraying material gunning scheme is determined. The method uses the carbonization chamber wall brick slag with the rocker arm manipulated outside a furnace, the method can be directly carried out for cleaning off broken brick residues of the internal wall body of the carbonization chamber under the conditions that operators do not need to enter the carbonization chamber and the temperature of the carbonization chamber is not reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

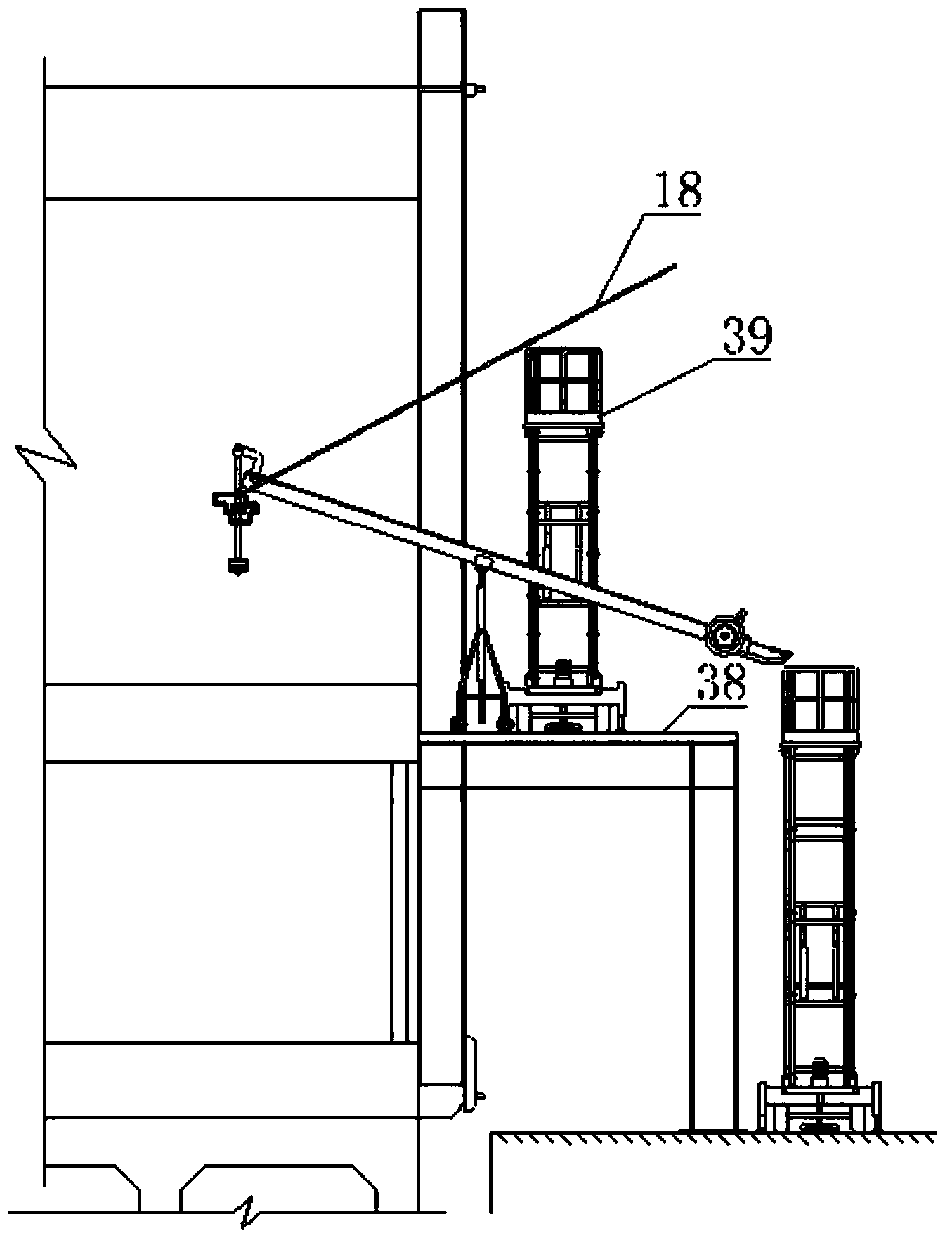

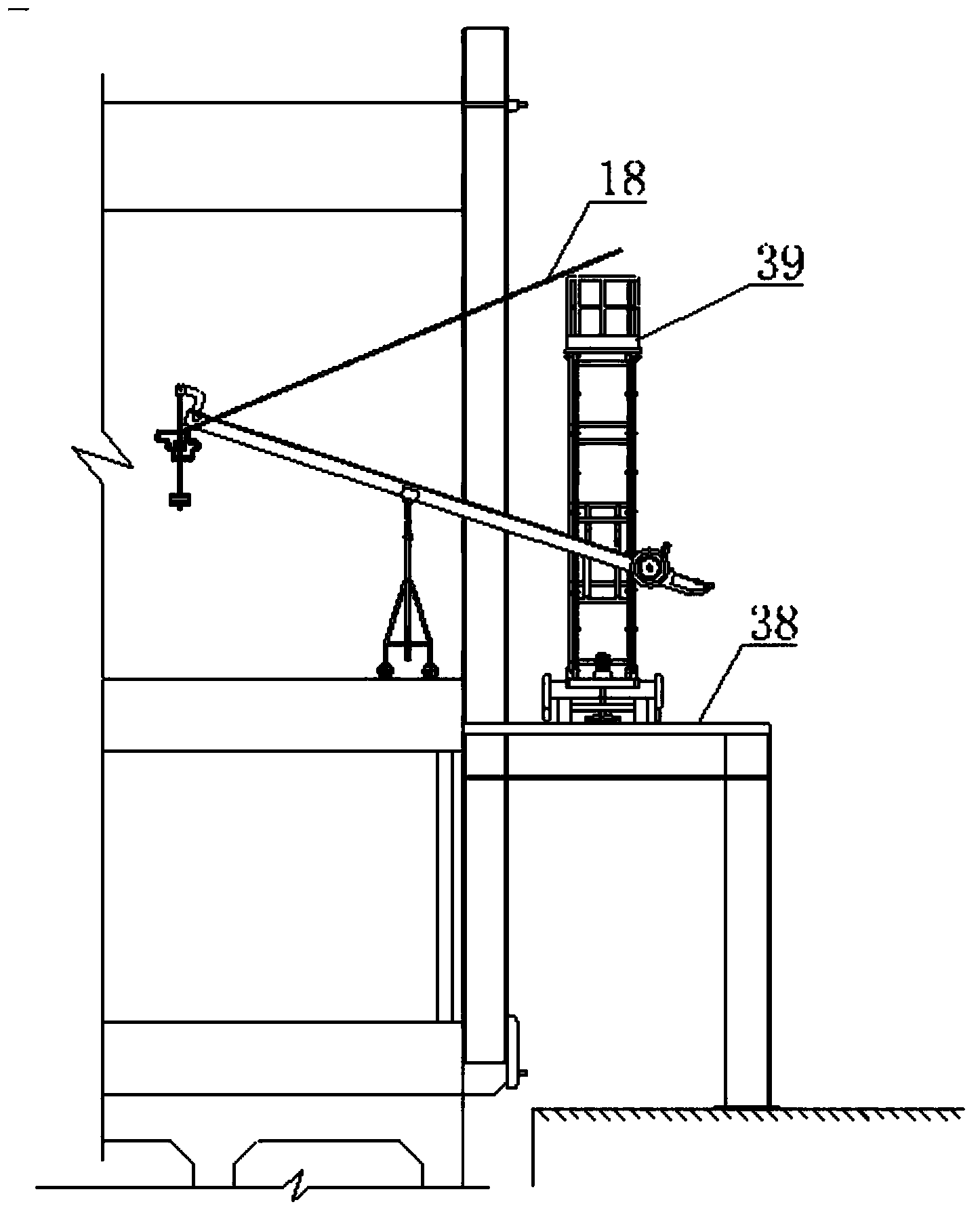

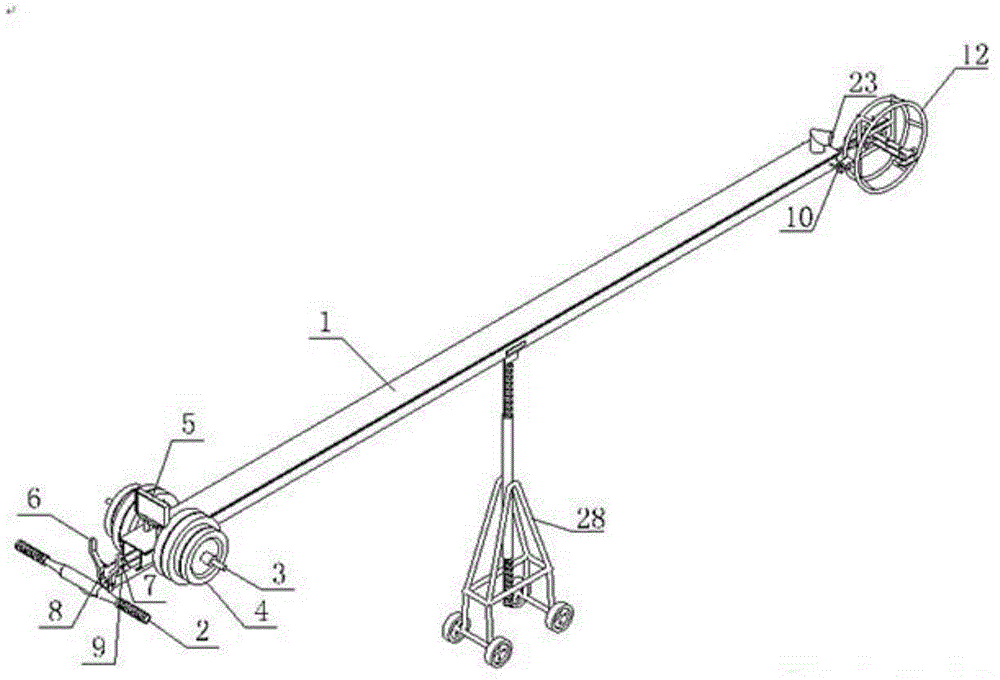

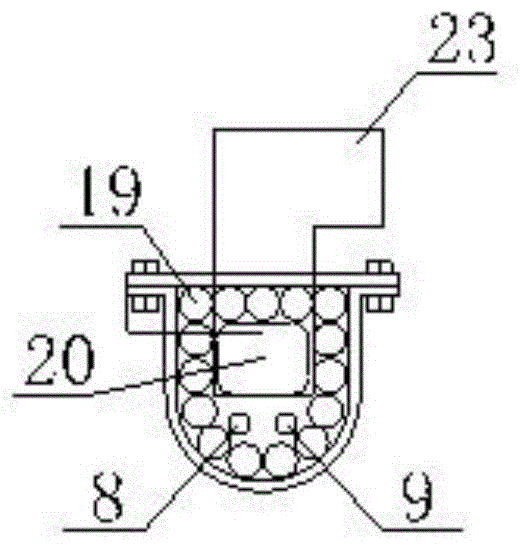

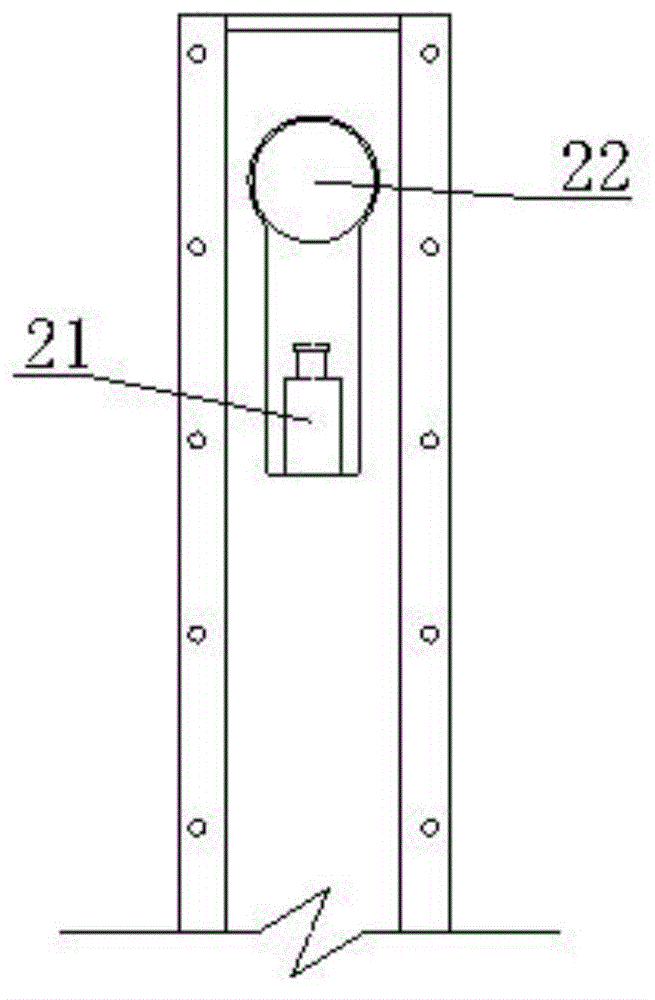

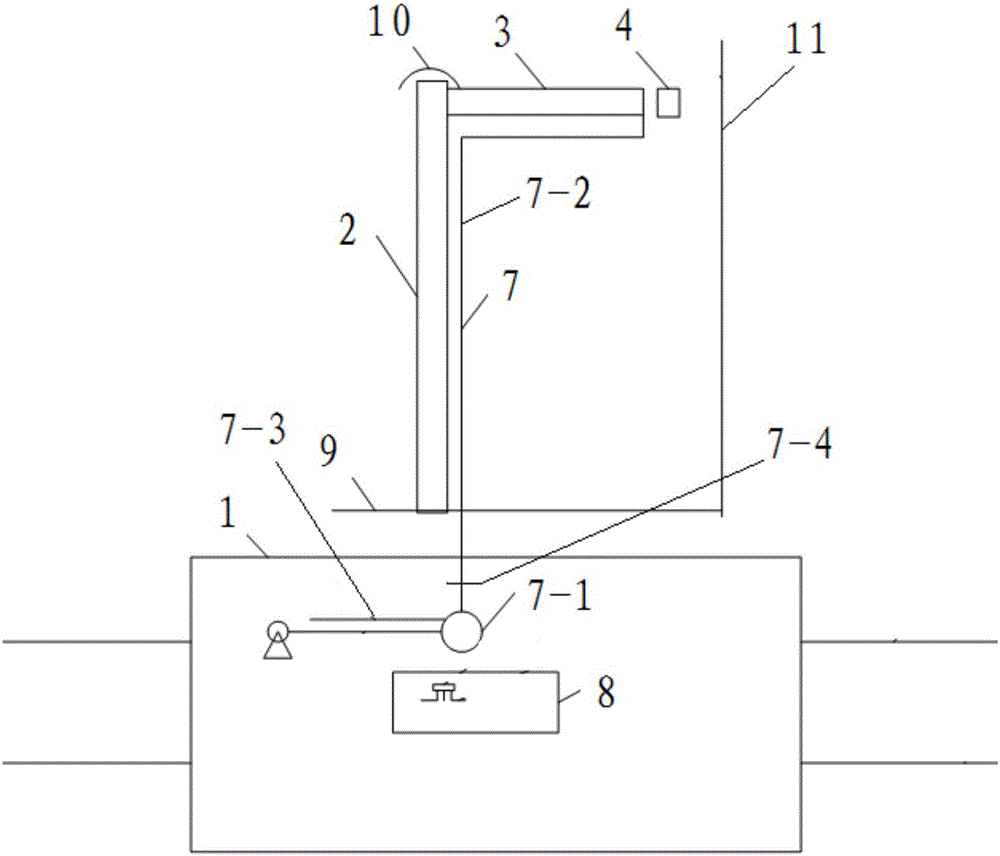

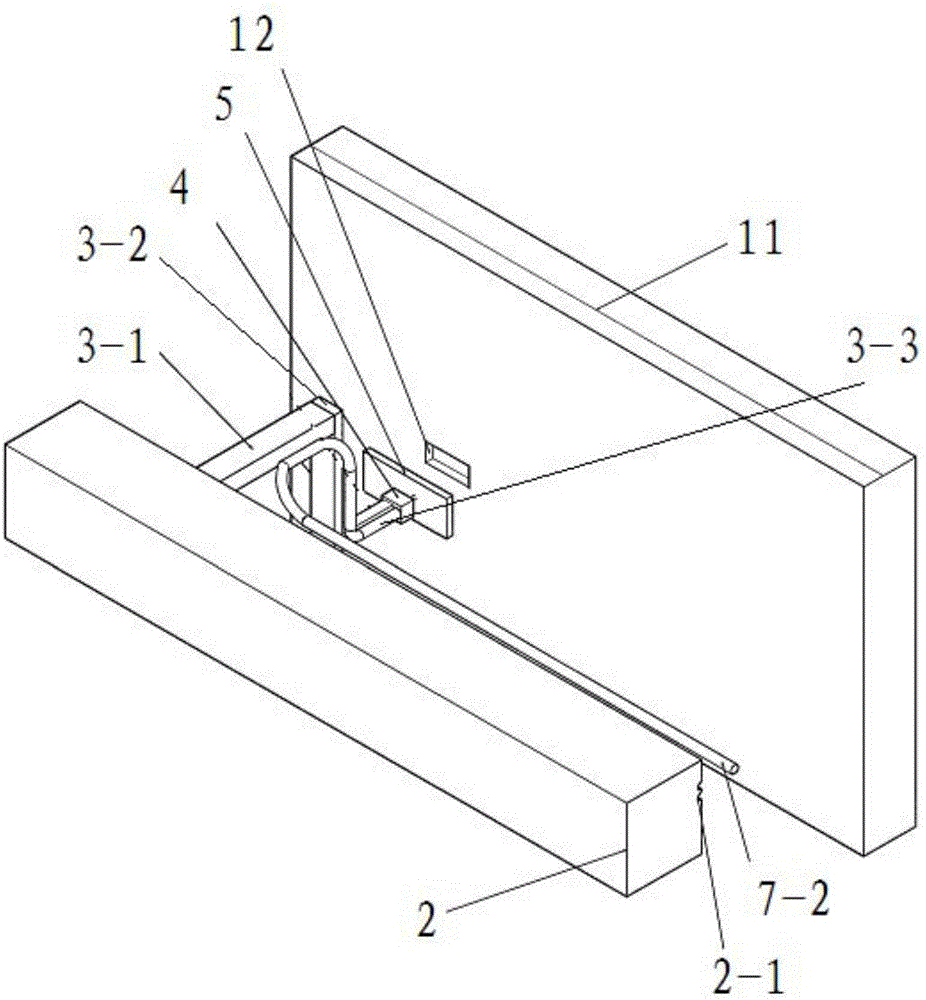

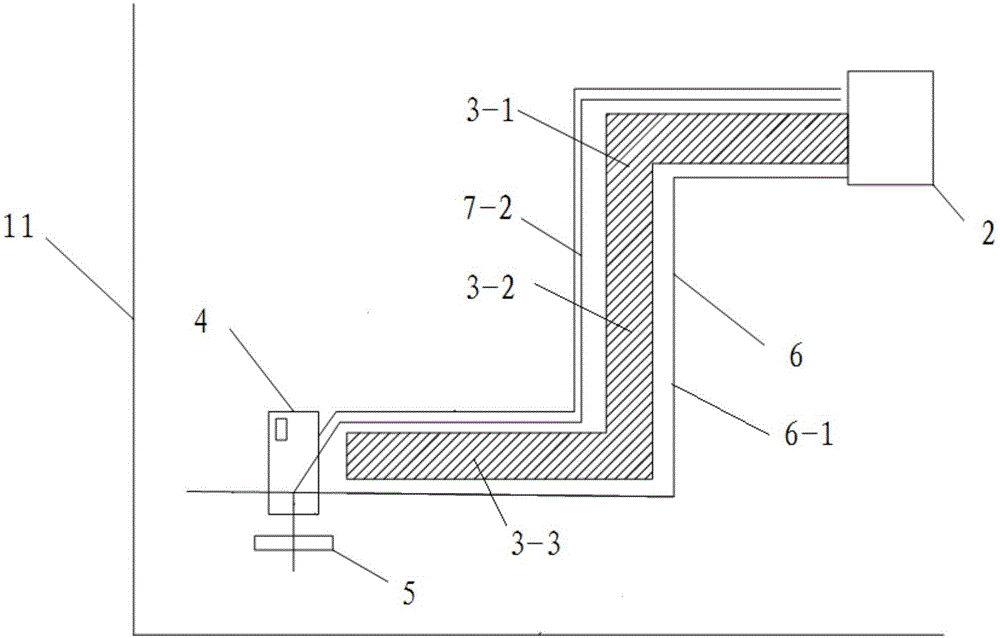

