Low heat composite cementing material

A composite gelling material and gelling material technology, applied in the field of gelling material synthesis, can solve the problems of less research content, high heat of hydration, low early strength, etc., achieve technological progress, solve heat of hydration and temperature The effect of high rise or low early intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

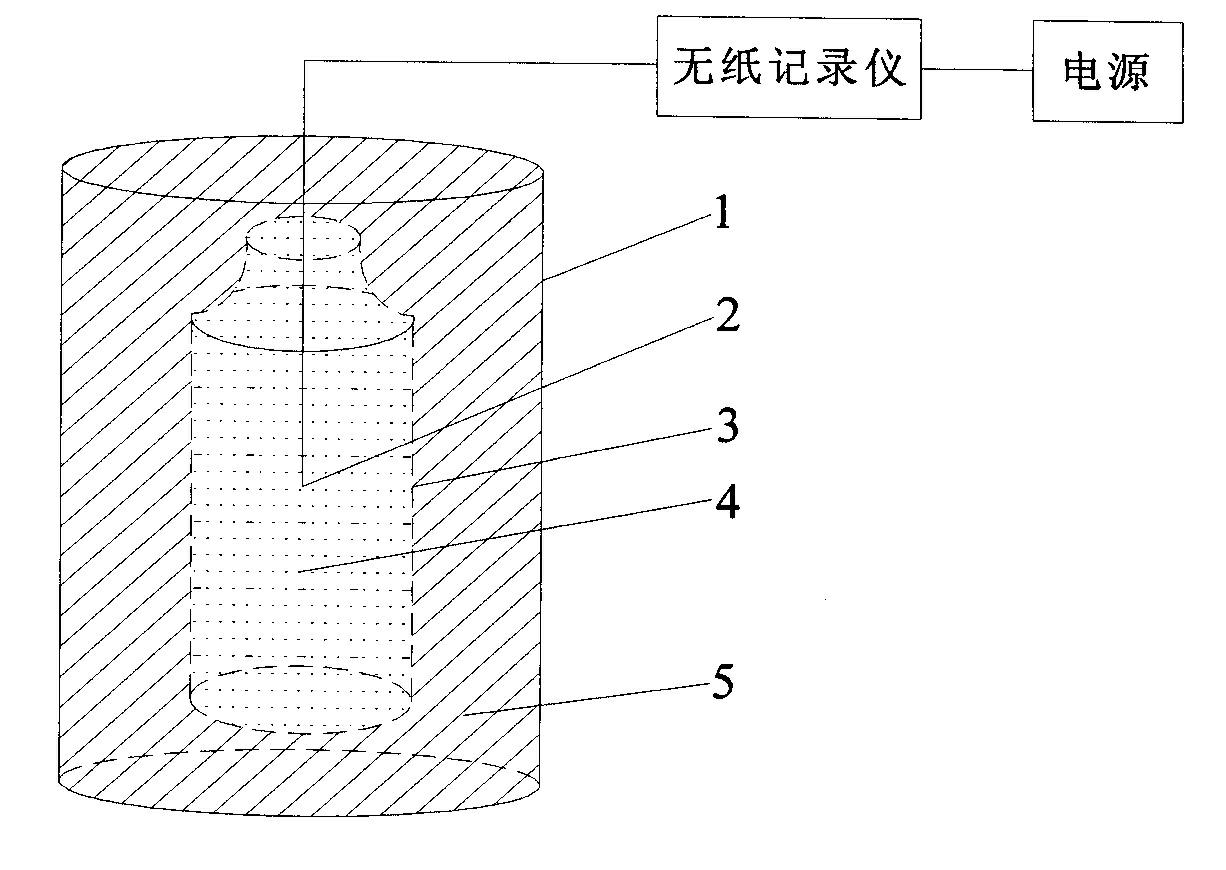

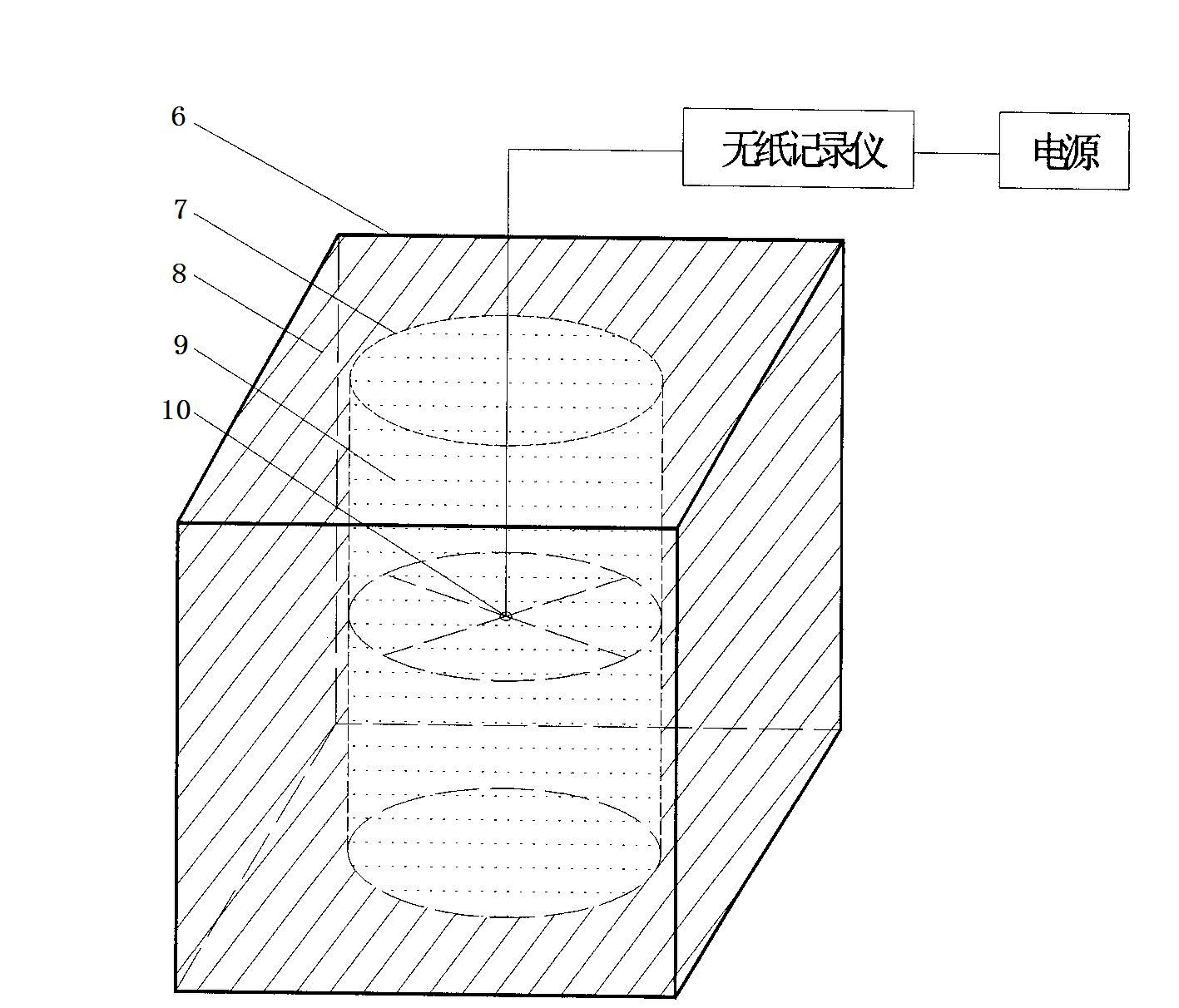

Image

Examples

Embodiment 1

[0028] Composite preparation of cementitious materials: Take 45 parts of 32.5 grade slag portland cement, 40 parts of grade I fly ash, 15 parts of metakaolin, and 1 part of anhydrous sodium sulfate in parts by weight, and place them in the mixer in sequence, at room temperature 1. Under normal pressure, stir at a speed of 120 rpm for 15 minutes, mix evenly, and obtain the gelled material;

[0029] Application molding: Take 97 parts by weight of the above-mentioned cementitious material, 3 parts of expansion agent, and 1 part of water reducer, and add them to the mixing pot of the cement paste mixer containing 30 parts of tap water in sequence within 20 seconds, press Mixing according to the speed and procedure stipulated in the national building materials industry standard JC / T 729-2005: at the speed of 140±5 rpm rotation and 62±5 rpm revolution, slow stirring for 120±3 seconds, stop mixing for 15± 1 second, and then at the speed of 285±10 revolutions / min and 125±10 revolution...

Embodiment 2

[0031] Composite preparation of cementitious materials: take 30 parts of 32.5R composite Portland cement, 50 parts of grade II fly ash, and 20 parts of metakaolin in parts by weight, and place them in the mixer in sequence. Stir at a speed of rpm for 10 minutes, mix evenly, and obtain the gelled material;

