High-performance concrete gel material for tunnel and application thereof

A cementitious material and concrete technology, which is applied in the field of concrete cementitious materials, can solve the problems of large amount of cement, insufficient durability of concrete, and high injection rebound rate, and achieves reduction of hydration heat, improvement of narrow-mouth passing ability, and comprehensive performance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

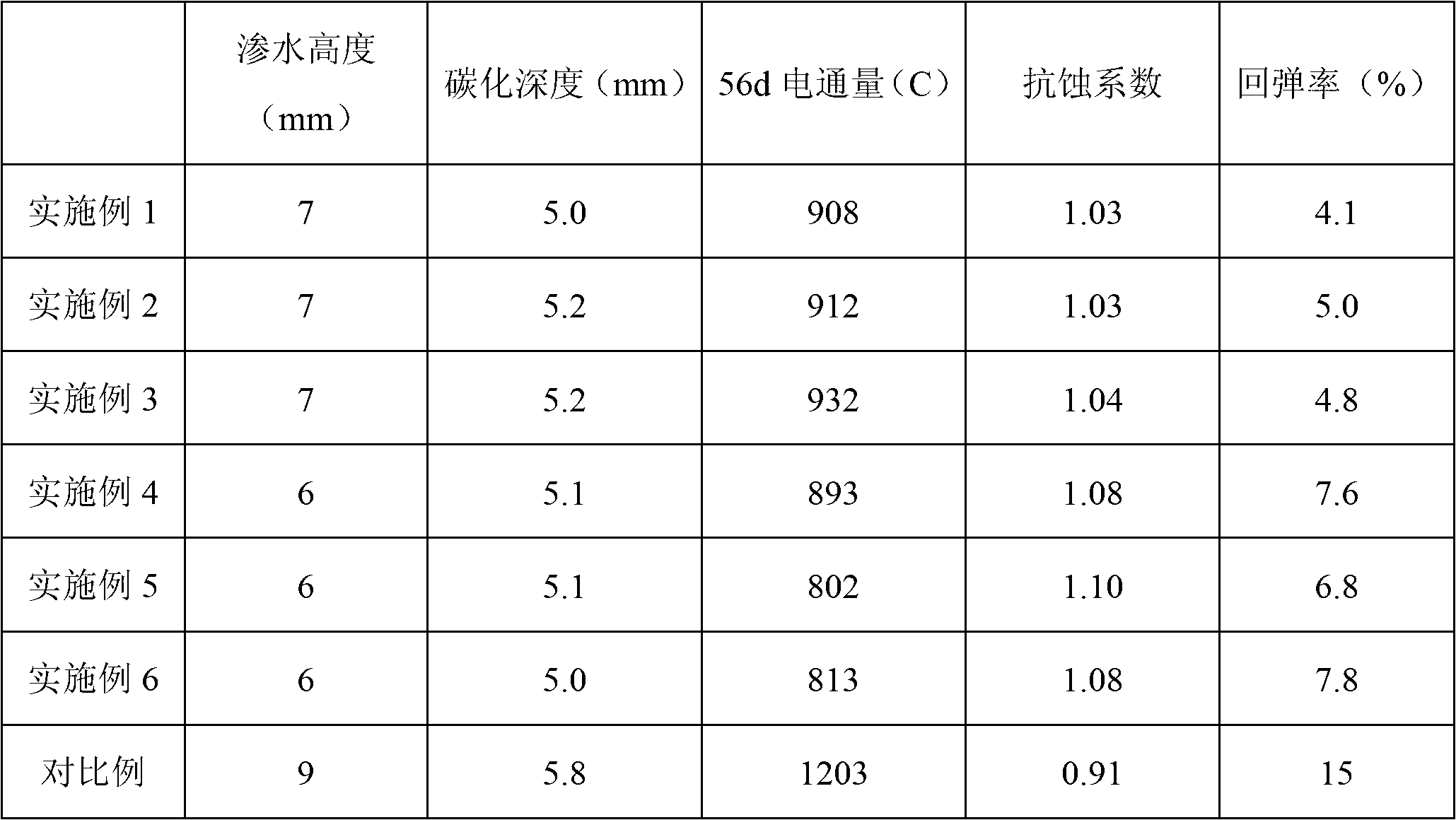

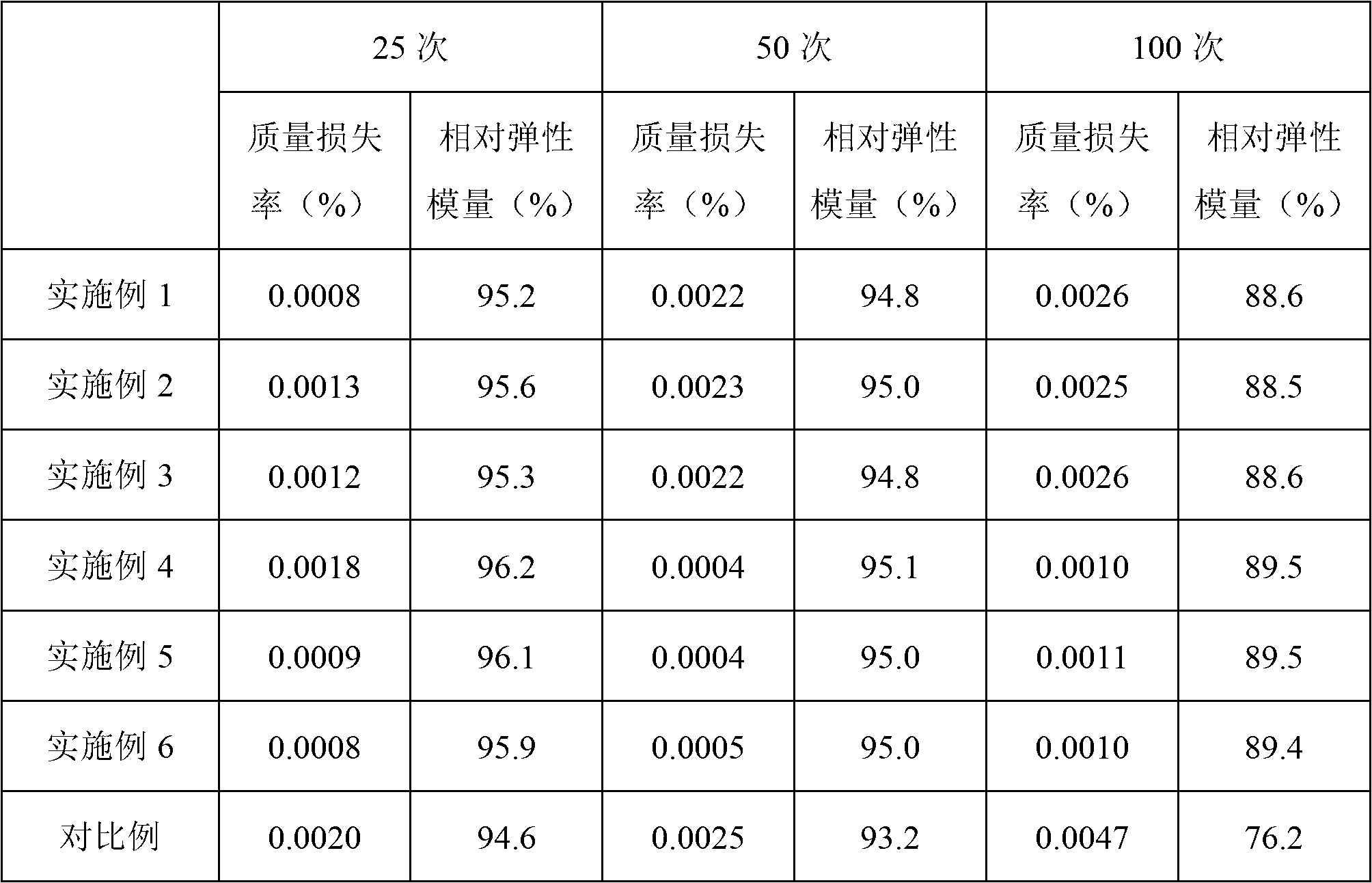

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following experimental examples, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

[0028] Add silica sol (or silica sol and nano-calcium carbonate) to concrete mixing water, stir evenly, mix it with cement and aggregate (or microbeads, fly ash, cement, aggregate), and mix it into For other admixtures, a reasonable mixing procedure should be formulated according to the state of the admixture and technical requirements, and the mixing time should be determined at the same time to obtain high-performance concrete for tunnels. Stirring time, aggregate, and water-cement ratio (water-binder ratio) do not belong to the content of the technical solution of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com