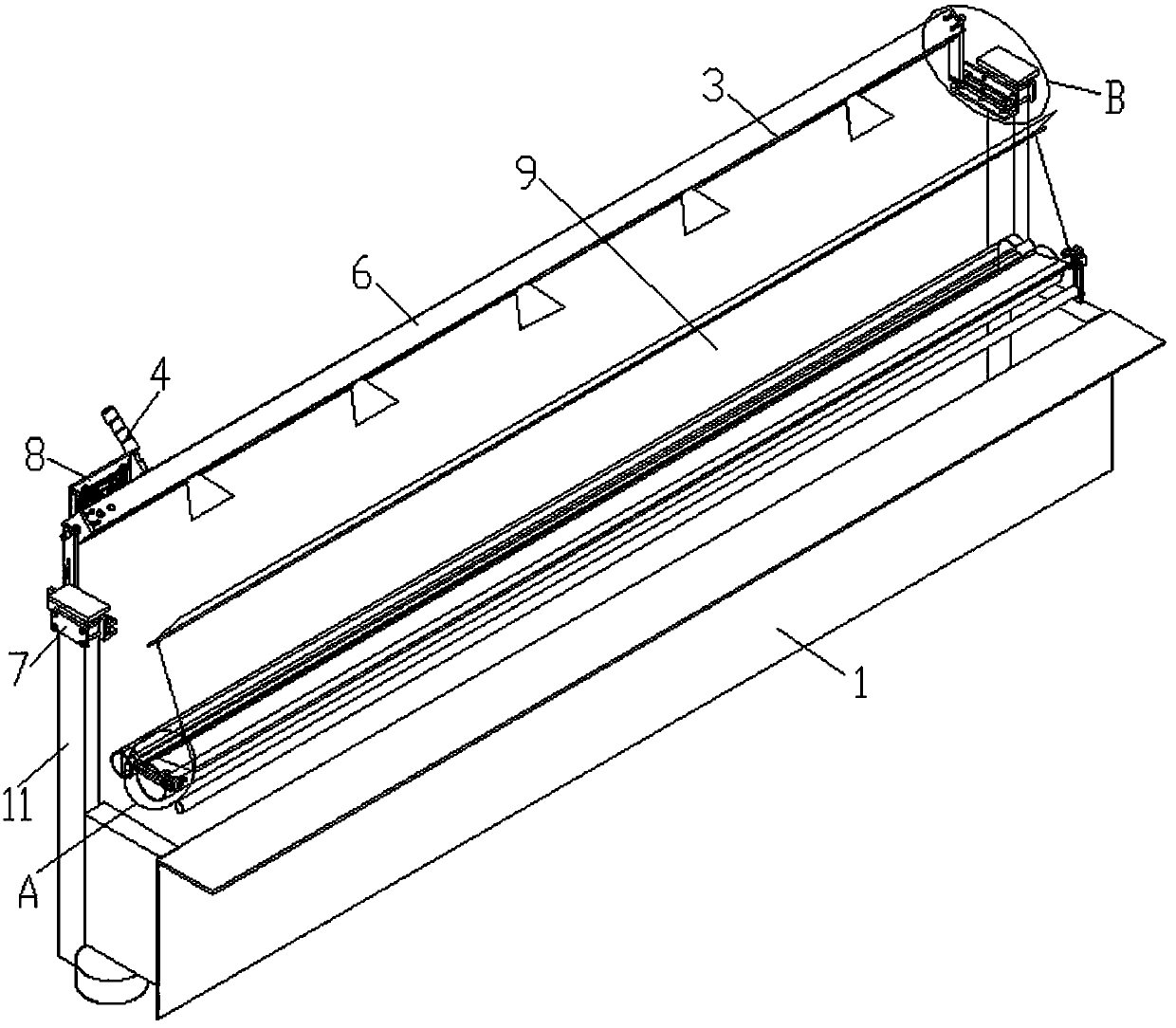

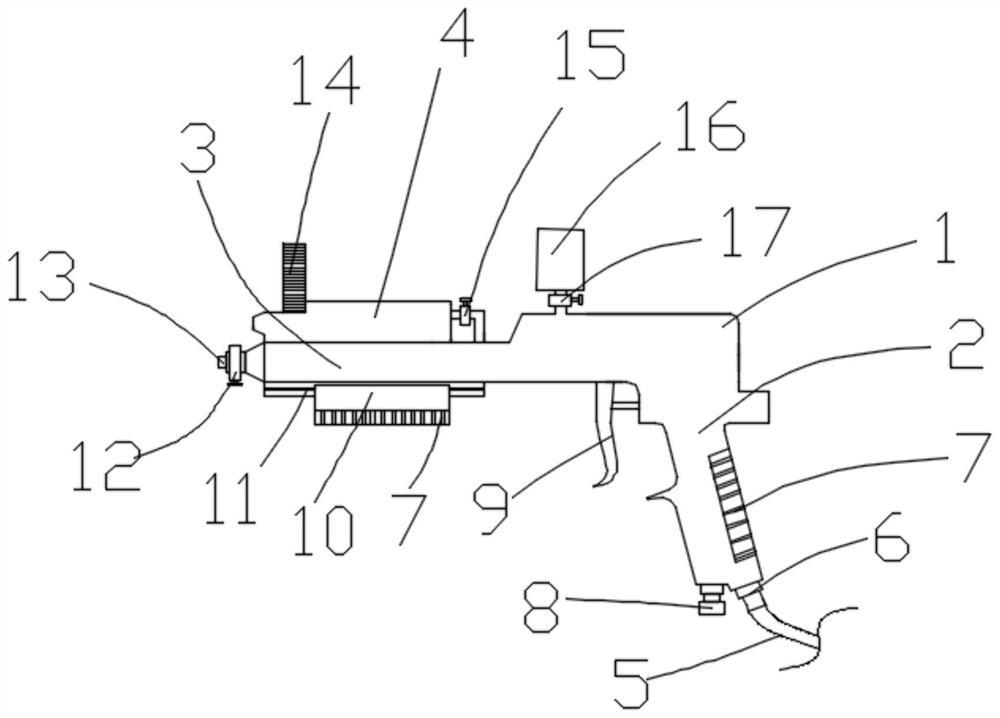

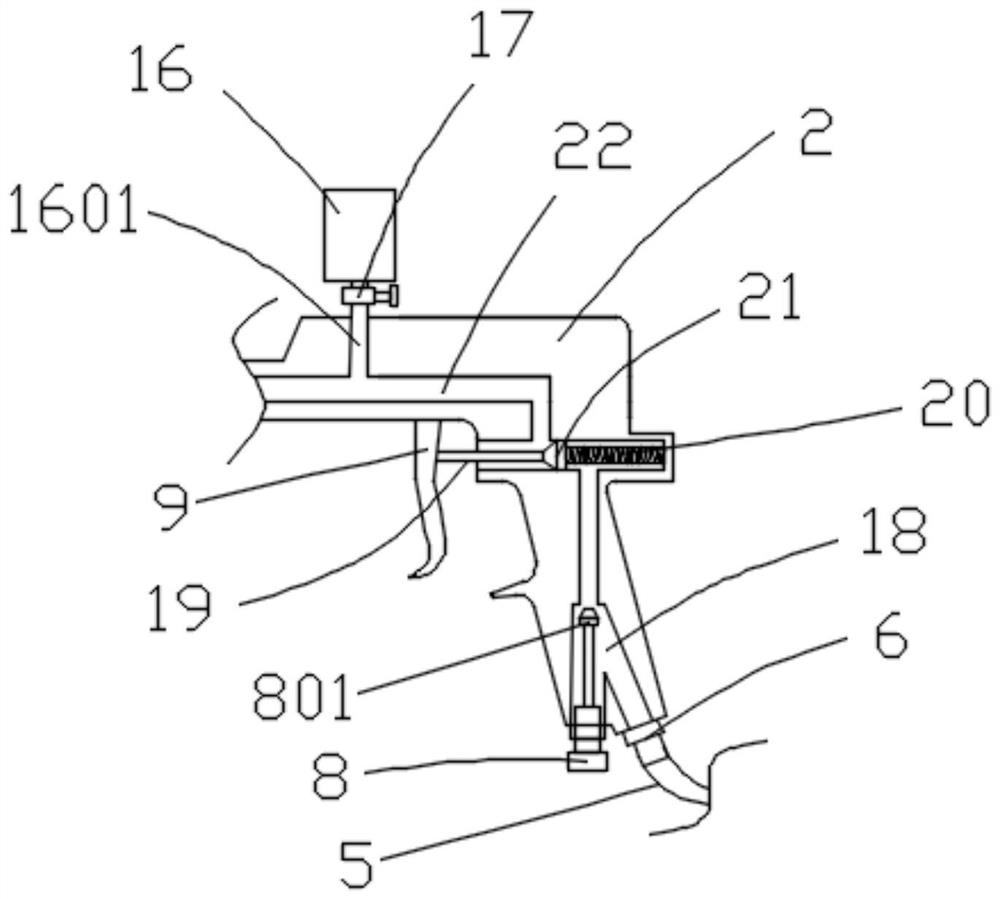

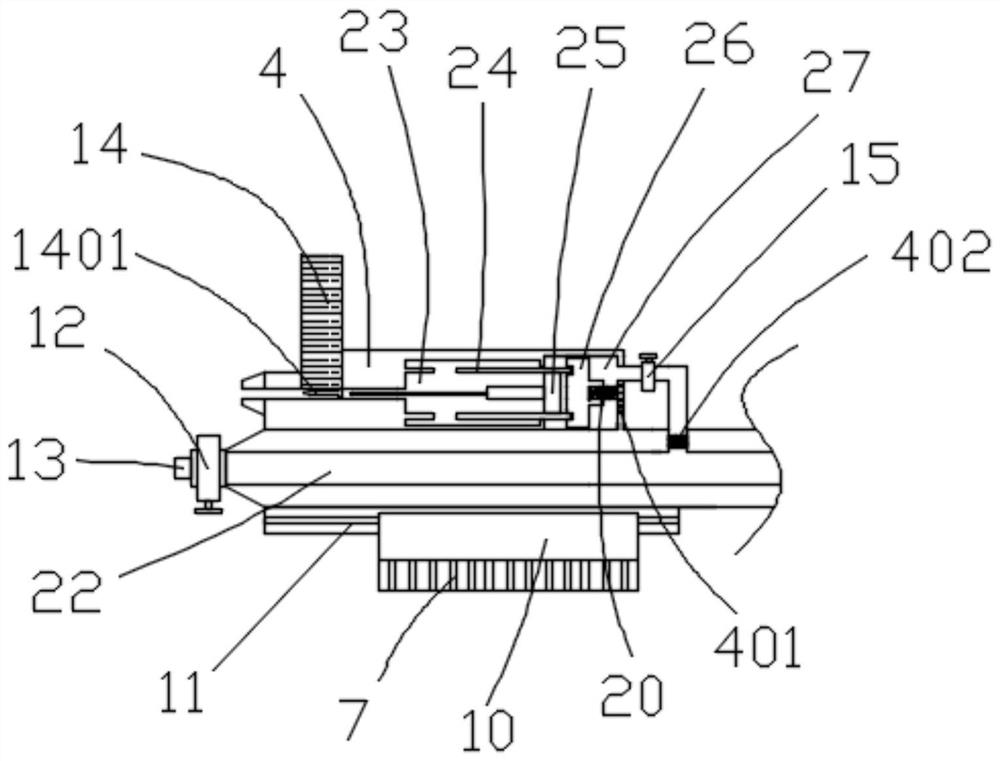

Carbonization furnace wall spray repair device and method

ActiveCN106244174AGood for longevityReduce labor intensityCoke oven safety devicesBrickwork leakage repair/preventionRepair timeProgrammable logic controller