[0032] Application molding: take 94 parts by weight of the above-mentioned cementitious material, 6 parts of expansion agent, and 1 part of water reducer, and add them to the mixing pot of the cement paste mixer containing 30 parts of tap water in sequence within 30 seconds, press Mixing according to the speed and procedure stipulated in the national building materials industry standard JC / T 729-2005: at the speed of 140±5 rpm rotation and 62±5 rpm revolution, slow stirring for 120±3 seconds, stop mixing for 15± 1 second, and then at the speed of 285±10 revolutions / min and 125±10 revolutions / min, stir rapidly for 120±3 seconds. The obtained slurry was tested according to nat...

Embodiment 3

[0034] Composite preparation of cementitious materials: take 30 parts of medium-heat Portland cement, 60 parts of grade I fly ash, 10 parts of metakaolin, 5 parts of calcium hydroxide, and 2 parts of anhydrous sodium sulfate in parts by weight, and place them in sequence In the mixer, under normal temperature and normal pressure, stir at a speed of 85 rpm for 12 minutes, mix evenly, and obtain the gelled material;

[0035] Application molding: Take 90 parts of the above-mentioned cementitious material, 10 parts of expansion agent, and 1.2 parts of water reducer in parts by weight, and add them to the mixing pot of the cement paste mixer containing 28 parts of tap water in sequence within 25 seconds, press Mixing according to the speed and procedure stipulated in the national building materials industry standard JC / T 729-2005: at the speed of 140±5 rpm rotation and 62±5 rpm revolution, slow stirring for 120±3 seconds, stop mixing for 15± 1 second, and then at the speed of 285±1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com