Thermal gunning material for RH furnace lower portion groove working lining magnesium-aluminum spinel brick

A technology of lining magnesia-aluminum spinel and hot-repairing gunning material, which is applied in the field of hot-repairing gunning material for lining refractory bricks in the lower groove of RH furnace, can solve the problem of long repairing operation time, high rebound rate, and unfavorable low-silicon steel smelting and other problems to achieve the effect of shortening the repair time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

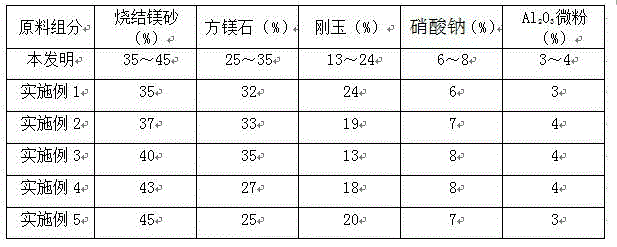

[0020] A thermal spraying material for lining magnesia-aluminum spinel bricks in the lower groove of an RH furnace, the weight percentages of the raw material components are: sintered magnesia 35%-45%, periclase 25%-35%, corundum 13% %~24%, Sodium Nitrate 6%~8%, Al 2 0 3 Micropowder 3% to 4%.

[0021] The preparation method of the product of the invention is as follows: firstly, the magnesia and sintered magnesia are crushed and pulverized; Mix in the machine for 15-20 minutes, and then put it into the finished bag.

[0022] Examples of the present invention are shown in the following table.

[0023] Example table of thermal supplementary gunning material for working lining magnesia-aluminum spinel bricks in the lower groove of RH furnace

[0024]

[0025] After spraying the refractory bricks of the lower groove and the lower groove of the RH furnace with 30 tons of gunning material of the present invention, the rebound rate of the gunning material is only 2%, and no lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com