The invention discloses a carbonization furnace wall spray repair device and method belonging to the technical field of coke making. In the carbonization furnace wall spray repair device, one end of a positioning mechanism is movably arranged in a sliding chute; a high-temperature imaging instrument is arranged at the other end of the positioning mechanism; a closing plate is arranged at the other end of the positioning mechanism; one end of a purging mechanism is arranged on a coke leveling vehicle, and the other end is arranged on one side of the closing plate; one end of a refractory mortar conveying mechanism is arranged on the coke leveling vehicle, the other end is communicated with the closing plate, and the refractory mortar conveying mechanism is communicated with one end of the purging mechanism; and a programmable logic controller is connected with the positioning mechanism, the high-temperature imaging instrument, the purging mechanism, the refractory mortar conveying mechanism and the coke leveling vehicle. According to the carbonization furnace wall spray repair device and method, artificial high-temperature repair work in a carbonization chamber can be replaced, thus effectively relieving the labor intensity and ensuring the production safety; and no cooling treatment is needed, thus shortening the repair time, ensuring the production rhythm and being beneficial to the long service life of a carbonization chamber walling.

Owner:武汉钢铁有限公司

Cloth defect detection device and real-time detection method

ActiveCN110672635ASimple structureImprove practicalityOptically investigating flaws/contaminationComplex mathematical operationsCamera lensEngineering

The invention discloses a cloth defect detection device. The device comprises a background assembly, a light source assembly, a camera assembly and a main control device; the background assembly is arranged on a warp knitting machine and used for providing a background for to-be-detected cloth; the light source assembly is used for irradiating the to-be-detected cloth to provide illumination for the cloth; the camera assembly is used for shooting the to-be-detected cloth to acquire cloth images; the main control device is connected with the camera assembly; a background plate is arranged belowthe to-be-detected cloth; a linear light source is arranged above the to-be-detected cloth along the width direction of the cloth and irradiates the overlapped area of the to-be-detected cloth and the background plate; an industrial camera is arranged above the to-be-detected cloth; the lens of the industrial camera points to the intersection area of the irradiation light of the linear light source and the to-be-detected cloth; a distance L1 from the lens of the industrial camera to the intersection area of the irradiation light of the linear light source and the to-be-detected cloth is 800-1000 mm; and the an angle alpha between the axis of the lens of the industrial camera and a plane where the to-be-detected cloth is located is 55-75 degrees. The device can accurately detect defects onthe surface of cloth and give alarms, and is simple in structure and good in practicability.

