Concrete delayed coagulation air entraining agent

An air-entraining agent and concrete technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of unguaranteed durability, poor concrete encapsulation, and long-term non-solidification, etc., to achieve inhibition The effects of heat of hydration, low cost, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment further illustrate the present invention.

[0014] According to the weight ratio, 30kg of sodium lauryl sulfate with a content of ≥90%, 270kg of sodium dodecylbenzenesulfonate with a content of ≥80%, 170kg of white sugar with a content of >95%, and sodium hexametaphosphate with a content of ≥68% 140kg, 140kg of sodium gluconate with a content ≥ 98%, and 250kg of secondary fly ash are put into a mixer with an 11kw motor, a reducer model of BL-23-11, and a speed of 60 rpm in batches, and fully stir for 40 Minutes to get the product.

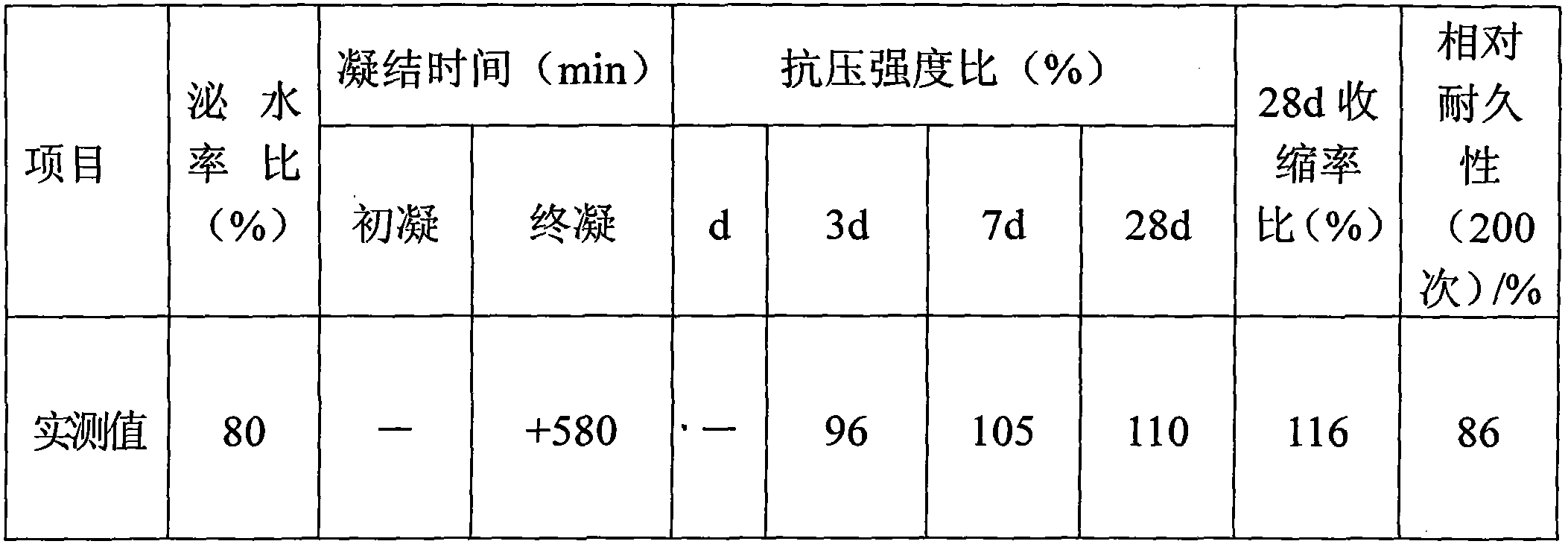

[0015] Sampling is carried out at 0.5% of the cementitious material, and the performance indicators of the tested concrete are shown in the table:

[0016]

[0017] Conclusion: From the properties of the tested concrete, it can be seen that the retarded air-entraining agent of the present invention is mixed in concrete, which reduces the bleeding of concrete, has a significant retarding effect, effect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com