Conductor wire core for novel power cable

A technology for power cables and conductor cores, applied to power cables, conductors, non-insulated conductors, etc., can solve problems such as surface burrs, hidden dangers of accidents, uneven electric fields on the surface of conductor cores, etc., to reduce consumption, reduce labor, and unit Silk coordination deformation easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

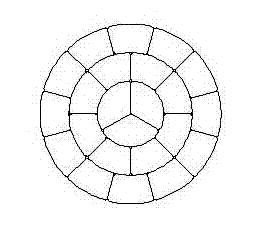

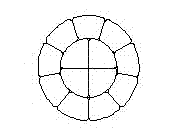

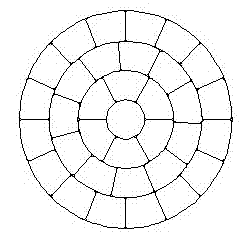

[0015] see figure 1 A preferred embodiment one of a new type of conductor wire core for power cables, in embodiment one, adopt the method described in the present invention to manufacture the nominal cross-sectional area is 120mm 2 The core of the copper cable conductor is 3 fan-shaped monofilaments in the middle part, and 2 layers of tile-shaped monofilaments are twisted in the outer layer. Add 4 more tile-shaped lines on the second outer layer. Among them, the section of fan-shaped wire monofilament in the middle molded wire part is 5.25mm 2 , Outer sector line 5.32mm 2 , sub-outer fan-shaped line 5.1mm 2 , The outer diameter of the entire conductor core is 12.61mm, which is 5.4% smaller than the outer diameter of the traditional compacted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com