Owner:HANGZHOU LIPO SCI & TECH

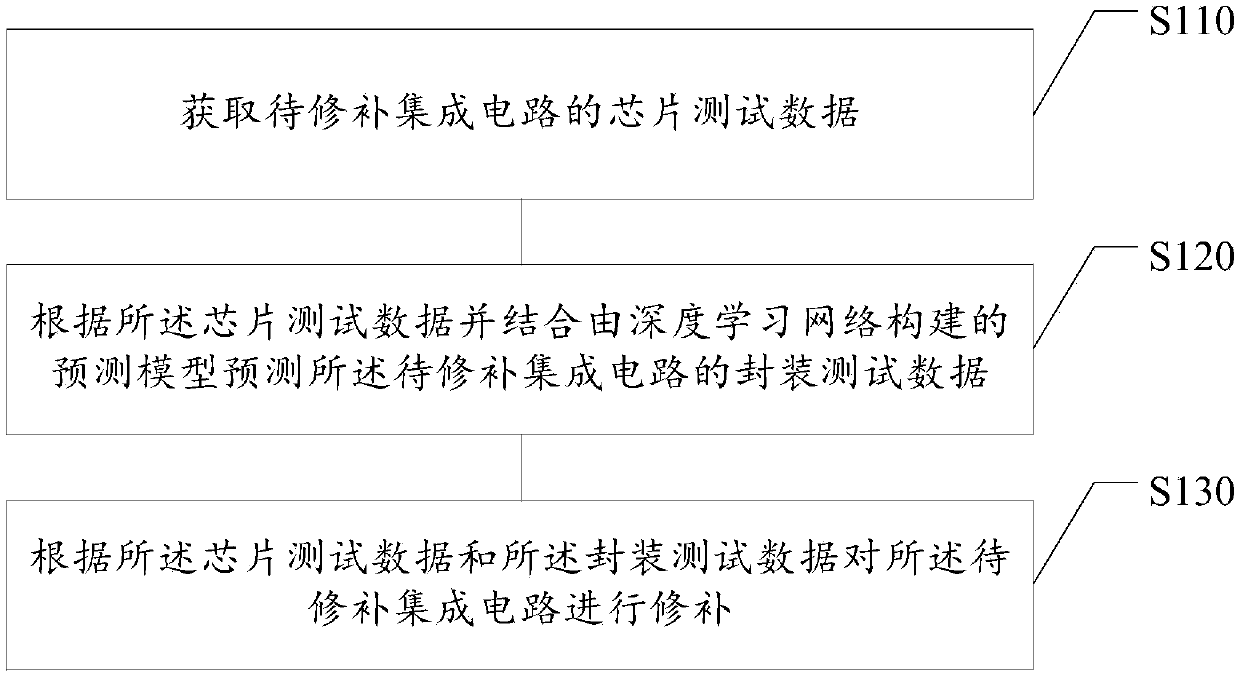

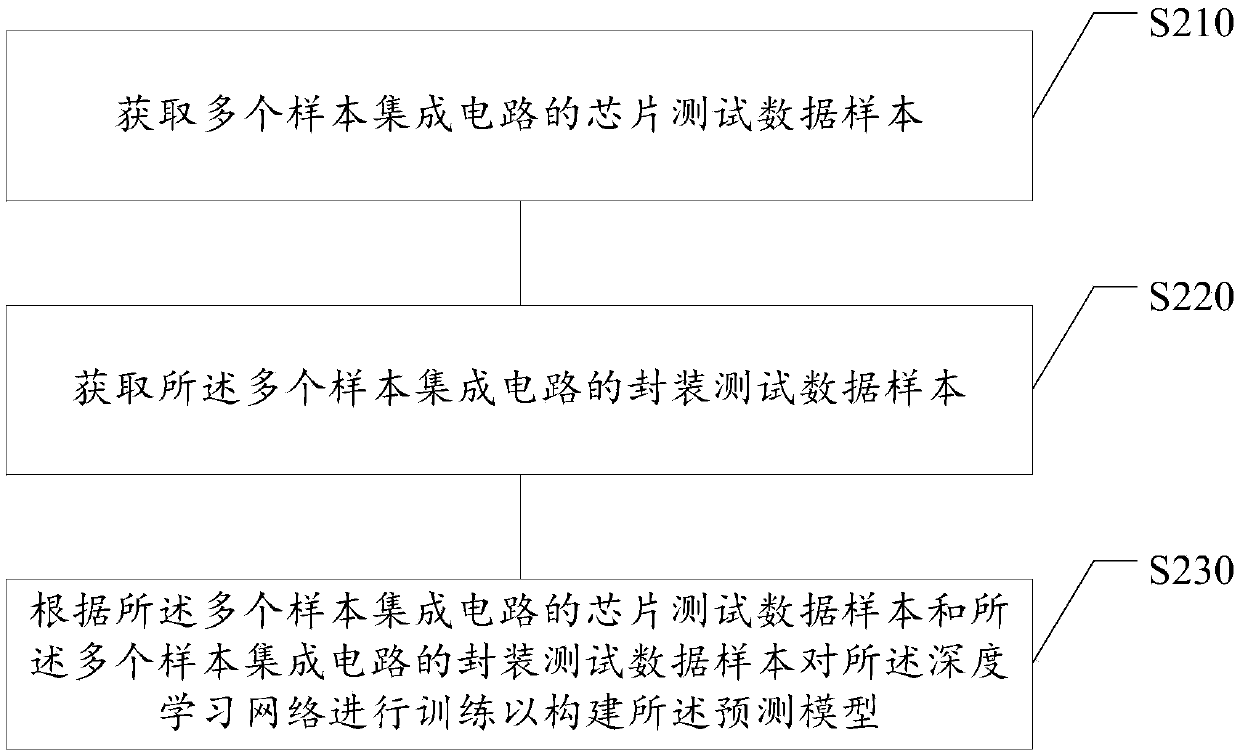

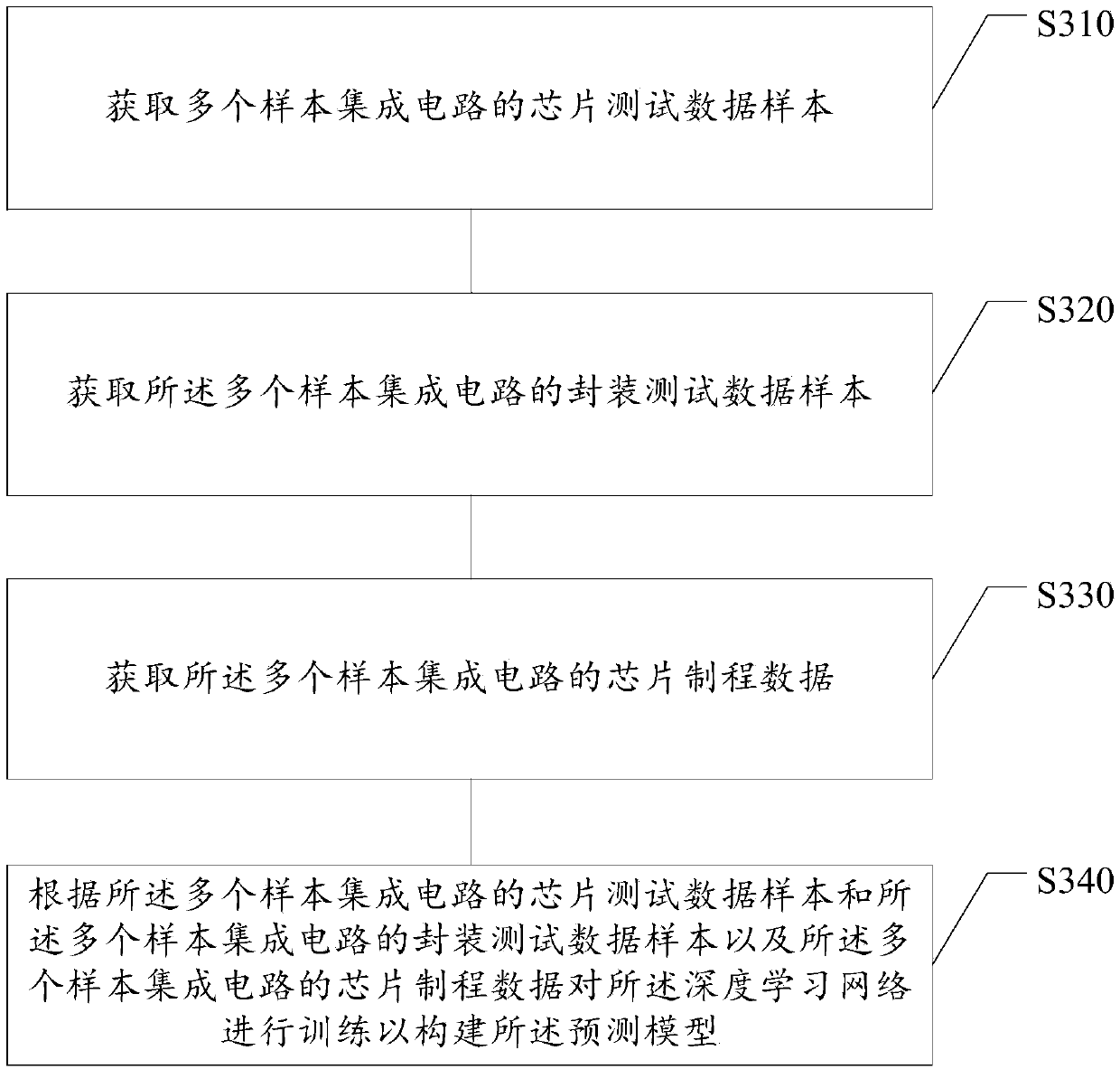

Integrated circuit repairing method and device, storage medium and electronic equipment

ActiveCN110991124AImprove forecast accuracyAvoid the influence of human factorsComputer aided designSpecial data processing applicationsIntegrated circuitHemt circuits

The invention relates to the technical field of computers, in particular to an integrated circuit repairing method and a device, a storage medium and electronic equipment. The method comprises the steps of obtaining chip test data of a to-be-repaired integrated circuit; predicting packaging test data of the to-be-repaired integrated circuit according to the chip test data in combination with a prediction model constructed by a deep learning network; and repairing the integrated circuit to be repaired according to the chip test data and the package test data. According to the method and the device, the influence of human factors is avoided, the prediction accuracy of the packaging test data is greatly improved, the phenomenon of circuit repair waste is further avoided, and in addition, theprediction accuracy of the packaging test data is greatly improved, so that the repair time can be well shortened, and the repair cost is reduced.

Owner:CHANGXIN MEMORY TECH INC

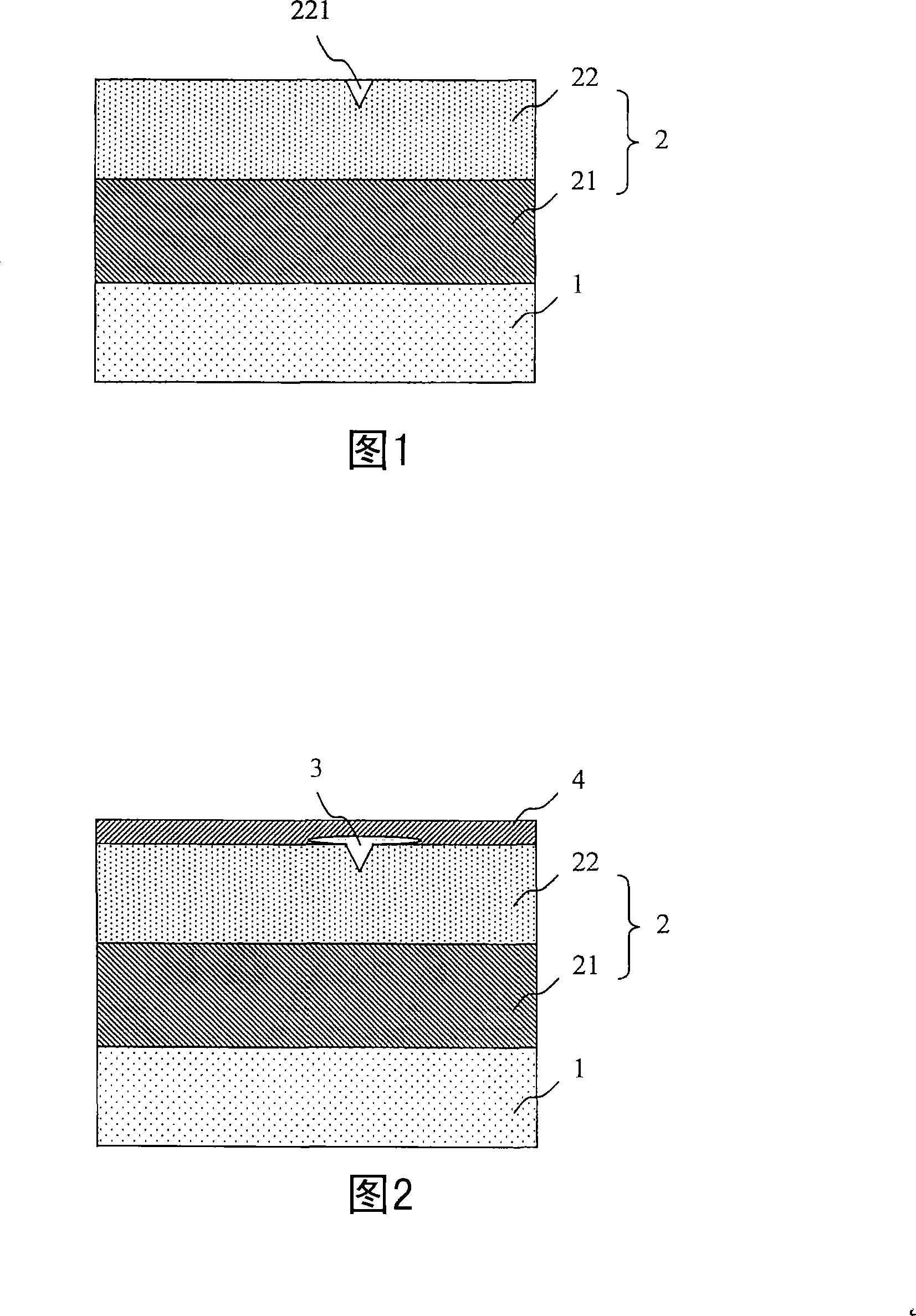

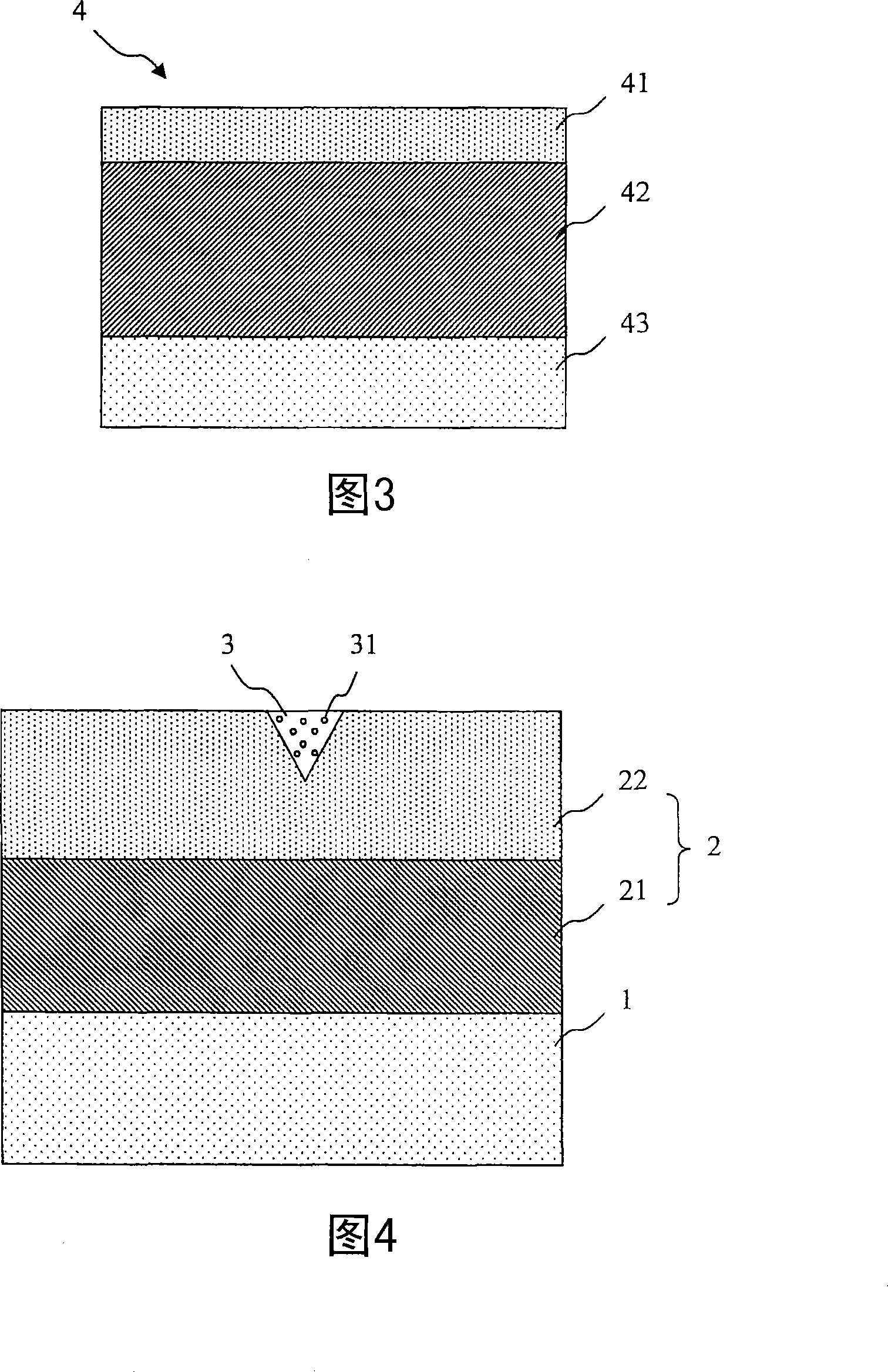

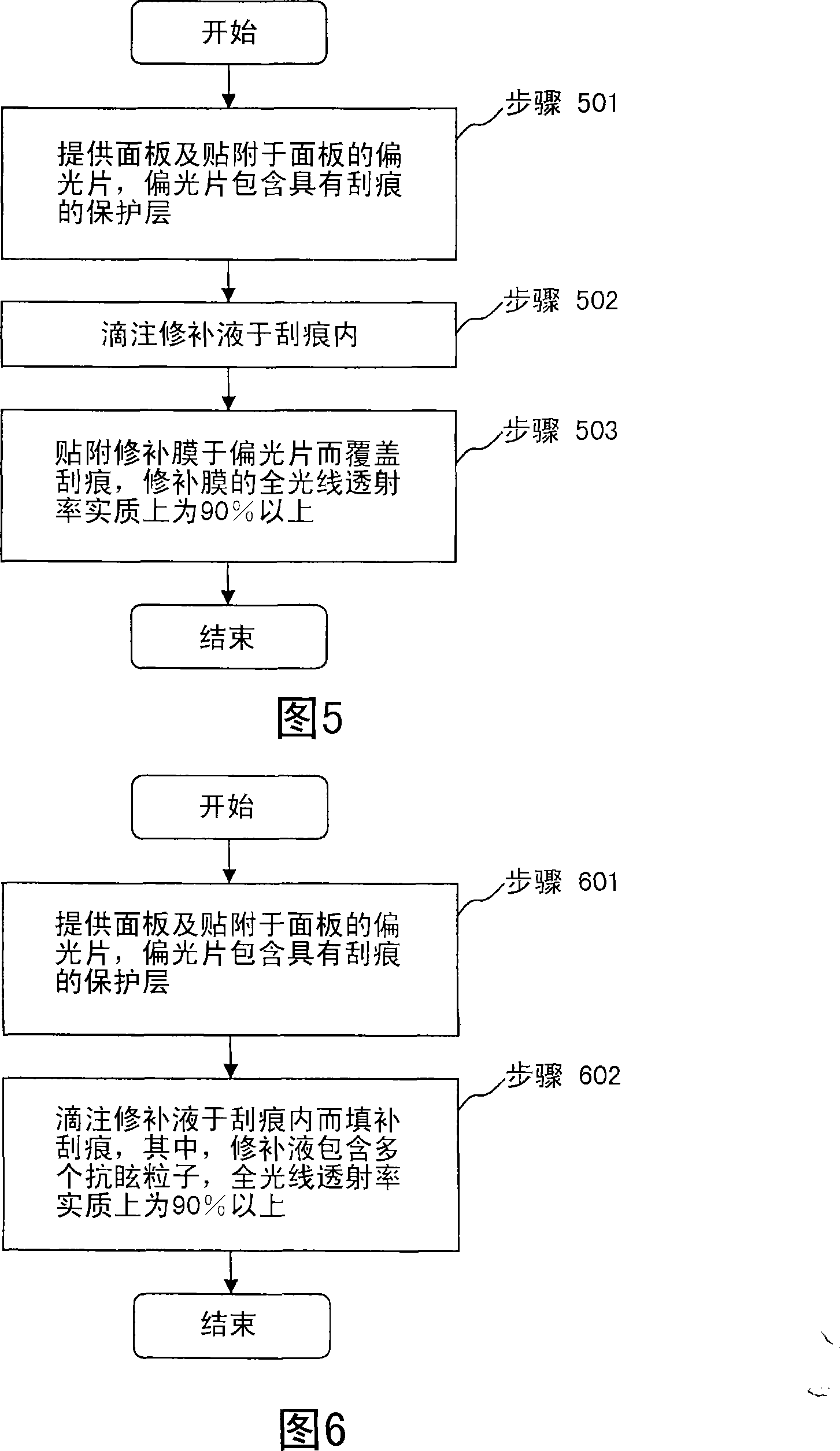

Liquid crystal display board, optoelectronic device and repairing method thereof

InactiveCN101162300ASimplify patchingShorten patching timeNon-linear opticsLiquid-crystal displayRepair time

The invention discloses a liquid crystal display panel and photo-electric device and a method for repairing the same, comprising a supplied panel and a polarizer sheet which is stuck on the panel, wherein, the polarizer sheet comprises a protective layer with scratches; the repair solution is dripped in the scratches and a repair film is stuck on the polarizer sheet for covering the scratches, the full light transmissivity of the repair film is actually over 90 percent. The invention can effectively simplify the repair procedure, greatly reduce the repair time of the scratches, lower the burden of the maintenance personnel and avoid the problem in the prior art that the display panel is easy to break when the polarizer sheet is torn off; thereby lowering the repair cost of the liquid crystal panel scratch.

Owner:AU OPTRONICS CORP

Carbonaceous repair material for converters and preparation method thereof

The invention provides a carbonaceous mending material for converters and a preparation method of the carbonaceous mending material. The carbonaceous mending material comprises the following components in parts by weight: 55-80 parts of magnesia, 4-15 parts of serpentine, 1-5 parts of iron oxide red powder, 0.3-3 parts of metal aluminum powder, 4-12 parts of a binder, 2-10 parts of resin powder, and 0.5-2 parts of a waterproof agent. By adopting the carbonaceous repair material for converters, the total repair time is 30-48 minutes, the repair time is short, the efficiency is high, the servicelife is 16-26 furnaces, the service life is long, a waterproof effect is achieved, and the storage time is long.

Owner:武汉钢铁有限公司

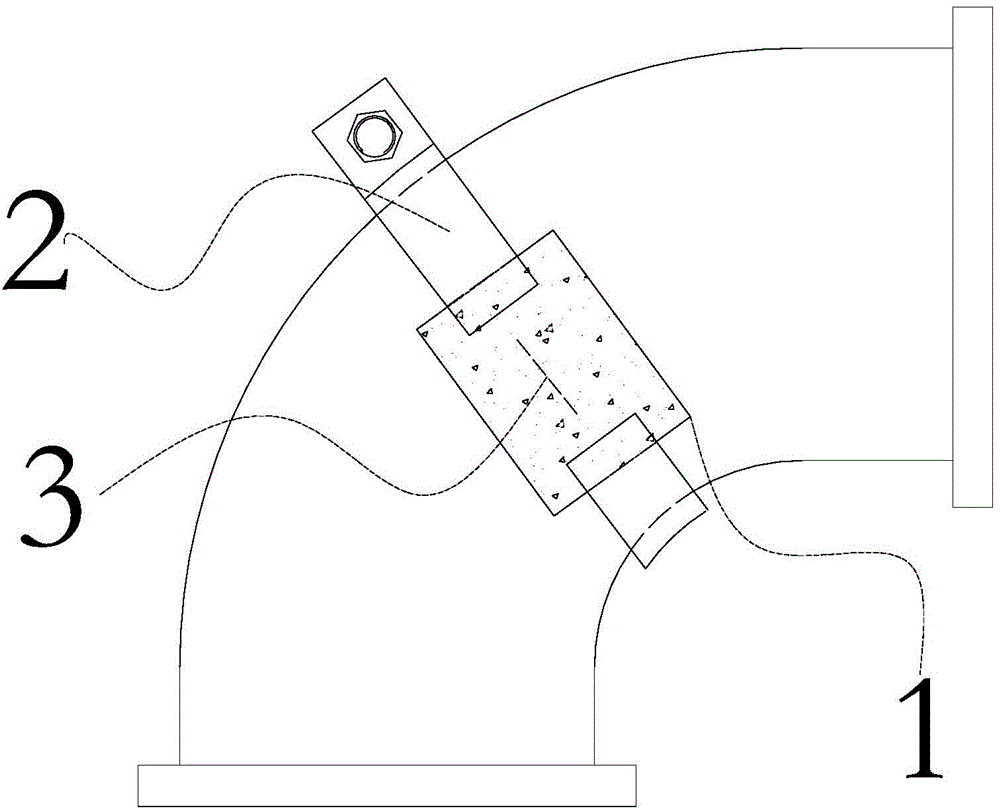

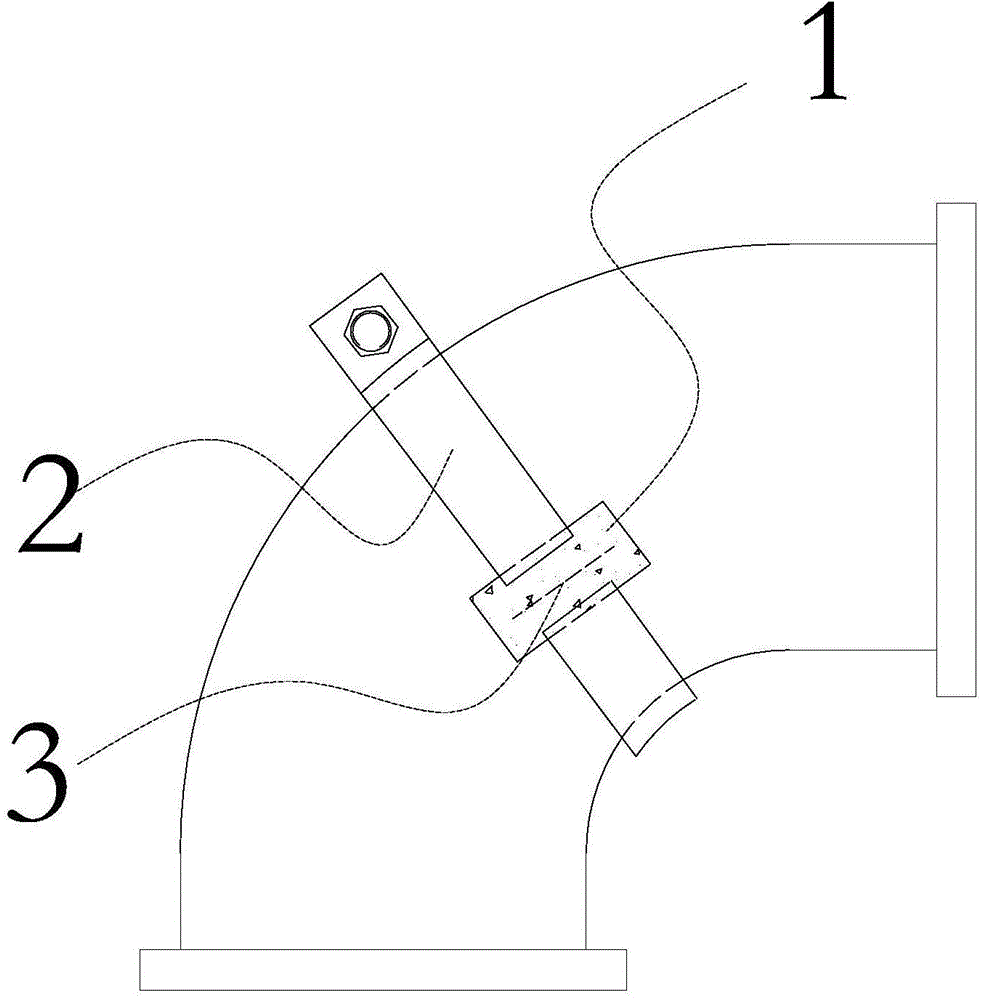

Ring wrapping leakage treatment method of coke oven bridge pipe

InactiveCN104694140AExtend the life cyclePrevent looseningCoke oven detailsDistillation gas withdrawalAdhesiveCoke oven

The invention relates to the field of overhaul of coke oven bridge pipes, and provides a ring wrapping leakage treatment method of a coke oven bridge pipe. The ring wrapping leakage treatment method comprises the following steps of: cutting a metal pressure plate according to the length of a crack of the bridge pipe; bending the cut metal pressure plate, so that the radian of an inner bending surface is identical to that of the outside surface of the bridge pipe at the crack position; respectively welding a section of arc-shaped connecting part at each of two ends of the metal pressure plate so that the metal pressure plate and the two arc-shaped connecting parts form a wrapping sleeve; modulating a high-temperature resistant adhesive; uniformly smearing the adhesive to the crack position of the bridge pipe; sleeving and pressing the wrapped metal pressure plate at the crack position of the bridge pipe so that the metal pressure plate wraps the crack and is firmly adhered to the bridge pipe; and fixedly connecting the arc-shaped connecting parts at two ends of the metal pressure plate together. The bridge pipe is unnecessary to cut and carry by using the ring wrapping leakage treatment method of the coke oven bridge pipe; therefore, the construction difficulty is reduced; the repair time is shortened; the repaired bridge pipe can be continuously used; the service cycle of the bridge pipe is increased; the production cost is saved; and the ring wrapping leakage treatment method of the coke oven bridge pipe disclosed by the invention is applied to treating leakage of pipelines in a high-temperature low-pressure or negative-pressure environment.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

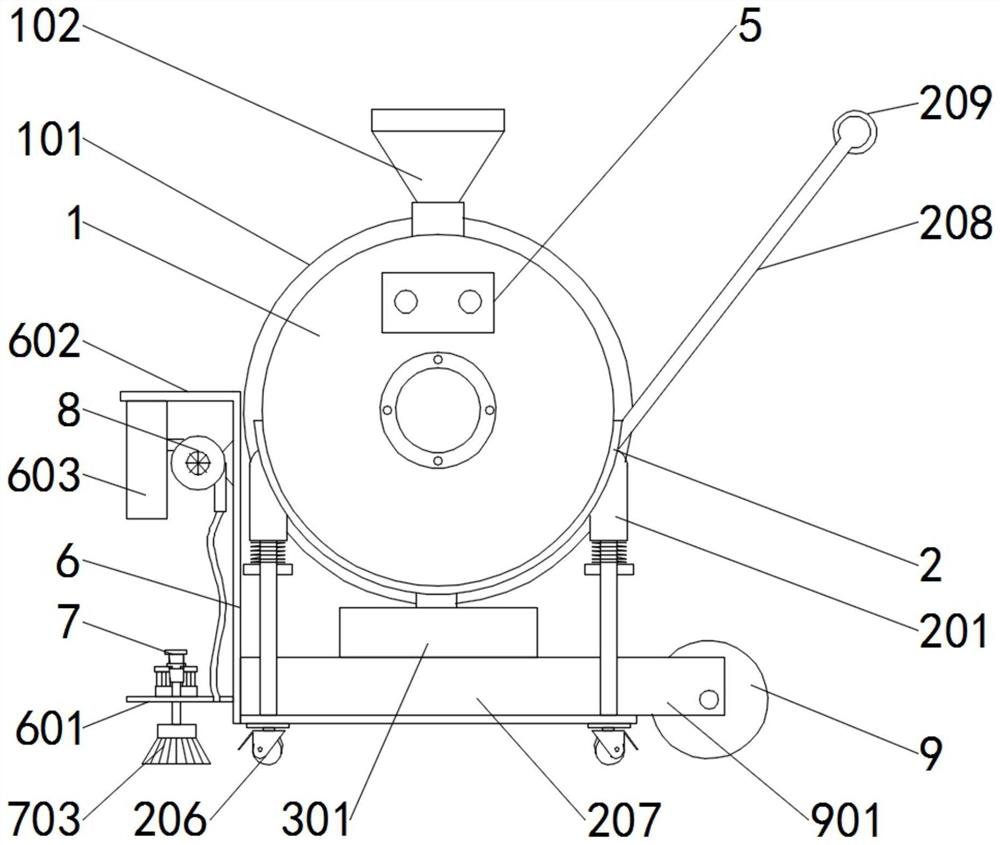

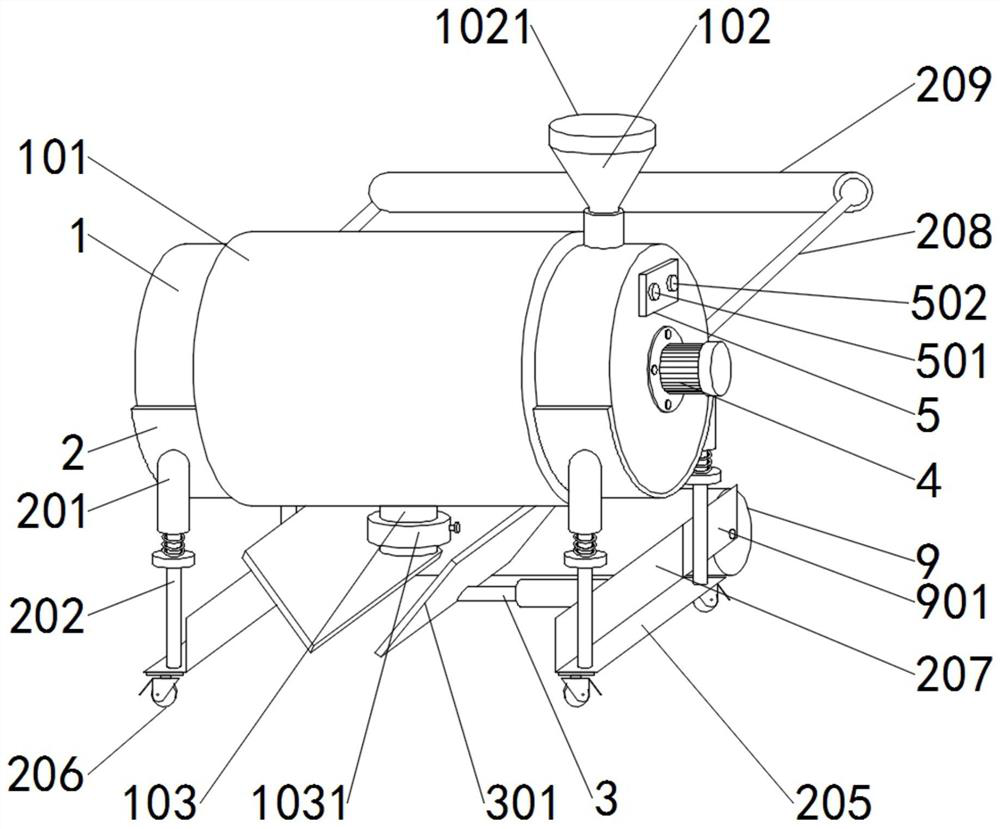

Quick repair device for damaged position of corrugated paper

ActiveCN112918020AQuick jetSave human effortMechanical working/deformationLiquid spraying apparatusAdhesive glueStructural engineering

The invention relates to the field of corrugated paper repair, in particular to a quick repair device for the damaged position of corrugated paper. The quick repair device comprises a spraying gun, a gun body, a gun barrel, a shooting block, an air outlet hole, a hose, an air inlet, an anti-skid layer, an air adjusting valve, an adjusting block, a trigger, a gun stock, paper breaking teeth, a connecting arm, balls, a repairing paper rolling shaft, fixing shafts, a sliding groove, a flow valve, a feeding channel, a spraying head, a magazine, a nail, a nail supporting plate, a partition plate, a magazine wall, a shooting valve, a glue tank, a glue tank valve, an air inlet channel, a telescopic rod, a spring, an air inlet block, an air outlet channel, an inner cavity, sliding blocks, a piston head, an impact block, an air storage chamber and repairing paper. According to the quick repair device for the damaged position of the corrugated paper, the spraying gun sprays glue out through the air outlet channel through compressed air in the spraying gun, the damaged position of the corrugated paper is glued, the repairing paper in the gun stock is drawn out through the gun stock to be pasted to the damaged position, finally, the repairing paper is nailed through the shooting block, and the corrugated paper is repaired.

Owner:佛山市荣粤桂印刷有限公司

Highway crack treatment device for highway engineering

PendingCN113152233AShorten patching timeImprove work efficiencyDispersed particle filtrationRoads maintainenceTransmission beltElectric machinery

The invention belongs to the technical field of highway engineering devices, and relates to a highway crack treatment device for highway engineering, which comprises a storage tank, the lower end of the storage tank is communicated with a discharge pipe, the lower side of the outer wall of the storage tank is abutted against two arc-shaped supporting plates, and supporting plates are mounted below the two arc-shaped supporting plates. The lower end faces of the two supporting plates are each provided with two trundles, the rear sides of the two arc-shaped supporting plates are provided with handles, the front sides of the two supporting plates are fixedly connected with side plates, the front end faces of the side plates are fixedly connected with a bottom plate and a top plate, the upper end face of the bottom plate is detachably connected with a second motor, and the output end of the second motor is provided with a transmission belt. A plurality of rotating rods are rotationally connected to the inner wall of the transmission belt, and brushes are fixedly connected to the lower ends of the multiple rotating rods; when the whole device moves forwards, a second motor is started to drive a plurality of brushes to clean the periphery of the crack, and after the crack is cleaned, the repairing agent in the material storage tank is discharged into the crack, so that the working efficiency of repairing the crack is improved.

Owner:于晓礼

Upper metal die with injection tube mouth having heating line fixing slot

A top mold of an injection molding machine is disclosed. The top mold of this invention has a cylinder housing having a pouring gate, a manifold housing having a manifold and mounted on the lower surface of the cylinder housing, and a nozzle housing having an injection nozzle and mounted on the lower surface of the manifold housing. The top mold also has a heating wire guide hole formed on the lower surface of the nozzle housing. A heating wire extends from an external power source to the injection nozzle through the heating wire guide hole. A clip holding slit is formed on the sidewall of the heating wire guide hole. The top mold of this invention allows a user to easily and simply repair or replace a heating wire within a short period of time without entirely disassembling the top mold. This top mold is thus reduced in its maintenance cost, and reduces the time the injection molding process is stopped while repairing or replacing the heating wire, reduces the adverse effect about industry.

Owner:YUDO

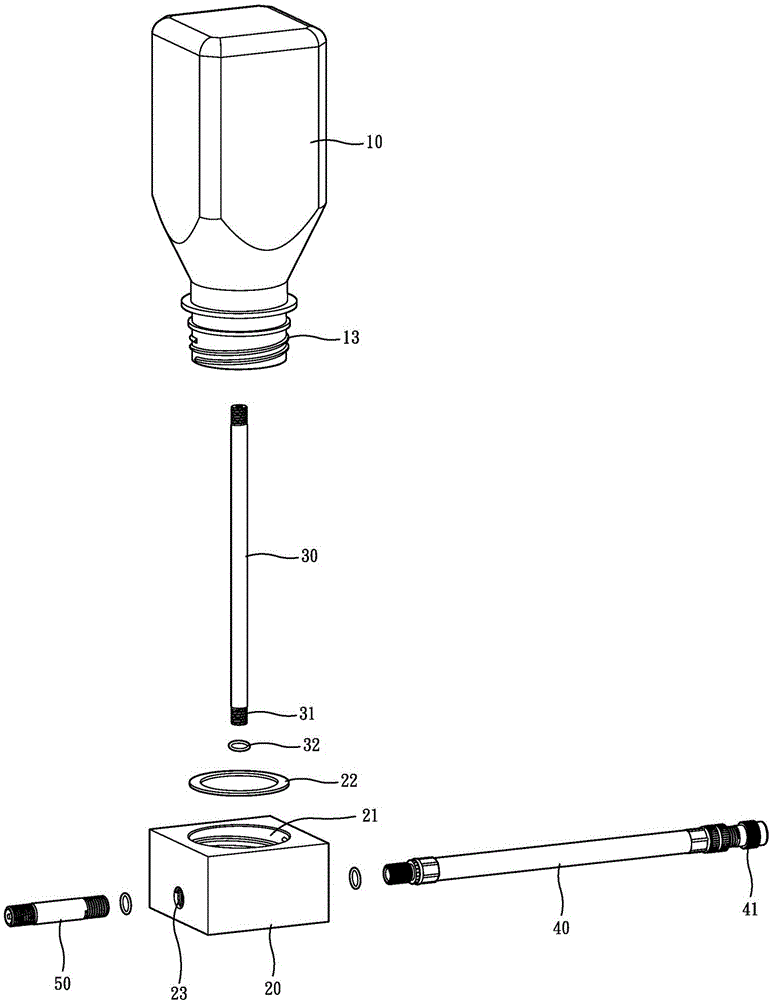

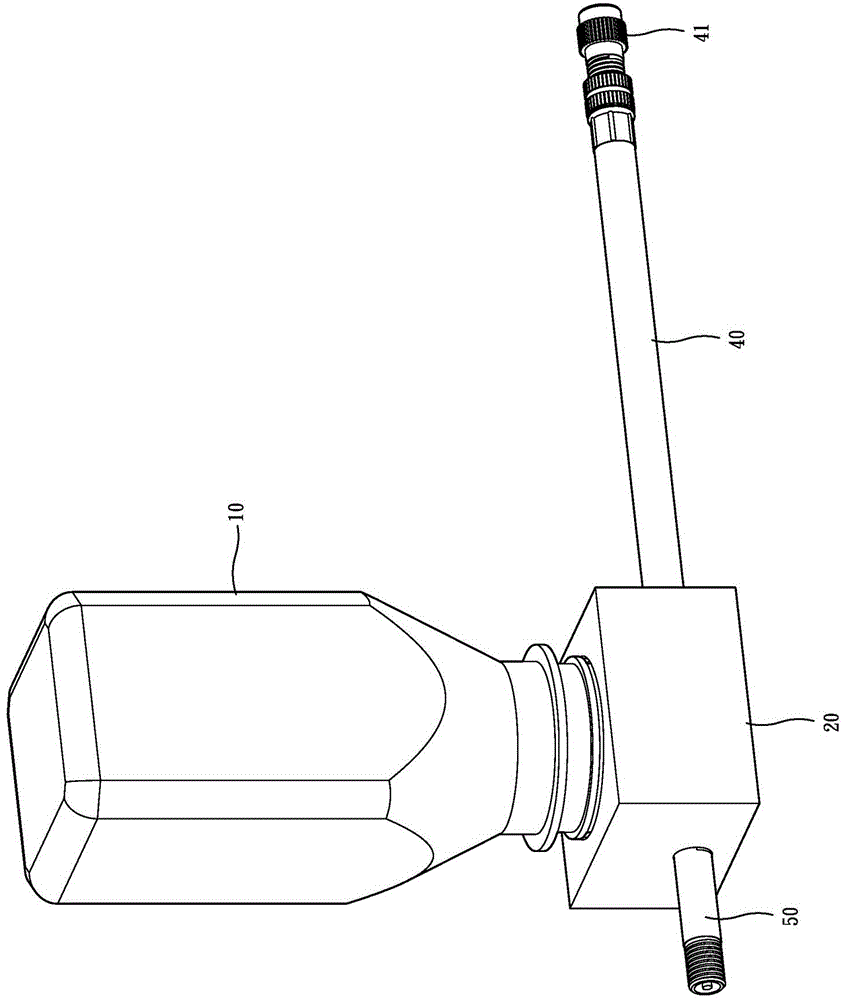

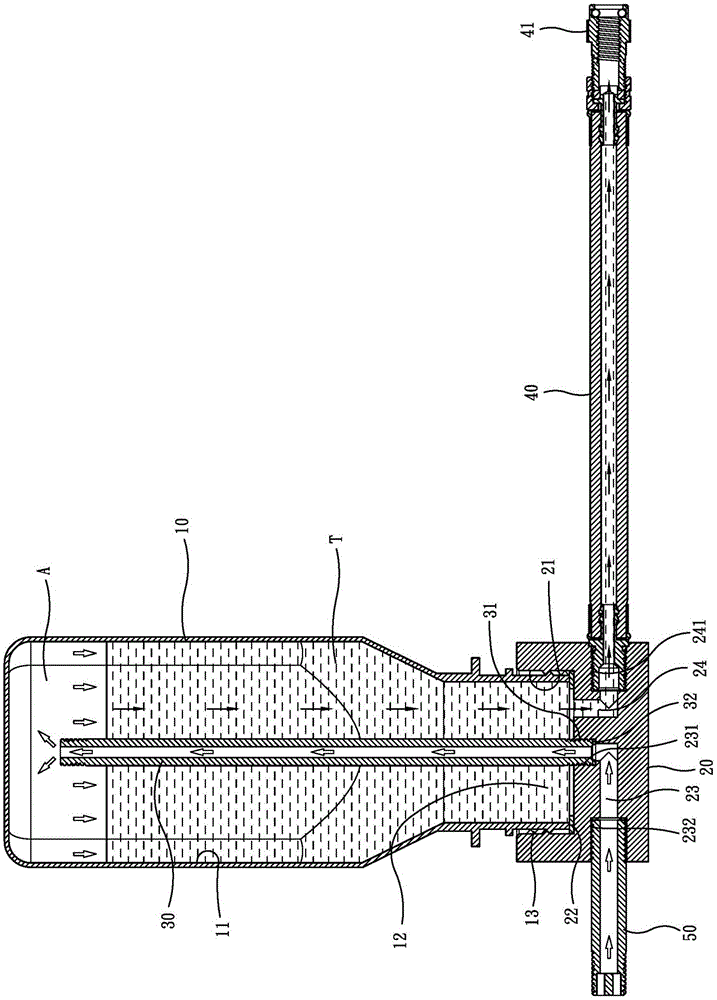

Pneumatic tire repairing device

InactiveCN106182831AShorten the path into the diversion channelSimple structureTyresInlet channelBottle

The invention discloses a pneumatic tire repairing device. The bottom end of a bottle body is provided with a bottle opening enabling the interior and the exterior of the bottle body to communicate, and the bottle opening is sealed through a detachable valve deck. A containing chamber of the bottle body is filled with tire repairing liquid, and an air chamber is formed between the top edge of the containing chamber and the liquid level of the tire repairing liquid. The valve deck is provided with an air inlet channel and a flow guiding channel, and the air inlet channel and the flow guiding channel enable the interior and the exterior of the containing chamber to communicate. The air inlet channel is externally connected with an air source. One end of the flow guiding channel communicates with the bottom end of the bottle opening. The air inlet channel is provided with an air guiding pipe, and the top end of the air guiding pipe is kept protruding out of the liquid level of the tire repairing liquid to communicate with the air chamber on the top edge of the containing chamber. The flow guiding channel is externally connected with a throat pipe. An air nozzle which can be connected with a valve core of a tire in an assembled mode is mounted on the throat pipe. In this way, the purposes of simplified structure, stable pressure and high tire repairing liquid injection speed are achieved.

Owner:BETO ENG & MARKETING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com